Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Reduce local overheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

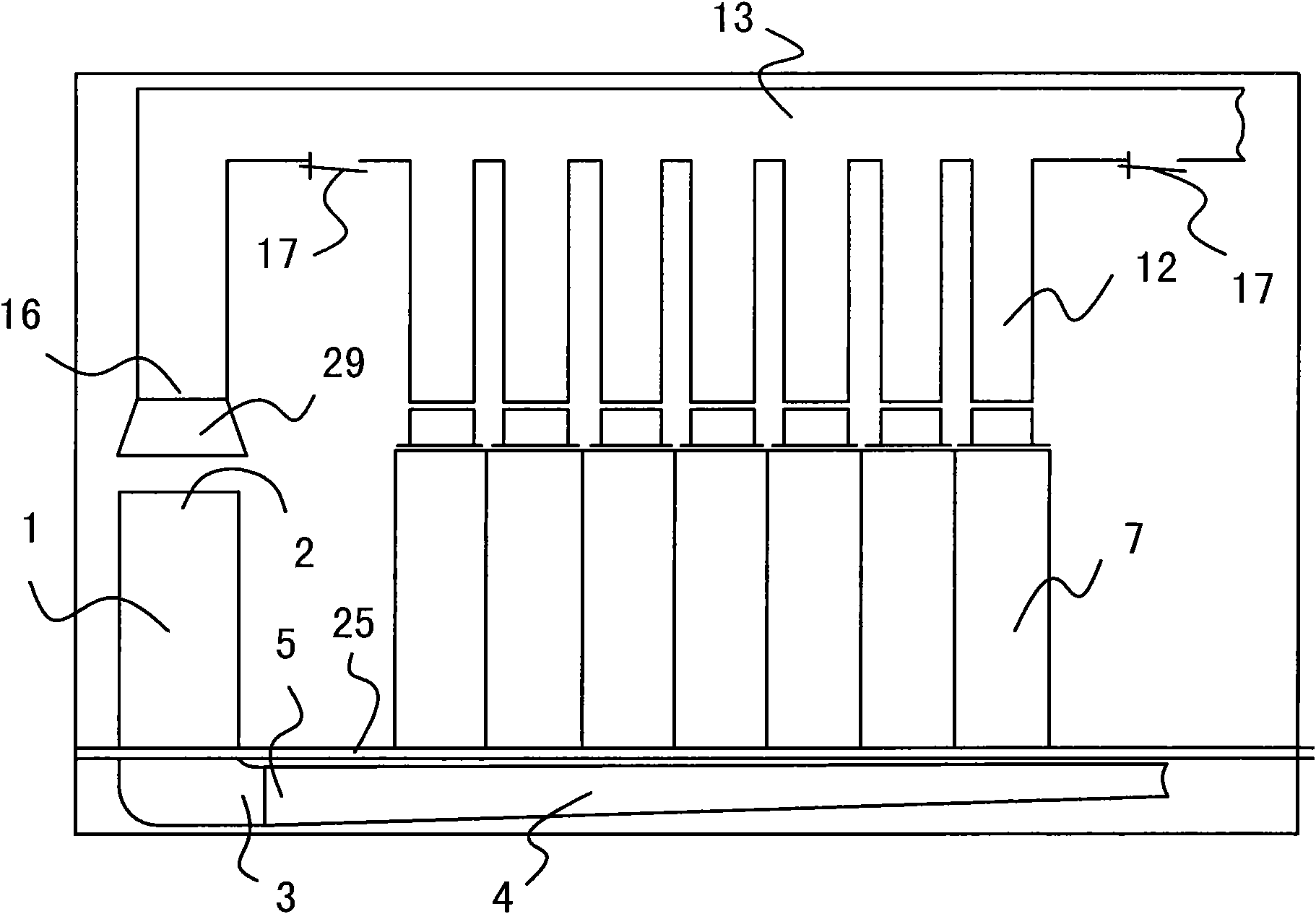

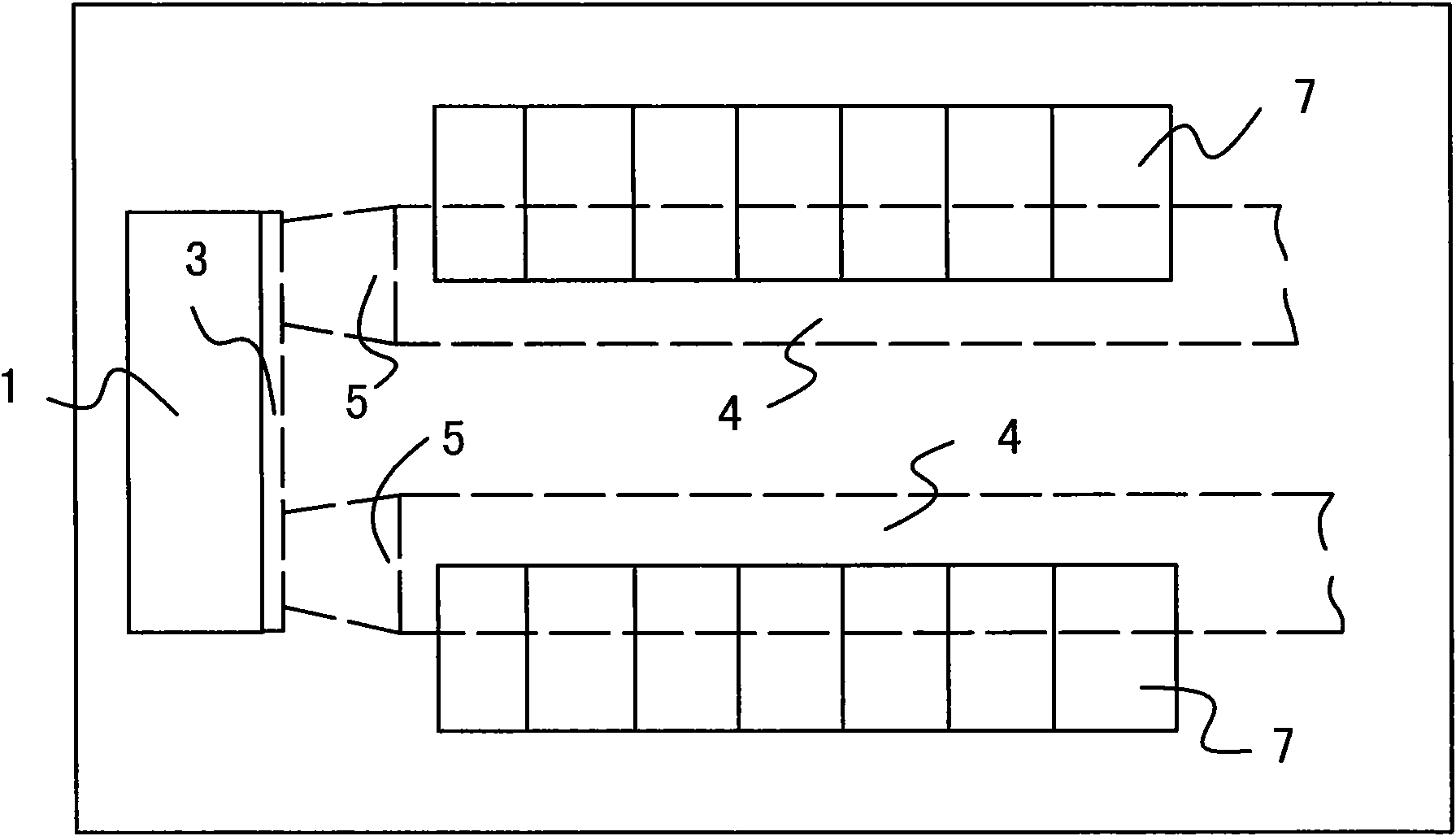

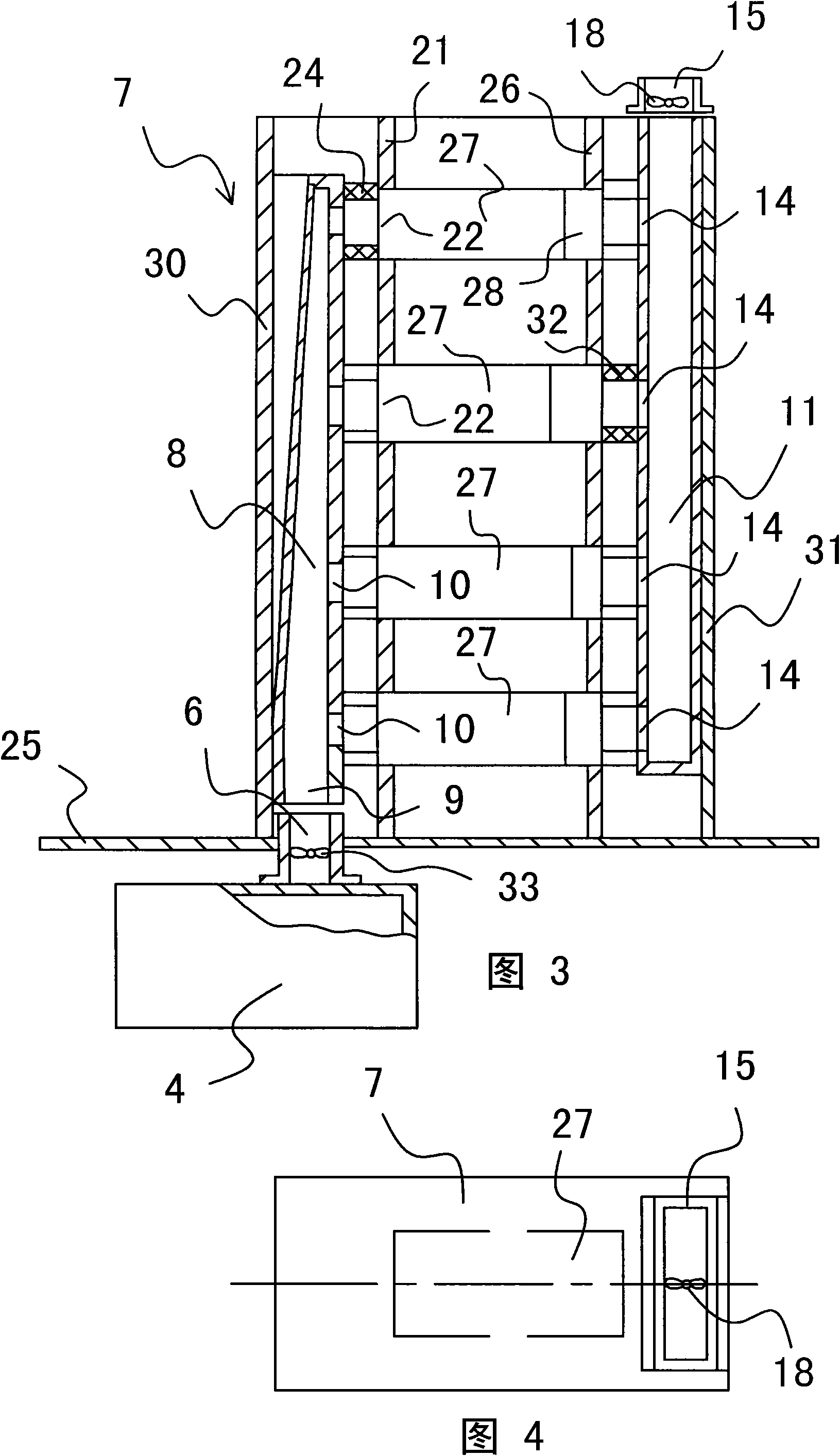

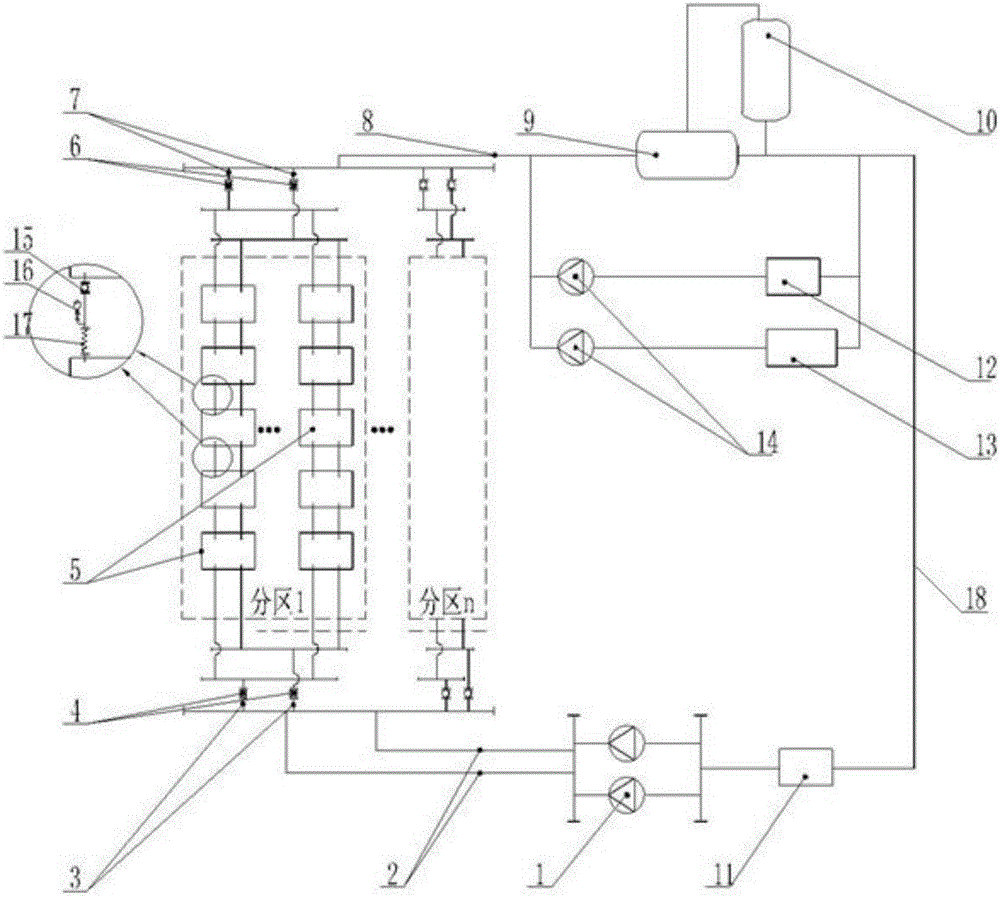

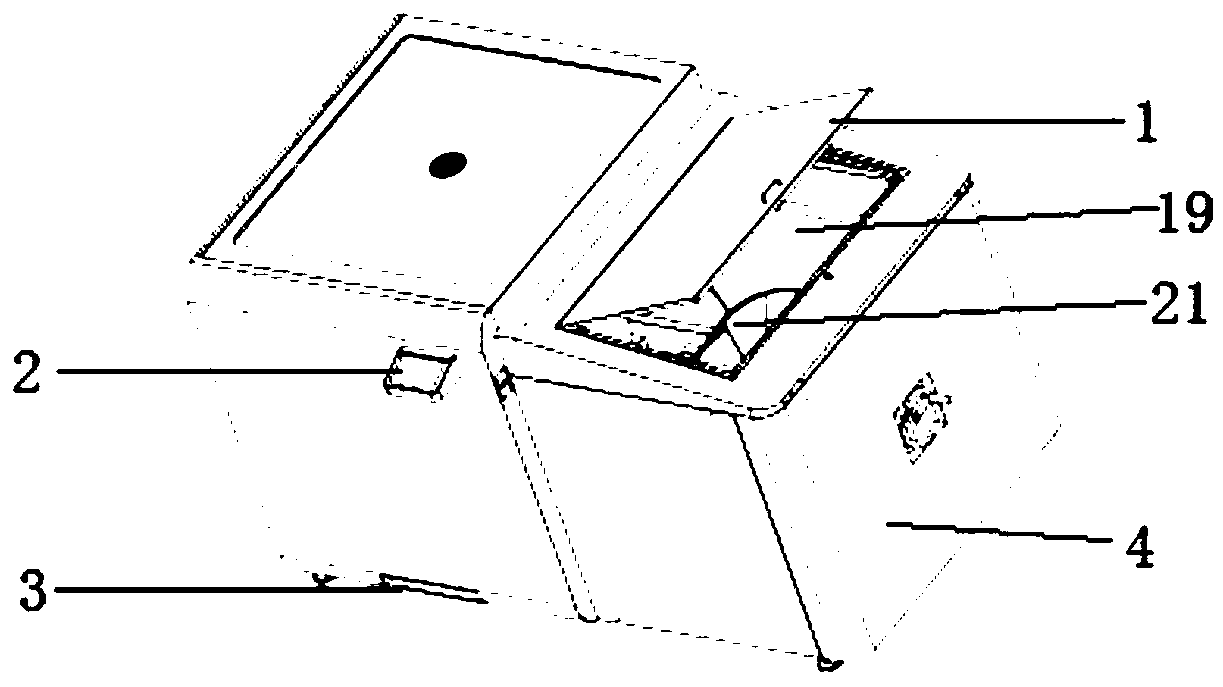

Data center machine room cooling system featuring cool air distribution according to needs

ActiveCN101790300AFacilitate conductionReduce energy consumptionDucting arrangementsCooling/ventilation/heating modificationsCold airData center

The invention relates to a data center machine room cooling system featuring cool air distribution according to needs, comprising an air-conditioning unit and a heat dissipation air channel. Cold air provided by a refrigerating unit is distributed to equipment cabinets through an air inlet header pipe and an air inlet adapter pipe according to cold energy the equipment cabinets need and then is distributed to servers according to the cold energy the servers in the equipment cabinet need through a cold air distribution box, so as to carry out forced air cooling on heated components. The cooling system optimizes airflow movement and realizes air distribution according to needs, thus being an efficient and energy-saving data center machine room cooling system heat dissipation solution.

