Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Reduce cutting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

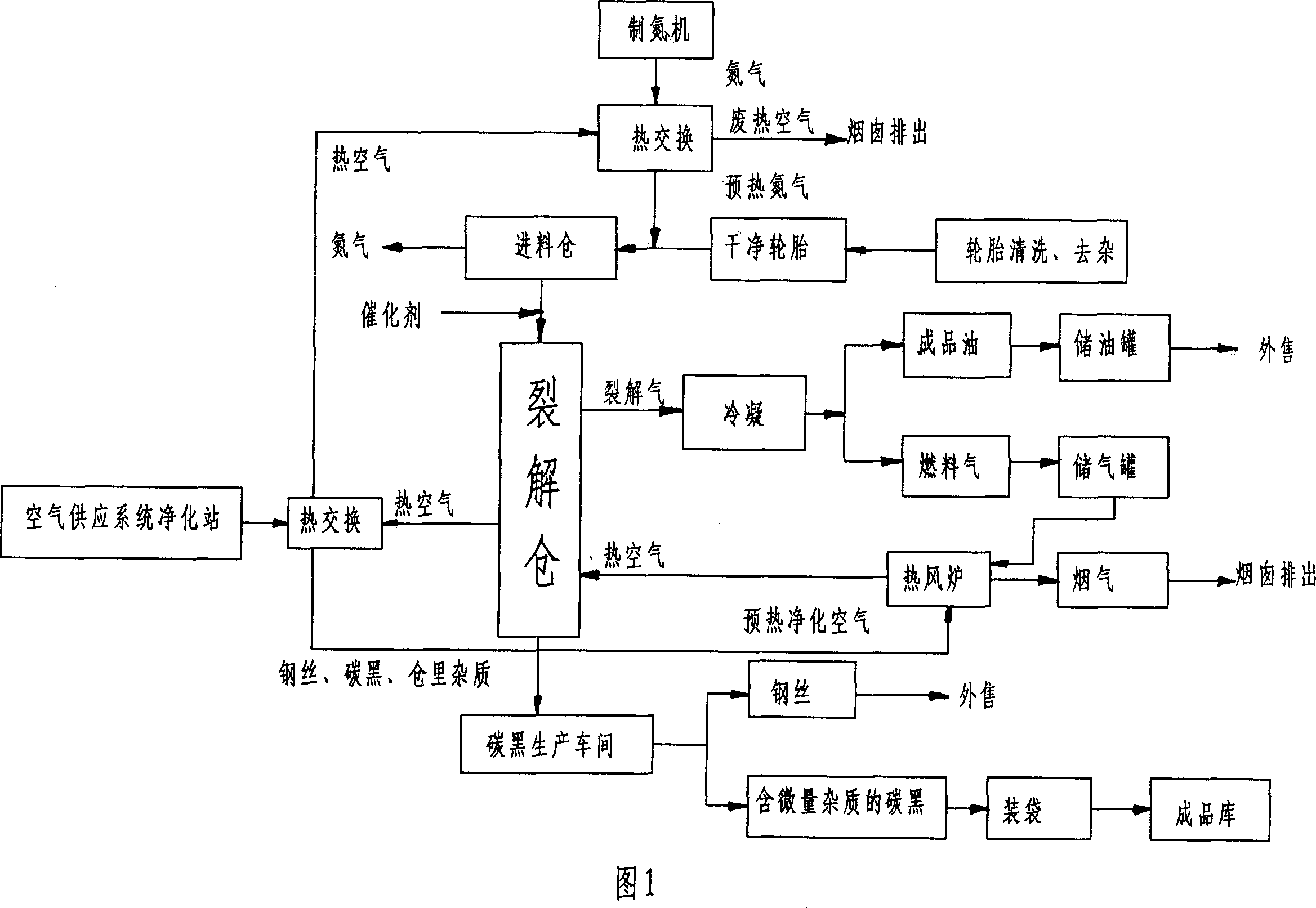

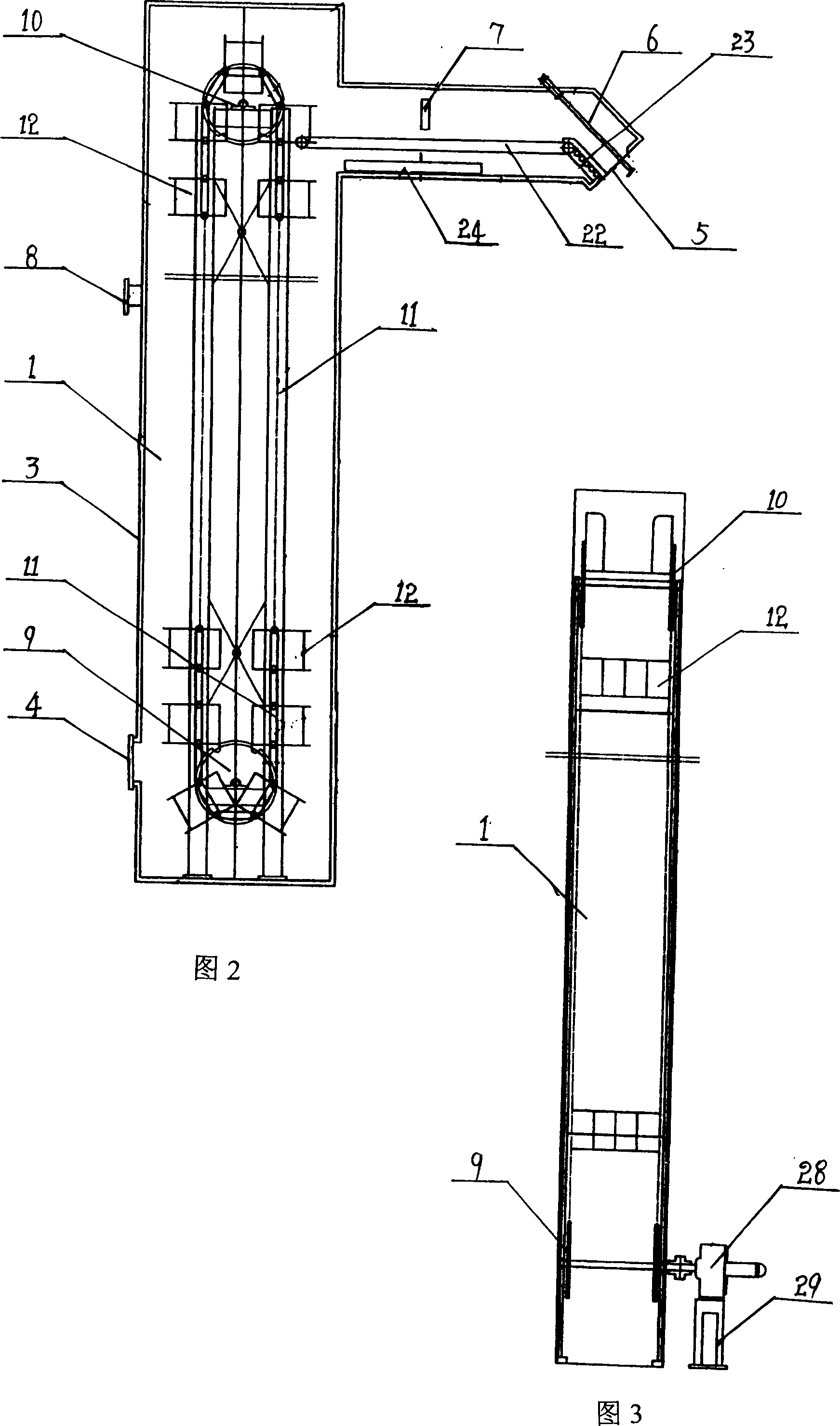

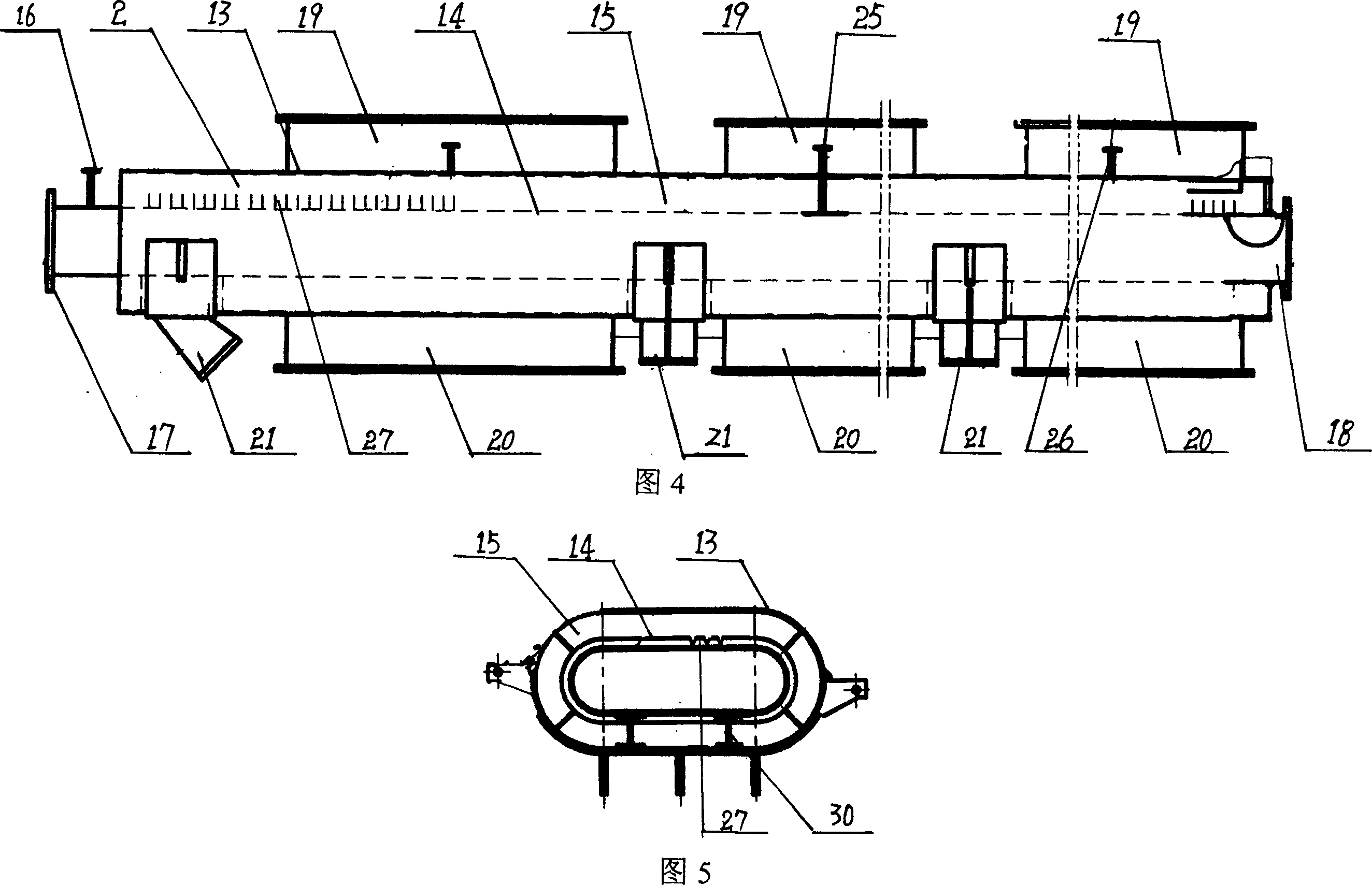

Waste tyre cracking process and apparatus

InactiveCN101089124AOptimizing the dosage ratioAvoid it happening againPigmenting treatmentLiquid hydrocarbon mixture productionNitrogenFuel oil

The present invention relates to waste tyre treatment, and is especially waste tyre cracking process and apparatus. The waste tyre catalytically cracking process includes the steps of washing, depurating, preheating in a feeding bin with heated nitrogen, cracking in a cracking bin in the presence of catalyst in the amount of 0.5-2 wt% tyre, feeding the steel wire and carbon black produced through cracking into the discharging bin, and condensating cracked gas in the condensator. The present invention has low temperature catalytically cracking process, optimized tyre / catalyst weight ratio, maximized fuel oil output, low cost, nitrogen protection, continuous cracking and high safety.

