Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Guaranteed vacuum environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

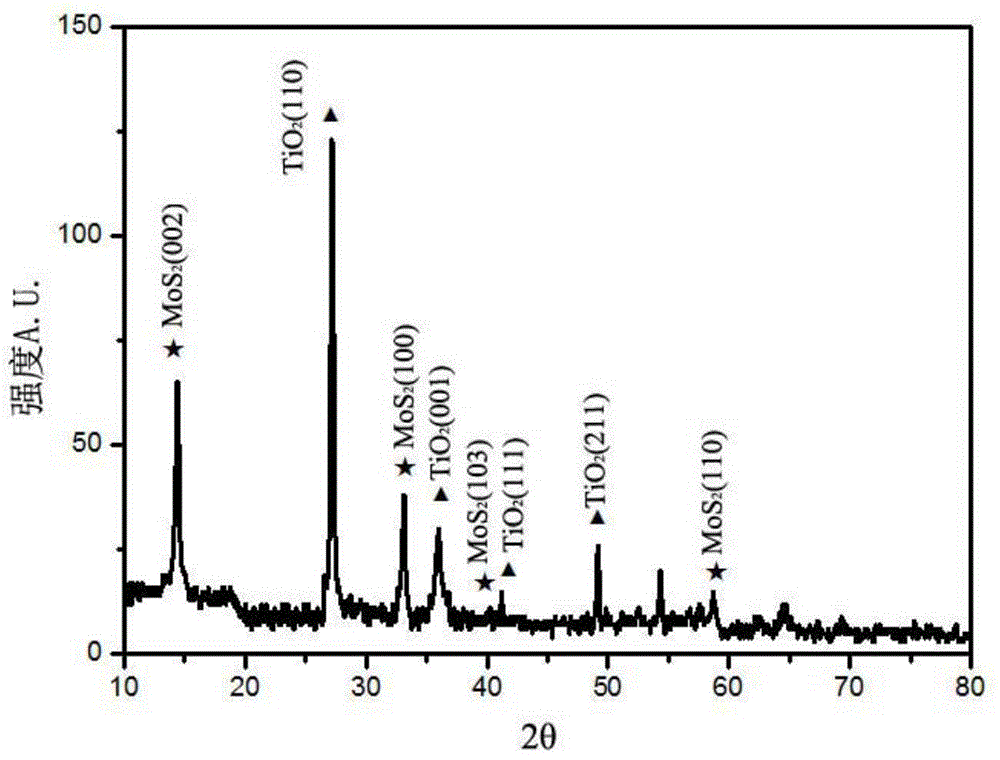

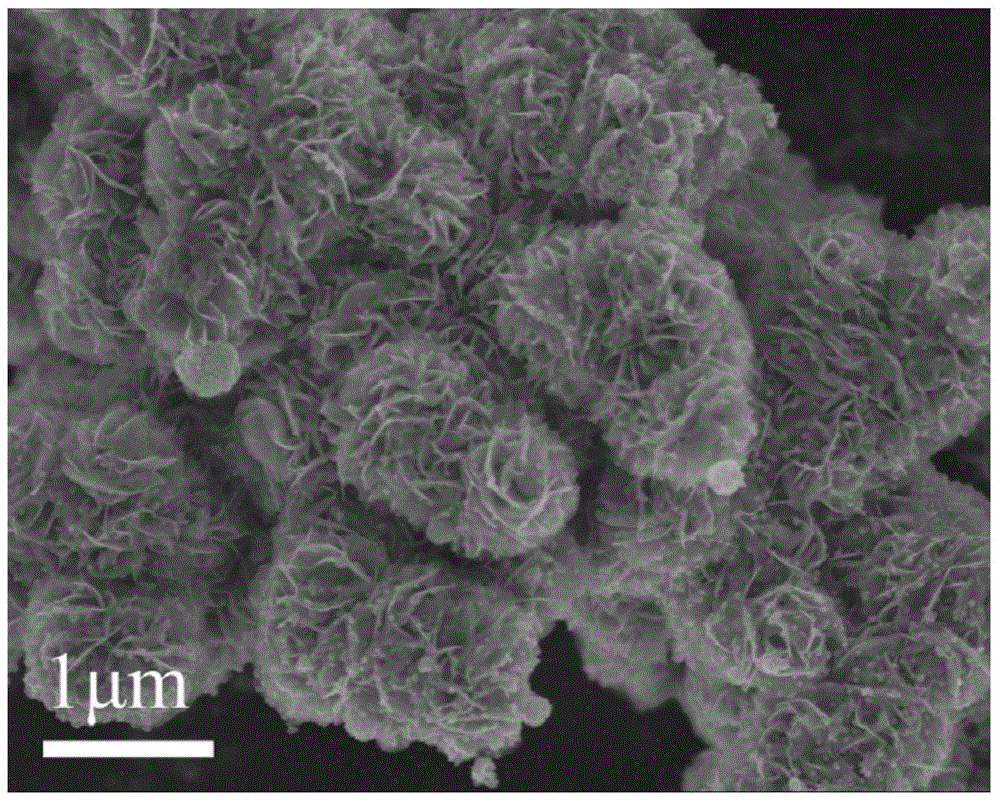

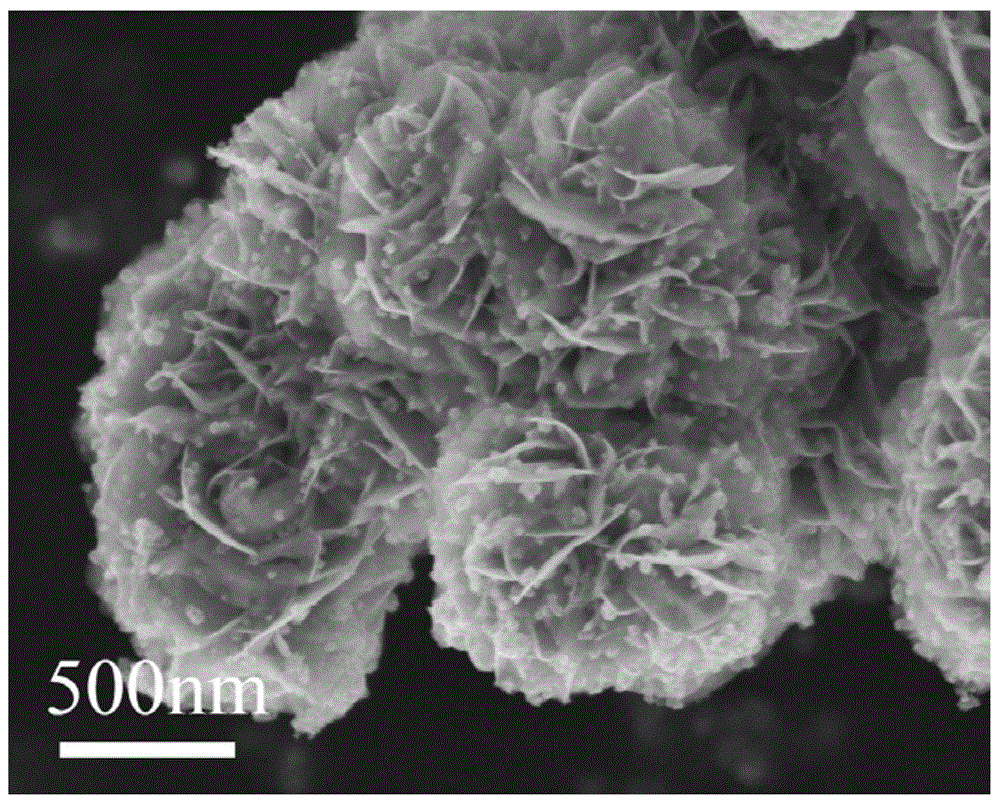

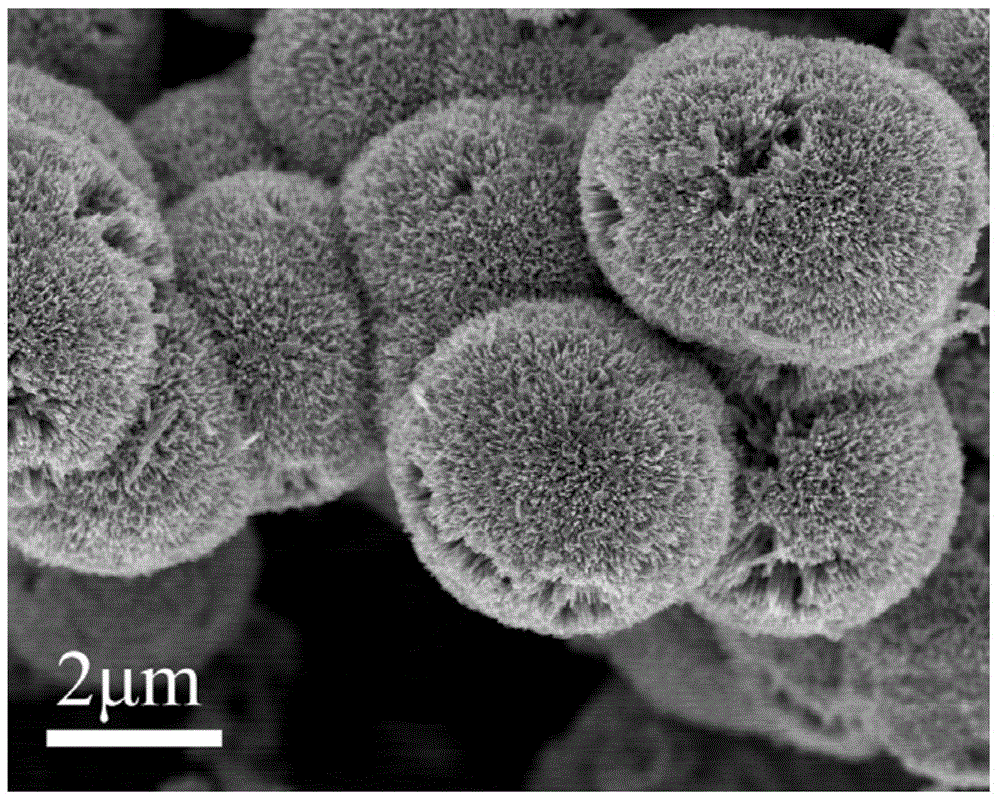

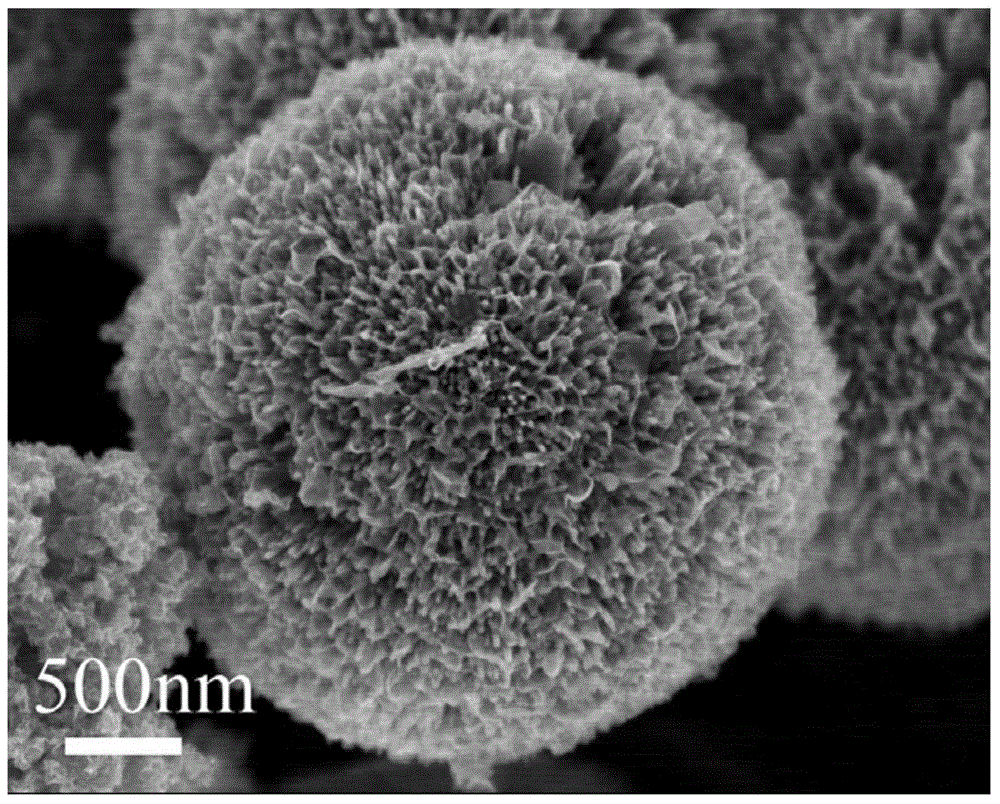

TiO2-quantum-dot-and-MoS2-nanometer-flower-combined heterojunction semiconductor material and preparation method thereof

