Protection for preventing heat-engine plant reheater cold segment pipe from generating water impact

A reheater, water shock technology, applied in steam generation, lighting and heating equipment, control systems, etc., can solve problems such as inability to meet requirements, overheating of reheated steam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

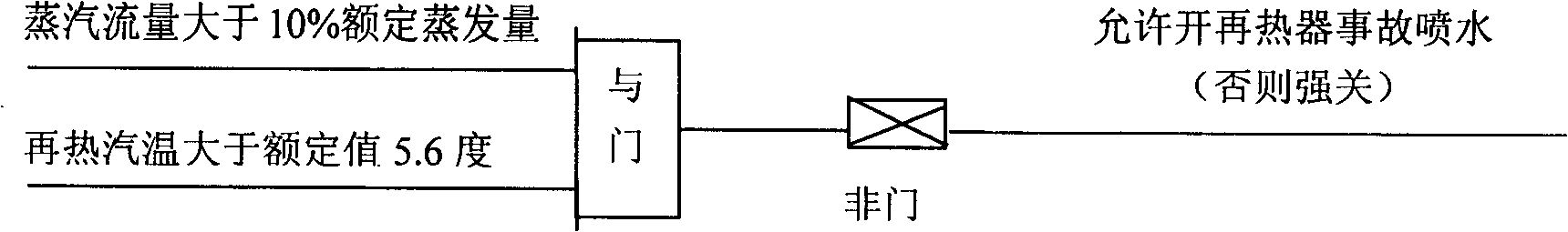

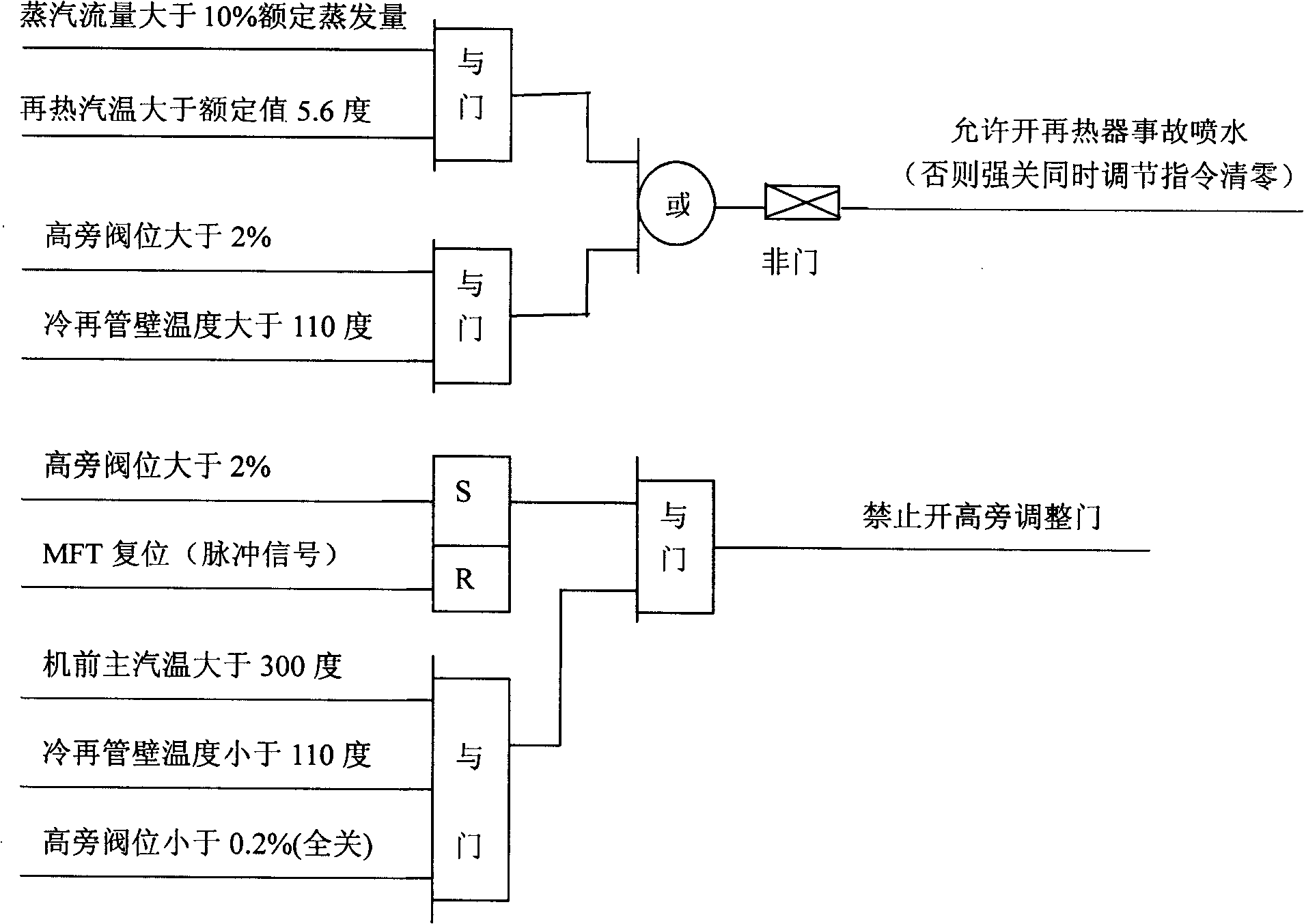

[0009] In the case that the high and low pressure bypass control system of the steam turbine and the reheater accident spray control system can operate normally, the following two control methods can basically protect the cold section of the reheater from being damaged during the start-up process of the unit: Water Shock:

[0010] (1) When the opening of the high side is greater than 2% and the wall temperature of the cold re-pipeline after the high side is greater than 110 degrees, it is allowed to open the reheater emergency water spray valve (stop valve and regulating valve) to control the hot re-steam temperature, And the adjustment instruction must be controlled below 30%. And once the condition is not met, make the reheater emergency spray valve and shut-off valve self-close, and clear the control command.

[0011] (2) When the temperature of the main steam before the high side is greater than about 300 degrees, and the wall temperature of the cold pipe of the reheater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com