Owner:傅建勋

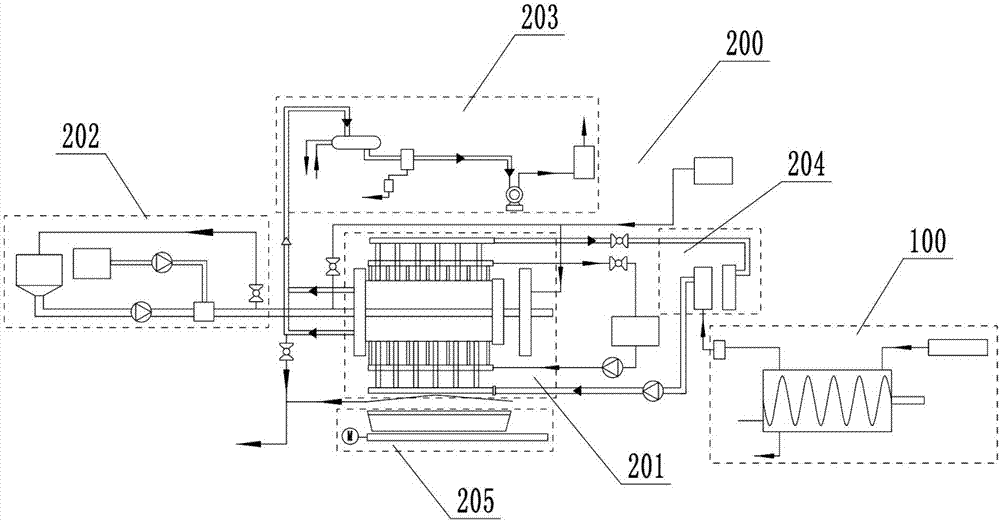

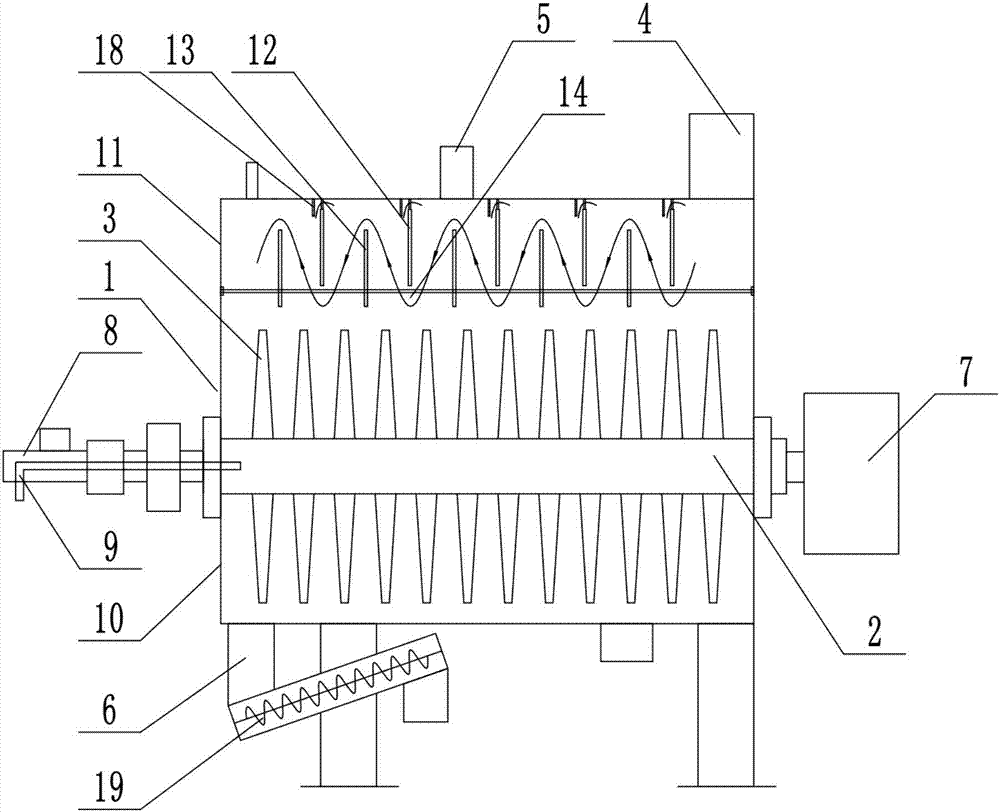

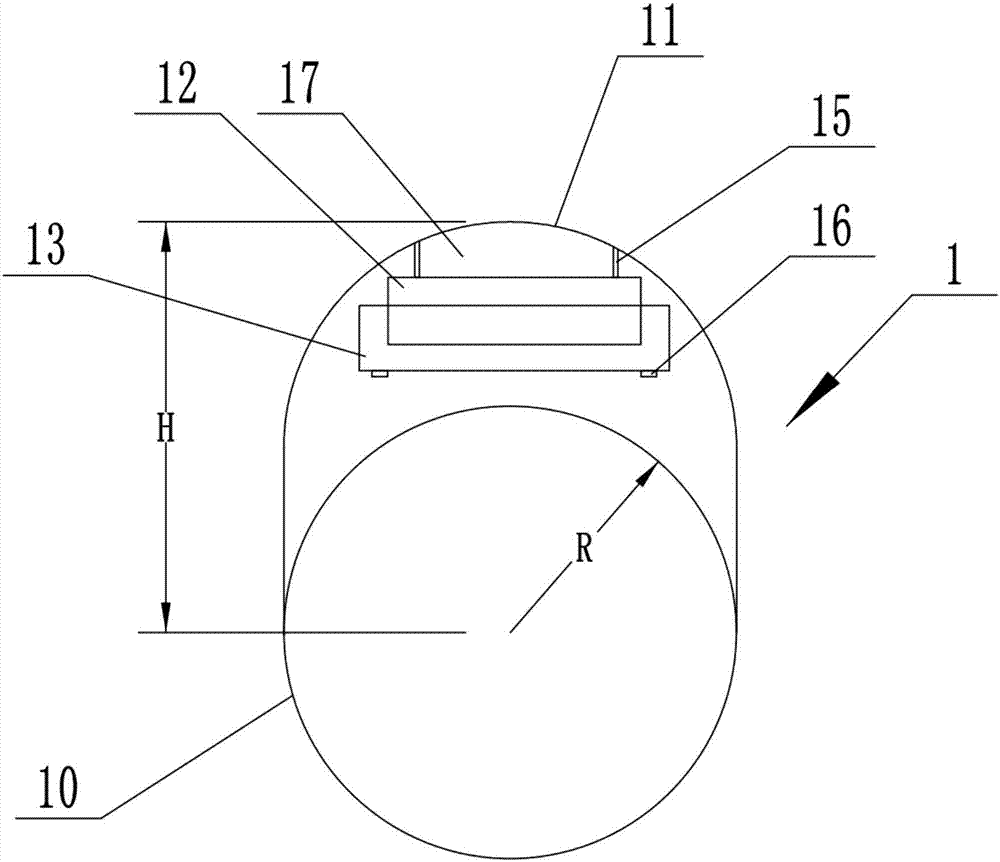

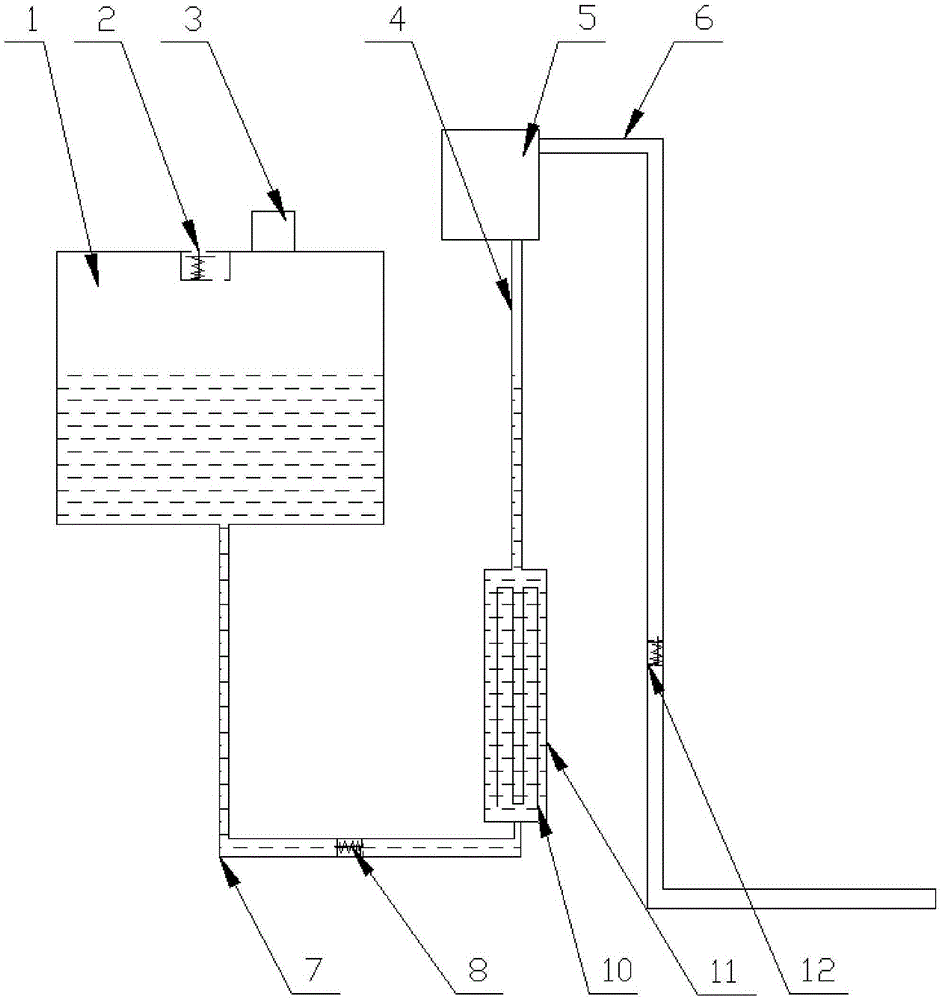

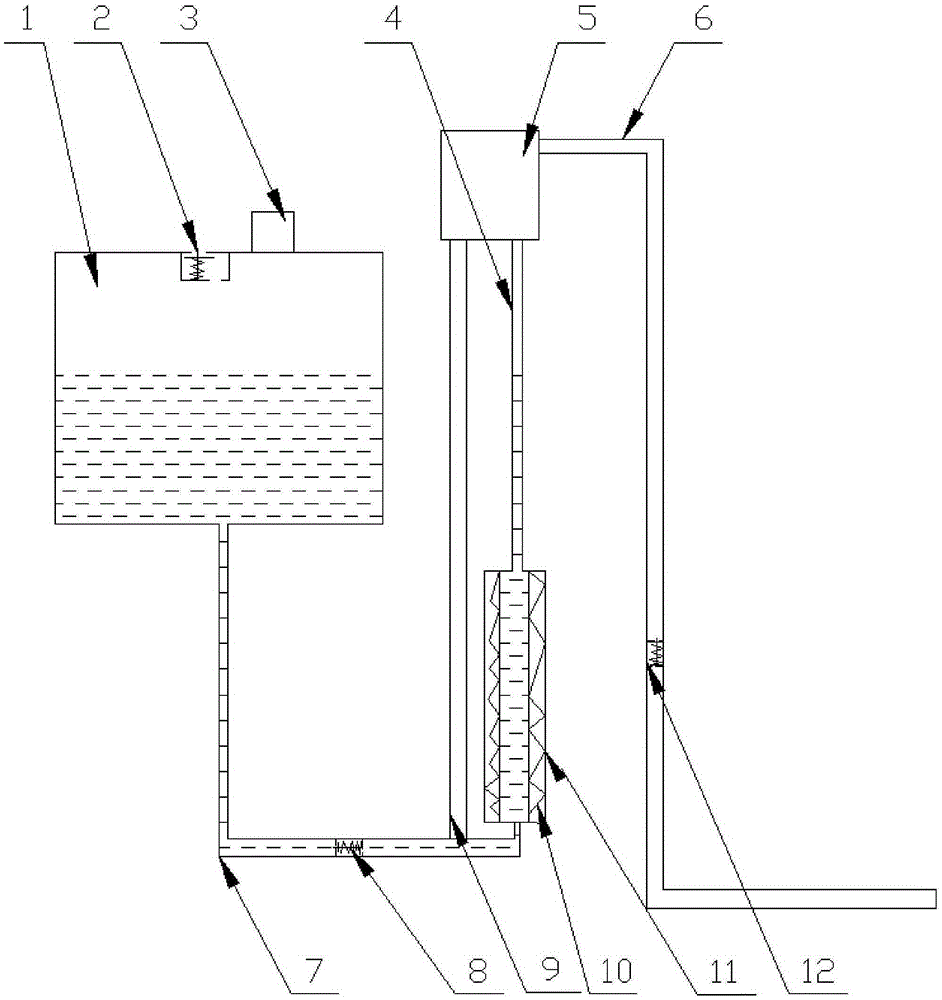

Disc type sludge drying system based on cascade utilization of energy

PendingCN107162379AReduce drying energy consumptionReduce local overheatingSludge treatment by de-watering/drying/thickeningSludgeElectric machinery

The invention relates to a disc type sludge drying system based on cascade utilization of energy. The system comprises a disc type drying system and a filter-press drying system, wherein the disc type drying system comprises a casing, a stirring shaft is mounted in the casing, discs are mounted on the stirring shaft in a spaced manner, a sludge inlet and a steam outlet are formed in the top of the casing, a dry sludge outlet is formed in the bottom of the casing, the stirring shaft is driven by a stirring motor at one end, the stirring shaft adopts a hollow structure, one end of the stirring shaft is a hot steam inlet, and a condensed water outlet pipe is inserted into the end; the filter-press drying system comprises a filter-press system, a sludge feeding system connected with the filter-press system, a vacuumization system, a hot water circulating system and a sludge output system, the sludge feeding system is connected with a sludge feeding end of the filter-press system, the sludge output system is connected with is connected with a sludge discharging end of the filter-press system, the vacuumization system is used for keeping the filter-press system in a negative pressure state during filter pressing of sludge, and the hot water circulating system is connected with the steam outlet of the disc type drying system.

Owner:无锡绿麦环保科技有限公司

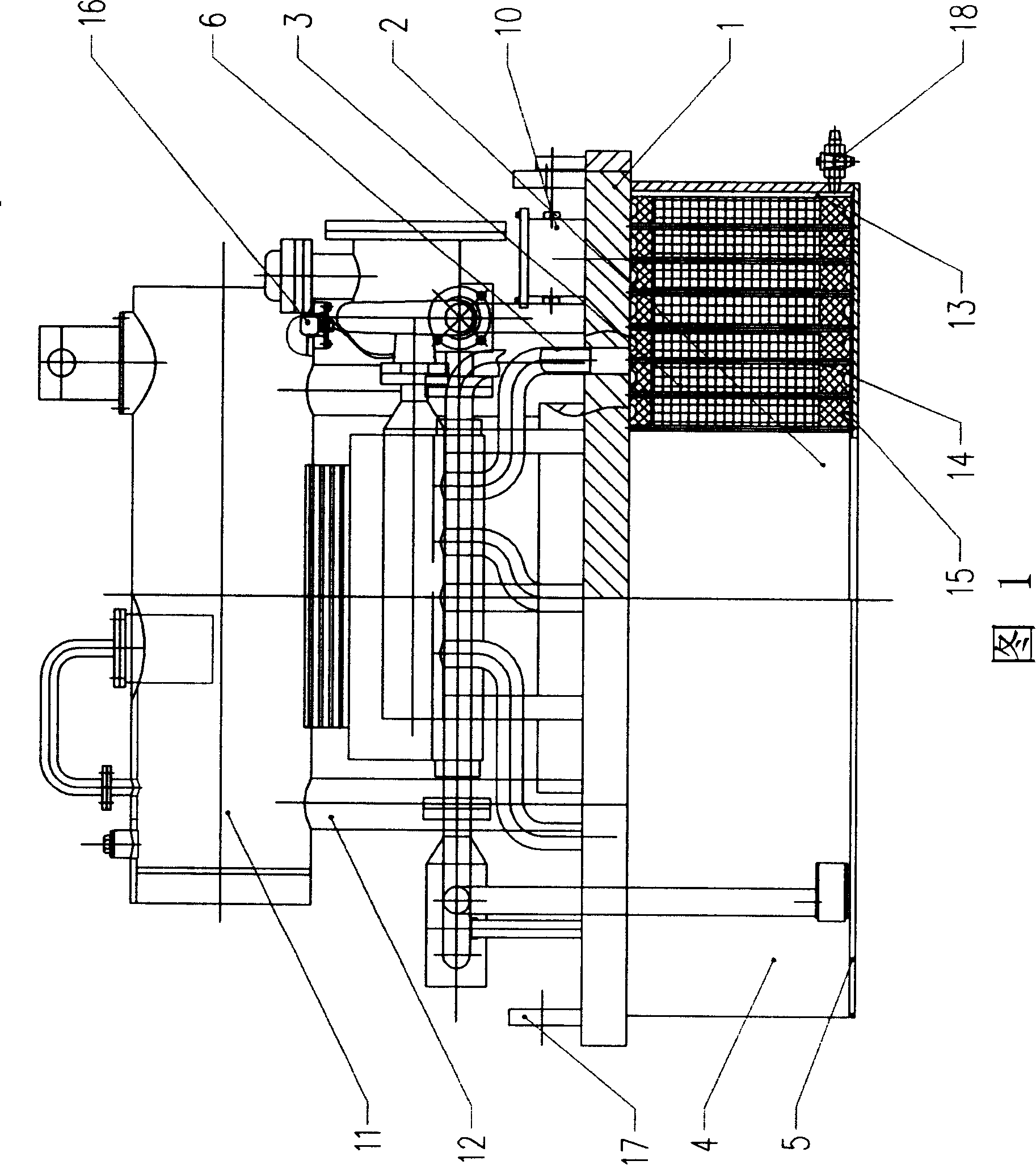

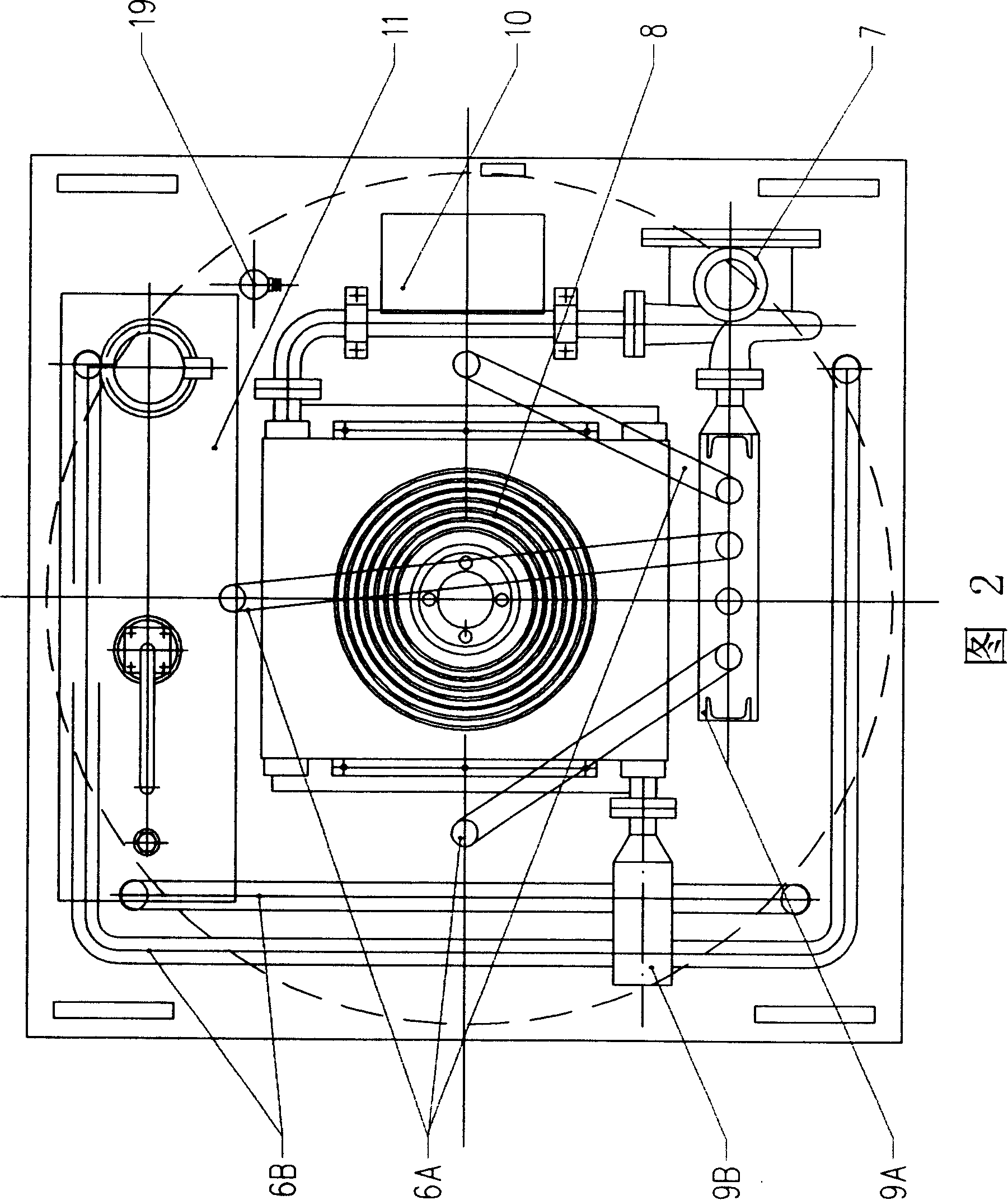

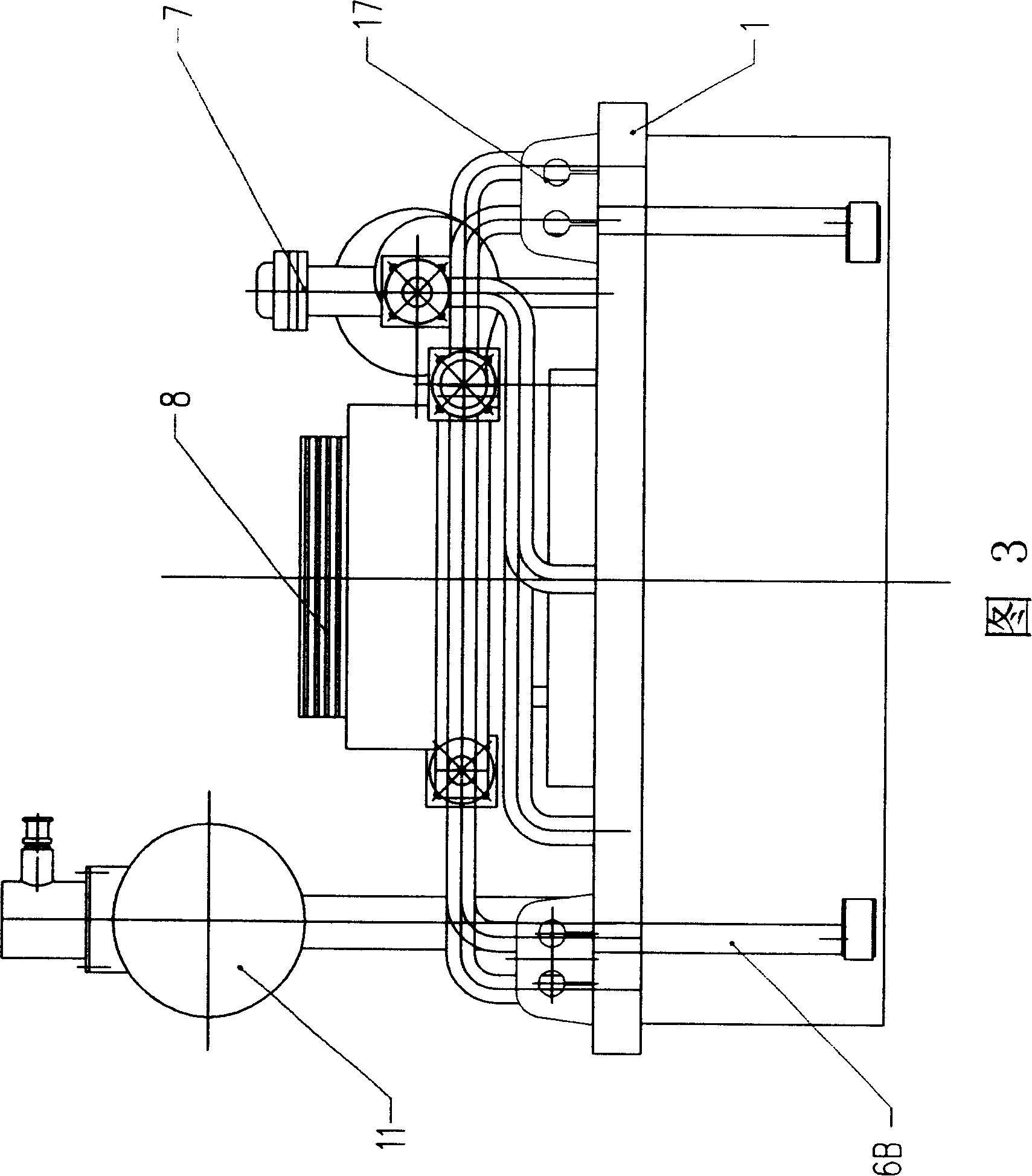

Circulating oil-cooling type electric-magnetic iron remover

ActiveCN101234364AIncrease oil intakeIncrease oil outletMagnetic separationSuperconducting magnets/coilsShunt DeviceWorking life

The invention relates to a circular oil cooling electric magnetic iron remover consisting of a header tank, cooling system and a oil cooling magnetic system; wherein, the cooling system consists of a power pump, a radiator and an internal and external cyclic hydraulic circuit; an internal oil circuit is a cooling medium channel in the oil cooling magnetic system; an outer cyclic oil circuit affluxes into a current divider by an oil pipe which is communicated with an inner cavity of the oil cooling magnetic system, then into the radiator with an outlet being connected with another current divider which is connected with the oil pipe which is communicated with an inner cavity of oil cooling magnetic system; the power pump is arranged in a pipe between the radiator and the current divider. By adopting the cooling system with internal and external circulation, the circular oil cooling electric magnetic iron remover allows the whole machine to raise temperature evenly and obviously low, thereby reducing the local excessive heating phenomenon, raising magnetic potential utilization ratio, further raising magnetic attraction force, raising the working life of the circular oil cooling electric magnetic iron remover and ensuring safe and reliable operation of the invention. The circular oil cooling electric magnetic iron remover is in particular suitable for the bad working conditions with moistness, large amount of bug dusts and salt spray corrosion.

