Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Realize semi-continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

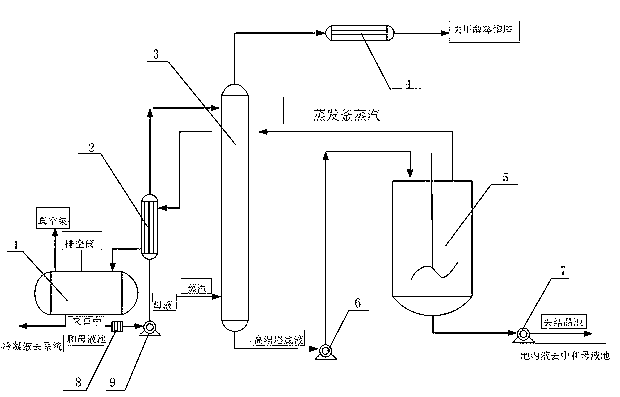

Device and production technology for treating ternary-monomer wastewater and extracting sodium sulfate

ActiveCN103253819AReduce maintenance workloadExtend the life cycleMultistage water/sewage treatmentAlkali metal sulfites/sulfatesThermodynamicsDistillation

The invention discloses a device and a production technology for treating ternary-monomer wastewater and extracting sodium sulfate. The device comprises a plate-and-frame filter press, a mother liquid heat exchanger, a stripping tower and a condenser which are sequentially communicated through a pipeline, wherein the condenser is communicated with a methane distillation tower through the pipeline. The production technology comprises the following steps of: (1) pumping neutralized mother liquid into the plate-and-frame filter press, preheating the mother liquid through the mother liquid heat exchanger, and then pumping the mother liquid into the stripping tower from the top of the stripping tower; (2) pumping steam into the stripping tower from the bottom of the stripping tower, after methane in the mother liquid is brought out by the steam, condensing the steam through the condenser, then entering the methane distillation tower, and separating to obtain methane; (3) pumping liquid at the bottom of a high-temperature tower into an evaporation and concentration kettle to be concentrated, steaming out moisture, and using the steam generated by the evaporation and concentration kettle for heating the mother liquid heat exchanger; and (4) after concentrating a material in the evaporation and concentration kettle, placing the concentrated material in a crystallizing pond, and feeding the mother liquid, Na2SO4.10H2O in which is separated out in the crystallizing pond, into a mother liquid neutralization pond to be reused.

Owner:WEIFANG WORLD CHEM

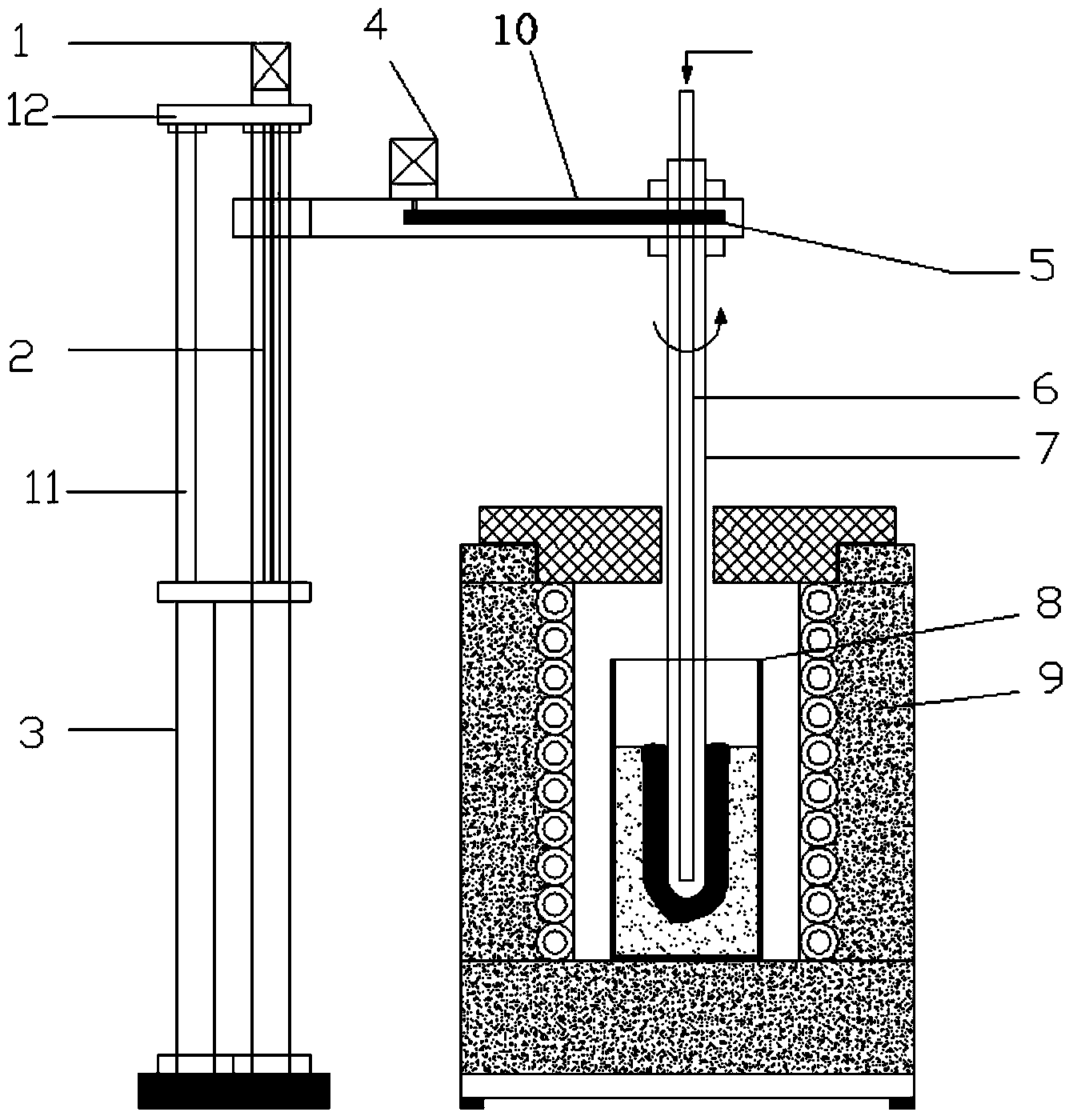

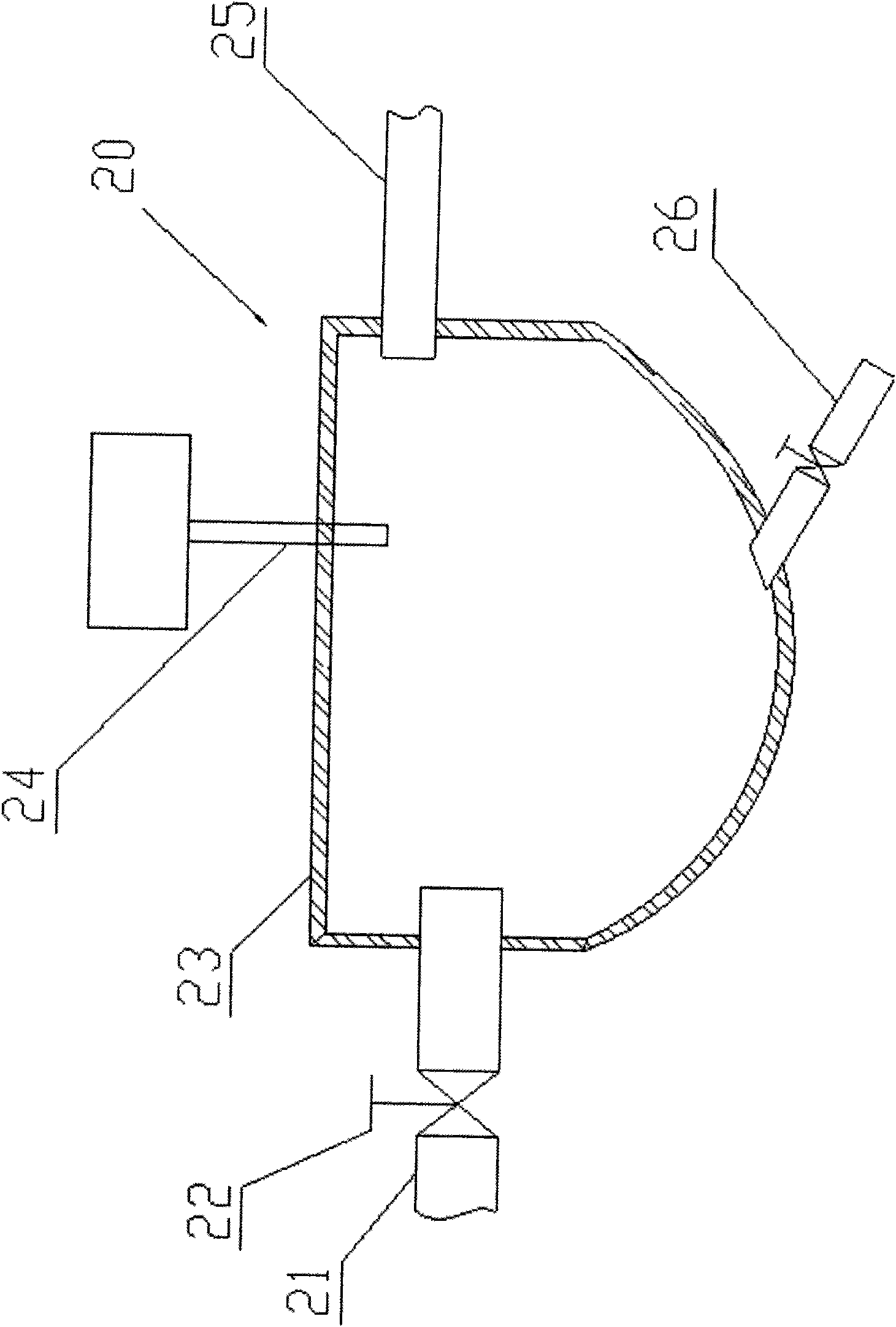

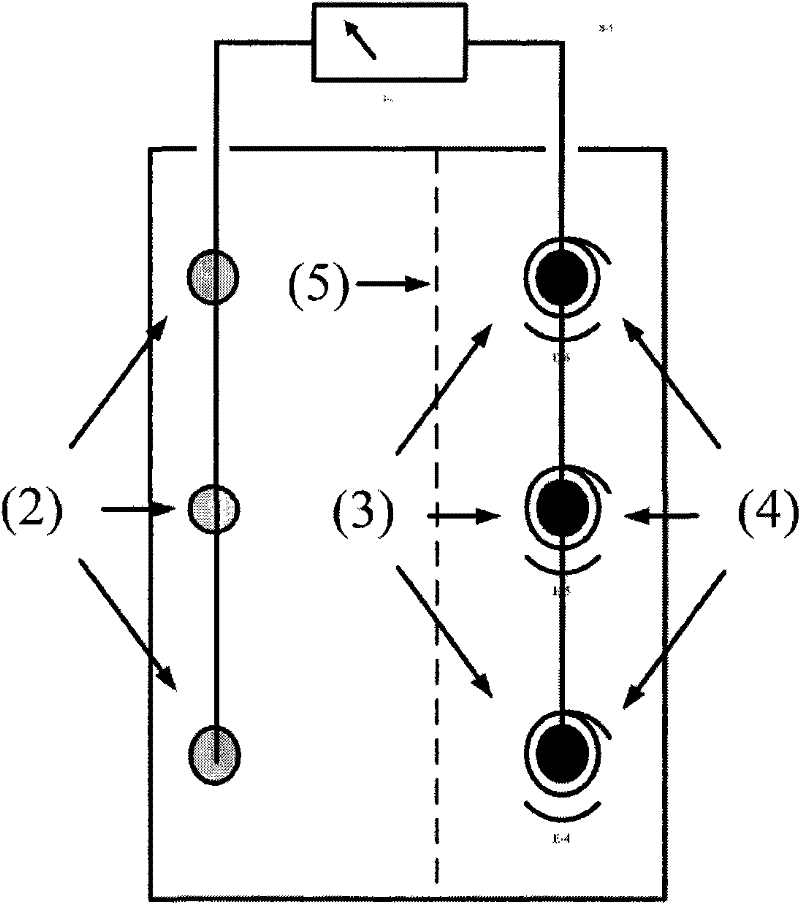

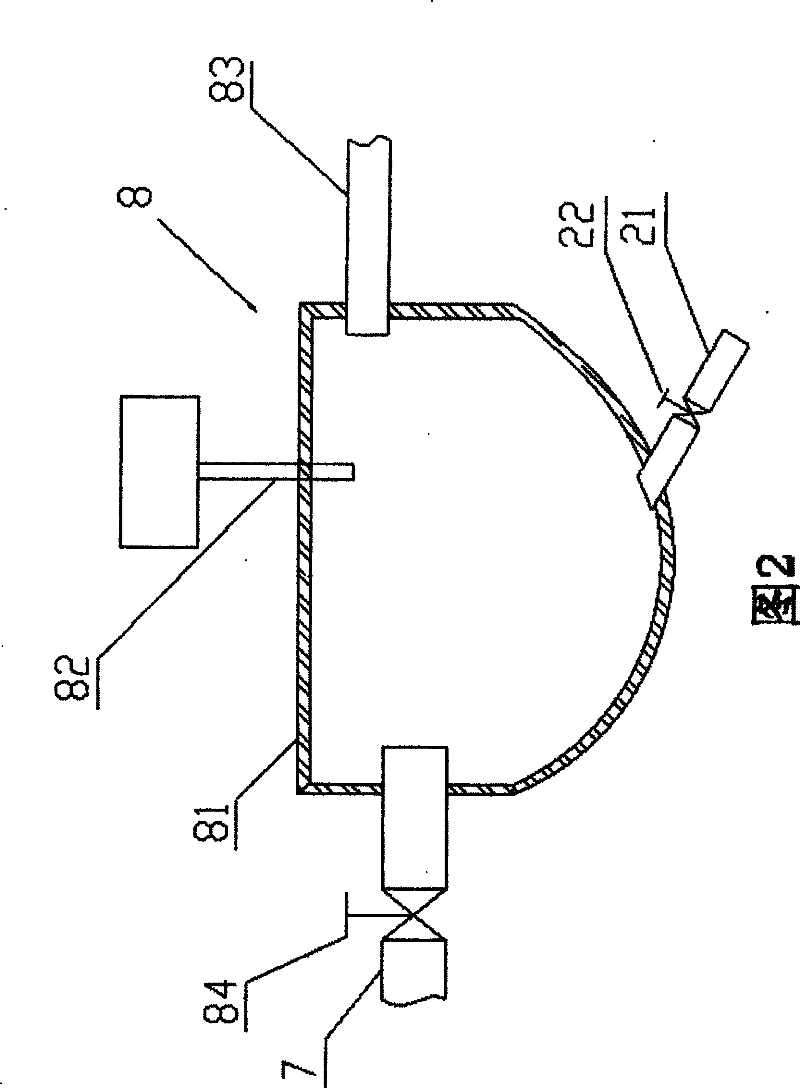

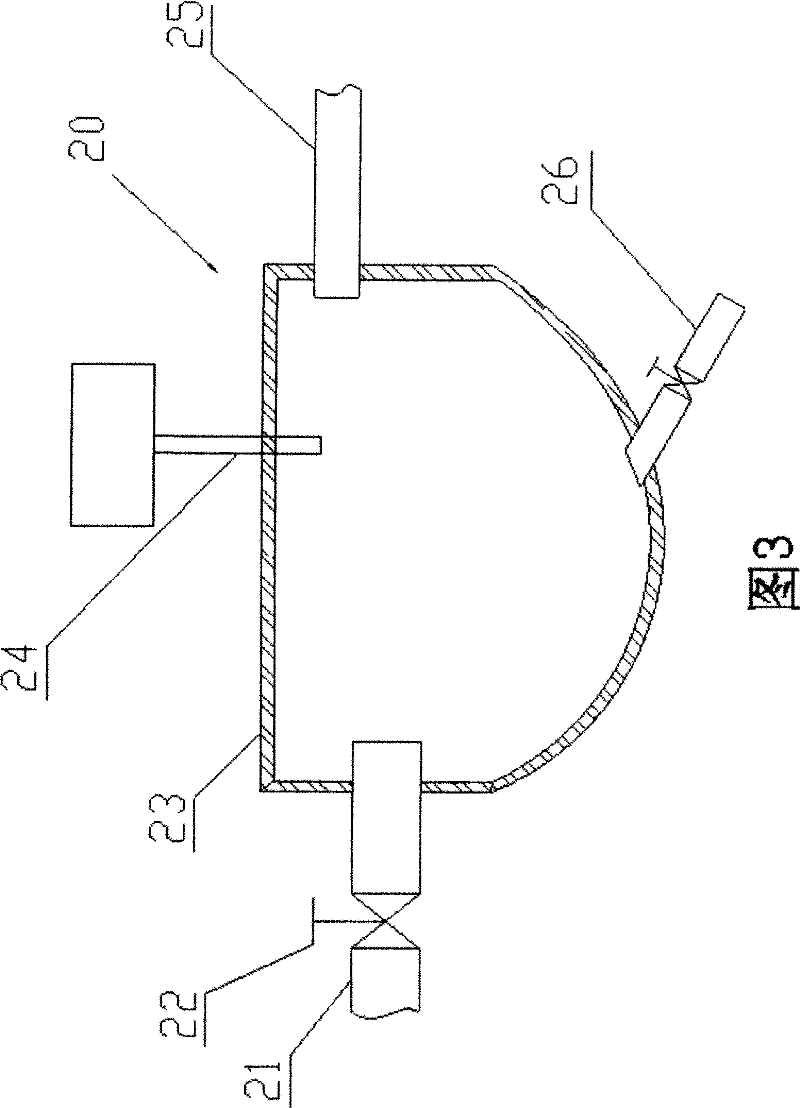

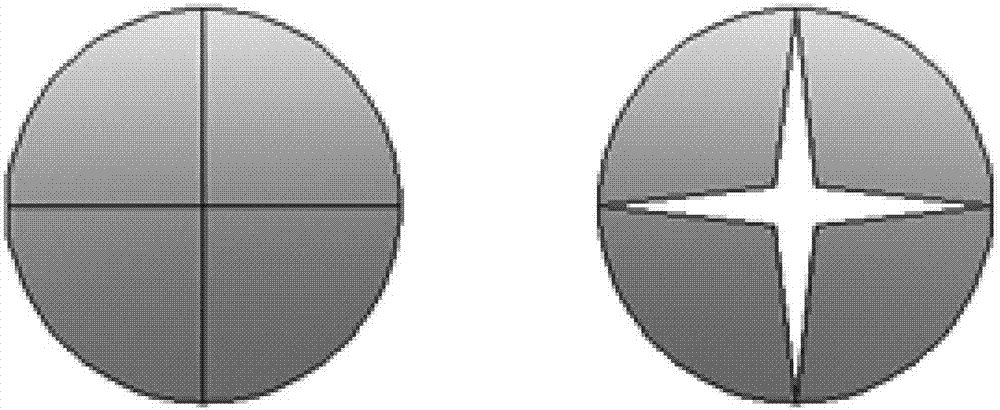

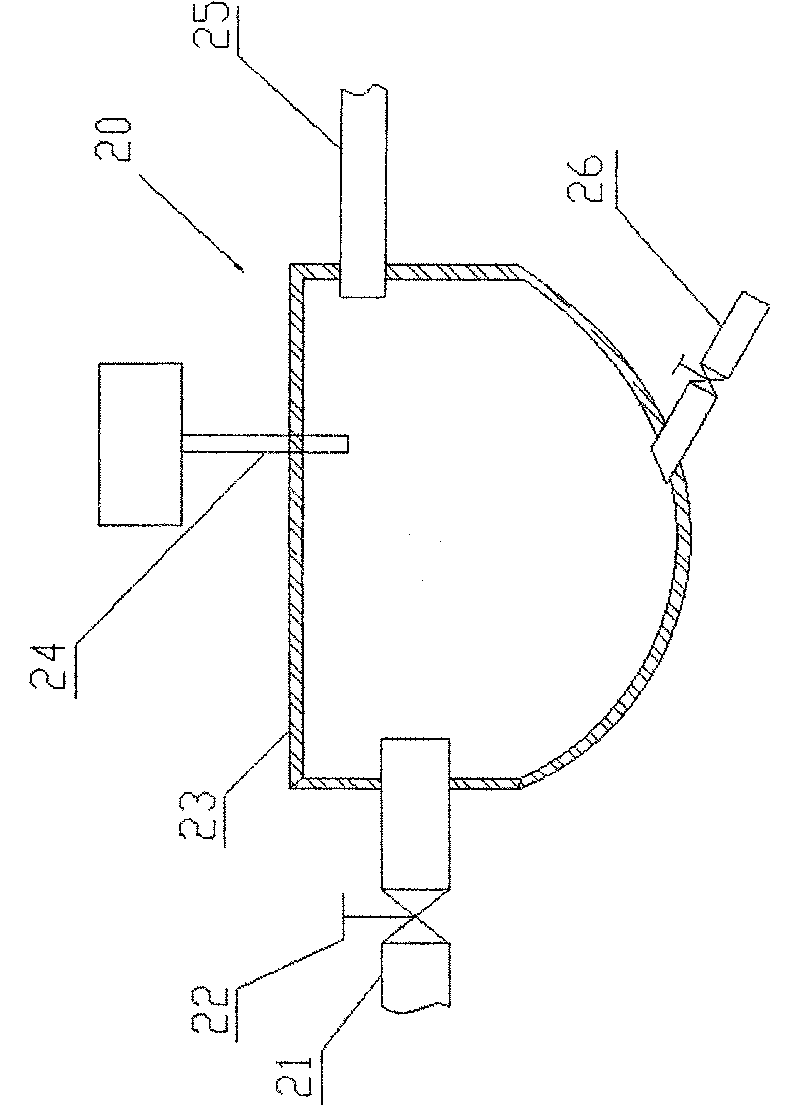

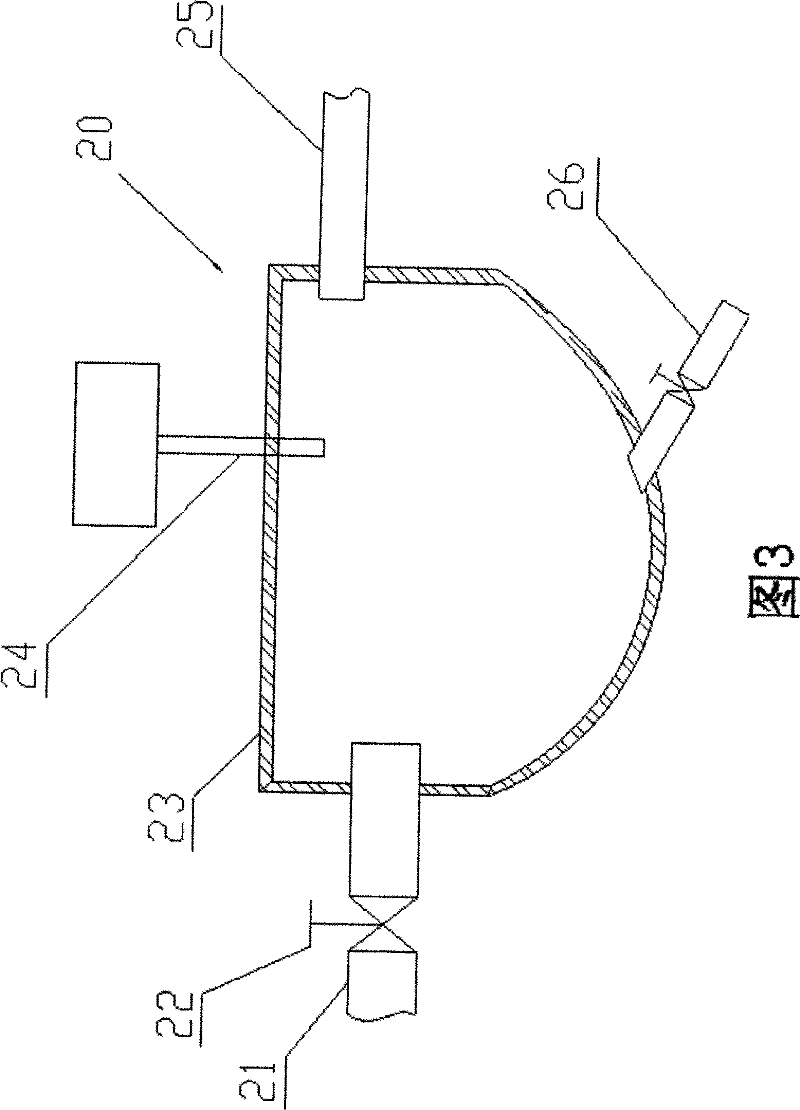

Method for purifying silicon through semi-continuous crystallization in silicon alloy melt

