Function guidance product partition ammonia process desulfurization oxidation circulation tank device and method

An oxidation cycle and ammonia desulfurization technology, applied in the field of ammonia flue gas desulfurization, can solve the problems of continuous and stable discharge of ammonium sulfate by-products and poor flue gas desulfurization effect, so as to avoid mutual inhibition, reduce cavitation, and ensure The effect of continuous and stable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific examples, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the protection scope of the present invention.

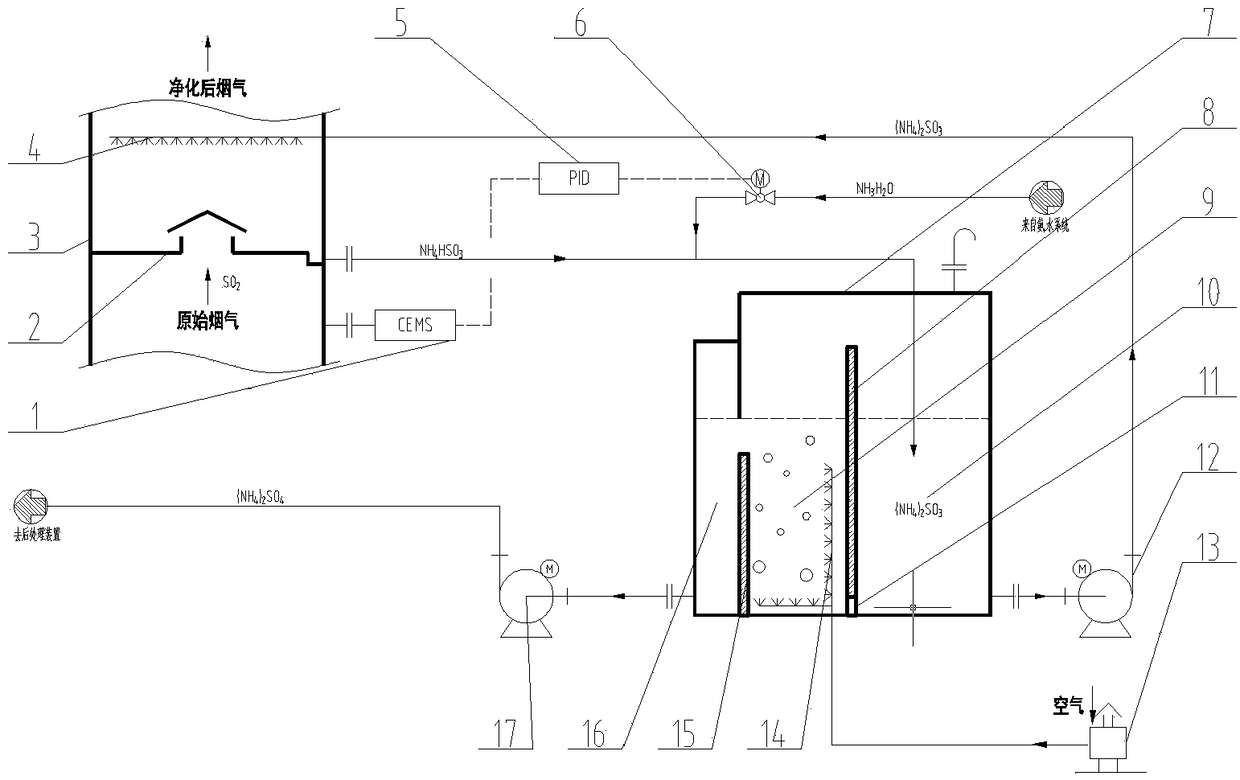

[0029] A function-oriented product-partitioned ammonia desulfurization and oxidation circulation tank device proposed by the present invention comprises: a desulfurization tower absorption section 3 and an oxidation circulation tank 7, and the desulfurization tower absorption section 3 and the oxidation circulation tank 7 are connected by pipelines;

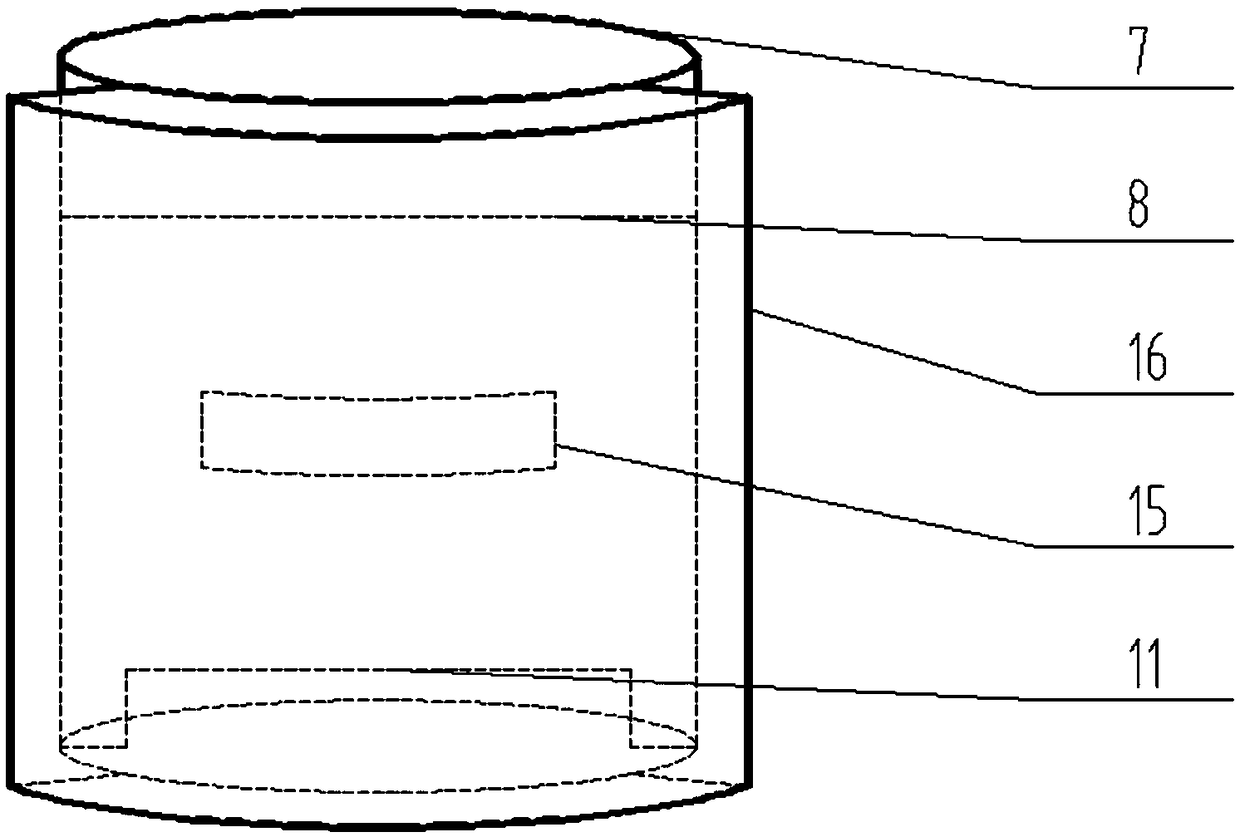

[0030] The oxidation circulation tank 7 is successively separated into three areas of a single-phase liquid zone 16, an oxidation zone 9 and a reduction zone 10 by a tank wall plate 15 and a partition plate 8; one side of the reduction zone 10 communicates with the oxidation zone 9, The othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com