Owner:LONGI MAGNET CO LTD

Special hydrocracking catalyst and preparation method and application thereof

ActiveCN102794203AEvenly dispersedCooperate wellMolecular sieve catalystsCatalyst activation/preparationAfter treatmentMetal

The invention relates to a special hydrocracking catalyst, and a preparation method and application thereof. According to the preparation method for the catalyst, a solution after-treatment method is adopted to ensure that metal is uniformly deposited on a carrier and does not migrate in the subsequent drying process, so that uniform dispersion of the metal is realized; and by the preparation method for the catalyst, the metal is uniformly dispersed, the carrier and the metal are well matched, and the catalytic performance is greatly improved. The hydrocracking catalyst is most suitable for the middle distillate type hydrocracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

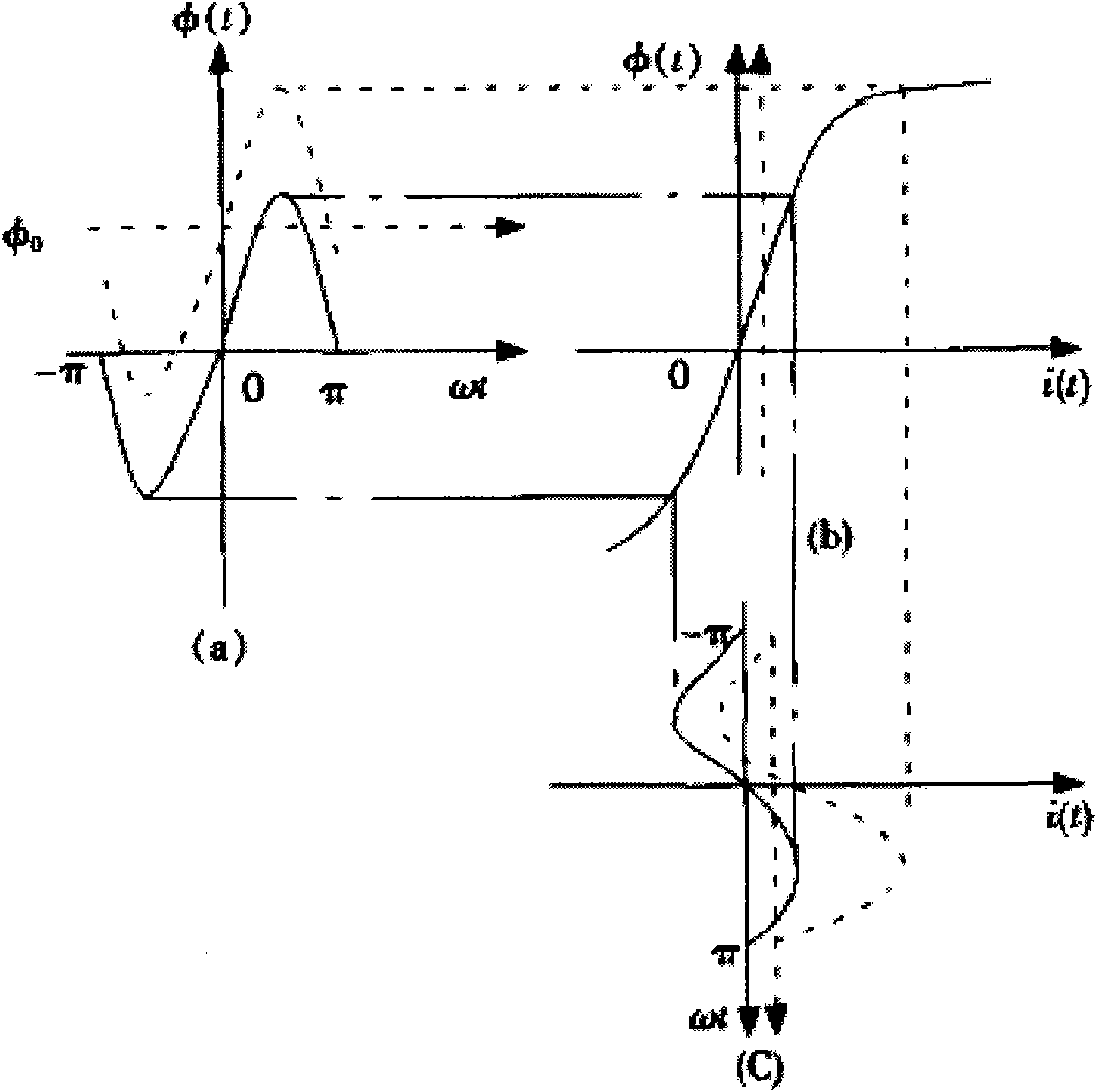

Converter transformer for inhibiting DC magnetic biasing

ActiveCN101930831AHarm reductionIncrease no-load currentTransformers/inductances magnetic coresInductances/transformers/magnets manufactureEngineeringTransformer

The invention relates to a method for realizing a converter transformer for inhibiting DC magnetic biasing. In the method, joint widths among core laminations of the transformer are increased, and the method specifically comprises the following steps of: calculating the widths and heights of the laminations of each level according to the preserved joint width between every two laminations, the section of a core, the width between every two columns and the height of a window; cutting the laminations according to the calculated widths and heights of the laminations; laminating the laminations in a way of laminating every two laminations according to the sequence of the levels, and alternately arranging the laminations on a core frame according to the levels; and tightening the laminations of each level after all the laminations are laminated. The method has the advantages of effectively reducing the damage of DC magnetic biasing current to the transformer and further reducing the influence and damage of the transformer influenced by the DC magnetic biasing current on / to a power system.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

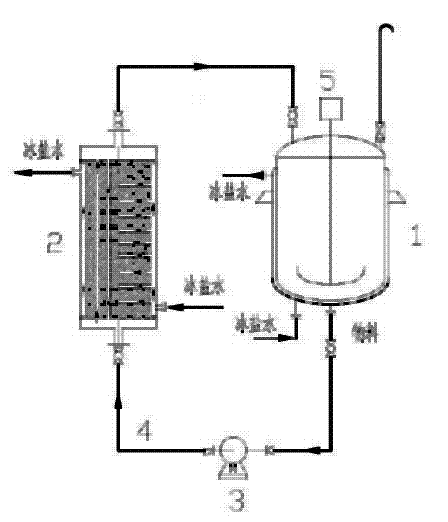

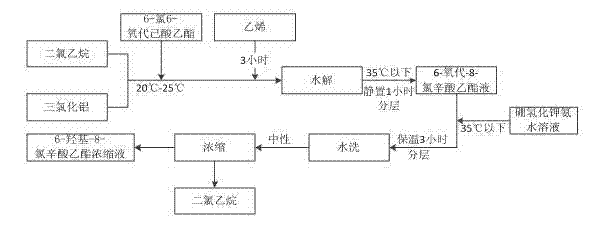

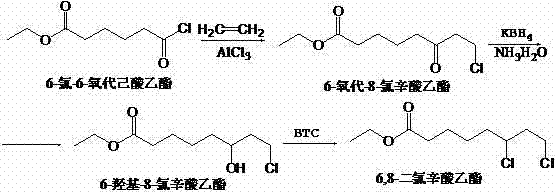

Preparation method of ethyl 6-oxo-8-chloro-caprylate

ActiveCN102731307ATemperature controlLess quantityOrganic compound preparationCarboxylic acid esters preparationReaction temperatureOxygen

The invention relates to a preparation method of ethyl 6-oxo-8-chloro-caprylate, which comprises the steps of: carrying out addition reaction on ethyl 6-chloro-6-oxo-caproate and ethylene in dichloroethane solution with aluminum trichloride as a catalyst; mixing the addition reaction liquid with water in a hydrolysis kettle; introducing the mixture of the reaction liquid and water into a graphite condenser for cooling through a circulating pump; returning to the hydrolysis kettle; and continuously circulating until hydrolysis is finished. The method solves the technical problems caused by hydrolysis of the addition product, effectively controls the hydrolysis reaction temperature, shortens the hydrolysis reaction time, increases the reaction yield by about 10% and saves the water consumed by the hydrolysis reaction by 50%.

Owner:JIANGSU TOHOPE PHARMA

Improved blast furnace soft water closed circulation system and method

ActiveCN106498106AReduce the number of testsImprove leak detection efficiencyCooling devicesWater leakageWorking pressure

The invention discloses an improved blast furnace soft water closed circulation system and method. The system comprises a host controller, a cooling wall cooling unit, an expansion and degasification unit, a secondary circulation water unit and a primary circulation water supply unit. According to the improved blast furnace soft water closed circulation system and method, multiple water supply main pipes are adopted, the redundancy degree of the system is increased, and blast furnace production safety is guaranteed; a cooling wall is zoned, grading and leakage detecting are facilitated, the time needed for leakage detecting is reduced, and guarantees are provided for stable production and cost reduction; and secondary circulation water setting is reasonable, the work pressure of secondary circulation water cooling equipment is reduced, the risk of water leakage is reduced, and the gas contents in primary circulation water and secondary circulation water are reduced.

Owner:HUATIAN ENG & TECH CORP MCC

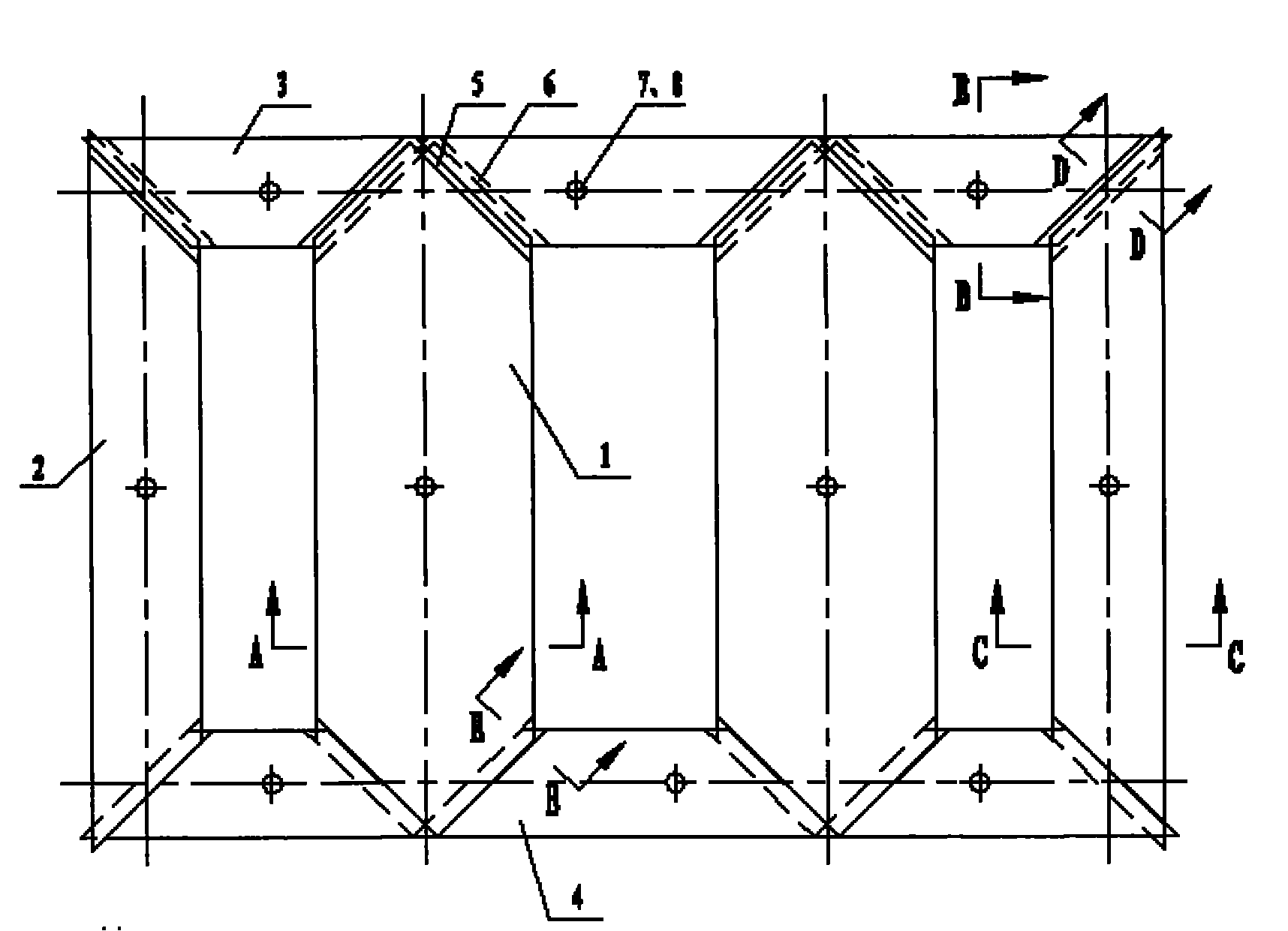

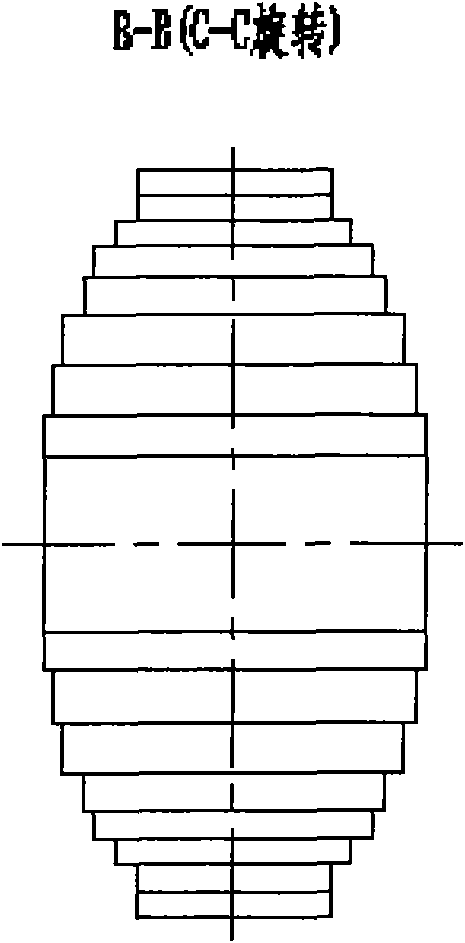

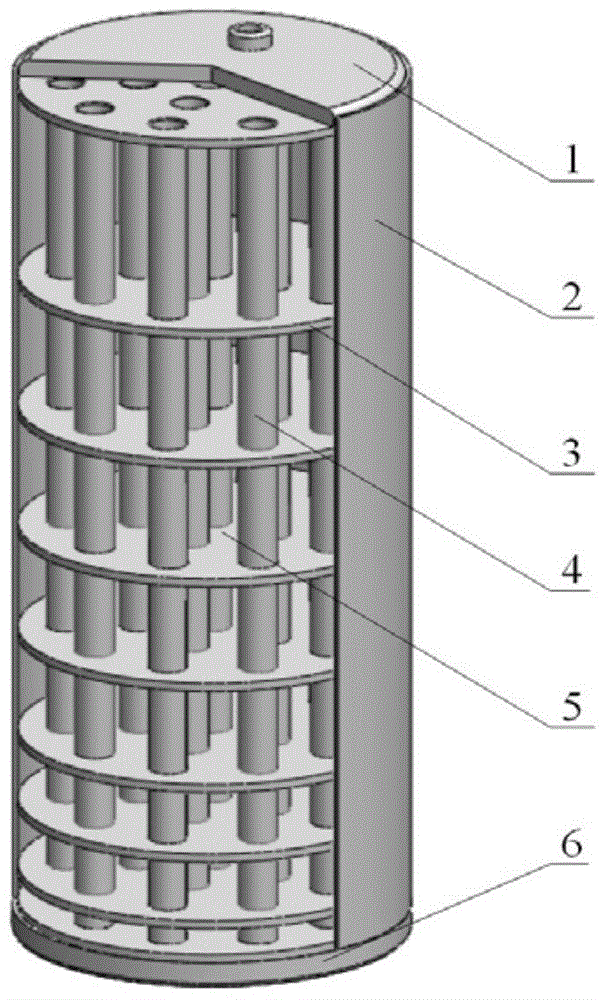

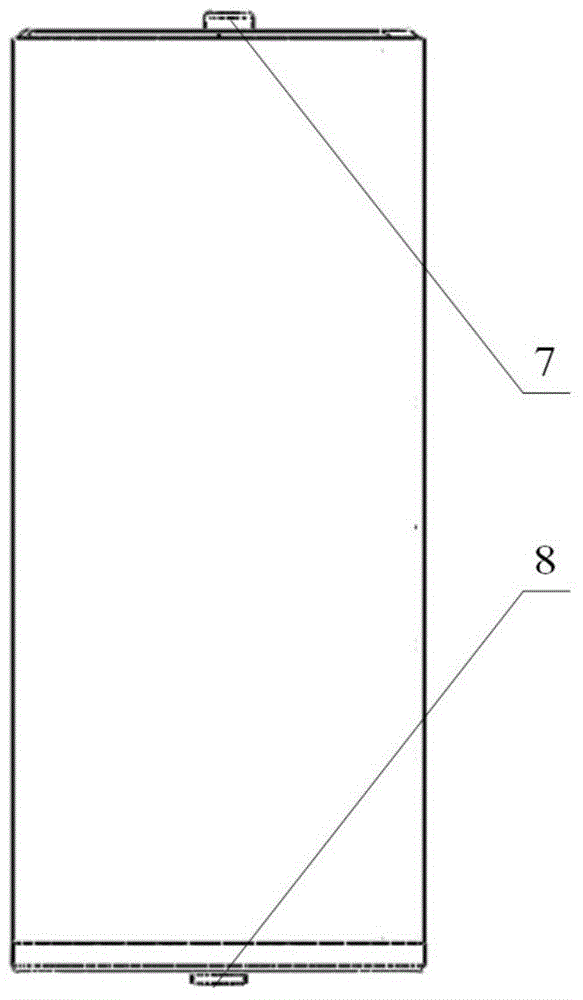

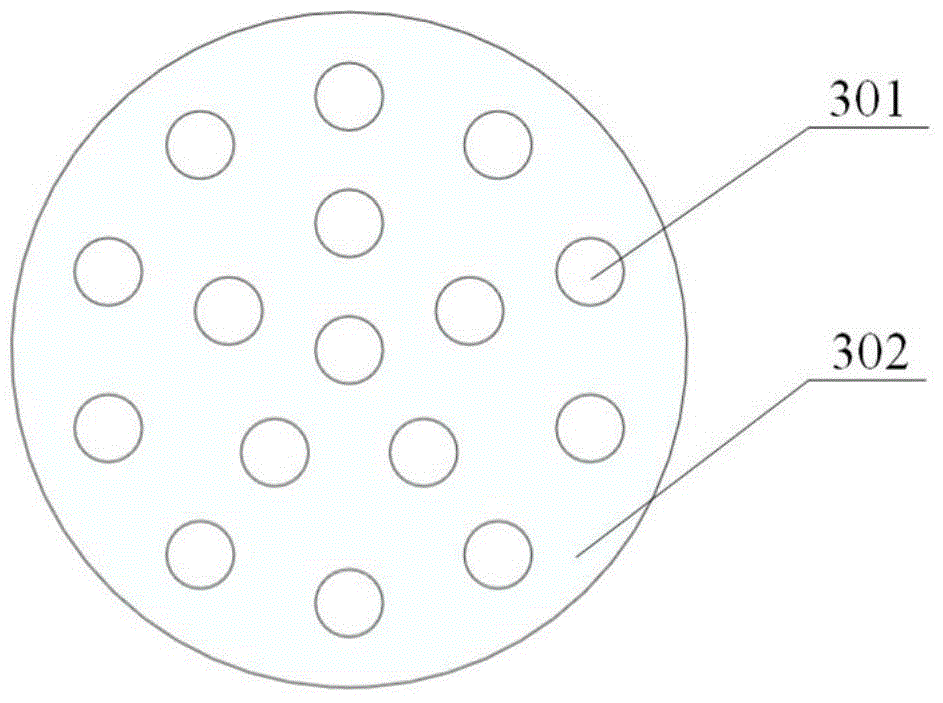

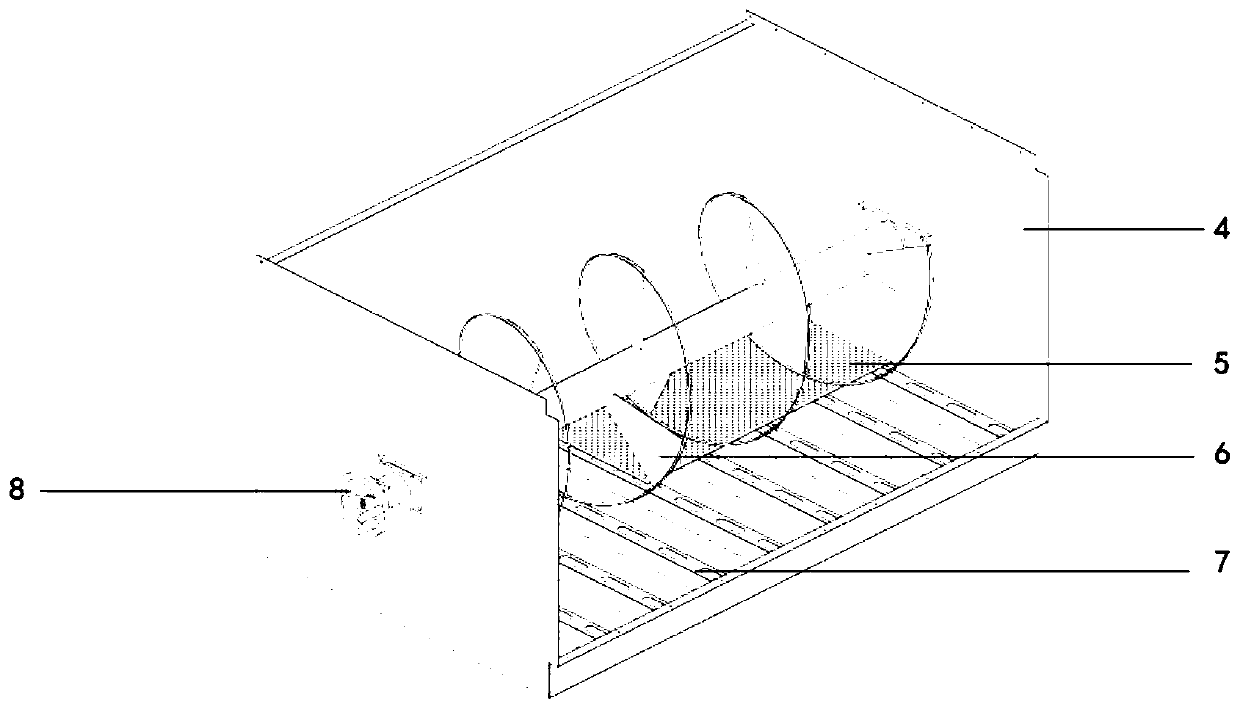

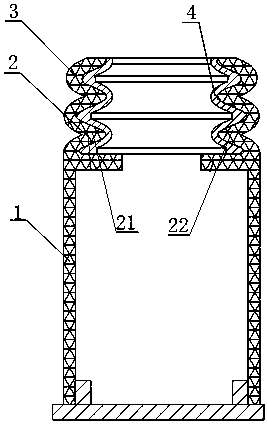

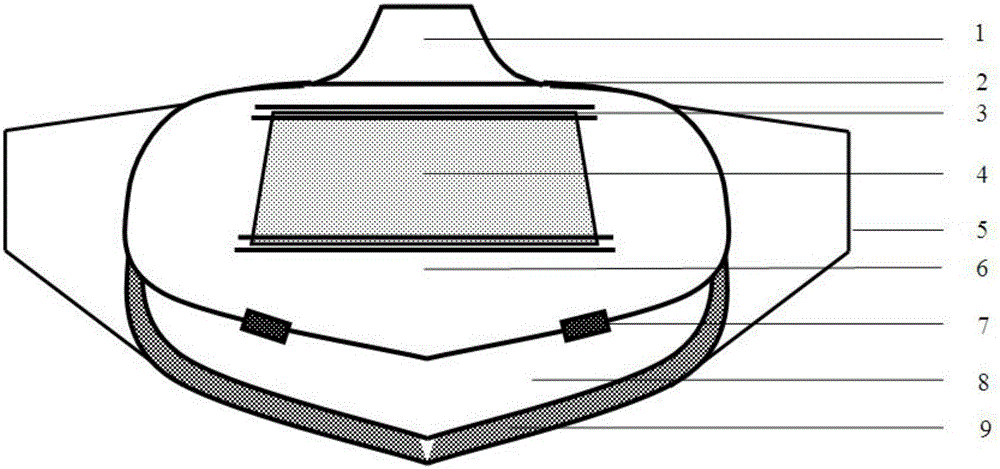

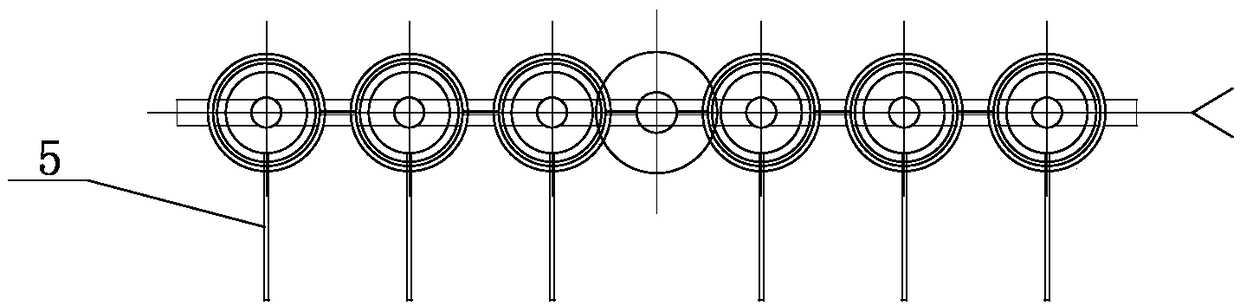

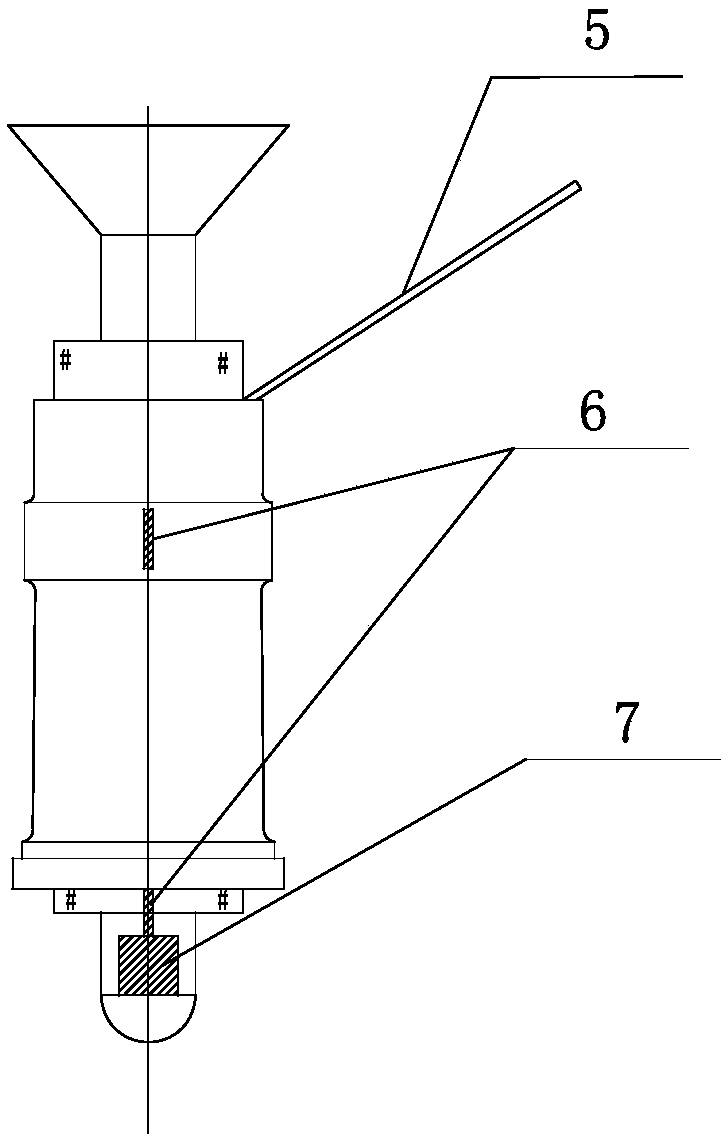

Cylindrical structure gradual-change fin phase change heat accumulator

InactiveCN104864757AReduce overheatingPromote meltingHeat storage plantsTemperature differenceEngineering

