Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce firing heat consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

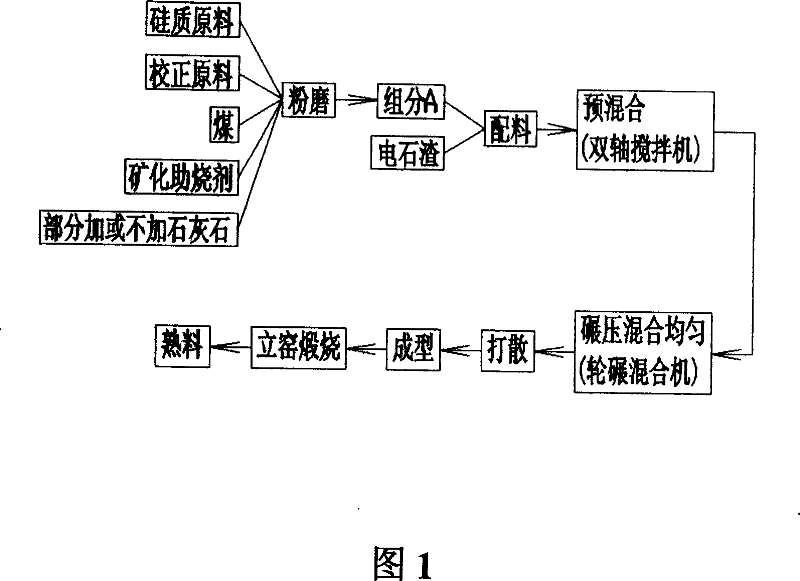

New technique for producing cement by using carbide mud residue ingredient of shaft kiln

The invention discloses a shaft kiln new craft to produce cement through supplying carbide slag dosage, which comprises the following steps: using carbide slag to replace lime rock in the cement slurry and dosage completely or partly; making carbide slag after filter-pressing as raw material; mixing evenly with grinding slurry and dosage directly; producing raw material rod or raw material ball; entering into shaft kiln; calcining to clinker. This invention is an energy-saving and environmental new technology, which can save coal, water and lime rock source.

Owner:尹小林

Technique for using dry discharging carbide slag to completely substitute natural calcareous raw material for producing cement chamotte

ActiveCN101265041ASolve the problem of environmental pollution that is difficult to deal withSolve pollutionCement productionCycloneSlag

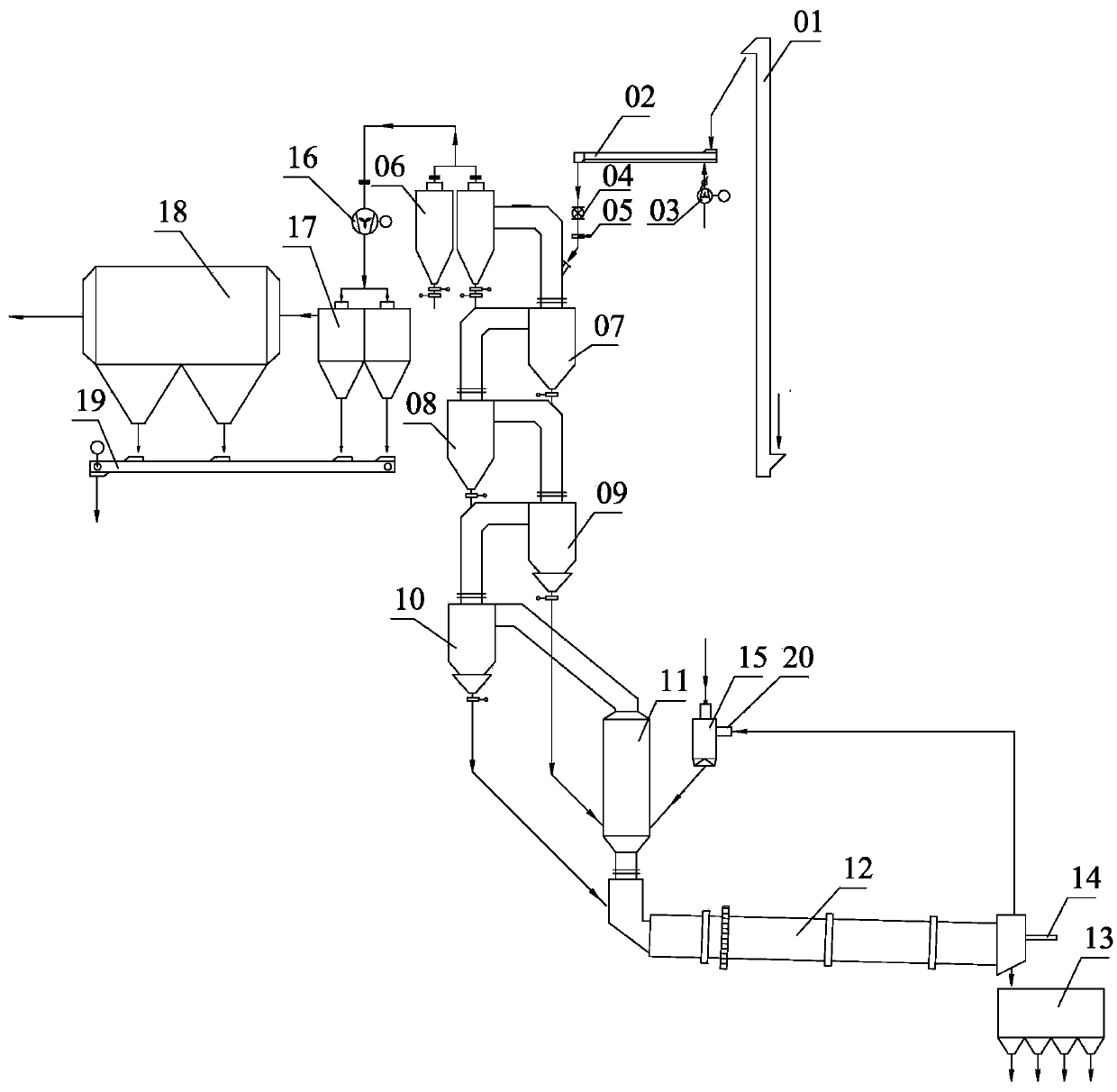

The invention discloses a method for producing cement clinkers from dried carbide slag completely instead of natural limy materials, which relates to the field of building materials. Firstly, three auxiliary materials (including sand rock, coal ash and sulfur acid residue) are compounded, pulverized and sieved, and the fine powder is fed into a dryer. Then, the carbide slag with a water content less than or equal to 12% is fed into the dryer, and undergoes intensive heat exchange with the hot flue gas at the charge side, realizing complete drying and mixture. The crude material powder is fed into first-stage, second-stage and third-stage cyclone cylinders to undergo multiple suspension heat exchange with the hot flue gas, and then enter a rotary kiln for calcination. The hot flue gas inside the klin undergoes the heat exchange in a pipeline calciner and a wind pipe and then reversely flows into the third-stage, second-stage and first-stage third-stage cyclone cylinders, the dryer, a cyclone dust collector, a system fan and an airbox pulse bag-shaped dust collector sequentially, and the purified gas is discharged into the external atmosphere. The coal powder jets into the calciner at the charge side for further combustion, and the crude material powder undergoes decomposition reactions: Ca(OH)2-H2O+CaO. The clinker burned in the rotary kiln is cooled by a grate cooler and then delivered to a clinker storage room. In the invention, the waste carbide slag is completely dried by using the exhaust gas at the discharge side, and the heat consumption for clinker combustion is reduced by about 25%, thereby realizing energy conservation and exhaust reduction.