InactiveCN104402052AEfficient compositeSolution conditionsMaterial nanotechnologyPhysical/chemical process catalystsHeterojunctionSemiconductor materials

The invention discloses a TiO2-quantum-dot-and-MoS2-nanometer-flower-combined heterojunction semiconductor material comprising MoS2 nanometer flower and TiO2 nanometer particles. A large amount of the TiO2 nanometer particles are uniformly distributed on the surface of the MoS2 nanometer flower, and are well compounded on the pedals. The TiO2 nanometer particle phase is in a punctiform dense distribution. The invention also discloses a preparation method of the TiO2-quantum-dot-and-MoS2-nanometer-flower-combined heterojunction semiconductor material. According to the method, with a two-step solvothermal method, the punctiform TiO2 nanometer particles are uniformly grown on the MoS2 nanometer flower, such that the material with a good composite morphology is obtained. The method provided by the invention has the advantages of simple operation, high yield, low preparation cost, and the like. The material provided by the invention has great development and application potential in the fields of photo-catalysis industrial wastewater and field emission.

Owner:EAST CHINA NORMAL UNIV

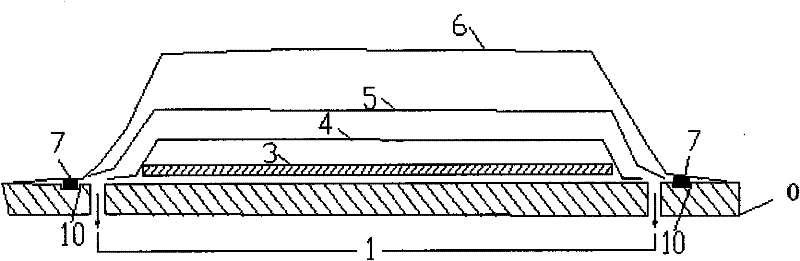

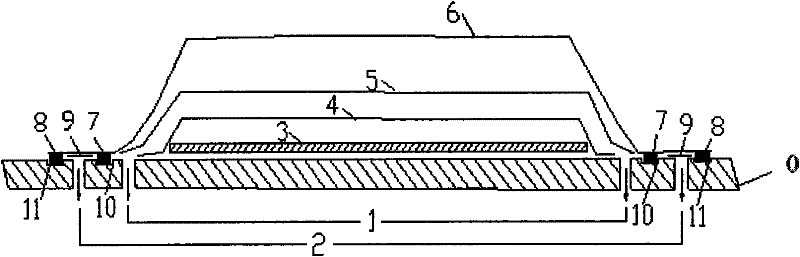

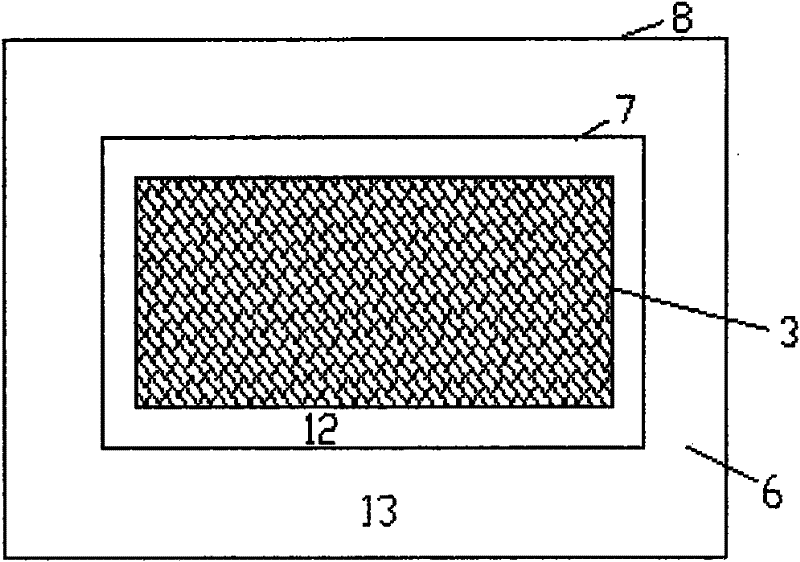

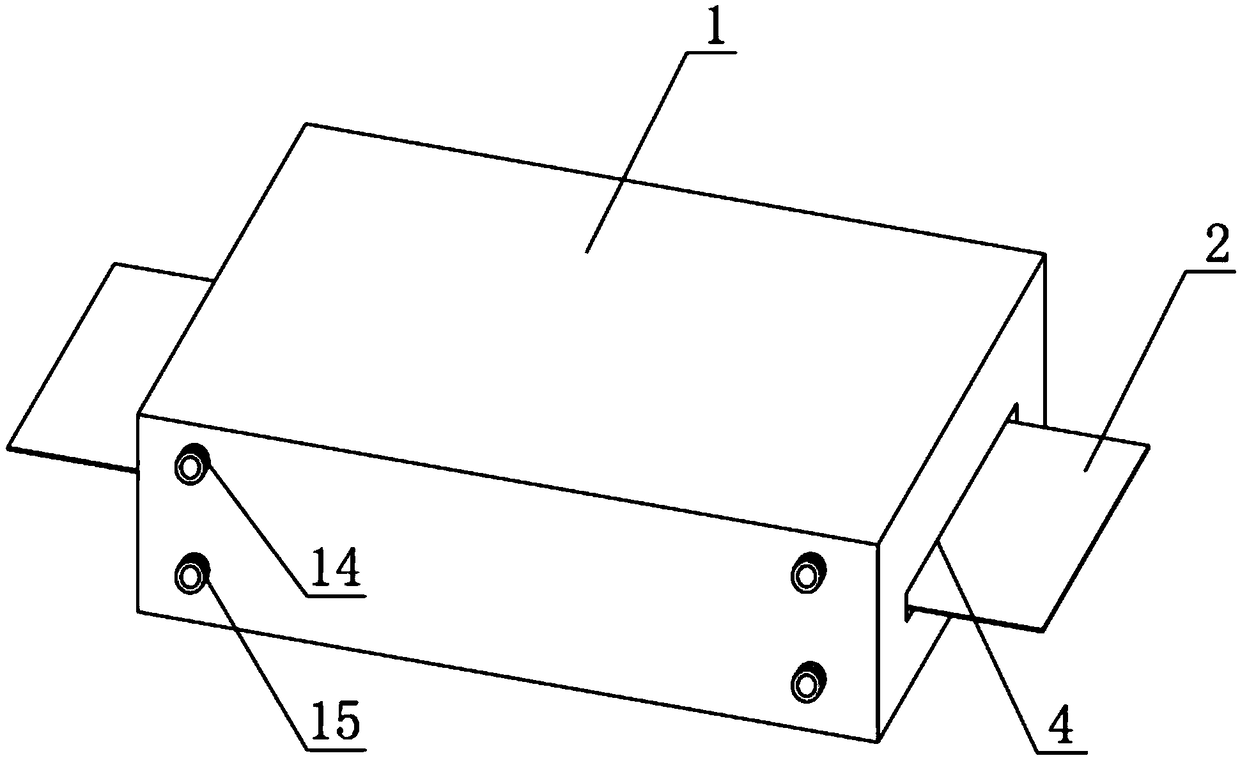

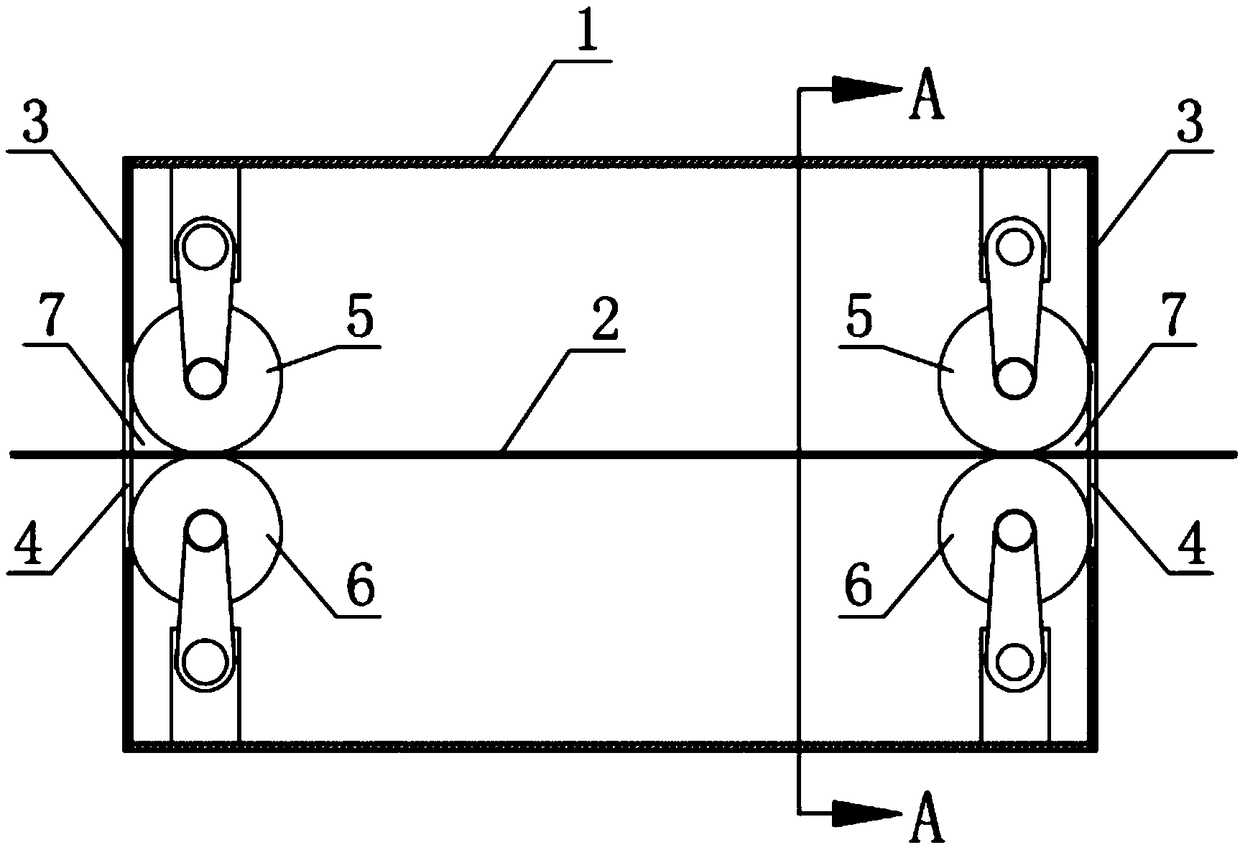