The invention belongs to the technical field of heat accumulation, and particularly relates to a cylindrical structure gradual-change fin phase change heat accumulator. The heat accumulator comprises an upper end face (1), a heat accumulation shell (2), annular fins (3), heat exchange pipe bundles (4), a phase change material (5) and a bottom face (6). The heat exchange pipe bundles are vertically arranged between the upper end face and the lower end face in a peripheral array mode and are arranged at equal intervals in parallel. The annular fins are parallel to the upper end face and the lower end face and horizontally arranged between the upper end face and the lower end face, each level of annular fins is connected with all the heat exchange pipe bundles to form a sealed channel, and heat exchange fluid flows in the channel. The heat accumulation shell wraps a cylindrical space between the upper end face and the bottom face, and the phase change material is stored in the cylindrical space. The intervals of the annular fins are changed gradually, the more the annular fins are close to the bottom face, the intervals are smaller, the heat exchange temperature difference of the heat accumulator more tends to be consistent, and the phenomena that the phase change material is partially excessively hot, and the heat stress of a heat accumulation container is excessively high are reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Drying method of heat sensitive reducer

InactiveCN101571343AHigh decomposition temperatureAvoid oxidation reactionsDrying using combination processesDyeing processCold airEmulsion

The invention discloses a drying method of a heat sensitive reducer, in particular to a drying method of a heat sensitive reducer used in printing and dyeing industry. The drying method comprises the following steps: adding a heat stabilizer to the prepared heat sensitive reducer and fully stirring the mixture; pumping cold air to condense the reducer in emulsion state and getting rid of the surface water; controlling the vacuum degree in a microwave drying cavity to be below 0.1MPa and temperature between 50 DEG C and 60 DEG C and carrying out microwave heating for 6-10min; closing microwave and pumping hot air to carry out tempering on the reducer material for 5-10min; opening the microwave again, controlling the temperature between 80 DEG C and 100 DEG C and drying for 2-3min; grinding and packaging the reducer material. The water ratio of the dried reducer material is 3-5% and the reducer material is milky white. The method can effectively protect the product performance of the heat sensitive reducer material, shorten drying time, reduce energy consumption and save drying cost.

Owner:FUZHOU UNIV +1

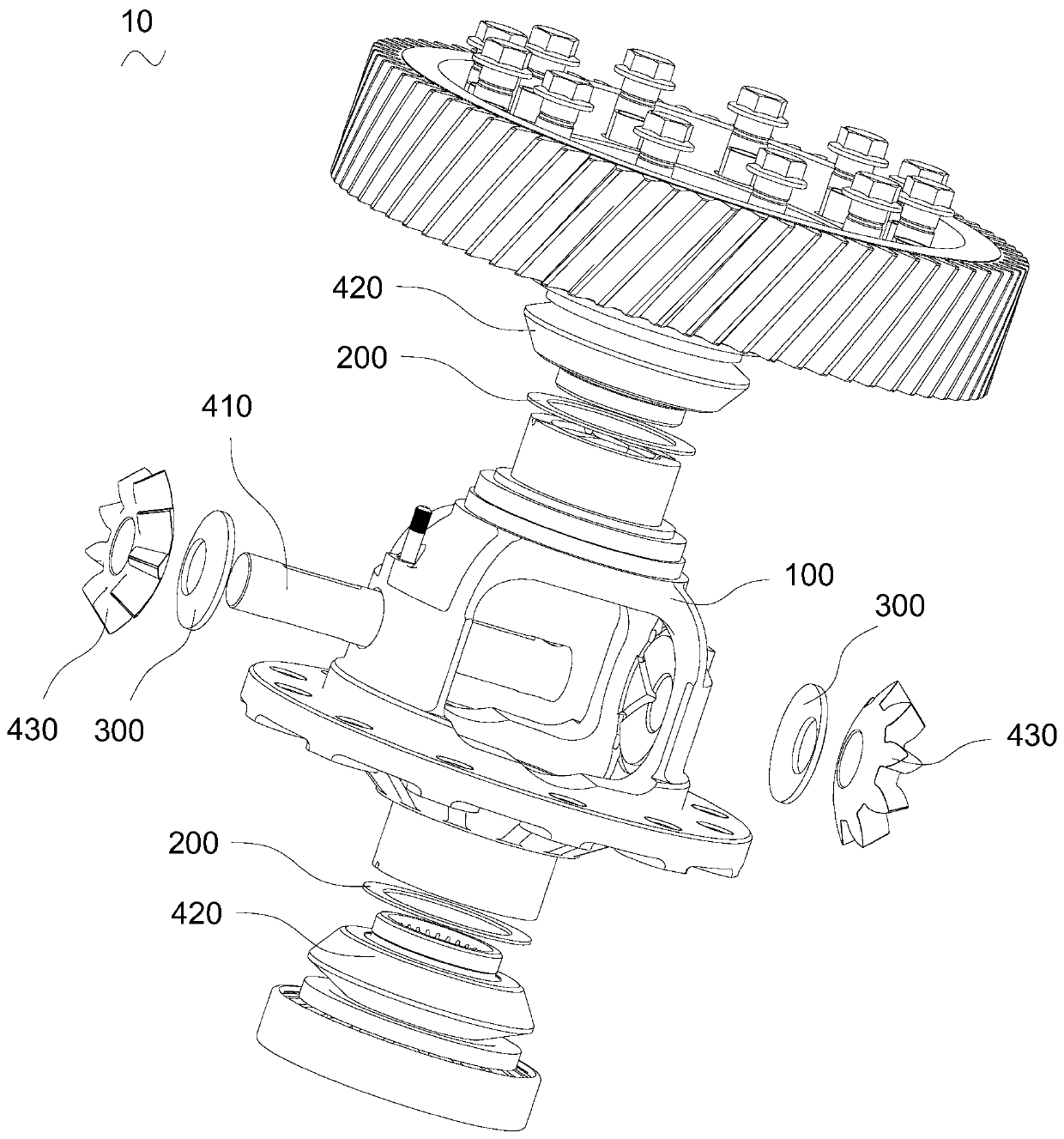

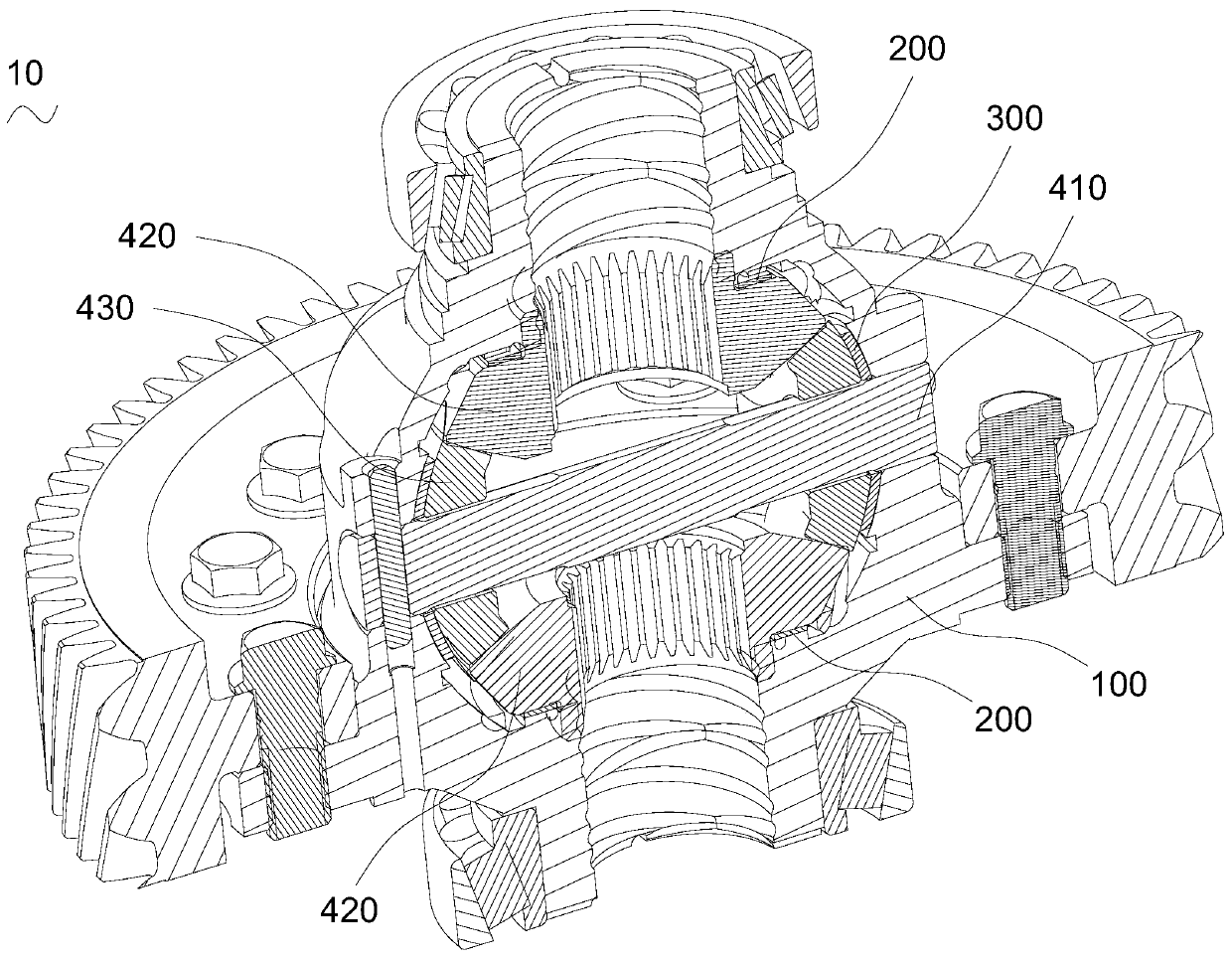

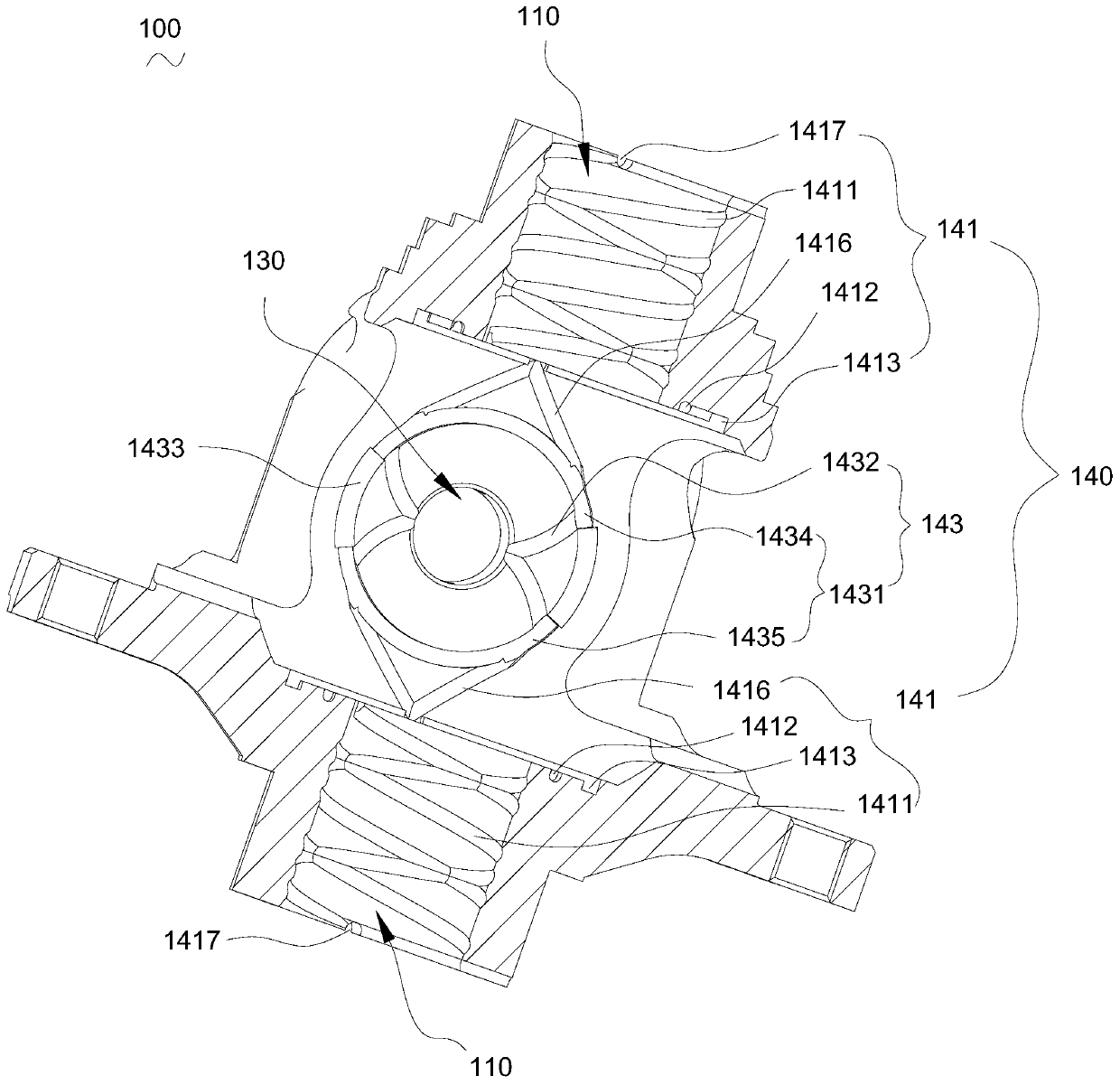

Differential mechanism and differential mechanism shell thereof

PendingCN110131395AImprove reliabilityReduce the temperatureGear lubrication/coolingEngineeringMechanical engineering

The invention relates to a differential mechanism and a differential mechanism shell thereof. The side wall of the differential mechanism shell is provided with half shaft installing through holes used for installing half shafts and a planet gear installing through hole used for installing a planet gear shaft; the differential mechanism shell is further provided with a lubricating pathway; the lubricating pathway comprises half shaft lubricating units and a planet gear lubricating unit; each half shaft lubricating unit comprises an oil guiding groove and a lubricating ring communicating with the oil guiding groove; the oil guiding grooves are formed in the hole walls of the half shaft installing through holes and spirally extend in the axial direction of the half shaft installing through holes; the lubricating rings are arranged on the portions, used for installing half shaft gear gaskets, of the inner wall of the shell in the circumferential direction of half shaft installing throughholes; the planet gear lubricating unit comprises an oil storing groove communicating with the lubricating rings and lubricating flow channels of which the two ends communicate with the oil storing groove and the planet gear installing through hole separately; the oil storing groove extends in the circumferential direction of the planet gear installing through hole; and the lubricating flow channels are arranged on the portions, used for installing planet gear gaskets, of the inner wall of the shell. Therefore, through arrangement of the lubricating pathway, the reliability of the differentialmechanism is greatly improved.

Owner:ZHUZHOU GEAR CO LTD

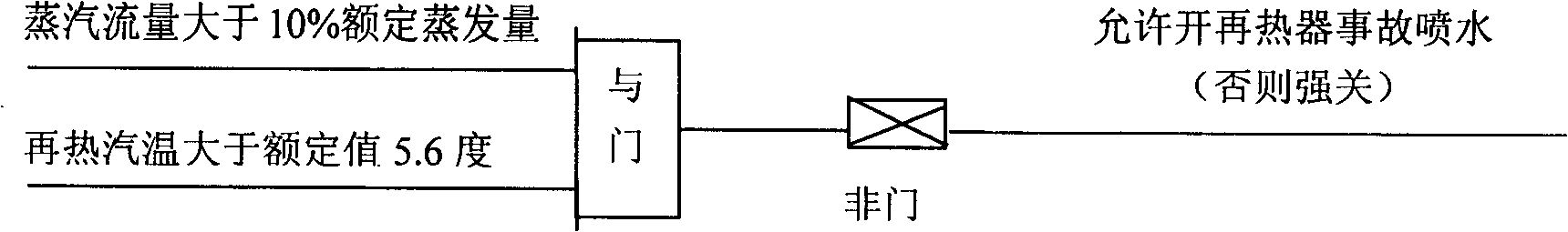

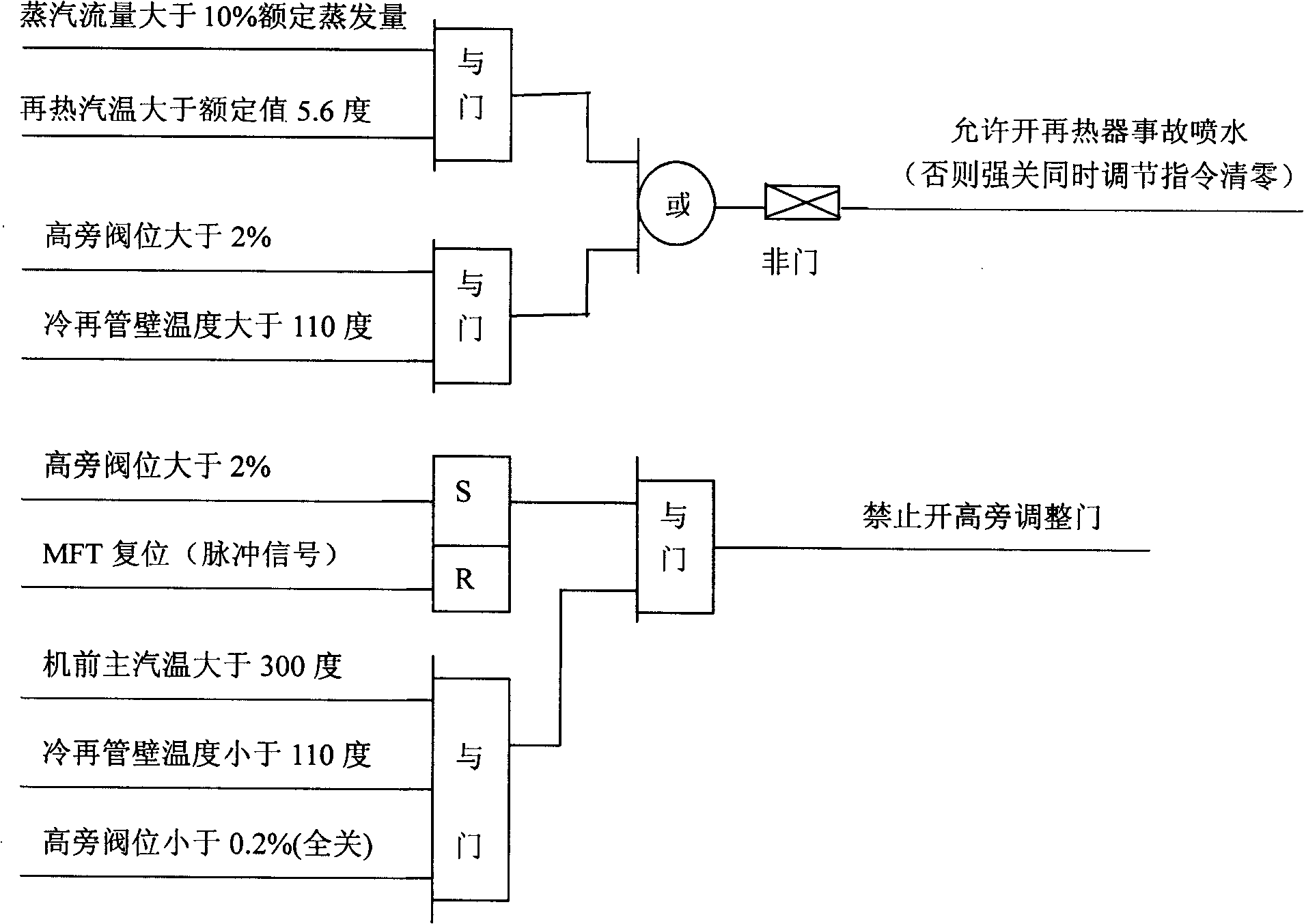

Protection for preventing heat-engine plant reheater cold segment pipe from generating water impact

InactiveCN101329061AReduce local overheatingReduce startup timeBoiler controlControl functionStart time

The invention relates to a protection technique used for preventing water shock from happening in a cold reheat pipe of a reheater in a heat-engine plant. The protection of the invention uses the basic control functions of a DCS system to realize the purpose of protecting the cold reheat pipe of the heat-engine plant and preventing water shock from happening in the cold reheat pipe of the reheater on the bases that the DCS control system, a bypass control system and a reheater cooling control system can all work normally and not only the requirements of relevant document of the power system can be met but also the conventional designed functions are not changed. Simultaneously, as a small quantity of water-spraying of the reheater is allowed to be input during the start of the unit, the temperature of reheated steam can be easily controlled, thus achieving the purpose of shortening the start time of the unit, saving energy and improving the economic efficiency of the unit. The protection technique can be widely applied to the thermal generator set with one-time intermediate reheating.

