Backlight module, display device and manufacturing method of diffusion sheet

A technology for a backlight module and a manufacturing method, which is applied to parts of lighting devices, lighting devices, fixed lighting devices, etc., can solve the problems of manpower consumption, waste of time, increase of manufacturing costs and man-hours, etc., so as to improve productivity and simplify assembly. process, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

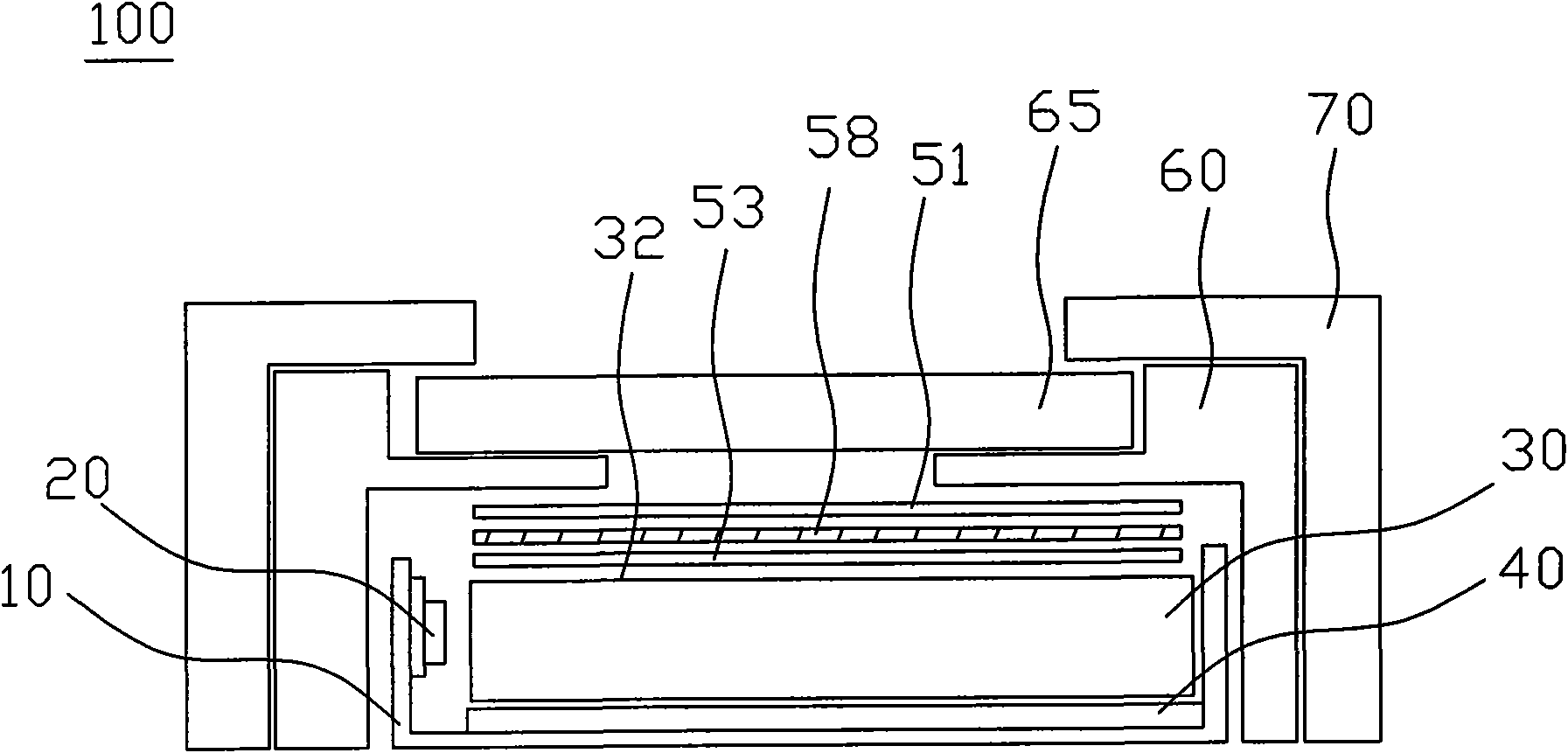

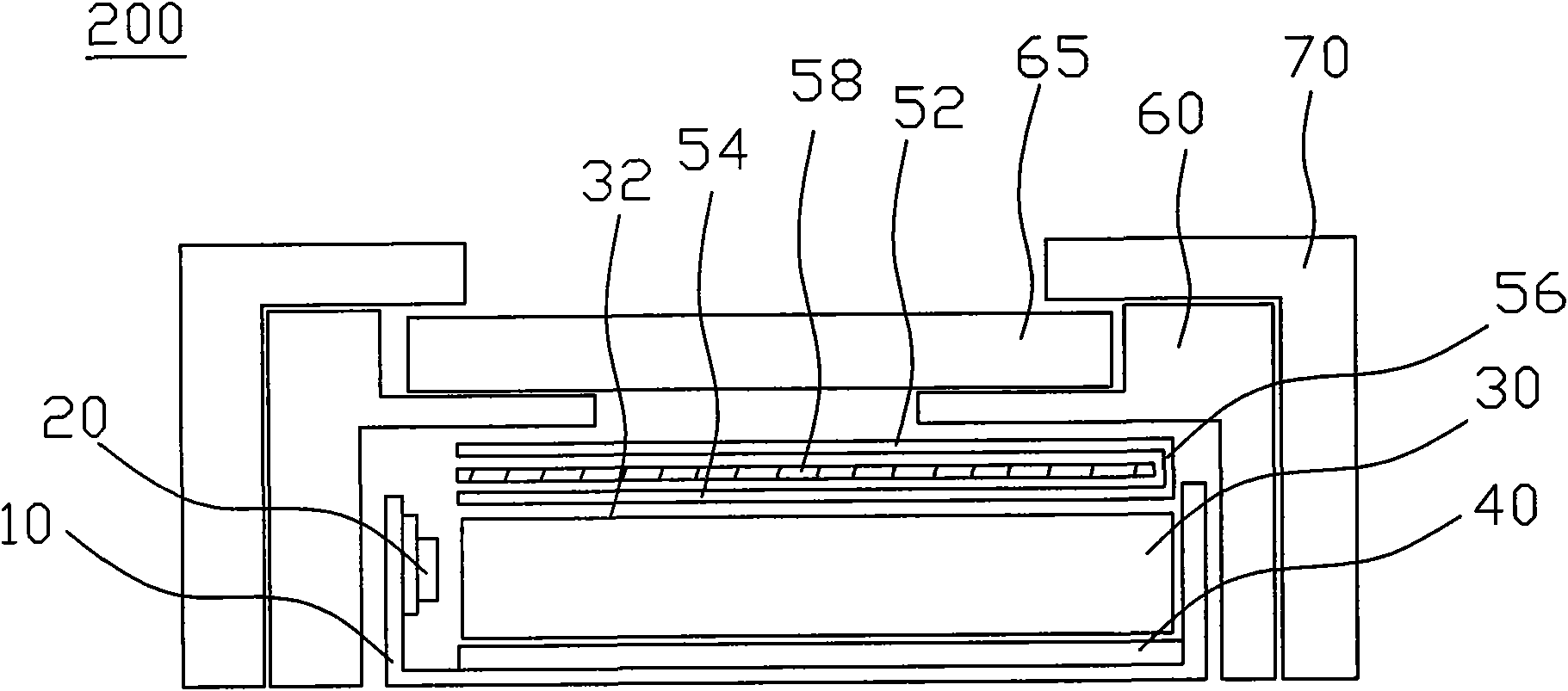

