Self-recovery rubber air spring

A rubber air spring, self-recovery technology, used in springs, springs/shock absorbers, shock absorber-spring combinations, etc. problems, to achieve the effect of reducing workload and scope of work, reducing local overheating, and reducing phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

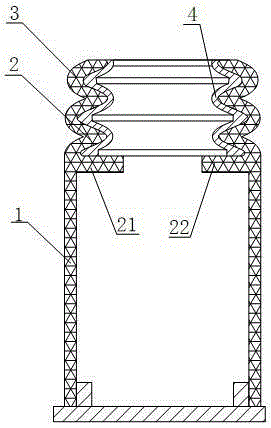

[0016] like figure 1 As shown, the self-restoring rubber air spring includes a cylindrical main body 1, at least one end of the cylindrical main body 1 is provided with a curved bag part 2, and the curved bag part 2 includes at least two or more curved bag units 3; each curved bag Both ends of the inner wall of the part 2 are provided with left and right protrusions 21, 22 toward the axial center of the cylindrical body 1, and a spring 4 is arranged between the left protrusion 21 and the right protrusion 22 inside each curved capsule part 2. , and the spring 4 is in a free state when the rubber air spring is working. The self-restoring rubber air spring of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com