Owner:任丽娟 +2

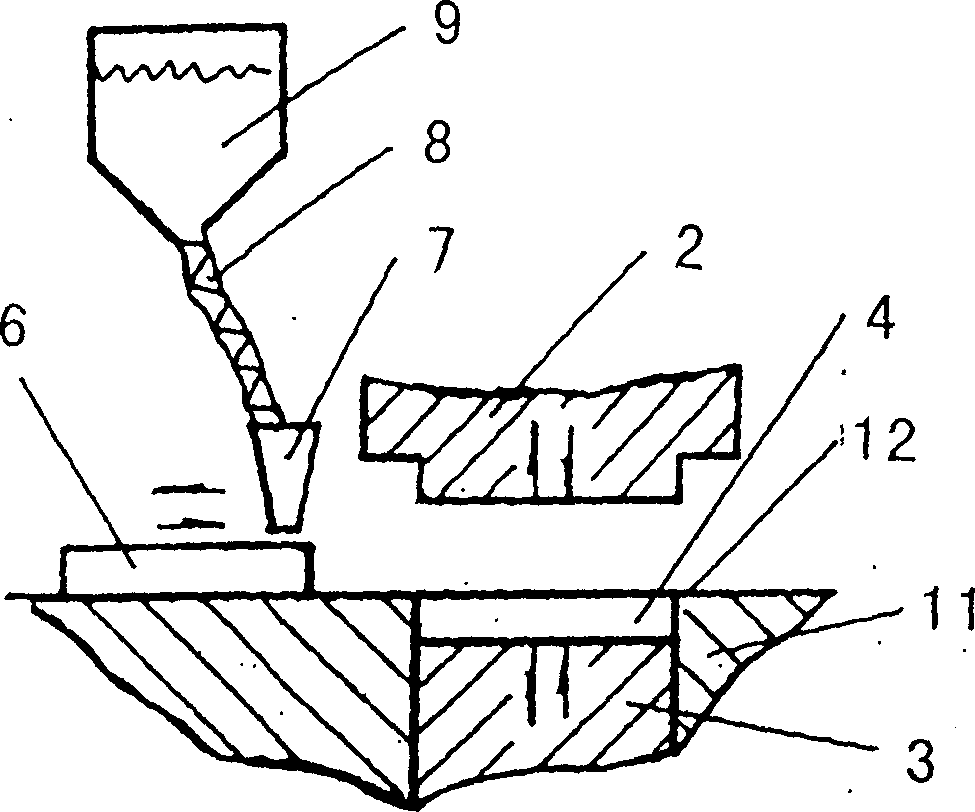

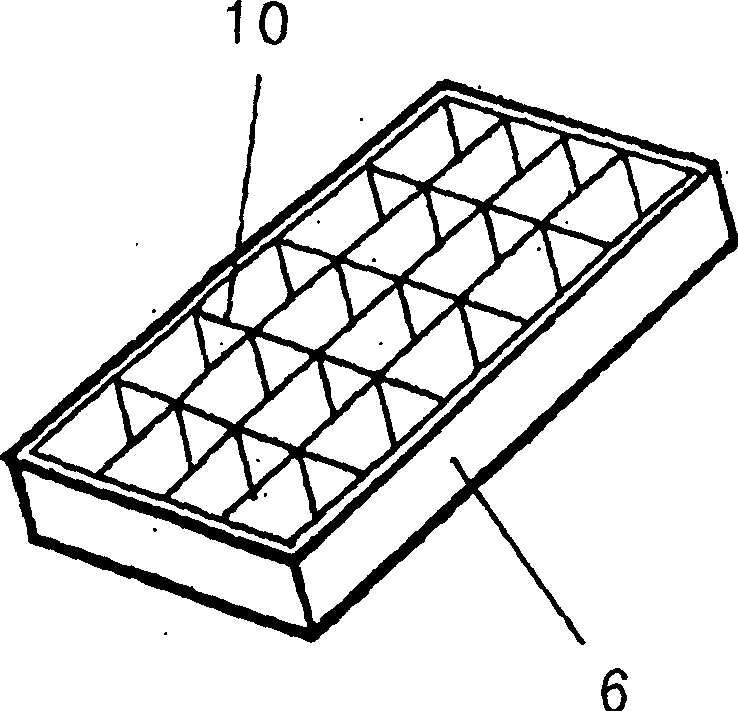

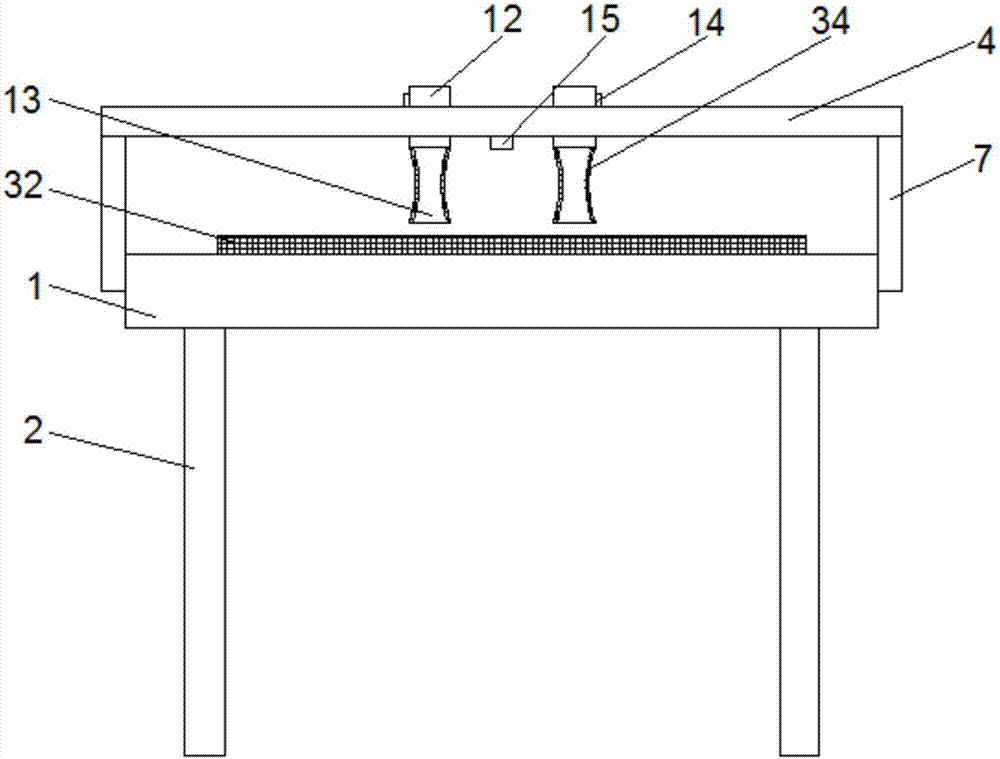

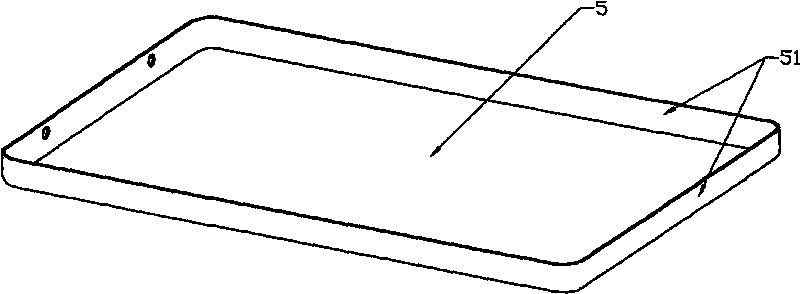

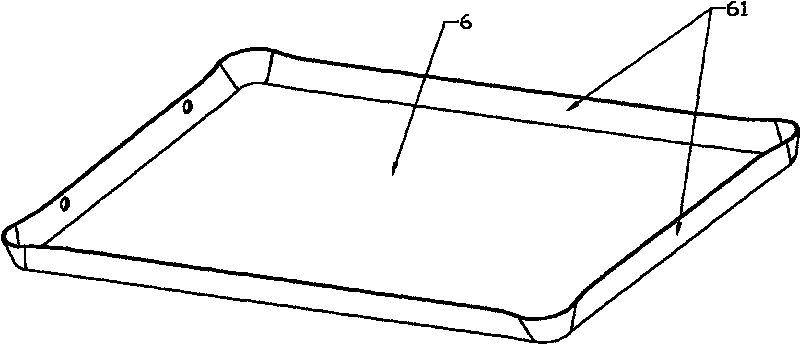

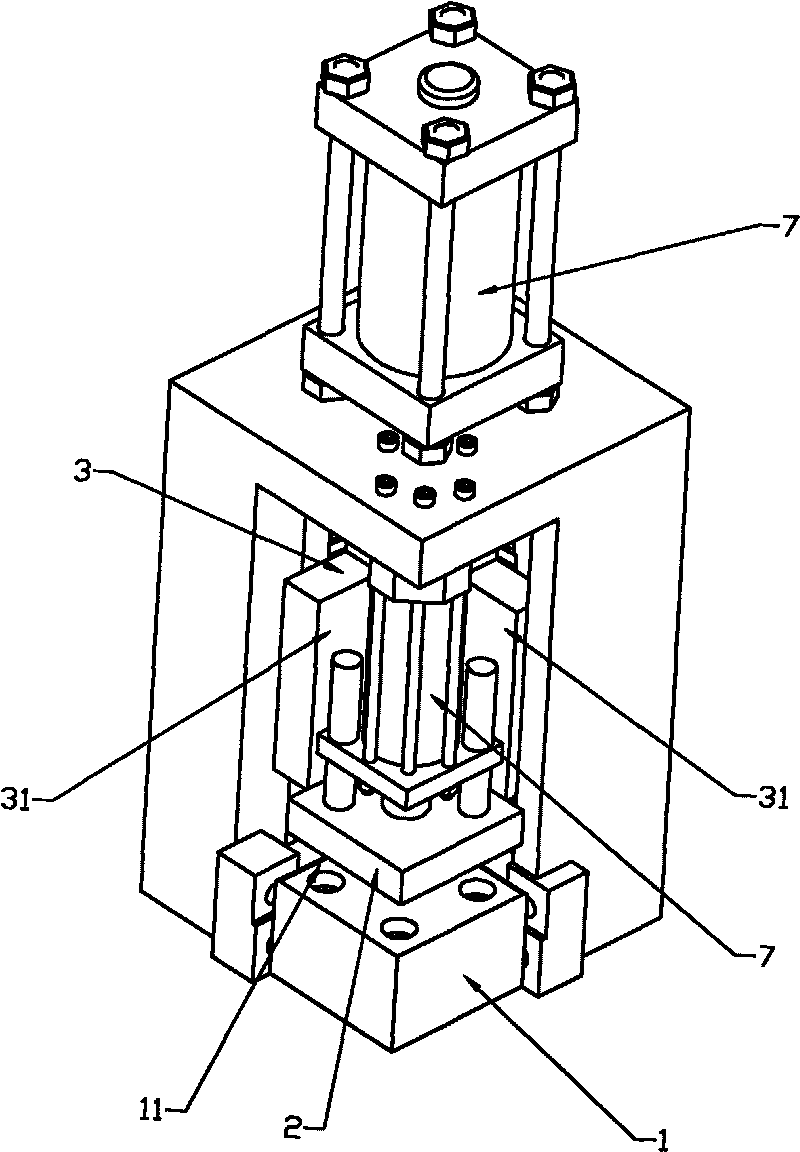

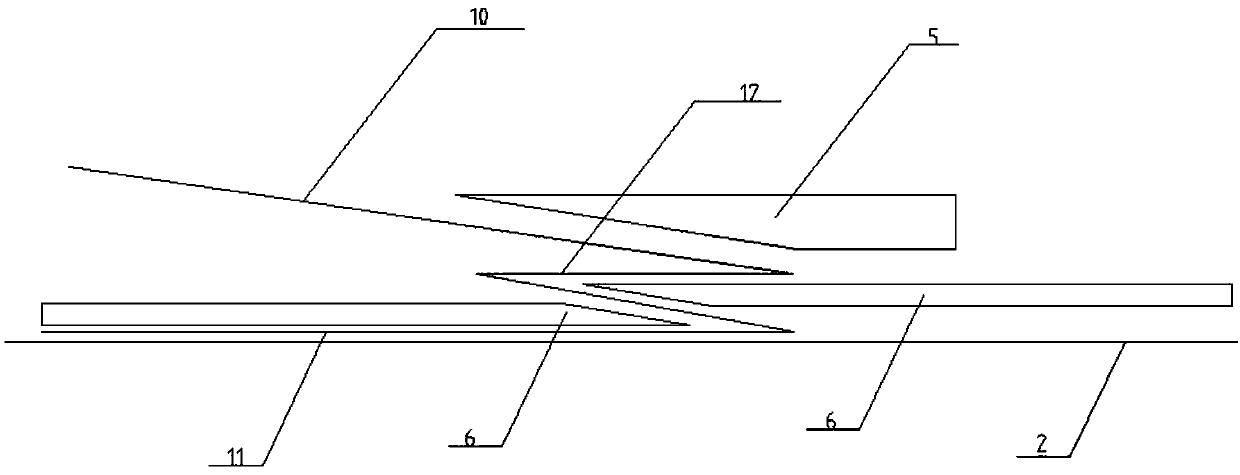

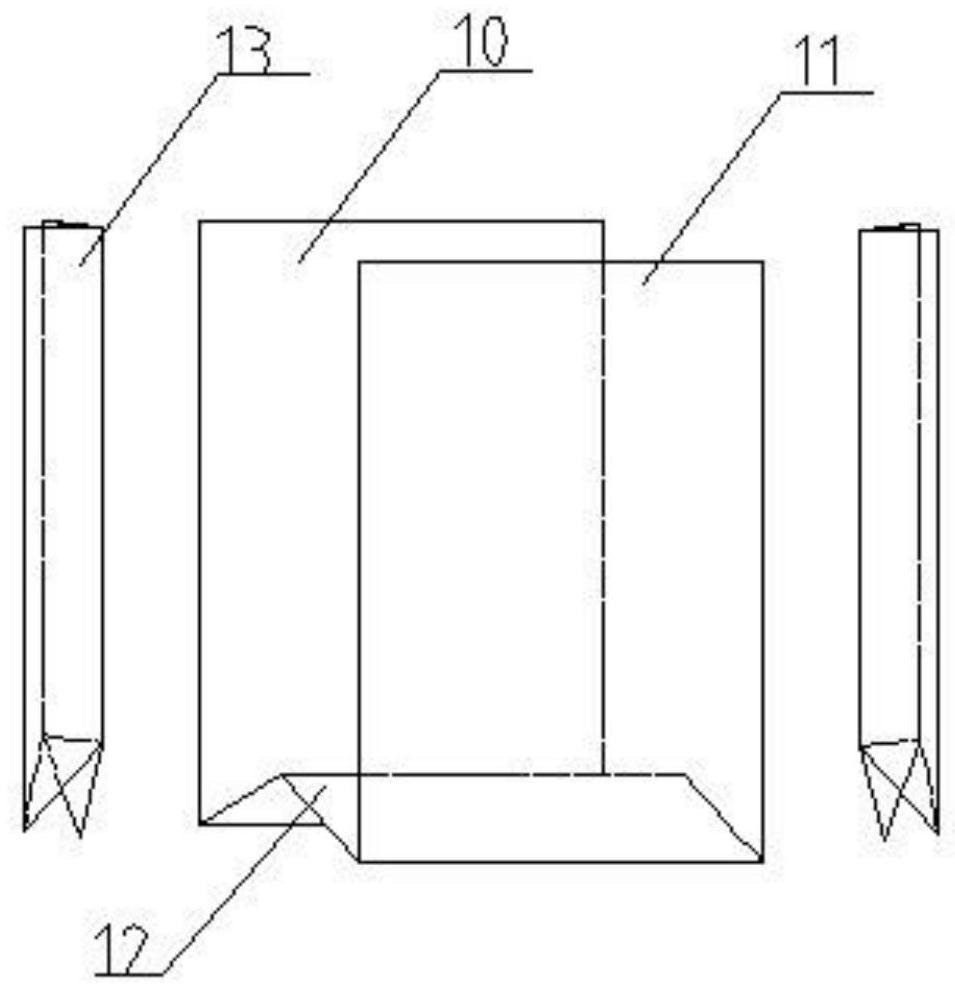

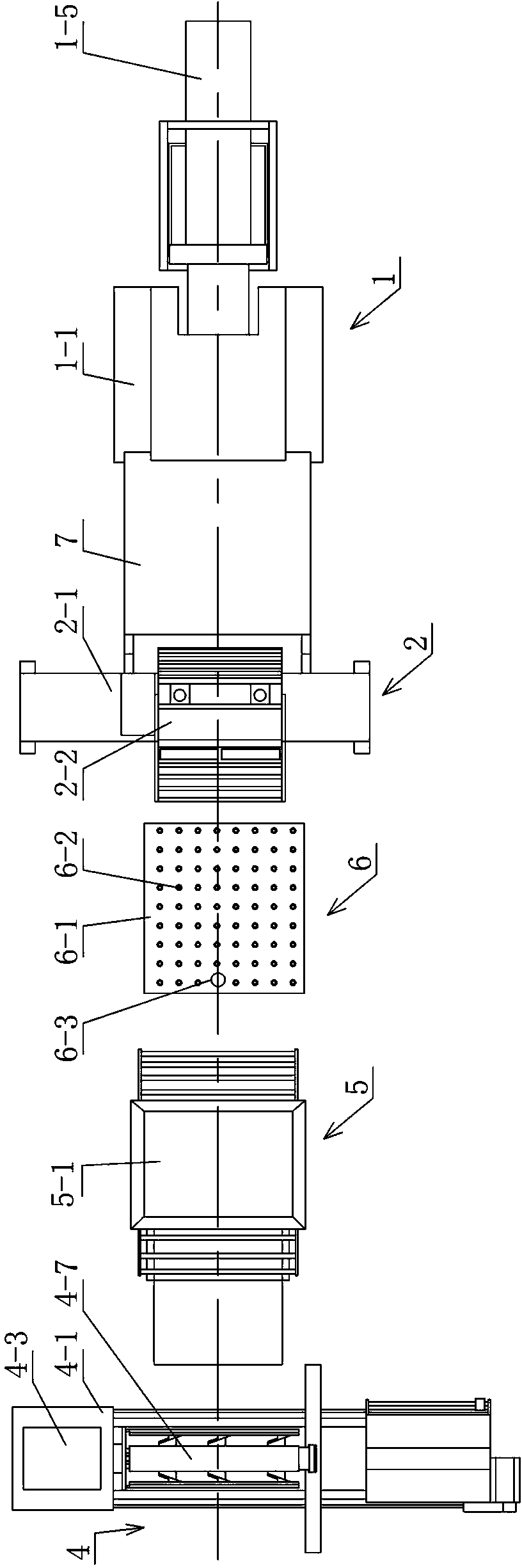

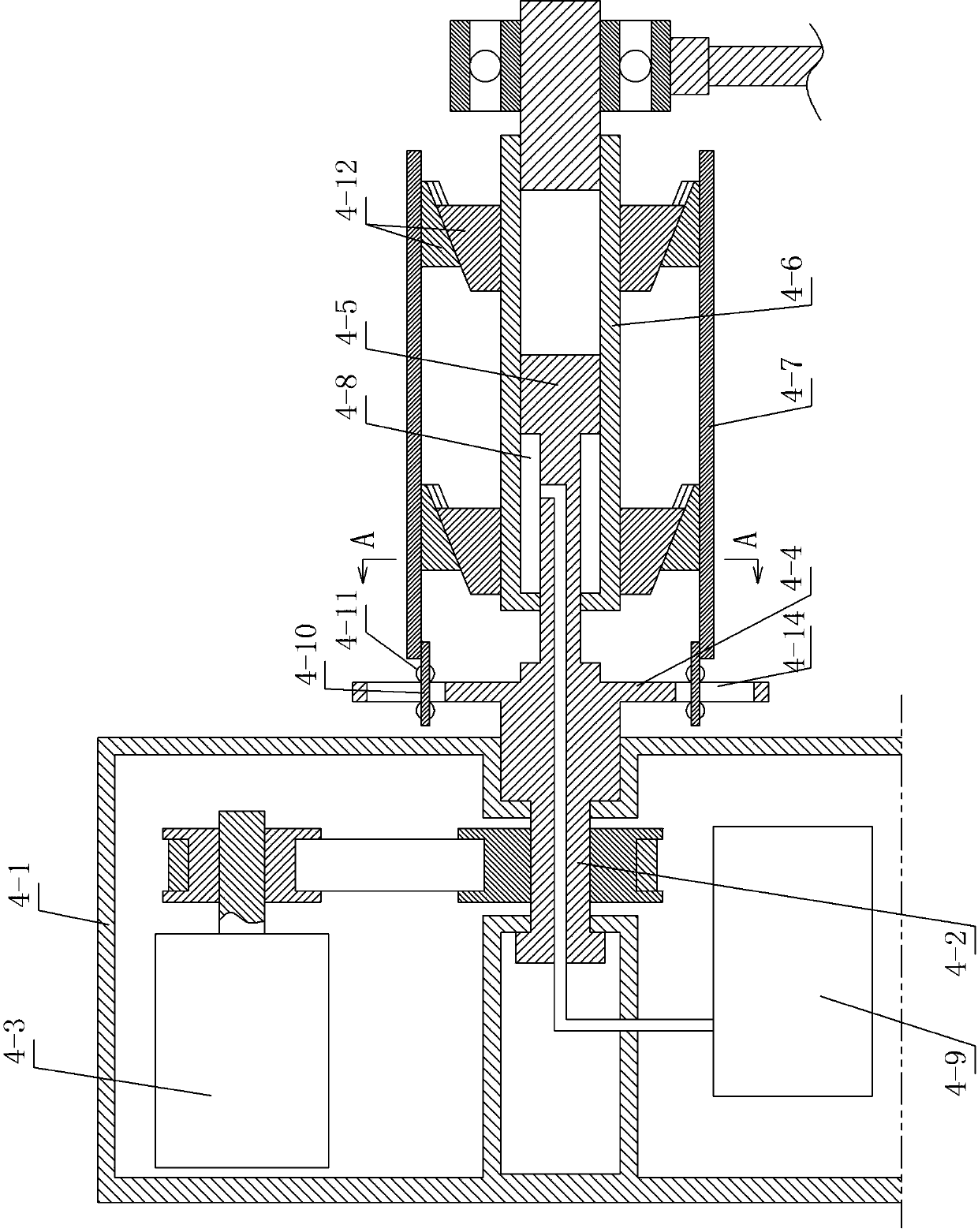

Ceramic tile forming equipment and forming method

InactiveCN1511688ARegular shapeReduce cutting processShaping conveyorsCeramic tilesMaterials science

The present invention is ceramic tile forming equipment and method. The equipment has material feeder to feed material to the belt conveyer; press with upper and lower punching heads; belt conveyer set between the upper and the lower punching heads; and sliding mold frame of rigid material set between the upper and the lower punching heads. The sliding mold frame may be made to move in the axial direction of the punching heads. The present invention makes it possible to produce ceramic tiles of different thickness for different decoration methods.

Owner:佛山市灵海陶瓷科技有限公司

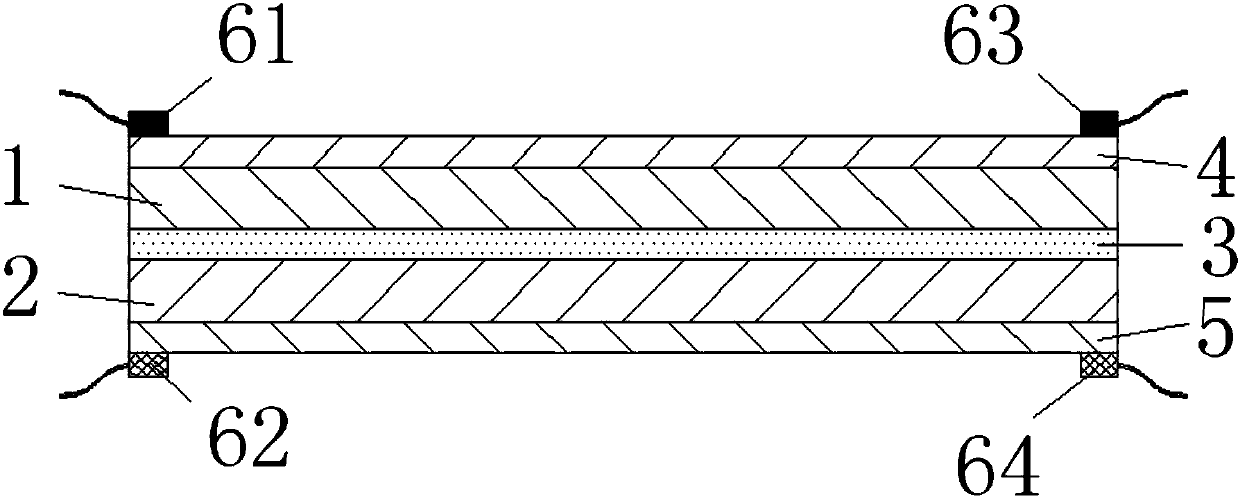

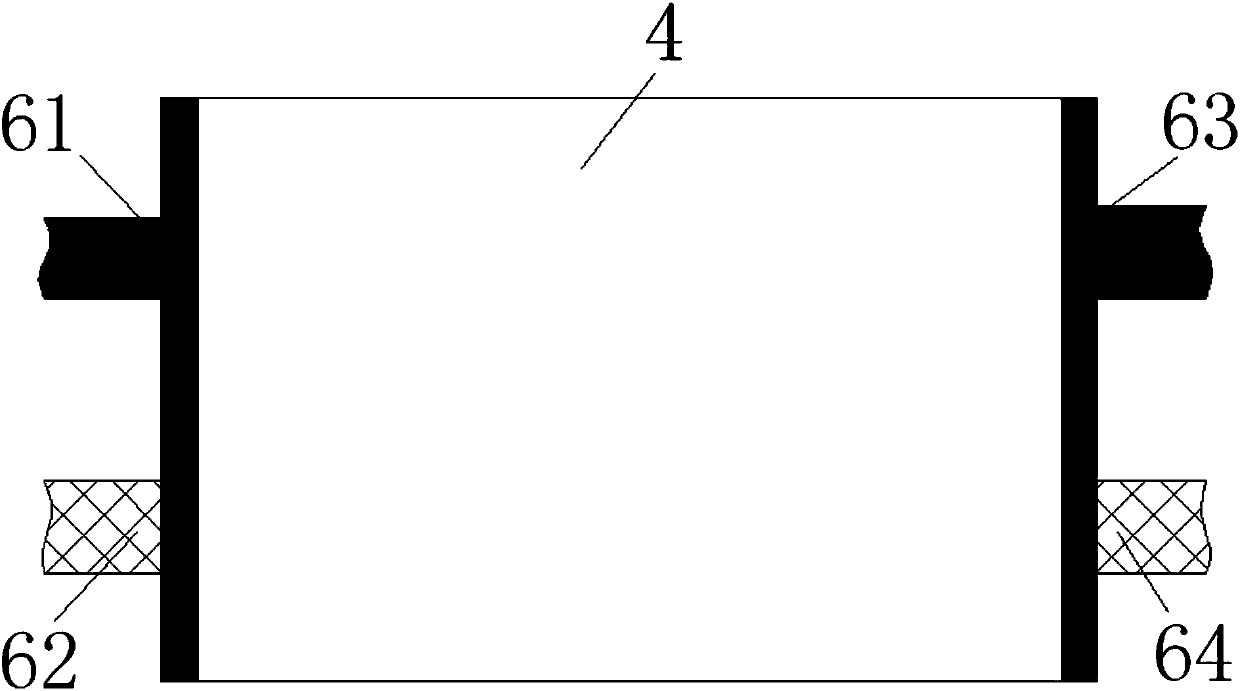

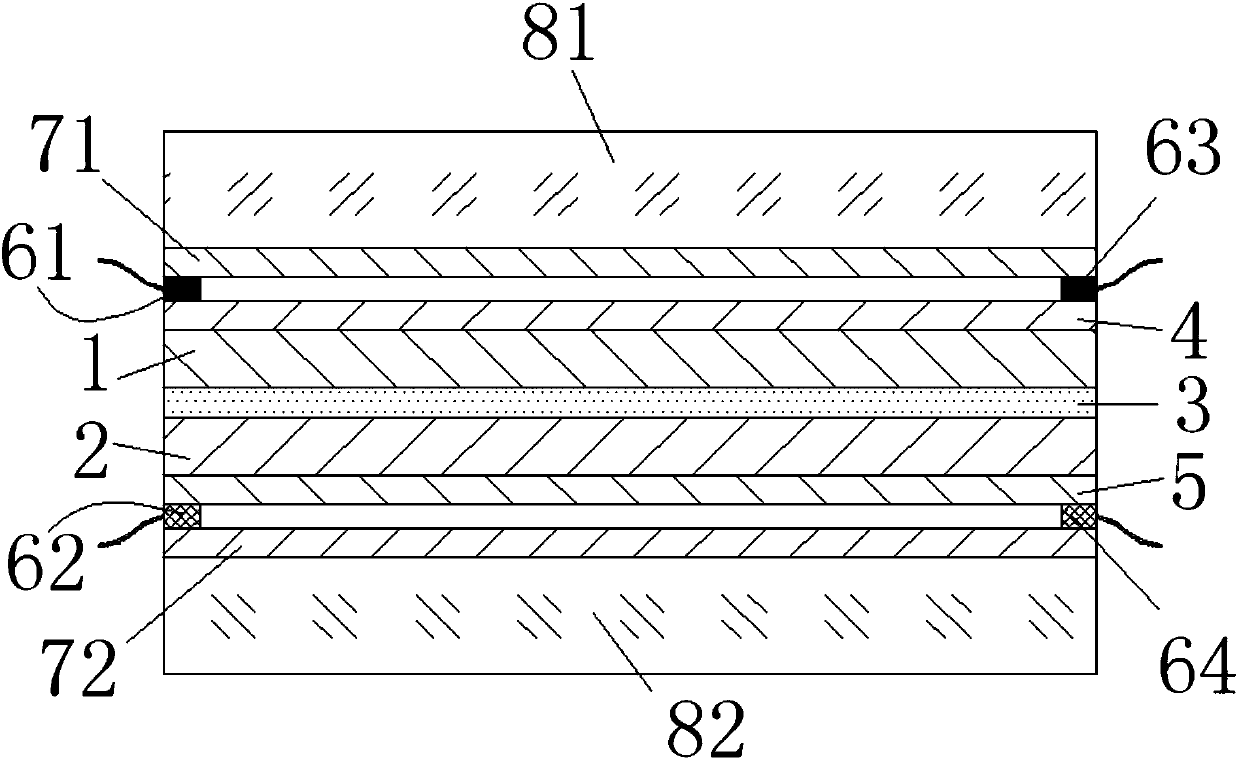

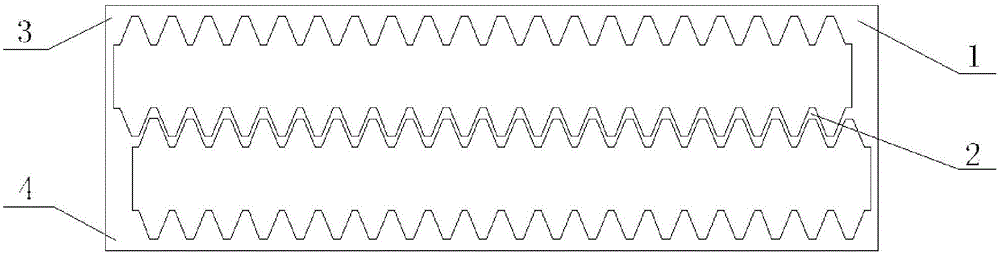

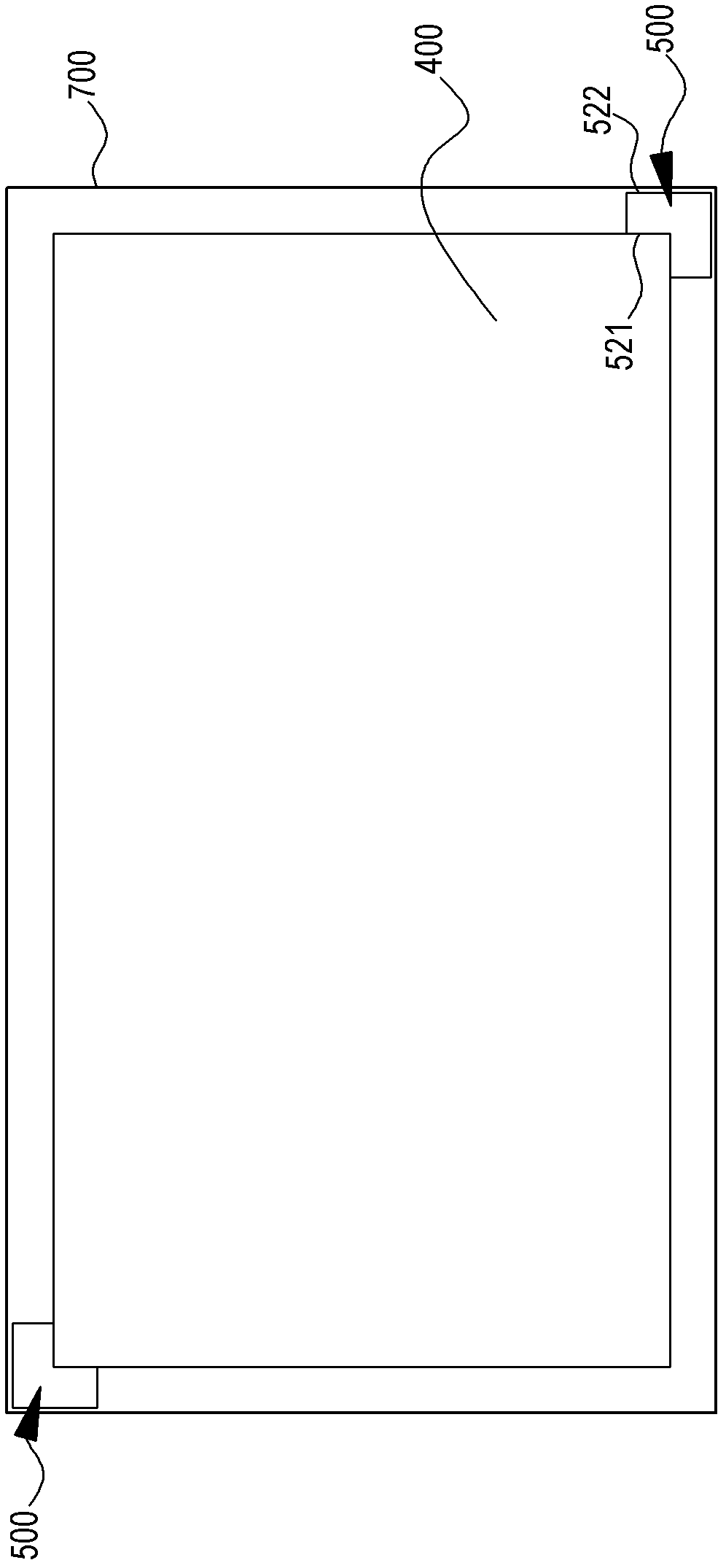

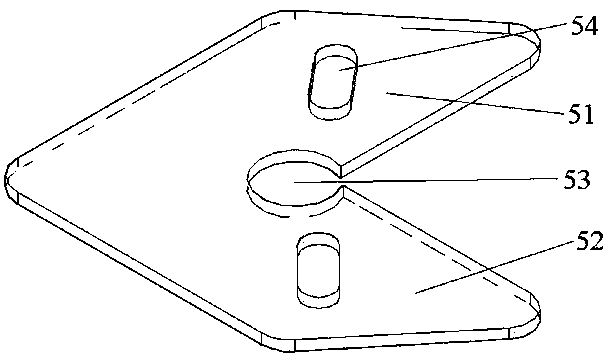

Liquid crystal dimming film and liquid crystal dimming laminated glass

InactiveCN108051959ASimplify the electrode fabrication processIncrease productivityWindowsWindscreensPolymerLiquid crystal

The invention relates to the technical field of liquid crystal dimming, in particular to a liquid crystal dimming film which comprises a first transparent substrate, a second transparent substrate anda polymer dispersion liquid crystal layer clamped between the first transparent substrate and the second transparent substrate. The liquid crystal dimming film is characterized in that the face, backing onto the polymer dispersion liquid crystal layer, of the first transparent substrate is provided with a first transparent conductive layer, the face, backing onto the polymer dispersion liquid crystal layer, of the second transparent substrate is provided with a second transparent conductive layer, a first electrode is arranged at the first edge of the first transparent conductive layer, a second electrode is arranged at the second edge of the second transparent conductive layer, and the first electrode and the second electrode are used for being electrically connected to the two ends of afirst power source. The liquid crystal dimming film has the advantages that the electrodes of the structure are convenient to install, and on the basis of the heating function, the problem that the dimming film cannot be in use under the cold condition is solved.