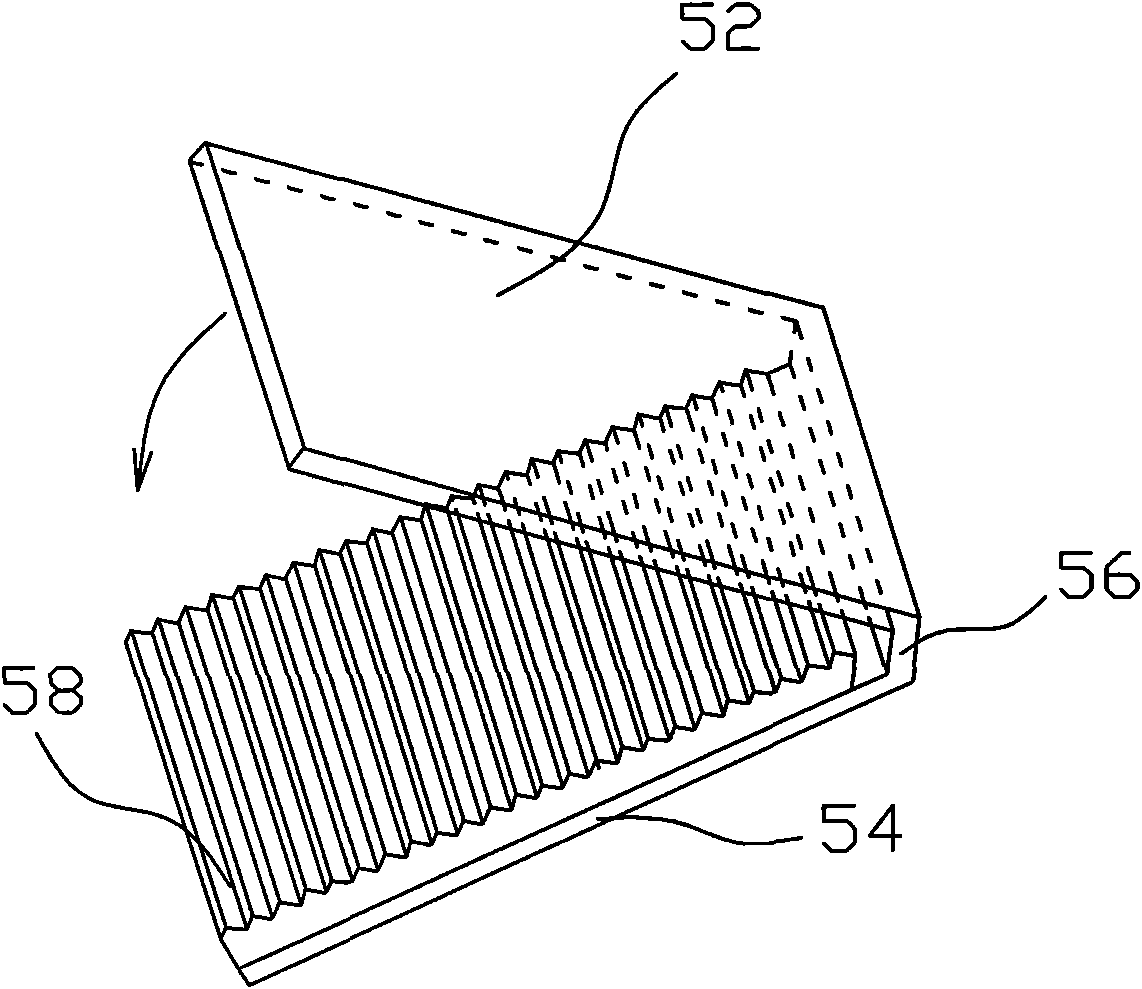

[0039] Please also refer to figure 2 , image 3 with Figure 4 , figure 2 is a cross-sectional view of the display device of the present invention, image 3 yes figure 2 Schematic diagram of the optical diaphragm in, Figure 4 It is a perspective view of the diffusion sheet of the present invention. According to this specific embodiment, the present invention provides a display device 200 , which includes a backlight module, a display panel 65 , and a front frame 70 . The backlight module includes a light guide plate 30 and a plurality of optical films. The light guide plate 30 has a light exit surface 32. These optical films are arranged on one side of the light exit surface 32. These optical films include a diffusion sheet 50 and a prism sheet 58. , the diffuser 50 is integrally formed and includes an upper diffuser 52 and a lower diffuser 54, and the diffuser 50 is bent so that the upper diffuser 52 and the lower diffuser 54 are parallel to each other and form an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com