Method and device for semi-continuously producing acetyl tributyl citrate

A technology of acetyl tributyl citrate and tributyl citrate, which is applied in the field of semi-continuous production of acetyl tributyl citrate, can solve the problems of heavy production process, poor equipment utilization rate, and low investment, and achieve the goal of device structure Simple, low labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

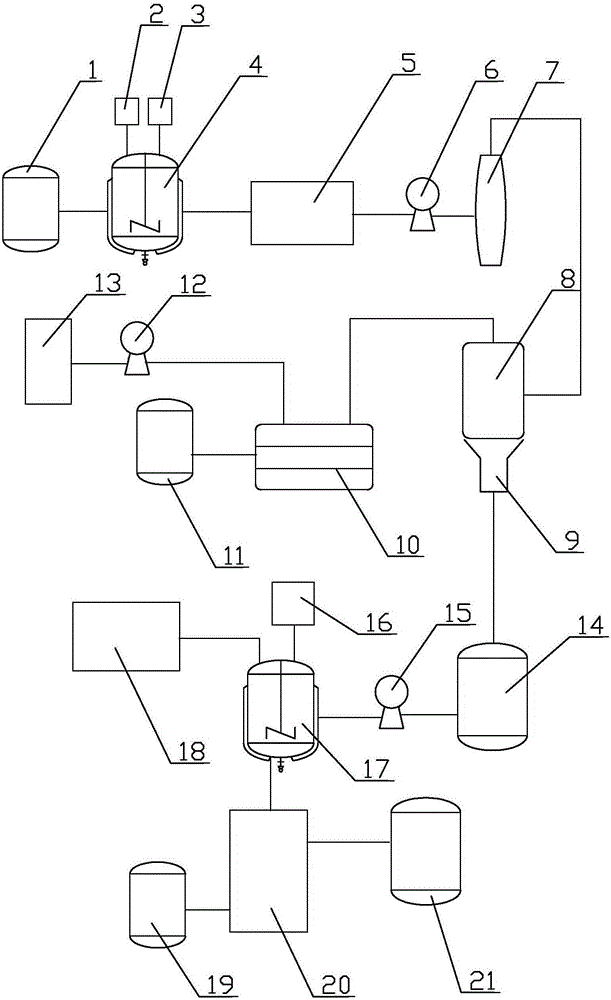

[0028] like figure 1 Shown, the used device of the method for the semi-continuous production of acetyl tributyl citrate of the present invention comprises reactor 4, is characterized in that: reactor 4 passes pipeline and surge tank 5, the first booster pump 6 , heater 7, deacidification tower 8, condenser 10, vacuum pump 12, non-condensable gas tank 13 are connected successively; Wherein, the outside of reactor 4 is also connected with tributyl citrate tank 1, acetic anhydride feeding device 2 and catalyst respectively The feeding device 3; the condenser 10 is also connected to the acetic acid storage tank 11; the lower part of the deacidification tower 8 is provided with a reboiler 9, and the reboiler 9 is also connected to the crude ester tank 14, the second booster pump 15, and the continuous water washing device in sequence;

[0029] The continuous water washing device includes a sodium hydroxide feeder 16, a mixing tank 17, a condensate tank 18, a recovery water tank 19,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com