Owner:FUYAO GLASS IND GROUP CO LTD

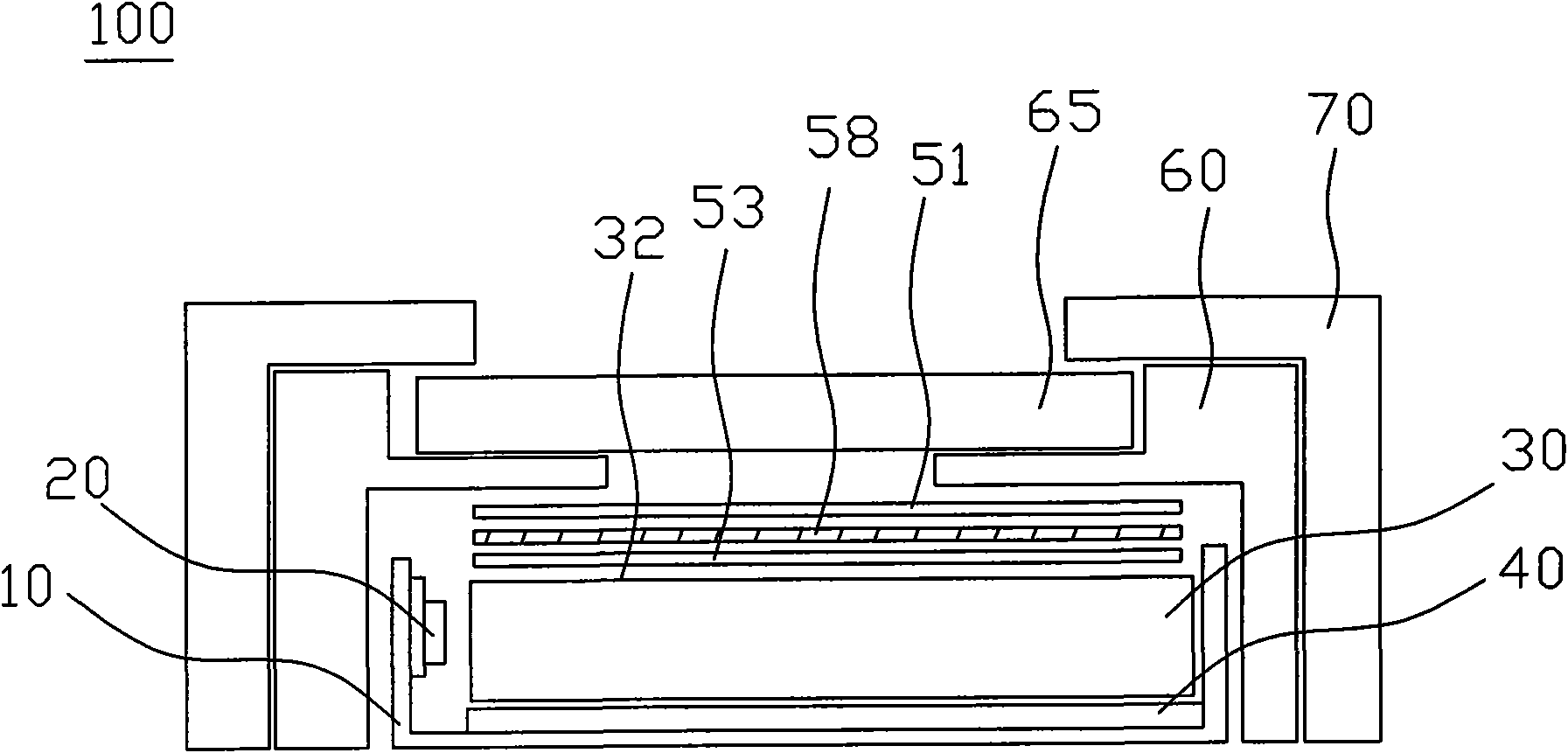

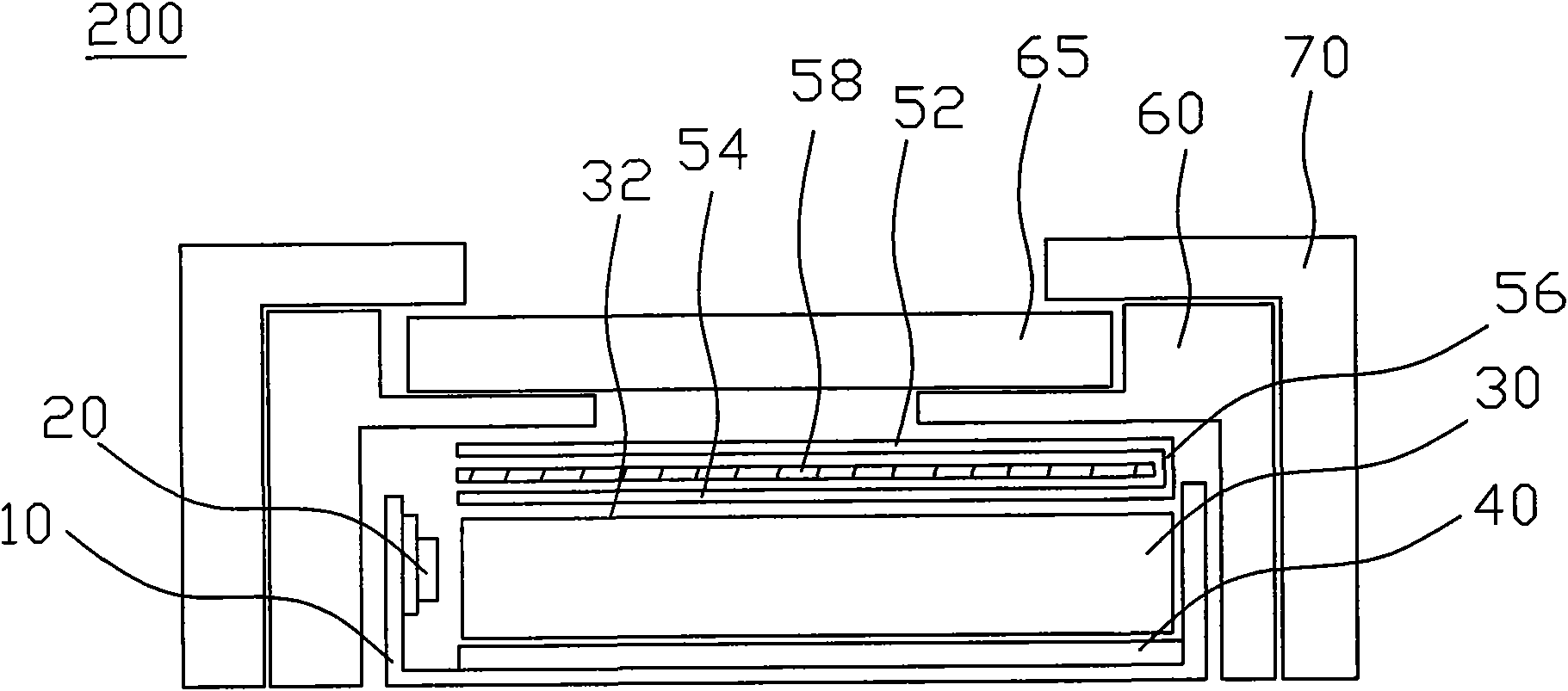

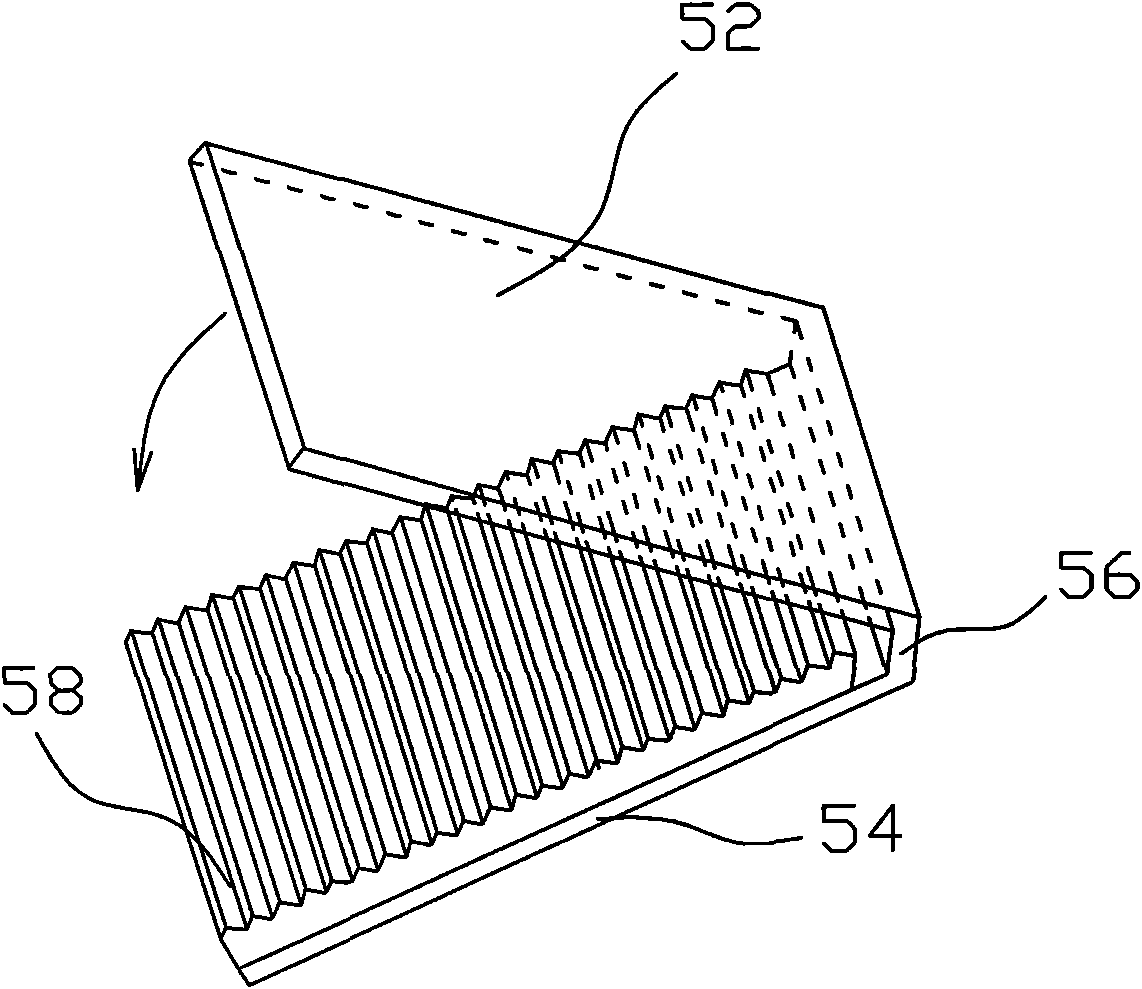

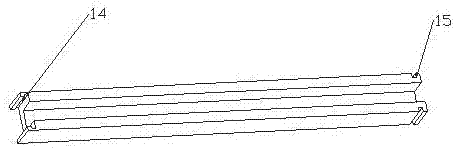

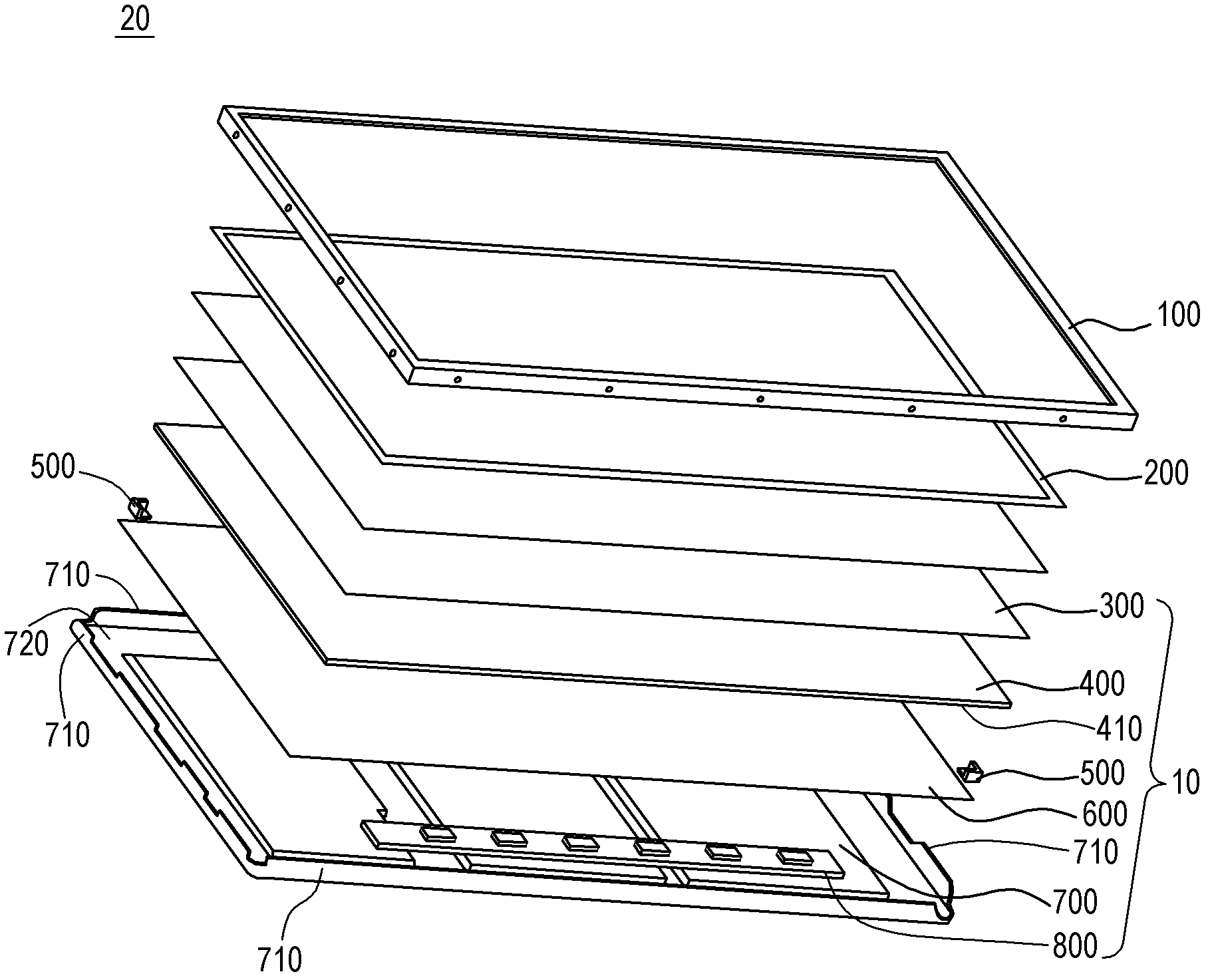

Backlight module, display device and manufacturing method of diffusion sheet

The invention relates to a backlight module, a display device and a manufacturing method of a diffusion sheet. The backlight module comprises a light guiding plate and a plurality of optical membrane sheets, wherein the light guiding plate is provided with a light-emitting surface, the optical membrane sheets are arranged at one side of the light-emitting surface, each optical membrane sheet comprises the diffusion sheet and a prism sheet, the diffusion sheet is integrally molded and comprises an upper diffusion sheet and a lower diffusion sheet, and the diffusion sheet is bent, so that the upper diffusion sheet and the lower diffusion sheet are parallel and opposite and form a containing space; and the prism sheet is clamped in the containing space. The upper diffusion sheet and the lower diffusion sheet of the backlight module are integrally molded, and when the optical membrane sheets are assembled, the prism sheet is clamped in the diffusion sheet by bending the diffusion sheet. The design can prevent the optical membrane sheet in a traditional backlight module from tripping, also can avoid material mixing when in assembly, simplifies the assembling working procedure and improves the production efficiency.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

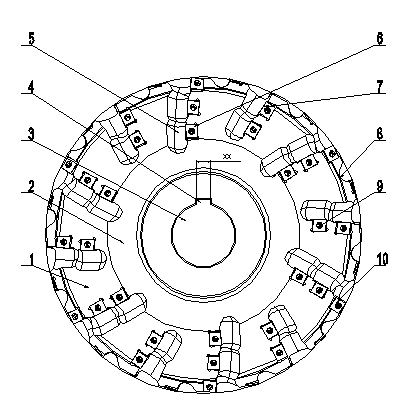

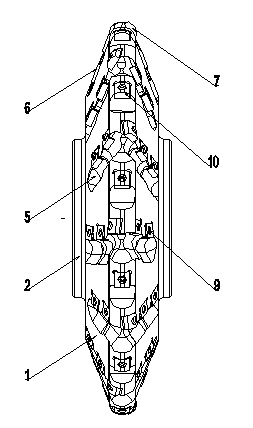

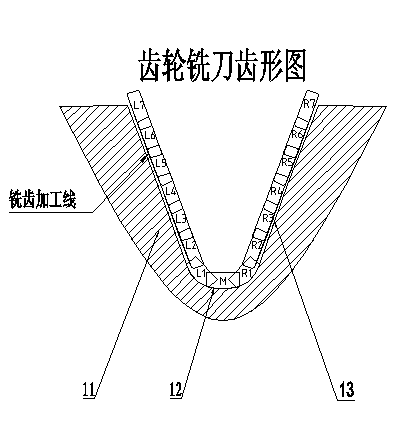

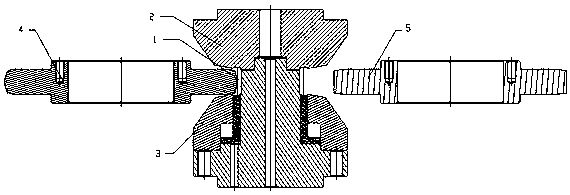

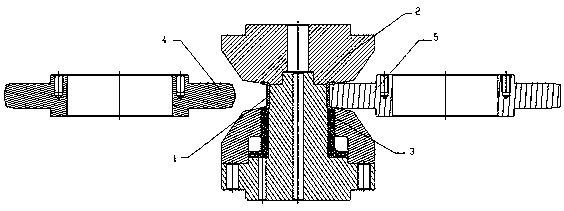

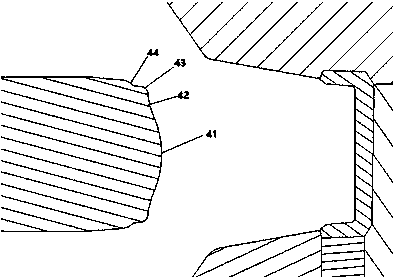

Gear tooth bottom forming milling cutter

InactiveCN103223532AReduce cutting processHigh speedGear teeth manufacturing toolsGear teethFluteHobbing

The invention relates to a gear tooth bottom forming milling cutter, which comprises a milling cutter body and a carbide blade, wherein a chip groove and a carbide blade assembling groove are arranged in the cutting position of the cutter body; an assembling axle hole, a radial positioning key groove, a hub, a chip flute, a blade assembling groove and a fixed blade bolt hole are arranged in the cutter body; and the carbide blade is fixedly arranged on a cutter-body groove through screws. The blade completes finish machining for a tooth bottom and carries out rough cutting machining for the involute profile of a tooth form at the same time. The gear tooth bottom forming milling cutter can decrease the tooth form cutting machining procedure, increase the cutting machining speed, reduce the cutting resistance of finish-milling teeth and finish-hobbing teeth, and increase the production efficiency. The gear tooth bottom forming milling cutter particularly increases the machining speed of the machining procedure of the finish-hobbing teeth and the finish-milling teeth of a gear and ensures that the machined gear has the stable and ideal precision and quality.

Owner:TANGSHAN SINOMA HEAVY MASCH CO LTD

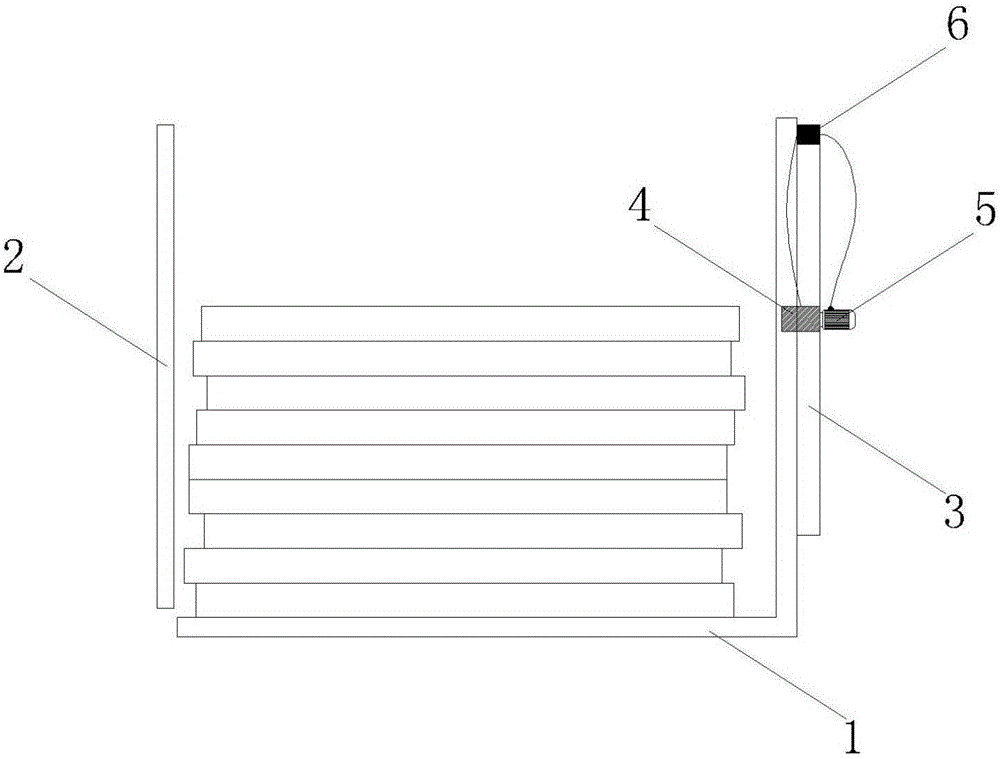

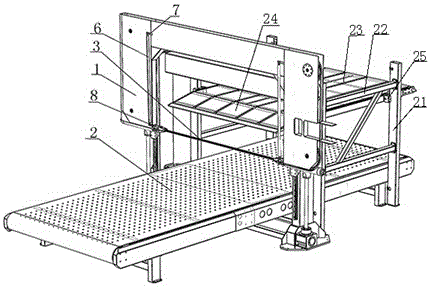

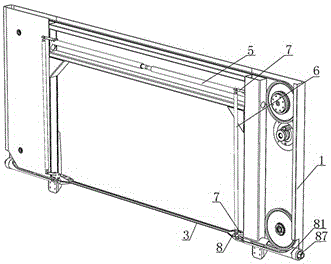

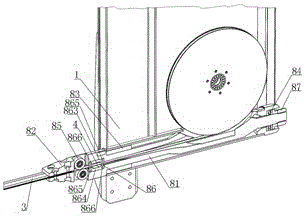

Automatic wood board feeding stock bin

InactiveCN105775668ANeatly stackedReduce cutting processConveyorsControl devices for conveyorsScrapElectricity

The invention provides an automatic wood board feeding stock bin which comprises a trough and a baffle. One side face and the upper portion of the trough are opened. The baffle is arranged at the position of a side face opening and can move forwards and backwards in the trough. A sliding rail in the vertical direction is arranged at one end of the trough wall, opposite to the baffle, of the trough and provided with an infrared detector. The infrared detector can walk up and down on the sliding rail through a stepping motor. Both the stepping motor and the infrared detector are electrically connected with a microprocessor. By the adoption of the automatic wood board feeding stock bin, wood boards are stacked tidily, cutting procedures are reduced, generation of cut waste is reduced as well, the reworking rate is low, and the machining efficiency is greatly improved.

