High stability glass fiber reinforced plastics production device and working method thereof

A production device and high-stability technology, applied in coating and other directions, can solve problems such as decreased production line stability, impact on production efficiency, and finished product bubble defects, and achieve improved process stability, improved recycling efficiency, and reduced defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

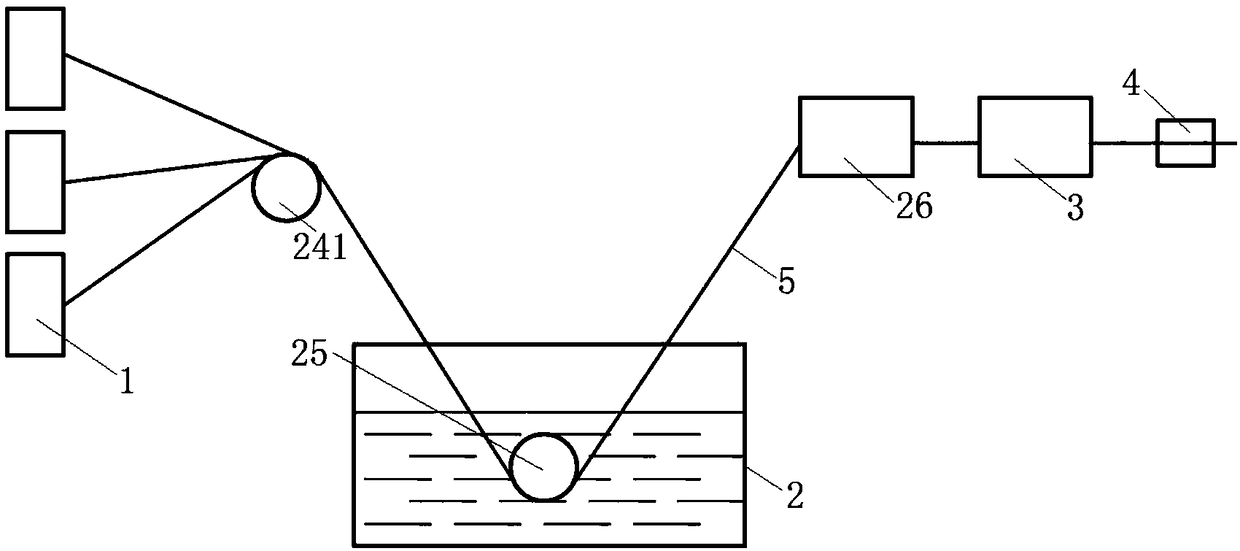

[0030] as attached figure 1 As shown, a high-stability FRP production device includes a creel 1, a glue tank 2, a forming mold 3 and a traction device 4; the fiber output end of the creel 1 is set correspondingly to the inlet end of the glue tank 2; The outlet end of the glue tank 2 is arranged correspondingly to the inlet end of the forming mold 3; the traction device 4 is arranged on the side of the outlet end of the forming mold 3, and pulls the fibers on the creel 1 to move away from the forming mold 3; the creel 1 After passing through the glue tank 2, the surface of the fiber on the fiber is adhered with resin, and then through the solidification process of the forming mold 3, it is transformed into a solid FRP piece. The production process continues under the action of the traction device 4.