InactiveCN103833038AIncrease productivityFast growthSilicon compoundsContinuous productionContinuous crystallization

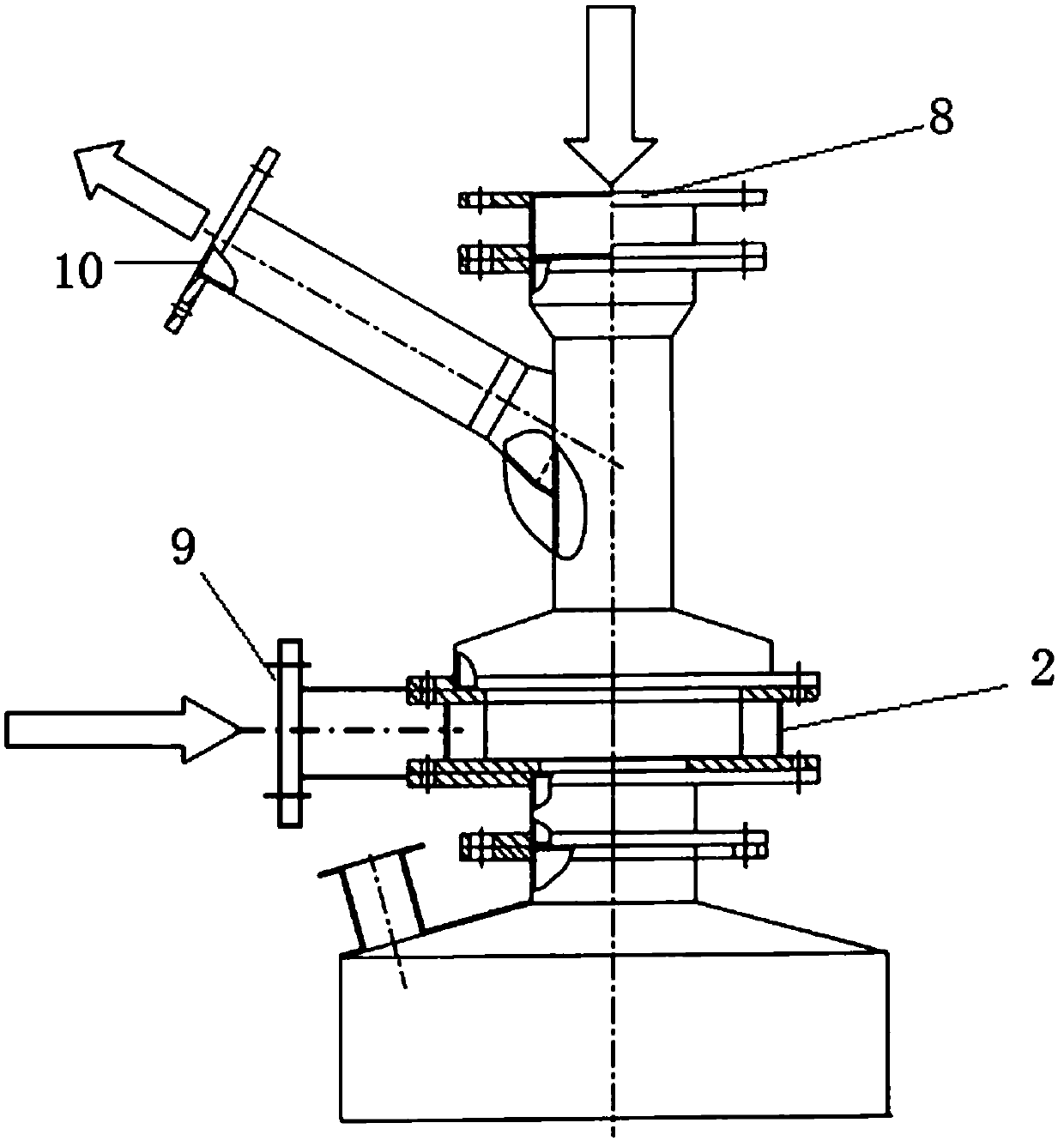

The invention discloses a method for purifying silicon through semi-continuous crystallization in silicon alloy melt. The method comprises the steps of heating and melting silicon and Al or Al alloy to form an Al-Si base alloy melt, inserting an air-cooled revolving crystallizing rod in the melt so that silicon crystal is separated out of the alloy melt while such major impurities as B and P are kept in the alloy melt, thus achieving an effect of removing impurities. The air-cooled continuous rotating crystallizing rod is inserted in the melt and relatively high cooling speed is adopted to improve crystal growth speed, so as to realize semi-continuous crystallizing growth in the silicon alloy melt. The method disclosed by the invention has the advantages of being low in energy consumption, free from pollution, high in production efficiency, capable of realizing semi-continuous production, small in investment scale, and simple in production process and equipment operation.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Preparation method of aluminum-scandium intermediate alloy, aluminum-scandium intermediate alloy and aluminum-scandium alloy

The invention provides a preparation method of an aluminum-scandium intermediate alloy, an aluminum-scandium intermediate alloy and an aluminum-scandium alloy. The preparation method comprises that a scandium-containing compound and an aluminum-containing raw material are added into a first reactor and undergo a thermal reduction reaction to produce a liquid aluminum-scandium intermediate alloy, wherein the aluminum-containing raw material contains aluminum and / or an aluminum alloy, the liquid aluminum-scandium intermediate alloy is added into a second reactor with melt salt and is subjected to slag extraction treatment, wherein the density of the melt salt is less than density of the liquid aluminum-scandium intermediate alloy, and the liquid aluminum-scandium intermediate alloy subjected to slag extraction treatment is cooled and cured so that an aluminum-scandium intermediate alloy cast ingot is obtained. The preparation method realizes a thermal reduction reaction and a slag extraction treatment process in different reactors, realizes semi-continuous production of the aluminum-scandium intermediate alloy, improves aluminum-scandium intermediate alloy production efficiency and improves aluminum-scandium intermediate alloy uniformity.