Owner:新疆凯盛建材设计研究院(有限公司)

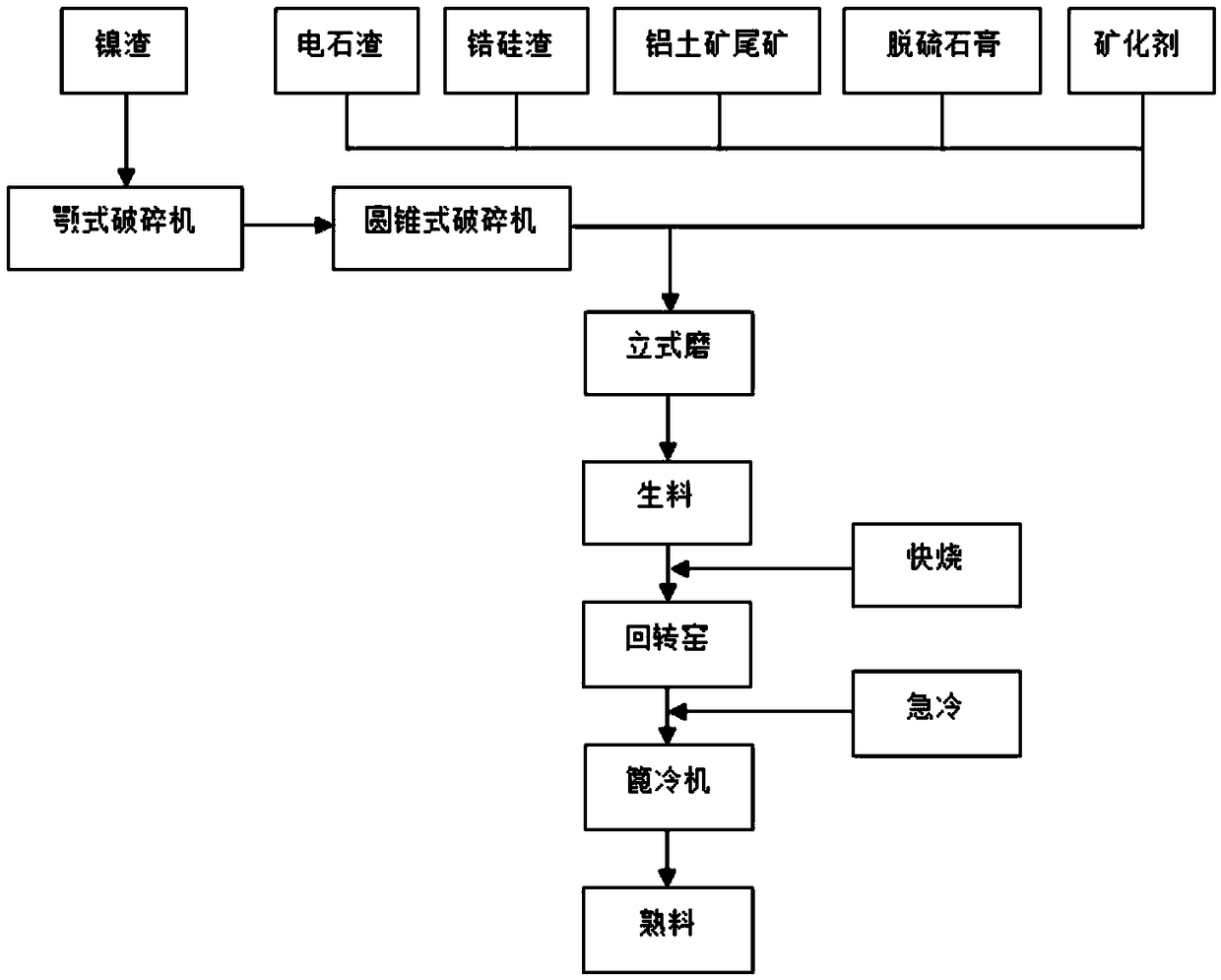

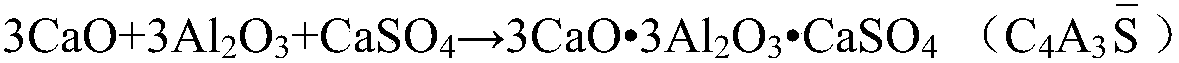

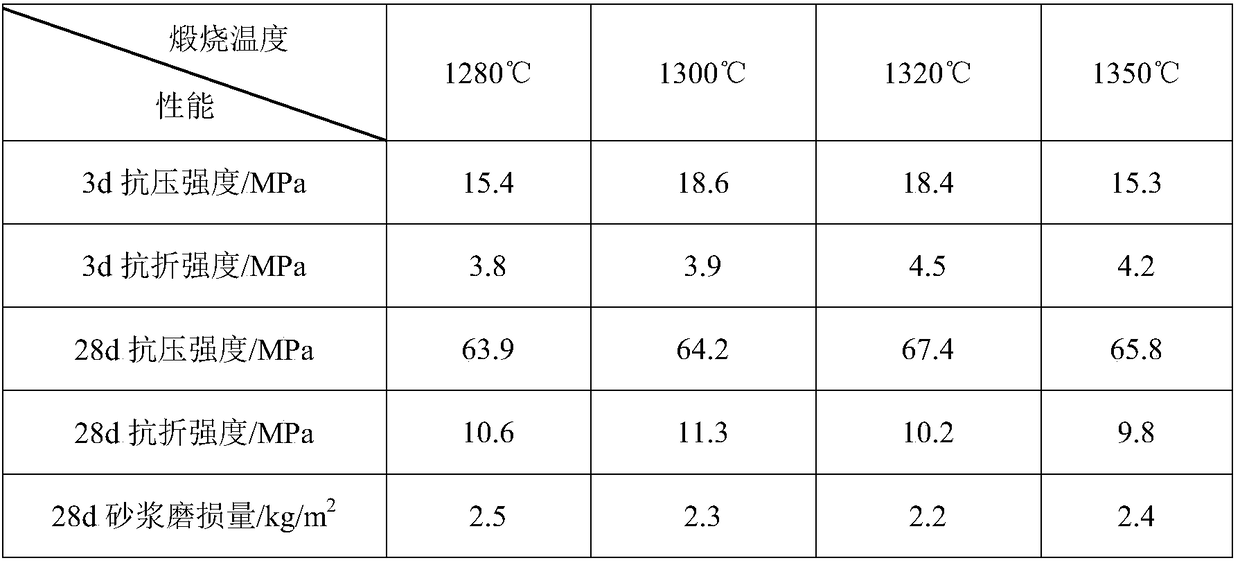

Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

ActiveCN109081615AStrong mechanical propertiesReduce consumptionCement productionSlagToxic industrial waste

The invention discloses road silicate cement clinker on the basis of industrial waste residues and a method for preparing the road silicate cement clinker. The road silicate cement clinker comprises nickel slag, calcium carbide residues, zirconium-containing silica residues, bauxite tailing, desulfurization gypsum and mineralizers. The method includes mixing, grinding and homogenizing the nickel slag, the calcium carbide residues, the zirconium-containing silica residues, the bauxite tailing, the desulfurization gypsum and the mineralizers to obtain cement raw materials; preheating the cementraw materials, then calcining the cement raw materials under the condition of the temperature of 1280-1350 DEG C for 30-35 min and then carrying out cooling to obtain the road silicate cement clinker.The road silicate cement clinker and the method have the advantages that the 28 d compressive strength of the road silicate cement clinker can reach 63.9-75.2 MPa, the strength grade of the road silicate cement clinker can reach 62.5 grade, the 28 d breaking strength of the road silicate cement clinker can reach 9.8-18.2 MPa, the 28 d mortar abrasion loss of the road silicate cement clinker is lower than 2.5 kg / m<2>, cement is high in stability, and the road silicate cement clinker is high in abrasion resistance and excellent in work performance; the method is simple, complicated working procedures can be omitted, and the road silicate cement clinker and the method are low in cost.