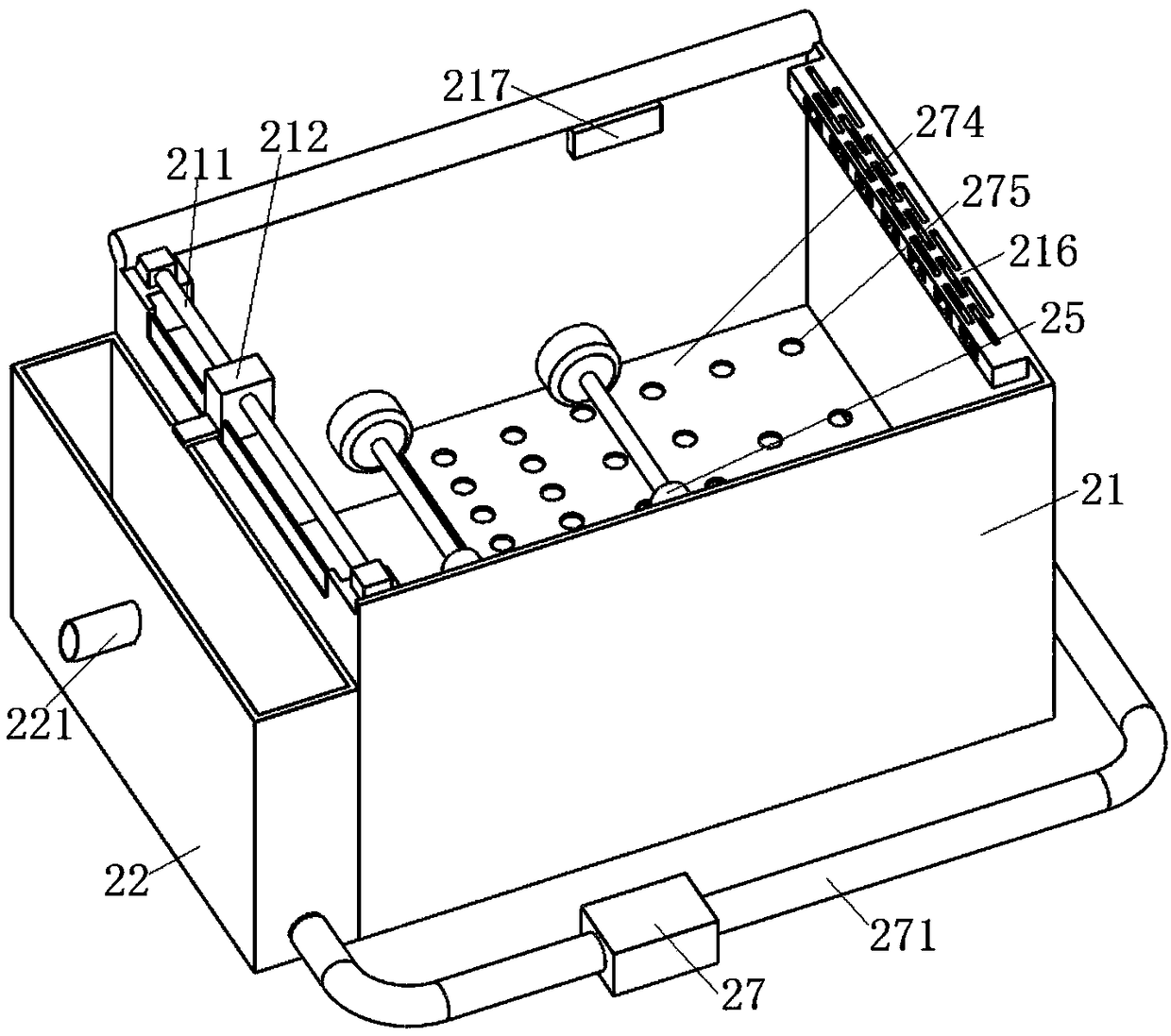

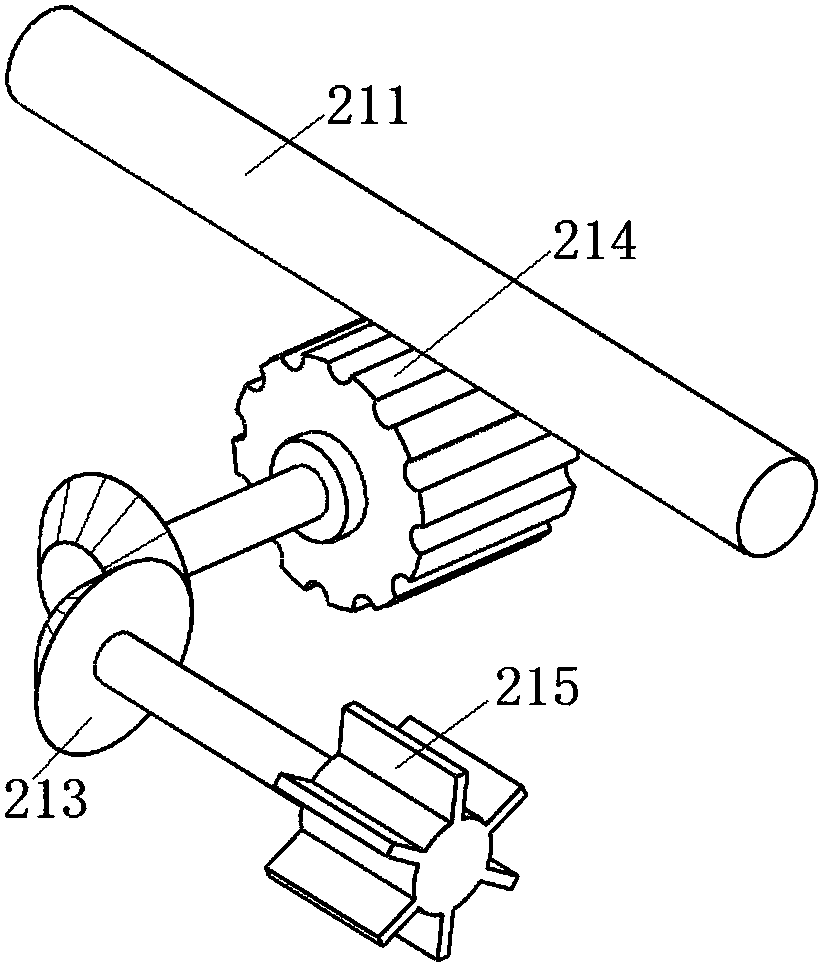

[0031]The glue tank 2 includes a tank body 21 and a transfer cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com