Owner:GRIREM ADVANCED MATERIALS CO LTD

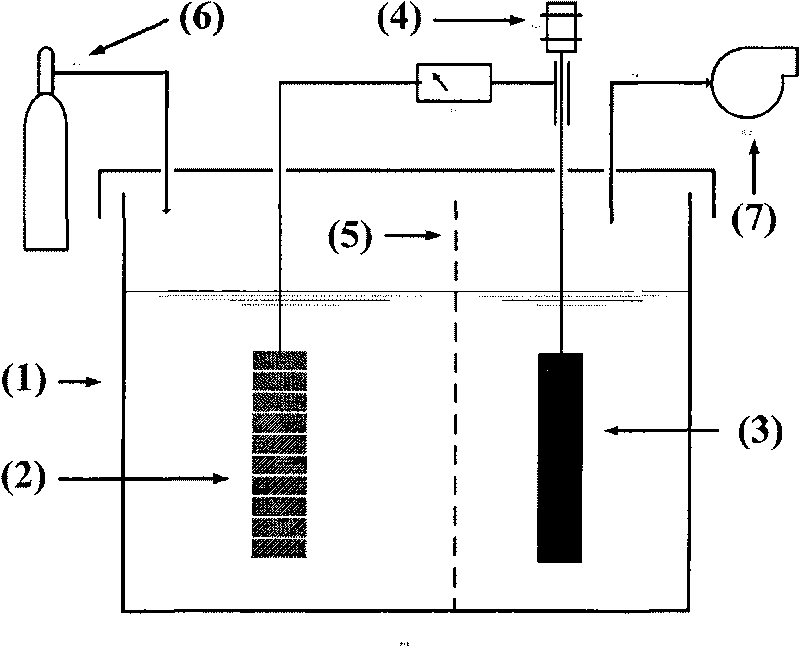

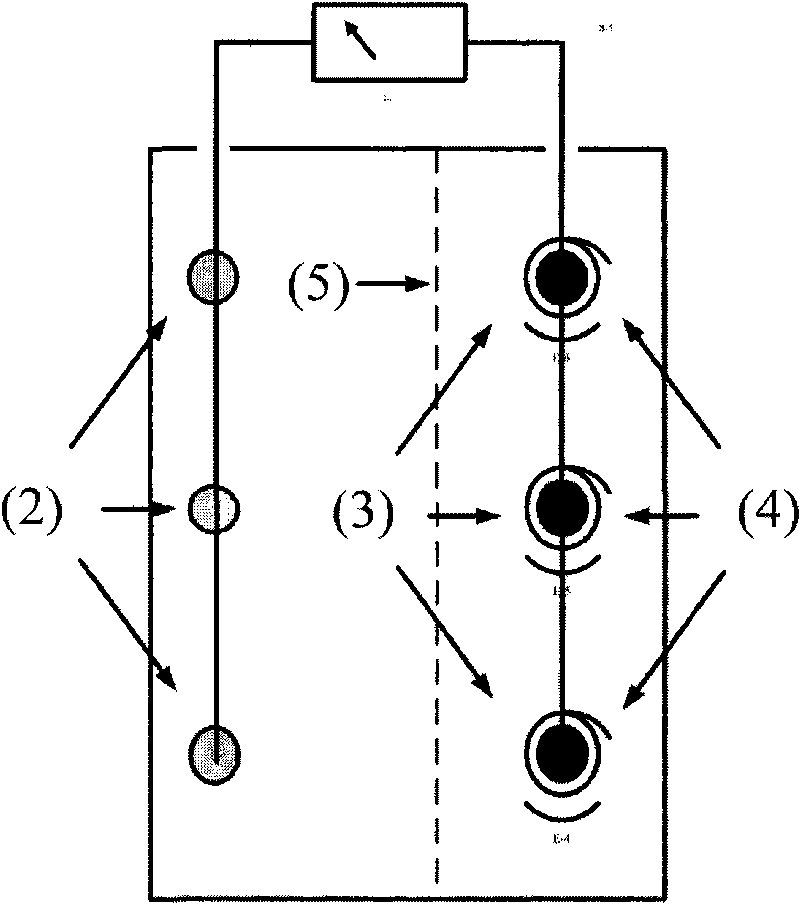

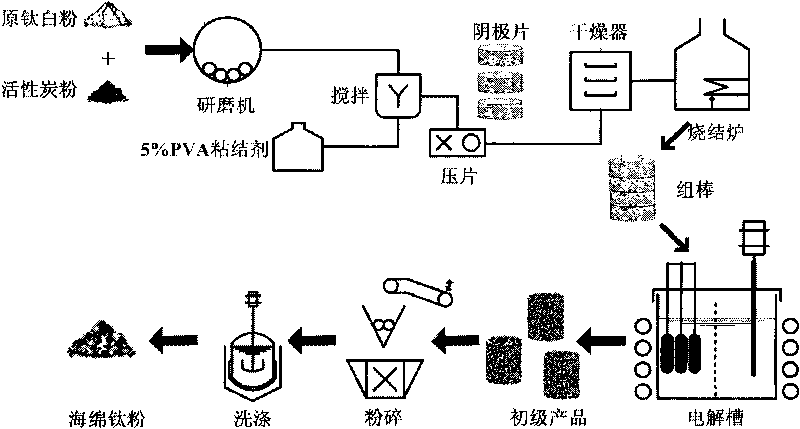

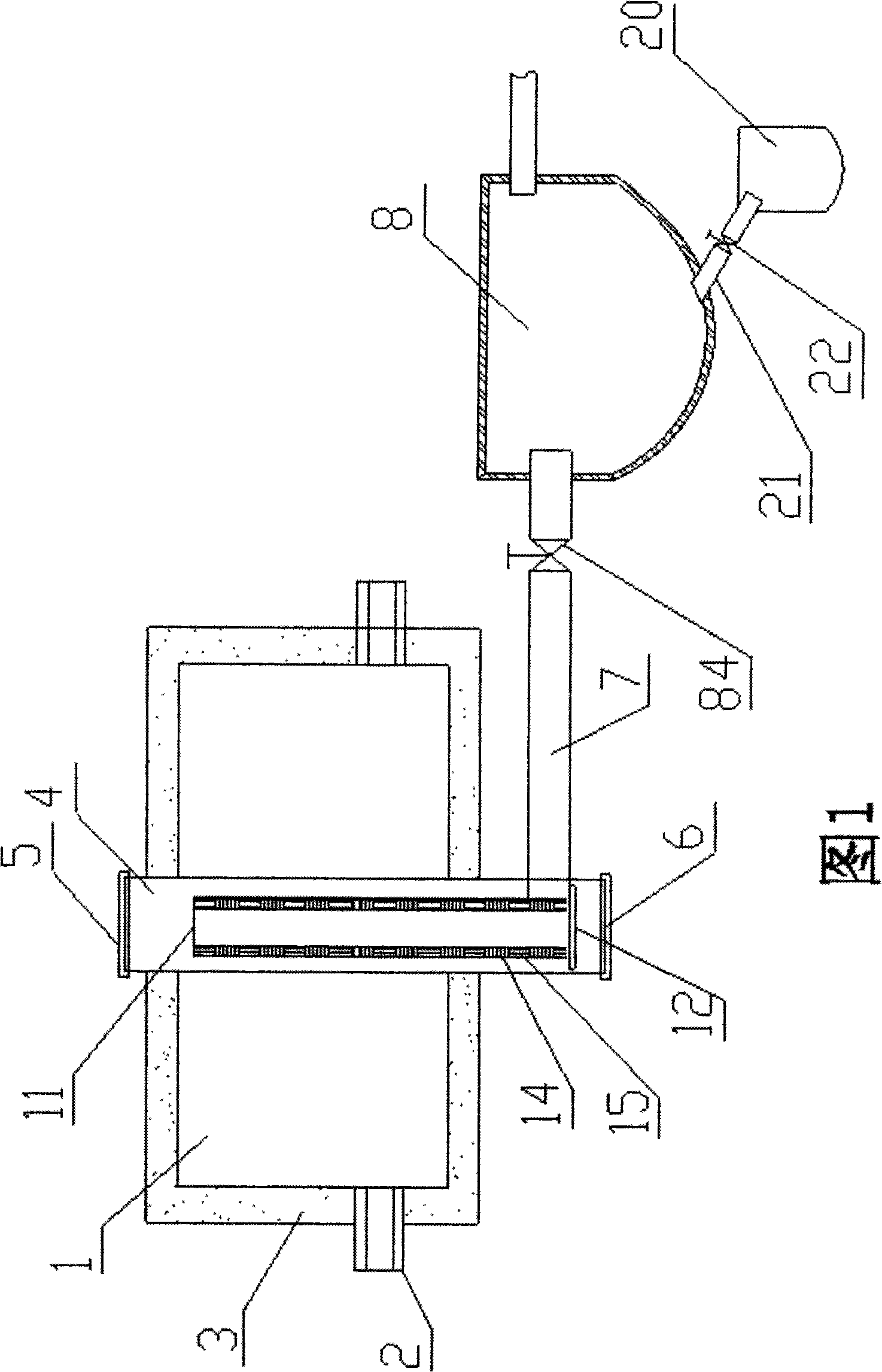

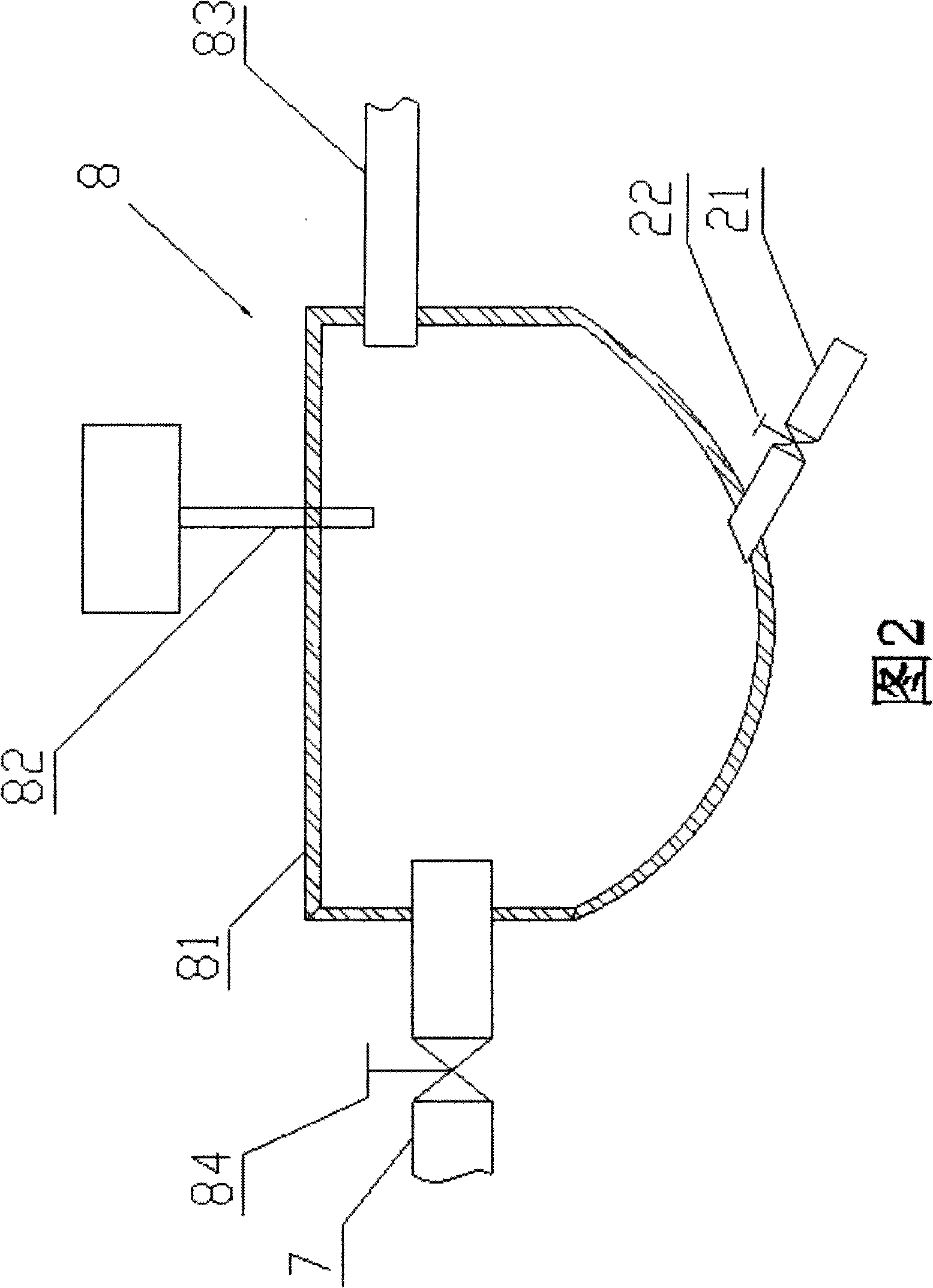

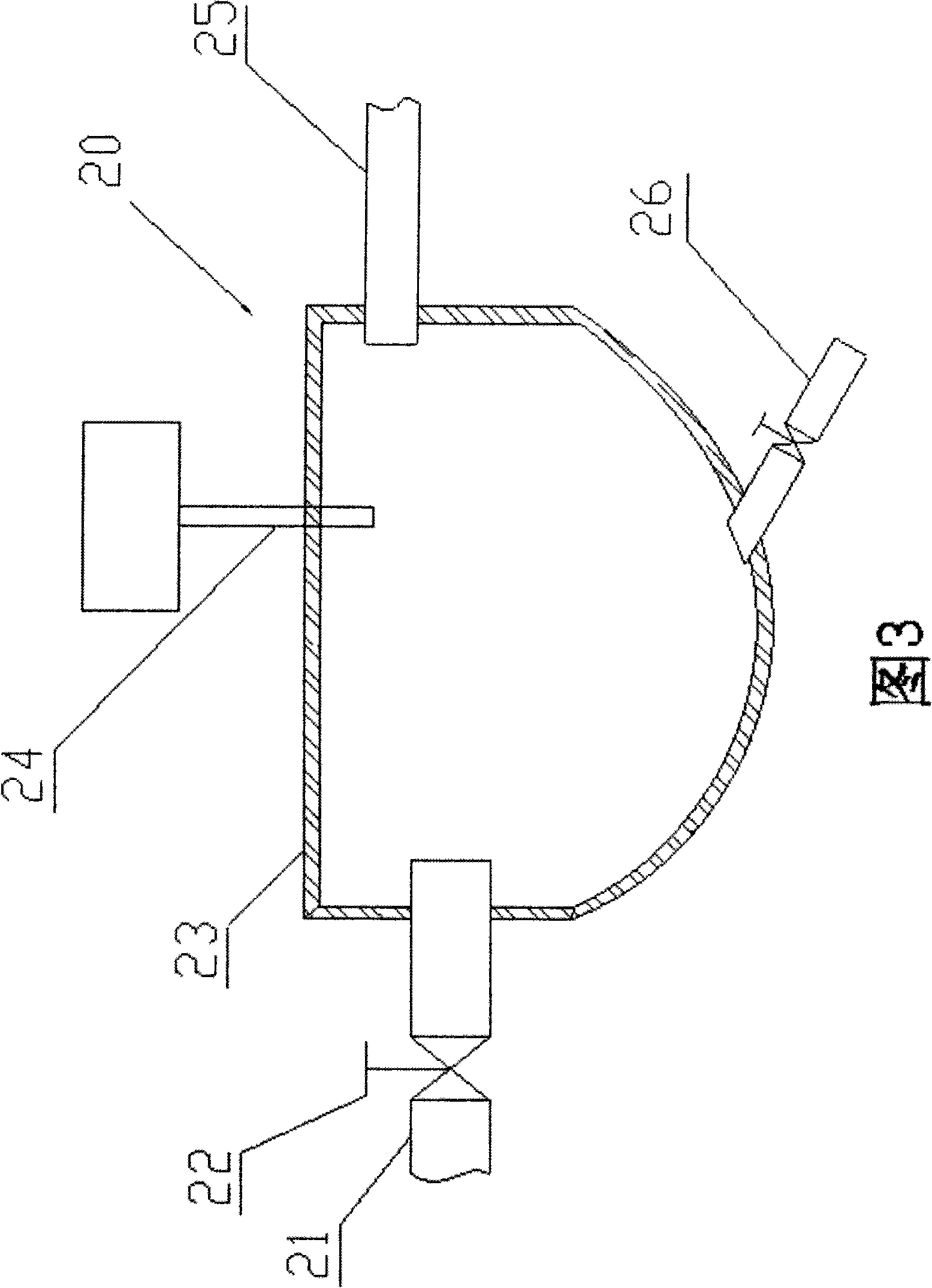

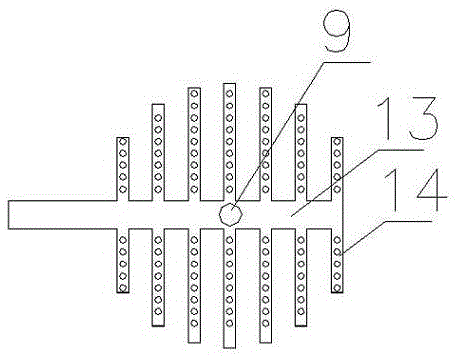

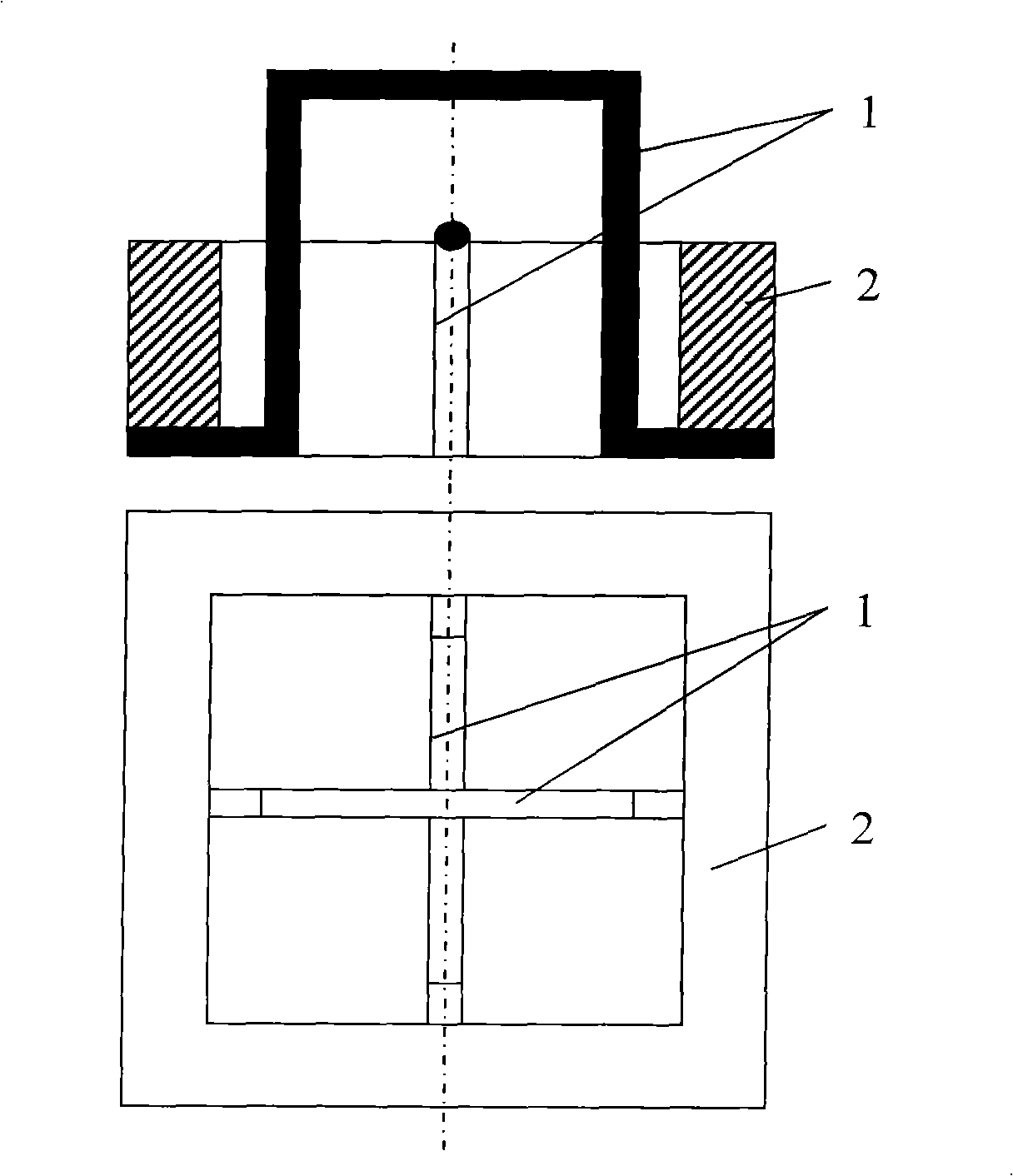

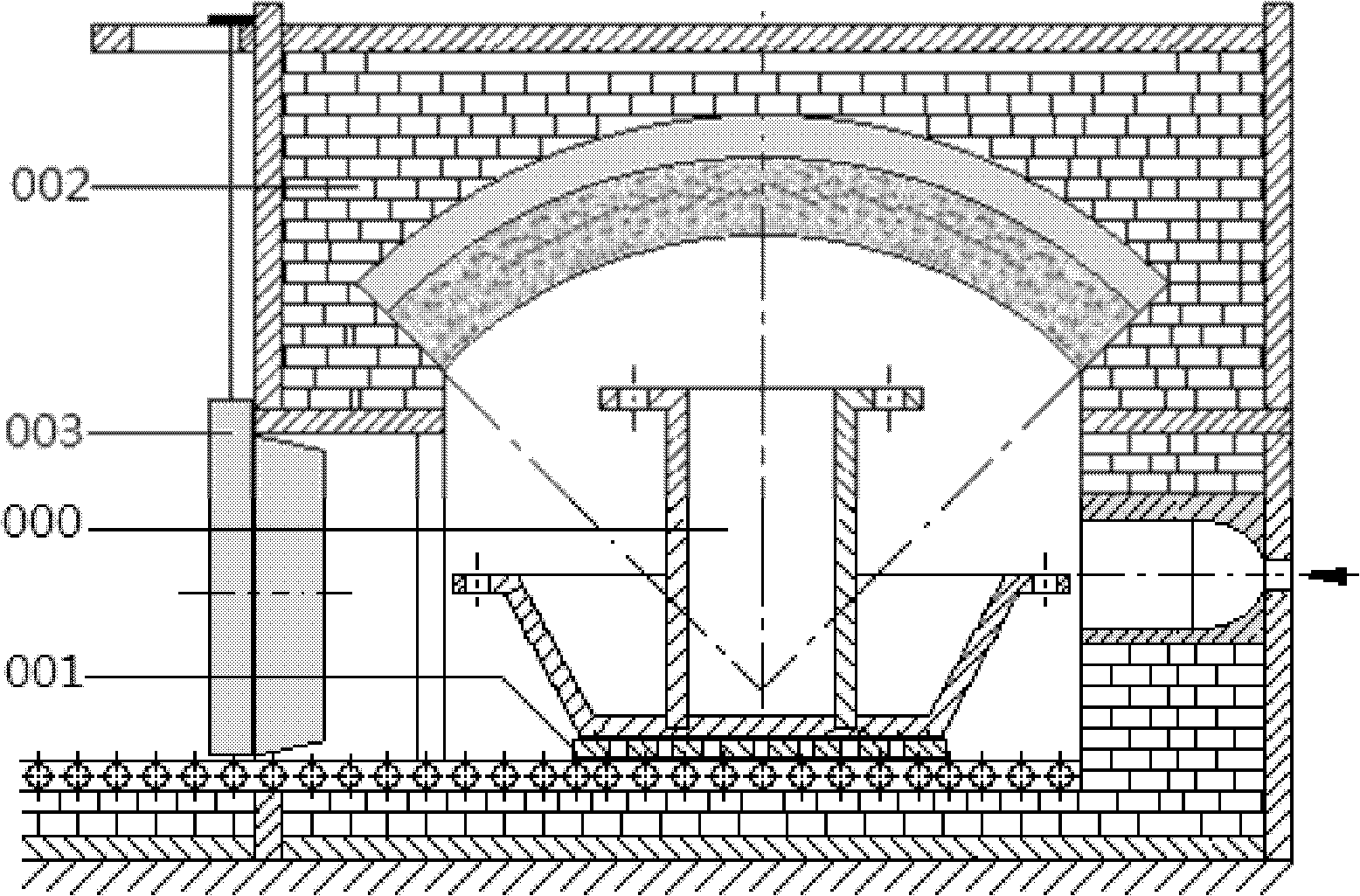

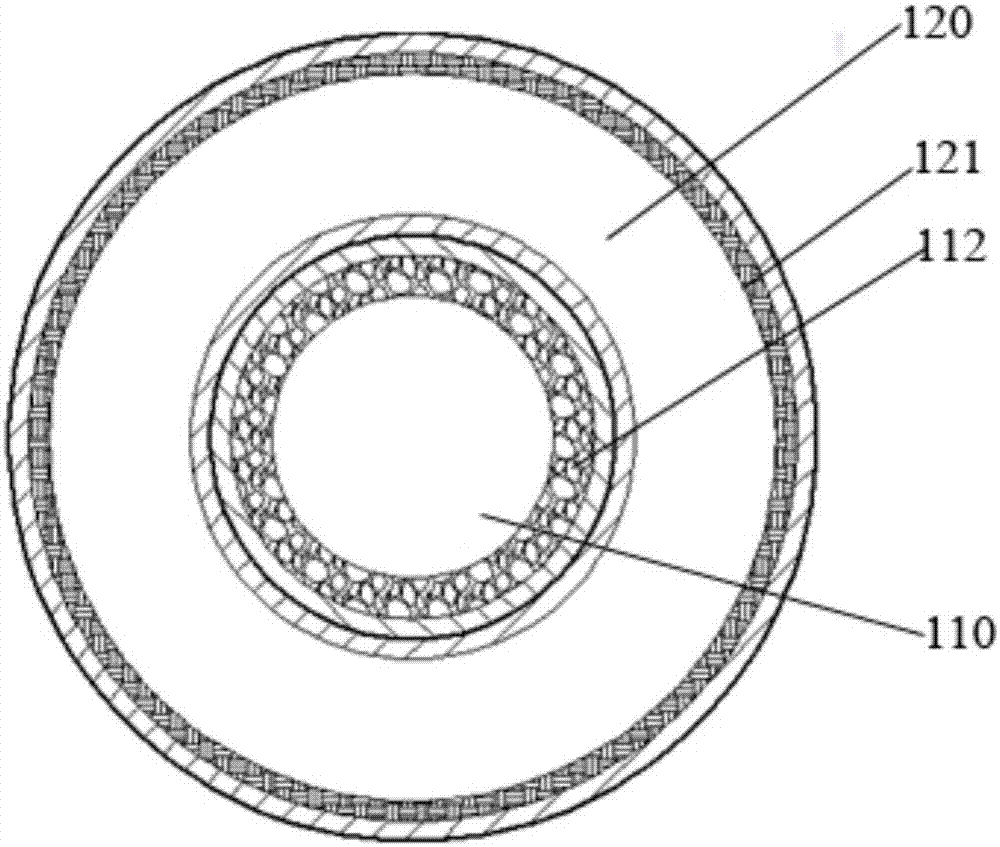

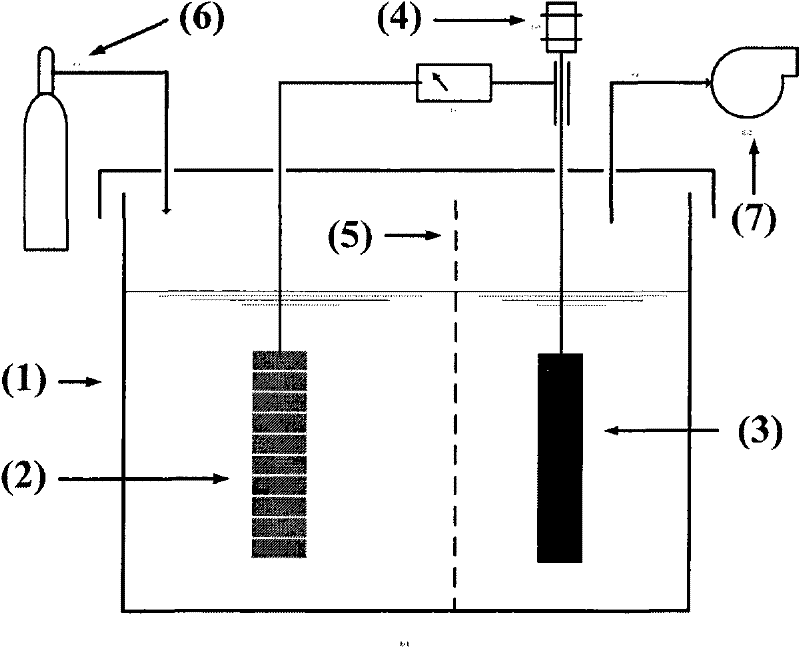

Electrolytic cell in electro-deoxidization metallurgy process

InactiveCN101701345AEliminate disadvantagesIncrease production capacityDiaphragmsElectricityMolten salt

The invention discloses an electrolytic cell in electro-deoxidization metallurgy process, which is divided into a negative electrode region and a positive electrode region, which have the effect of isolating the flow of fused salts while achieving free exchange of ions, thus suppressing the occurrence of side reaction of positive and negative electrode products; the positive electrode in the electrolytic cell is rotated to accelerate the deoxidization speed and simultaneously, the emission of tail gas in the positive electrode region is quickened up in a manner of oriented-circulating protective gas stream in order to avoid overhigh content of the tail gas within the electrolytic cell; the electrodes of the electrolytic cell are changed into be arrayed in parallel, which breaks the limitation of traditional single electrode, the negative electrode and the positive electrode correspondingly form counter electrodes so as to polarize the electro-deoxidization task of the electrodes. The parallel-type electrodes can also adjust the array number of the counter electrodes according to requirement so as to change production ability without more improvements on equipment and production conditions, and to guarantee product quality as well. The electrolytic cell according to the invention has large production ability and short production period and is capable of realizing semi-continuous product.

Owner:UNIV OF SCI & TECH BEIJING

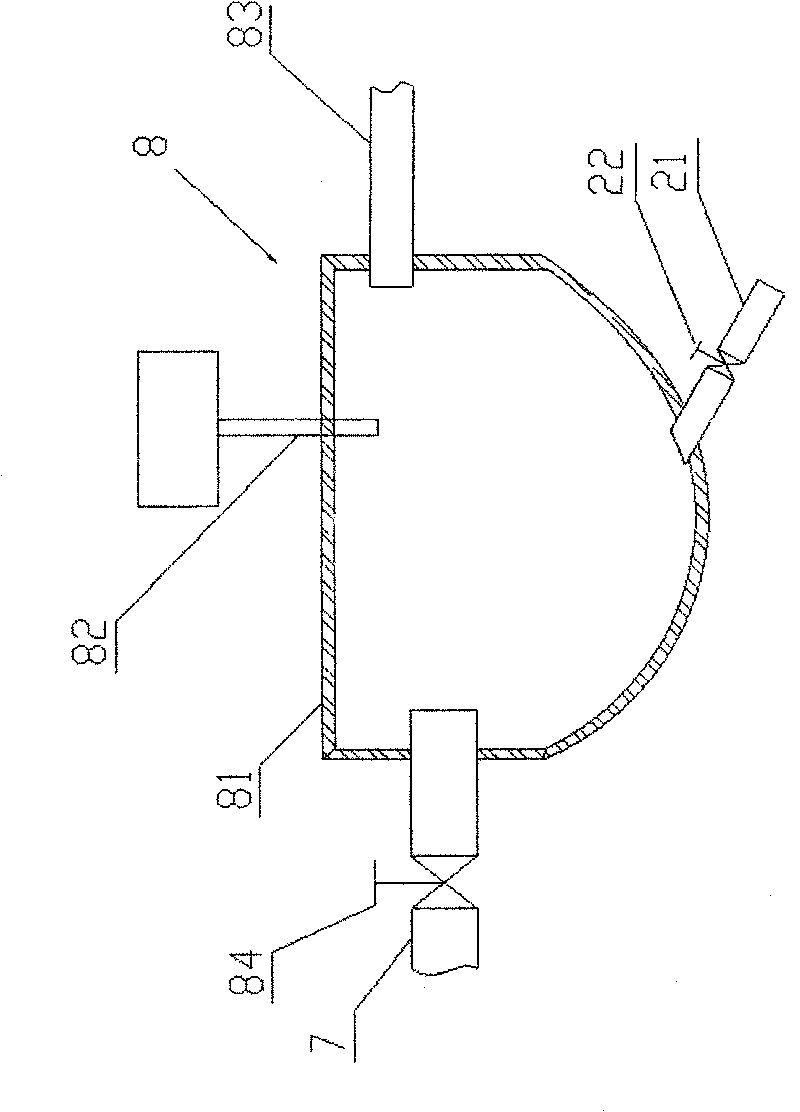

Semi-continuous metallothermic reduction process

The invention provides a method for semi continuous metallothermic reduction. In the method, a reduction pot is communicated with a liquid crystallizer arranged outside the reduction pot by a diversion device, therefore metal steams in the reduction pot enter the liquid crystallizer through the diversion device and are converted to liquid state and kept as the liquid state; liquid metal in the liquid crystallizer periodically and quantificationally flows into liquid pouring baskets; when a liquid pouring basket is filled up, another liquid pouring basket replaces the original liquid pouring basket to connect the liquid crystallizer so as to continuously collecting the liquid metal in the liquid crystallizer; after complete separation of the metal in the reduction pot, slag is removed, and new palletized feed stock is put in the reduction pot for starting a new reduction. The method has the advantages of realizing the semi continuous production of metal vacuum metallurgy, improving production efficiency and lowering production cost.

Owner:辛卫亚

Split type carbonization furnace set

InactiveCN105524629AAvoid environmental pollutionReduce work intensityBiofuelsEnergy inputBiomassProcess engineering

The invention discloses a split type carbonization furnace set. The split type carbonization furnace set comprises a combustion furnace, a hot gas pump and carbonization furnaces, wherein the combustion furnace, the hot gas pump and the carbonization furnaces are sequentially connected through pipelines, the combustion furnace and the carbonization furnaces are separated, and three or more carbonization furnaces are connected in parallel in a process. Wood, fruit peels, straw and other biomass raw materials are put in the closed carbonization furnaces with a dry distillation process, fuel is added to the combustion furnace and combusted to generate hot gas, the hot gas is sent into the carbonization furnaces through the hot gas pump to heat the biomass, accordingly, oxygen-free carbonization is realized, combustible byproducts generated in the carbonization process enter a combustion chamber through the pipelines for combustion, the gas after combustion enters a chimney and is discharged into the air after being treated through a smoke filter, and environment pollution is avoided. The combustion furnace and the carbonization furnaces are separated, multiple carbonization furnaces are connected in parallel, each carbonization furnace can be operated independently, other operation is not affected, semi-continuous production of the carbonization furnaces is realized, the working intensity is reduced, and the equipment production efficiency is improved.