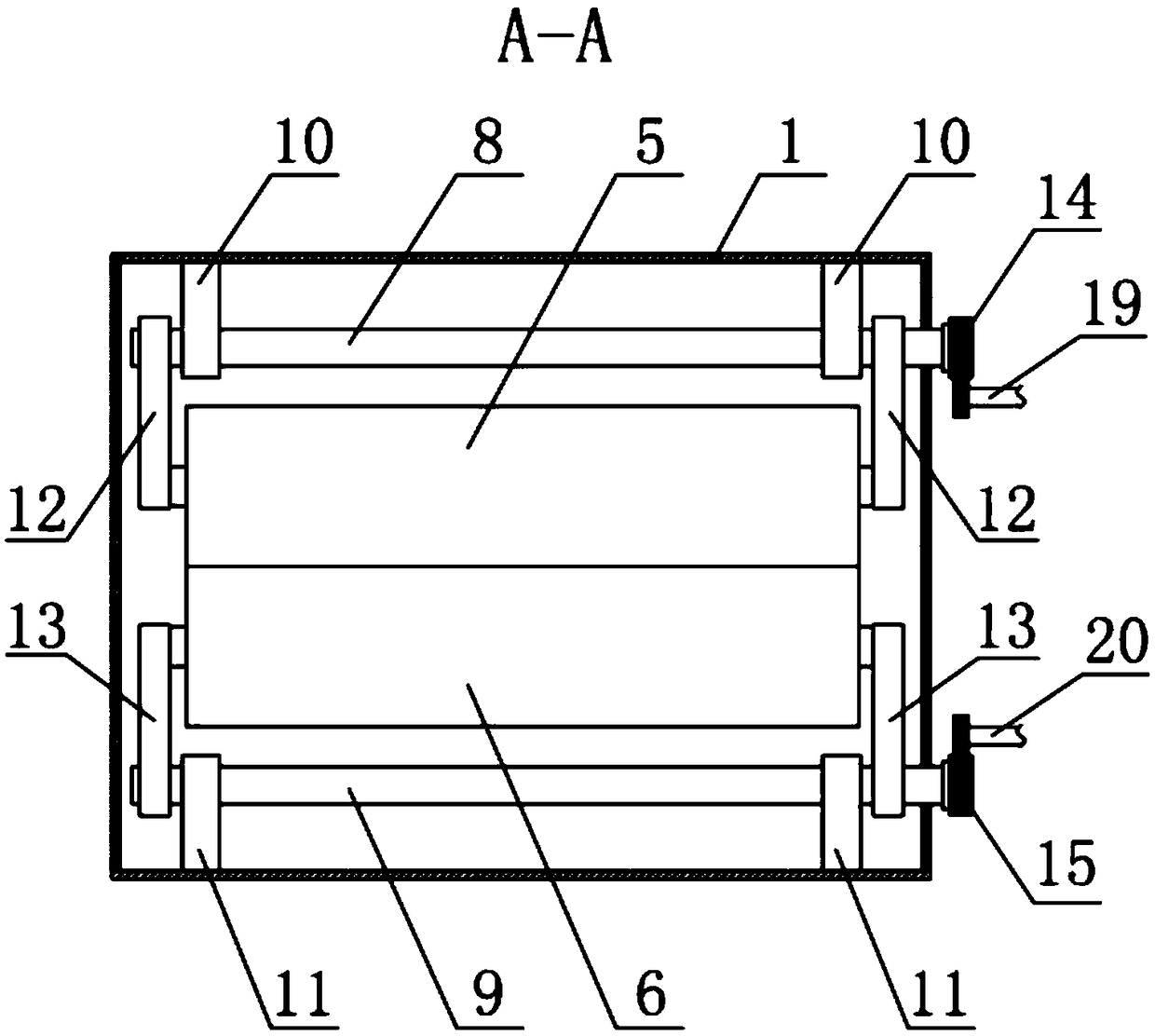

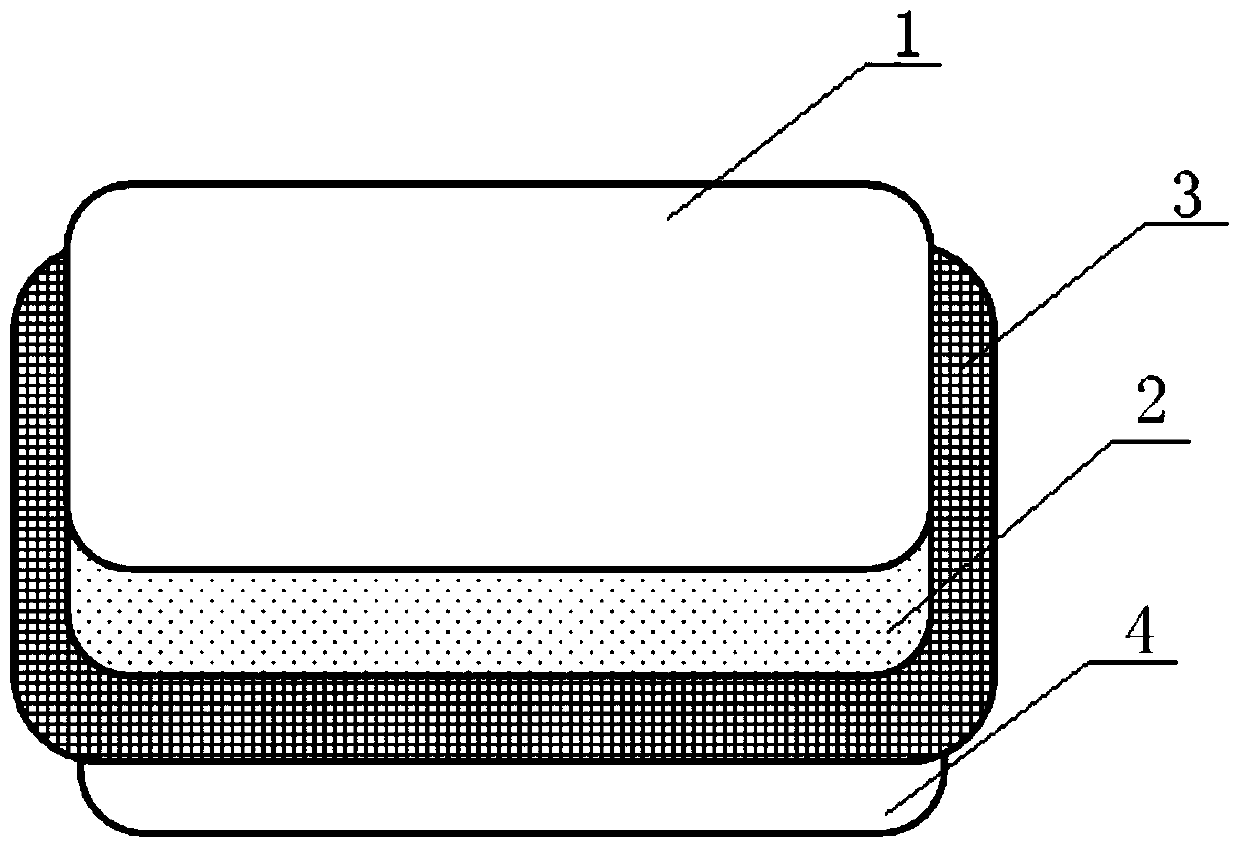

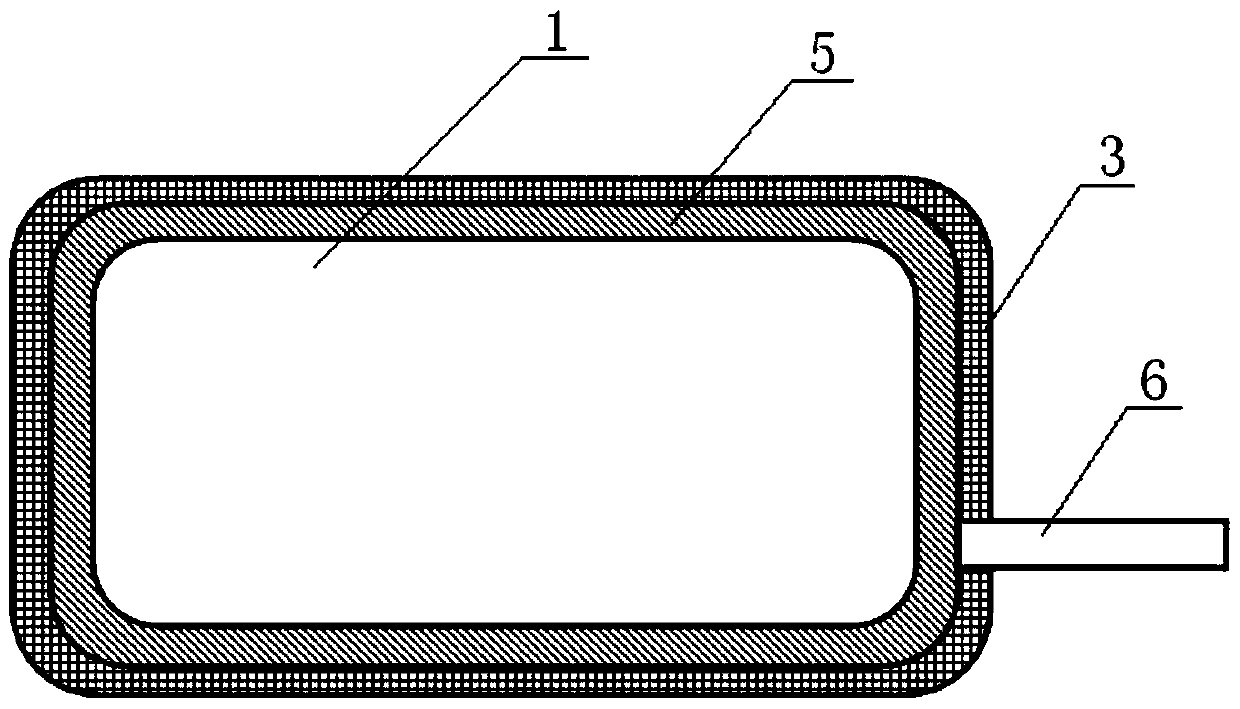

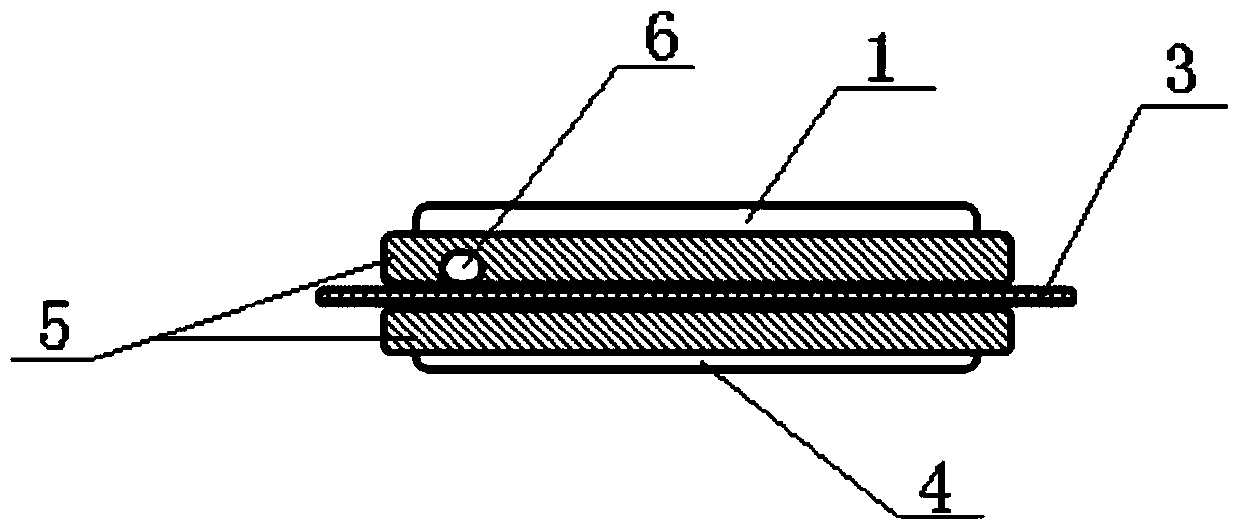

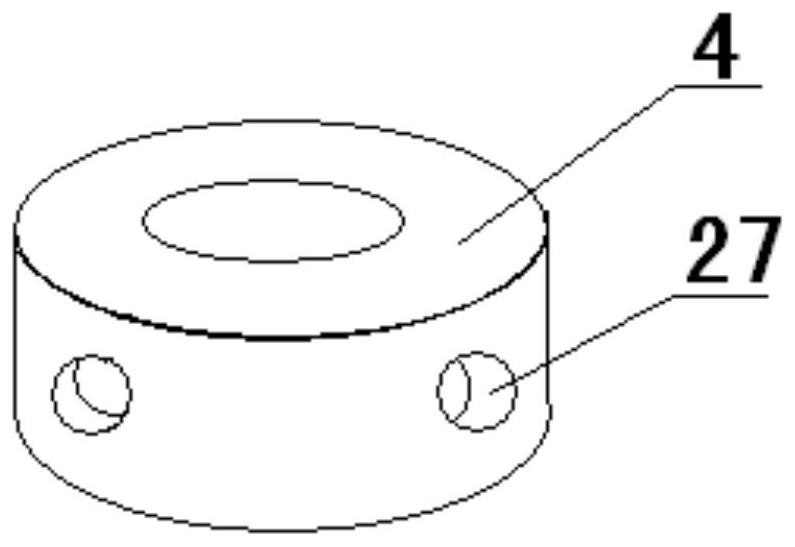

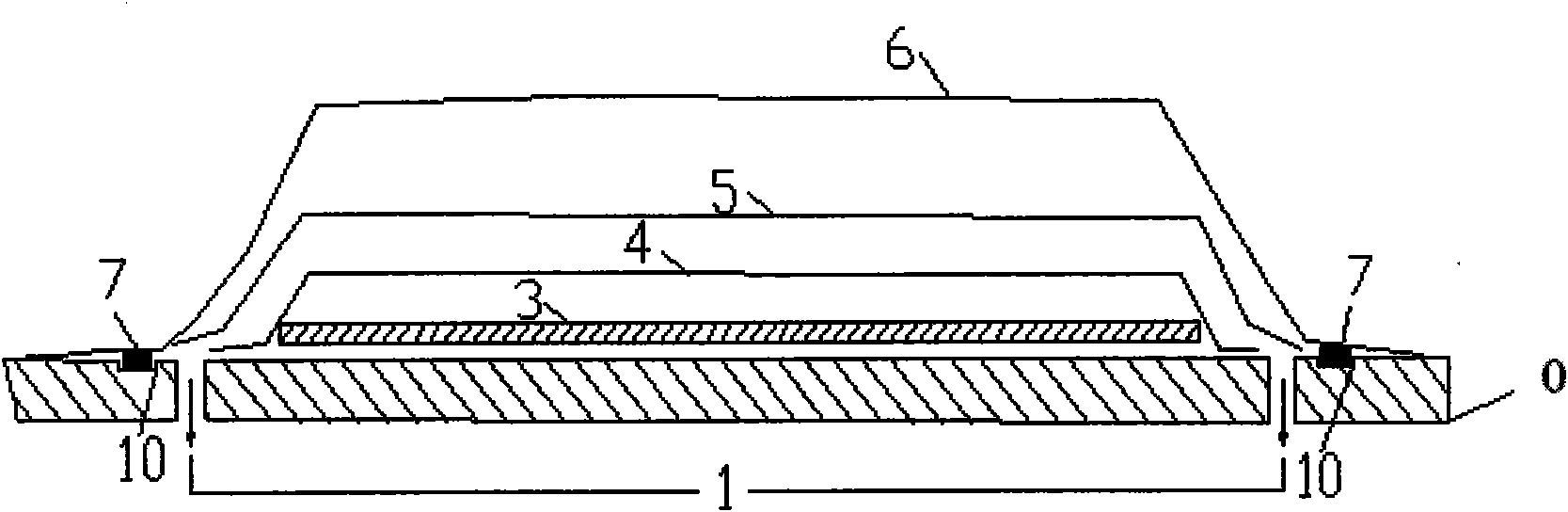

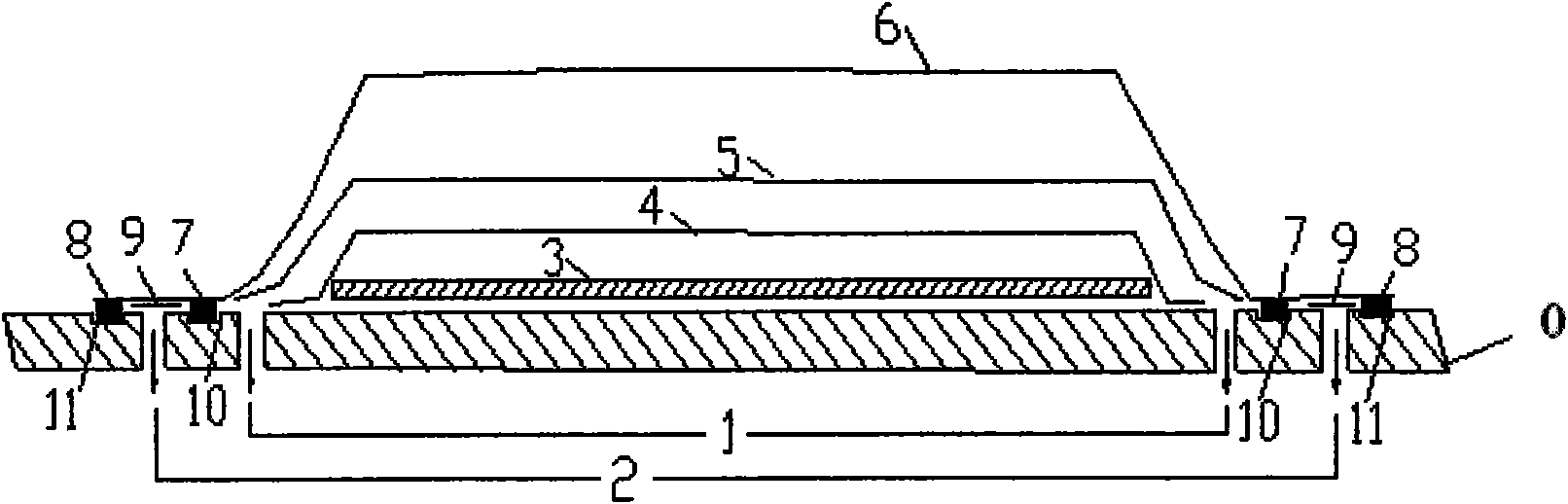

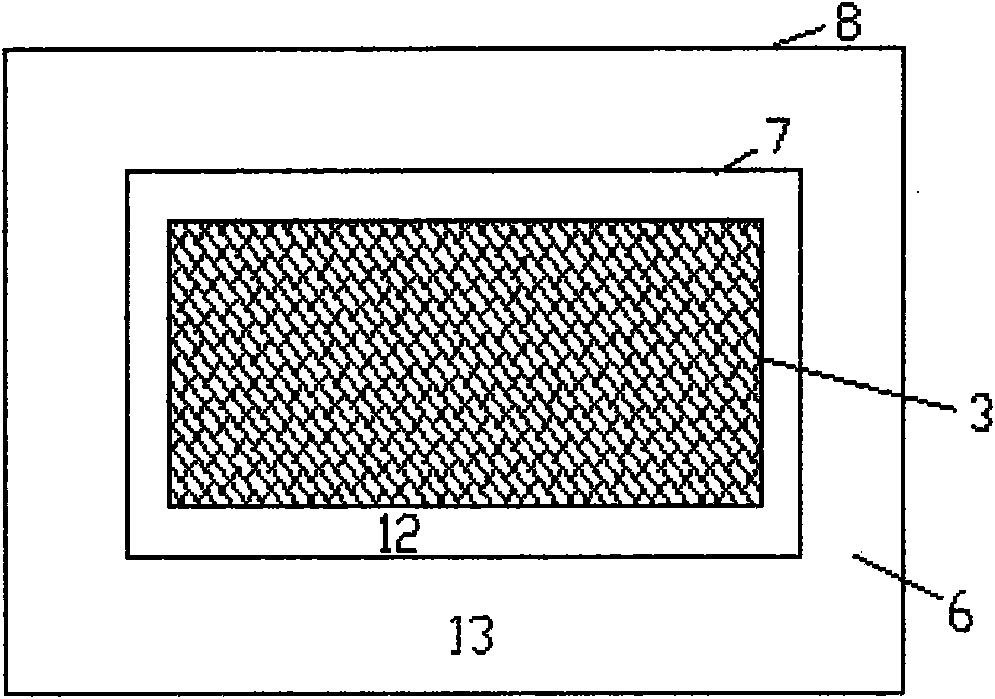

Encapsulation method for reducing vacuum leakage in composite material formation

ActiveCN102350803ASolving the problem of vacuum leaksGuaranteed vacuum environmentHigh pressureMaterials science

The invention belongs to the technical field of composite material formation, and relates to an encapsulation method for reducing vacuum leakage in composite material formation in an autoclave composite material forming process. An inner ring sealing rubber strip and an outer ring sealing rubber strip are arranged in the method, a first sealing space is formed between a prepreg and an inner ring sealing ring, and a second sealing space is formed between the inner ring sealing ring and an outer ring sealing ring. When the outer ring encapsulation material leaks, the second sealing space is communicated with the external space; and because the first sealing space is isolated with the second sealing space, the air of the external space can only enter the second sealing space, and vacuum environment of the first sealing space is kept. By adopting the encapsulation method, two sealing spaces are formed around a workpiece, so that the problem of vacuum leakage in solidifying formation of a composite material at a high temperature and under a high pressure can be effectively solved; and tests prove that the probability of vacuum leakage in the solidification process is reduced from original over 90 percent to below 20 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material and preparation method thereof

InactiveCN104437555AGuaranteed vacuum environmentWill not introducePhysical/chemical process catalystsHeterojunctionPhoto catalytic

The invention discloses a wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material. The wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material contains MoS2 nanosheets and TiO2 dandelion nanospheres, wherein the MoS2 nanosheets penetrate through the space among nanorods on the TiO2 dandelion nanospheres uniformly and can be stably combined with gaps among the nanorods,. The invention also discloses a method for preparing the wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material by a two-step solvent method. The wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material and the method have the advantages that the preparation operation is simple, the yield is high and the cost is low, and the wavy MoS2 nanosheet inlaid TiO2 dandelion nanosphere composite heterojunction semiconductor material has great potential and wide application prospect in the fields of photo-catalytic industrial wastewater and field emission.

