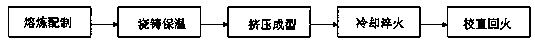

Continuous casting and extrusion process of aluminum alloy section

An aluminum alloy profile and continuous casting technology, applied in the field of aluminum alloy profile production, can solve the problems of restricting the promotion and sales of aluminum alloy profiles, high production cost of aluminum alloy profiles, complicated production process, etc., so as to save heating and cooling processes, The effect of simplifying the production process, reducing energy consumption and resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: A continuous casting and extrusion process of aluminum alloy profiles, the production process of the high weather resistance aluminum alloy profiles includes the following steps:

[0018] The first step, smelting preparation, first add aluminum into the furnace according to the proportion, and heat it to a molten state, then add an appropriate amount of modified fly ash and spread it evenly, then add an appropriate amount of grain refiner for refining, and finally Add alloying elements, and wait until the molten aluminum and the added alloying elements are fully melted and mixed evenly.

[0019] The second step is casting and heat preservation. The molten aluminum alloy is continuously cast and formed through the casting mold, and the high-temperature solid or semi-solid aluminum alloy ingot after casting is forced to cool down to 500 ° C, and then kept for 1 hour;

[0020] The third step is extrusion molding. Install the heat-insulated aluminum alloy ingo...

Embodiment 2

[0023] Example 2: The first step, smelting preparation, first add aluminum into the melting furnace according to the proportion, and heat it to a molten state, then add an appropriate amount of modified fly ash and spread it evenly, and then add an appropriate amount of grain refiner Refining, and finally adding alloying elements, after the molten aluminum and the added alloying elements are fully melted and mixed evenly,

[0024] The second step is casting and heat preservation. The molten aluminum alloy is continuously cast and formed through the casting mold, and the high-temperature solid or semi-solid aluminum alloy ingot after casting is forced to cool down to 600 ° C, and then kept for 0 hours;

[0025] The third step is extrusion molding. Install the heat-insulated aluminum alloy ingot on the extruder and force it to cool down to 400°C, and then pass through the extruder die to extrude a specific shape of aluminum profile. The extrusion speed is 50 meters. / minute;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com