Owner:XINJI YUAN XIANG GREEN ENERGY TECHOLOGY CO LTD

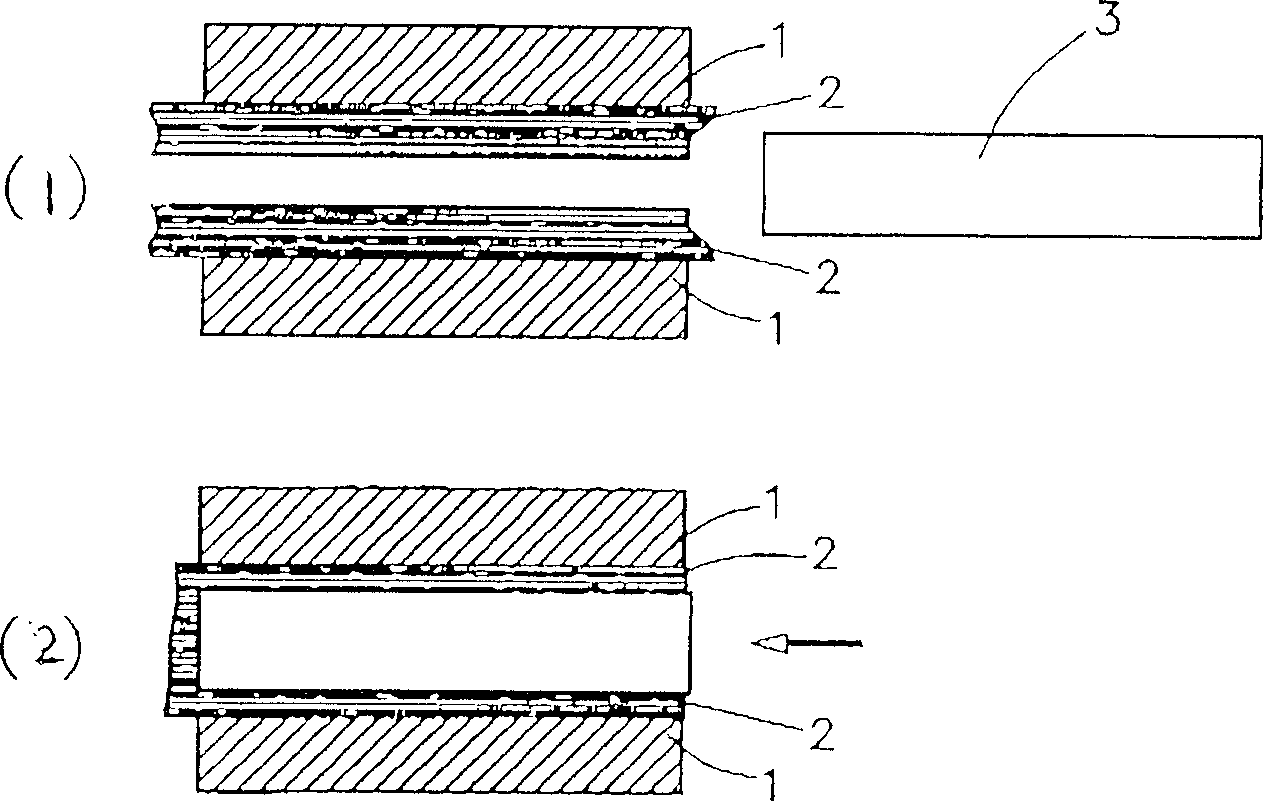

Polyimide formed body manufacture and device thereof

The present invention provides a method and an apparatus for producing a polyimide molding which have superior productivity and accuracy of dimension. The invention particularly relates to a tubular polyimide applicable to an electrophotographic device, such as a laser-beam printer and a copying machine, or a precision driving belt required for high strength and high dimensional stability. The method of producing a polyimide molding according to the present invention comprises the steps of: mixing a solution containing polyamic acid as a main component and a chemical curing agent; providing a mixture to a mold while the mixture is still fluid; after the polyamic acid contained in the mixture is changed into a semi-formed body which develops self-supporting properties, taking out the semi-formed body from the mold, or inserting a mold for heating without taking out the semi-formed body, or removing a part of the mold; and drying solvents which are present on the surface of or inside the semi-formed body by heating the semi-formed body to produce a polyimide molding.

Owner:KANEKA CORP

A technology for recover lithium battery

InactiveCN109193061AHigh selectivityImprove conversion rateWaste accumulators reclaimingBattery recyclingFiltrationRoom temperature

A technology for recover lithium battery includes disassemble lithium battery, taking out positive electrode sheet, and crushing into sheet. Mix the plate-like positive electrode with NaOH solution and stir at room temperature to react 15-20 min after that separation, the coating is obtain, and aluminum foil is obtained; Mix the dried coating with NMP, and adding at a temperature from 100-105 DEGC and stirring to dissolve for 30-40 min, filter by suction, washing that solid obtain by suction filtration and drying to obtain the active substance; Mix the active ingredient with the acid extract,and allowing reaction at a temperature of 60-65 DEG C for 30-40 min, filter, adding NaOH solution into that filtrate obtain by filtering until Fe 3 + is completely precipitated, filtering, washing and dry the precipitate obtained by separation to obtain Fe (OH) 3 precipitate, adding Na2CO3 solid into the filtrate obtained by separation until Li + is completely precipitated, and separating to obtain Li2CO3 solid. The recovery process provided by the invention has low energy consumption and can realize semi-continuous production.

Owner:武汉瑞杰特材料有限责任公司

Preparation method of lithium hexafluorophosphate

ActiveCN101570326BImprove product qualityRich sourcesLead-acid accumulatorsPhosphorus compoundsOleumPhosphoric acid

The invention relates to a preparation method of lithium hexafluorophosphate. The method comprises the following steps: (1), enabling anhydrous hydrogen fluoride and strong phosphoric acid to react under the protection of inert gas to prepare hexafluorophosphoric acid; (2), adding oleum to the hexafluorophosphoric acid prepared in the step (1) under cooling stirring to prepare phosphorus pentafluoride gas; (3), dissolving high-purity lithium fluoride in an anhydrous hydrogen fluoride solution to form an anhydrous hydrogen fluoride solution containing the lithium fluoride; (4), cooling and guiding the phosphorus pentafluoride gas into the anhydrous hydrogen fluoride solution containing the lithium fluoride, reacting, crystallizing, separating and drying to obtain a pure lithium hexafluorophosphate product; and (5), continuously guiding the unreacted and cooled phosphorus pentafluoride gas to the anhydrous hydrogen fluoride solution containing the lithium fluoride and continuously reacting to obtain a lithium hexafluorophosphate finished product. The phosphorus pentafluoride in the process is cooled to fully react so as to prevent incomplete reacted phosphorus pentafluoride powder from causing environmental-protection pressure.

Owner:DO FLUORIDE CHEM CO LTD

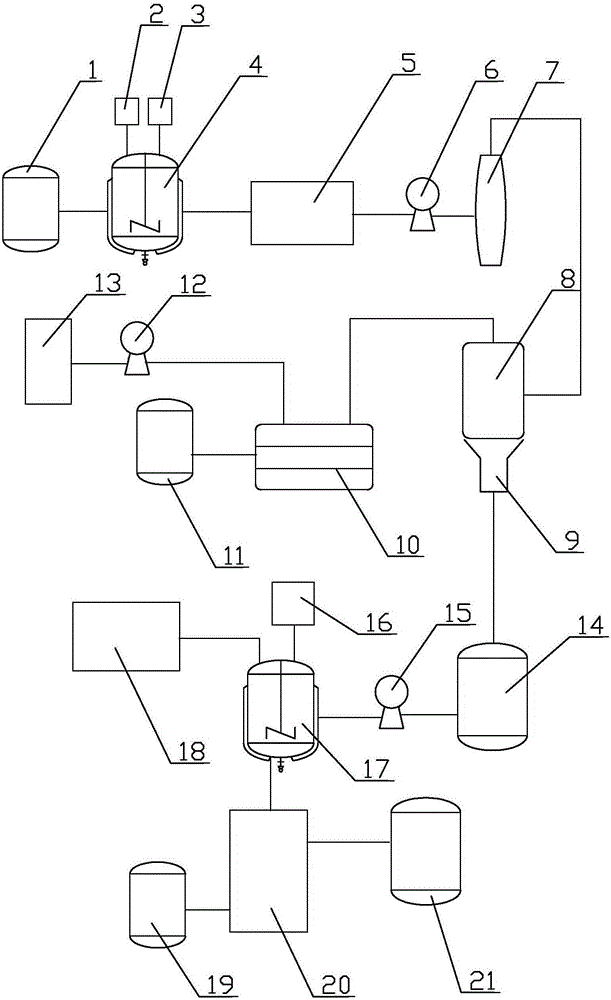

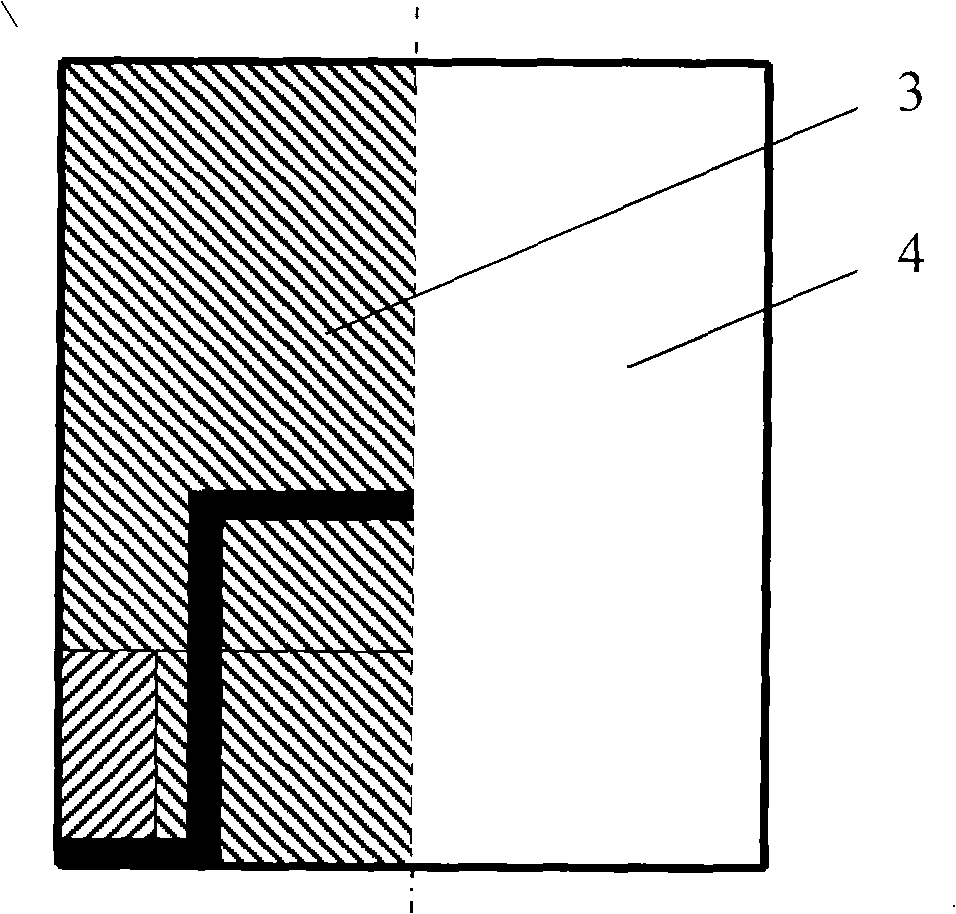

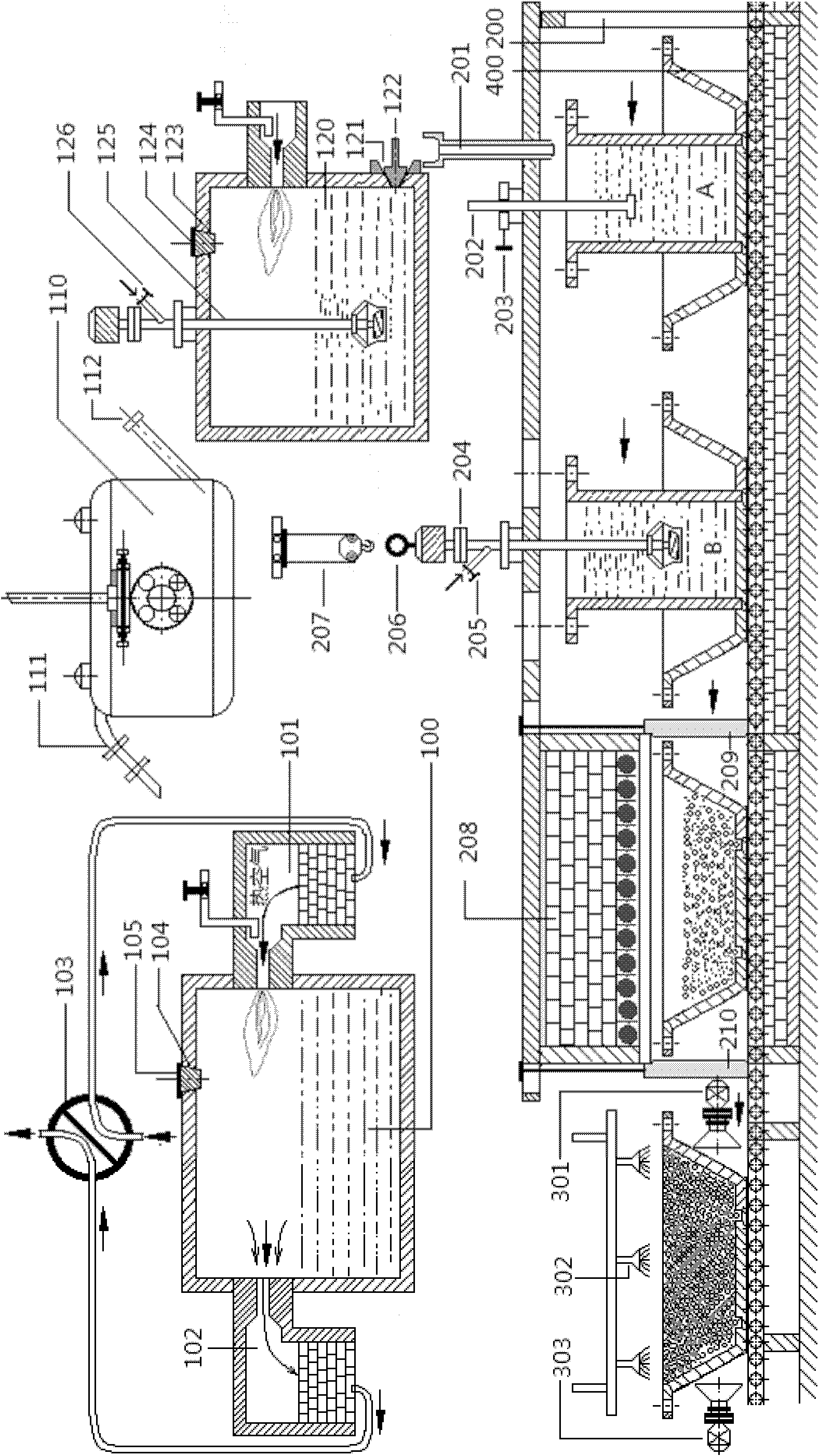

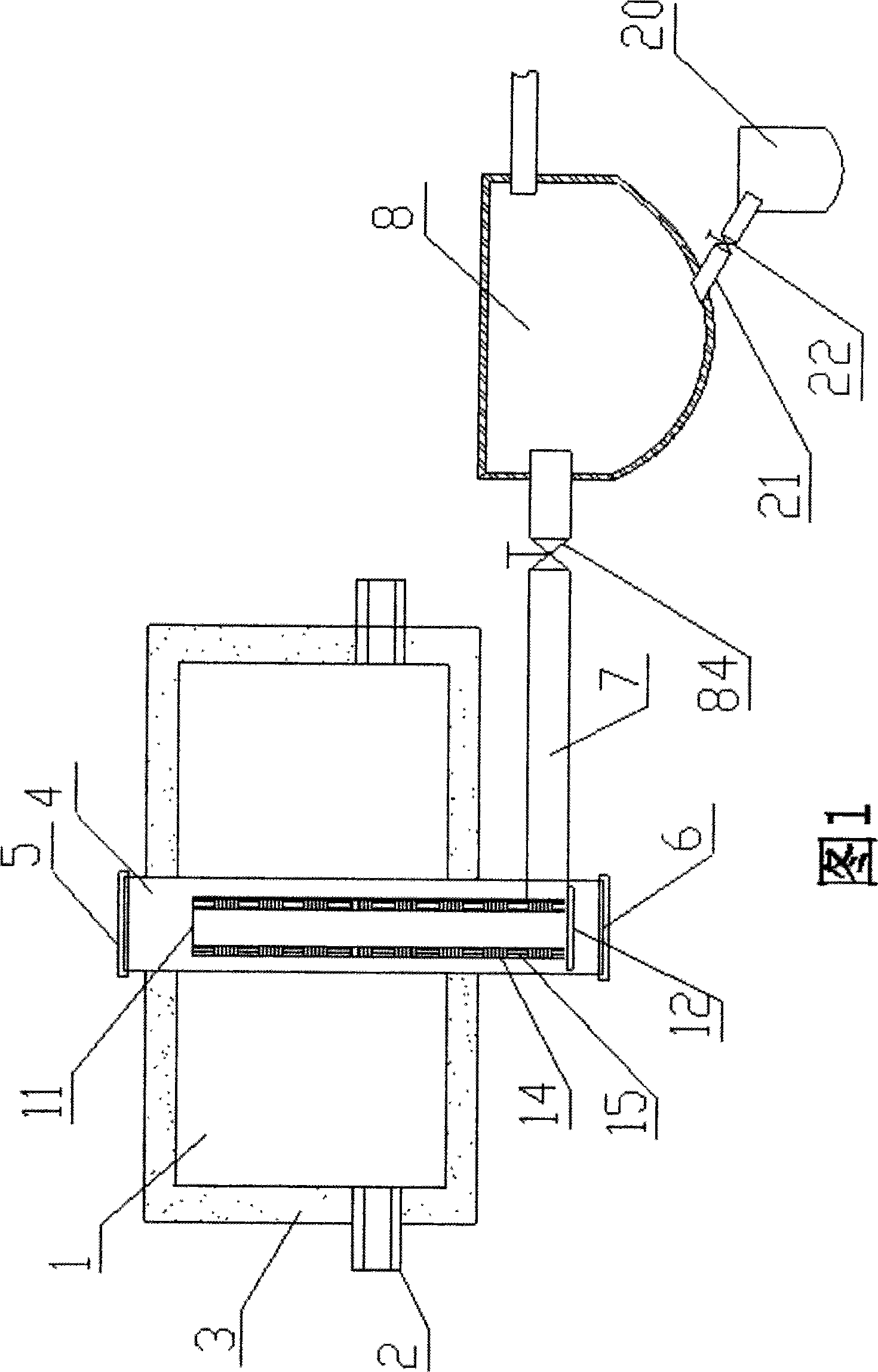

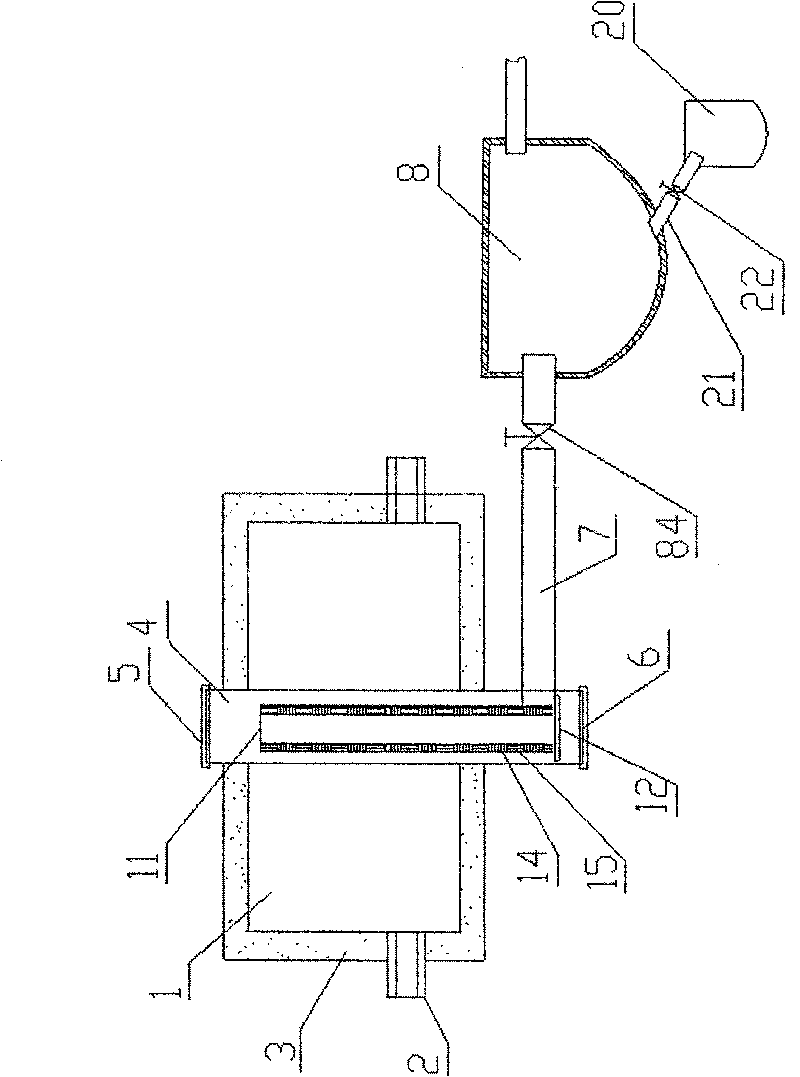

Method and device for semi-continuously producing acetyl tributyl citrate

ActiveCN105198739ARealize semi-continuous productionReduce labor intensityOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

The invention belongs to the technical field of rubber plasticizer production, and particularly relates to a method and device for semi-continuously producing acetyl tributyl citrate. The device comprises a reaction still. The reaction still is sequentially connected with a buffer tank, a first boosting pump, a heater, a deacidification tower, a condenser, a vacuum pump and a non-condensable gas tank through pipelines. The outer side of the reaction still is further connected with a tributyl citrate tank, an acetic anhydride feed device and a catalyst feed device. The condenser is connected with an acetic acid storage tank. The lower portion of the deacidification tower is provided with a reboiler which is sequentially connected with a raw ester tank, a second boosting pump and a continuous washing device. The method specifically includes the step that acetylated coarse products obtained in a reaction enter the continuous washing device to be washed after being flashed twice in the heater. The problems that in an existing process, yield is low, device utilization rate is low, and production process is cumbersome are solved; the device is simple in structure and easy to operate.