Owner:哈尔滨太行兴隆水泥有限公司

Method for producing cement clinker from stainless steel cold rolling dewatered sludge ingredient

InactiveCN101475325ACalcination temperature is lowBurn completelySludge treatmentWaste water treatment from metallurgical processAdditive ingredientPulverized fuel ash

The invention relates to a method for producing cement clinker through utilization of a stainless steel cold-rolled dehydrated sludge ingredient. The method comprises that: stainless steel cold-rolled dehydrated sludge and other materials of a cement green stock are evenly mixed to prepare the cement green stock; the cement green stock comprises the following compositions in percentage by weight: 70 to 79 percent of limestone, 10 to 14 percent of clay, 1 to 8 percent of the stainless steel cold-rolled dehydrated sludge, 5.3 percent of coal ash, 0 to 3 percent of iron ore powder and 0 to 0.5 percent of gypsum; and the prepared cement green stock is sintered to form silicate cement clinker. The obtained cement clinker and a corresponding cement product have no essential difference with the prior silicate cement clinker and a cement product in composition and performance; the quality of the cement clinker and the corresponding cement product meets the index requirement of national corresponding product standard and can be used as a normal high-quality commodity; and the method effectively utilizes and processes industrial sludge containing harmful metal elements, achieves the effects of resource optimization and utilization and has remarkable environment-friendly benefit.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD +1

Method for preparing foamed ceramic

The invention belongs to the technical field of manufacture of building materials, and relates to a method for preparing foamed ceramic, particularly relating to a method for preparing foamed ceramic with coal gangue as the main material. The method for preparing the foamed ceramic comprises the follow steps: taking 50-70 weight parts of coal gangue, 10-25 weight parts of sandstone, 15-27 weight parts of feldspar, 0-8 weight parts of dolomite and 0.5-3 weight parts of foaming agent; (2) mixing the materials in a ball mill, grinding by adding water according to the mass ratio of the materials to the water of 1:0.5 through a wet grinding method to prepare slurry, and performing mist spraying and granulation of the slurry by controlling the size of the slurry under 60 mum to obtain a powdery material; (3) loading the powdery material into kiln furniture, firing in a kiln at the firing temperature of 1120-1220 DEG C, thermally insulating for 0.5-2.5 hours, and cooling to obtain the foamed ceramic. The foamed ceramic prepared according to the method disclosed by the invention has small volume density, low heat conductivity coefficient, large compressive strength and high fire-protection rating, and can be applied to the fields of external wall insulation of a building.

Owner:GANSU WANTE TECH DEV

Method and device for preparing nickel iron roasted ore by utilizing lateritic nickel ore

ActiveCN103468930AFast heat and mass transferShorten decrystallization wateChemical reactionLaterite

The invention discloses a method and a device for preparing a nickel iron roasted ore by utilizing a lateritic nickel ore. The method comprises the following steps: firstly, grinding the lateritic nickel ore into an ore powder, then carrying out high-temperature roasting of the obtained ore powder, during the high-temperature roasting process, allowing the ore powder to be in a pre-reduction system and carry out a high-temperature preheating reduction reaction, followed by allowing the high-temperature roasted ore to go into a rotary kiln for high-temperature calcination, thus obtaining a roasted ore containing nickel pig iron after completing high-temperature calcination, and then after dipping the roasted ore into water for cooling, separating to obtain the nickel iron roasted ore. The device comprises a hopper-type elevator, an air chute, a chute draught fan, a rotary feeder, a sluice valve, a rotary kiln, a water-cooling stirring tank, a burner, a hot wind mixing chamber, a high-temperature draught fan, a cyclone dust remover, a bag-type dust remover, a chain-type conveyor, a burner and a pre-reduction system. The preparation method and the device allow the heat transfer area of the ore powder to be large, enable each particle to be uniformly and fully subjected to a chemical reaction, have short reaction time, and have high utilization rate of the lateritic nickel ore.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

Method for producing alpha-Al2O3 by employing predecomposition technology and taking aluminium hydrogen as raw material

ActiveCN103708515ARealize large-scale productionReduce energy consumptionAluminium oxide/hydroxide preparationCycloneHydrogen

The invention discloses a method for producing alpha-Al2O3 by employing a predecomposition technology and taking aluminium hydrogen as a raw material. The method adopts a feeding system, a Venturi dyer, a first cyclone preheater, a second cyclone preheater, a third cyclone preheater, a roasting furnace, a natural gas burner, a kiln natural gas burner, a rotary kiln, a cooler and a dust removal system. Special aluminum oxide alpha-Al2O3 is produced by adopting a predecomposition technology. Large-scale production, low energy consumption (950*4.18kj / kg) and stable quality can be achieved, and achievement of automatic production control is achieved. The method is fewer in used equipments, small in floor area, simple in operation, high in quality of produced alpha-Al2O3, high in production efficiency, and simple and convenient in operation process, reduction of the production cost is facilitated, the operation flow is greatly simplified, the production time is shortened, and improvement of economic benefits of enterprises is facilitated.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

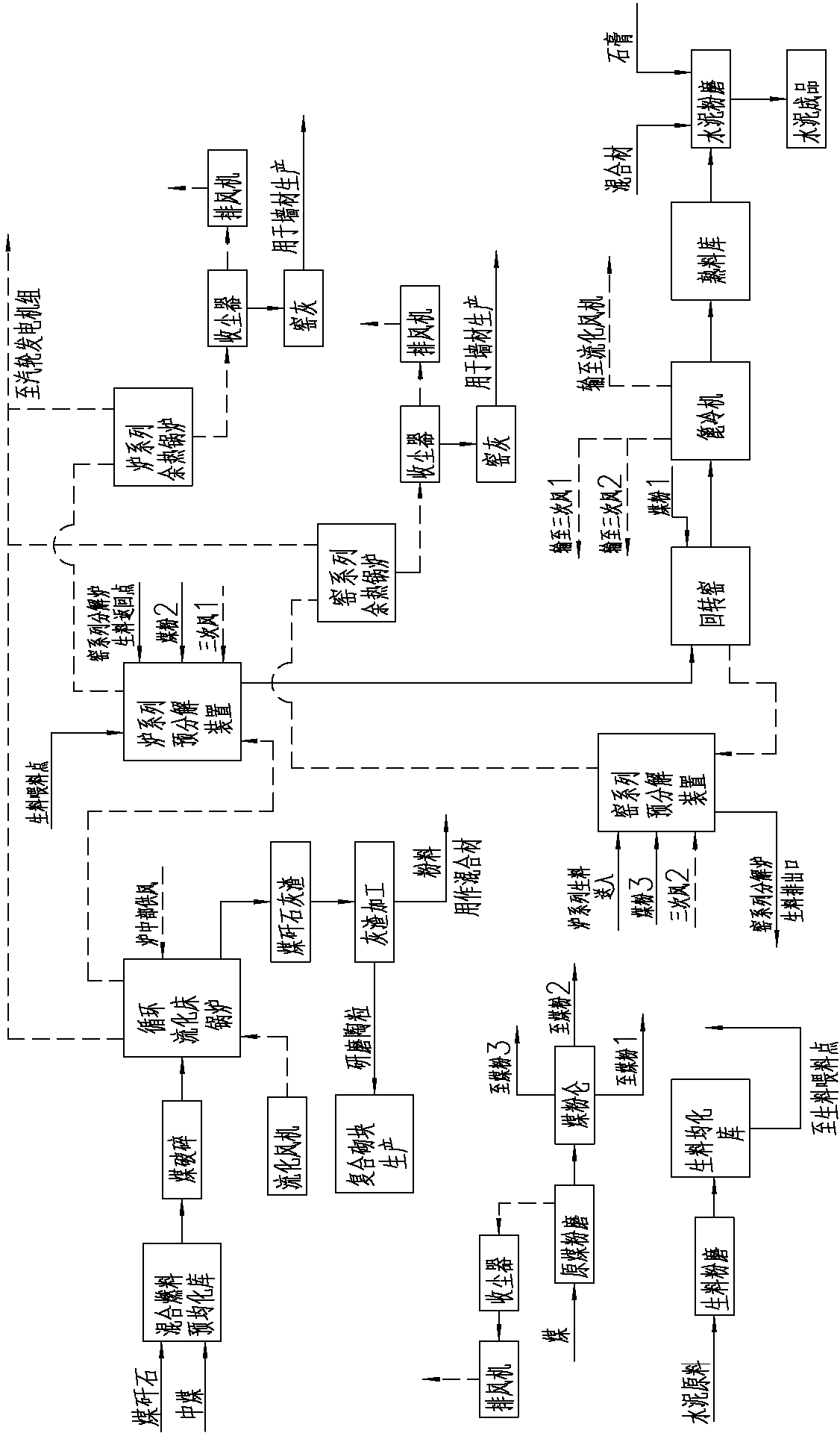

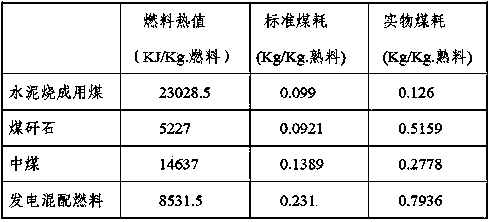

Multi-product cleaning and producing method with coal gangue comprehensive utilization