Owner:高利斌

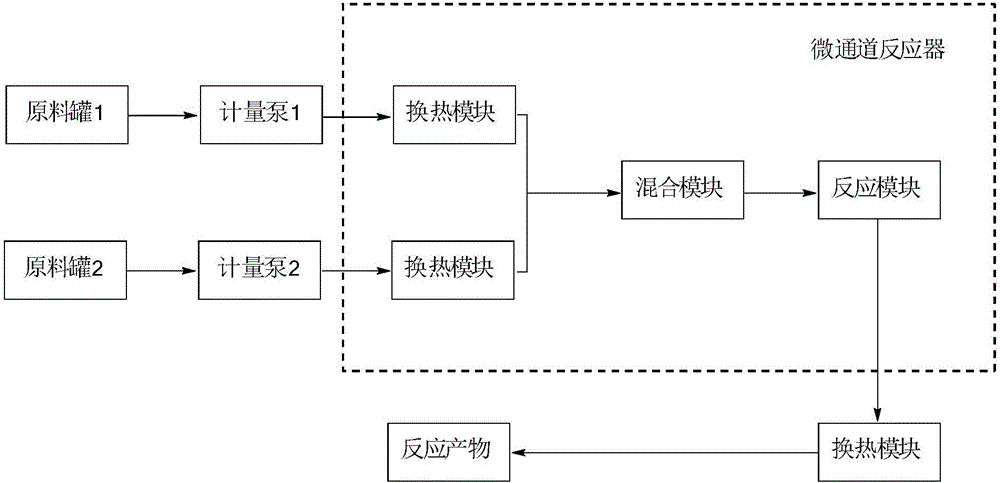

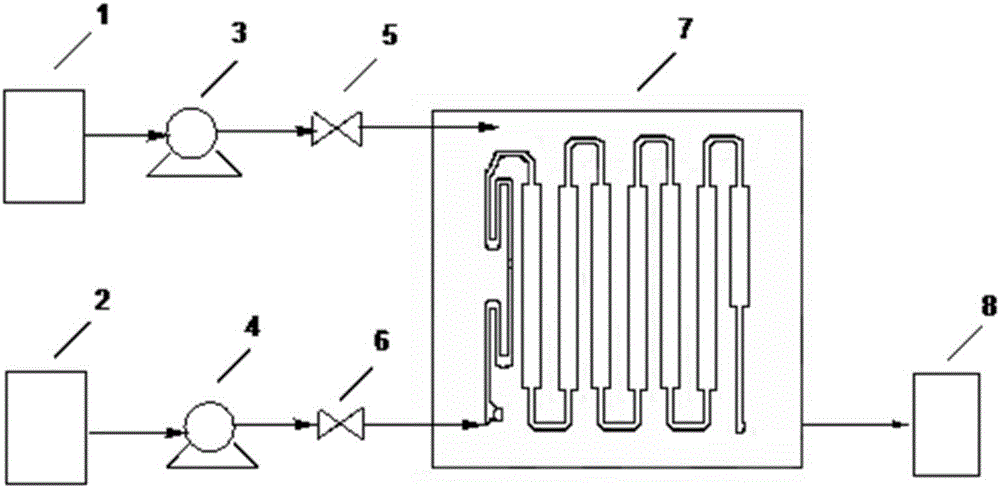

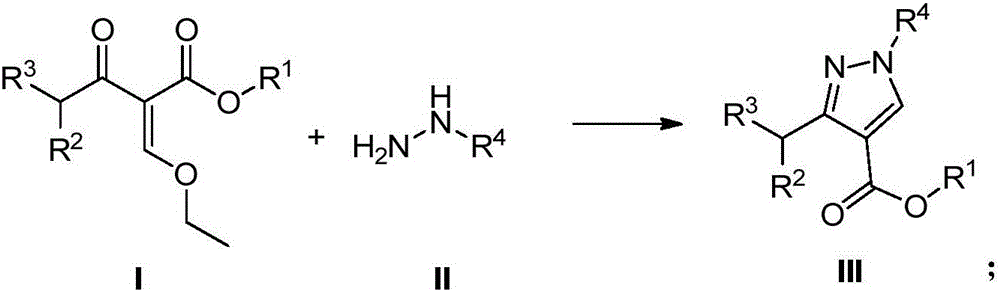

Pyrazole compound preparation method

InactiveCN106800535AEnhance heat and mass transferWell mixedOrganic chemistryHalogenRegioselectivity

The invention discloses a preparation method of a pyrazole compound which is shown as a formula III. The preparation method disclosed by the invention comprises the following step of introducing a compound which is shown as a formula I and a compound which is shown as a formula II into a micro-channel reactor through different pipelines to react to obtain the pyrazole compound, wherein reaction temperature is 10 to 60 DEG C, R1 is C1-C4 alkyl, R2 and R3 are halogen independently, and R4 is methyl or phenyl. The preparation method disclosed by the invention is performed through the micro-channel reactor, has extremely-short reaction time, accurate reaction condition control and high safety, is suitable for quickly preparing products, achieves continuous production and has low cost; furthermore, the micro-channel reactor is utilized to prepare the pyrazole compound, so that reaction region selectivity is high, target compound purity is good, and the preparation method is more suitable for large-scale industrial production.

Owner:LIANHE CHEM TECH TAIZHOU

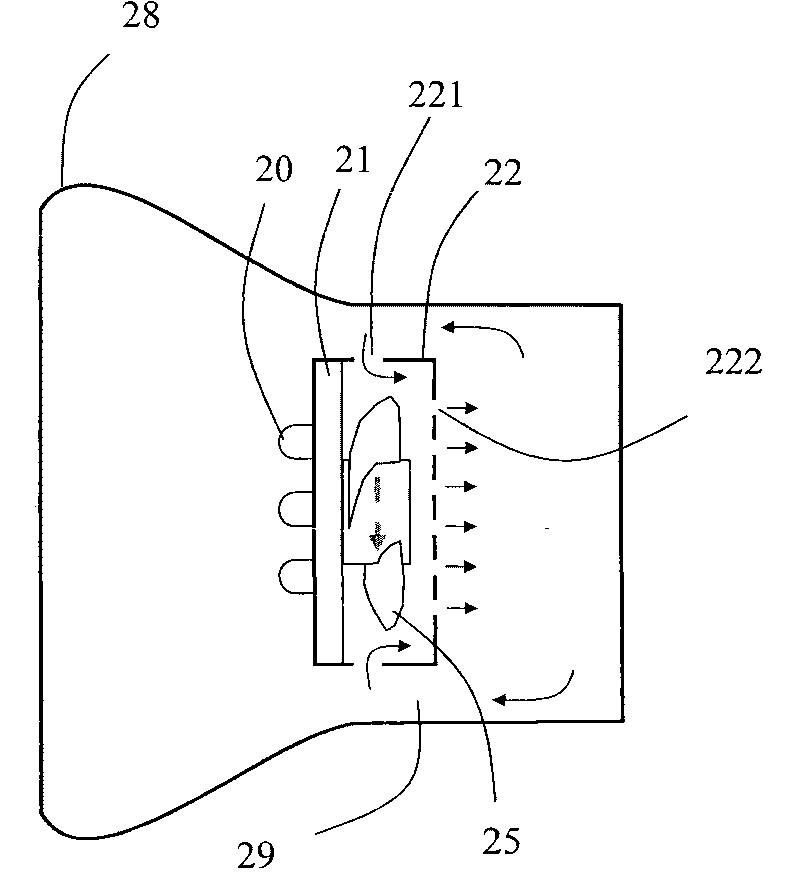

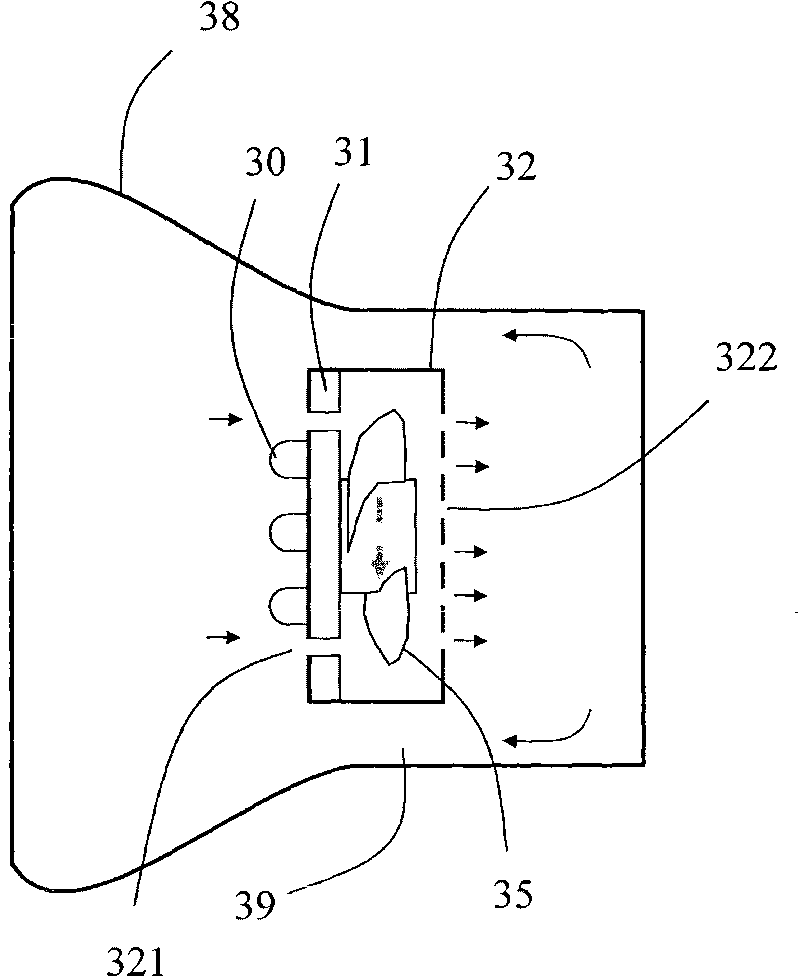

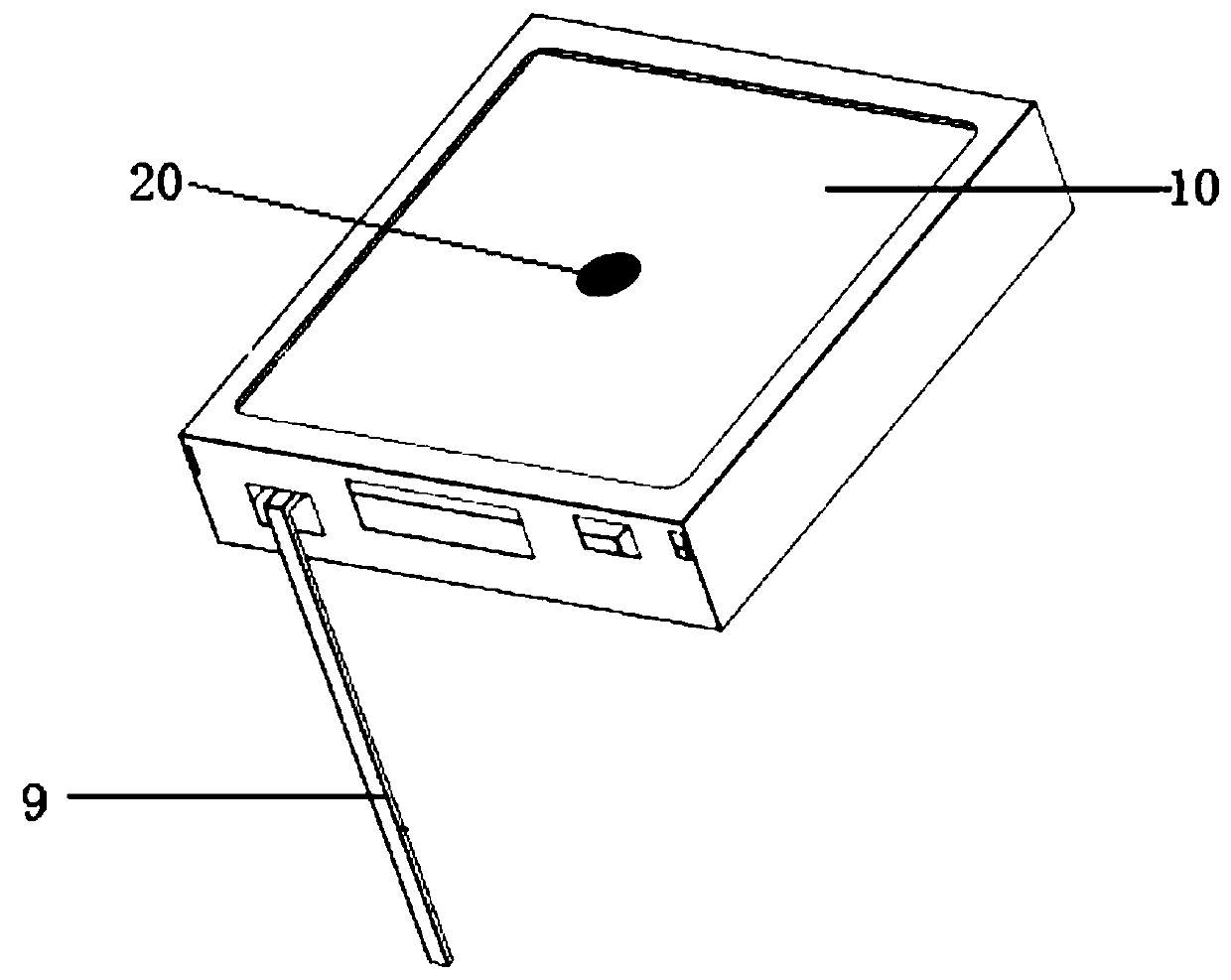

Sealed internal-circulation-forced LED (light-emitting diode) lamp

InactiveCN101737758AUniform distribution of internal temperatureReduce local overheatingPoint-like light sourceSemiconductor/solid-state device detailsEngineeringLED lamp

The invention discloses a sealed internal-circulation-forced LED (light-emitting diode) lamp. The lamp comprises a substrate, a fan, a sleeve frame and an outer cover, wherein the front face of the substrate is provided with a plurality of LED lamp bulbs, the fan is arranged at the back face or the side face of the substrate, the sleeve frame encloses at least one part of the fan, an air inlet is arranged around or behind the fan, the sleeve frame is provided with an air outlet in the blowing direction of the fan, and all the assemblies are enclosed and sealed by the outer cover. By arranging the fan in the sealed internal-circulation-forced LED lamp with the incorporation of the sleeve frame in the invention, the air in the sleeve frame can flow with the air outside the sleeve frame relatively when the fan rotates, so that the heat produced by the LED can be taken away, thereby distributing the internal temperature uniformly and preventing the LED luminous efficiency from lowering or a product from being burnt out as a result of the local overheating phenomena occurring near the LED lamp bulbs.

Owner:CHENG KUNG CAPITAL LLC

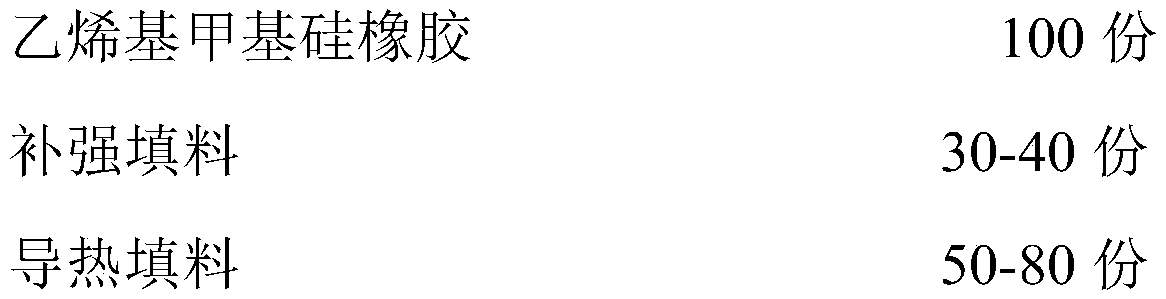

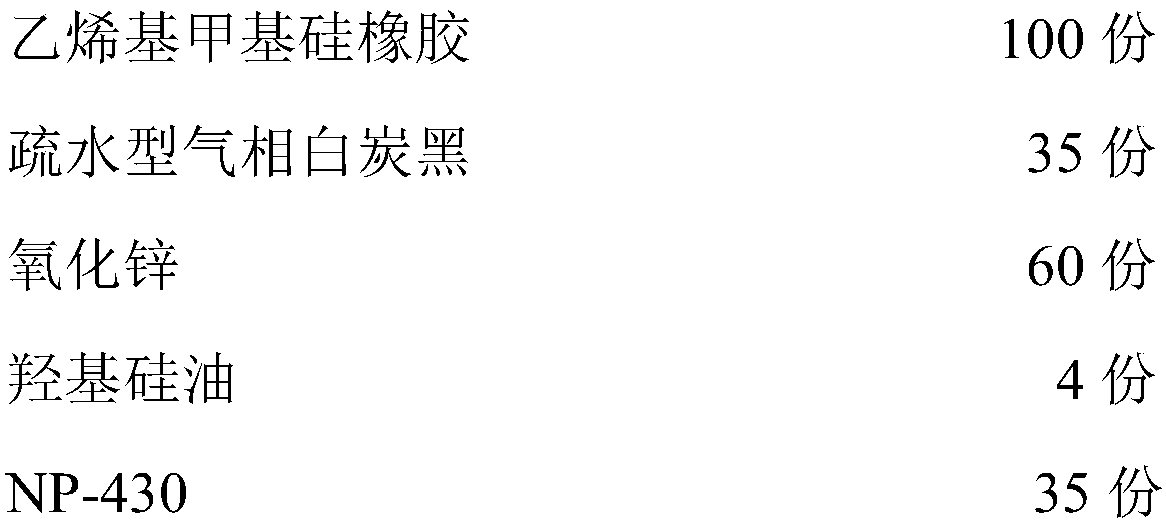

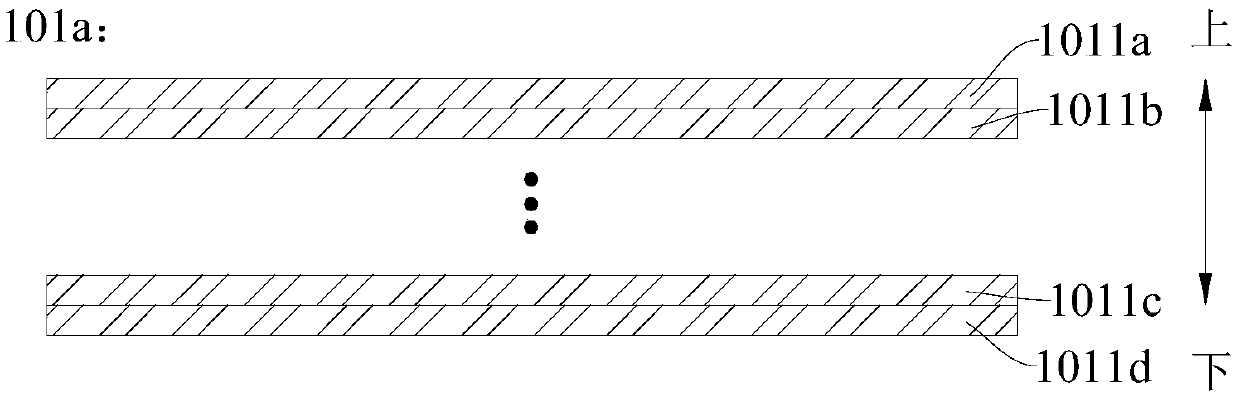

Silicon rubber insulation self-adhesive tape for electrical equipment and preparation method of silicon rubber insulation self-adhesive tape

InactiveCN109679576AAvoid accidentsGood for heat dissipationNon-macromolecular adhesive additivesMacromolecular adhesive additivesEngineeringFire retardant

The invention provides a silicon rubber insulation self-adhesive tape for electrical equipment. The self-adhesive tape comprises raw materials in parts by weight as follows: 100 parts of vinyl methylsilicone rubber, 30-40 parts of reinforcing filler, 50-80 parts of thermal conductive filler, 3-5 parts of a structure controlling agent, 25-40 parts of a flame retardant, 15-30 parts of temperature-indicating pigment, 5-15 parts of a crosslinking agent and 10-15 parts of polymethyl borosiloxane. The self-adhesive tape has the function of changing own color with temperature variation and has excellent insulativity and flame retardance.

Owner:WUHAN NANRUI ELECTRIC POWER ENG TECH EQUIP +1

Fermentation device and composting equipment with same

InactiveCN111470892AReduce local overheatingHeap body fermentation speed is uniformBio-organic fraction processingFertiliser treatment controlProcess engineeringSieve

The invention is applicable to the technical field of fermentation equipment, and provides a fermentation device and composting equipment with the same. The fermentation device comprises a shell and astirring assembly; the stirring assembly is connected with a rotating part; a plurality of supporting pieces are arranged in the shell, sieve plates are arranged on the supporting pieces, a ventilation assembly is arranged on the outer side of the shell and used for introducing gas into the shell, the ventilation assembly comprises an air inlet and an opening and closing piece which is arranged on the air inlet and used for adjusting the opening degree of the air inlet, and a driving mechanism used for driving the opening and closing piece to move is correspondingly arranged on the shell. Materials in a fermentation bin are stirred and mixed through the stirring assembly; the phenomenon of local overheating of internal materials due to the arrangement of an auxiliary heating device is reduced, and composting body fermentation speed is uniform; meanwhile, air is introduced into the shell through the ventilation assembly, the opening degree of the air inlet can be adjusted according toneeds, ventilation is facilitated, and the problems that materials are prone to local overheating and anaerobic fermentation is prone to occurring due to the closed environment in an existing compostbox are solved.