Owner:山东朗晖石油化学股份有限公司

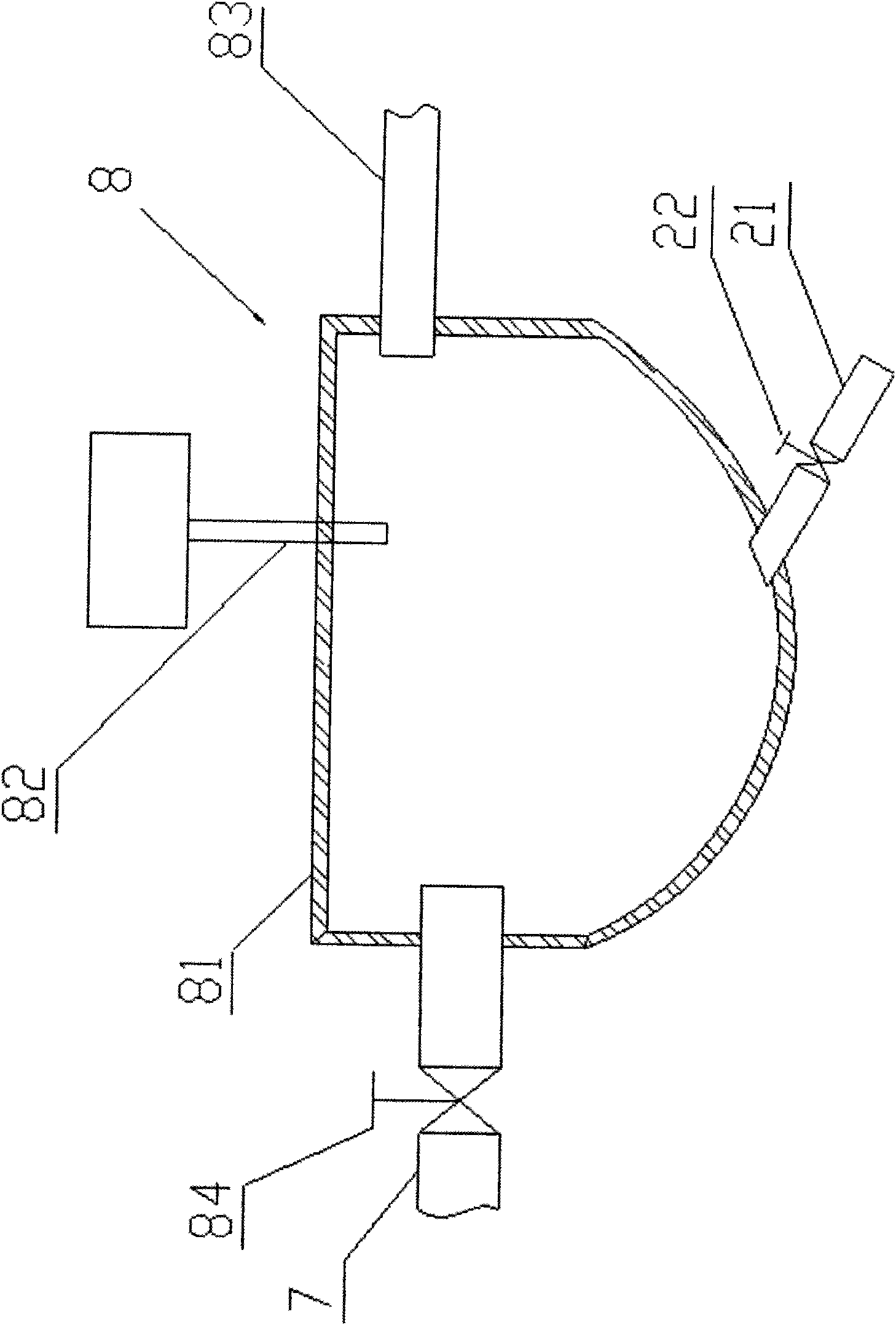

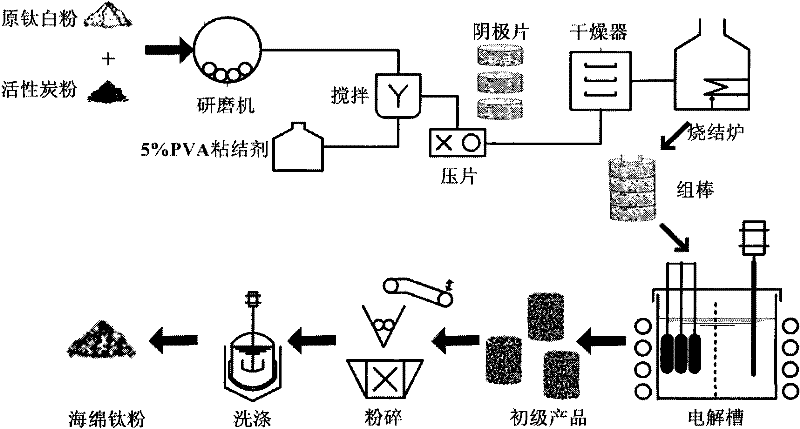

Semi-continuous production metal vacuum smelting reduction device

The invention relates to a semi-continuous production metal vacuum smelting reduction device which comprises a reduction tank that is communicated with a liquid state crystallizer arranged outside thereduction tank by a diversion device; the liquid state crystallizer comprises a crystallizer shell which is provided with a containing space, and is provided with a crystallizer heating control device used for controlling the temperature of the containing space and a crystallizer vacuum extractor used for controlling the vacuum degree of the containing space; and the crystallizer shell is also provided with an intermediate pipeline used for communicating a liquid state intermediate packet. The device can be used for realizing semi-continuous production of metal vacuum smelting, thus improvingthe production efficiency and reducing the production cost.

Owner:辛卫亚

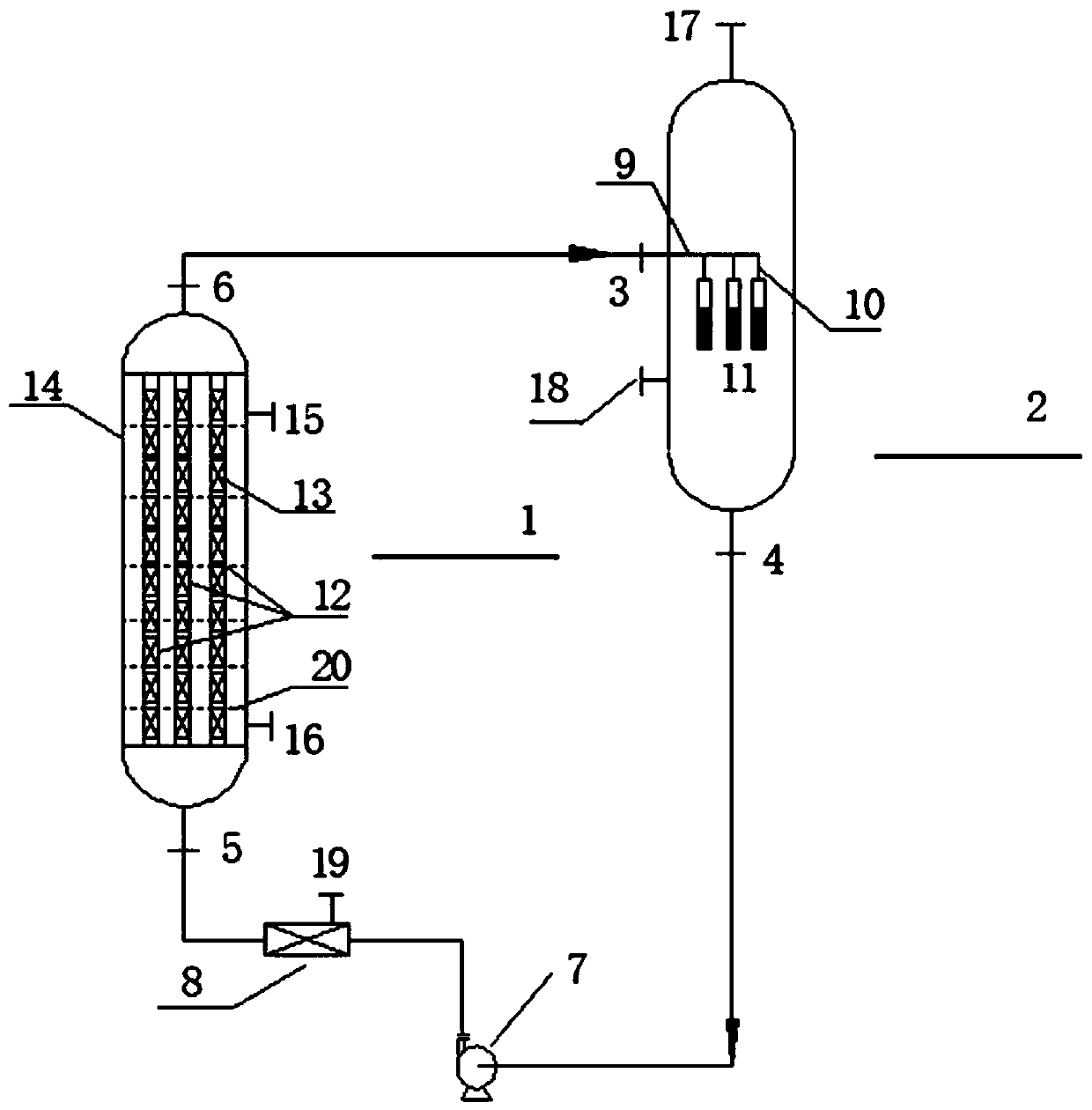

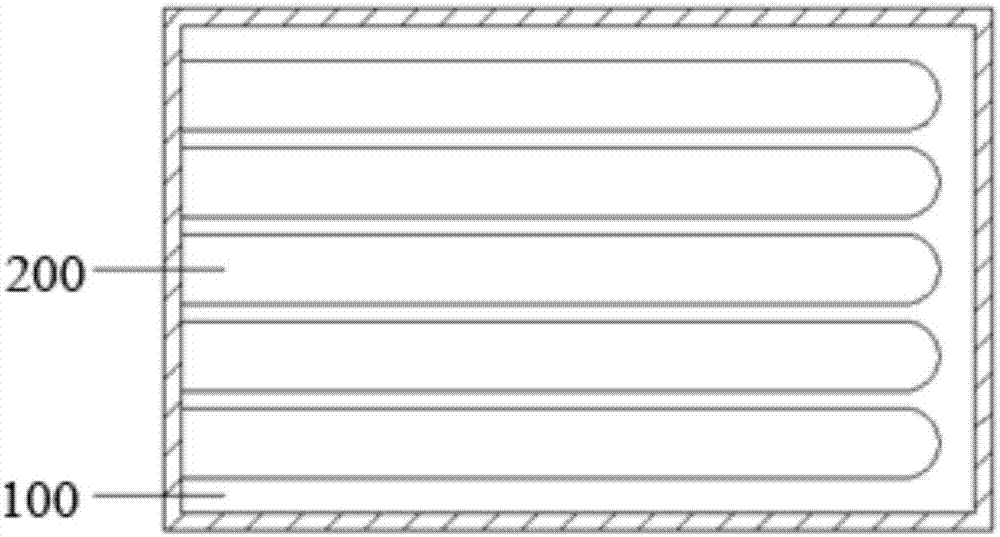

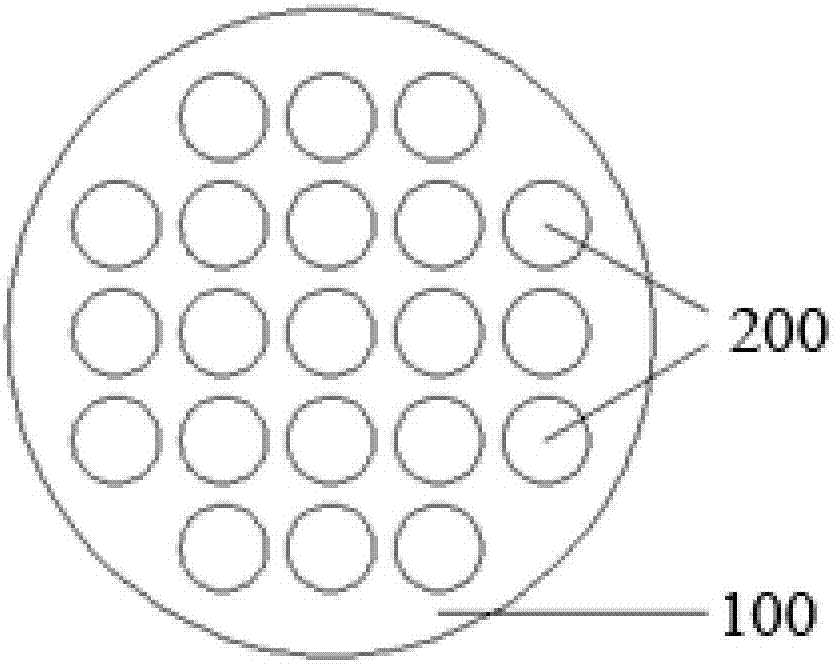

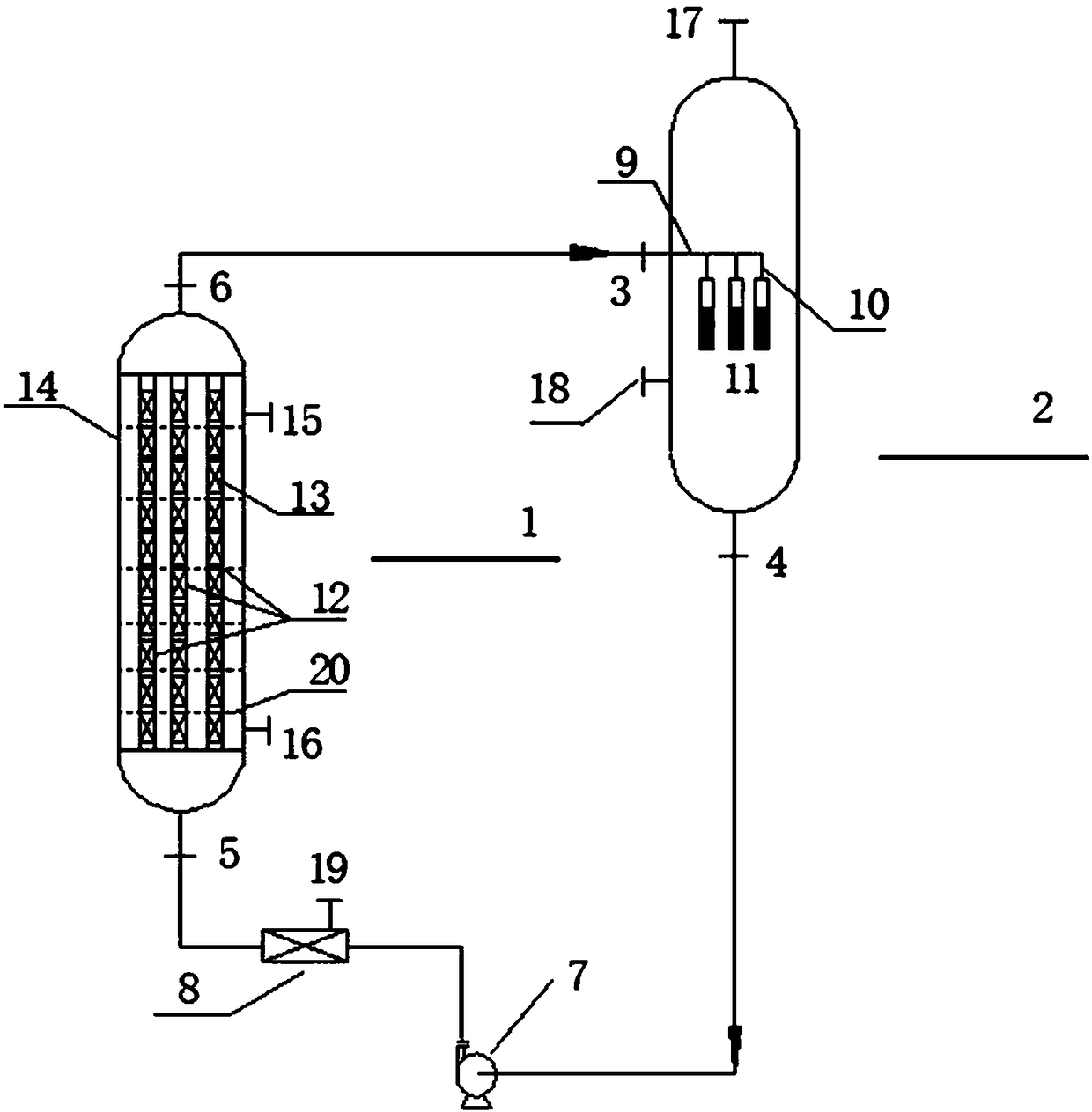

A production equipment for synthesizing low molecular weight polyphenylene ether

ActiveCN108371931BRealize semi-continuous productionHighly selective productionChemical/physical processesEtherPolyphenyl ether

A production apparatus for synthesizing low-molecular-weight polyphenylene ether. The production apparatus comprises a first reactor (1) and a second reactor (2), the first reactor (1) being a multi-tubular reactor, a first discharge port (6) on the first reactor (1) being connected to a second feed port (3) on the second reactor (2), and a second discharge port (4) on the second reactor (2) being connected to a first feed port (5) on the first reactor (1), the first reactor (1) and the second reactor (2) forming a circular reaction system.

Owner:上海载正化工科技发展有限公司

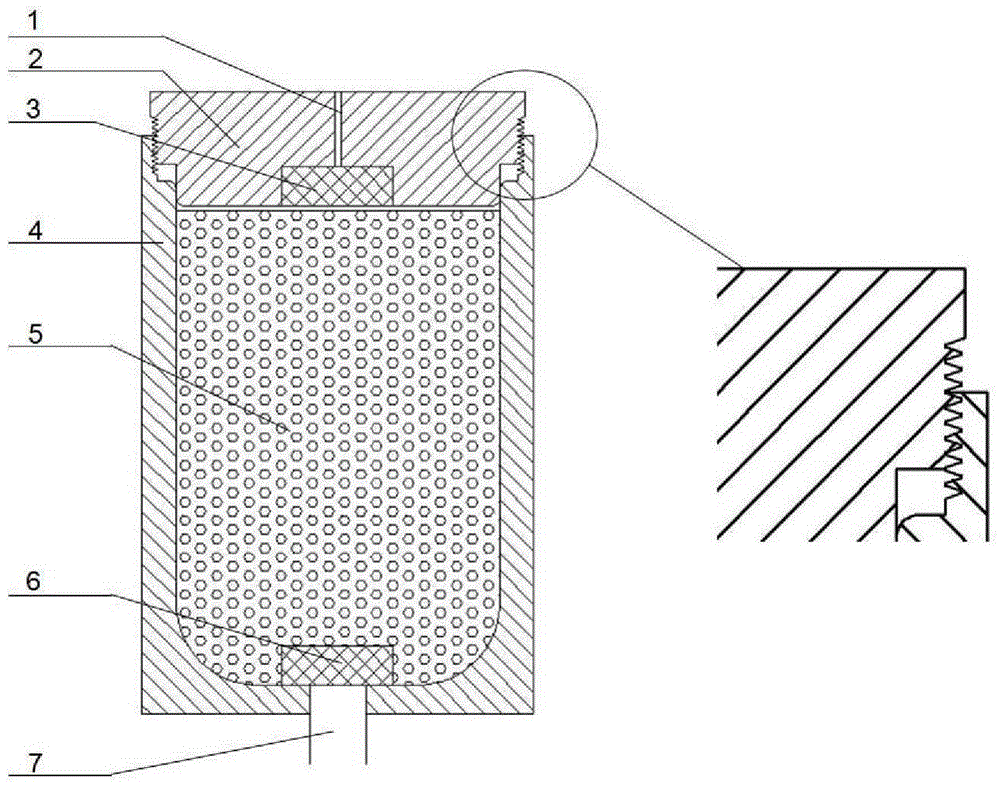

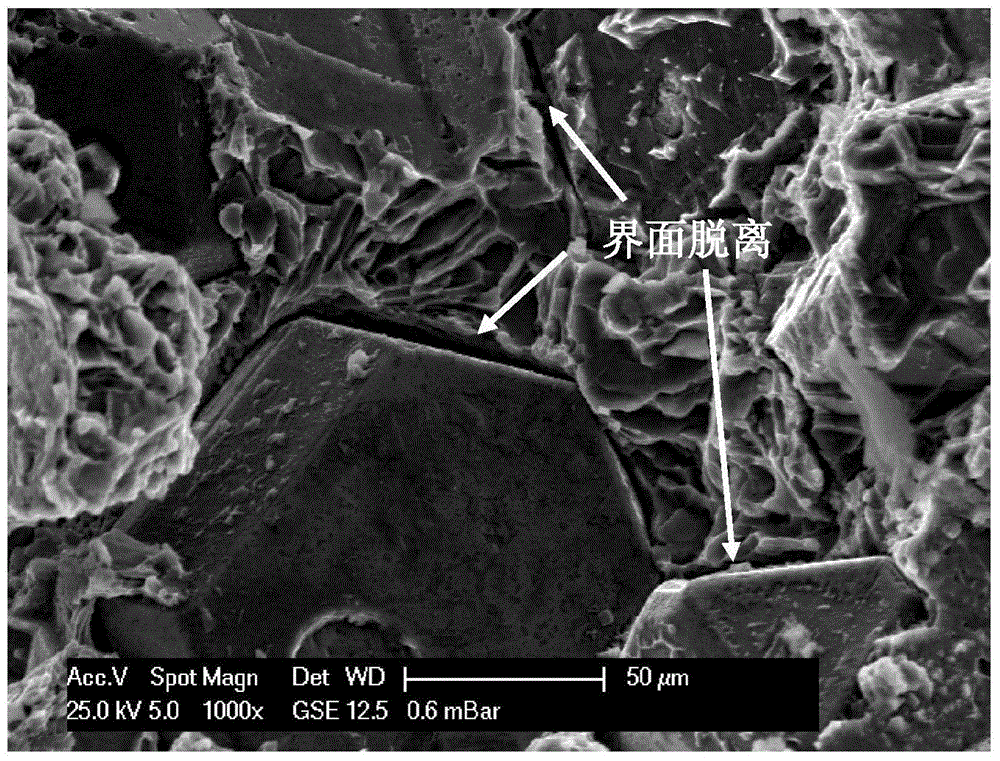

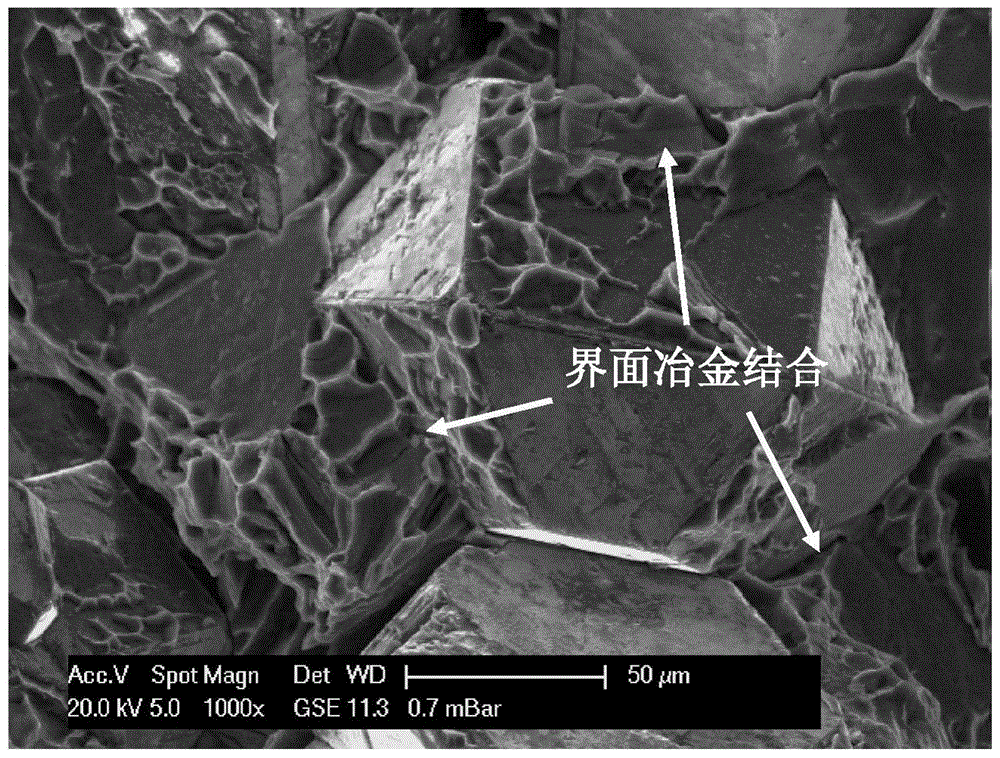

Method for producing steel/aluminum composite conductive pole

InactiveCN101494323AThe process is simpleHigh bonding strengthContact member manufacturingConnection contact member materialAluminum compositesPre treatment

The invention relates to a method for manufacturing a steel / aluminum composite conductive pillar, in particular to a method for obtaining the steel / aluminum composite conduction pillar through controlling the size of a steel head and processing the surface of the steel head with dip plating solution and finally utilizing liquid aluminum and solid steel. In the process of designing the steel head, area ratio of steel and aluminum of the same height on the steel / aluminum composite part is 1: (1.5 to 2.6); a strengthening rib is welded on the bottom of the steel head; surface pretreatments of degreasing, derusting and zirconium potassium fluoride water solution are carried out on a part of the steel head needing to be contacted with aluminum water before being poured with aluminum water; after the surface pretreatment, the steel head is heated for 25 to 35 minutes under temperature of 400 to 450 DEG C and the pouring temperature of the aluminum water is controlled within 750 to 800 DEG C; after the aluminum water is poured, cooling rate of an aluminum pole part is controlled within 10 to 40 DEG C / min to prevent aluminum from shrinking severely and avoid cracking of an interface. The method for manufacturing steel / aluminum composite conduction pillar can obviously improve bonding strength and service life of the steel / aluminum composite conduction pillar.