ActiveCN102703157AEasy to produceAvoid "secondary volatilizationSteam generation heating methodsSolid fuelsCoalPollution

The invention relates to a multi-product cleaning and producing method comprehensive utilization; coal carbon production, power generation by burning coal gangue, cement production, power generation by cement afterheat and wall material production technology are combined in a same industrial symbiont by using industrial symbiosis; optimal configuration between working procedures is realized; processing procedures of raw materials are converted into processing working procedures capable of separating raw materialsand fuels into different material flows and power flows which have different transport directions; mutually beneficial relationship is established between working procedures; a predetermined downstream working procedure is directly capable of digesting ''pollutant'' of an upstream working procedure; each working procedure utilizes different raw material component and different gradient energy source so as to produce multiple products; so that energy and matter flow in a multi-channel manner; and a little-pollution multi-prduct cleaning and producing technology is formed.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

Method for synergistically treating heavy metal sludge in cement production

InactiveCN105000815AImprove burnabilityReduce firing heat consumptionCement productionPre treatmentCo-processing

The present invention discloses a method for synergistically treating heavy metal sludge in cement production. The method comprises: (1) carrying out a drying pretreatment on heavy metal sludge so as to make the moisture content be less than or equal to 40 wt%; (2) mixing the obtained heavy metal sludge and a cement raw material to prepare a raw material for cement; and (3) after the raw material for cement is homogenize, firing into a cement clinker. According to the present invention, with the method, the harmless treatment of the sludge and the production of the cement clinker and the product thereof can be simultaneously achieves, such that the heavy metal sludge with characteristics of complex components and difficult recycling is completely digested, and the quality performance of the cement product is not affected.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing cement clinker by employing phosphorus slag

A disclosed method for producing cement clinker by employing phosphorus slag comprises the following steps: (a) crushing rough materials, namely, crushing the rough materials mainly composed of limestone, phosphorus slag, shale, sandstone and iron ore, so as to respectively obtain limestone particle, phosphorus slag particle, shale particle, sandstone particle and iron ore particle; (b) pre-homogenizing the rough materials, namely, performing layered stacking on the various particles obtained in the step (a); (c) preparing raw material; (d) homogenizing the raw material; (e) preheating and decomposing; (f) sintering and obtaining clinker; and (g) grinding the clinker, namely, cooling the sintered clinker, and grinding the clinker to obtain a needed granularity, so as to finish cement production. The method helps to improve the sintering easiness of the raw material, improve the clinker quality, improve the kiln decomposition rate, improve rotary kiln operation ratio, reduce clinker sintering heat consumption and cement comprehensive electricity consumption, increase clinker output, and substantially reduce cement production cost.

Owner:陈永忠

A method for producing cement clinker with unlimited compatibility with carbide slag and limestone as raw materials

ActiveCN102260052ARealize resource utilizationSolve the problem of stacking and polluting the environmentClinker productionCalcium in biologySlag

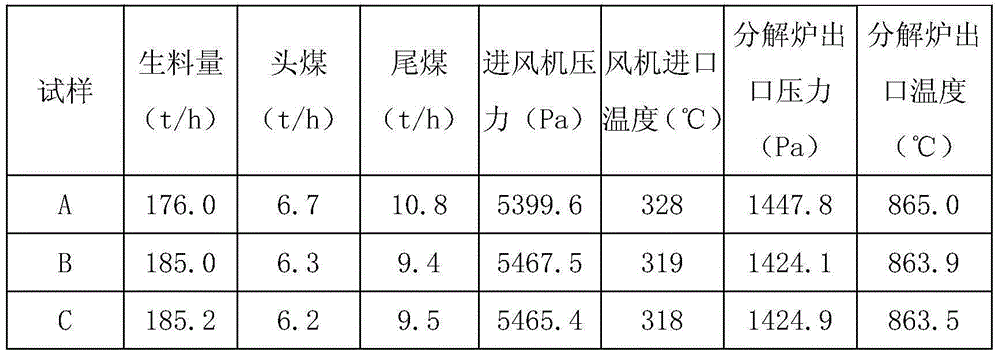

The invention relates to an unlimited compatible method for producing cement clinker by using carbide slag and limestone as raw materials, belonging to the technical field of resources and environment. The method uses the carbide slag as the calcareous raw materials, and the cement clinker is calcined by using a novel dry technology, which is characterized in that: either 100 percent of carbide slag or 100 percent of limestone can be used as the calcareous raw materials, or the carbide slag and the limestone can be mixed at any ratio for use. A main process comprises the following steps of: (1) kiln rear feeding, in which a preheater can be switched between the stage 3 and the stage 5 through changing a position of a material feeding point; (2) raw material pre-decomposition, in which a five-stage preheater which is switchable to a three-stage preheater and an enhanced suspension spray type decomposition furnace are used in order to combust the fuels and decompose the raw materials, wherein the outlet temperature of the decomposition furnace is controlled between 700 and 890 DEG C; and (3) rotary kiln calcining, in which the decomposed raw materials enter the kiln to be calcined into the cement clinker. The method has the characteristics of high resource regeneration level of the carbide slag, obvious energy-saving and emission-reduction effect, strong system compatibility andthe like.

Owner:成都建筑材料工业设计研究院有限公司

Method for preparing cement from manganese iron slag

InactiveCN105174756AImprove burnabilityAccelerates the formation of mineralsCement productionDecompositionRotary kiln

The invention discloses a method for preparing cement from manganese iron slag, which comprises the following steps: (a) raw material crushing: crushing the raw materials mainly composed of limestone, manganese iron slag, shale, sandstone and iron ore to respectively obtain limestone particles, manganese iron slag particles, shale particles, sandstone particles and iron ore particles; (b) raw material prehomogenization: carrying out stratified piling on various particles obtained in the step (a); (c) green material preparation; (d) green material homogenization; (e) preheating and decomposition; (f) clinker firing; and (g) clinker milling: cooling the fired clinker, and milling the clinker to the required particle size, thereby completing the cement production. The method can improve the sinterability of the green material, improve the clinker quality, enhance the in-kiln decomposition rate, increase the operation rate of the rotary kiln, lower the clinker firing heat loss and cement comprehensive power consumption, enhance the cement yield and greatly lower the cement production cost.

Owner:SICHUAN MINGCHUAN CHENGYU ELECTRICAL & MECHANICALCO

Multiphase dynamic catalytic oxidation combustion method of novel dry-process rotary kiln pulverized coal

ActiveCN101886806AAvoid survivalEmission reductionCombustion using catalytic materialCombustion apparatusCombustionLiquid state

The invention discloses a multiphase dynamic catalytic oxidation combustion method of novel dry-process rotary kiln pulverized coal. Nanoscale molecular multiplex catalyst precursor and the like are continuously added into kiln head pulverized coal in a liquid state mode; multiphase dynamic high-temperature flame catalytic oxidation combustion is carried out in the kiln; parts of nanoscale functional metallic oxide catalyst formed by the high-temperature flame section enter the coal, material and wind suspension system in the decomposing furnace by pulling wind; and catalytic oxidation combustion is carried out again. The waste functional metal ion oxide serves as high-efficiency ion-type sintering aid in the kiln to accelerate C3S in the cement clinker to be generated and lower fCaO, thus realizing stable production, high yield and good quality. The invention burns two bundles of fire of a novel dry-process kiln, effectively lowers clinker sintering thermal loss, improves clinker quality and kiln yield, reduces the discharge value of CO2 and CO and has obvious effect on energy saving, emission reduction and cost reduction.