Owner:苏州启清环境科技有限公司

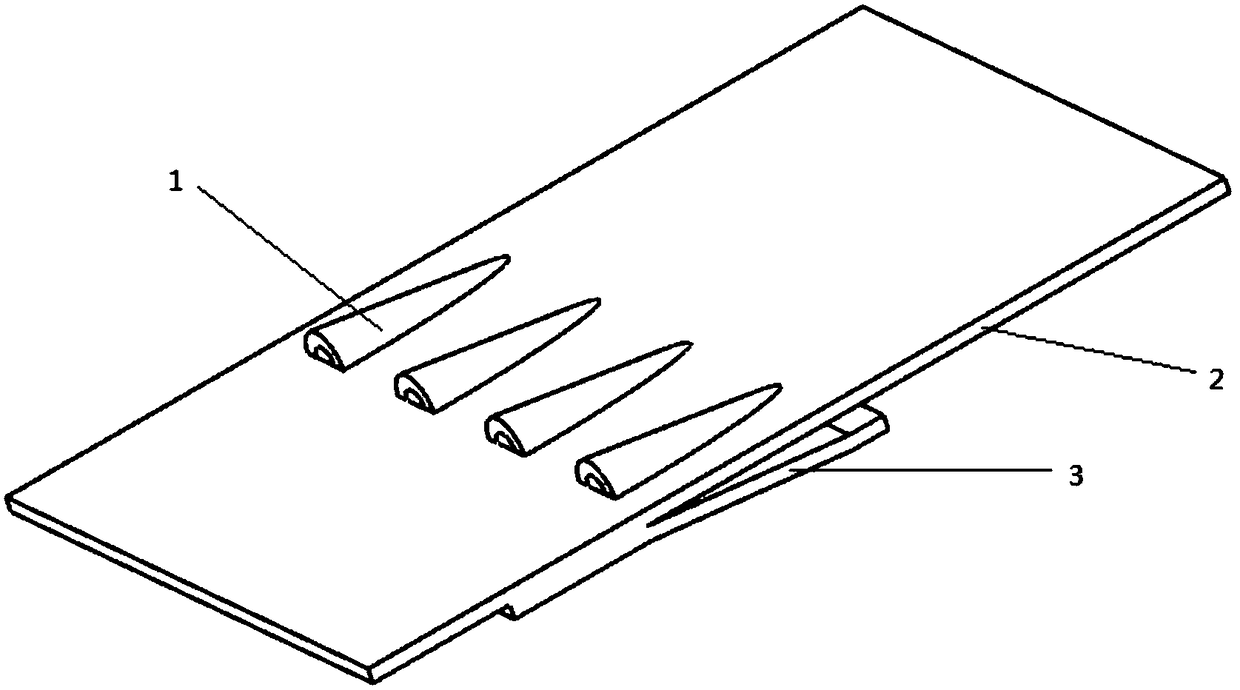

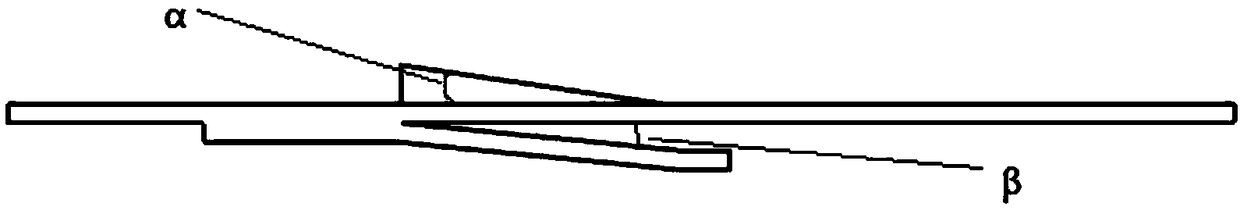

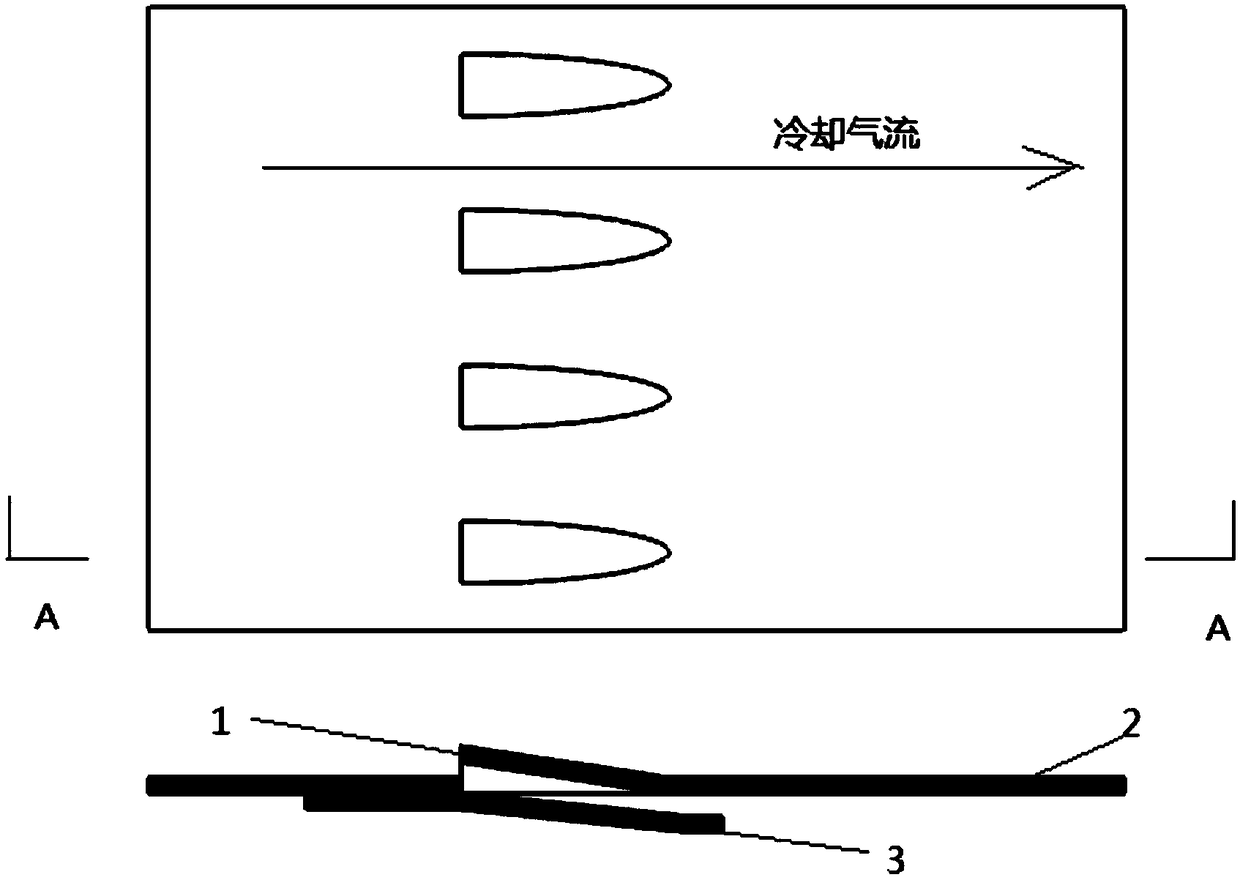

Combustion chamber flame tube wall adopting novel convex-wall inclined holes

InactiveCN109340825AImprove cooling efficiencyImprove flow coefficientContinuous combustion chamberCombustion chamberWorking life

The invention provides a combustion chamber flame tube wall adopting novel convex-wall inclined holes. Convex-wall inclined hole channels which obliquely penetrate through and protrude from the flametube wall are evenly distributed in the flame tube wall in the circumferential direction, the front and back adjacent convex-wall inclined hole channels are arranged in a staggered mode in the axial direction of a flame tube, and flow baffles are arranged on the inner wall of the flame tube and matched with the convex-wall inclined hole channels. Compared with existing flame tube wall structures,the combustion chamber flame tube wall has the advantages that after cooling airflow flows through the convex-wall inclined hole channels, a layer of uniform cooling air membrane which is tight in front-back connection is formed on the inner wall of the flame tube, cooling efficiency is high, the cooling airflow channels are not liable to be blocked, local overheat is not prone to being caused, and the working life of a combustion chamber is greatly prolonged. The combustion chamber flame tube wall is simple in structure and easy to process and manufacture and has great application value in practical work.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

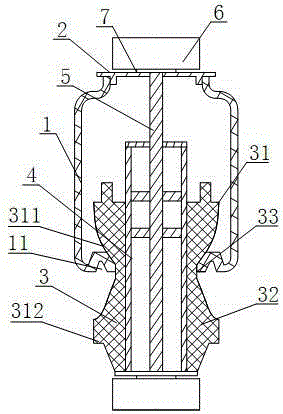

Instant steam generation device

InactiveCN105299610AGuarantee safe and reliableLow costSteam generation heating methodsWater storage tankEngineering

The invention provides an instant steam generation device which comprises a water storage tank with a water filling nozzle and a volume-type heater. The instant steam generation device is characterized by further comprising a steam buffer section, the bottom of the water storage tank is communicated with an inlet in the bottom of the volume-type heater through a water pipe with a one-way valve, an outlet in the top of the volume-type heater is communicated with the bottom of the steam buffer section through a steam pipe, and the upper portion of the steam buffer section is connected with a steam supply pipe with a one-way valve; and the bottom of the water storage tank is higher than the top of the volume-type heater and the bottom of the steam buffer section is higher than the highest liquid level of the water storage tank. By the adoption of the instant steam generation device, no outer power pump is used, control is easy, convenient, safe and reliable, and the generation device generates steam as a common steam heating water storage tank.

Owner:北京古龙嘉兰生物技术有限公司

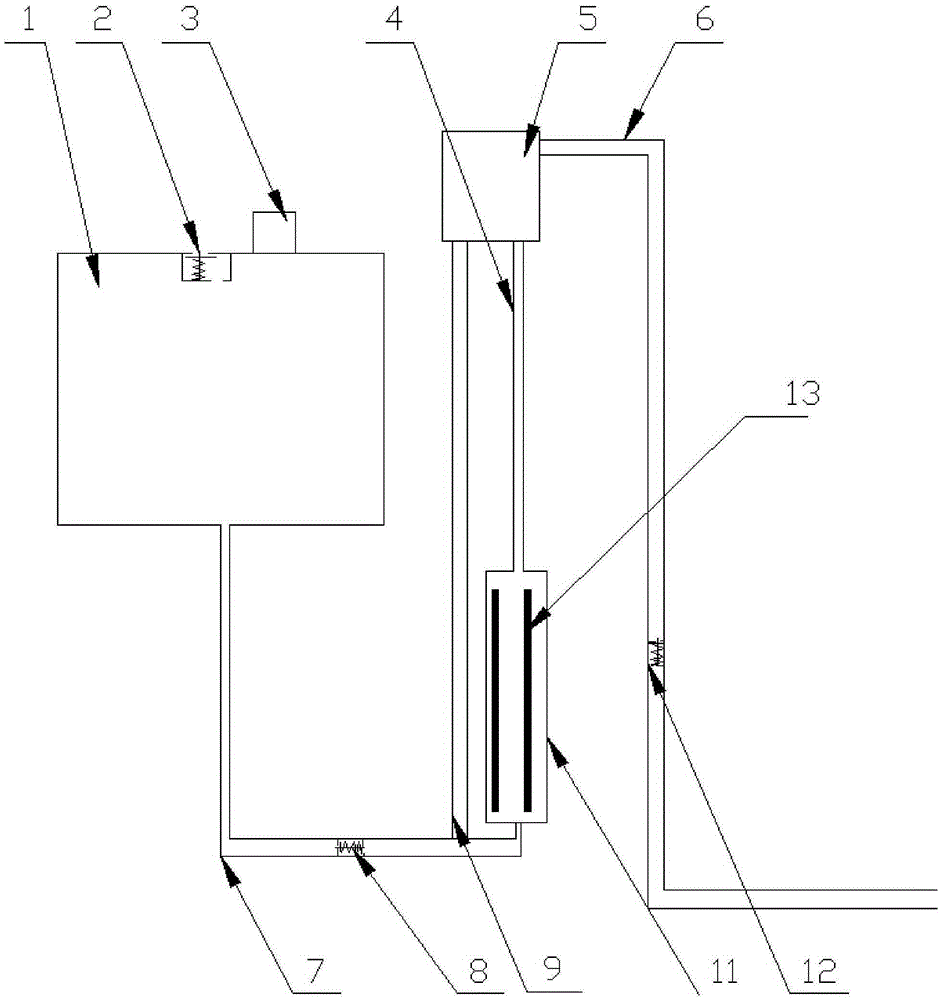

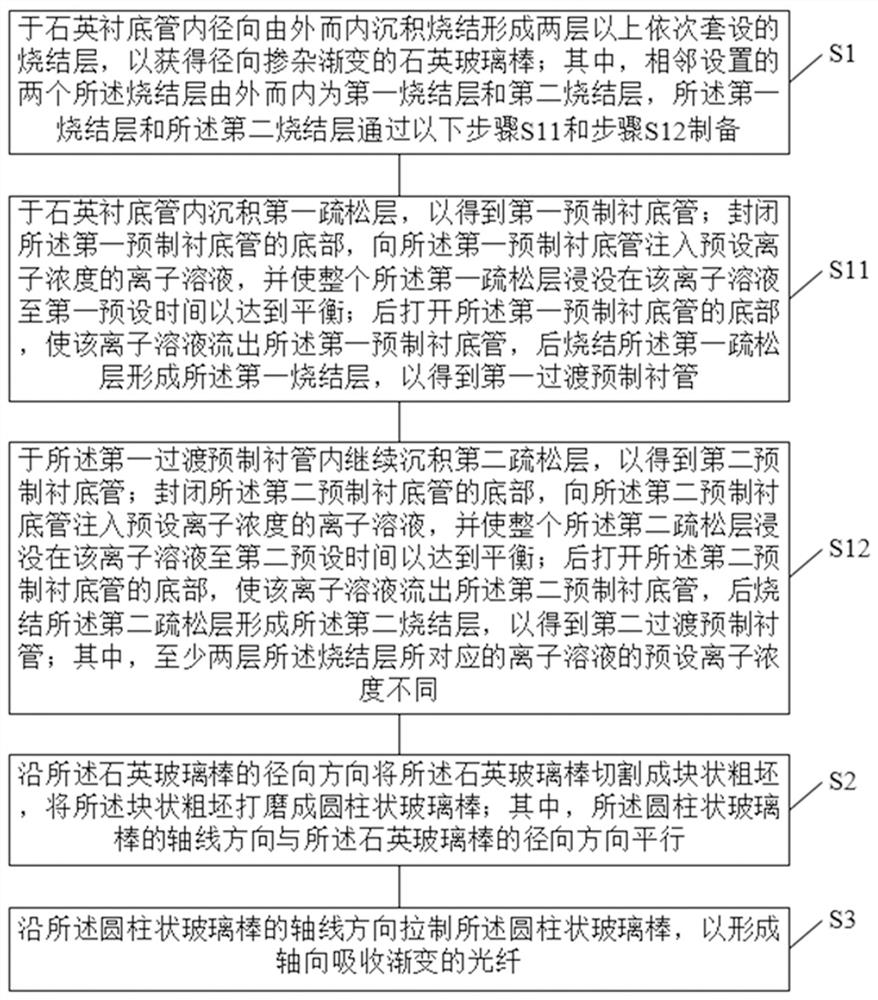

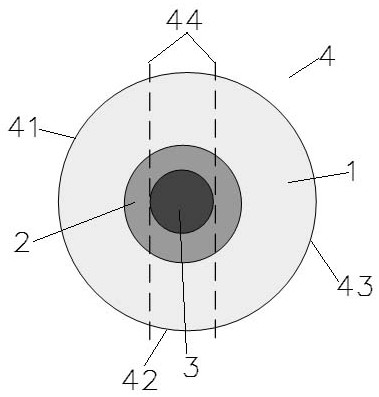

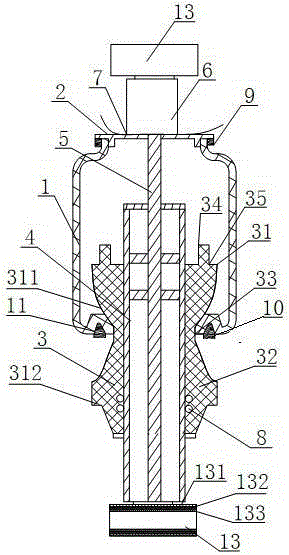

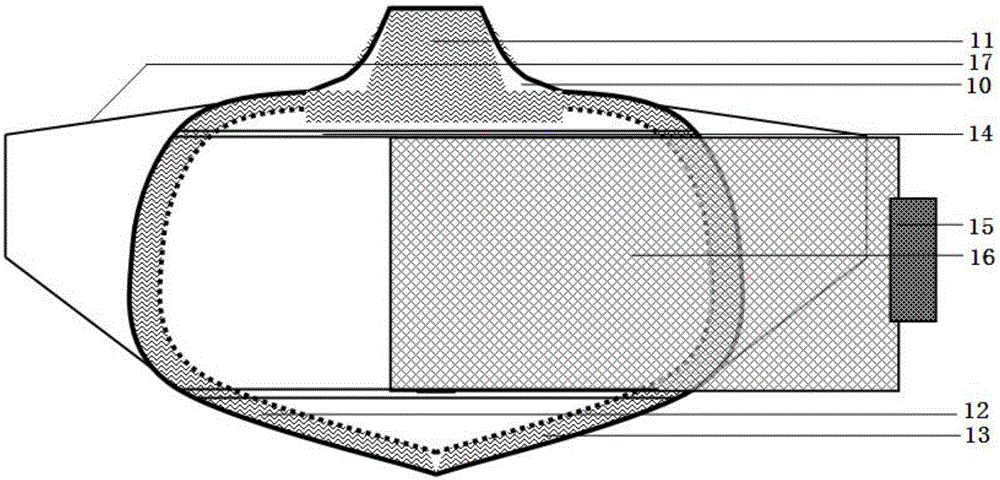

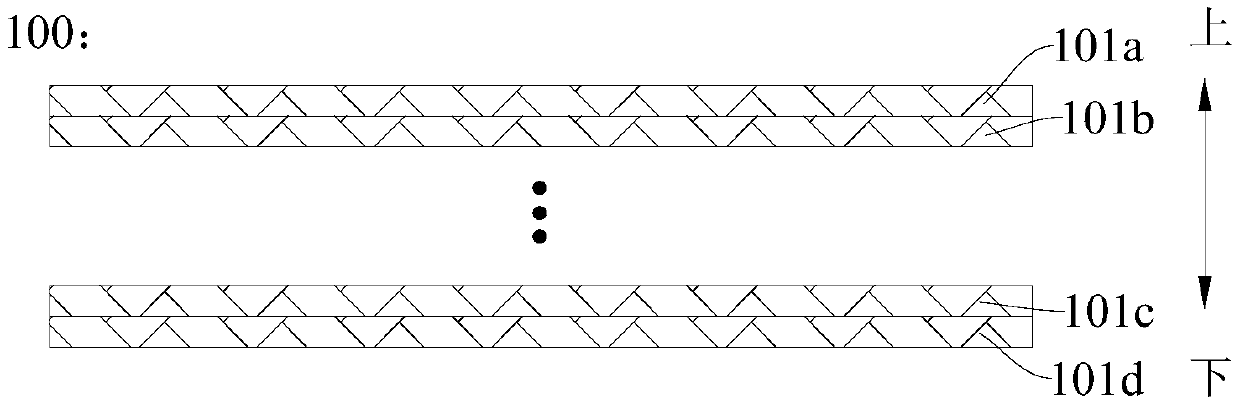

A kind of axial absorption graded optical fiber and its preparation method, fiber laser

ActiveCN112142319BIncrease Mode Instability ThresholdImprove cooling effectGlass making apparatusActive medium shape and constructionHigh power lasersErbium lasers

The invention discloses an axially absorbing graded optical fiber, a preparation method thereof, and a fiber laser. The preparation method comprises the steps of: depositing and sintering in a quartz substrate tube radially from the outside to the inside to form two or more sintered layers sequentially sleeved; In order to obtain a quartz glass rod with a radial doping gradient; the quartz glass rod is cut into a block-shaped rough blank along the radial direction of the quartz glass rod, and the block-shaped rough blank is ground into a cylindrical glass rod; wherein , the axial direction of the cylindrical glass rod is parallel to the radial direction of the quartz glass rod; the cylindrical glass rod is drawn along the axial direction of the cylindrical glass rod to form an optical fiber with an axial absorption gradient. The invention solves the problem of uneven thermal load and mode instability in the high-power fiber laser, and realizes higher power laser output; and the invention has the advantages of simple structure, easy realization, stability and reliability, and the like.

Owner:武汉光谷航天三江激光产业技术研究院有限公司

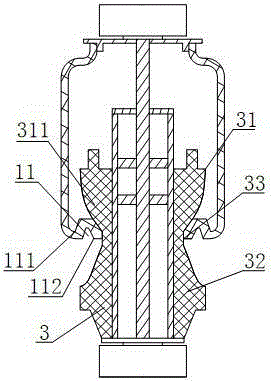

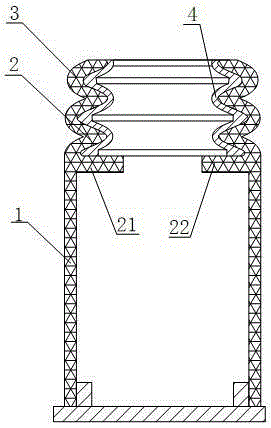

Piston type rubber air suspension assembly for vibration reduction of vehicle cab

InactiveCN105172911AReduce deformationImprove working conditionSpringsShock absorbersAir springReducer

The invention discloses a piston type rubber air suspension assembly for vibration reduction of a vehicle cab. The assembly comprises a bag type body, an end cover, a piston, a vibration reducer and a support rod, wherein the end cover and the piston are respectively connected to the two ends of the bag type body; the vibration reducer coats the internal part of the piston; the support rod coats the internal part of the vibration reducer to slide, and extends to the top position of the end cover; a connecting head is arranged at the outer side, in the top position of the end cover, of the support rod; the piston comprises an insertion end and a free end; the insertion end is inserted in the bag type body; and a connecting head is arranged at the tail end of the free end. The assembly is simple in structure, convenient for manufacturing and easy to realize a process, and improves the phenomenon of shorter service life and local heating of a rubber airbag caused by excessive deformation and strain due to frequent use of a rubber air spring in the use process, so that the service life of the rubber air spring is prolonged, and the quality of the rubber air spring is enhanced.

Owner:GASTECH VEHICLE PARTS

Self-restoring rubber air spring

InactiveCN105179578BRelieve work stressExtend working lifeSpringsGas based dampersBladder partSelf recovery

The invention discloses a self-recovery rubber air spring. The self-recovery rubber air spring comprises a column-shaped main body. At least one end of the column-shaped main body is provided with a bent bladder part. Each bent bladder part comprises two or more bent bladder units. The two ends of the inner wall of each bent bladder part are provided with a left protrusion and a right protrusion which are towards the axial center position of the column-shaped main body respectively, and a spring is arranged between the left protrusion and the right protrusion in each bent bladder part. In addition, the springs are in a free state when the rubber air spring works. According to the self-recovery rubber air spring, the structural features are improved, so that the self-recovery capability of the rubber air spring during work is improved; the strength and self-adjusting capability of the rubber air spring is enhanced; the service life is prolonged, and the quality is improved.

