Fuel gas type equipment

A gas-fired and equipment technology, applied in the field of metallurgy, can solve problems such as high labor intensity, and achieve the effects of reducing heat loss, low energy consumption, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] Metal oxides and metal minerals have high melting points, so they cannot be sucked into the vacuum reaction chamber after melting like alloys. The feeding and retrieving of metal oxides and metal minerals must open the vacuum reaction chamber. The invention adopts a detachable reaction chamber, which makes the structure of the equipment more flexible and convenient, and is especially suitable for the reduction of metal oxides and metal minerals.

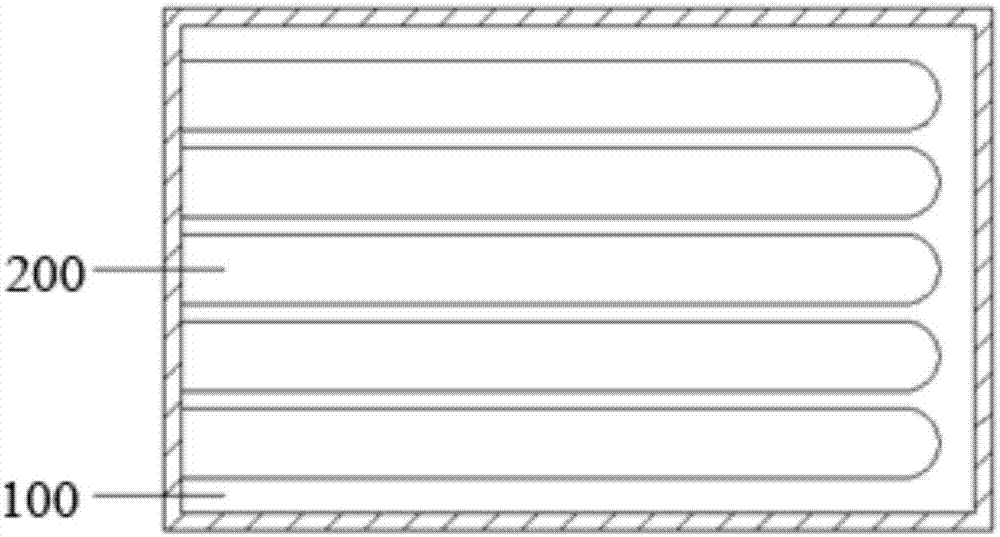

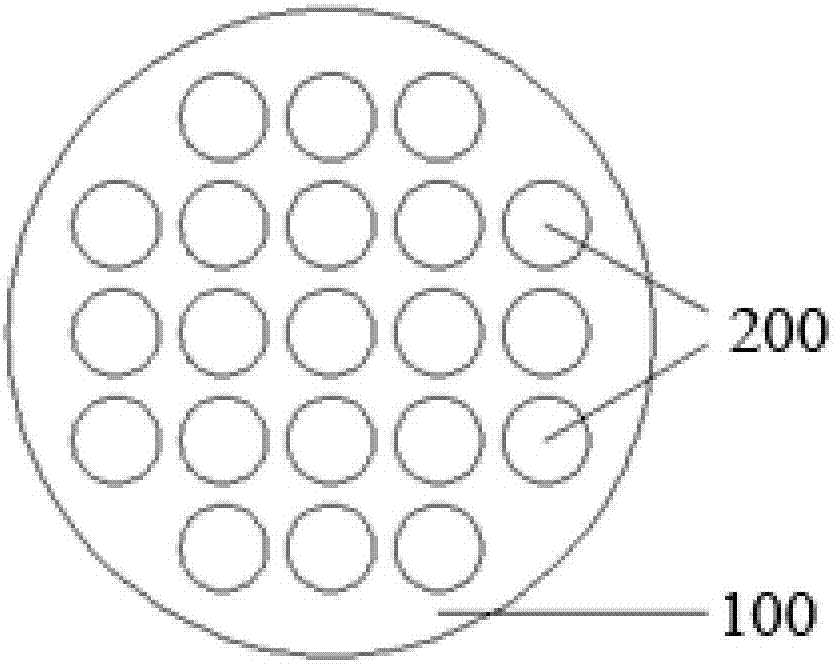

[0029] refer to figure 1 and figure 2 , which schematically shows the combustion chamber 100 and its internal structure. The combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com