Owner:长沙紫宸科技开发有限公司

Preparation method of phosphorus slag portland cement chamotte and preparation method thereof

InactiveCN1603268ASave resources and energyEmission reductionCement productionRiver sandDecomposition

The invention relates to a preparation method of the phosphorus residue portland clinker. The clinker is includes limestone, pyrite residue, river sand, phosphorus reside and gangue raw material. It is formed by the following steps that the raw material is mixed in proportion, used pulverizing together and fired by the pre-decomposition kiln system at the condition of new type dry method cement system. The weight mixing proportion of the raw material orderly is from seventy to eighty five, from five to seven, from one point five to three, from eight to fifteen, and from zero point five to five. The invention can use the industry waste that phosphorus reside, pyrite residue and gangue as the raw material to prepare the low temperature loading type portland clinker. So it can solve the shortage of the fat limestone, clay, and iron ore, as well as supply a perfect approach for industry waste processing. Moreover, it can save the resource and energy source, reduce the pollution discharging, and is good for reducing cost, protecting environment, and increasing output and quality of the clinker, so that it is easy to popularly use in the new type dry method cement plant.

Owner:WUHAN UNIV OF TECH

Multiphase dynamic catalytic oxidation combustion method of novel dry-process rotary kiln pulverized coal

ActiveCN101886806BAvoid survivalEmission reductionCombustion using catalytic materialCombustion apparatusCombustionLiquid state

The invention discloses a multiphase dynamic catalytic oxidation combustion method for dry-process rotary kiln pulverized coal. Nanoscale molecular multiplex catalyst precursor is continuously added into kiln head pulverized coal in a liquid state mode; multiphase dynamic high-temperature flame catalytic oxidation combustion is carried out in the kiln; parts of nanoscale functional metallic oxide catalyst formed by the high-temperature flame section enter the coal, material and wind suspension system in the decomposing furnace by pulling wind; and catalytic oxidation combustion is carried out again. The waste functional metal ion oxide serves as high-efficiency ion-type sintering aid in the kiln to accelerate C3S in the cement clinker to be generated and reduce fCaO. According to the invention, two bundles of fire of a dry-process kiln are burned, clinker sintering thermal loss is effectively lowered, clinker quality and kiln yield are improved, the discharge value of CO2 and CO are reduced, thus saving energy and reducing emission, as well as lowering cost.

Owner:长沙紫宸科技开发有限公司

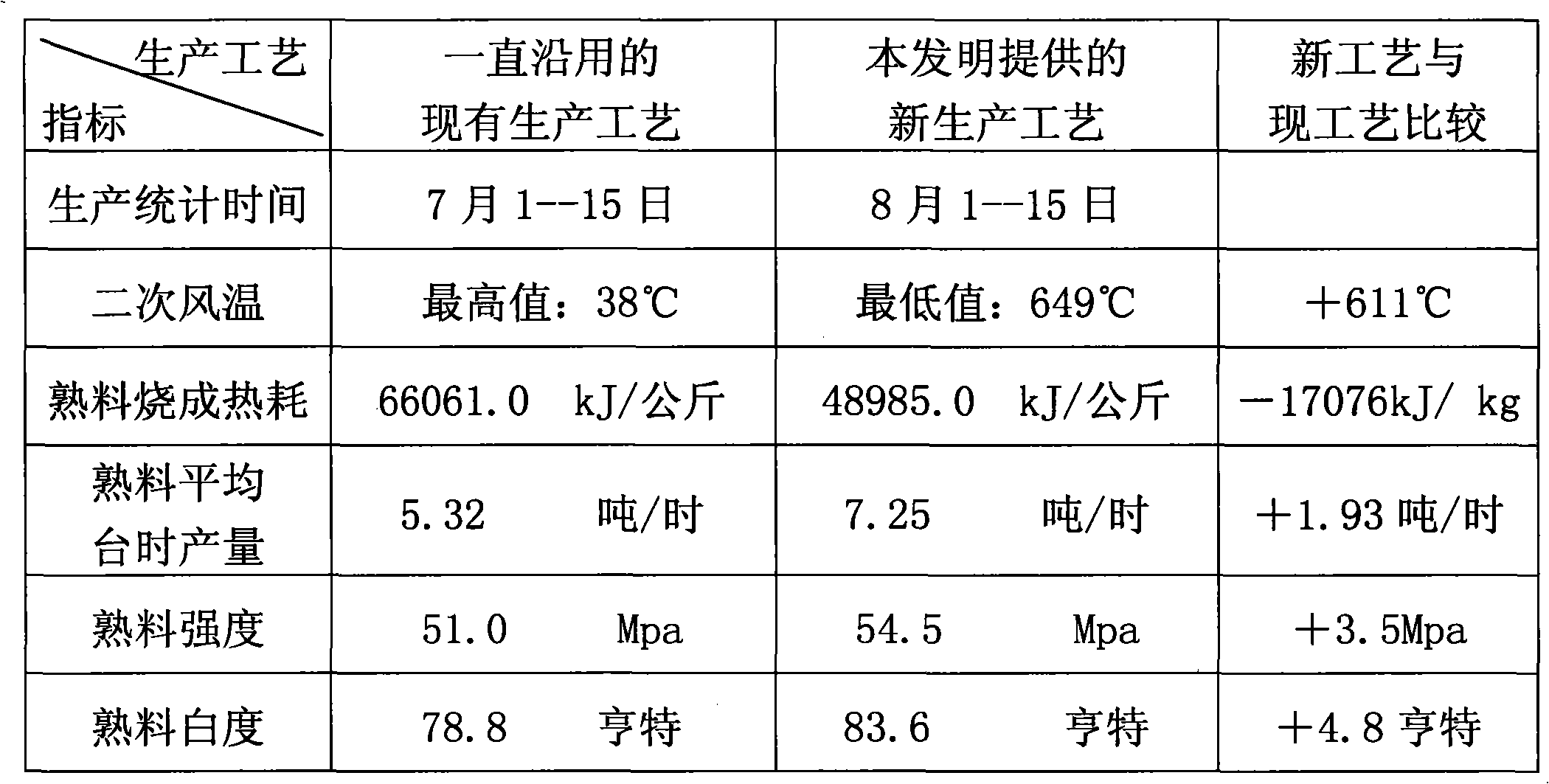

Cooling bleaching production technique of white portland cement clinker

The invention relates to a cooling bleaching production technique of white silicate cement clinker, comprising the following steps: discharging calcined high-temperature white silicate cement clinkerfrom a kiln, conveying the clinker into an air heat exchanger for 5-500 seconds of bleaching by wind cooling; delivering the hot air that conducts heat exchange with the high-temperature clinker intoa clinker calcining kiln so as to be used as secondary combustion air; and transferring the clinker bleached by the air heat exchanger into a normal spray-type or soak-type cooling bleaching machine for spray-type or soak-type cooling bleaching until the clinker is cooled down to the temperature of 20-100 DEG C. Compared with the existing production technique, the white silicate cement clinker isbeneficial to decreasing the heat consumption for calcining the clinker, and promoting the sufficient combustion of fuels, thus improving the calcining yield of the kiln; besides, two times of coolingbleaching with different media is beneficial to improving the quality of the white cement clinker.

Owner:吴飞龙

Ultrafine fly ash and preparation method thereof

InactiveCN109721262AReduce manufacturing costStable quality and performanceCement productionSlagShrinkage rate

The invention relates to the technical field of cement production. A purpose of the present invention is to replace or reduce the clinker consumption for cement production by using ultrafine fly ash so as to reduce the production cost of enterprises. The invention relates to ultrafine fly ash and a preparation method thereof, wherein the ultrafine fly ash comprises the following raw materials by weight: 40-50% of dry fly ash, 20-30% of steel residue, 1.5-3% of lime, 0.8-1.5% of a defoamer, 15-25% of waste sand, 3-5% of waste gypsum, and 5-8% of slag. According to the present invention, the ultrafine fly ash is prepared through breaking, magnetic separation, mixing, grinding, dehydration and other processes; and the method has advantages of simple and practical operation, effectively reduced cement clinker consumption, reduced heat consumption of clinker firing, production cost reducing, cement quality stabilizing, dry shrinkage rate improving, cement solidification rate enhancing, cement strength enhancing and the like, and is conducive to the promotion and application of energy saving and emission reduction.