Owner:EAST CHINA NORMAL UNIV

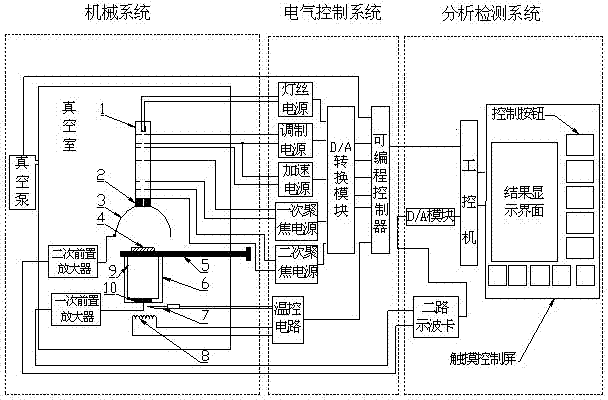

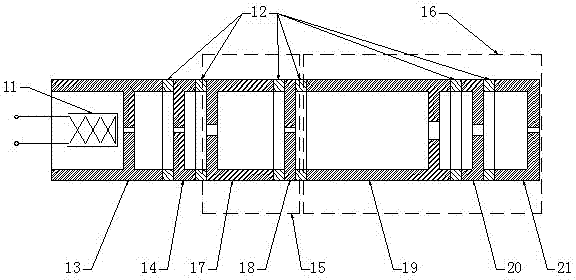

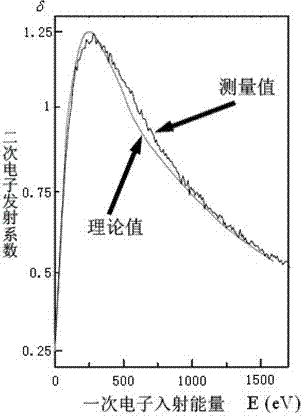

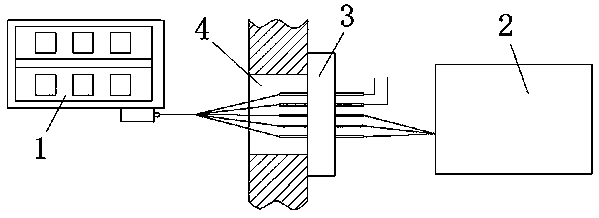

Solid material secondary electron emission coefficient testing device with intelligent measurement and control technology

InactiveCN102288628AReduce lossesAvoid compromising accuracyTube electron sourcesMaterial analysis by measuring secondary emissionHemt circuitsEngineering

The solid material secondary electron emission coefficient testing device with intelligent measurement and control technology of the present invention includes a mechanical system, an electrical control system and an analysis and detection system; the mechanical system includes a vacuum chamber, a vacuum pump, an electron gun, an electron collection device and a heating device, and Provide a vacuum environment, generate and collect secondary electrons; the electrical control system includes a power supply, a programmable controller and a temperature control circuit, and the programmable controller controls the power supply voltage through a digital and analog conversion module; the analysis and detection system includes an industrial computer , digital-to-analog conversion module, two-way oscilloscope card and touch control screen, and KingView is installed on the industrial computer to store, analyze and process the detected electronic signals, and display the secondary electron emission coefficient of the measured solid material The relation curve between electron energy and electron gun exiting electron energy. The invention can better meet the needs of industrial antistatic design, engineering material selection and static electricity prediction for measuring the secondary electron emission coefficient of solid materials.

Owner:SOUTH CHINA UNIV OF TECH

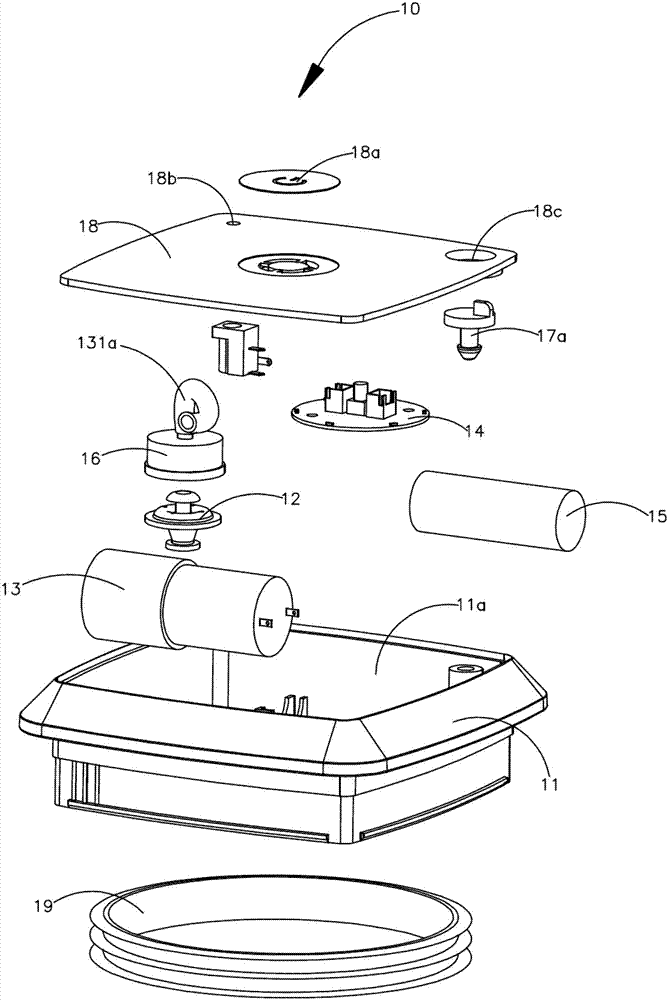

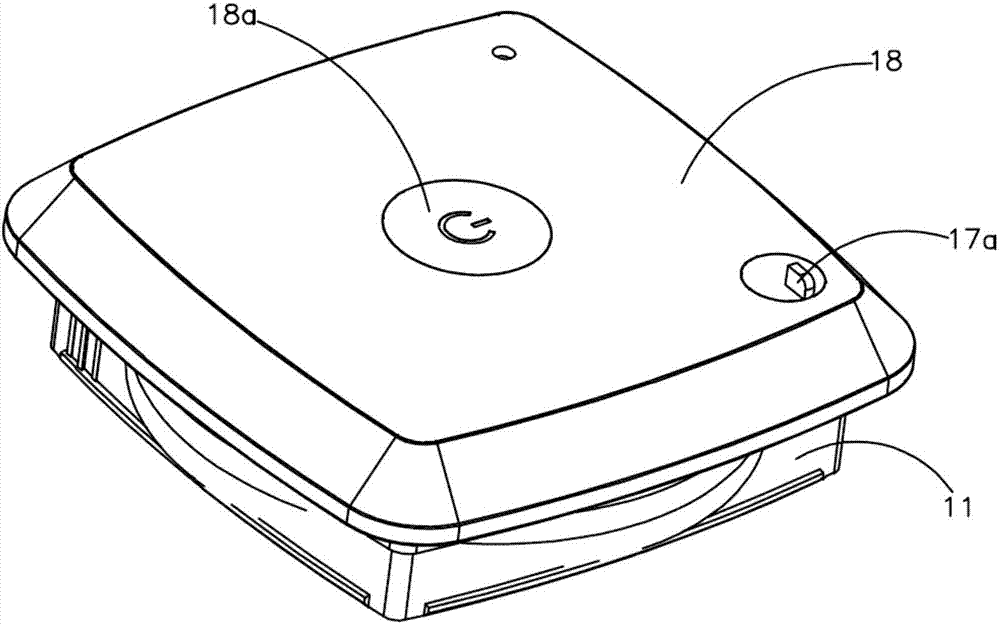

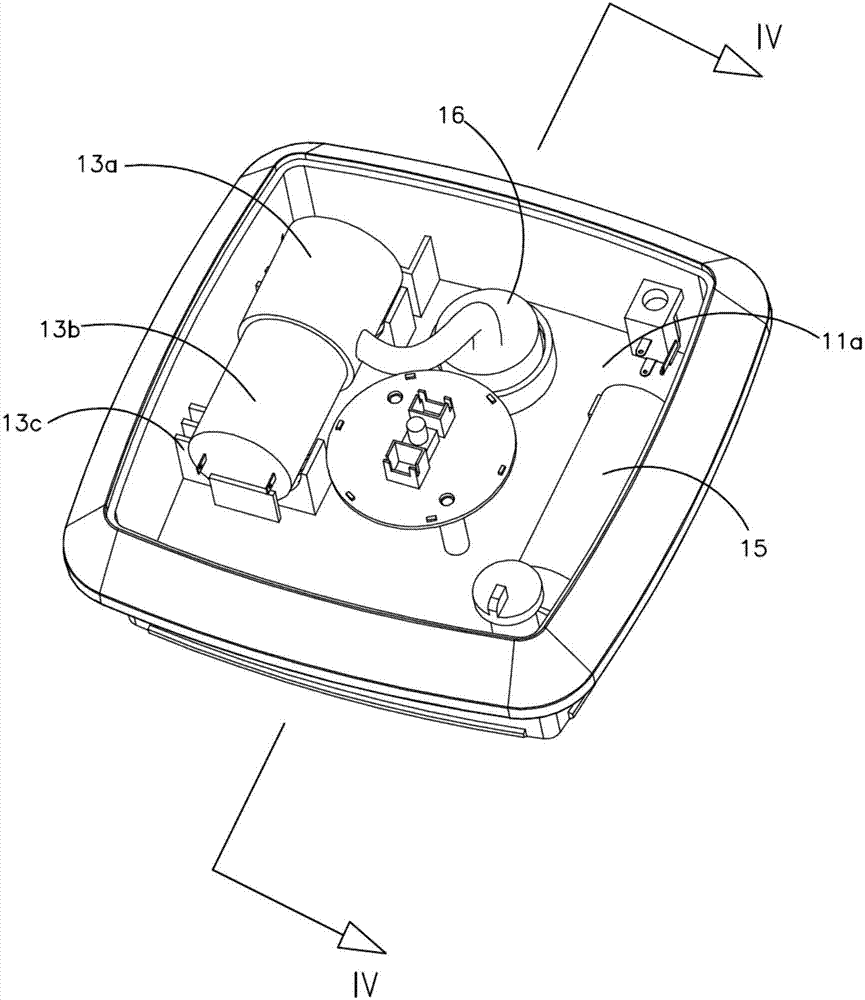

Vacuum cover, stirring device with vacuum cover and storage device

InactiveCN107499717AEasy to operateWide range of applicationsClosuresMixer accessoriesAirflowEngineering

The invention relates to a vacuum cover, a stirring device with the vacuum cover and a storage device. The vacuum cover comprises a vacuum cover body, a one-way valve, a minipump, a circuit board and a power source, and an air exhaust opening is arranged in a containing cavity of the vacuum cover body; the one-way valve is arranged in the extraction opening, and the one-way valve is provided with an air flow groove communicated to the air exhaust opening; the minipump is arranged in the containing cavity and comprises an air exhaust nozzle and an air discharging nozzle, and the air exhaust nozzle is connected to the air flow groove of the one-way valve through a pipe; and the circuit board and the power source are arranged in the containing cavity and are electrically connected to the minipump. According to the vacuum cover, the minipump is arranged in the containing cavity, and the vacuum cover has the vacuumizing function. When a stirring container needs to be vacuumized, only a cover of the common stirring container needs to be replaced with the vacuum cover, and the aims of stirring after vacuumizing can be achieved. when a user only needs a single stirring function, only the vacuum cover needs to be replaced with the cover with the common stirring container, allocation of two stirring machines is not needed, and the requirements of the user for achieving different functions through one stirring machine are met.