Owner:JIANGSU UNIV

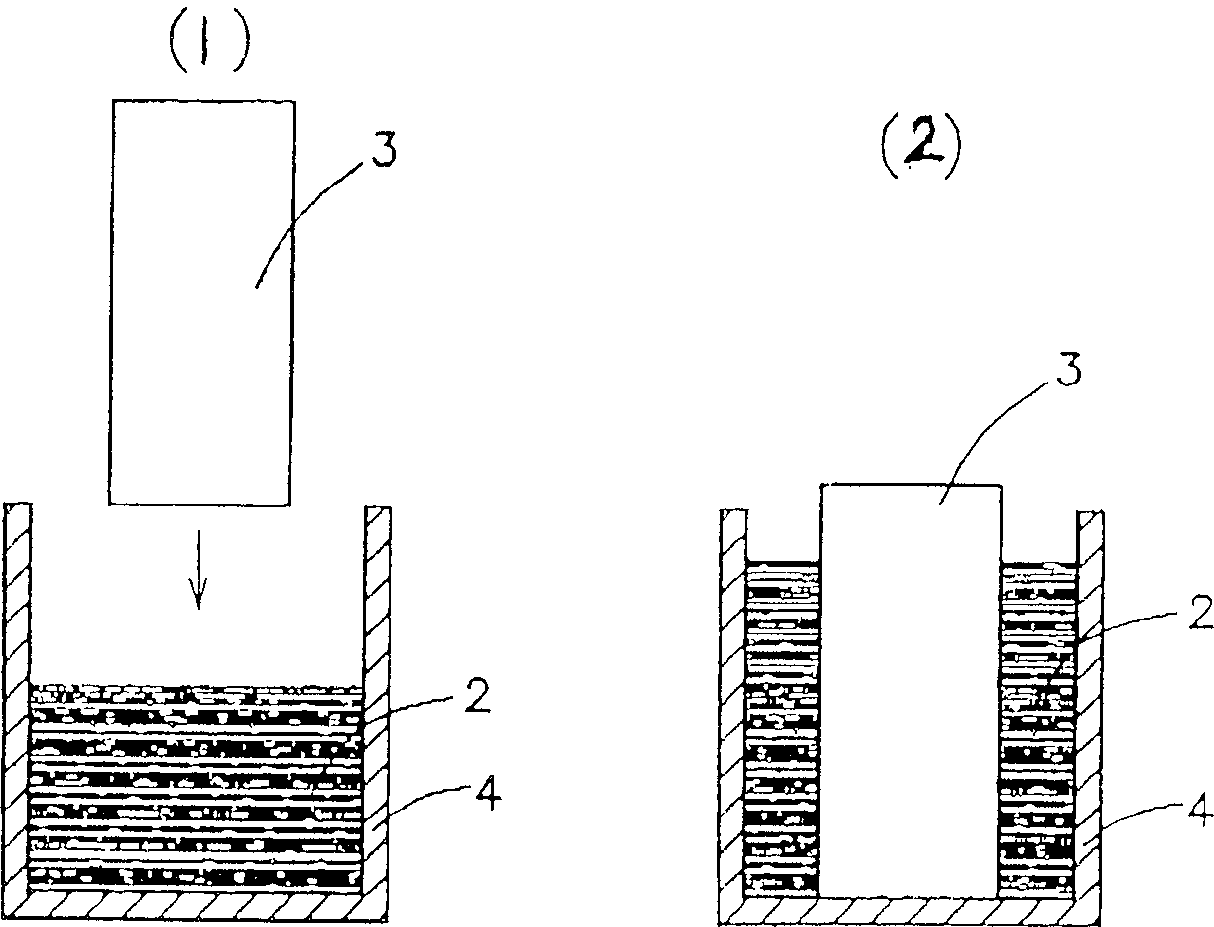

Semi-continuous production process for closed-cell foamed aluminum

The invention discloses a semi-continuous production process for closed-cell foamed aluminum. The semi-continuous production process comprises the following steps of assembling and preheating a composite mold, smelting a melt in a smelting furnace, quantitatively conveying the melt in the smelting furnace to a middle ladle by a vacuum lifting ladle, adding a tackifying component into the melt in the middle ladle, semi-continuously supplying the melt in the middle ladle into a transition crucible of the composite mold, adding a foaming agent into the transition crucible of the composite mold under stirring, separating the transition crucible in the composite mold from a filling mold, keeping the temperature of the filling mold into which the melt is filled and foaming, and cooling the filling mold in a fully-automatic cooling system after foaming is finished. The foamed aluminum can be semi-continuously produced, the labor intensity is reduced, a foamed aluminum product with super large specification can be also prepared, and furthermore, the consistency of the performance of the aluminum products can be effectively ensured.

Owner:CENT SOUTH UNIV

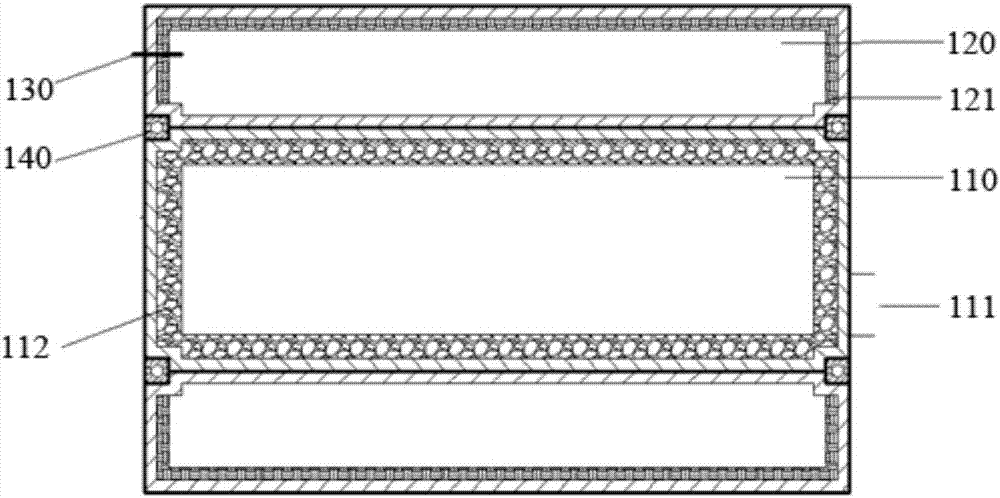

Horizontal gas system

PendingCN107965764AImprove convenienceUniform temperatureGaseous fuel burnerCombustion chamberEngineering

The invention discloses a horizontal gas system, which comprises a furnace body, a heat storage device, a rotary driving device, a condensing device and a vacuum device. The furnace body includes a reaction chamber and a combustion chamber, the heat storage device is connected with the combustion chamber of the furnace body, and the rotary driving device is connected with the reaction chamber of the furnace body. The condensing device is connected with the reaction chamber. The vacuum unit is connected to the condensing unit. The invention adopts a rotatable reaction chamber connected with a combustion chamber, which can make large batches of materials evenly heated, and improves the convenience of equipment operation. The connection between the condensation chamber and the reaction chamber can be cut off at any time, which enhances the sealing of the reaction chamber.

Owner:SHENWU TECH GRP CO LTD

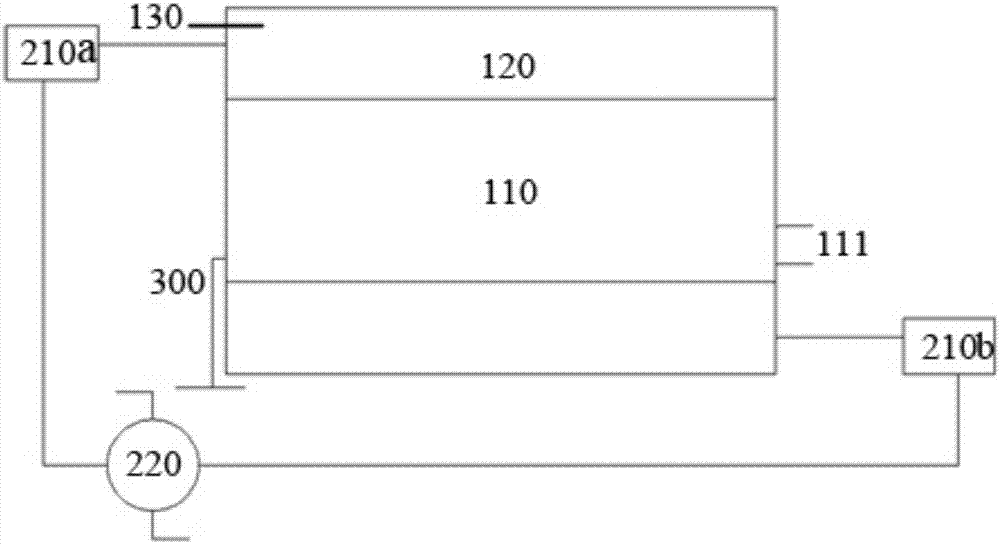

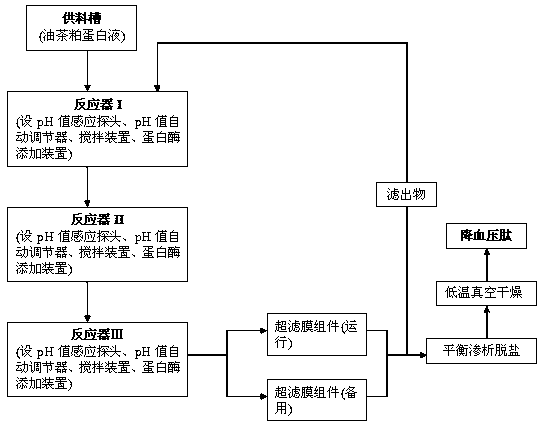

A semi-continuous preparation method of camellia oleifera meal protein hypotensive peptide

InactiveCN104450846BRealize semi-continuous productionExcellent hypotensive functional factorPeptide preparation methodsFermentationBiotechnologyPeristaltic pump

The invention relates to a semi-continuous preparation method of an antihypertensive peptide of an oil-tea meal protein. The preparation method comprises the following steps: (1) preparing an oil-tea meal protein liquid with mass concentration of oil-tea meal proteins being 2-6%; feeding the oil-tea meal protein liquid into a charging tank and continuously supplementing the oil-tea meal protein liquid to a reactor by using a peristaltic pump; (2) enabling the oil-tea meal protein liquid obtained to sequentially pass through reactors I, II and III filled with protease, wherein each reactor region is provided with a pH value induction probe and an automatic pH value adjustor; (3) carrying out ultra-filtration; (4) feeding the filtrate obtained by ultra-filtration into a collecting tank; (5) desalting; and (6) drying to obtain the antihypertensive peptide. By adopting the preparation method provided by the invention, the antihypertensive peptide of the oil-tea meal protein can be semi-continuously prepared and the ash content of the prepared antihypertensive peptide of the oil-tea meal protein is smaller than 1.0%, the protein recovery rate is 93.0% and the ACE inhibition rate is greater than 94.0%. The antihypertensive peptide of the oil-tea meal protein has a remarkable blood-pressure-reducing effect on a rat with primary hypertension.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

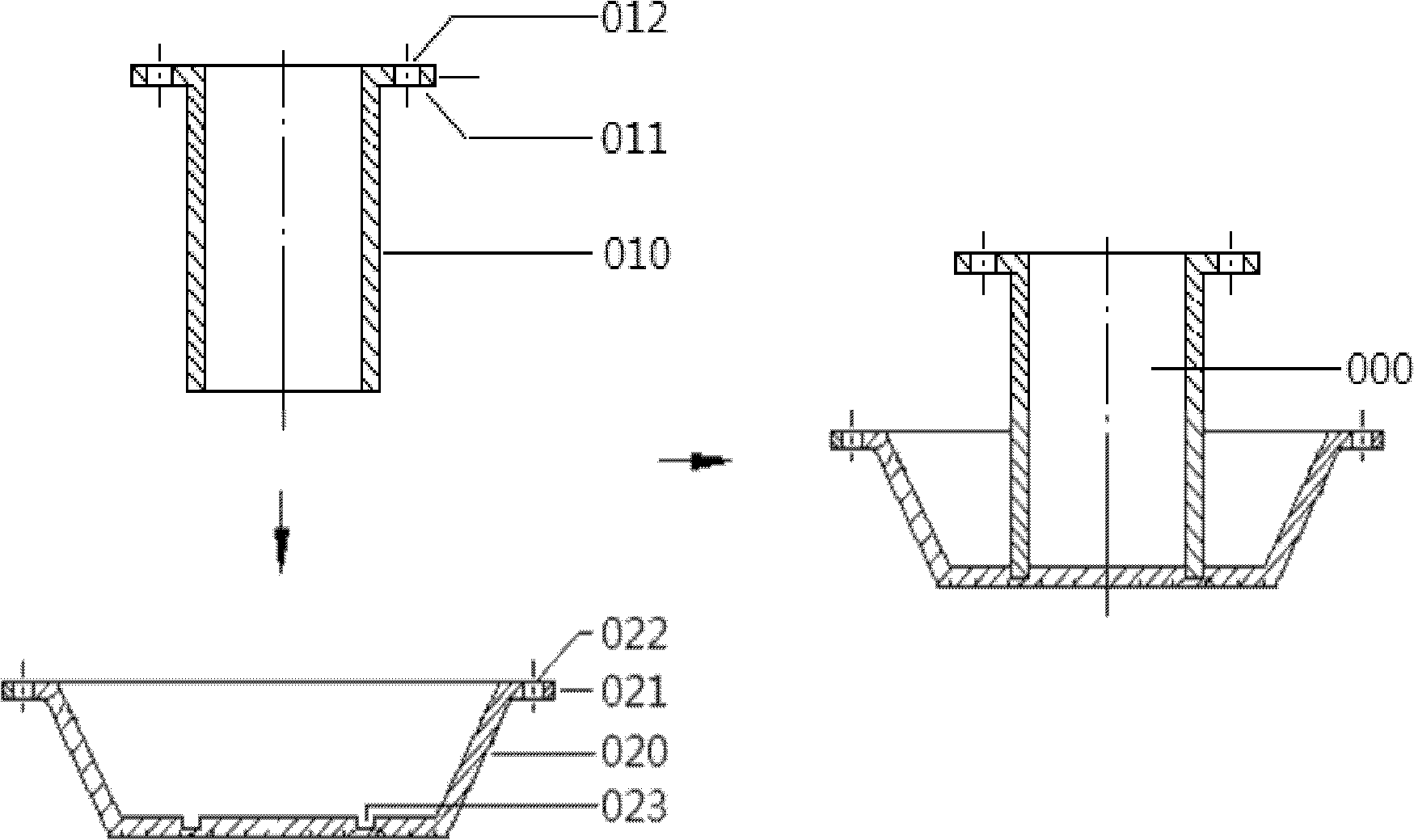

Liquid tundish

The invention provides a liquid pouring basket, comprising a pouring basket body, wherein the pouring basket body is provided inside with a receiving space communicated with a liquid crystallizer; the pouring basket body is provided with a pouring basket heating control device and a pouring basket vacuum extractor; the pouring basket heating control device can keep the temperature in the receiving space of the liquid pouring basket within the preset range, and the pouring basket vacuum extractor can make receiving space of the liquid pouring basket keep the preset vacuum degree; the pouring basket body is also provided with a liquid outlet used for discharging liquids. The liquid pouring basket has the advantages of realizing the semi continuous production of metal vacuum metallurgy, improving production efficiency and lowering production cost.