Owner:无锡市金希达新型建材有限公司

Process and processing system for co-processing shellfish waste with cement clinker production line

ActiveCN104003634AImprove waste heat utilizationReduce firing heat consumptionIncreasing energy efficiencyWaste heat treatmentExhaust gasCo-processing

The invention discloses a high-efficiency process for co-processing shellfish wastes with a cement clinker production line. The process comprises the steps: placing collected shells in a piling shed, rinsing cleanly with water, sending the air-dried shells to a dryer, introducing dedusted hot wind of a kiln tail of a rotary kiln in the cement clinker production line into the dryer, drying the shells, directly discharging emptily deodorization-treated tail gas discharged by the dryer, sending the dried shells into a crusher, crushing, sending the crushed shell broken material as a cement clinker raw material to the cement clinker production line for producing cement clinker or being directly used as a cement raw material. Not only is the shellfish waste utilized, but also energy sources are saved. The invention also discloses a system suitable for the process.

Owner:广东省建筑材料研究院有限公司

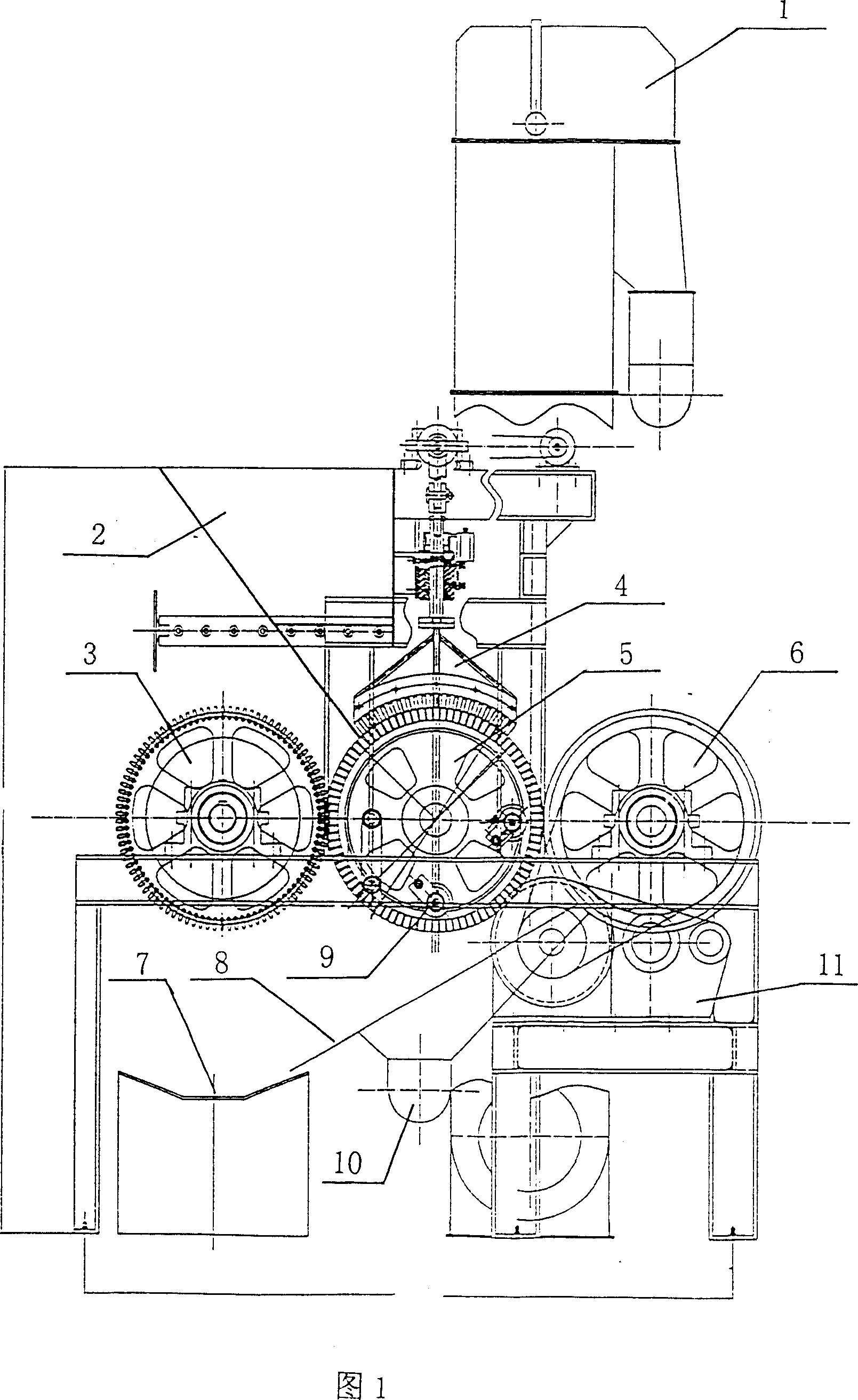

Vertical kiln raw material comminutor

InactiveCN1951552AReduce moisture contentLow ventilation resistanceGranulation by pressingReducerSlurry

The invention relates to a shaft kiln slurry pelleting machine. Wherein, there is stuff device (4) connected to the mother mould (5) under the hopper (2); the mother mould (50 is connected to mould discharger (3), mould repair ring (60, mould release block (9) above the vibration screen (8); the mother mould (5) is mounted with ball mould bottom pin; the speed reducer (11) via bearing is connected to the mother mould (5), mould discharger (3), and mould repair ring (6). The invention has the advantages that: it has low water content as 6-8%; it has uniform particles; and it has low energy consumption. The invention can improve 20% yield and 5-8MPa strength.

Owner:缪建通 +1

Denitrification combustion method used for production of cement kiln

InactiveCN112595096AReduce the temperatureImprove kiln decomposition rateRotary drum furnacesPulverulent fuel combustion burnersThermodynamicsProcess engineering

The invention discloses a denitrification combustion method used for production of a cement kiln. The denitrification combustion method comprises a smoke chamber, a decomposition furnace and a tertiary air duct, wherein one end of the smoke chamber is connected with the decomposition furnace through a pipeline, the other end of the smoke chamber is connected with the cement kiln, the tertiary airduct is connected with the decomposition furnace, and a coal feeding device and a four-stage blanking pipe are arranged at the top of the smoke chamber. Compared with the prior art, the denitrification combustion method used for production of the cement kiln has the advantages of being high in reliability, high in resource utilization rate and low in running cost.

Owner:贵州省鑫瀚蓝环保科技有限公司

High-activity MgO roasting technology and special device thereof

The invention discloses a high-activity MgO roasting technology and device. The roasting technology comprises the following steps: firstly, enabling magnesium carbonate powder and hot air to be in contact and mixed to absorb heat, and pre-heating the material until the temperature is about 350 DEG C; then carrying out cyclone calcination and calcining and decomposing in a temperature range of 800DEG C to 1000 DEG C to obtain an MgO and CO2 mixture; conveying the cooled MgO and CO2 mixture into a separation device and carrying out gas-material separation; conveying collected powder into a finished-product cabin and storing; after treating escaped waste gas through a water gas treatment device, discharging the waste gas into the atmosphere through a chimney. According to the high-activity MgO roasting technology and device, disclosed by the invention, the disadvantages of an existing high-activity MgO calcination device of large equipment investment, short running period, large repairing strength, high heat consumption and great product quality fluctuation are changed and the High-activity MgO roasting technology and the special device thereof are developed; the device has the advantages of less investment, simple equipment, long service life, low repairing difficulty, low firing heat consumption and good product activity stability.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