Owner:ZHONGSHAN JUNGUO ELECTRICAL APPLIANCES CO LTD

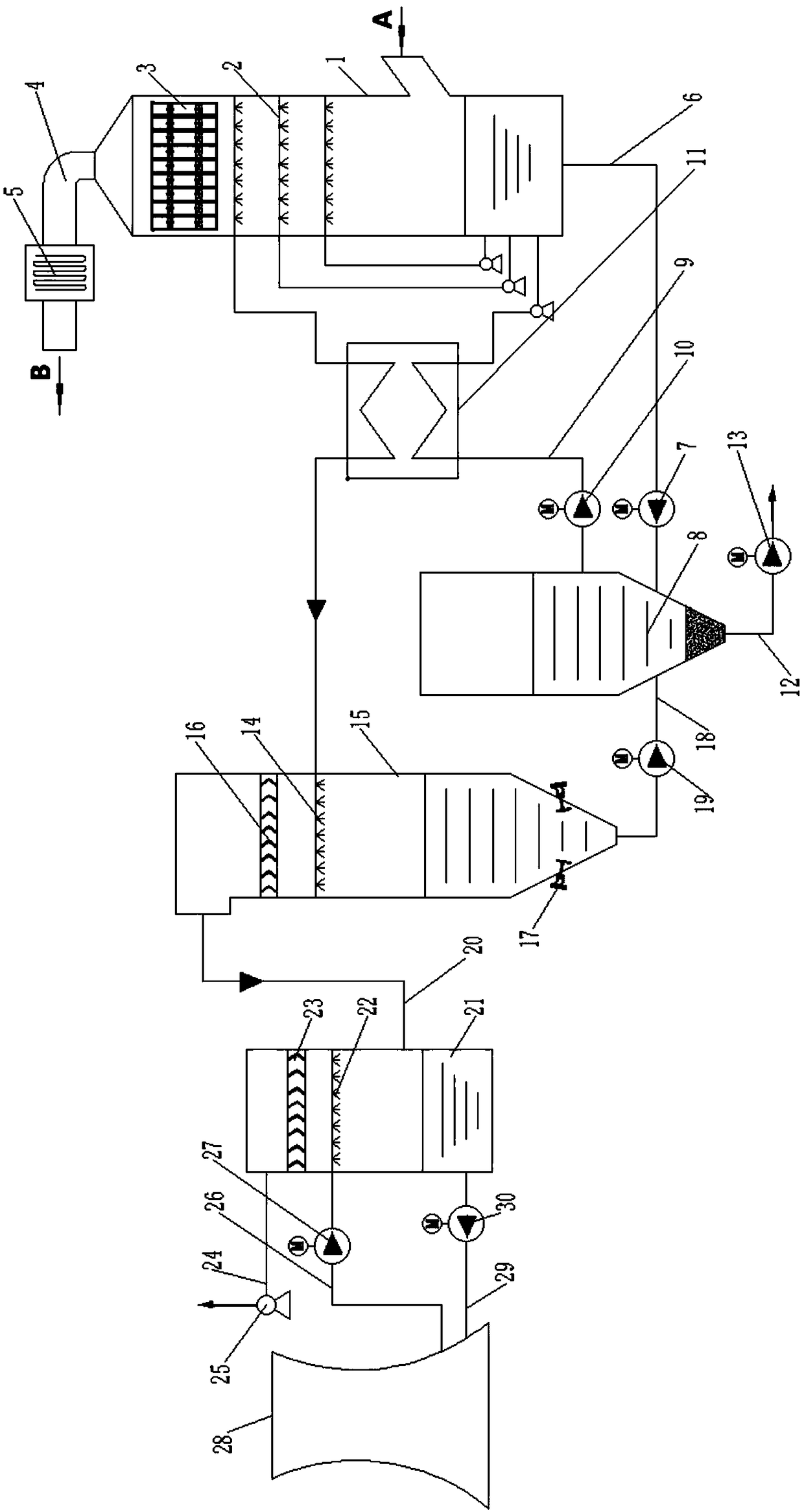

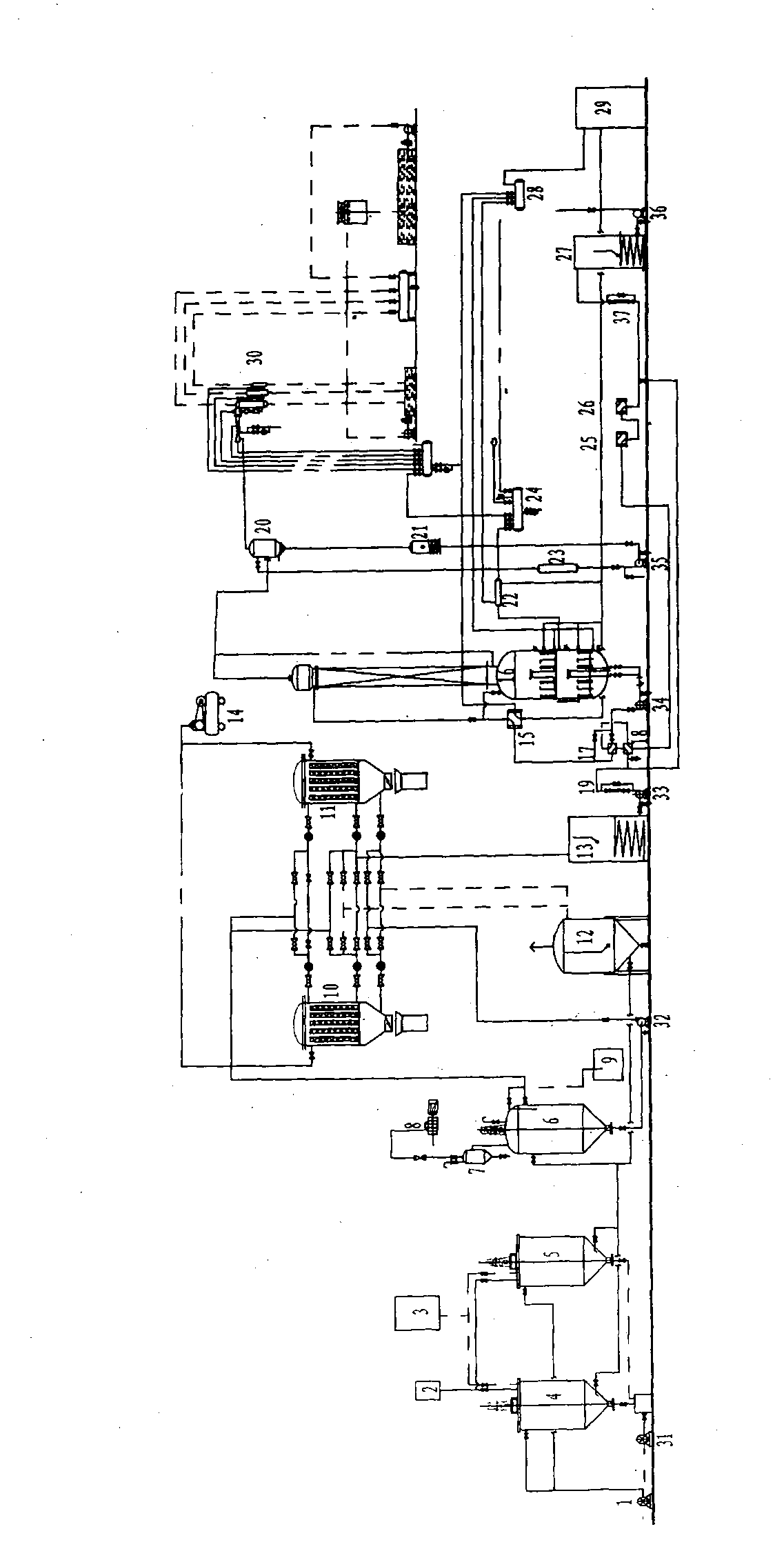

Desulfurization waste water zero discharge and white smoke purification combined treatment system

PendingCN108295646AGuaranteed vacuum environmentReduce the temperatureGas treatmentUsing liquid separation agentCooling towerSludge

The invention relates to a desulfurization waste water zero discharge and white smoke purification combined treatment system, which comprises a desulfurization tower, a desulfurization slurry circulation spraying system, a desulfurization tower defogging device, a desulfurization tower outlet flue, a smoke gas reheater, a desulfurization waste water discharging pipeline, a desulfurization waste water discharging pump, a buffer tower, a desulfurization waste water clean liquid circulation pipeline, a desulfurization waste water clean liquid circulation pump, a heat exchanger, a sludge conveyingpipeline, a sludge conveying pump, an evaporation tower, an evaporation tower defogging device, a stirring device, a desulfurization waste water clean liquid backflow pipeline, a desulfurization waste water clean liquid backflow pump, a water steam conveying pipeline, a condensing tower, a condensing tower spraying device, a condensing tower defogging device, a vacuum pump pipeline, a vacuum pump, a cooling tower water conveying pipeline, a cooling tower water conveying pump, a cooling tower, a cooling tower water return pipeline and a water return pump. The operation cost is low; the desulfurization tower slurry is condensed; the smoke gas temperature is lowered; the smoke gas is reheated; the s white smoke purification is realized; the heat adsorbed by condensation is used for evaporating the desulfurization waste water; the energy consumption is low. The treatment system can be widely applied to power station boiler and industrial boiler smoke gas desulfurization systems.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

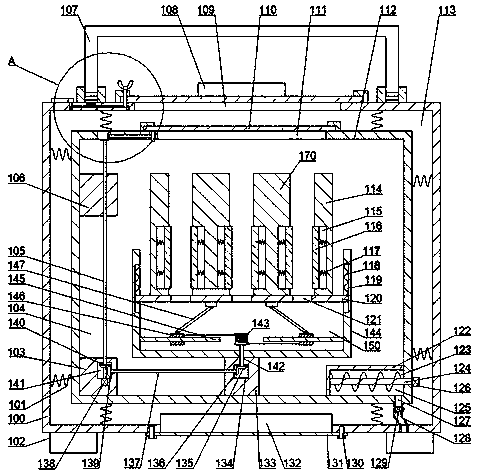

Stem cell transportation box

ActiveCN109969597AGuaranteed uptimeEasy accessPackaging under vacuum/special atmosphereShock-sensitive articlesDamping functionPassword

The invention discloses a stem cell transportation box. A main box body is included and internally provided with a liquid nitrogen cavity. An inner box body is arranged in the liquid nitrogen cavity.The outer end of the inner box body and the inner wall of the liquid nitrogen cavity are elastically connected through damping springs, and the four sets of damping springs are arranged and achieve the damping function. Stand bars symmetrically arranged left and right are fixedly arranged at the bottom end of the main box body. A liquid nitrogen box plate is arranged at the bottom end of the mainbox body and tightened to the bottom end of the main box body through screws in a threaded manner. A liquid nitrogen box located in the liquid nitrogen cavity is fixedly arranged at the top end of theliquid nitrogen box plate and can volatilize liquid nitrogen, and heat preservation is achieved for the inner box body. A stem cell transportation box opening mechanism is provided with passwords, itcan be guaranteed that the transportation box cannot be opened at will, and a storage and taking mechanism facilitates storage and taking of stem cell test tubes. The device is good in damping and buffering function, a transmission structure of the device is simple, and faults are not likely to happen.