Owner:ANHUI ZHI CHANG BAMBOO TECH CO LTD

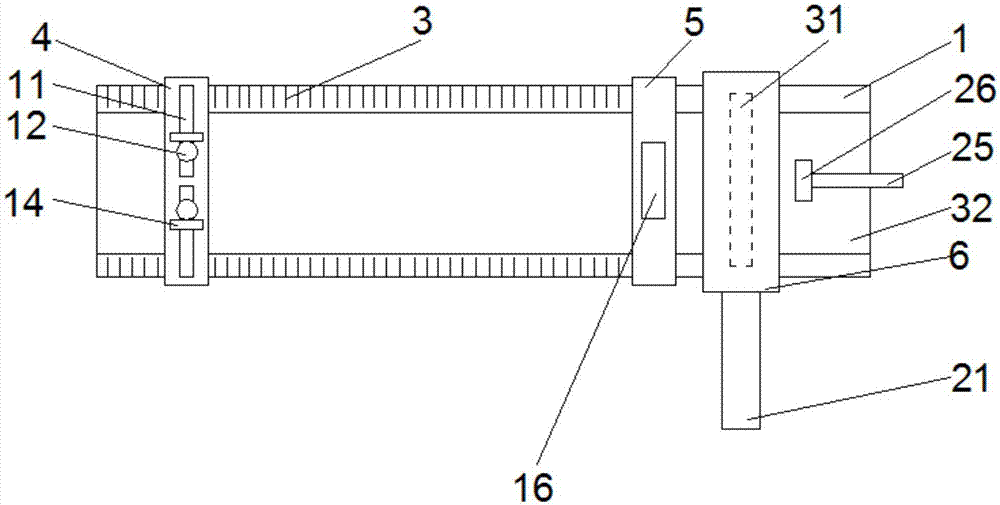

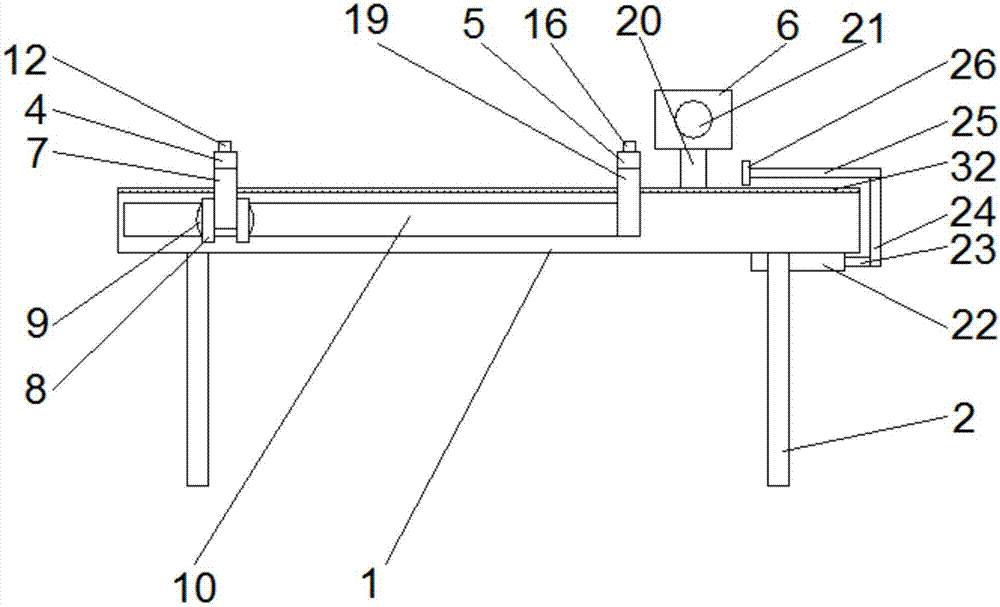

Pipe fixed-length cutting device

InactiveCN107457817AImprove cut-to-length efficiencyReduce cutting processMetal working apparatusEngineeringFixed length

The invention discloses a pipe material fixed-length cutting device, which comprises a bottom plate of the device, four outriggers are evenly arranged on the bottom of the bottom plate of the device, scales are arranged on both sides of the upper surface of the bottom plate of the device, and the top of the bottom plate of the device is sequentially arranged from left to right The first cross bar, the second cross bar and the cutting device, the two ends of the first cross bar are fixed with the first vertical rod, and the first limit blocks are arranged on both sides of the bottom of the first vertical rod, and the first vertical rod Pulleys are arranged on the bottom of the inner side of the pole, and the front and rear sides of the bottom plate of the device are provided with chutes matching the pulleys. The pulleys are connected to the chute by rolling, and the upper surface of the first cross bar is symmetrical. A through slot passing through the first cross bar is provided. The beneficial effects of the present invention are: the simple structure is used to automatically determine the length of the pipe to be cut without using a manual drawing ruler to determine the length, which greatly improves the efficiency of the fixed-length cutting of the pipeline, the precision of the fixed length is relatively accurate, and the pipeline cutting process is shortened. easy to use.

Owner:张文瀚

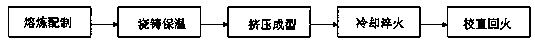

Continuous casting and extrusion process of aluminum alloy section

InactiveCN103451483ASimple production processReduce cutting processEnergy consumptionContinuous casting

The invention discloses a continuous casting and extrusion process of an aluminum alloy section, which comprises steps such as smelting and preparing, casting and temperature keeping, extrusion and molding, cooling and quenching, straightening and tempering, and the like. The aluminum alloy section production process omits multiple heating and cooling procedures in the traditional process and omits an aluminum alloy section cutting procedure, thus greatly simplifying the aluminum alloy section production procedure, improving the production efficiency, reducing the loss of the aluminum alloy section in the cutting process, greatly improving the production efficiency, lowering the production cost of the aluminum alloy section, greatly reducing energy consumption and resource loss, and reducing pollution to the natural environment.

Owner:HENAN HUILONG ALUMINUM IND

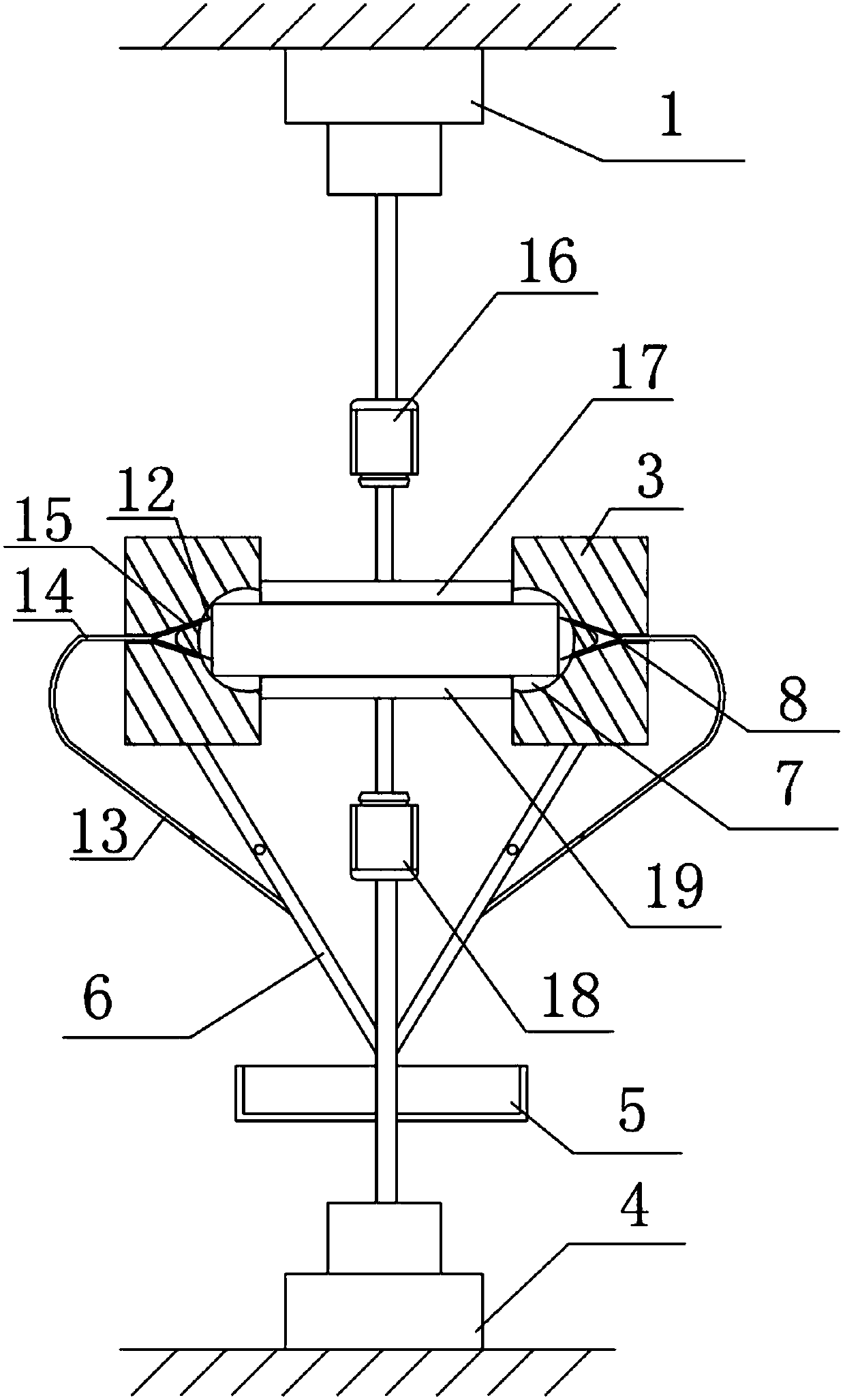

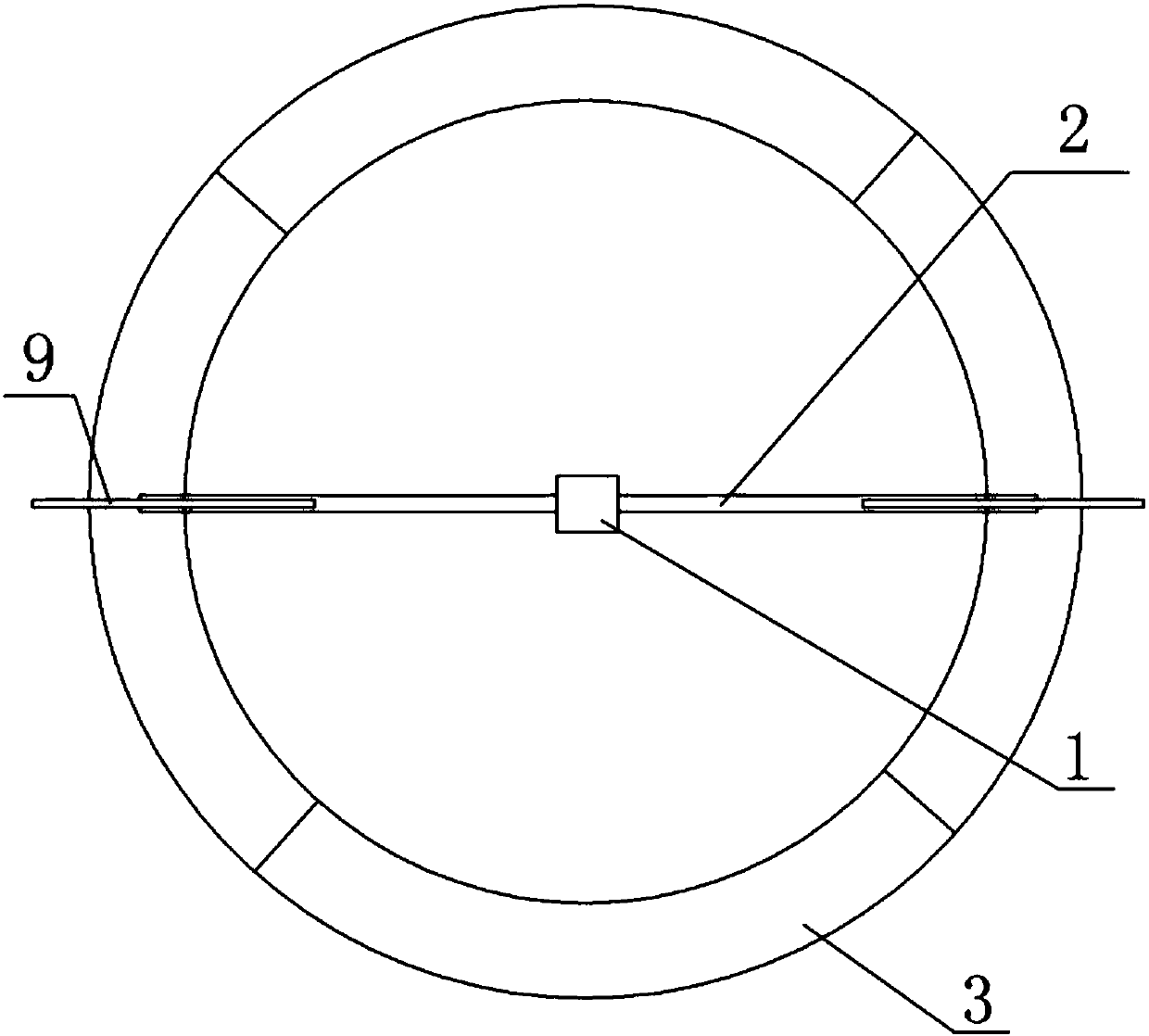

Grinding technology for optical filter

ActiveCN108032442AImprove efficiencyReduce cutting processOptical surface grinding machinesWorking accessoriesLight filterMechanical engineering

The invention relates to the field of lens manufacturing, in particular to a grinding technology for an optical filter. According to the grinding technology, a first fastening mechanism, a second fastening mechanism, a first cutting mechanism, a second cutting mechanism, a first grinding mechanism and a second grinding mechanism are arranged; the first fastening mechanism comprises a first air cylinder and two first fastening units; the second fastening mechanism comprises a second air cylinder and two second fastening units; arc-shaped through grooves are formed in the inner side walls of fastening blocks; Y-shaped through holes are formed in the middle of the fastening blocks in the radial direction; the first cutting mechanism comprises a first supporting rod, a first pushing rod, two first adjusting rods and two first cutters; the second cutting mechanism comprises a second supporting rod, a second pushing rod, two second adjusting rods and two second cutters; the first grinding mechanism comprises a first motor and a first grinding disc; and the second grinding mechanism comprises a second motor and a second grinding disc. According to the technical scheme of the grinding technology, double-sided grinding can be simultaneously carried out on the round optical filter, and meanwhile, the cutting operation can be completed.

Owner:华汉致信(宁波)供应链管理有限公司

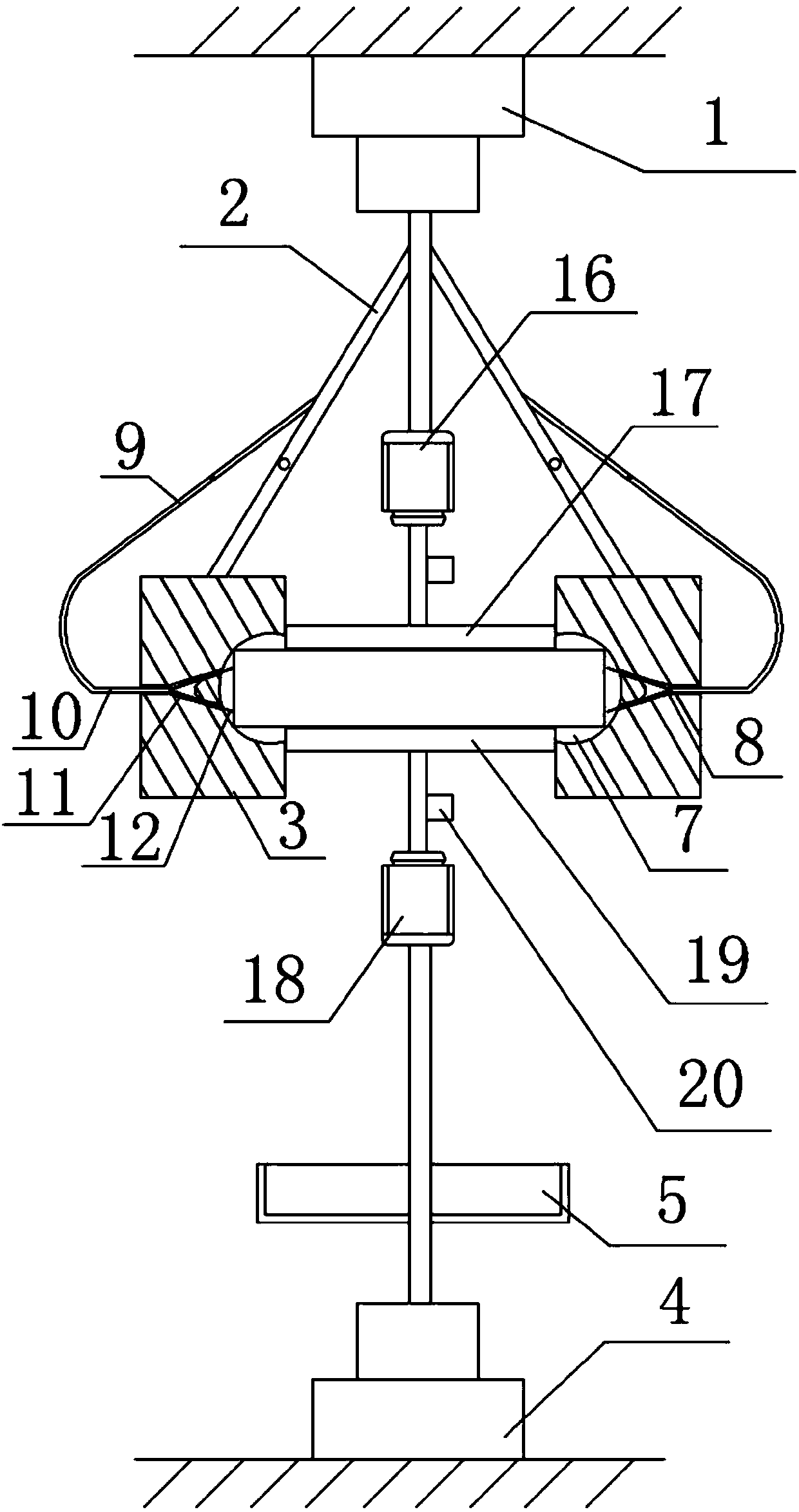

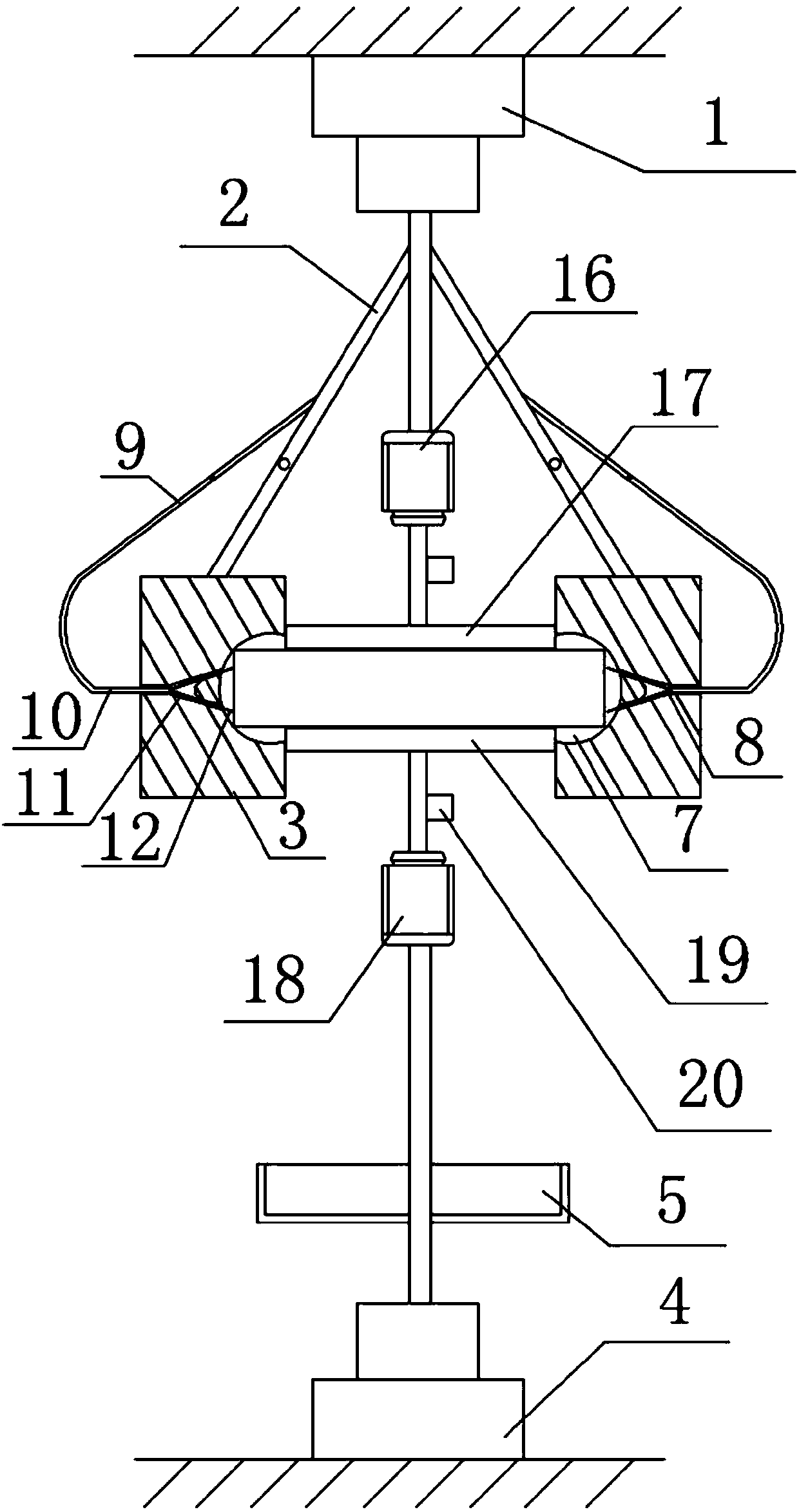

Lens manufacturing equipment

ActiveCN108015639AImprove processing efficiencyImprove grinding efficiencyOptical surface grinding machinesGrinding/polishing safety devicesEngineeringLens plate

The invention relates to the field of lens manufacturing, in particular to lens manufacturing equipment. The lens manufacturing equipment comprises a first fastening mechanism, a second fastening mechanism, a first cutting mechanism, a second cutting mechanism, a first polishing mechanism and a second polishing mechanism; the first fastening mechanism comprises a first air cylinder and two first fastening units, and the second fastening mechanism comprises a second air cylinder and two second fastening units; arc-shaped through grooves are formed in the inner side walls of fastening blocks, and Y-shaped through holes are formed in the middle portions of the fastening blocks in the radial direction; the first cutting mechanism comprises a first supporting rod, a first pushing rod, two firstadjusting rods and two cutting knives; the second cutting mechanism comprises a second supporting rod, a second pushing rod, two second adjusting rods and two cutting knives; the first polishing mechanism comprises a first motor and a first polishing disc; and the second polishing mechanism comprises a second motor and a second polishing disc. When the technical scheme is adopted, cutting operation is completed when dual-face polishing is carried out on a round glass lens.