Owner:QINGDAO MODERN BOILER

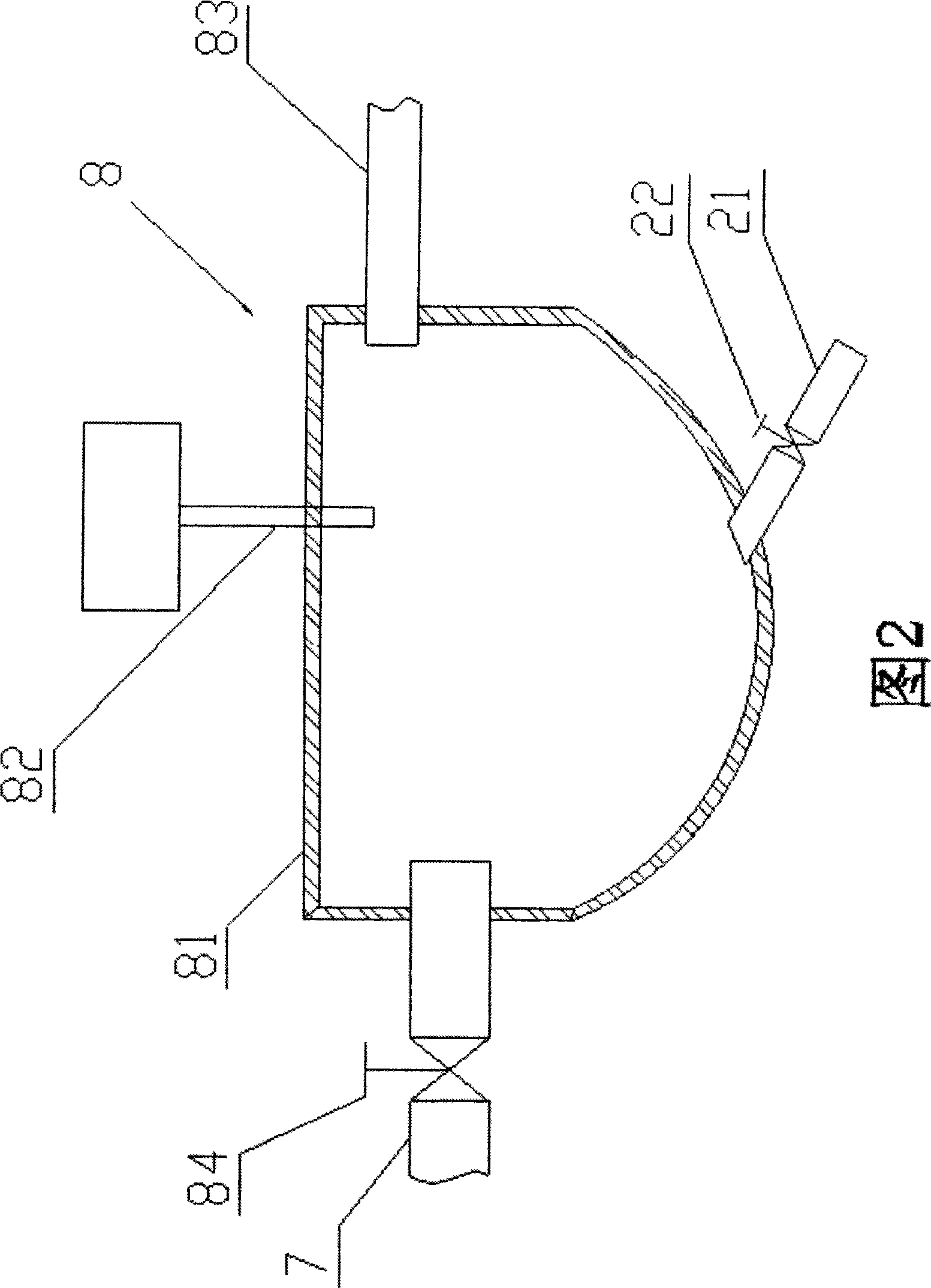

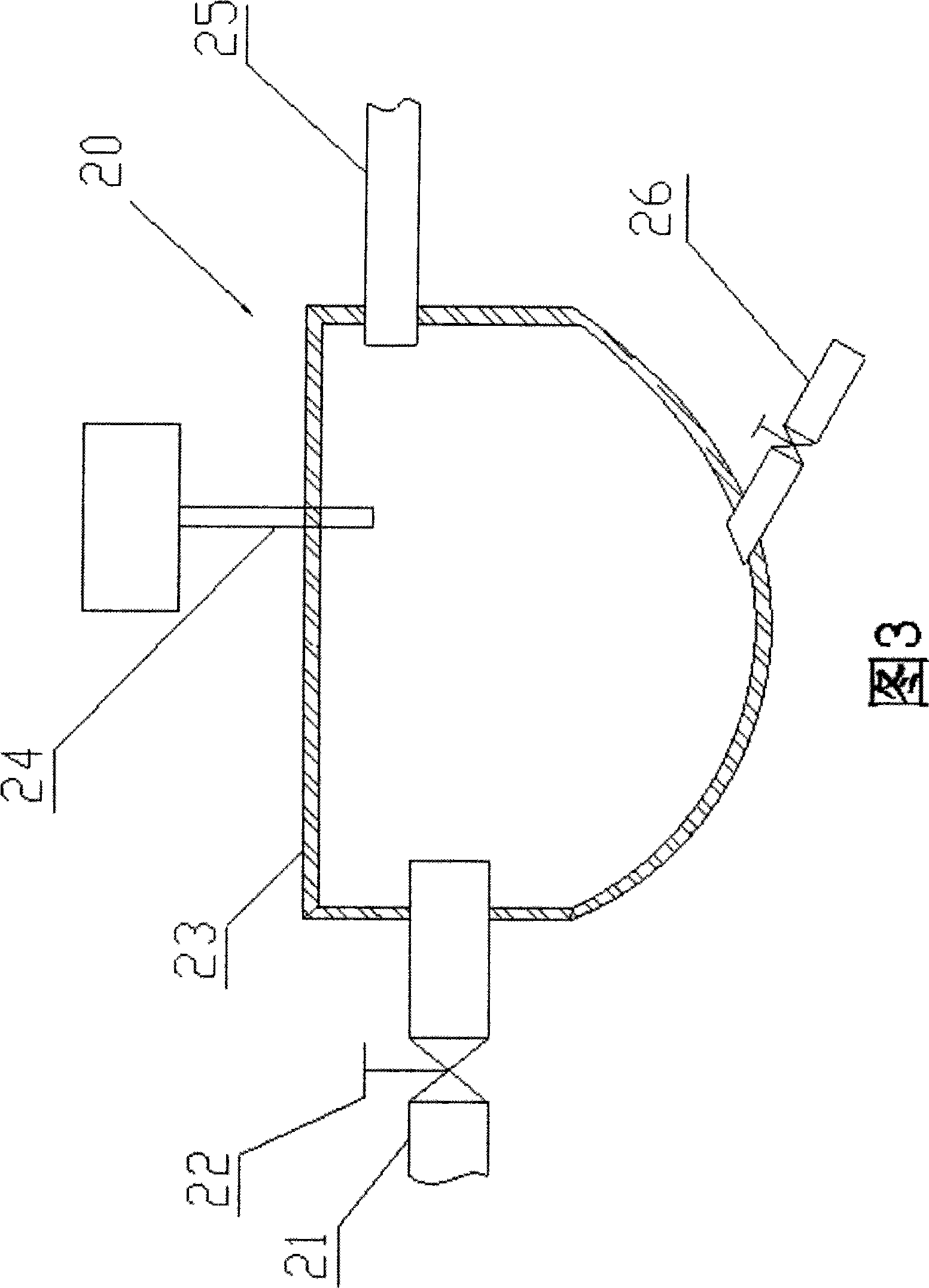

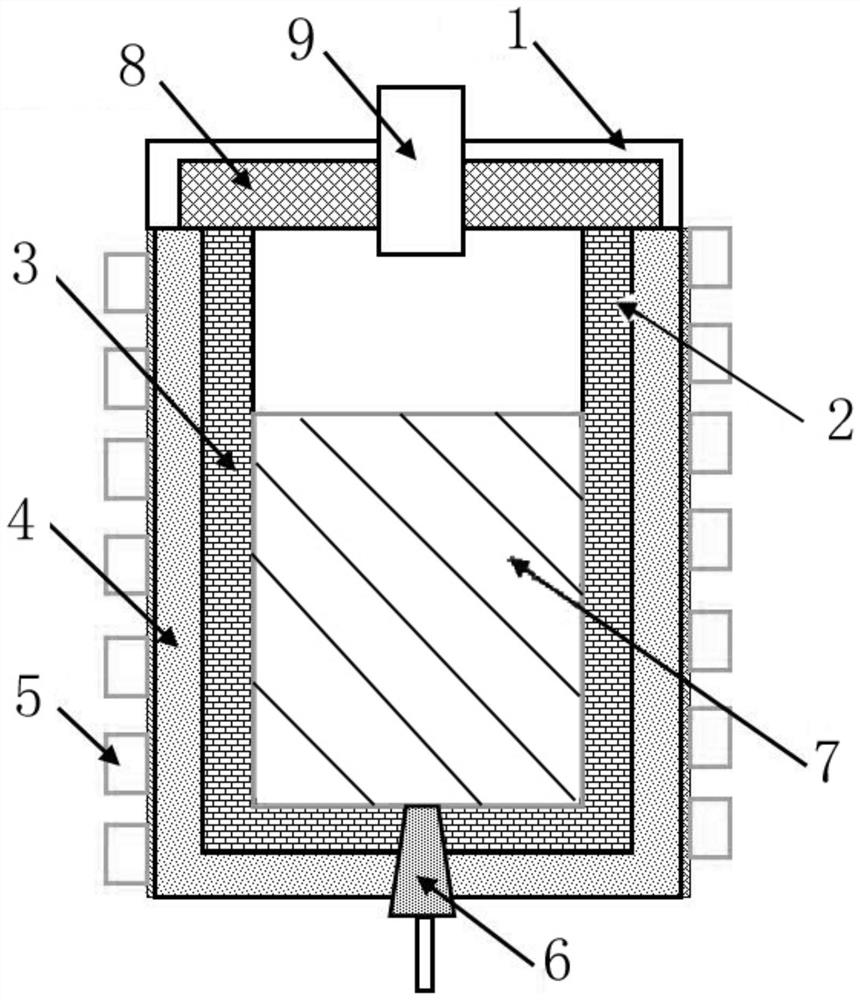

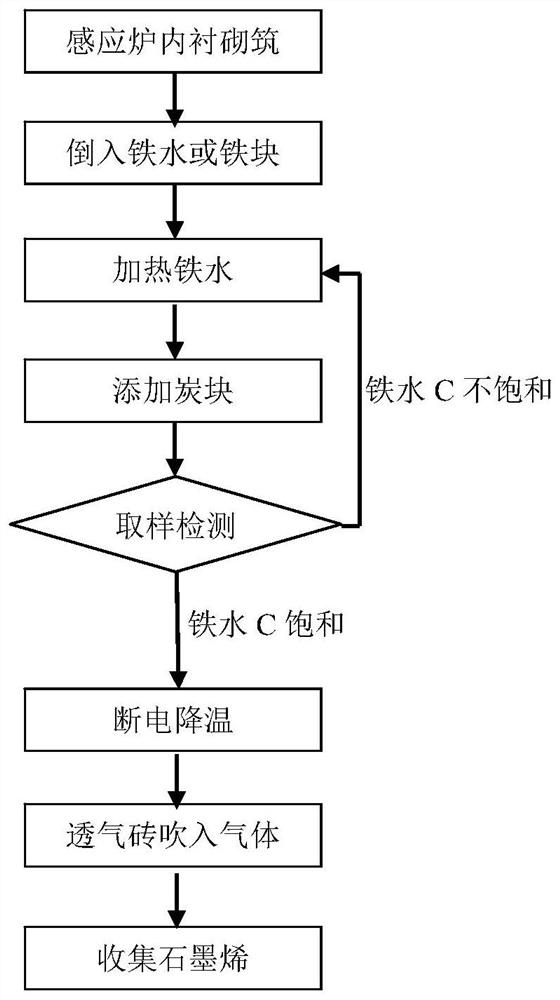

Graphene production device and method

The invention provides a graphene production device and method.The device comprises a furnace cover and an electric induction furnace, the electric induction furnace comprises a furnace body and an induction coil copper pipe, the furnace body is made of furnace lining ramming materials, the induction coil copper pipe surrounds the outer side of the furnace body, and high-purity carbon bricks are built on the inner wall of a hearth of the electric induction furnace. Air bricks are arranged at the bottom of the furnace body, and a collecting pipeline is arranged on the furnace cover. According to the graphene production device and method, semi-continuous production of graphene can be achieved, and the prepared graphene is directly blown out through inert gas, easy to collect and convenient to transfer.

Owner:岫岩满族自治县恒锐镁制品有限公司

Electrolytic cell in electro-deoxidization metallurgy process

InactiveCN101701345BEliminate disadvantagesIncrease production capacityDiaphragmsElectricityMolten salt

The invention discloses an electrolytic cell in electro-deoxidization metallurgy process, which is divided into a negative electrode region and a positive electrode region, which have the effect of isolating the flow of fused salts while achieving free exchange of ions, thus suppressing the occurrence of side reaction of positive and negative electrode products; the positive electrode in the electrolytic cell is rotated to accelerate the deoxidization speed and simultaneously, the emission of tail gas in the positive electrode region is quickened up in a manner of oriented-circulating protective gas stream in order to avoid overhigh content of the tail gas within the electrolytic cell; the electrodes of the electrolytic cell are changed into be arrayed in parallel, which breaks the limitation of traditional single electrode, the negative electrode and the positive electrode correspondingly form counter electrodes so as to polarize the electro-deoxidization task of the electrodes. The parallel-type electrodes can also adjust the array number of the counter electrodes according to requirement so as to change production ability without more improvements on equipment and production conditions, and to guarantee product quality as well. The electrolytic cell according to the invention has large production ability and short production period and is capable of realizing semi-continuous product.

Owner:UNIV OF SCI & TECH BEIJING

Liquid crystallizer

The invention relates to a liquid crystallizer, which comprises a crystallizer shell body which is provided with containing space. The containing space communicates with a reduction pot through a flow guide device; a heating control device of the crystallizer for controlling the temperature of the containing space and a vacuum extractor of the crystallizer for controlling the vacuum degree of thecontaining space are arranged on the liquid crystallizer; an intermediate pipeline is also arranged on the crystallizer shell body and used for communicating with a liquid pouring box. By using the liquid crystallizer, the semi-continuous production for metal vacuum smelting can be realized, the productivity effect is increased, and the manufacturing cost is lowered.

Owner:辛卫亚

Fuel gas type equipment

PendingCN107965766AHeating evenlyRealize semi-continuous productionGaseous fuel burnerCombustion chamberFlue gas

The invention discloses a gas type equipment, which comprises a combustion chamber and a reaction chamber, and the reaction chamber is detachably arranged in the combustion chamber. The equipment of the present invention can increase the number of reaction chambers and combustion chambers according to the amount of materials to be processed, and all reaction chambers can share one combustion chamber for heating, and only need to increase the number of burners and flue gas pipes to achieve uniform heating Purpose.

Owner:SHENWU TECH GRP CO LTD

A method for preparing diamond-al composite material by extrusion impregnation

Owner:SOUTHEAST UNIV

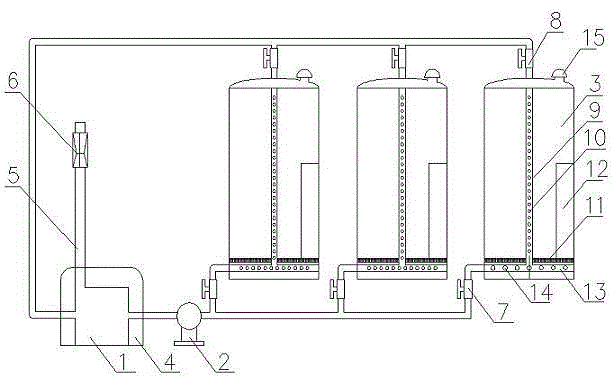

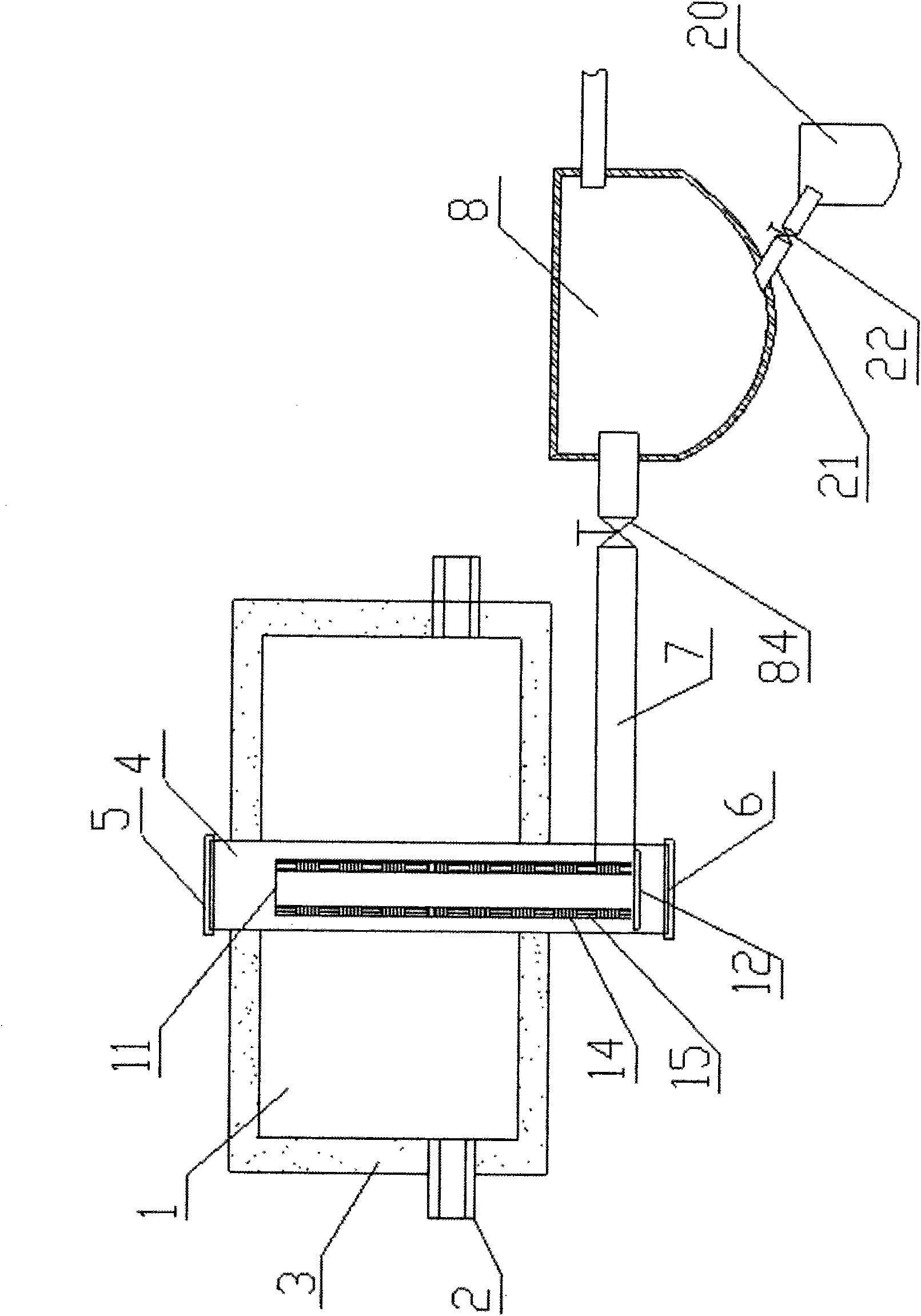

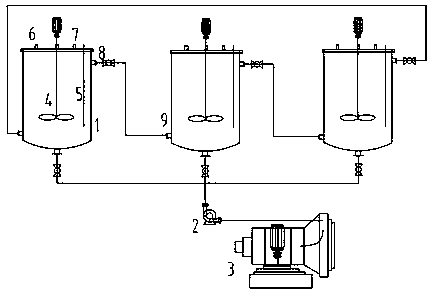

A kind of production device and technology of nickel-cobalt-manganese ternary hydroxide

ActiveCN107986338BRealize semi-continuous productionReduce energy consumptionNickel compoundsPhysical chemistryManganese

The invention discloses a production device and technology of nickel-cobalt-manganese hydroxide. The production device mainly comprises closed vessel type reaction kettles, a discharging pump, a centrifugal machine and a connecting pipeline, an overflow hole is formed in the side wall of the upper part of each reaction kettle, a feeding hole is formed in the side wall of the lower part of each reaction kettle, and the overflow hole of each reaction kettle is connected with the feeding holes of other reaction kettles by virtue of pipelines. In the technology, overflow of the previous reaction kettle is taken as base solution of the next reaction kettle, ageing is carried out in the next reaction kettle, before continuous precipitation, an ageing process promotes wear off of large crystals in the base solution and growth of small crystal particles in the base solution, crystal particles begin to grow after overall tending to be uniform. Each reaction kettle of the production device of nickel-cobalt-manganese hydroxide has two functions, namely precipitation synthesis and ageing, each reaction kettle can overflow to other two reaction kettles, the overflow is aged and then is subjected to parallel flow precipitation and synthesis, and the production device of nickel-cobalt-manganese hydroxide has the advantages that end point granularity can be easily controlled and product size distribution is narrow.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

Production device for synthesizing small-molecular-weight polyphenyl ether

ActiveCN108371931ARealize semi-continuous productionHighly selective productionChemical/physical processesProcess engineeringPolyphenyl ether

The invention discloses a production device for synthesizing small-molecular-weight polyphenyl ether. The production device comprises a first reactor and a second reactor, the first reactor is a tubular reactor, a first discharging port in the first reactor is connected with a second feeding port of the second reactor, a second discharging port of the second reactor is connected with a first feeding port in the first reactor, and the first reactor and the second reactor form a circular reaction system.

Owner:上海载正化工科技发展有限公司

Semi-continuous metallothermic reduction process

The invention provides a method for semi continuous metallothermic reduction. In the method, a reduction pot is communicated with a liquid crystallizer arranged outside the reduction pot by a diversion device, therefore metal steams in the reduction pot enter the liquid crystallizer through the diversion device and are converted to liquid state and kept as the liquid state; liquid metal in the liquid crystallizer periodically and quantificationally flows into liquid pouring baskets; when a liquid pouring basket is filled up, another liquid pouring basket replaces the original liquid pouring basket to connect the liquid crystallizer so as to continuously collecting the liquid metal in the liquid crystallizer; after complete separation of the metal in the reduction pot, slag is removed, andnew palletized feed stock is put in the reduction pot for starting a new reduction. The method has the advantages of realizing the semi continuous production of metal vacuum metallurgy, improving production efficiency and lowering production cost.

Owner:辛卫亚

Semi-continuous production metal vacuum smelting reduction device

The invention relates to a semi-continuous production metal vacuum smelting reduction device which comprises a reduction tank that is communicated with a liquid state crystallizer arranged outside the reduction tank by a diversion device; the liquid state crystallizer comprises a crystallizer shell which is provided with a containing space, and is provided with a crystallizer heating control device used for controlling the temperature of the containing space and a crystallizer vacuum extractor used for controlling the vacuum degree of the containing space; and the crystallizer shell is also provided with an intermediate pipeline used for communicating a liquid state intermediate packet. The device can be used for realizing semi-continuous production of metal vacuum smelting, thus improving the production efficiency and reducing the production cost.

Owner:辛卫亚

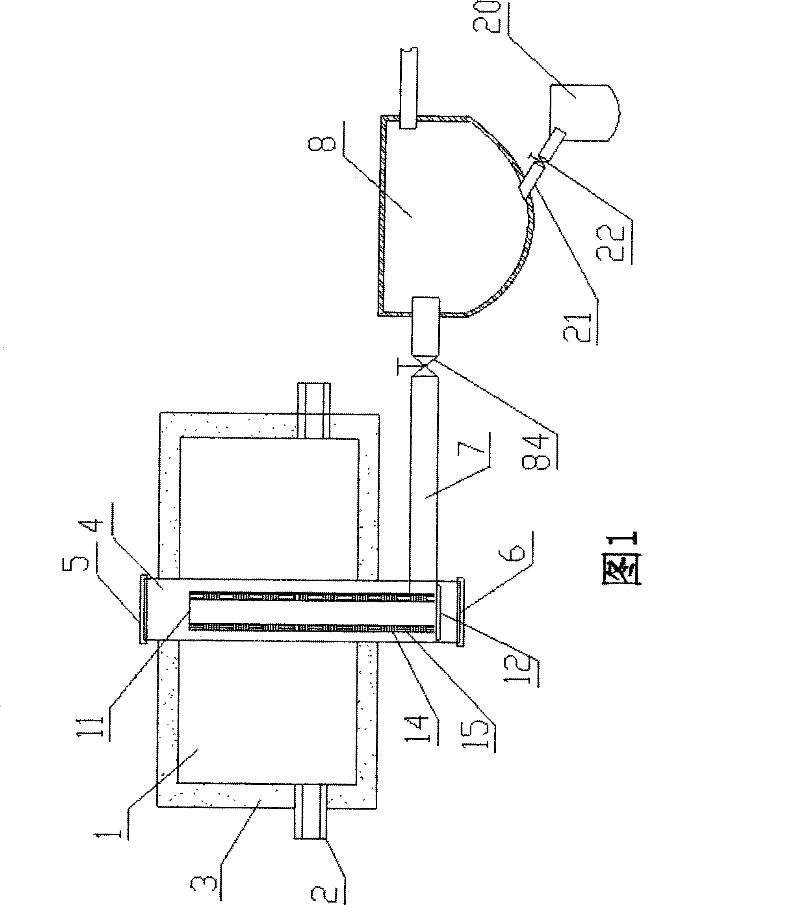

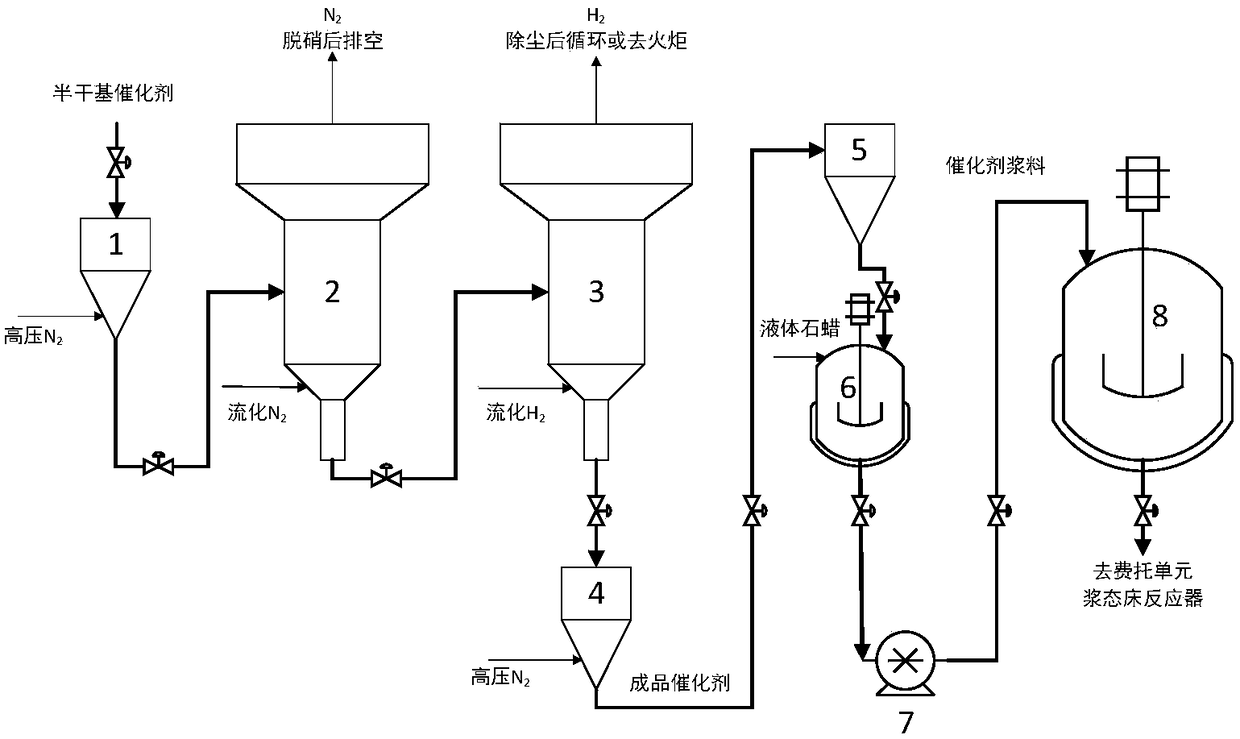

Industrial roasting reduction method of cobalt-based slurry bed Fischer-Tropsch synthesis catalyst supported on activated carbon