Owner:GASTECH VEHICLE PARTS

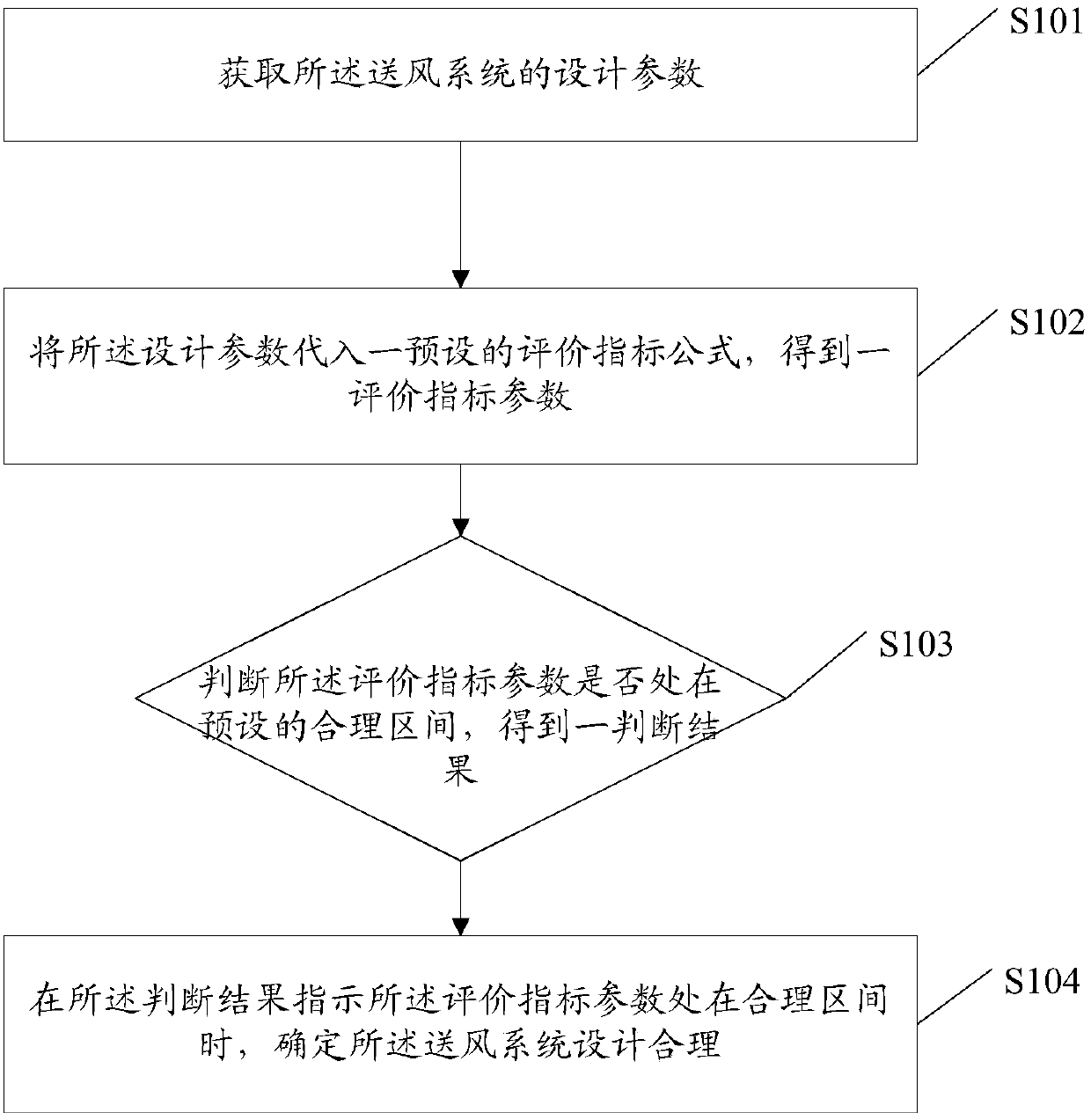

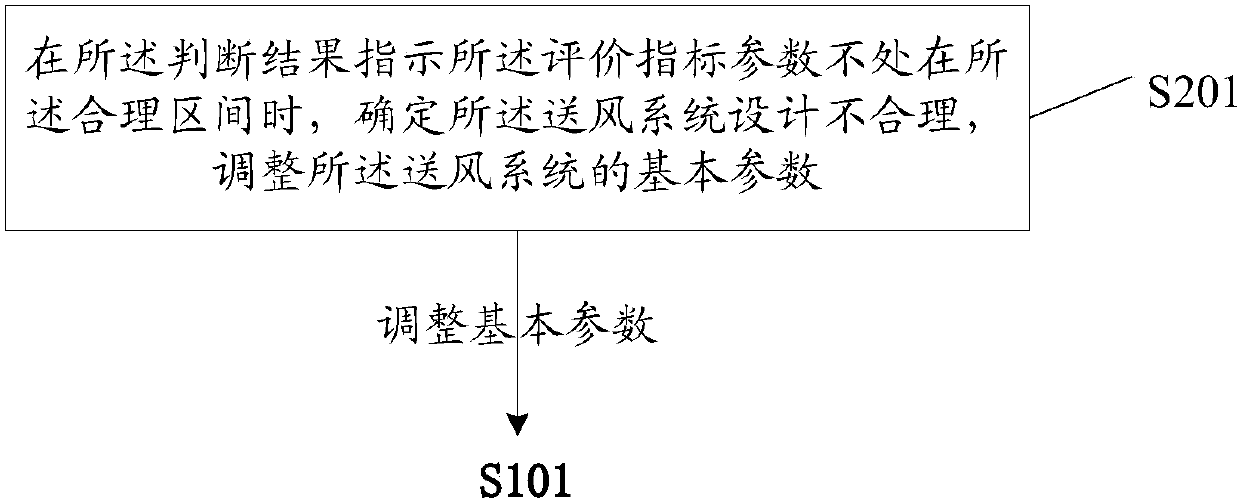

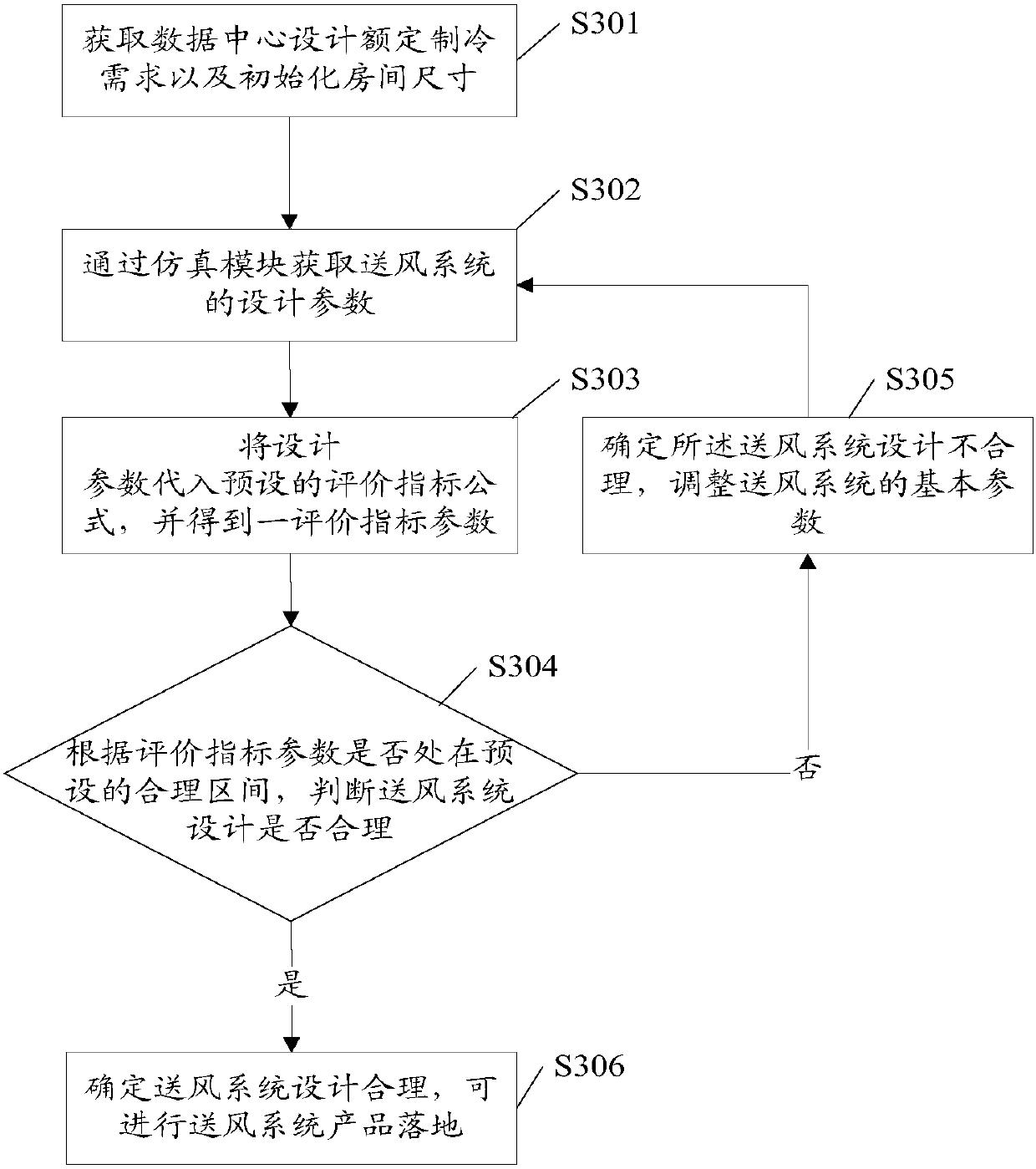

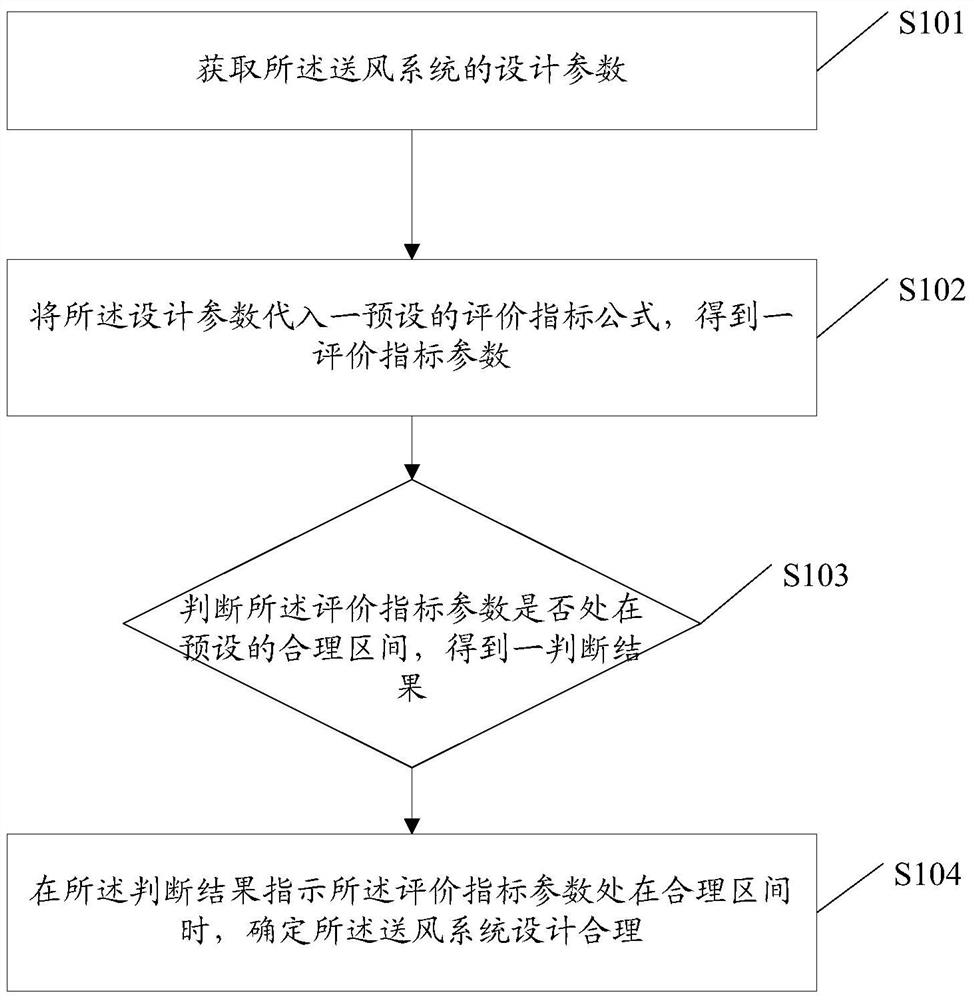

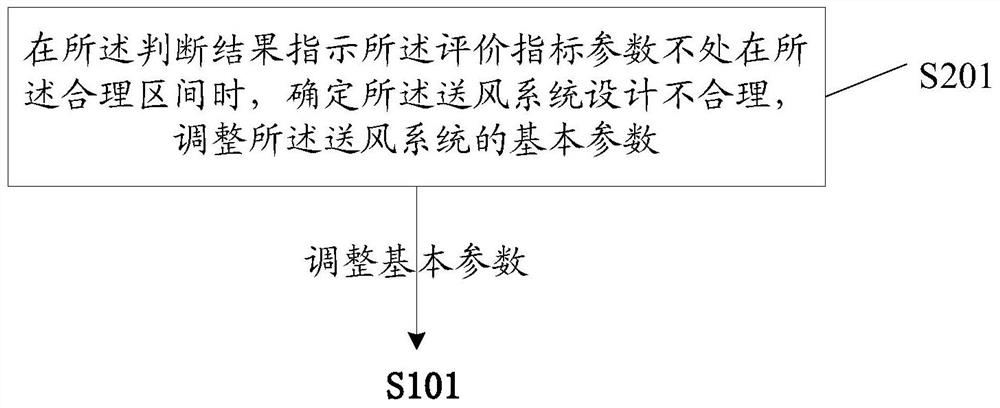

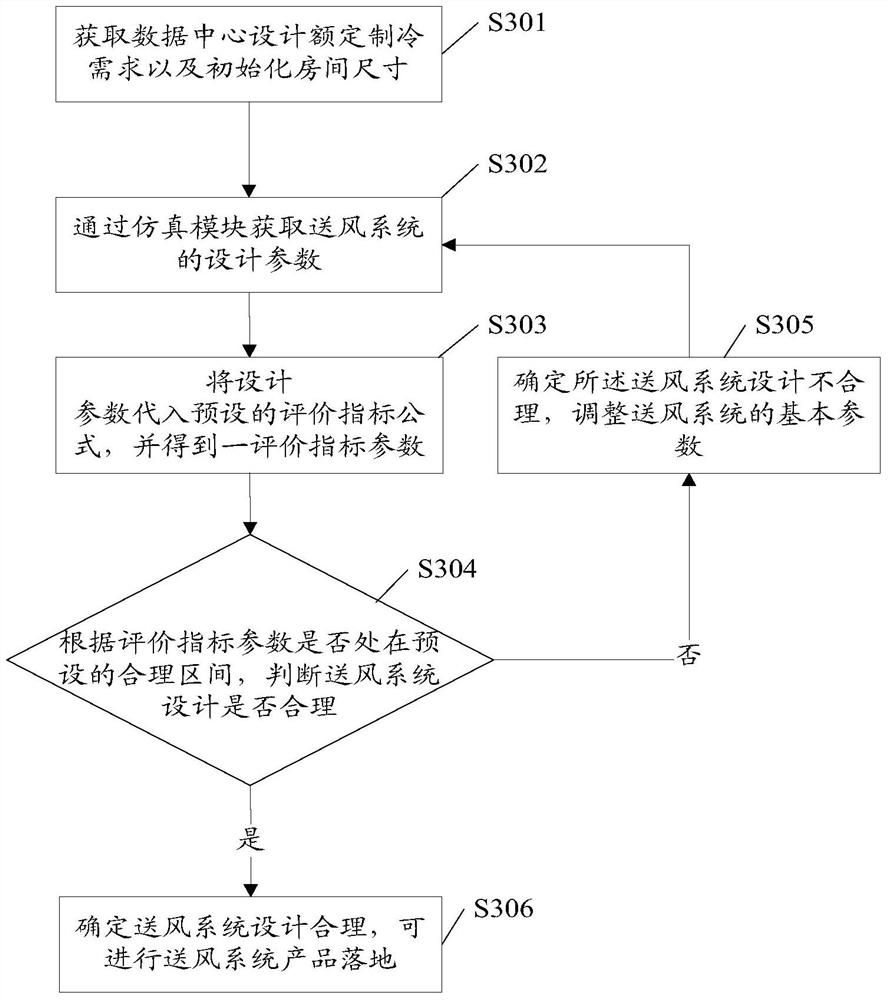

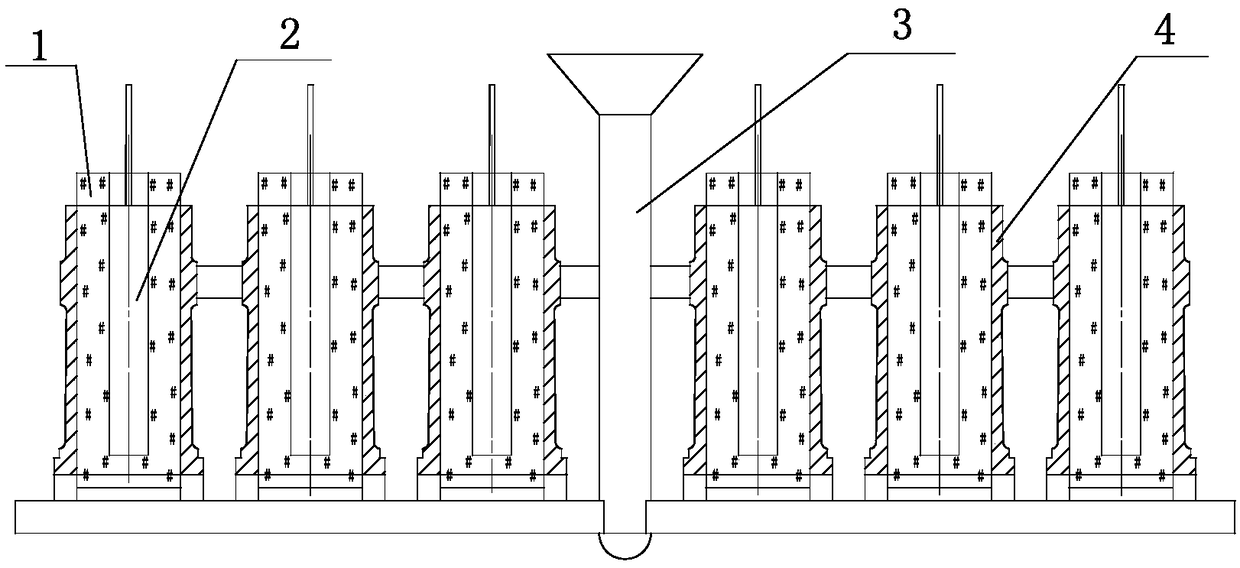

Evaluation method and apparatus for air supply system

ActiveCN107609204AReasonable designImprove uniformitySpace heating and ventilation safety systemsLighting and heating apparatusSystems designIndustrial engineering

The invention provides an evaluation method for an air supply system. The method comprises the steps of obtaining design parameters of the air supply system; substituting the design parameters into apreset evaluation index formula to obtain an evaluation index parameter; judging whether the evaluation index parameter is in a preset reasonable interval or not to obtain a judgment result; and whenthe judgment result indicates that the evaluation index parameter is in the reasonable interval, determining that the air supply system is reasonable in design. The uniformity of the air supply distance and the air supply speed of the air supply system can be effectively improved; and local overheating of the air supply system is reduced.

Owner:ZTE CORP

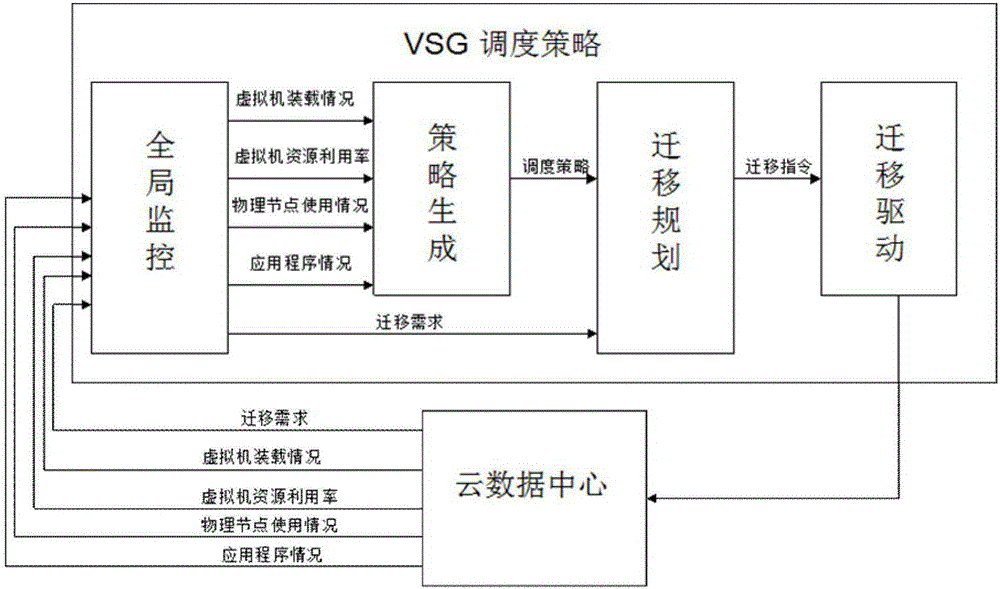

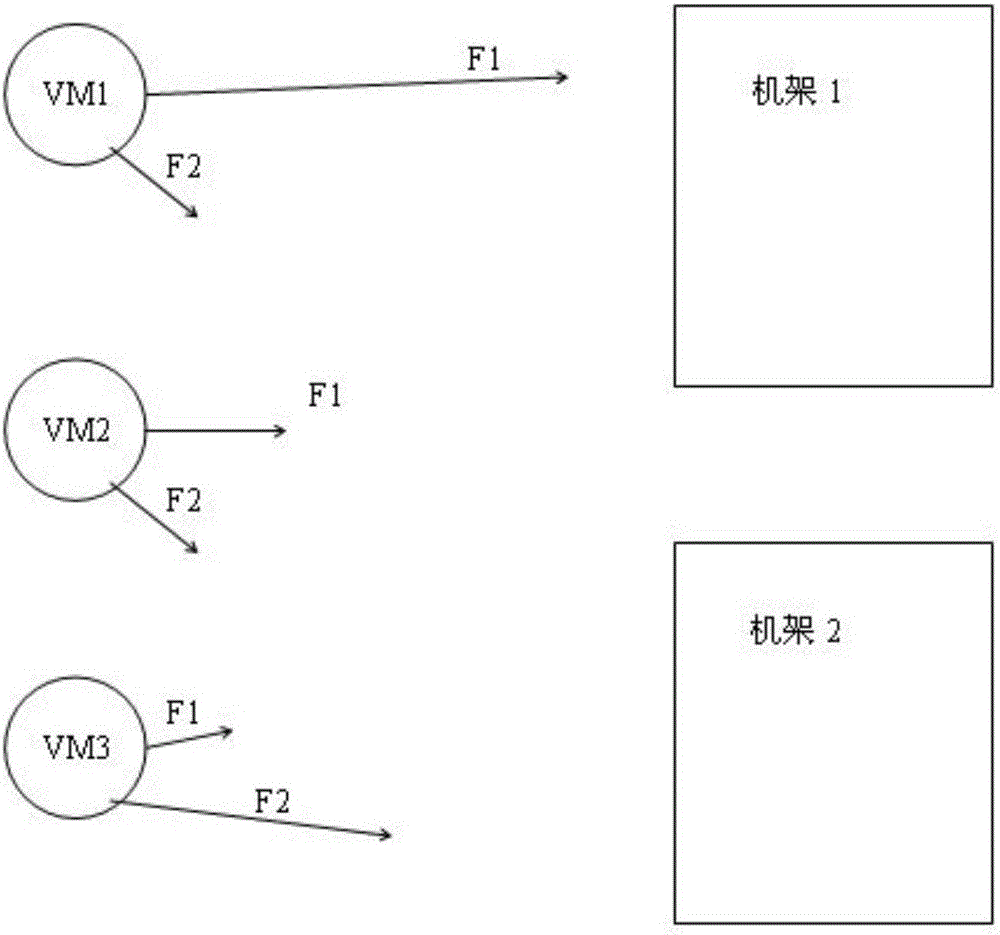

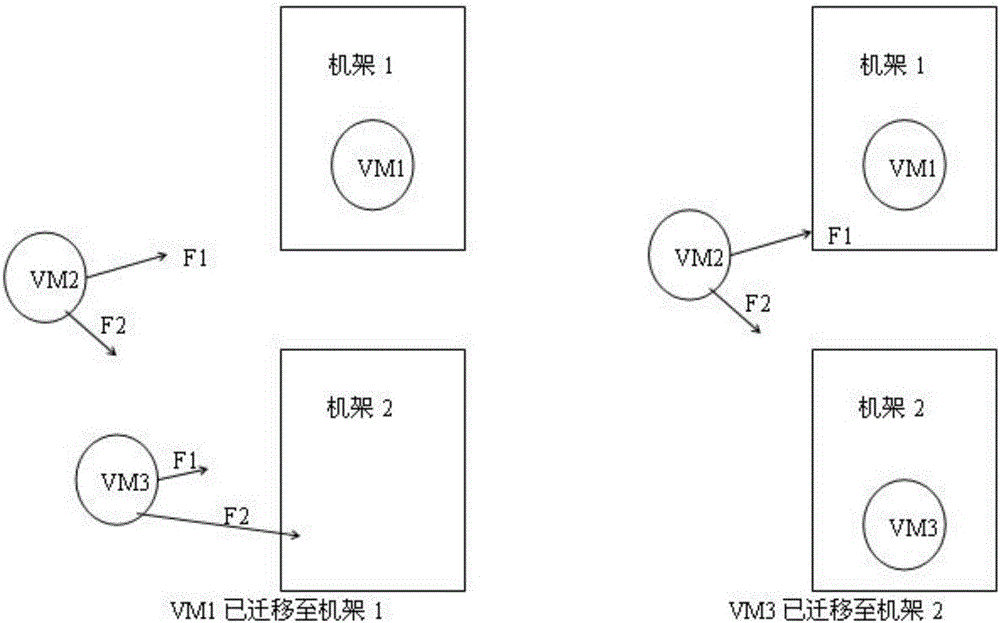

Virtual machine migration method facing green cloud computing

ActiveCN105955795AAvoid local overheatingReduce local overheatingProgram initiation/switchingEnergy efficient computingMassive gravityDiffusion

