Device for preparing high-strength alloy through semi-continuous extrusion of metal powder and preparation process

A technology for high-strength alloys and metal powders, which is applied in the field of devices for preparing high-strength alloys by semi-continuous extrusion of metal powders, can solve the problem of low mechanical properties, poor quality of high-strength alloy ingots or profiles, and inability to achieve semi-continuous production and other problems, to achieve the effect of improving the mechanical properties of materials, increasing the scope of application and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

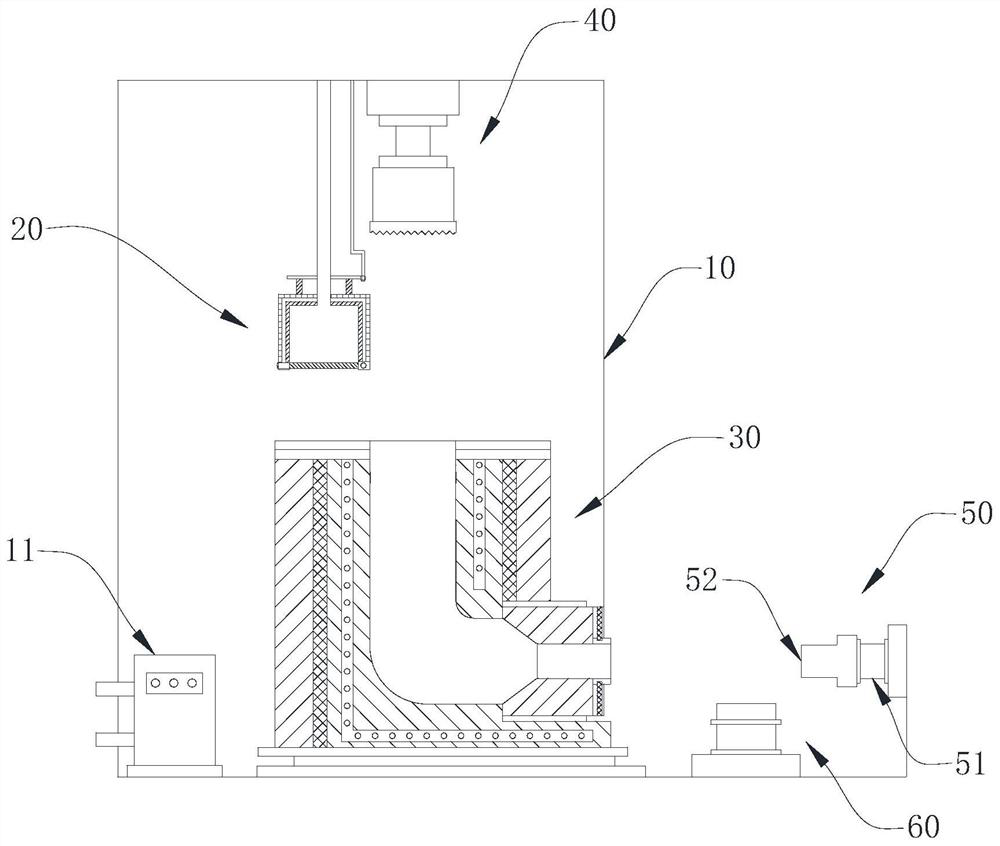

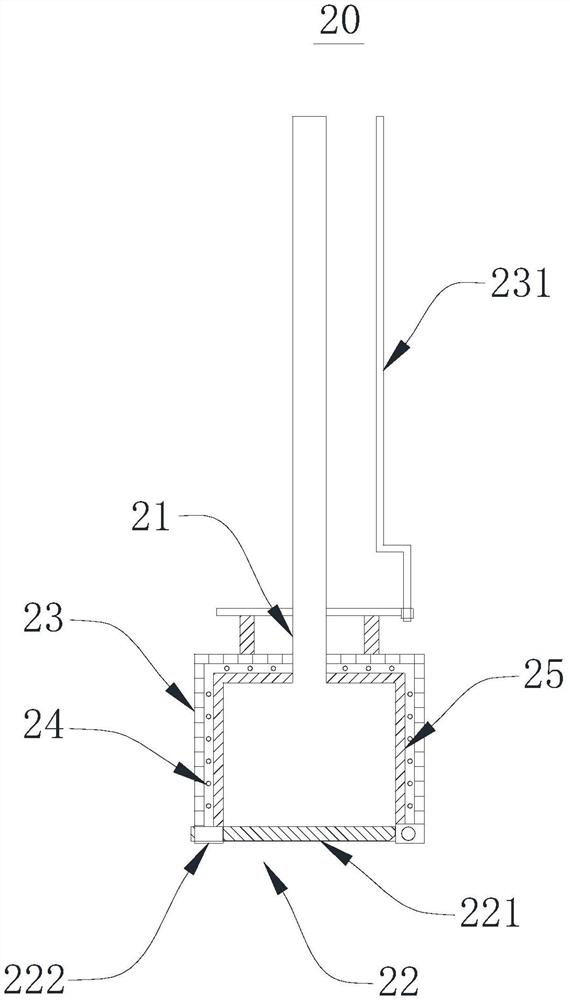

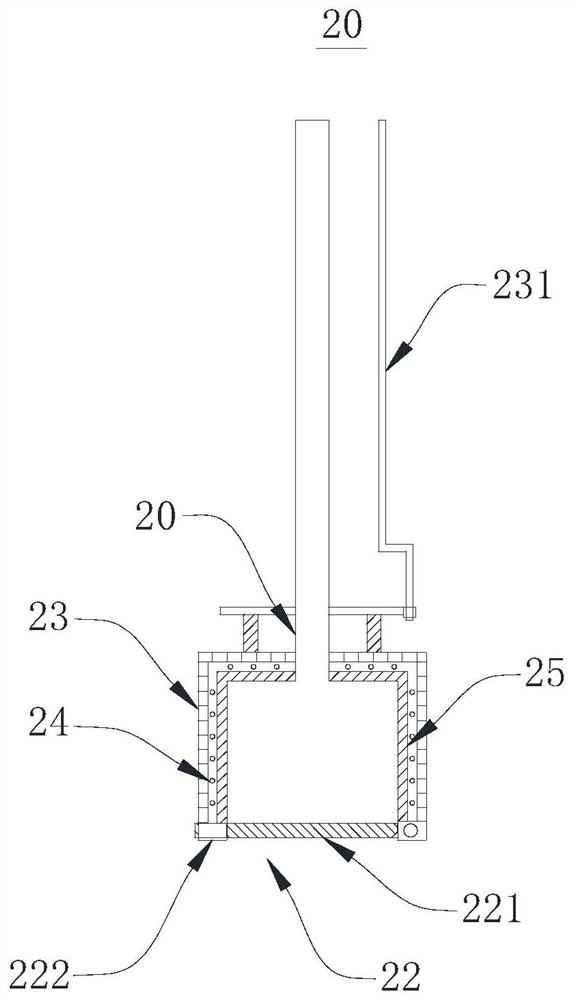

[0054] Please refer to figure 1 , a device for preparing high-strength alloys by semi-continuous extrusion of metal powder, including: a preparation chamber 10, a heat preservation device 20, a forming device 30, an extrusion device 40, a pre-jacking device 50 and a cutting device 60. The preparation bin 10 is a closed structure, and its inside is provided with a vacuum device 11, which is a conventional vacuum device, which can reduce the degree of vacuum in the preparation bin 10 to 10°C. -1 ~10 -2 Pa, used to extract the air in the preparation chamber 10 to prevent excessive oxidation of metal powder and adsorption of gas. The preheating device 20 is arranged on the inner top wall of the preparation bin 10, the molding device 30 is arranged on the inner bottom wall of the preparation bin 10, the extrusion device 40 is arranged on the top side wall of the preparation bin 10, and the extrusion device is opposite to the molding device 30 Setting, the pre-jacking device 50 is...

Embodiment 2

[0068] A high-strength alloy preparation process based on the semi-continuous extrusion of metal powder in embodiment 1 to prepare a high-strength alloy device, comprising the following steps:

[0069] S1: Feed the externally heated metal powder into the heat preservation box 25 from the powder inlet 21, heat the heat through the first heating device 24, and keep the temperature stable. The occurrence of melting and other phenomena shall prevail (such as AZ31B magnesium alloy powder, the holding temperature is 150-200 ℃);

[0070]S2: Extend the pressing head 51 of the pre-ejecting device 50 into the forming extrusion chamber 315, block the forming extrusion chamber 315, and set the pre-ejecting pressure of the pre-ejecting device 50;

[0071] S3: Start the second heating device 32, heat the molding channel, and keep the temperature stable. The preheating temperature is based on the fact that the powder processing performance is good, and the phenomena such as excessive precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com