PendingCN109420500AIncrease productivityImprove product qualityCatalyst activation/preparationLiquid hydrocarbon mixture productionActivated carbonFluidized bed

The invention relates to an industrial roasting reduction method of a cobalt-based slurry bed Fischer-Tropsch synthesis catalyst supported on activated carbon, which is independent of a Fischer-Tropsch synthesis process and belongs to a key link in a catalyst production process. The process is divided into three steps: catalyst calcination, catalyst reduction and catalyst slurry preparation, whichare carried out in two fluidized bed reactors or fixed bed reactors and one stirring kettle respectively. Typical operating conditions are that the fluidized bed temperature is 20-500 DEG C, the pressure is 1-200 kPa, the gas volume space velocity is 100-2000h<-1>, the empty tower gas velocity is 0.02-1m / s. 2-10 tons of semi-dry-based catalyst is processed per batch to give 1-8 tons of finished catalyst. The method can be used to control and optimize the above three steps respectively, which is beneficial to synthesize catalyst products with superior performance. Particularly, the semi-continuous production can be realized by the method, which is helpful to improve the production efficiency and reduce the cost of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

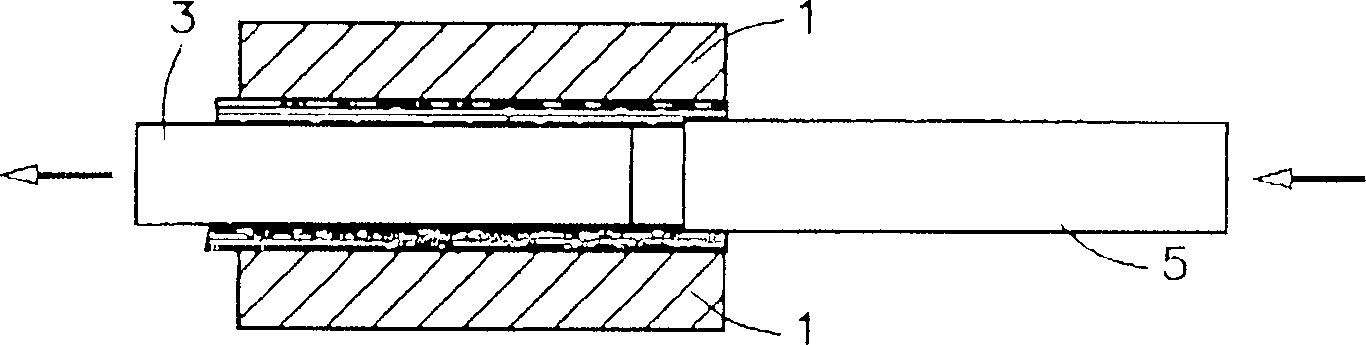

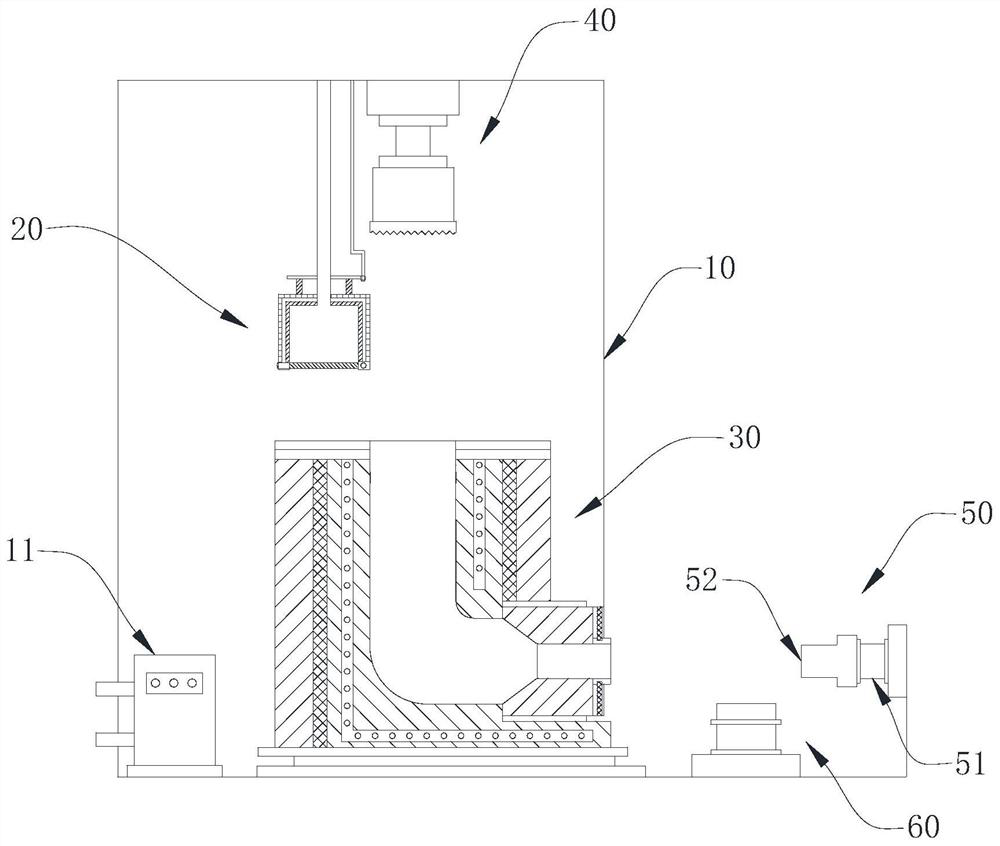

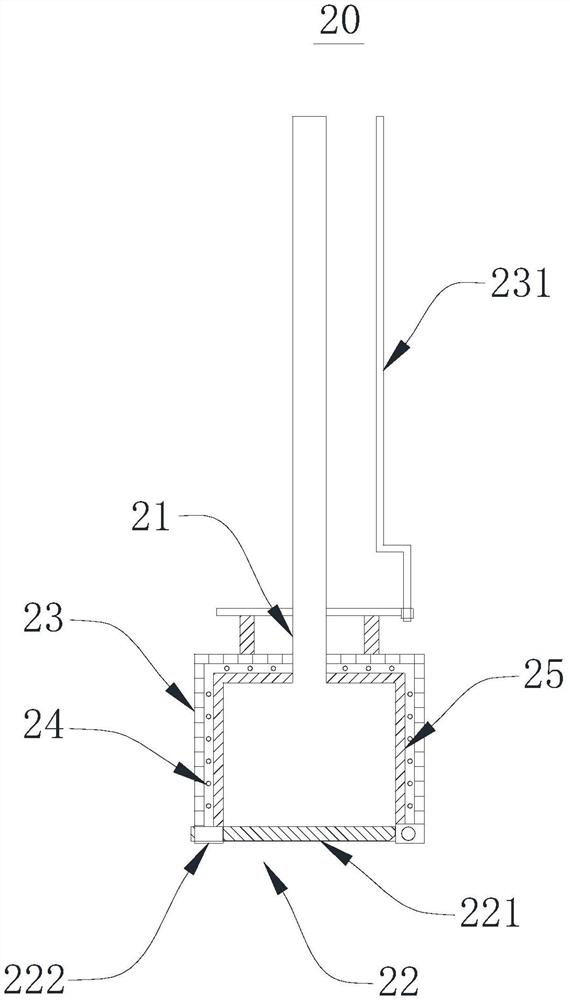

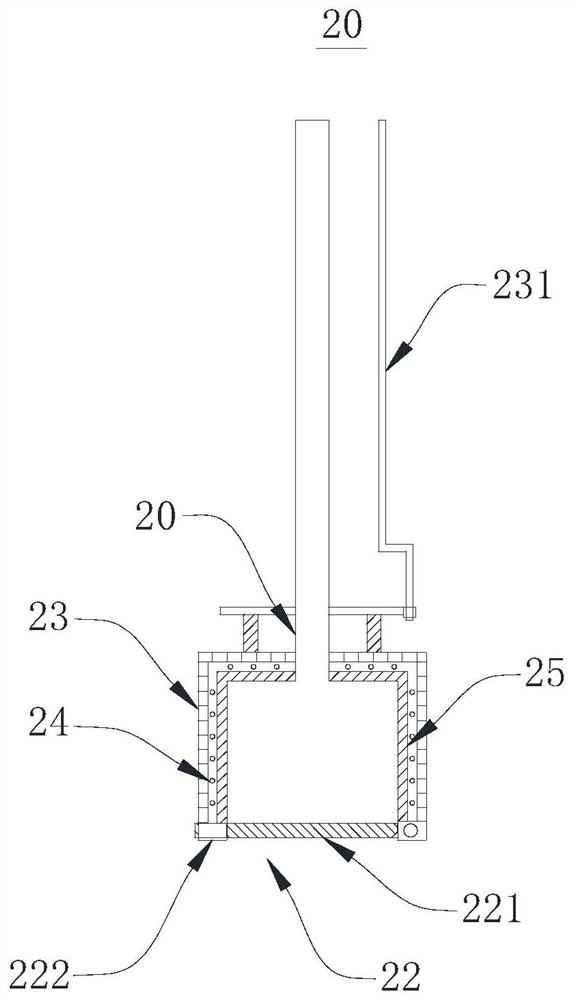

Device for preparing high-strength alloy through semi-continuous extrusion of metal powder and preparation process

ActiveCN113828777AAchieve large sizeSimple structureIncreasing energy efficiencyMetallic materialsIngot

The invention discloses a device for preparing a high-strength alloy through semi-continuous extrusion of metal powder and a preparation process, and belongs to the technical field of metal material forming machining. The device comprises a preparation bin, a heat preservation device, a forming device, an extrusion device, a pre-jacking device and a cutting device, wherein the heat preservation device, the forming device and the extrusion device are arranged in the preparation bin, and the pre-jacking device and the cutting device are arranged outside the preparation bin; and after being subjected to heat preservation in the heat preservation device, metal powder is heated by the forming device, extruded by the extrusion device, pre-jacked by the pre-jacking device and cut by the cutting device, and finally a high-strength alloy ingot or profile is formed. Compared with a traditional production mode of the high-strength alloy, the technologies of powder metallurgy, warm pressing forming, warm extrusion, plastic rheological shearing and the like are combined, the defects of a traditional production technology of the high-strength alloy are overcome, and large-size and semi-continuous production of the high-strength alloy can be achieved.

Owner:四川科匠轻金属材料科技有限公司

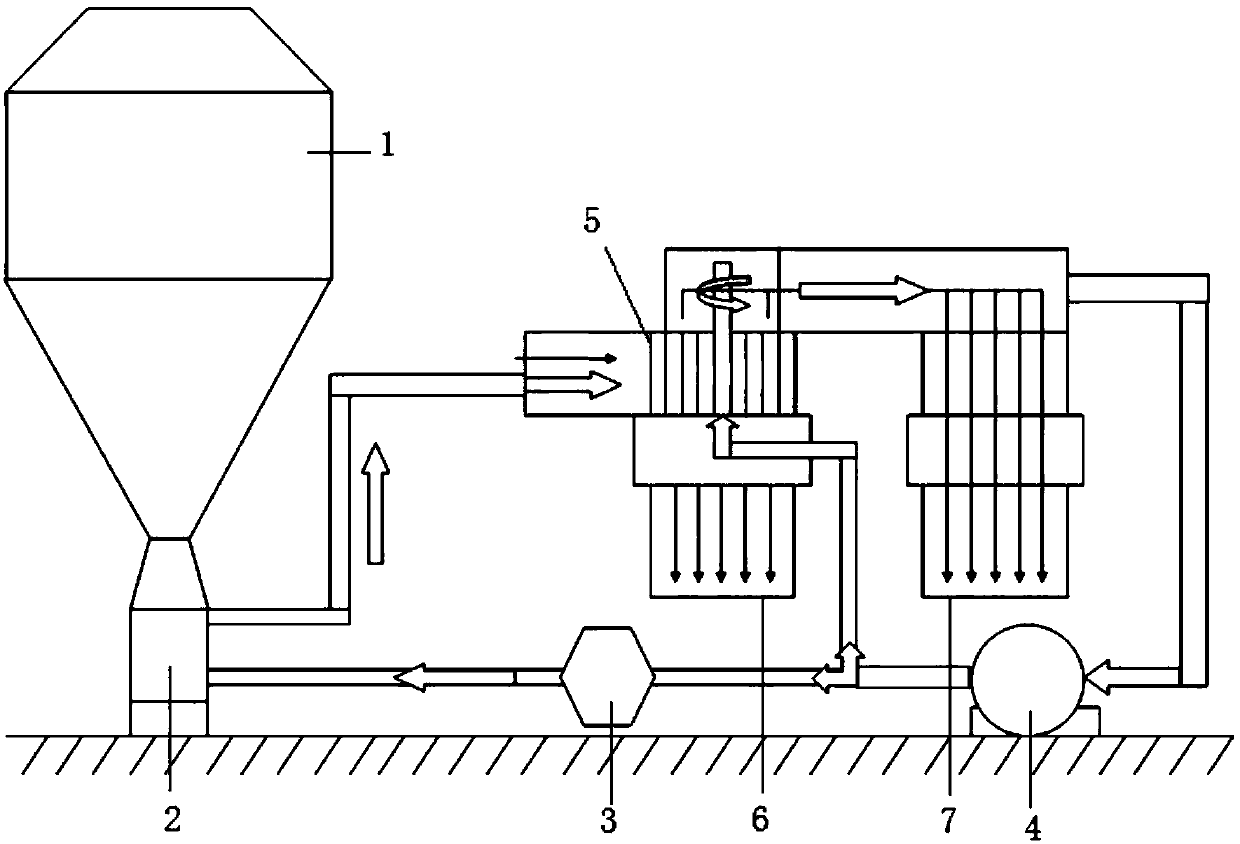

smt produces airflow delivery device with tin-based spherical solder powder

The invention discloses an airflow conveying device for producing tin-based spherical solder powder for SMT, which comprises a centrifugal atomization chamber, a cyclone conveyor is arranged at the lower part of the centrifugal atomization chamber, and the cyclone conveyor passes through a feed inlet provided at the upper end and the centrifugal atomization chamber The lower part is connected, the side of the cyclone conveyor is provided with an air inlet, and the upper part of the cyclone conveyor is also provided with a discharge port; the air outlet of the centrifugal blower is divided into two paths, and one path is connected to the cooler and the air inlet of the cyclone conveyor in turn through the pipeline , the other way communicates with the upper part of the coarse powder collection chamber through the pipeline, the top of the coarse powder collection chamber is equipped with a classifying impeller, the discharge port of the cyclone conveyor is connected with the side of the classifying impeller through the pipe, and the output end of the classifying impeller communicates with the fine powder collecting chamber through the pipe , The fine powder collection chamber is provided with an air outlet connected to the air inlet of the centrifugal blower. Solve the problem of dust escaping caused by powder handling in the process of welding powder production, and the temperature rise of centrifugal atomized powder in the transfer barrel to change its microstructure and properties.

Owner:云南锡业新材料有限公司

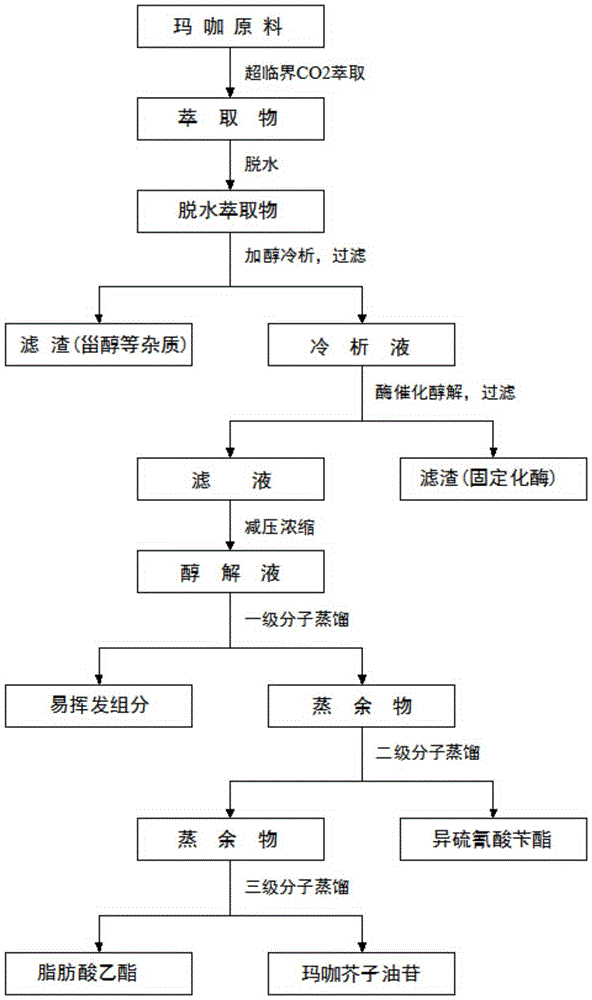

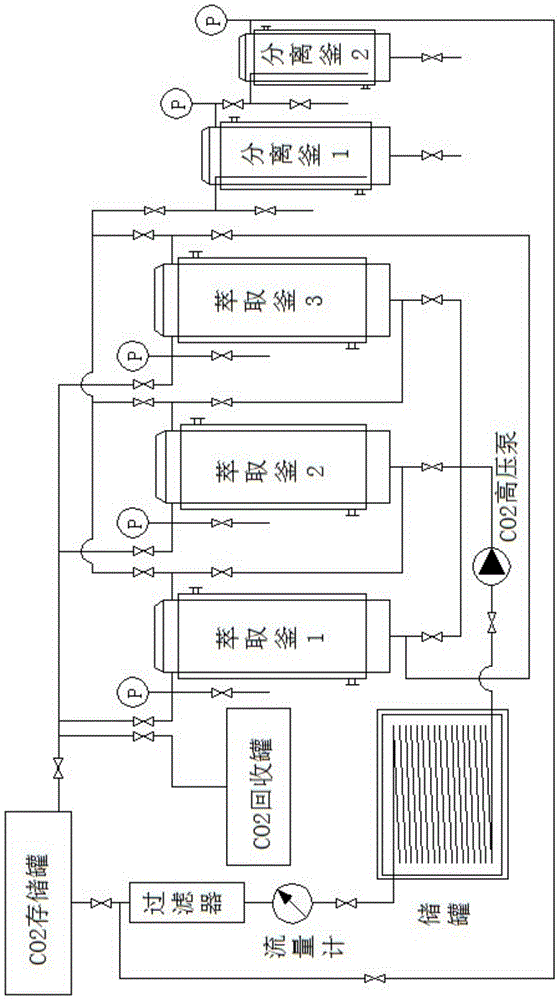

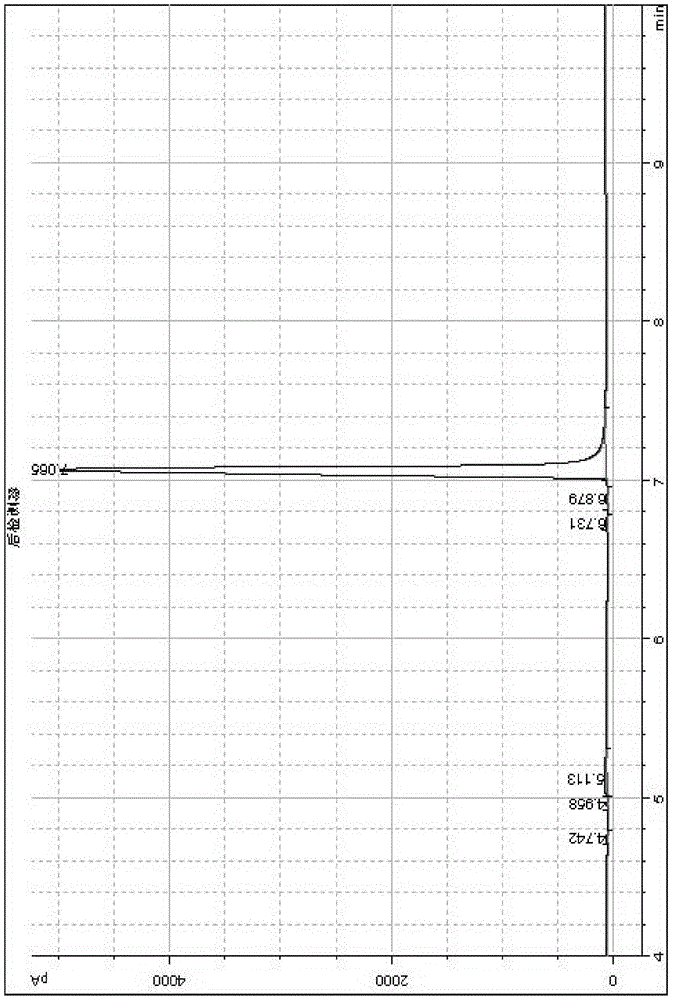

A kind of preparation method of glucosinolate and its metabolite benzyl isothiocyanate

ActiveCN104356178BAvoid heat damageLow extraction temperatureSugar derivativesSugar derivatives preparationMetaboliteDistillation

The invention discloses a preparation method of glucosinolate and benzyl isothiocyanate as a metabolite of glucosinolate. The preparation method comprises the following steps: firstly carrying out supercritical CO2 extraction on enzyme-deactivated Maca powder to extract fat-soluble components, removing impurities such as sterol by a cold precipitation method, carrying out ethyl esterification on the grease in the extract by an enzyme-catalyzed alcoholysis method and finally carrying out two-stage molecular distillation to obtain benzyl isothiocyanate and glucosinolate. Since ethanol is only used as a solvent, the preparation method is safe, non-toxic, free of pollution and simple in process and the scale production is easily achieved.

Owner:丽江英煌集生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com