Owner:广东金瀚生物科技有限公司

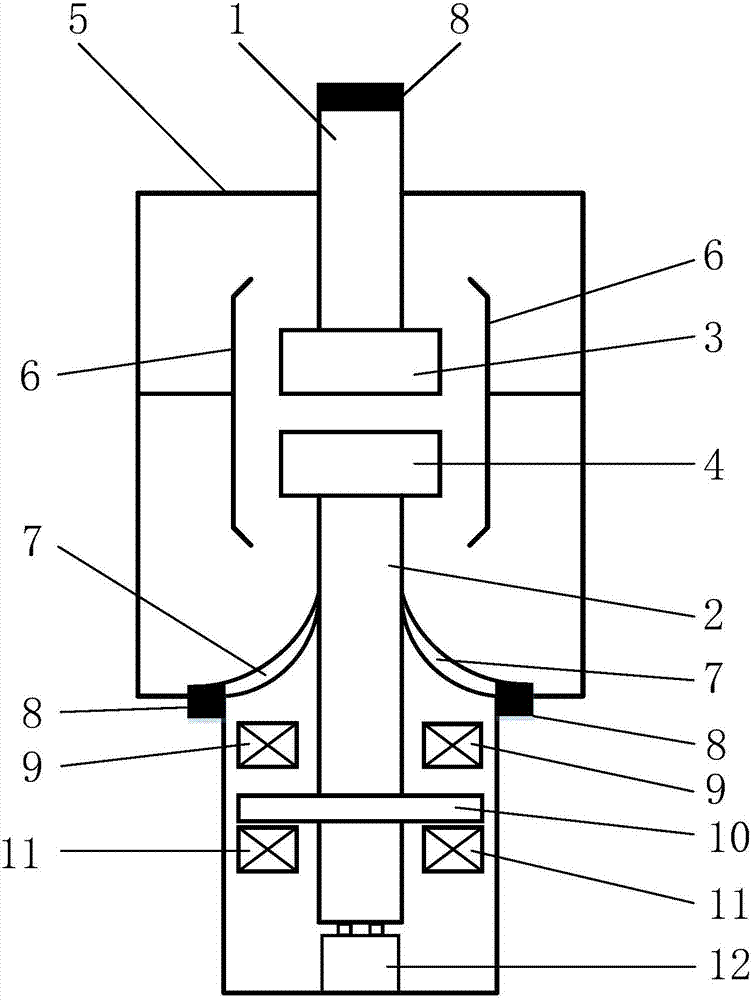

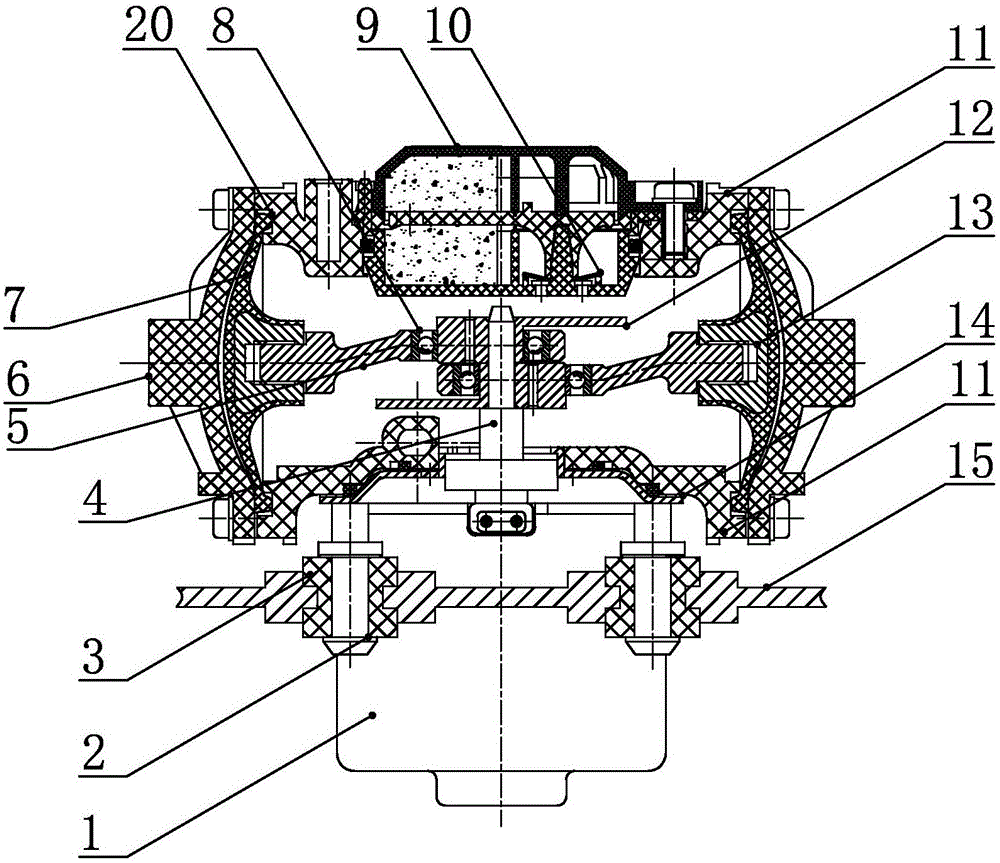

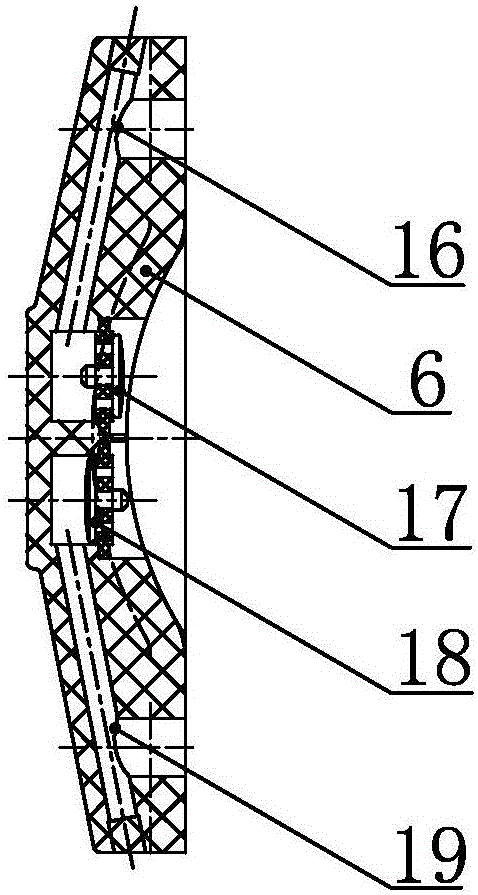

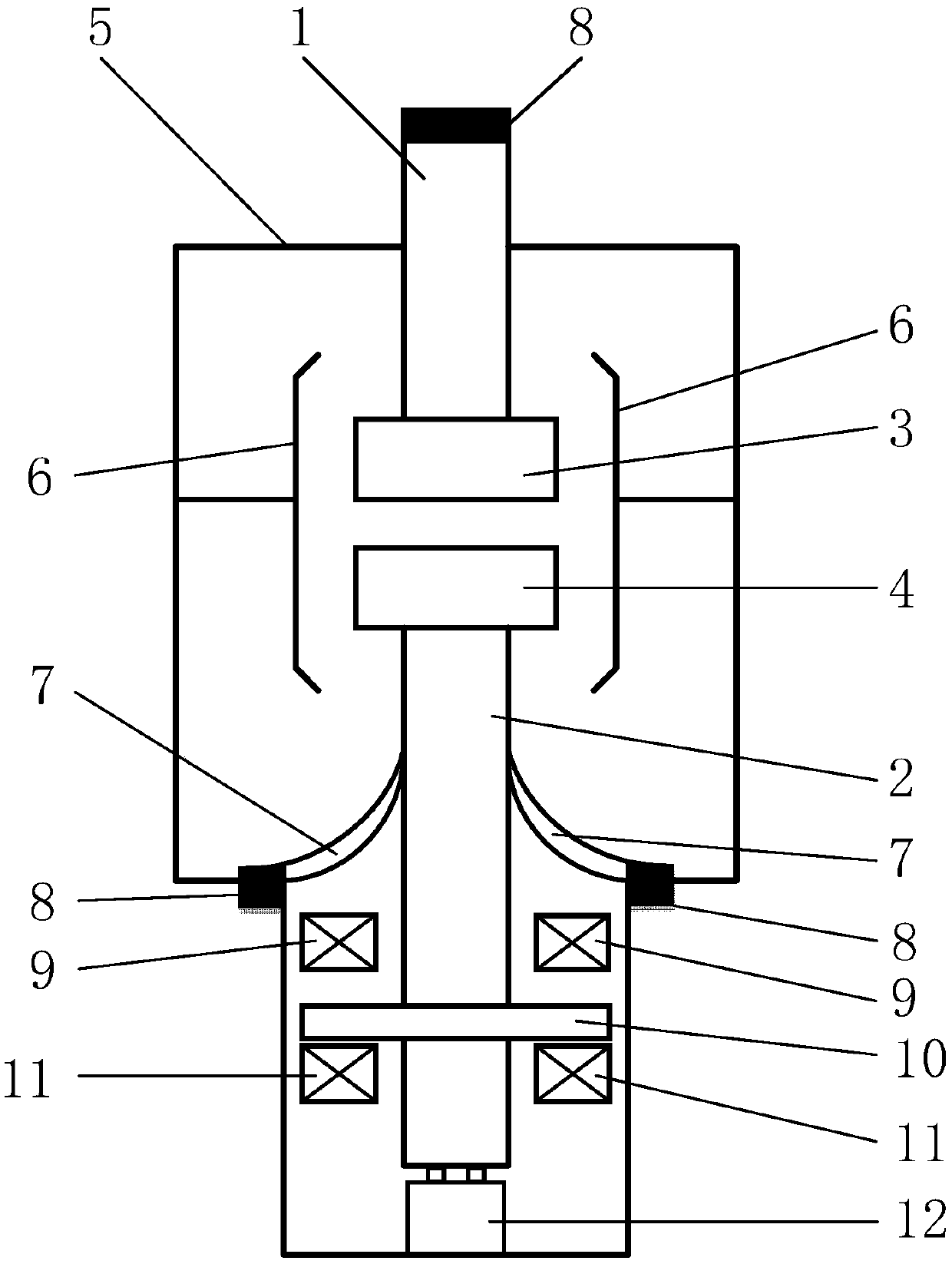

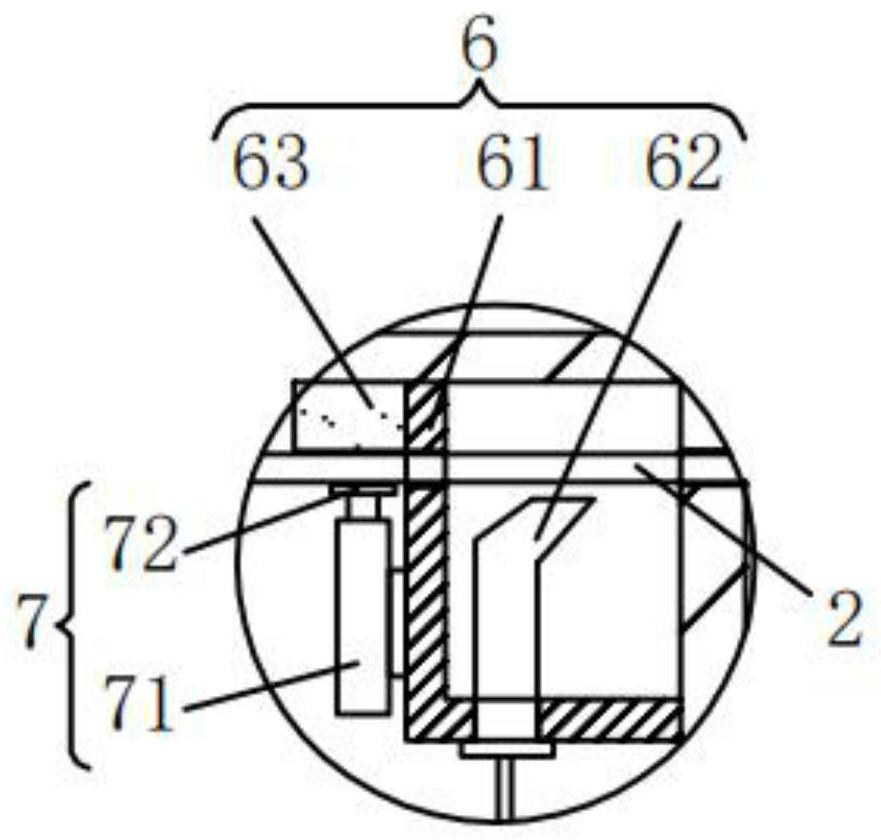

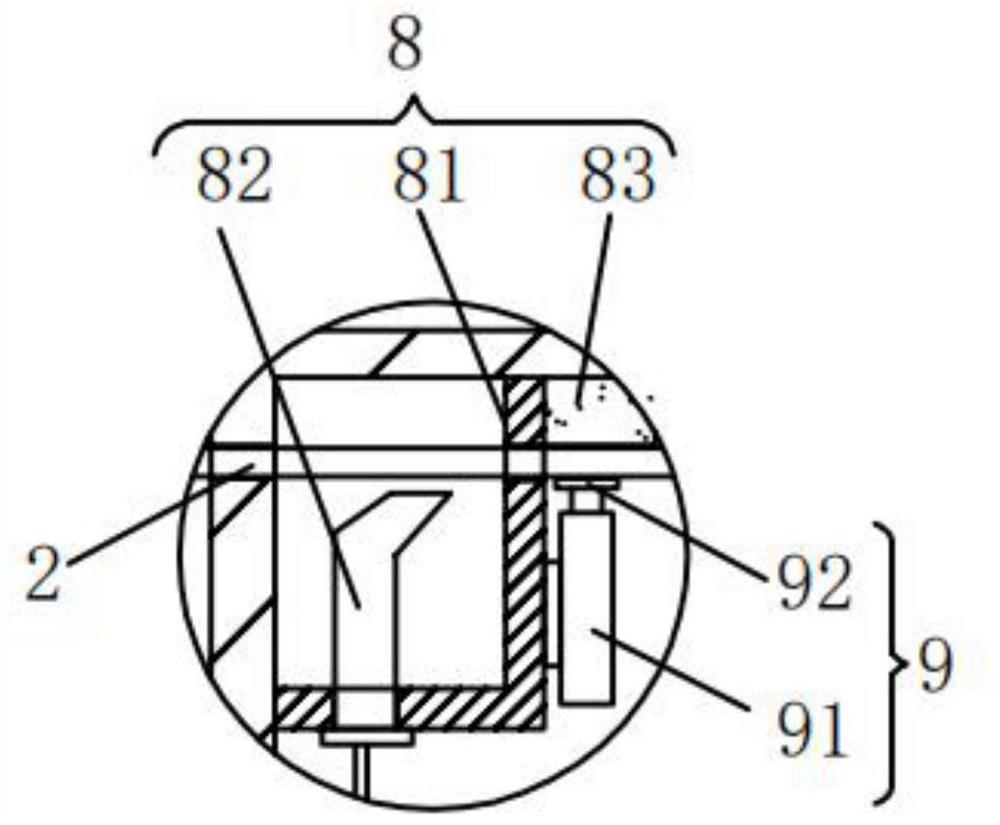

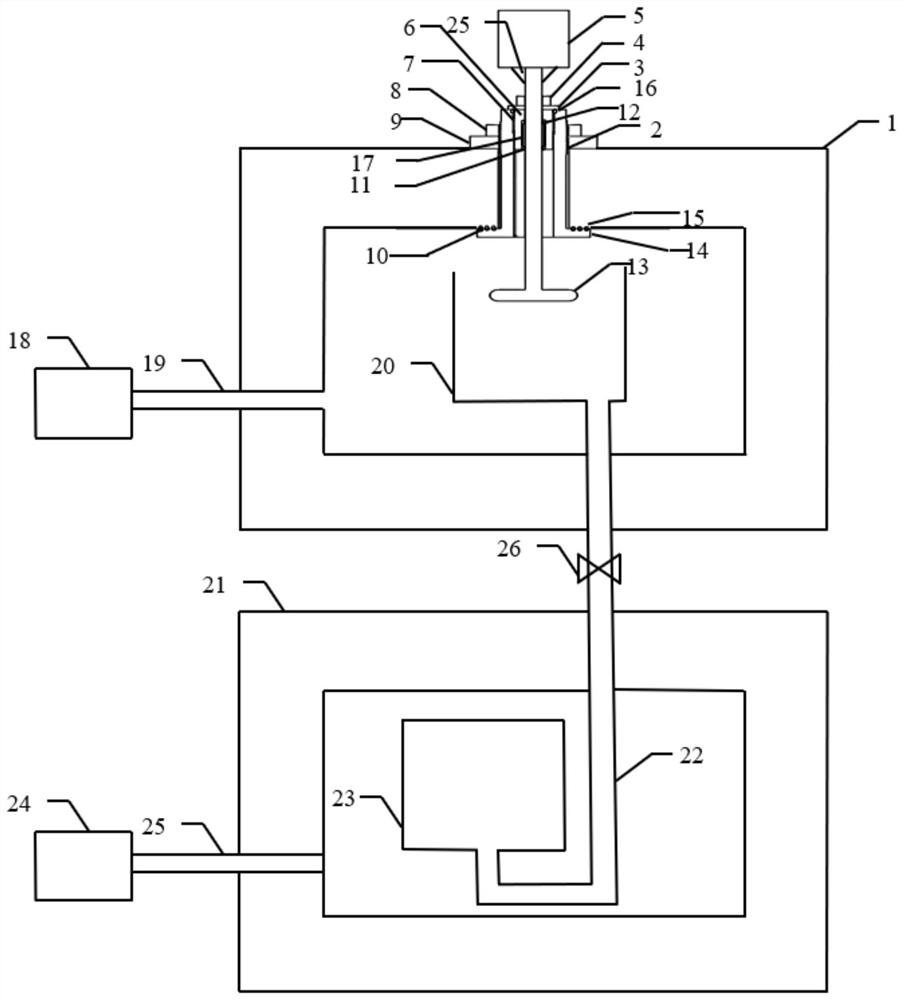

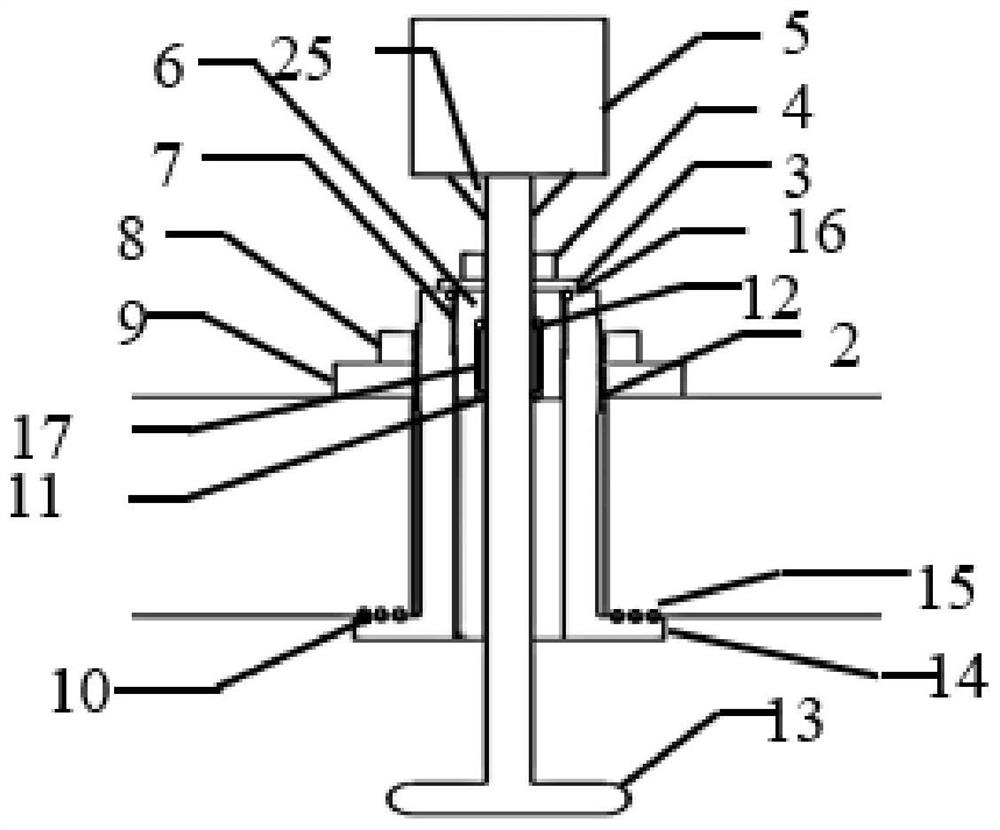

Automatic operating vacuum arc extinguish chamber and automatic operating method thereof

InactiveCN107481889AReduce volumeSmall footprintHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum arc

The invention discloses an automatic operating vacuum arc extinguish chamber and an automatic operating method thereof. The vacuum arc extinguish chamber comprises a static conductive rod, a movable conductive rod, a static contact, a movable contact, an arc extinguish chamber housing, a shielding cover, a flexible conductor, a main circuit terminal, a gate-opening driving coil, a magnetic repulsion disk, a gate-closing driving coil and a bistable retention structure. The invention discloses an automatic operating method of the automatic operating vacuum arc extinguish chamber. A conventional arc extinguish chamber and an operation mechanism are integrated to greatly reduce the part number and size of the operation mechanism and operation power of the mechanism. A bellows structure of a conventional arc extinguish chamber is eliminated, and the automatic operating vacuum arc extinguish chamber has the advantages of simple structure, compactness, long service lifetime and low cost.

Owner:XI AN JIAOTONG UNIV +3

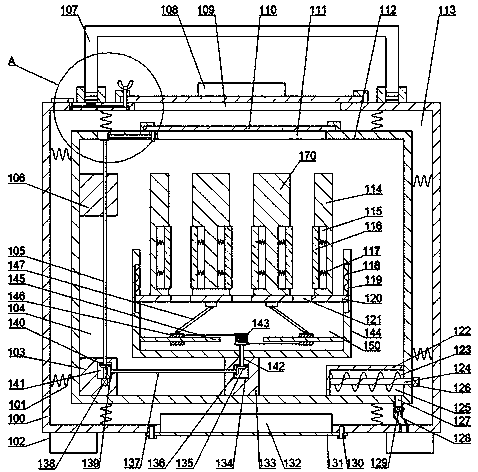

