A semi-continuous preparation method of camellia oleifera meal protein hypotensive peptide

A semi-continuous technology for antihypertensive peptides, which is applied in the field of semi-continuous preparation of antihypertensive peptides from camellia oleifera protein, can solve the problems of low yield of polypeptides, low antihypertensive activity, continuous production, etc., and achieve production costs Low, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

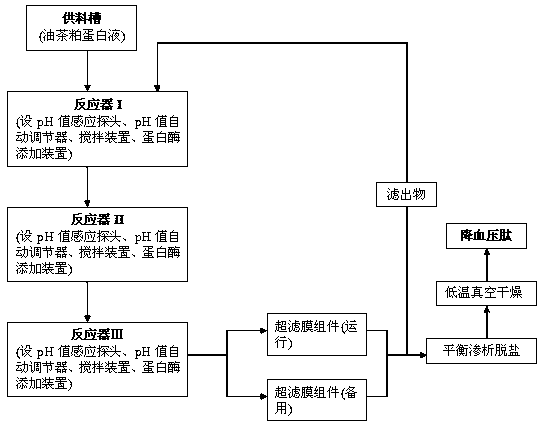

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] (1) adopt the camellia oleifera meal protein of low degree of denaturation, its nitrogen solubility index (NSI) is 96.0%, the preparation of camellia oleifera meal protein mass concentration is the 3% camellia meal protein solution; The peristaltic pump continuously replenishes the camellia oleifera protein liquid into the reactor; the preparation method of the low-denaturation camellia oleifera protein: adopts cold pressing method to produce oil at 61°C, and extracts the camellia oleifera meal by alkali-dissolving and acid-precipitating method The protein was dried under vacuum (0.035MPa) at low temperature (38°C) to obtain camellia oleifera meal protein with low degree of denaturation; the degree of denaturation was characterized by Nitrogen Solubility Index (NSI);

[0023] (2) The camellia oleifera meal protein solution obtained in step (1) passes through reactors I, II, and III equipped with proteases I, II, and...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] (1) adopt the camellia oleifera meal protein of low degree of denaturation, its nitrogen solubility index (NSI) reaches 98.0%, the preparation of the camellia oleifera meal protein mass concentration is 3.5% the camellia oleifera meal protein solution; The peristaltic pump continuously replenishes the camellia oleifera protein liquid into the reactor; the preparation method of the low-denaturation camellia oleifera protein: adopts the cold pressing method to produce oil at 62°C, and extracts the camellia oleifera meal by alkali-dissolving and acid-precipitating The protein is dried under vacuum (0.032MPa) at low temperature (39°C) to obtain the camellia oleifera meal protein with low denaturation degree; the degree of denaturation is characterized by Nitrogen Solubility Index (NSI);

[0033] (2) The camellia oleifera meal protein solution obtained in step (1) passes through reactors I, II, and III equipped with prot...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] (1) adopt the camellia oleifera meal protein of low degree of denaturation, its nitrogen solubility index (NSI) reaches 96.5%, the preparation of camellia oleifera meal protein mass concentration is the 4.0% camellia meal protein solution; The peristaltic pump continuously replenishes the camellia oleifera protein liquid into the reactor; the preparation method of the low-denaturation camellia oleifera protein: adopts cold pressing method to produce oil at 63°C, and extracts the camellia oleifera meal by alkali-dissolving and acid-precipitating method The protein is dried under vacuum (0.030MPa) at low temperature (40°C) to obtain the camellia oleifera meal protein with low denaturation degree; the degree of denaturation is characterized by Nitrogen Solubility Index (NSI);

[0043] (2) The camellia oleifera meal protein solution obtained in step (1) passes through reactors I, II, and III equipped with proteases I, I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com