Owner:华汉致信(宁波)供应链管理有限公司

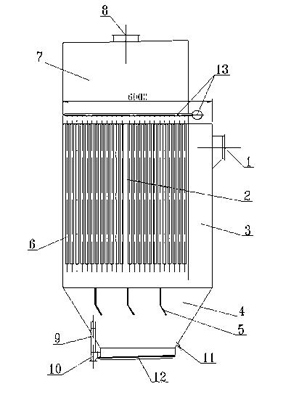

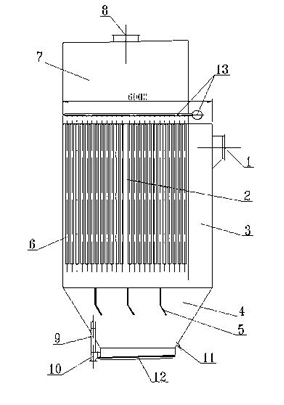

Bag-type dust remover for dry purifying system

The invention discloses a bag-type dust remover for a dry purifying system, which comprises a middle box body (2) of the bag-type dust remover, a dust hopper (4), a filter bag (6) and an upper box body (7), wherein the middle box body (2) is provided with an air inlet (1); the upper box body (7) is provided with an air outlet (8); and the dust hopper (4) is provided with an overflow pipe (9) for discharging dust and an exhaust opening (10) for cleaning and exhausting slag. The overflow pipe can discharge materials in the dust hopper, adjust the height of a sleeve pipe in a way of adding the sleeve pipe so as to adjust and control the height of a stored material in the dust hopper and more favorably ensure the supply of a recycling material adsorbent; and the exhaust opening is convenient to clean and exhaust the slag during shutdown. A recycling material opening can redeliver an adsorbing material without adsorbed saturation to the dry purifying system, is convenient for the direct recycling material addition of the system and is beneficial to the energy saving of the system, and the installation of a boiling bed aims to facilitate the adjustment of the smoothness of the material at the bottom of the dust hopper.

Owner:GUIYANG AL-MG DESIGN & RES INST

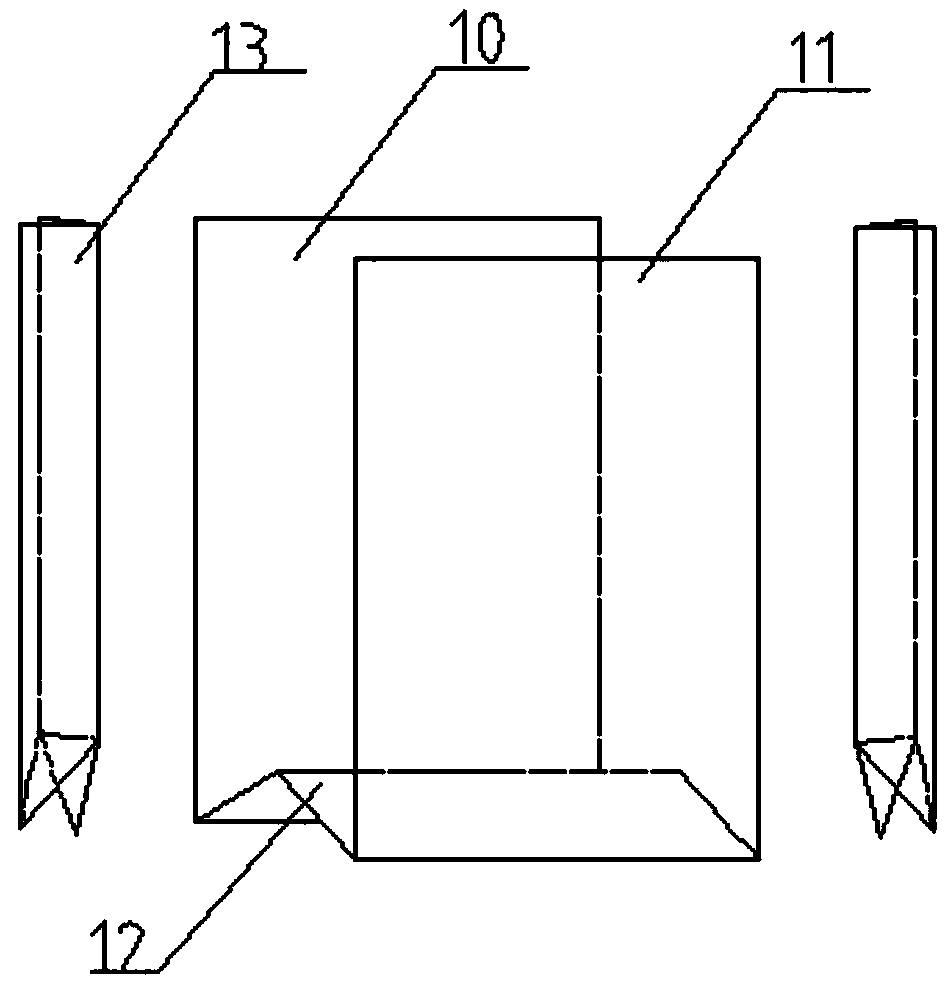

Vertical angle machine and method for manufacturing panel with edgefold

InactiveCN101708522AReduce cutting processImprove surface qualityShaping toolsDevice PanelEngineering

The invention relates to a vertical angle machine for manufacturing panels of various devices such as a panel for switchgears and the like. The vertical angle machine comprises a lower template, an upper template, a stretching die and a cutting die, wherein the lower template is arranged horizontally and is provided with a working angle part in a right-angle shape, and the working angle part is formed by intersecting of two mutually perpendicular working edges; the upper template is arranged above the lower template, is parallel to the lower template and can move up and down; the stretching die capable of moving up and down is arranged above the outer side of the working angle part and is composed of two side plates arranged vertically, the two side plates are mutually vertical and intersected, and the horizontal distances between the two side plates and the two working edges of the lower template adapt to the thickness of the material plate to be processed; and the cutting die capable of moving along the horizontal direction is arranged below the outer side of working angle part of the lower template, and is matched with the working angle part of the lower template for cutting operation. The invention can mould the angle part of a panel conveniently and rapidly and has high processing efficiency and good surface quality of the processed panel product.

Owner:镇江大全智能电气有限公司

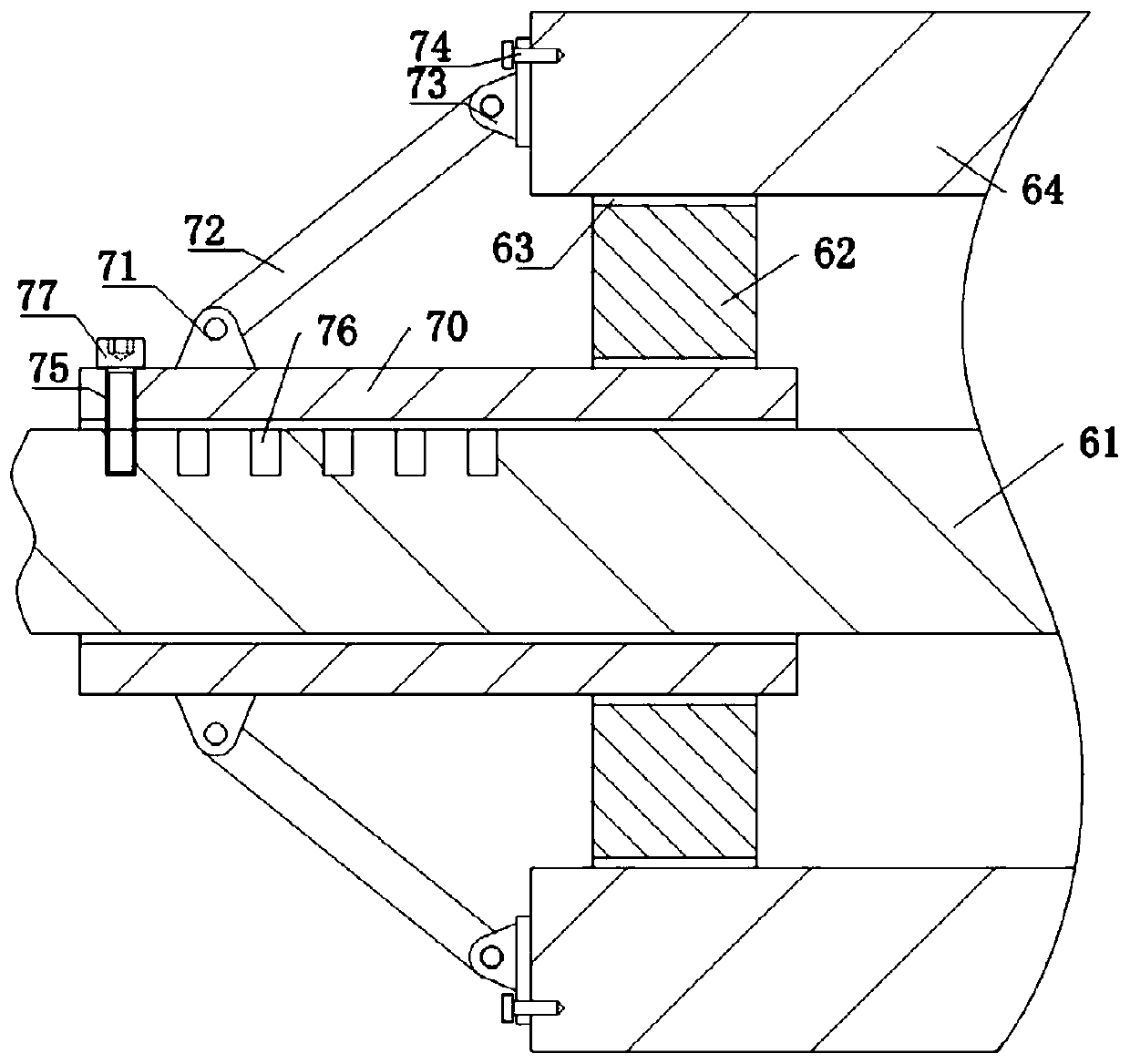

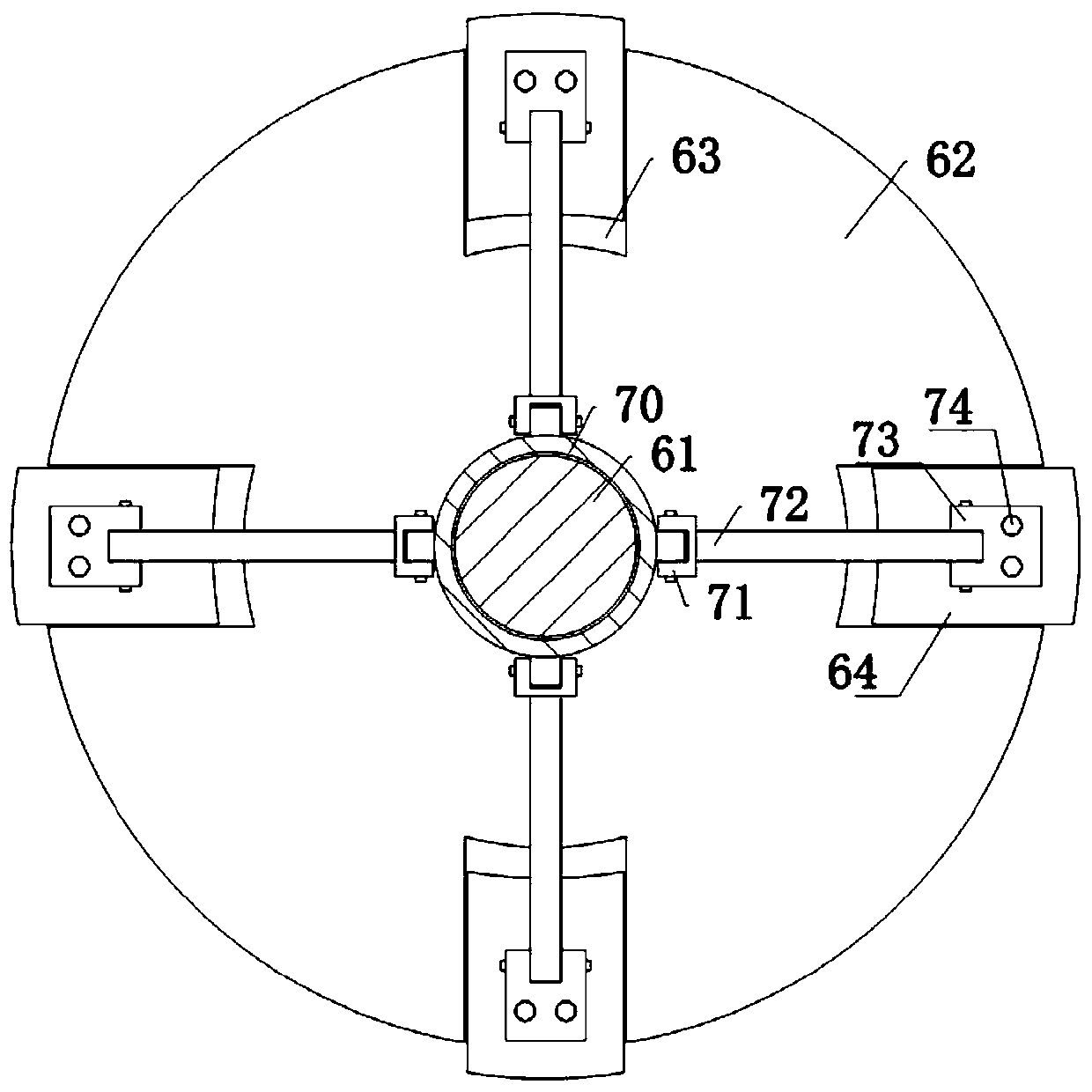

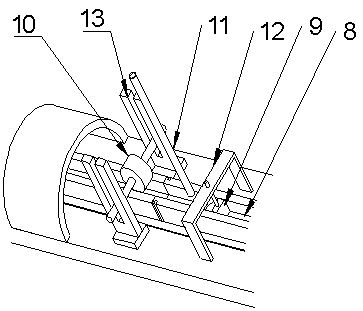

Detachable drum body for regenerated cellulose film paper rolling machine and paper rolling machine

The invention provides a detachable drum body for a regenerated cellulose film paper rolling machine and the paper rolling machine with the detachable drum body. The detachable drum body comprises a transmission shaft. Three cylindrical supporting plates are welded to the transmission shaft, each cylindrical supporting plate is vertical to the transmission shaft, four sliding mounting grooves areevenly distributed in the side wall of each cylindrical supporting plate, a batten is mounted in every three horizontally-arranged sliding mounting grooves jointly, an adjusting device is arranged between each cylindrical supporting plate and the corresponding batten, shaft heads are welded to the two ends of the transmission shaft correspondingly, a mounted aligning bearing is mounted on each shaft head, an air expanding shaft, the detachable drum body and a transmission controller are arranged on a main support side by side, and the air expanding shaft is parallel to the detachable drum body. The detachable drum body for the regenerated cellulose film paper rolling machine has the beneficial effects that the external diameter of the drum body can be freely adjusted, the drum body is detachable, low in production cost and high in production efficiency, films cannot wrinkle, and the operation is easy.

Owner:SHANDONG HENGLIAN NEW MATERIALS CO LTD

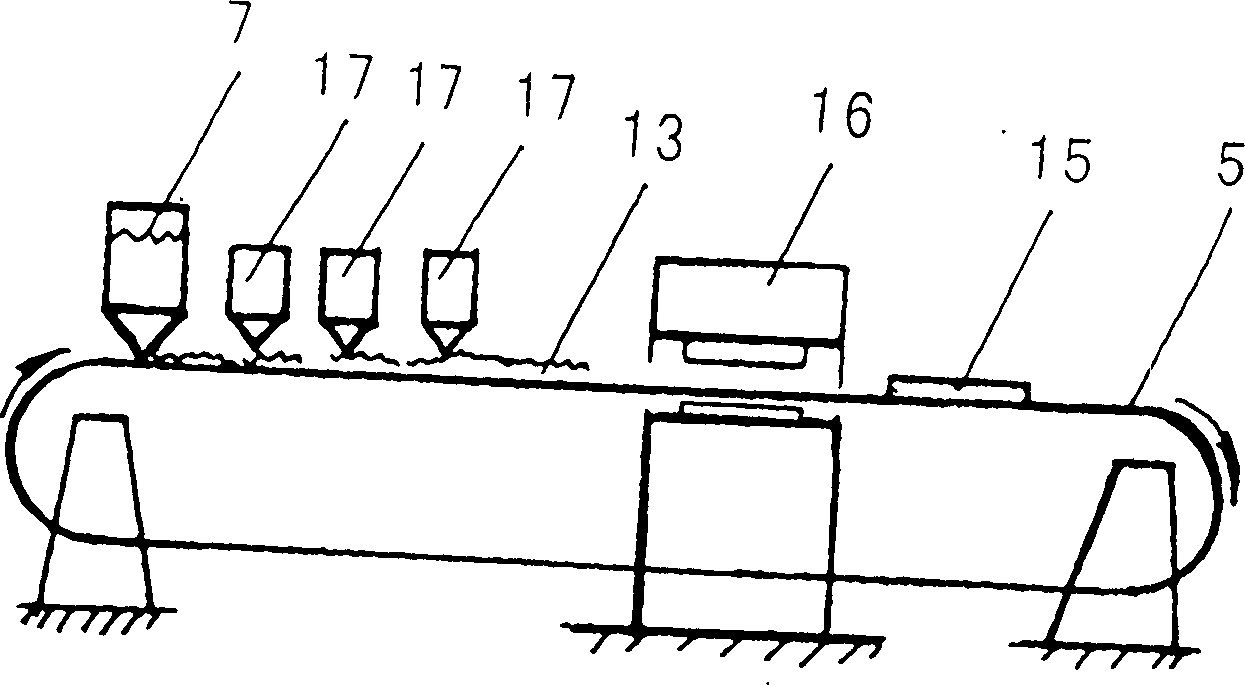

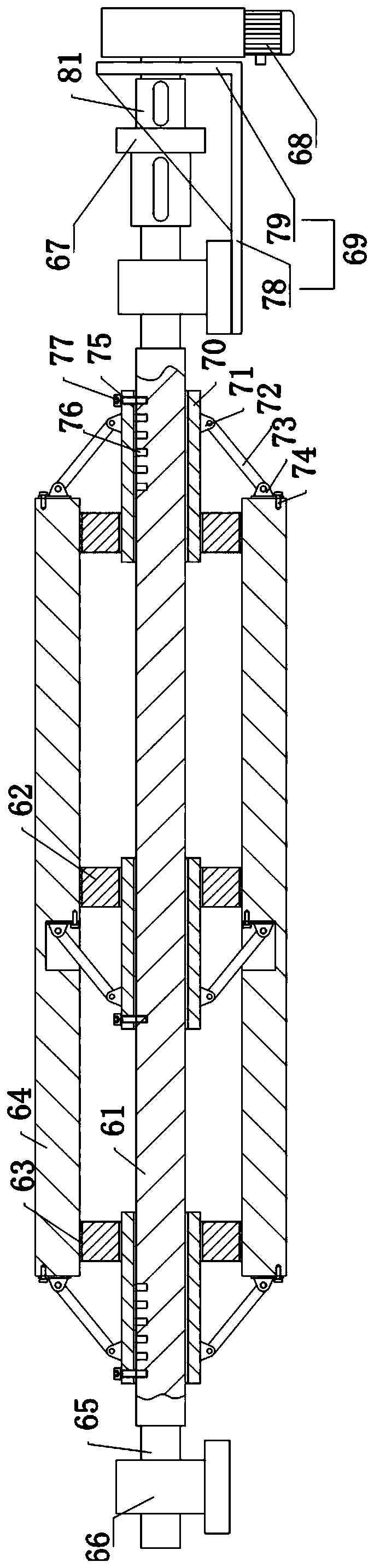

Optical glass small strip material molding device

ActiveCN107500514AReduce cutting processAvoid stickingGlass reforming apparatusInstabilityPower apparatus

The invention discloses an optical glass small strip material molding device, and belongs to the technical field of optical glass molding. The optical glass small strip material molding device solves the problems that optical glass forming devices in the prior art cannot overcome production instability and low yield rate caused by mold sticking and deformation of small strip material glass. The optical glass small strip material molding device is characterized in that the optical glass small strip material molding device comprises a transmission mechanism, a preheating part, a forming part and an annealing part, wherein the transmission mechanism comprises a frame body, a roller, a conveyer belt and a power device; the preheating part, the forming part and the annealing part are respectively located at the front end, the middle end and the terminal end of the transmission mechanism; the conveying belt is provided with a forming groove which passes through the preheating part, the forming part and the inner cavity of the annealing part, molten glass moves synchronously with the forming groove when molded in the forming part, and the upper surface can be leveled by a rolling wheel. Small strip material glass with the end surface with the side length of 5 mm or more can be drawn, the optical glass small strip material molding device has the advantages of small and uniform cold marks and high forming consistency, by use of the thin square material, the cutting process of large blocks of glass can be saved, excess glass material and loss are less, and labor cost is low.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

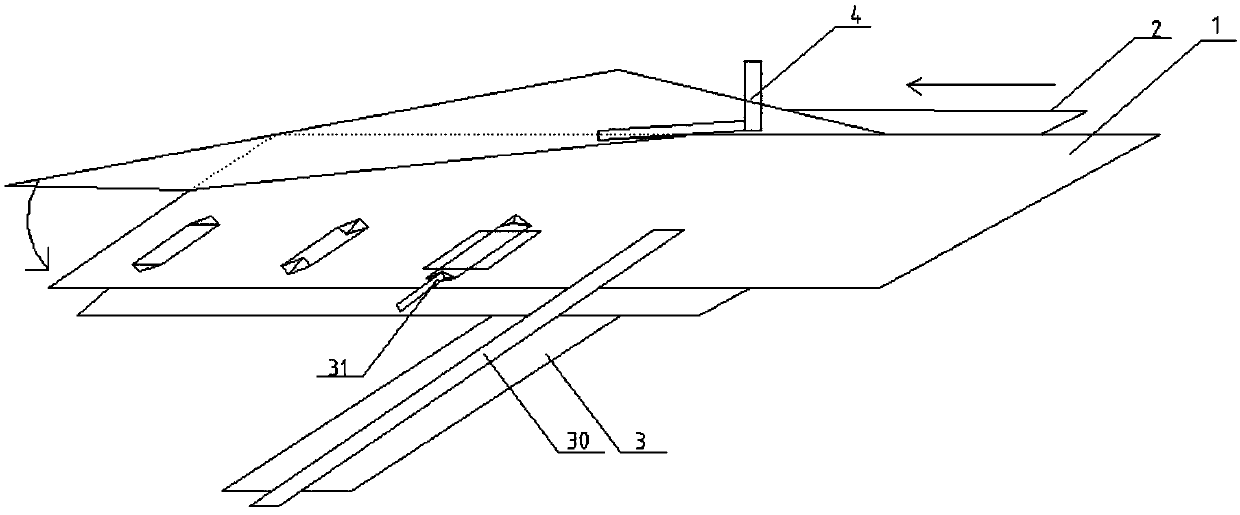

Common cutting technology for spud leg main cord rack plates of self-elevating drilling platform

InactiveCN105149725AReduce cutting processReduce the number of liftingGas flame welding apparatusEngineeringAtmospheric pressure

The invention relates to a common cutting technology for spud leg main cord rack plates of a self-elevating drilling platform. The common cutting technology can reduce the cutting procedures on the premise of guaranteeing the cutting quality of the rack plates, meanwhile, reduces generation of waste materials, improves the raw material utilization ratio and therefore achieves the purpose of lowering the project cost. The difficulty lies in finding the position of a common cutting line of edge-sharing parts of the two rack plates and adjusting such cutting parameters as the size of a cutting nozzle, the cutting air pressure and the cutting speed according to the position of the cutting line to ensure that after finish of cutting of the edge-sharing parts, the demand on precision of tooth curves can be met. Therefore, the computer drawing technology is adopted to draw common cutting tooth curves and calculate the widths of stitches at the edge-sharing parts, and the appropriate cutting nozzle and the corresponding cutting speed and cutting air pressure are selected according to the computer drawing result.

