A kind of production device and technology of nickel-cobalt-manganese ternary hydroxide

A nickel-cobalt-manganese ternary hydrogen and oxide technology, applied in nickel compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of low production efficiency, unstable batch quality, high energy consumption, etc., and achieve high production efficiency , The effect of narrow product particle size distribution and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

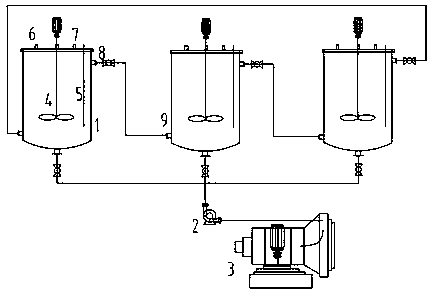

[0024] A nickel-cobalt-manganese ternary hydroxide production device includes three 1m3 identical reaction kettles, a discharge pump, a centrifuge and connecting pipes. The reaction kettle is a water-sealed closed tank reaction kettle with stirring and electric heater. The upper part is equipped with a feed liquid inlet and a gas inlet; each reaction kettle is equipped with an overflow port at 0.95H on the upper side wall and 0.15H on the lower side wall The feed ports are all set, and the overflow port of each reactor is connected to the feed port pipes of other reactors, and valves are set near the overflow ports on the pipes connecting the overflow ports to the feed ports of other reactors. The bottom of each reactor is provided with a slurry discharge port, which is connected to the discharge pump and the centrifuge through a pipeline, and the pipeline connecting the slurry discharge port of the reactor with the discharge pump is set near the slurry discharge port. The val...

Embodiment 2

[0032] Its equipment is basically the same as in Example 1, except that the reaction volume is 10 m³.

[0033] A production process of nickel-cobalt-manganese ternary hydroxide comprises the following steps.

[0034] (a) Add 0.8mol / L ammonia solution to each reactor as the bottom liquid, and the bottom liquid level will submerge the bottom stirring paddle.

[0035] (b) 1# Reactor is turned on and stirred, heated to 70 o After C, add reducing agent and protective gas, and add the metal solution with the total concentration of the three metal ions of nickel, cobalt, manganese and 2.0mol / L, 8.0mol / L sodium hydroxide solution, and 10.0mol / L ammonia solution into the 1# reaction kettle at the same time , to carry out the nucleation reaction, control the flow rate of molten metal to 50L / h, control the pH range of the mixed solution in the reactor to 12.0, and the total ammonia concentration to 0.8mol / L.

[0036] (c) When the 1# reactor begins to overflow, the overflow enters the 2...

Embodiment 3

[0041] Its equipment is basically the same as in Example 1, except that the reaction volume is 5 m³.

[0042] A production process of nickel-cobalt-manganese ternary hydroxide comprises the following steps.

[0043] (a) Add 0.5mol / L ammonia solution to each reactor as the bottom liquid, and the bottom liquid level will submerge the bottom stirring paddle.

[0044] (b) 1# reactor is turned on and stirred, heated to 55 o After C, add reducing agent and protective gas, and add the metal solution with a total concentration of three metal ions of nickel, cobalt and manganese of 1.5mol / L, 6.0mol / L sodium hydroxide solution, and 7.5mol / L ammonia solution into the 1# reaction kettle at the same time , to carry out the nucleation reaction, control the flow rate of molten metal to 25L / h, control the pH range of the mixed solution in the reactor to 11.0, and the total ammonia concentration to 0.5mol / L.

[0045] (c) When the 1# reactor begins to overflow, the overflow enters the 2# reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com