Method for adhering large-scale plane targetto back plate

A bonding method and flat target technology, which are used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high working temperature, deformation of target materials, and difficulty in meeting the requirements of bonding strength, so as to improve the bonding rate, The effect of reducing the amount of bubbles and being easy to promote and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand and implement the present invention, the present invention will be further described below in conjunction with specific examples.

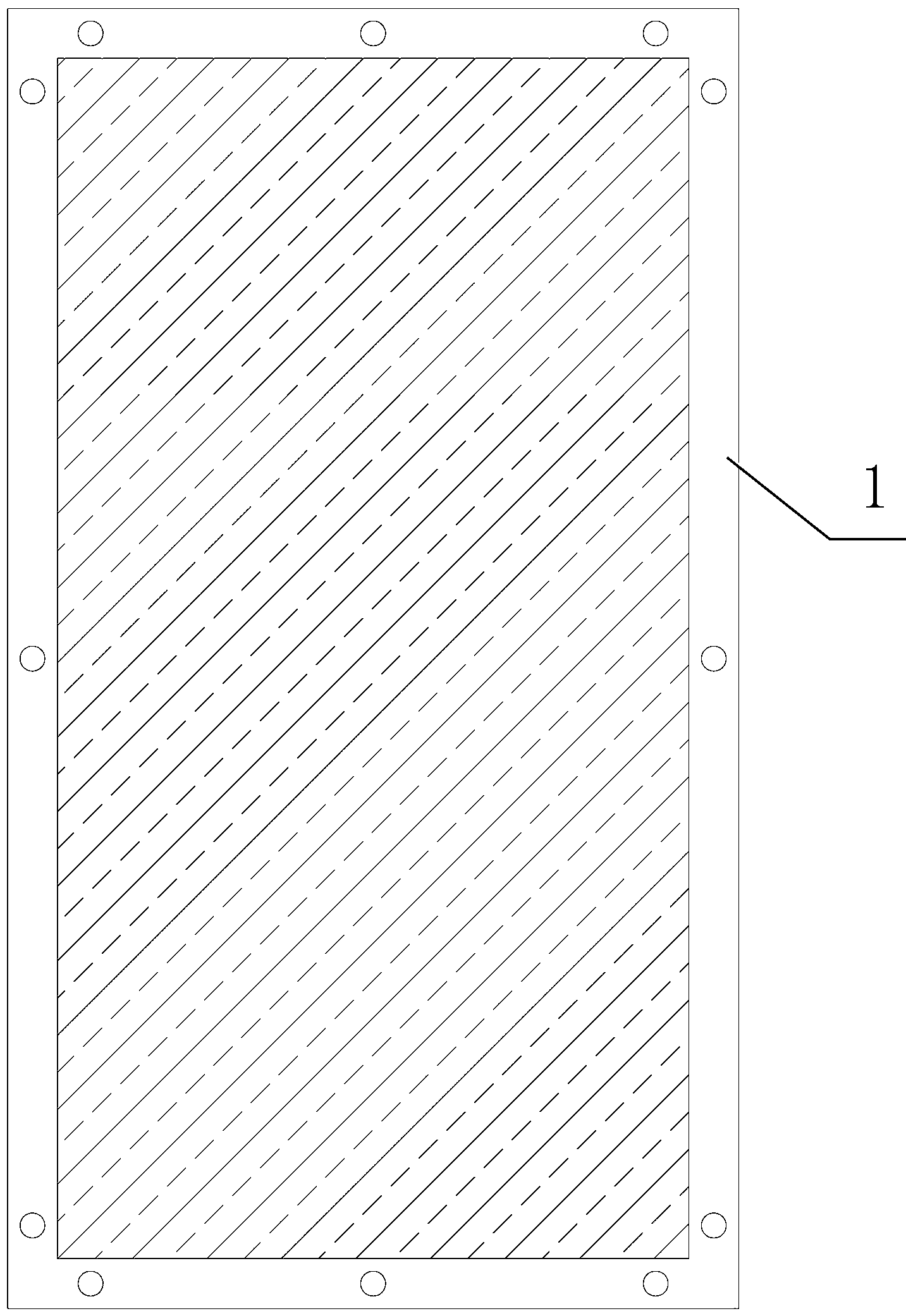

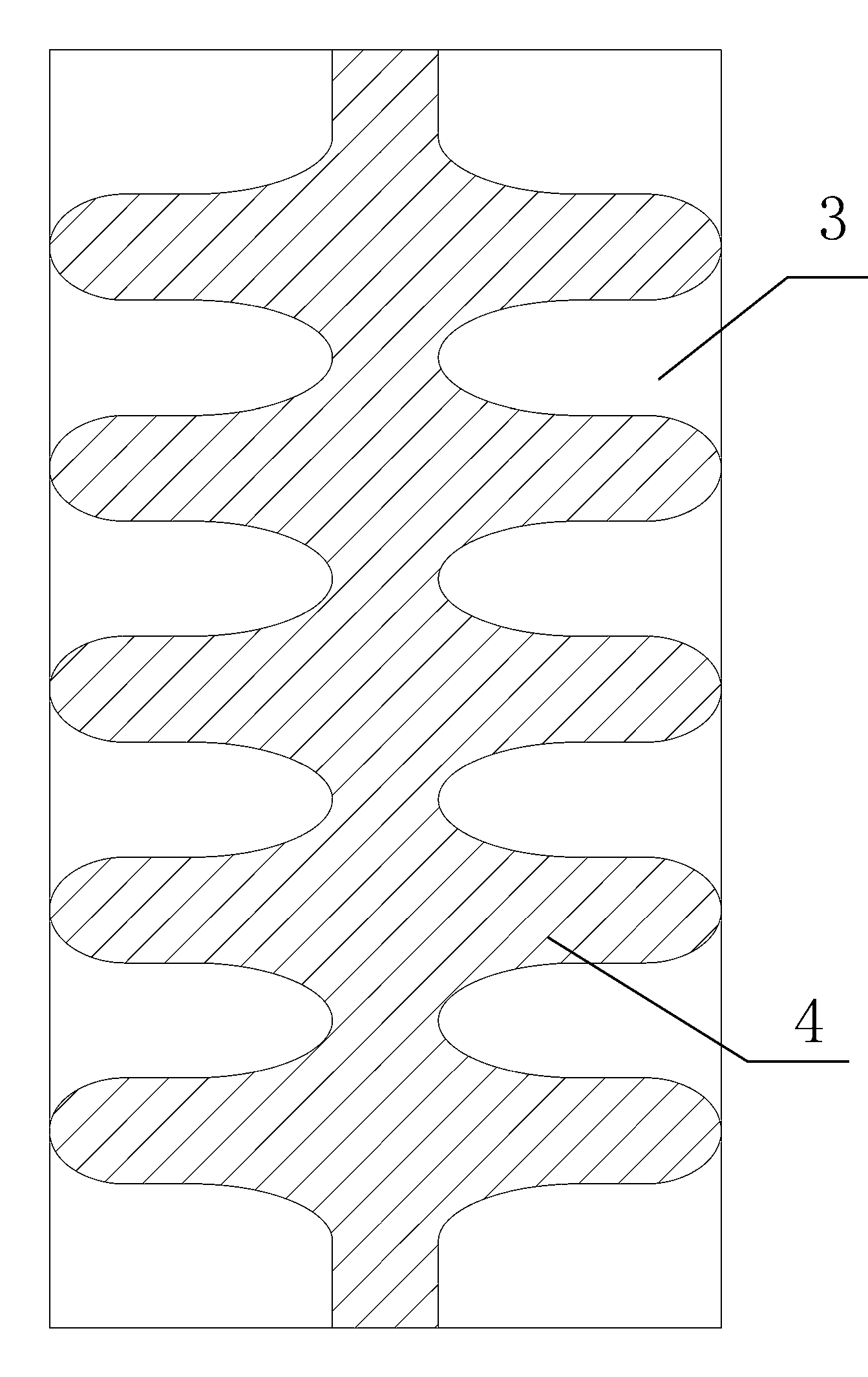

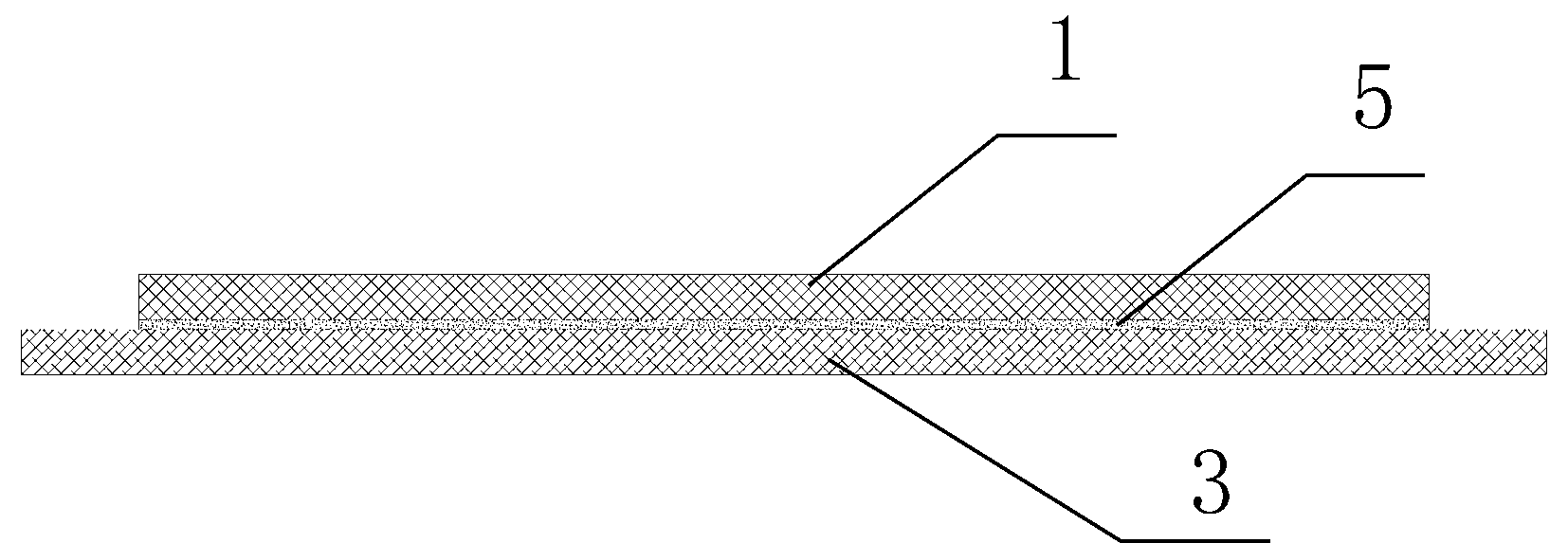

[0025] Such as figure 1 , 2 As shown, a bonding method for a large planar target and a backplane includes the following four steps in sequence:

[0026] Ⅰ. Pre-bonding treatment: Grinding the surface of the target material 3 and the back plate 1, so that the surface roughness reaches 0.32 μm to 0.8 μm, the flatness tolerance is less than ±0.1mm, and the external dimension tolerance is controlled to be less than ±0.2 mm; then several layers of transition material are plated on the bonding surface; the transition material refers to a metal whose thermal expansion coefficient is between the target material 3 and the back plate 1, such as Cr, Ni, etc.

[0027] Ⅱ. Pre-coating solder: heat the backplane 1 and target 3 to a temperature 10-50°C higher than the liquidus of the solder, and then coat the solder on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com