Owner:TIANJIN HOIDI OFFSHORE ENG

Upper and lower film integrated packaging bag and processing equipment and method thereof

ActiveCN110435218AReduce lossReduce cutting processBag making operationsPaper-makingEngineeringSecondary Packaging

The invention discloses an upper and lower film integrated packaging bag. A bag body structure of the packaging bag comprises an upper film, a lower film, a bottom sheet material and a side accordion,wherein the upper film, the lower film and the bottom sheet material are of an integrated structure; and the bottom sheet material is positioned between the upper film and the lower film. The packaging bag has the beneficial effects that the upper film, the lower film and the bottom sheet are of the integrated structure, cutting is not needed, the cutting process is reduced, and film loss is reduced; the upper film and the bottom sheet material as well as the lower film and the bottom sheet material in the integrated structure do not need secondary packaging, so that the strength of the bag body is enhanced, and the service life is prolonged; and technical equipment is simple in structure, convenient to operate and high in applicability.

Owner:SHANGHAI ZHOUTAI LIGHT IND MACHINE MFG

Tension wheel spinning production process

InactiveCN110711812ASave raw materialsAvoid wastingMetal-working apparatusMechanical engineeringIndustrial engineering

The invention relates to a tension wheel spinning production process. The tension wheel spinning production process is characterized by comprising the specific production steps of S1, blanking; S2, performing; and S3, forming; in the production process, a seamless steel tube blank with the less breadth is adopted and is attached to the outer contour of a die without leaving a gap; the seamless steel tube blank is subjected to squeezing extension through a performing wheel to form an arc-shaped surface; and a tension wheel is formed through cooperative squeezing extension of a forming wheel andthe die. Compared with the conventional production technology, the tension wheel spinning production process has the advantages that the tension wheel can be formed directly without cutting the edges, raw materials are saved, and waste of cut portions is avoided; and meanwhile, the subsequent cutting procedure is omitted, the technological steps are reduced, and the production efficiency is improved.

Owner:NANTONG FULEDA AUTOMOBILE FITTINGS

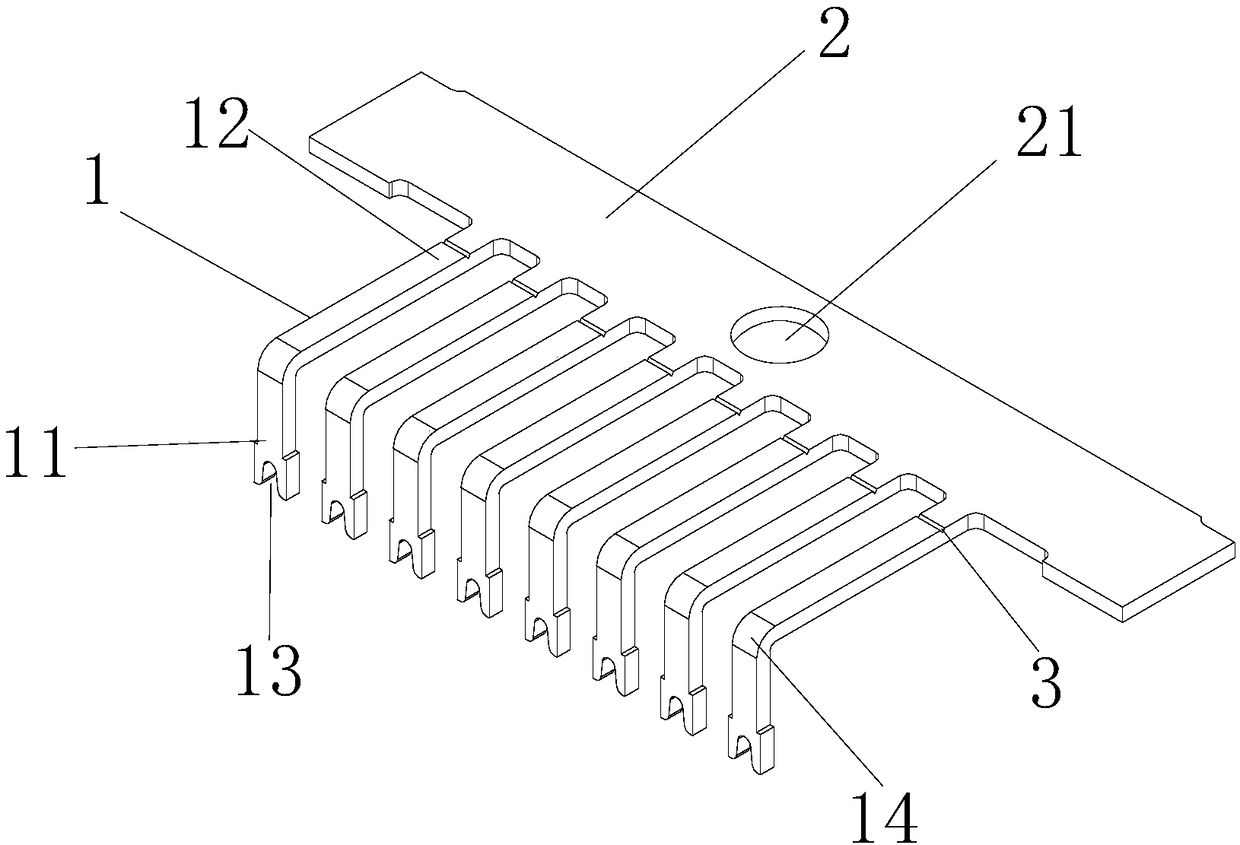

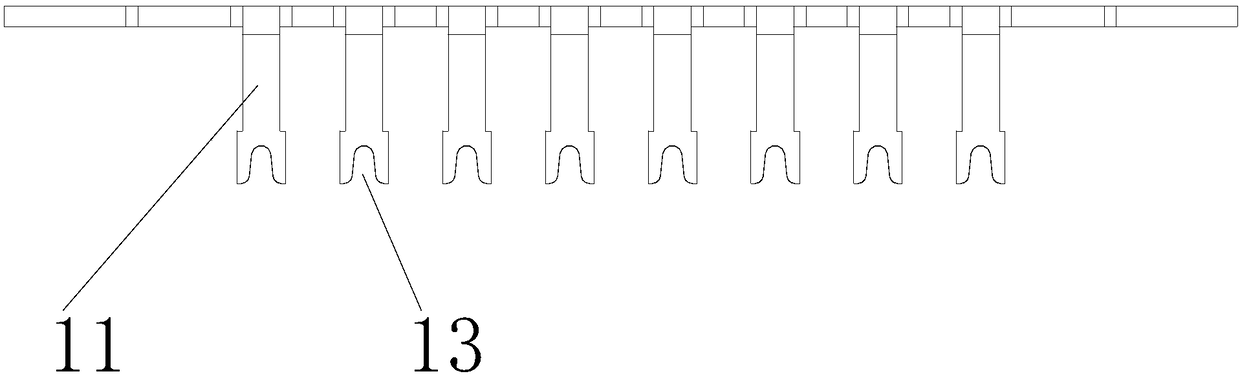

PIN needle material strip

PendingCN108539461AReduce widthReduce lossContact member manufacturingTransformers/inductances coils/windings/connectionsMetal stripsPins needles

The present invention discloses a PIN needle material strip. The PIN needle material strap comprises a PIN needle and a side strip, there is one side strip, the PIN needle is a stripe-shaped structure, one end of the PIN needle is a wiring pin, the other end of the PIN needle is a welding pin, a plurality of PIN needles are connected with the edge of the side strip through one end of the welding pin, and the top ends of the wiring pins of the PIN needles directly form insertion wire grooves for wiring. The PIN needle material strip employs the structure of the PIN needles being connected withthe single side strip, and the wiring pins of the PIN needles directly form the insertion wire grooves to change the wiring mode so as to effectively reduce the wiring efficiency, improve the wiring efficiency, reduce the cutting processing process, effectively improve the processing efficiency, reduce the electroplating area, reduce the material loss caused by cutting, reduce the whole width of the PIN needle material strip, reduce the width of the costumed metal strip and effectively reduce the cost of manufacturing the PIN needle material strip.

Owner:DEYANG ZHIDA PRECISION ELECTRONICS

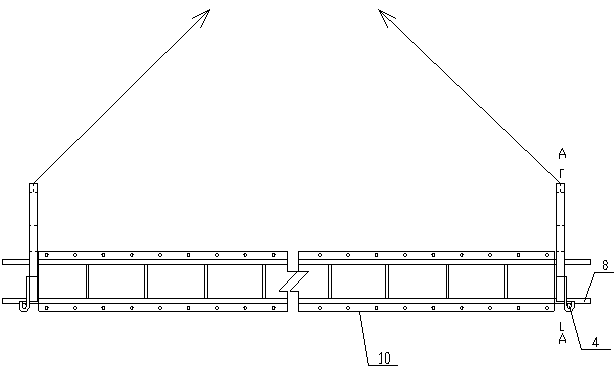

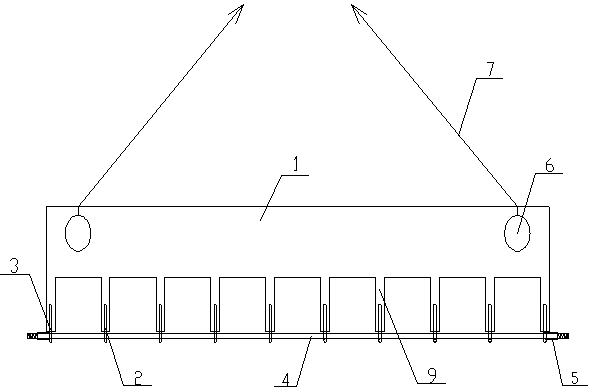

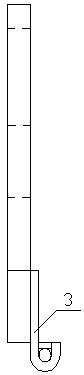

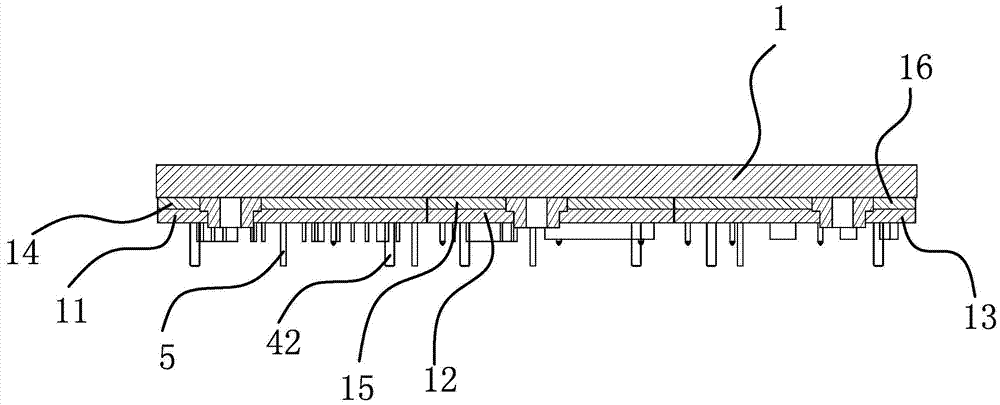

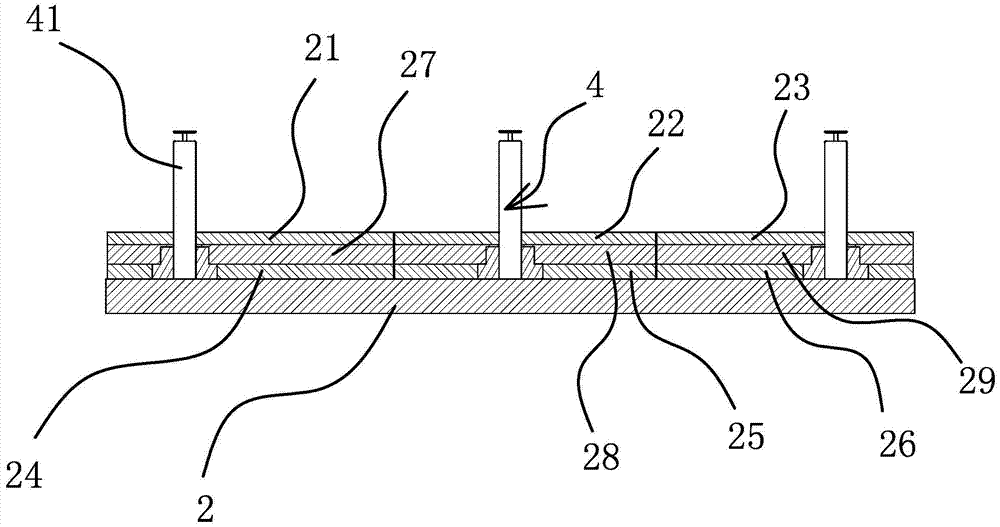

Hoisting tool special for prefabricated bridge deck slabs

PendingCN108221696AEasy to liftSafe and efficient hoistingBridge structural detailsBridge erection/assemblySteel platesRebar

The invention relates to a hoisting tool special for prefabricated bridge deck slabs. The hoisting tool comprises a load-bearing comb-shaped steel plate, hoisting ropes, reinforcing steel bar hooks, reinforcing steel bar bolt and limit parts and is characterized in that two sides of the load-bearing comb-shaped steel plate are provided with hoisting holes, the hoisting ropes penetrate the hoistingholes, and a plurality of comb teeth are arranged at the lower end of the load-bearing comb-shaped steel plate; the reinforcing steel bar hooks are welded to the comb teeth at the lower end of the load-bearing comb-shaped steel plate; the reinforcing steel bar bolt is arranged in the reinforcing steel bar hooks, and the limit parts are arranged at two ends of the reinforcing steel bar bolt. The hoisting tool has the advantages that the hoisting of the prefabricated bridge deck slabs can be facilitated, damage to the prefabricated bridge deck slabs can be avoided, reinforcing steel bar hoisting rings embedded into the prefabricated bridge deck slabs can be avoided, the subsequent reinforcing steel bar hoisting ring cutting procedure is omitted, the potential channel corrosion hazard causedby the residual embedded reinforcing steel bar hoisting rings is eliminated, the construction procedures of the prefabricated bridge deck slabs are simplified, and the hoisting tool is safe and efficient in hoisting.

Owner:NANCHANG UNIV

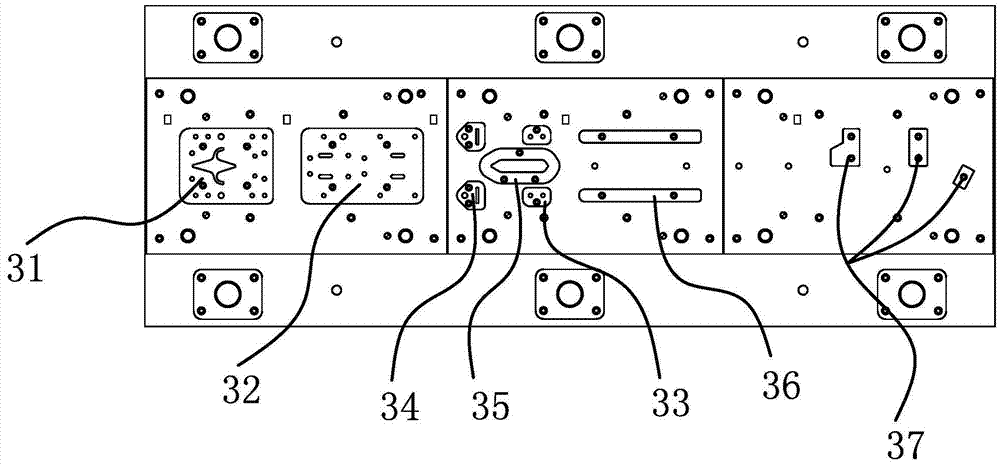

Progressive die of side plate of rocking chair underframe

The invention provides a progressive die of a side plate of a rocking chair underframe, and belongs to the technical field of dies. The progressive die solves the technical problems that an existing die of a side plate of an existing rocking chair underframe is low in production efficiency and the like. The progressive die of the side plate of the rocking chair underframe comprises an upper die base, a lower die base and a guide column between the upper die base and the lower die base, the lower end of the upper die base is sequentially provided with a first clamping plate, a second clamping plate and a third clamping plate, the upper end of the lower die base is provided with a first supporting plate, a second supporting plate and a third supporting plate, the first supporting plate, the second supporting plate and the third supporting plate correspond to the first clamping plate, the second clamping plate and the third clamping plate respectively, the first clamping plate is sequentially provided with a first punching insert and a second punching insert, the second clamping plate is sequentially provided with a first waste cutter insert, a second waste cutter insert, a third punching insert and a pier hole insert, and the third clamping plate is provided with a product cutter. The progressive die has the advantages of being high in efficiency, saving production cost and the like.

Owner:ZHEJIANG FEILI TECH

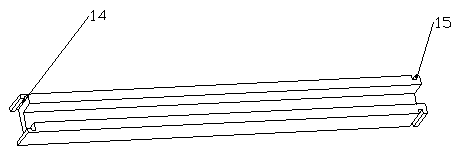

LCD (Liquid Crystal Display) device and backlight module thereof

InactiveCN102620210AReduce cutting processReduce manufacturing costOptical light guidesNon-linear opticsPolyethylene terephthalateLiquid-crystal display

The invention discloses an LCD (Liquid Crystal Display) device which comprises a panel module and a backlight module. The backlight module comprises a light guide plate, a framework for accommodating the light guide plate, a reflector plate, at least one light-emitting assembly and a fixing unit, wherein the light guide plate comprises a light incident surface; the framework comprises a bottom plate and side walls positioned at the periphery of the bottom plate; the reflector plate is configured between the light guide plate and the bottom plate of the framework; the at least one light-emitting assembly is opposite to the light incident surface of the light guide plate; the fixing unit consists of at lest two fixing pieces; and each fixing piece is provided with a base part and a bending part vertically extending towards the same direction from at least one end of the base part, the top face of the base part abuts against the light guide plate, the inner side of the bending part abuts against the light guide plate, the outer side of the bending part, opposite to the inner side, abuts against the side walls, and the fixing pieces are made from at least one of PET (polyethylene terephthalate) and PS (polystyrene).

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

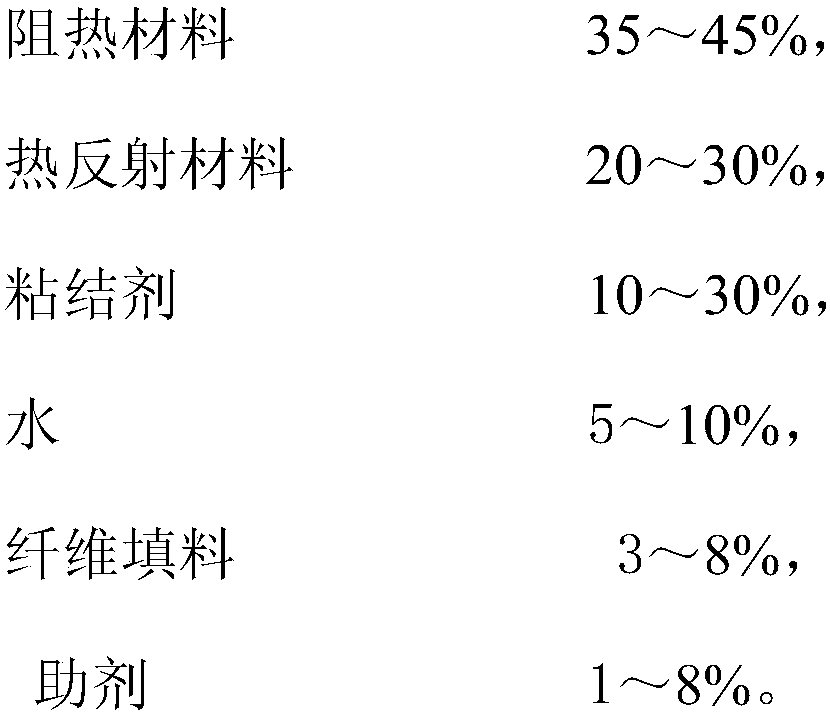

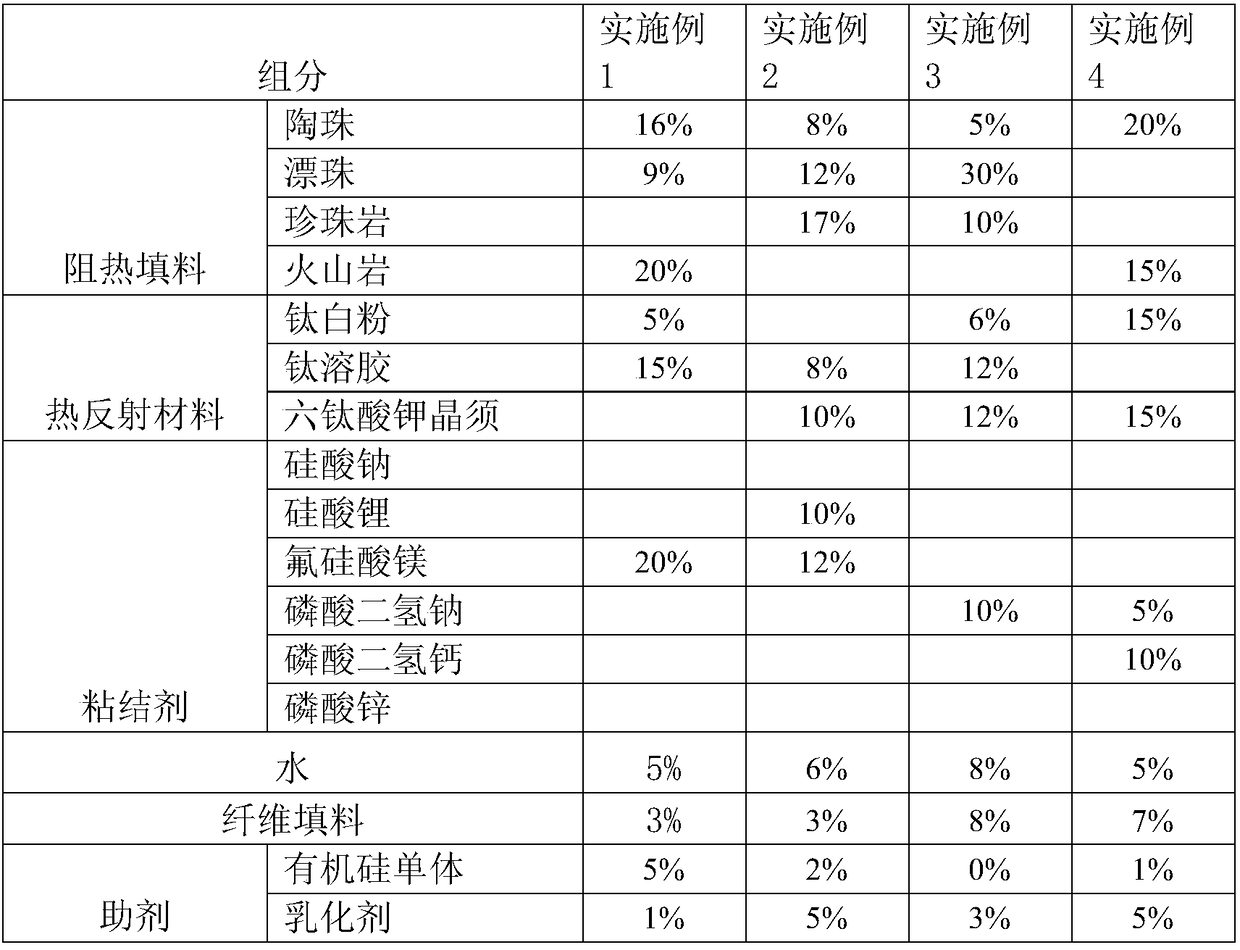

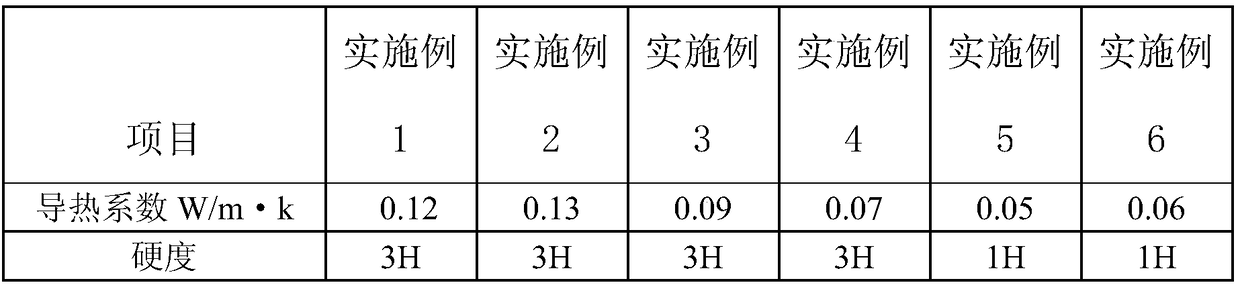

Multi-layer high-strength thermal-insulation material and preparation method thereof