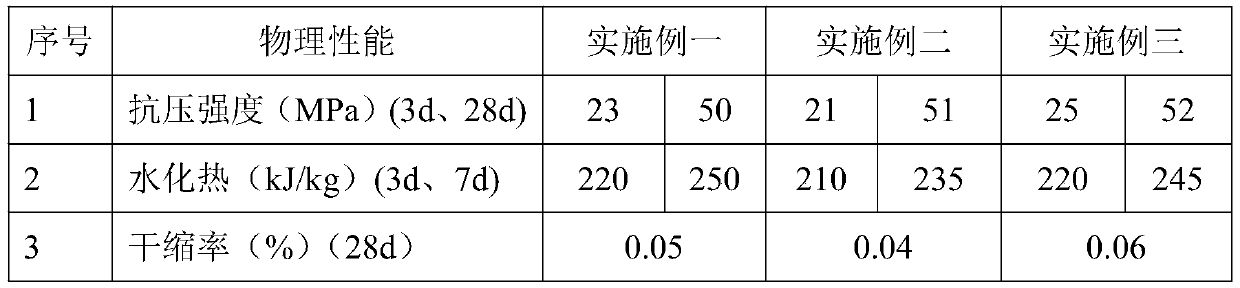

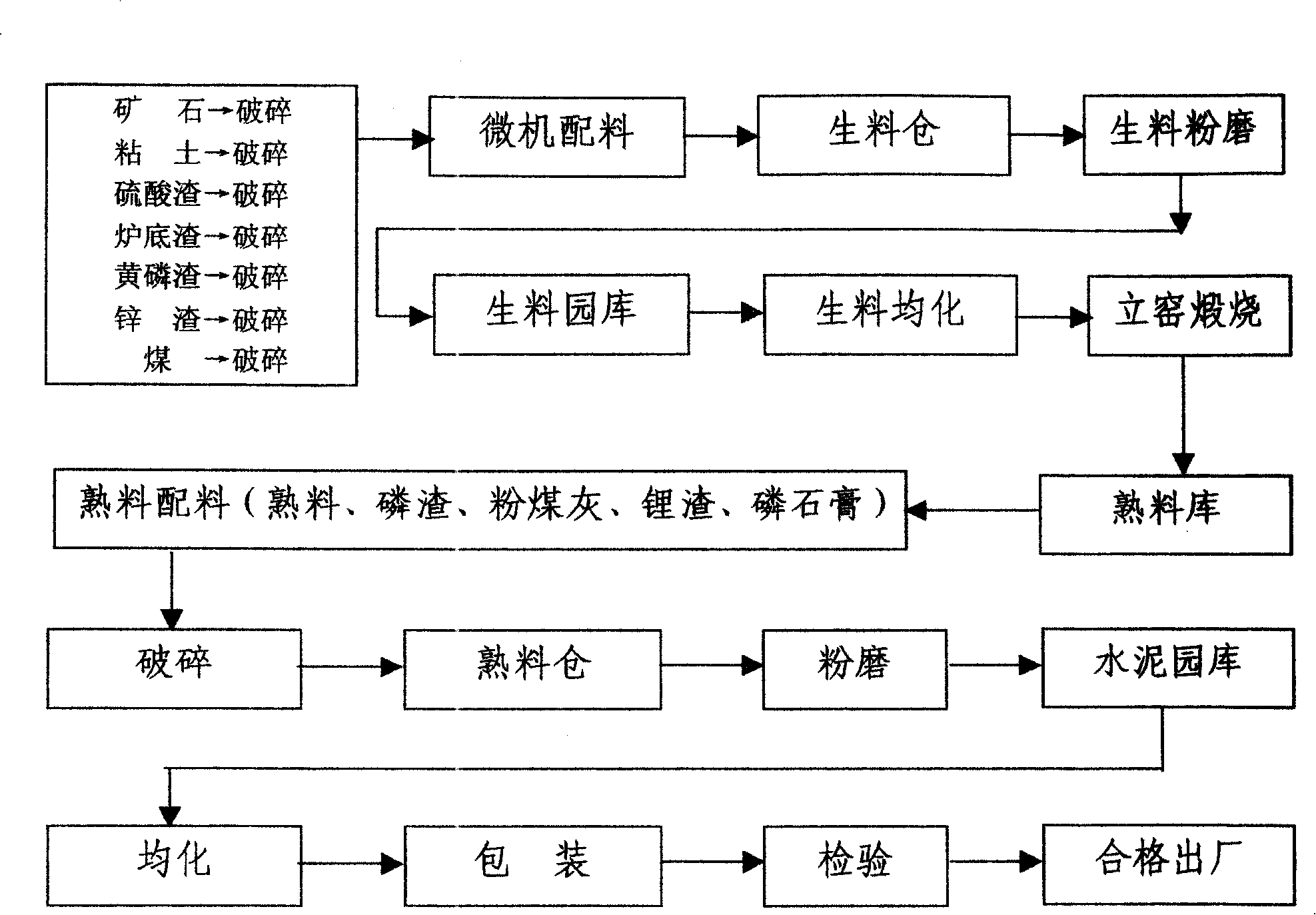

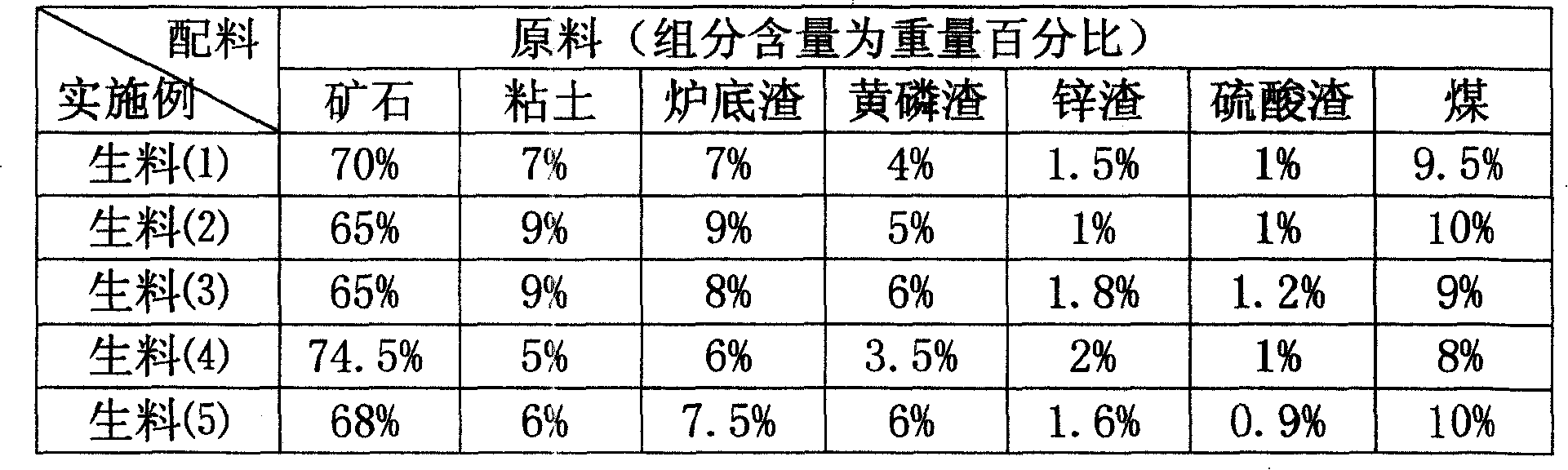

Composite portland cement produced by full utilization of industrial waste slag

InactiveCN100387539CImprove burnabilityReduce burning coal consumptionClinker productionIndustrial wasteSilicate Cement

The invention discloses a composite silicate cement. Wherein, doping the mineralizer of more than 12wt% slag contained the phosphoric slag, zinc slag, hearth slag, and sulfuric slag into the raw material comprised ore, clay and coal to crush and grind to obtain the material with 0.98+ / -0.02 KH, 2.4+ / -0.1 N and 1.4+ / -0.1 P; adding the mixed material of more than 30wt% contained phosphoric slag, coal ash, ardealite and lithium slag into the calcining grog; then, homogenizing, crushing, grinding, and obtaining the product. The product has high early strength, fast growth of later strength, and all physicochemical index super to the GB12958-1999 standard. This invention improves the combustibility of raw material effectively, reduces heat consumption and fCaO content of grog, and saves material and energy.

Owner:绵竹市齐福水泥厂

Steel residue composite powder and preparation method thereof

InactiveCN110734232AMeet the use requirementsImprove curing rateCement productionDefoaming AgentsMaterials science

The invention relates to the field of cement building material production technology application. A purpose of the invention is mainly to reduce the production cost of enterprises by replacing or reducing clinker consumption for cement production with steel residue composite powder. The invention discloses steel residue composite powder and a preparation method thereof, wherein the steel residue composite powder comprises the following raw materials by weight: 36-42% of steel residue, 4-6% of gypsum, 12-18% of fly ash, 3-6% of silica fume, 2-4% of pumice, 5-8% of clay, 12-17% of quartz sand, 10-15% of coal gangue, 2-4% of a surface enhancer, 1.5-2.5% of a grinding aid and 2-4% of an aqueous defoaming agent. The preparation method comprises: crushing, aging, primary magnetic separation, secondary magnetic separation, mixing, grinding and dehydration. According to the invention, through the technological innovation, waste raw materials such as steel residue, fly ash and the like are utilized to improve the technological formula, so that the waste resources and the like are fully utilized, and the purpose of changing of waste into treasure is achieved; the method is simple and practical in operation, and can effectively reduce the clinker sintering heat consumption, improve the dry shrinkage rate of the cement clinker, enhance the curing rate and the compressive strength of the cement clinker, prolong the service life of cement and ensure the construction quality.

