Preparation method of titanium-aluminum-silicon alloy target

A technology of alloy target, titanium-aluminum-silicon, which is applied in the field of preparation of titanium-aluminum-silicon alloy target, which can solve the problem of difficulty in obtaining high-quality and high-density targets, large-size difficult targets, and uneven relative density of hot-pressed targets and other problems, to achieve the effects of fine grain size, improved powder utilization rate and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

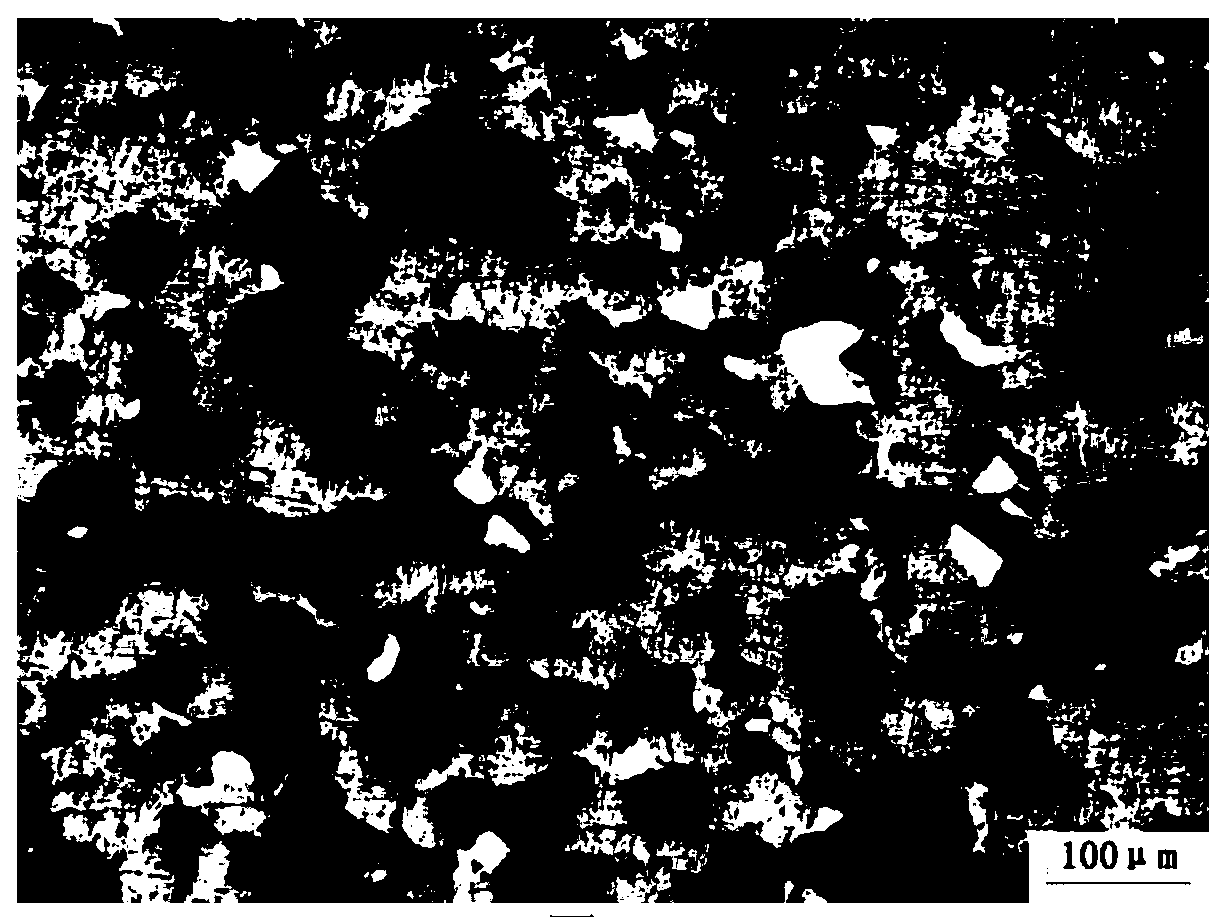

Image

Examples

Embodiment 1

[0024] The titanium-aluminum-silicon alloy target provided in this embodiment is composed of the following atomic percentages: 50% titanium, 40% aluminum, and 10% silicon.

[0025] The preparation method of the titanium-aluminum-silicon target in this example comprises the following steps:

[0026] Step 1: Weigh 63.8 parts of titanium powder with a purity of 99.6%, 28.8 parts of aluminum powder with a purity of 99.7%, and 7.4 parts of silicon powder with a purity of 99.9% according to the design requirements of the above-mentioned target material composition. Alloy powder with an average particle size of 40 μm (ie pre-alloyed powder);

[0027] The atomization powder making process is to use an arc melting method for metal melting, and an inert gas-metal atomization powder making method to prepare alloy powder;

[0028] Step 2, the obtained alloy powder is put into a cold isostatic pressing forming mold, and cold isostatic pressing is performed under a pressure of 200 MPa, and...

Embodiment 2

[0035] The titanium-aluminum-silicon alloy target provided in this embodiment is composed of the following atomic percentages: 9% titanium, 90% aluminum, and 1% silicon.

[0036] The preparation method of the titanium-aluminum-silicon target in this example comprises the following steps:

[0037] Step 1, according to the above design requirements of the target material composition, weigh 14.9 parts of titanium powder with an average particle size of 80 μm and a purity of 99.6%, 84.1 parts of aluminum powder with a purity of 99.7%, and 1 part of silicon powder with a purity of 99.9%, and weigh them in V Mixed in a type mixer for 3 hours, vacuumed for protection during the mixing process, and the vacuum degree was controlled at 10 -2 About Pa;

[0038] Step 2, put the mixed alloy powder into a cold isostatic pressing mold, and perform cold isostatic pressing under a pressure of 150 MPa, and the holding time is 10 minutes;

[0039] Step 3: Put the blank after cold isostatic pre...

Embodiment 3

[0045] The titanium-aluminum-silicon alloy target provided in this example is composed of the following atomic percentages, titanium 5%,

[0046] Aluminum 75%, silicon 20%.

[0047] The preparation method of the titanium-aluminum-silicon target in this example comprises the following steps:

[0048] Step 1, according to the design requirements of the above target material composition, weigh 8.5 parts of titanium powder with an average particle size of 150 μm and a purity of 99.7%, 71.7 parts of aluminum powder with a purity of 99.9%, and 19.8 parts of silicon powder with a purity of 99.9%, and weigh them in V Mix in a type mixer for 5 hours, and fill in high-purity argon for protection during the mixing process;

[0049] Step 2, put the mixed powder into a cold isostatic pressing mold for cold isostatic pressing, the cold isostatic pressing pressure is 200MPa, and the holding time is 20min;

[0050] Step 3, put the cold isostatic pressing billet into a metal sheath of approp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com