InactiveCN109336538AOptional specificationsReduce cutting processCeramicwareThermal insulationRelative humidity

The invention discloses a multi-layer high-strength thermal-insulation material and a preparation method thereof. The technical scheme comprises the following steps: placing an aerogel core material in a mold, and pulling by a metal wire so that the aerogel core material keeps the same spacing with two side walls of the mold; mixing structure supporting layer materials, guiding and introducing themixed structure supporting layer materials into spaces at two sides of the aerogel core material in the mold; and naturally drying for 12-28 H at a relative humidity of 45% to obtain a high-strengththermal-insulation plate. According to the invention, the aerogel core material is coated with the multi-layer high-strength thermal-insulation material by utilizing structure supporting layers, so that the material has thermal insulation properties while the strength of the material is improved, and the problem of falling off of powder on the surface of the material is solved.

Owner:中山科邦化工材料技术有限公司

Optical glass strip forming device

ActiveCN107500514BReduce cutting processAvoid stickingGlass reforming apparatusOptical glassMolten glass

The invention discloses an optical glass small strip material molding device, and belongs to the technical field of optical glass molding. The optical glass small strip material molding device solves the problems that optical glass forming devices in the prior art cannot overcome production instability and low yield rate caused by mold sticking and deformation of small strip material glass. The optical glass small strip material molding device is characterized in that the optical glass small strip material molding device comprises a transmission mechanism, a preheating part, a forming part and an annealing part, wherein the transmission mechanism comprises a frame body, a roller, a conveyer belt and a power device; the preheating part, the forming part and the annealing part are respectively located at the front end, the middle end and the terminal end of the transmission mechanism; the conveying belt is provided with a forming groove which passes through the preheating part, the forming part and the inner cavity of the annealing part, molten glass moves synchronously with the forming groove when molded in the forming part, and the upper surface can be leveled by a rolling wheel. Small strip material glass with the end surface with the side length of 5 mm or more can be drawn, the optical glass small strip material molding device has the advantages of small and uniform cold marks and high forming consistency, by use of the thin square material, the cutting process of large blocks of glass can be saved, excess glass material and loss are less, and labor cost is low.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

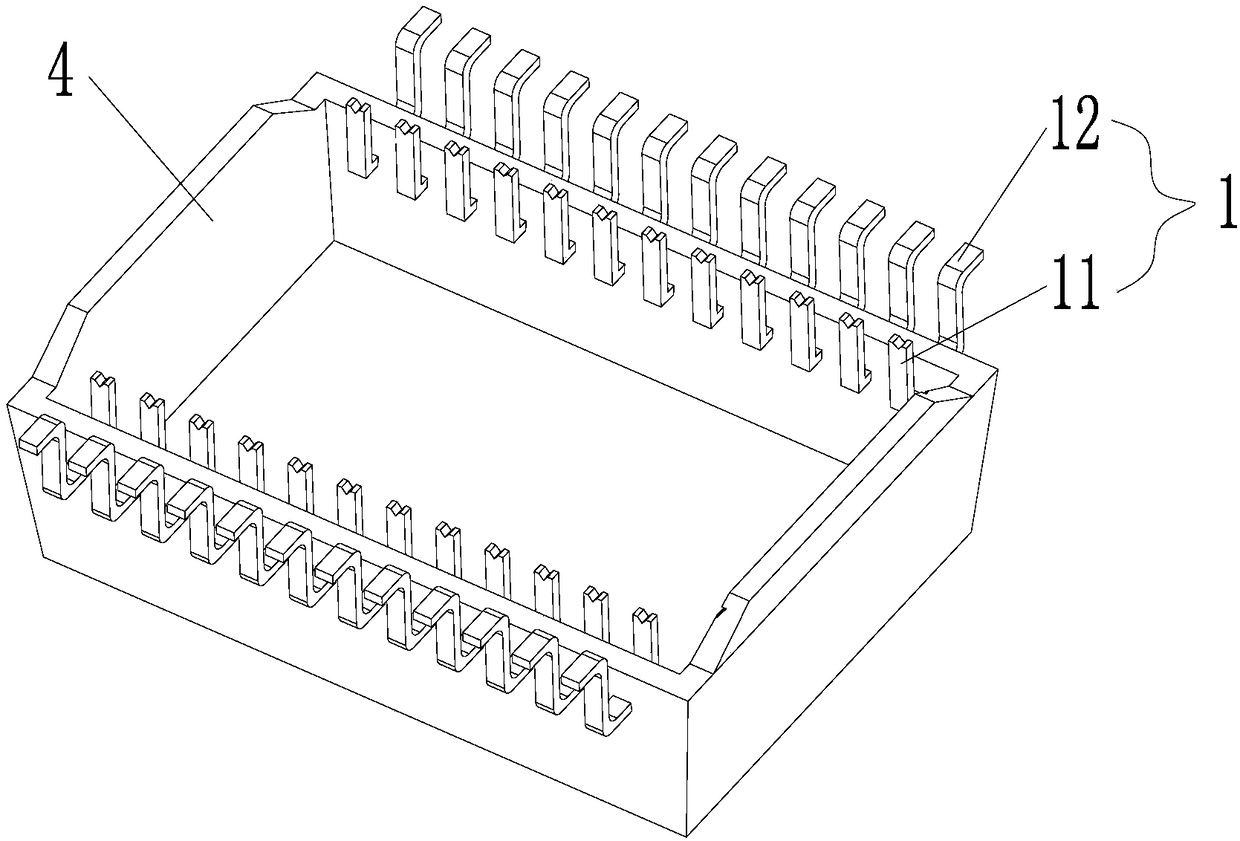

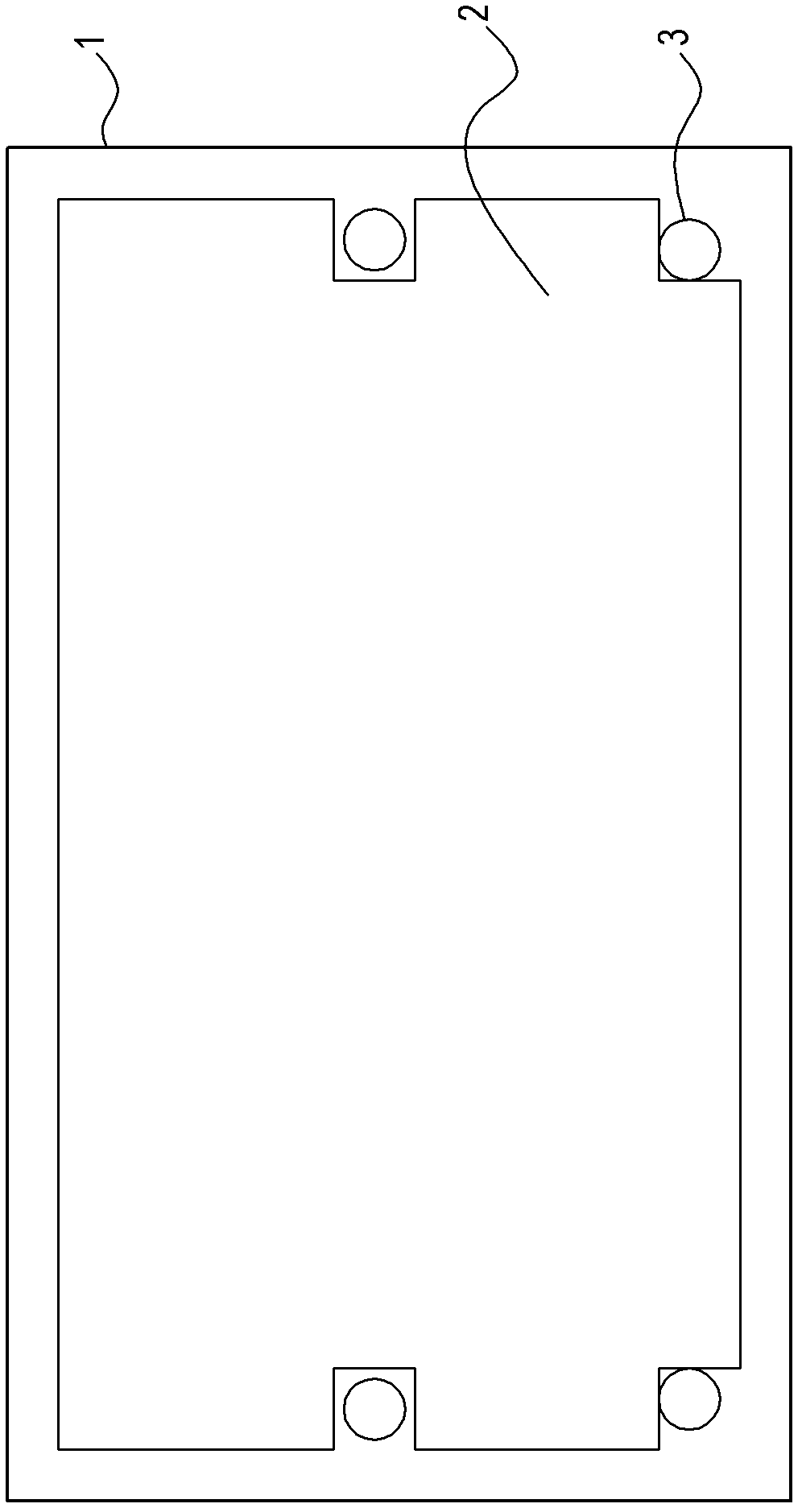

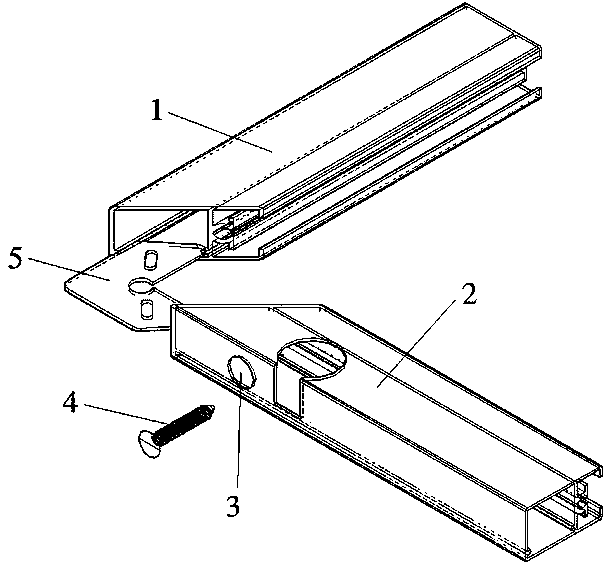

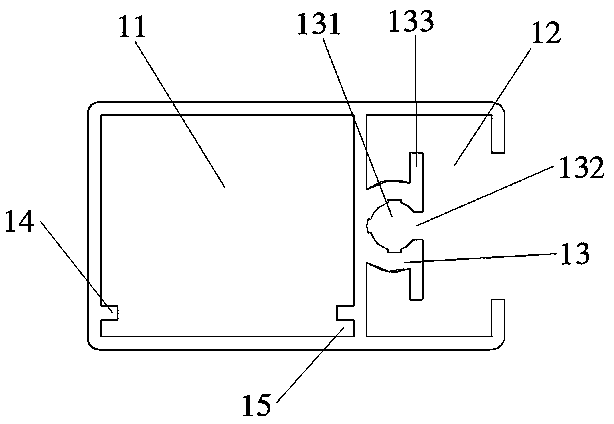

Diagonal splicing connection structure of all aluminum furniture frame

ActiveCN106351924BReduce manufacturing costLow costFurniture joining partsFurniture joiningAbdominal cavityEngineering

The invention relates to a full aluminum furniture side frame inclined splicing connecting structure, which comprises a first side frame (1) and a second side frame (2), wherein the first side frame (1) and the second side frame (2) are arranged in a way of being vertical to each other and are connected through a connection screw (4); the first side frame (1) comprises an abdominal cavity (11) and a clamp groove (12); a screw connecting part (13) is arranged in the abdominal cavity or the clamp groove of the first side frame (1); the connection screw (4) extends the abdominal cavity or the clamp groove of the first side frame (1) from the length edge direction to the short edge direction of the second side frame (2) to be connected with the screw connection part (13) arranged in the abdominal cavity or the clamp groove. The full aluminum furniture side frame inclined splicing connecting structure provided by the invention has the advantages that the screw is used for replacing an original corner connector; the original corner cutting work procedure is omitted; the connection and the installation are more convenient; the production and manufacturing cost of furniture is greatly reduced.

Owner:嘉斯顿家居江苏有限公司

Traditional Chinese medicine decoction piece processing equipment and processing method thereof

InactiveCN112958520AEasy to cleanAvoid stickingPharmaceutical product form changeCleaning using toolsMedicinal herbsEngineering

The invention relates to the technical field of pharmaceuticals, and discloses traditional Chinese medicine decoction piece processing equipment and a processing method thereof. The traditional Chinese medicine decoction piece processing equipment comprises a fixing plate; front and rear side faces of the fixing plate are fixedly connected with front and rear side plates; grooves are formed in the right sides of the front and rear side plates and a sliding side plate is arranged in each groove in a sleeved manner; four sets of bottom plates A and bottom plates B are arranged on the front and rear side plates in a sleeved manner; the bottom plates A and the bottom plates B are arranged, and in the process of processing medicinal materials by the equipment, continuous switching between a corrugated state and a transverse state can be formed; in the corrugated state, a better cleaning effect on the medicinal materials can be achieved with the cooperation of sharp protrusions and pressing and pushing of a brush plate on the medicinal materials; sharp ends of connecting pads can conform to recesses in the medicinal materials through deformation after being in contact with the medicinal materials, so that wrinkles on the medicinal materials are cleaned, and the cleaning effect is improved; and the equipment can be in the transverse state after rubbing once, so that rubbed off impurities are accommodated in the connecting pads and are discharged alone, thus avoiding the problem that the impurities are adhered to or embedded into the medicinal materials in subsequent rubbing.

Owner:北京图腾猎技科技有限公司

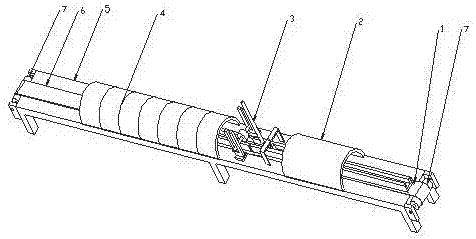

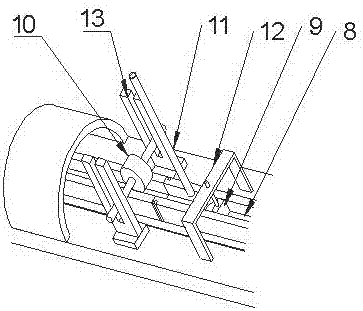

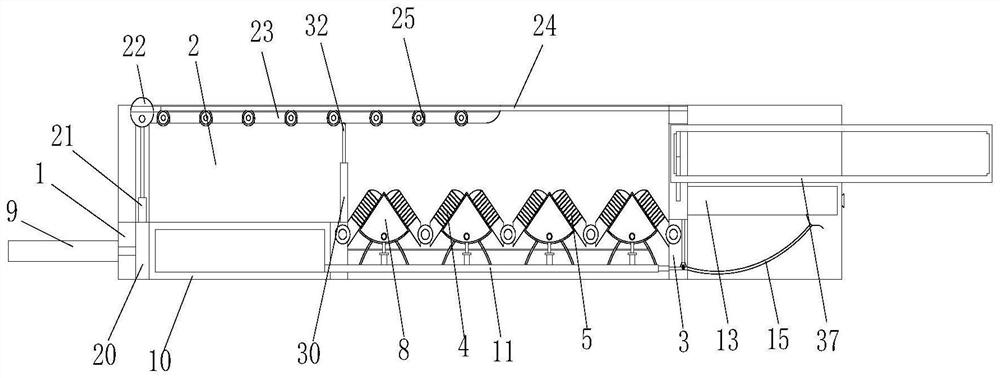

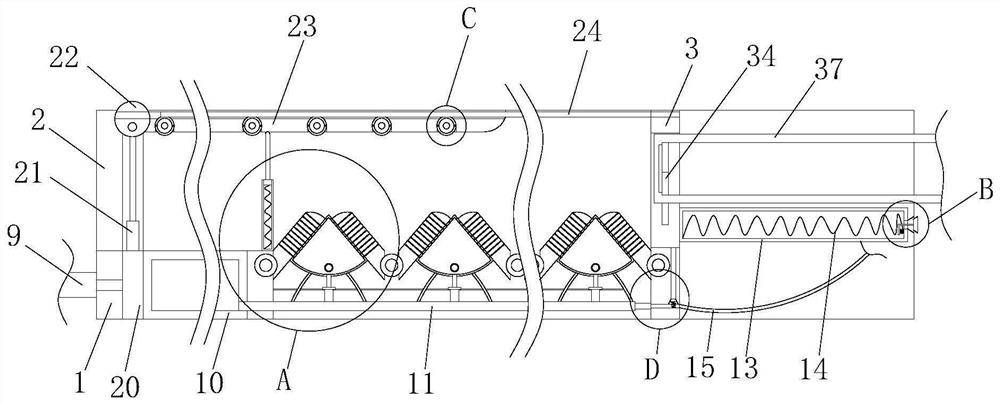

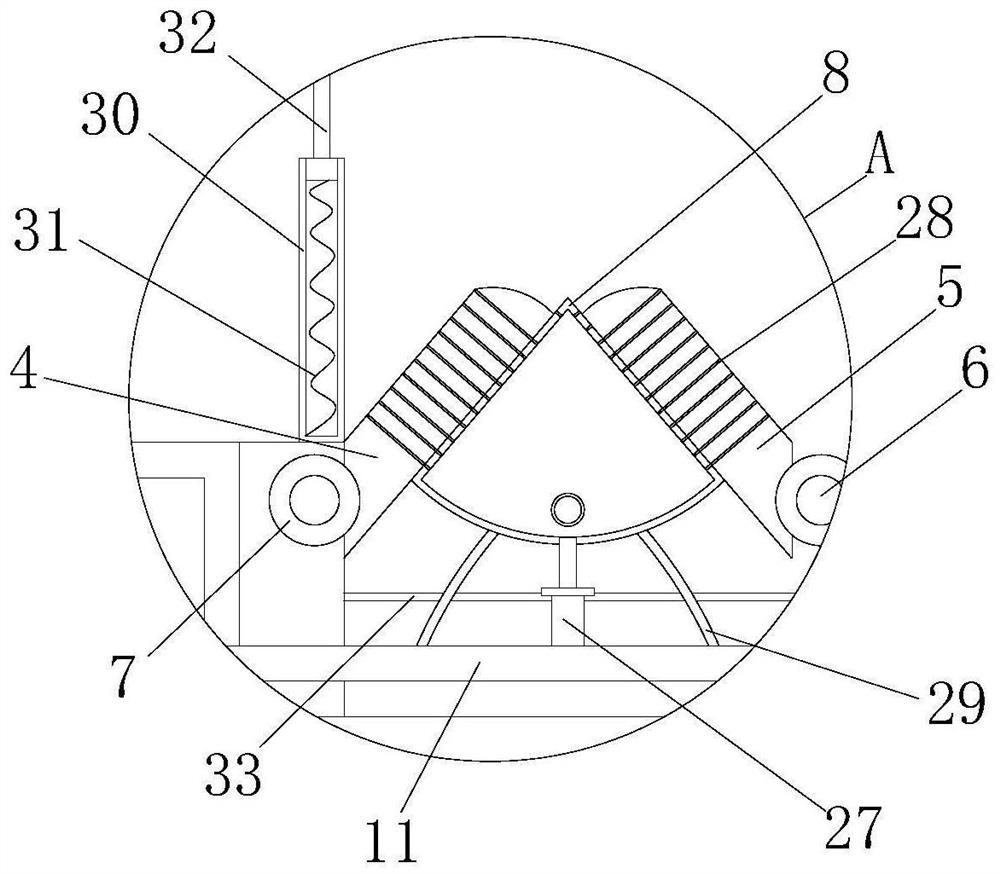

Sponge cutting machine that can be rotated and sliced and can be divided and delivered

ActiveCN104772785BReduce cutting processSave cutting efficiencyMetal working apparatusDrive shaftEngineering

The invention relates to a horizontal sponge cutting machine capable of rotationally slicing and discharging materials in a separating mode. The sponge horizontal cutting machine comprises a rack, a working table, a cutter box, a blade, driving shafts, pull rods, rotating arms and rotating mechanisms. The rack is installed at the two sides of the working table, the cutter box is installed at the lower end of the rack, the blade is installed in the cutter box, the two ends of the cutter box are fixedly installed at the lower end of the rack through the rotating mechanisms, the corresponding rotating arms are connected with the upper ends of the rotating mechanisms, the driving shafts are installed at the upper end of the rack, one sides of the driving shafts are connected with driving motors, the corresponding rotating arms are installed at the upper ends of the driving shafts, and the rotating arms at the upper ends of the driving shafts are connected with the rotating arms at the upper ends of the rotating mechanisms through the pull rods. The horizontal sponge cutting machine has the advantages that under the action of the driving shafts, the rotating mechanisms can drive the cutter box to rotate, the cutter can rotate by positive 360 degrees and minus 360 degrees to achieve vertical cutting, and the machining efficiency of sponge cutting is improved; a scraper knife can be directly inserted from the cut position to separate the materials, a conveying mechanism is capable of conveying the cut materials out, the materials can be separated and conveyed without waiting for being cut completely, and the producing and machining efficiency is greatly improved.