Owner:无锡市金希达新型建材有限公司

Method and device for preparing nickel iron roasted ore by utilizing lateritic nickel ore

The invention discloses a method and a device for preparing a nickel iron roasted ore by utilizing a lateritic nickel ore. The method comprises the following steps: firstly, grinding the lateritic nickel ore into an ore powder, then carrying out high-temperature roasting of the obtained ore powder, during the high-temperature roasting process, allowing the ore powder to be in a pre-reduction system and carry out a high-temperature preheating reduction reaction, followed by allowing the high-temperature roasted ore to go into a rotary kiln for high-temperature calcination, thus obtaining a roasted ore containing nickel pig iron after completing high-temperature calcination, and then after dipping the roasted ore into water for cooling, separating to obtain the nickel iron roasted ore. The device comprises a hopper-type elevator, an air chute, a chute draught fan, a rotary feeder, a sluice valve, a rotary kiln, a water-cooling stirring tank, a burner, a hot wind mixing chamber, a high-temperature draught fan, a cyclone dust remover, a bag-type dust remover, a chain-type conveyor, a burner and a pre-reduction system. The preparation method and the device allow the heat transfer area of the ore powder to be large, enable each particle to be uniformly and fully subjected to a chemical reaction, have short reaction time, and have high utilization rate of the lateritic nickel ore.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

A kind of magnesium slag granulation method

ActiveCN109437609BReduce firing heat consumptionImprove mineralizationSmelting processMixed materials

The invention provides a magnesium slag granulation method, which comprises the following steps of 1, mixing waste and abandoned glass and borax according to a mass ratio of (20 to 50):1; then, performing crushing and ball milling on the mixed material to obtain a magnesium slag optimizing agent; 2, using calcined dolomite, a silicon iron reducing agent, a mineralizer as metallic magnesium production raw materials; adding a certain amount of magnesium slag optimizing agent into the metallic magnesium production raw materials; performing uniform mixing to form a mixed material; 3, putting the mixed material into a reduction tank; smelting magnesium according to a Pidgeon process; in the magnesium smelting process, separating out metallic magnesium in a steam form; the waste slag is coated with a liquid phase formed by the magnesium slag optimizing agent; a hard shell body is formed after natural cooling; granulous magnesium slag is finally obtained. The method provided by the inventionhas the advantages that the process is simple; the cost is low; the granulation and agglomeration of the magnesium slag are completed in one step in the metallic magnesium smelting process; meanwhile,the consumption of the mineralizer can be reduced.

Owner:NANJING KISEN INT ENG

Multi-product cleaning and producing method with coal gangue comprehensive utilization

ActiveCN102703157BChange the status quo of accumulationEliminate emissionsSteam generation heating methodsSolid fuelsPollutionEnergy source

The invention relates to a multi-product cleaning and producing method comprehensive utilization; coal carbon production, power generation by burning coal gangue, cement production, power generation by cement afterheat and wall material production technology are combined in a same industrial symbiont by using industrial symbiosis; optimal configuration between working procedures is realized; processing procedures of raw materials are converted into processing working procedures capable of separating raw materialsand fuels into different material flows and power flows which have different transport directions; mutually beneficial relationship is established between working procedures; a predetermined downstream working procedure is directly capable of digesting ''pollutant'' of an upstream working procedure; each working procedure utilizes different raw material component and different gradient energy source so as to produce multiple products; so that energy and matter flow in a multi-channel manner; and a little-pollution multi-prduct cleaning and producing technology is formed.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

Coal-firing efficient additive for dry cement process and its use

The invention belongs to coal additive field, especially a dry method concrete technology burning high efficiency additive. The feature is that it is made up of 20-30 portions of steel ground slag, 10-30 portions of barium slag, 5-10 portions of potassium permanganate, 1-2 portions of modification paper making sewage, 5-10 portions of citric acid, and 30-50 portions of high calcium fly ash. It could enhance the fire feature, and decline the firing temperature and no negative effect to concrete clinker aggregate.

Owner:WUHAN UNIV OF TECH

Preparation method of phosphorus slag portland cement chamotte and preparation method thereof

The invention relates to a preparation method of the phosphorus residue portland clinker. The clinker is includes limestone, pyrite residue, river sand, phosphorus reside and gangue raw material. It is formed by the following steps that the raw material is mixed in proportion, used pulverizing together and fired by the pre-decomposition kiln system at the condition of new type dry method cement system. The weight mixing proportion of the raw material orderly is from seventy to eighty five, from five to seven, from one point five to three, from eight to fifteen, and from zero point five to five. The invention can use the industry waste that phosphorus reside, pyrite residue and gangue as the raw material to prepare the low temperature loading type portland clinker. So it can solve the shortage of the fat limestone, clay, and iron ore, as well as supply a perfect approach for industry waste processing. Moreover, it can save the resource and energy source, reduce the pollution discharging, and is good for reducing cost, protecting environment, and increasing output and quality of the clinker, so that it is easy to popularly use in the new type dry method cement plant.

Owner:WUHAN UNIV OF TECH

Method of using industrial solid slag to produce silicate cement for nuclear power engineering

InactiveCN106396437ALow costReduce energy consumptionCement productionEcological environmentNuclear power

The invention relates to a silicate cement production method, and specifically relates to a method of using industrial solid slag to produce silicate cement for nuclear power engineering. The silicate cement comprises the following raw materials in percentage by weight: 72.0 to 78.0% of limestone mining waste, 7.0 to 16.0% of silica mining waste, 1.0 to 5.5% of blast furnace granulated slag, and 8.0 to 12.0% of tailings of iron ore mining. The abovementioned raw materials are mixed and milled and then the powder is subjected to heat change in a pre-heater, a gas-solid separation treatment, carbonate decomposition in a decomposing furnace, calcining in a dry-process rotary kiln, and cooling so as to obtain silicate cement clinker. According to the method, limestone mining waste, silica mining waste, blast furnace granulated slag, and tailings of iron ore mining are taken as the raw materials to produce silicate cement that is qualified for nuclear power engineering, a large amount of natural raw materials is saved, the energy consumption is reduced, the cost is saved, and the ecological environment is protected.

Owner:酒钢(集团)宏达建材有限责任公司

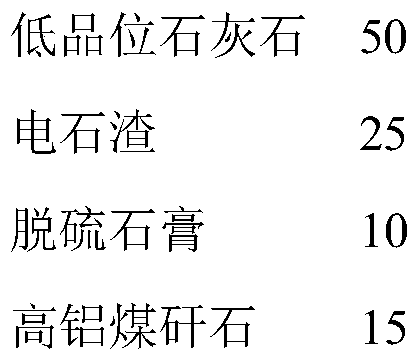

Method for preparing expanded concrete clinker by utilizing low-grade limestone

ActiveCN107304108BRealize high-grade applicationSolving the social problem of pollutionEcological environmentSludge

The invention discloses a method for preparing a concrete expanded clinker by utilizing low-grade limestone. Low-grade limestone tailing is used as a main calcium raw material; acetylene sludge is used as an adjusting material for the calcium raw material; desulfurization gypsum is used as a sulfur raw material; high alumina gangue is used as an aluminum raw material; and the concrete expanded clinker is prepared from the following raw materials in parts by weight: 50-55 parts of low-grade limestone, 25-30 parts of acetylene sludge, 5-15 parts of desulfurization gypsum and 10-15 parts of high alumina gangue. The invention develops a new method for preparing the concrete expanded clinker in the manner of treating waste with waste, can efficiently solve the social problem of the pollution to ecological environment by industrial waste, can realize the resource reutilization, can reduce the production cost of the concrete expanded clinker, can promote the market competitiveness of the concrete expanded clinker and has obvious social and economic benefits.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com