The invention discloses a virtual machine migration method facing green cloud computing; the method combines with physics gravitation correlation concepts according to cloud data center server disposition and temperature control mode real conditions, and defines concepts like logic gravitation, correction factor and correction gravitation between physics nodes and the virtual machines; the logic gravitation gathers virtual machines in sequence onto certain data node or data nodes of adjacent areas, thus closing idle nodes; the correction factor can realize virtual machine diffusion on locally heated data nodes, thus stabilizing the system, and preventing node system from collapsing or being damaged; the correction gravitation can preferably gather the virtual machines onto the data node with good thermal diffusivity according to the heat distribution condition and thermal diffusion performance priority strategy in the cloud data center, thus realizing heat distribution balance, and preventing overheating of a frame portion with poor thermal diffusivity; the method can obviously reduce data center energy consumption, can gather the virtual machines, can close partial computing nodes and related refrigeration nodes, thus maximumly saving energy consumption.

Owner:SUZHOU LANGDONG NET TEC CO LTD

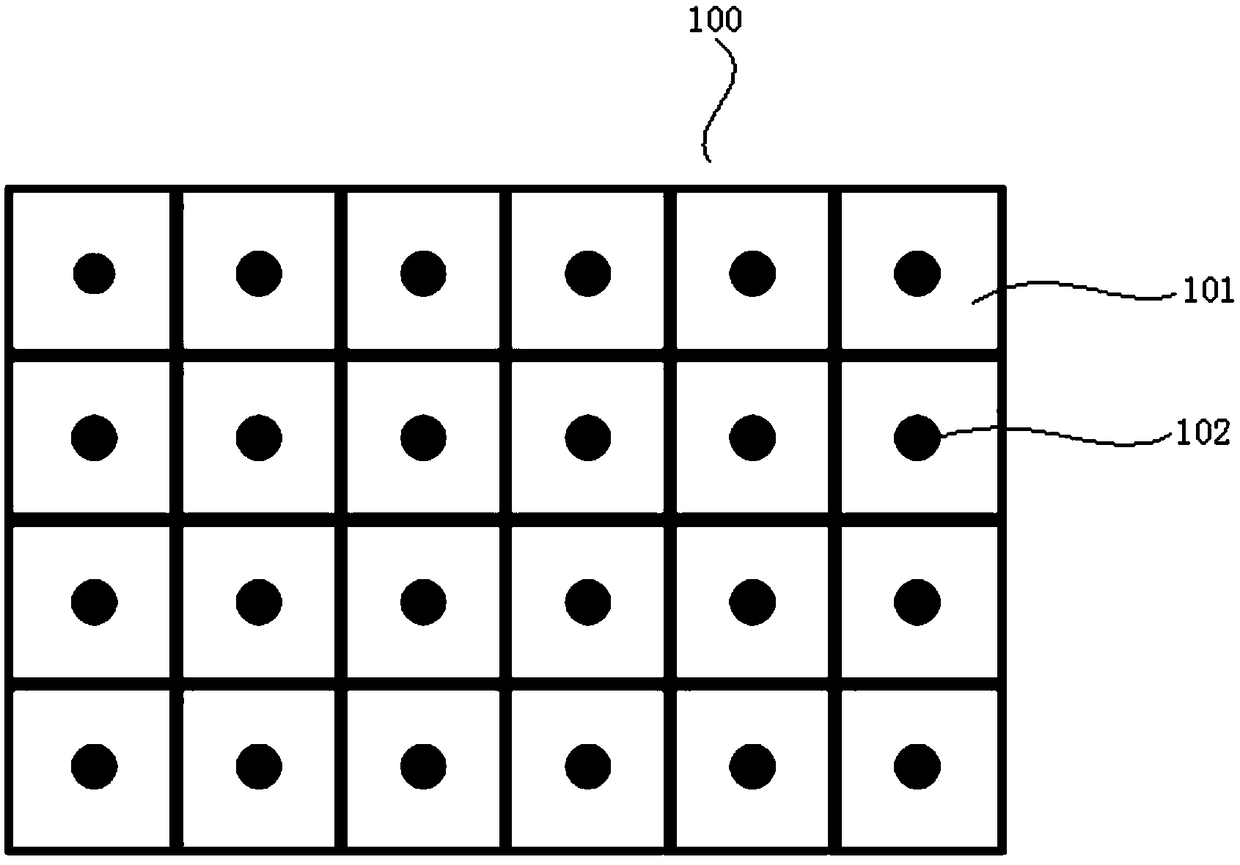

Far infrared treatment rehabilitation equipment

PendingCN109125940AControl heating powerAverage temperature distributionLight therapyFiberCarbon fibers

The invention provides far infrared treatment rehabilitation equipment. The equipment comprises a central controller and at least one carbon fiber plate taking as a heat source. Each carbon fiber plate is formed through splicing a plurality of carbon fiber lattices. Each carbon fiber lattice is connected to a power supply unit and the lattice is provided with a temperature sensor. Each power supply unit and each temperature sensor are electrically connected to a central controller. By using the far infrared treatment rehabilitation equipment, the carbon fiber plate is divided into the plurality of carbon fiber lattices, which means that a heating area is divided into a plurality of sub areas. Each sub area is provided with one carbon fiber lattice. Through each temperature sensor, the real-time temperature of each carbon fiber lattice is fed back to the central controller to control the heating power of each carbon fiber plate so that the temperature distribution of each area of the carbon fiber plate is average as far as possible, a condition that the local temperature of one carbon fiber plate is too high is reduced, and a treatment rehabilitation effect and a user experience feeling are improved.

Owner:SUZHOU ZHONGKE ADVANCED TECH RES INST CO LTD

Hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and solution polymerization preparation method thereof

The invention discloses a hexadecafluoro-1-octene modified polyperfluoro ethylene-propylene resin and a solution polymerization preparation method thereof. According to the solution polymerization preparation method, tetrafluoroethylene, hexafluoropropylene and hexadecafluoro-1-octene serve as copolymerizable monomers, wherein a molar fraction of the tetrafluoroethylene to hexafluoropropylene to hexadecafluoro-1-octene is (80-95):(4.9-15):(0.1-5). The preparation process comprises the following steps: adding a fluorine-containing solvent and copolymerizable monomers into a reactor at a certain temperature, raising the temperature to 20-60 DEG C, adding a perfluoro initiator to initiate a polymerization reaction under the pressure of 1.1-1.5MPa, supplementing the copolymerizable monomers in the reaction process, and finally preparing the modified polyperfluoro ethylene-propylene. The modified monomers are taken as polyperfluoro monomers, so that the prepared modified polyperfluoro ethylene-propylene resin is excellent in heat resistance, causes no aggregate dyeing phenomenon, can serve as a high-speed extrusion grade product and can be stably coated on a cable surface at a high speed of 300-500m / min.

Owner:JUHUA GROUP TECH CENT

Self-recovery rubber air spring

The invention discloses a self-recovery rubber air spring. The self-recovery rubber air spring comprises a column-shaped main body. At least one end of the column-shaped main body is provided with a bent bladder part. Each bent bladder part comprises two or more bent bladder units. The two ends of the inner wall of each bent bladder part are provided with a left protrusion and a right protrusion which are towards the axial center position of the column-shaped main body respectively, and a spring is arranged between the left protrusion and the right protrusion in each bent bladder part. In addition, the springs are in a free state when the rubber air spring works. According to the self-recovery rubber air spring, the structural features are improved, so that the self-recovery capability of the rubber air spring during work is improved; the strength and self-adjusting capability of the rubber air spring is enhanced; the service life is prolonged, and the quality is improved.

Owner:GASTECH VEHICLE PARTS

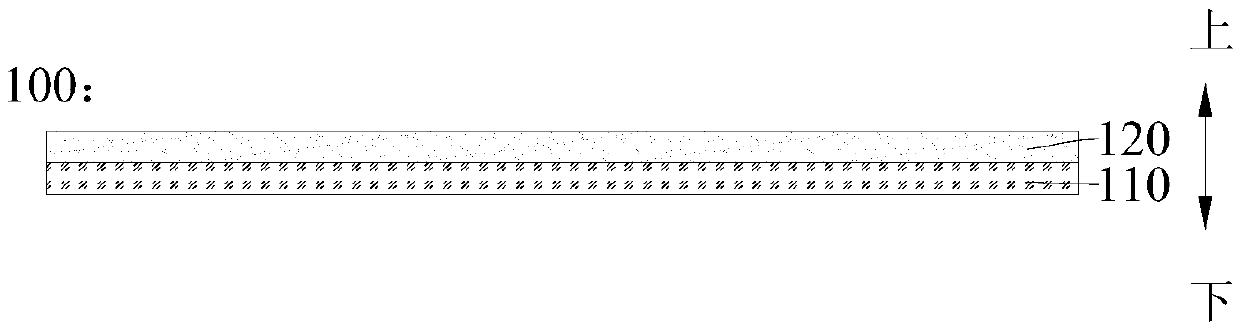

PM2.5 double-purpose dust protection mask and manufacturing technology thereof

ActiveCN105148420AAvoid enteringGuaranteed individual suitabilityBreathing masksManufacturing technologyEngineering

The invention discloses a PM2.5 double-purpose dust protection mask and a manufacturing technology of the mask, and belongs to the technical field of occupational health supplies. A pressing type individual dust protection mask comprises a nasal bracket, a tract groove I, an outer cover rotating shaft, a dust blocking filter membrane I, hang lugs or a safety cap connecting piece I, an outer cover, a sealing clamping buckle, a bottom frame and a sealing layer; and the outer edge of the inner side of the nasal bracket and the outer edge of the inner side of the bottom frame are of rough protruding structures. A tract type individual dust protection mask comprises an outer side supporting piece, a nasal inner sealing layer, a right face inner sealing layer, a left face inner sealing layer, a tract groove II, a tract handle, a dust blocking filter membrane II, and hanging lugs or a safety cap connecting part II; and the outer side supporting piece is connected with the nasal inner sealing layer, the right face inner sealing layer and the left face inner sealing layer. According to the mask, a relatively flexible dust protection manner can be provided for workers, in the area with the higher dust concentration, the good dust protection effect is achieved, and in the low dust concentration site, the requirement of workers for the oxygen intake amount is met.

Owner:JILIN ELECTRIC POWER RES INST +2

Coating and cooking utensil

ActiveCN110754951AGood non-stickSimple preparation processCooking-vessel materialsPressure-cookersPolymer scienceParacrystalline

The invention relates to a coating, a preparation method thereof and cooking utensil. The coating comprises multiple sub-coatings containing quasi-crystal materials, wherein the multiple sub-coatingsare sequentially stacked from bottom to top, and the particle size of the quasi-crystal material in at least one coating is greater than that of the quasi-crystal material in at least one above sub-coating. The coating disclosed by the invention is good in non-stickness, low in cost, simple in preparation process, easy to industrialize, and especially suitable for the cooking utensil.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

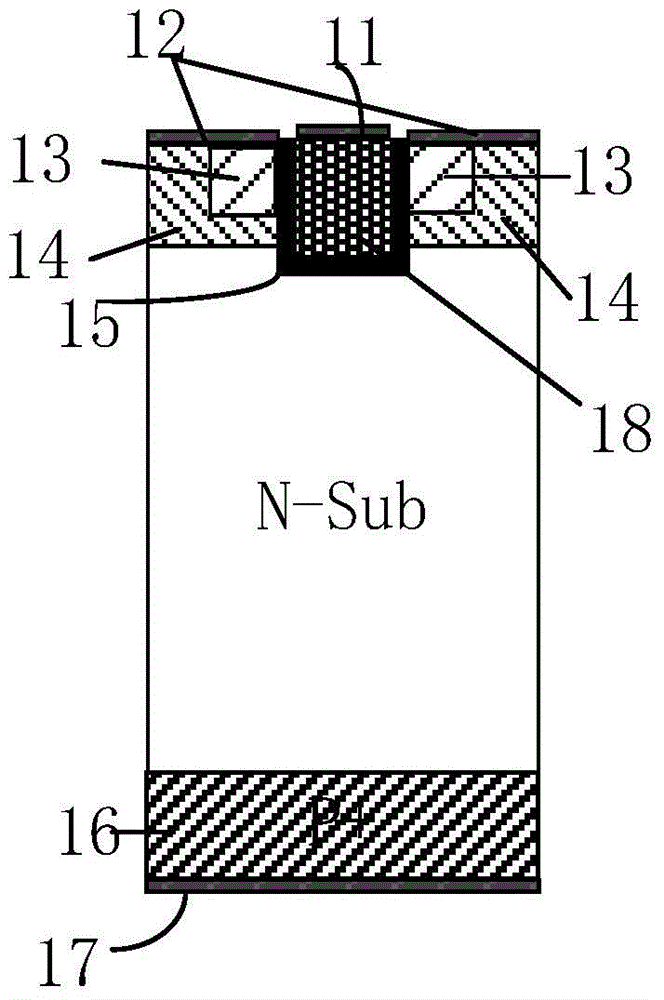

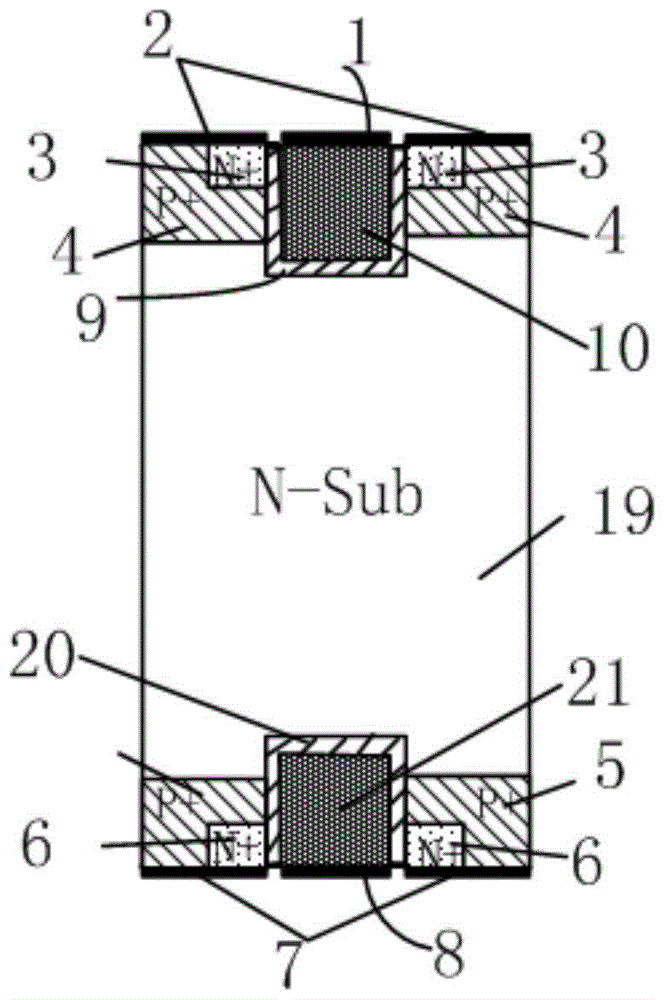

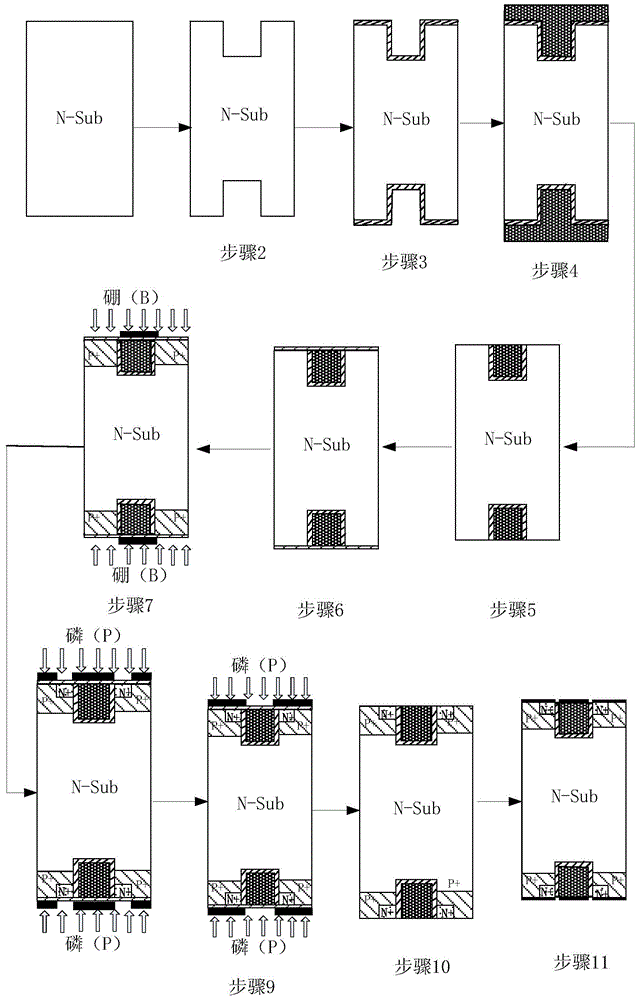

Trench type insulated gate bipolar transistor capable of double-terminal control and preparation method thereof

InactiveCN103762162BReduce latch-upReduce threatTransistorSemiconductor/solid-state device manufacturingSemiconductorTransistor

The invention discloses a double-end-controllable groove type insulated gate bipolar transistor which comprises a substrate. The two ends of the transistor are of structures with the same shape and variable parameters. The invention further discloses a preparation method of the double-end-controllable groove type insulated gate bipolar transistor. The double-end-controllable groove type insulated gate bipolar transistor effectively solves the problems that a common groove IGBT reverse blocking capability is poor and the turn-off time is long. The double-end-controllable groove type insulated gate bipolar transistor is high in applicability, and can replace a small circuit with bidirectional characteristics composed of a plurality of semiconductor devices, energy is greatly saved, the electric energy utilization rate is greatly improved, and the urgent affair that not enough power is supplied in China at present is relieved.

Owner:XIAN JIEHANG ELECTRONICS SCI & TECH CO LTD

An evaluation method and device for an air supply system

ActiveCN107609204BReasonable designImprove uniformityGeometric CADSpace heating and ventilation safety systemsControl engineeringComputer science

The present invention provides an evaluation method for an air supply system, comprising: obtaining design parameters of the air supply system, substituting the design parameters into a preset evaluation index formula to obtain an evaluation index parameter, and judging the evaluation index parameter Whether it is within a preset reasonable interval, a judgment result is obtained, and when the judgment result indicates that the evaluation index parameter is within the reasonable interval, it is determined that the design of the air supply system is reasonable. The embodiment of the present invention can effectively improve the air supply distance and the uniformity of the air supply speed of the air supply system, and at the same time reduce local overheating of the air supply system.

Owner:ZTE CORP

Casting production process and device for boron cast iron cylinder liner

PendingCN109014048AReduce local shrinkage tendencyReduce weightFoundry mouldsFoundry coresNiobiumLaboratory test

The invention belongs to the technical field of diesel engine part processing, and particularly relates to casting production process and device for a boron cast iron cylinder liner. The casting production process for the boron cast iron cylinder liner comprises the steps of adding pig iron, ferrochrome, ferromanganese and part of waste steel into a medium frequency furnace for smelting, and slagging off; then adding ferrophosphorus, ferroboron, copper, silicon carbide and residual scrap steel, stirring, smelting, taking a sample for laboratory test, and tapping when the base iron requirementis met; adding a nucleating agent, stirring, and slagging off to obtain a casting solution; and molding: adopting a furan resin sand mold for making a core, horizontally parting, using the casting solution for vertically casting six pieces in one box, and obtaining a finished product. The casting production device for the boron cast iron cylinder liner comprises a sand box and a sand core, whereina sprue, an ingate and a cross gate are arranged in the sand box; and an air outlet hole is formed in the side wall of the top part of the sand core. According to the casting production process and device for the boron cast iron cylinder liner provided by the invention, one box includes six pieces, so that the cost can be saved, the production efficiency is improved, and the product quality is improved; and the wear resistance of the manufactured boron cast iron cylinder liner is greatly improved, and the cost is reduced compared with a niobium cylinder liner.

Owner:ZICHAI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com