Owner:NANTONG MUYE MACHINERY

An integrated packaging bag with upper and lower films and its processing equipment and method

ActiveCN110435218BReduce lossReduce cutting processBag making operationsPaper-makingEngineeringFilm material

The invention discloses an integrated packaging bag with an upper and lower film. The bag body structure of the packaging bag includes an upper film, a lower film, a bottom sheet and a side organ. The upper film, the lower film and the bottom sheet are One-piece construction; the bottom panel is positioned between the upper and lower membranes. Its beneficial effects are: the technology described in the present invention is an integrated structure of the upper film, the lower film and the bottom sheet, without cutting, reducing the cutting process and reducing the loss of film materials; in the integrated structure, the upper film, the bottom sheet, and the lower film There is no secondary packaging with the bottom sheet material, which is beneficial to enhance the strength of the bag body and increase the service life; the technical equipment of the present invention has simple structure, convenient operation and high applicability.

Owner:SHANGHAI ZHOUTAI LIGHT IND MACHINE MFG

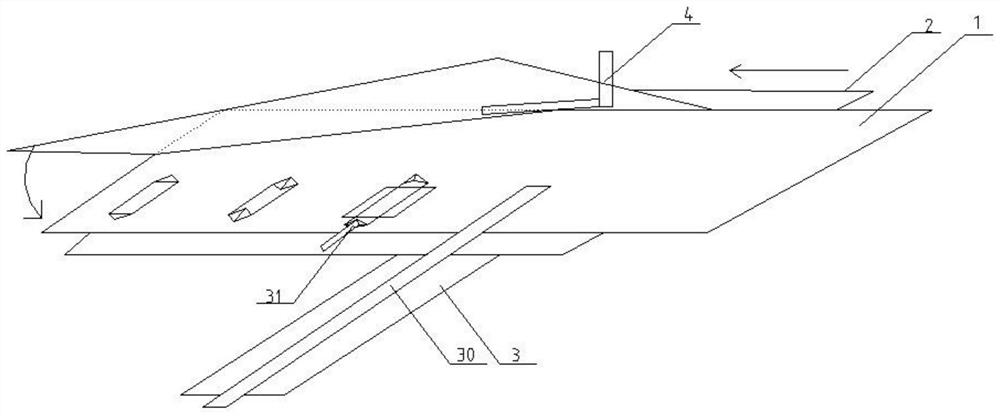

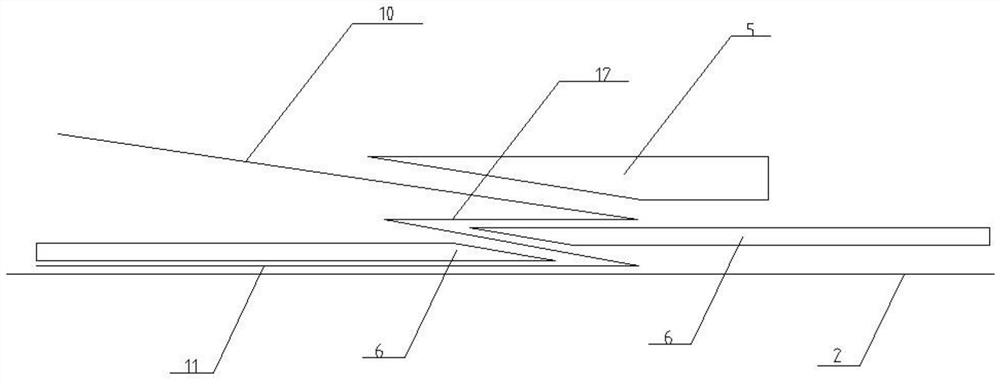

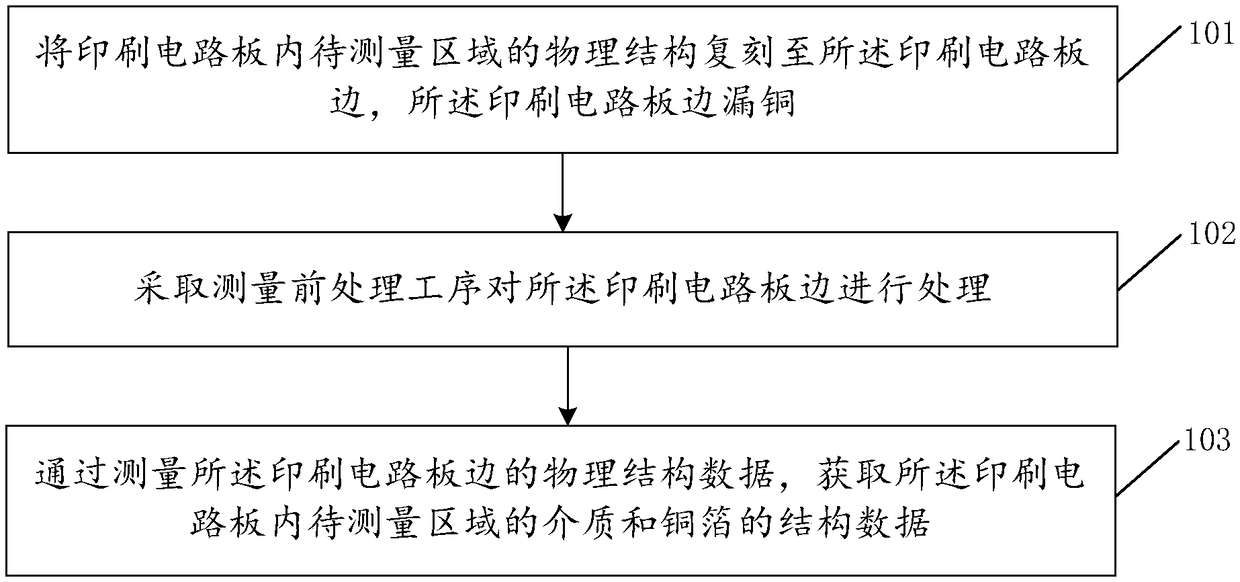

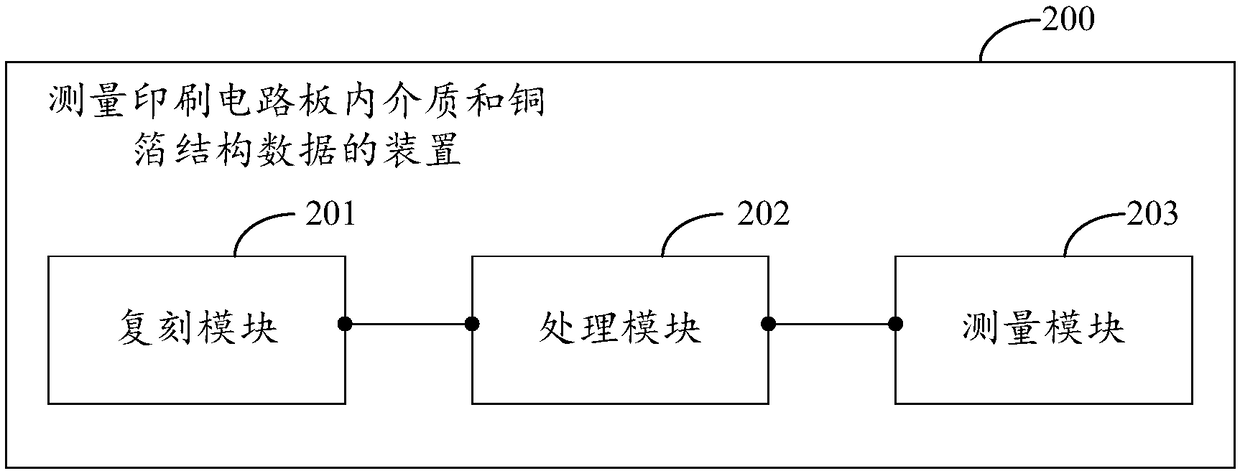

Method and device for measuring structural data of medium and copper foil in printed circuit board

The embodiment of the invention discloses a method for measuring the structural data of a medium and a copper foil in a printed circuit board. Based on a PCB board with copper leakage at the edge of the board, measuring of the data structure of the medium and the copper foil in the PCB board can be realized. The method includes the steps that firstly, the physical structure of a to-be-measured area in the PCB board is copied to the edge of the PCB board, and copper leakage occurs at the edge of the PCB board; then, a treatment procedure before measuring is adopted to pretreat the PCB board edge of the physical structure of the to-be-measured area in a replica board; and then, by measuring the physical structure data of the PCB board edge after pretreatment, the structural data of the medium and the copper foil of the to-be-measured area in the PCB board are obtained. Thus, on the premise of not destroying the structure of the PCB board, the structural data of the medium and the copperfoil in the PCB board are measured, and reuse of test samples can be ensured; and in addition, compared with the prior art, the method reduces the cutting process, greatly reduces the measurement timeconsumed in the measurement process, and improves the measurement efficiency.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

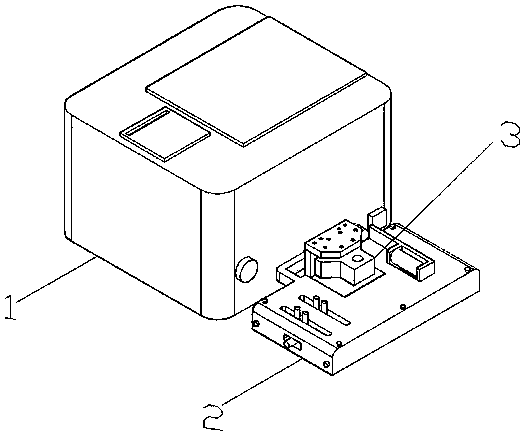

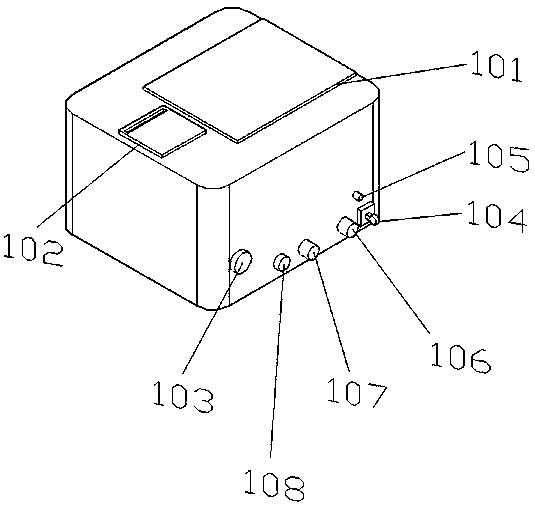

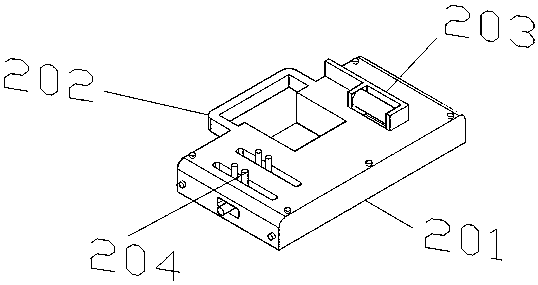

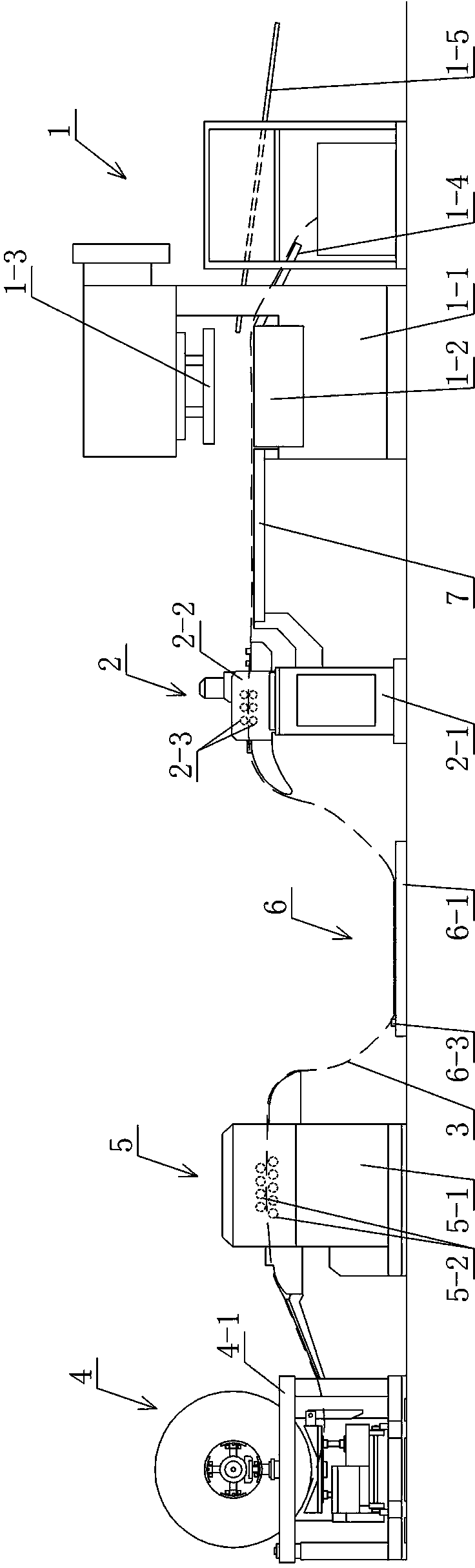

N20 air permeability detector

PendingCN111458271AImprove measurement efficiencyReduce cutting processPermeability/surface area analysisHuman–machine interfaceComputer printing

The invention discloses an N20 air permeability detector. The N20 air permeability detector comprises a box body, a detection device, a laminar flow element, a pressure adjusting device and a PLC; a human-computer interface is arranged at the right end of the top surface of the box body; a printer is arranged at the left end of the top surface of the box body; a pressure regulating valve interface, a test interface, a test head cylinder interface, a test head cable interface, a manual test switch and a key switch are arranged on the front surface of the box body; and a high-precision pressuresensor, a high-precision differential pressure sensor and a stepping motor controller are arranged in the box body; the detection device is composed of a test head and an automatic paper guide system;the pressure adjusting device comprises an electromagnetic valve, a precision pressure adjusting valve and a stepping motor; and the PLC is installed in the box body. The detector is simple in structure, easy and convenient to operate, capable of automatically counting and outputting printed measurement results, convenient for a user to process and store data and high in accuracy.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

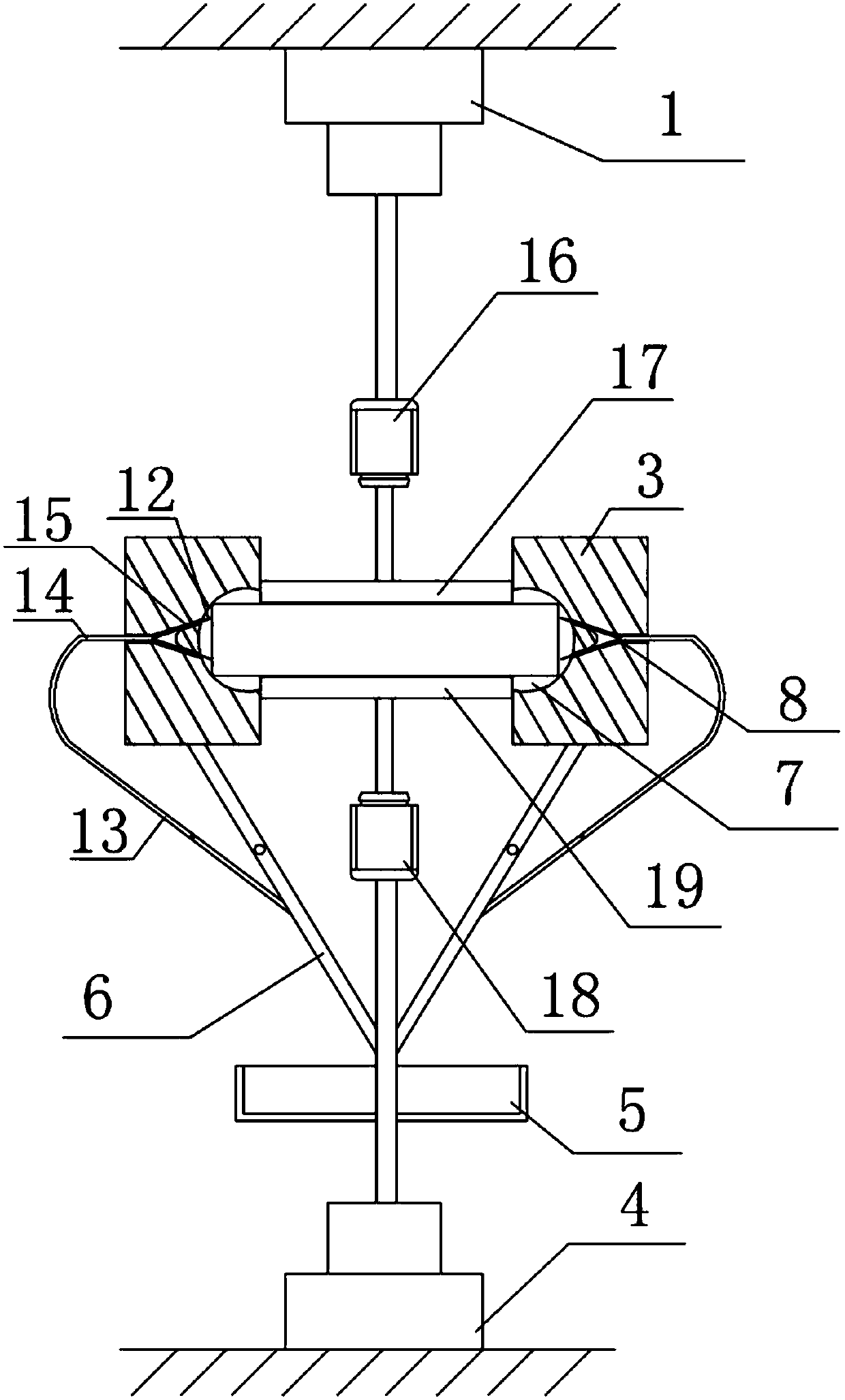

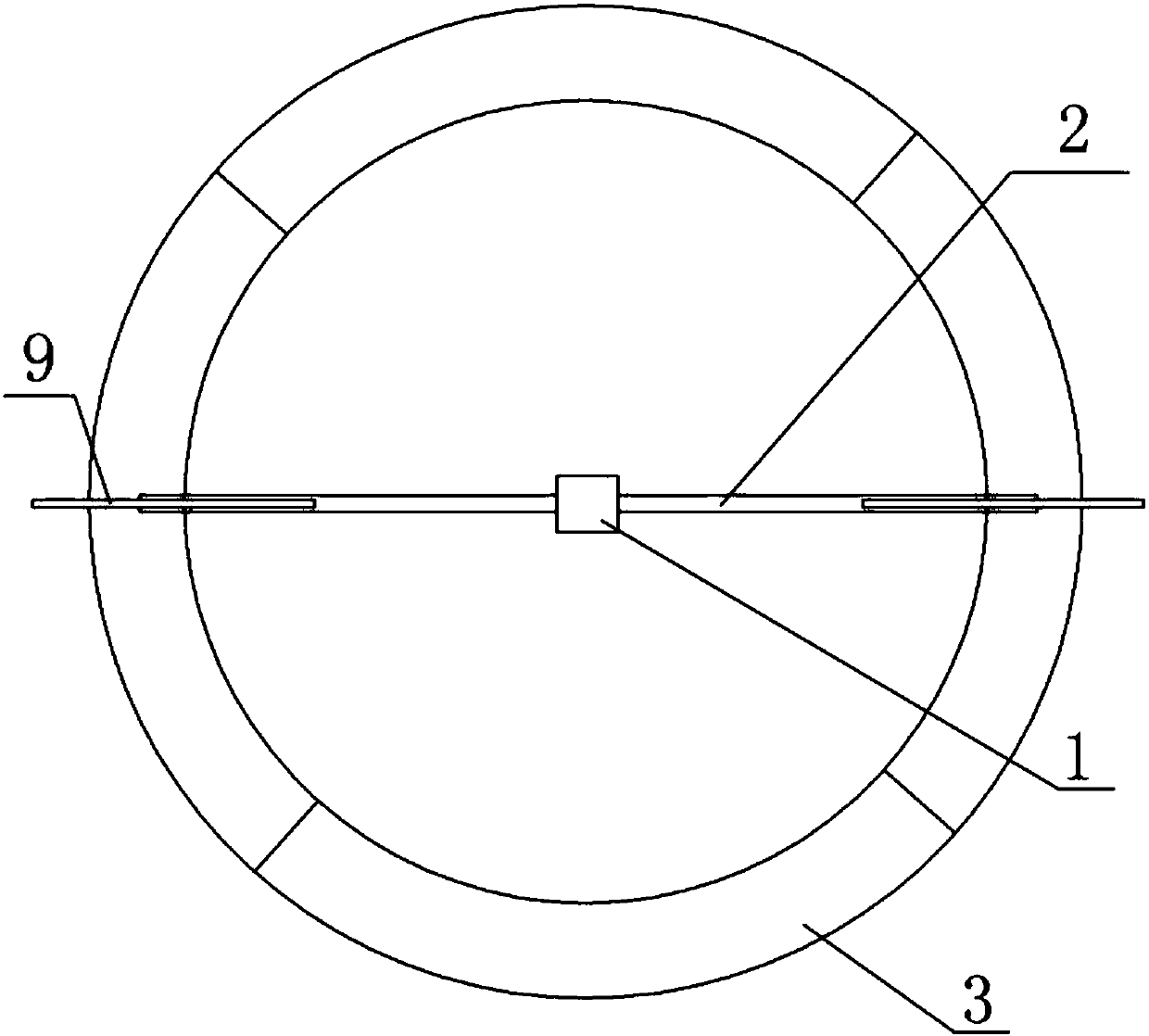

Swing stamping mechanism

ActiveCN102319786BReduce cutting processReduce wasteMetal-working feeding devicesManufacturing stator/rotor bodiesNumerical controlEngineering

The invention relates to a swing stamping mechanism, which comprises a stamping machine, wherein the stamping machine comprises a stamping frame, a lifting stamping die arranged on the stamping frame as well as a lifting control device for driving the lifting stamping die to carry out stamping work. The swing stamping mechanism is characterized by further comprising a numerical control device and a deflection feeding machine arranged at the rear side of the stamping machine; the deflection feeding machine comprises a fixed bracket, a movable stand, a transverse translation driving device and a material forward conveying device, wherein the movable stand is arranged on the fixed bracket and can be used for transversely translating along a direction vertical to the forward direction of materials relative to the fixed bracket; the transverse translation driving device is connected between the fixed bracket and the movable stand and is used for driving the movable stand to transversely translate; the material forward conveying device is arranged on the movable stand and can be used for conveying the materials to move along the forward direction of the materials; and the numerical control device is respectively connected with the lifting control device, the transverse translation driving device and the material forward conveying device for transmitting a control command. According to the swing stamping mechanism disclosed by the invention, work procedures can be reduced, the production efficiency can be improved and the waste of raw materials can be reduced.

Owner:靖江市易凯通风设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com