Vacuum pressure test device

InactiveCN105444965AReduce trafficPrecise position controlMeasurement of fluid loss/gain rateVacuum pressureMotor drive

The invention discloses a vacuum pressure test device, including an electric control box and a vacuum box located above the electric control box. The vacuum box comprises a door body, a motor base plate, an automatic feeding mechanism located on the motor base plate, a motor driving the automatic feeding, a pressure sensor, and a temperature sensor. The electric control box contains a power supply, a switchboard, a vacuum generator, a PCB control panel and a motor driver. A plurality of support portions and tail plug modules are mounted fixedly on the motor base plate. A plurality of guide shafts are disposed below the automatic feeding mechanism. The guide shafts are disposed on the support portions and the tail plug modules in a penetrating and sliding manner. The automatic feeding mechanism comprises a carrier plate, a plurality of accommodating cavities located in the carrier plate, and a sealing plate mounted fixedly with the accommodating cavities. The accommodating cavities and the tail plug modules can be mounted in a plugging manner. The door body is provided with an accommodating portion for accommodating the sealing plate. The sealing plate and the door body are mounted in a sealed manner. The vacuum pressure test device is good in vacuum sealing performance, simple and convenient to operate, high in automation degree and easy to maintain and implement.

Owner:KUSN MAIZHI FIXTURE TECH

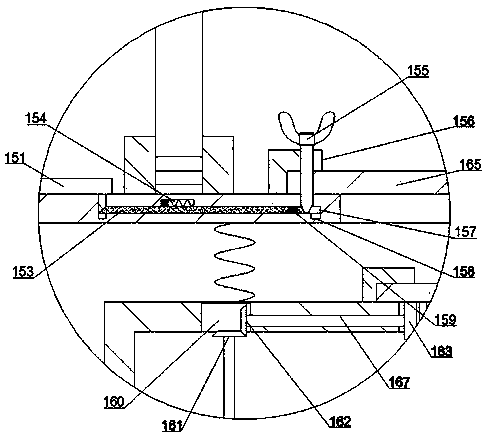

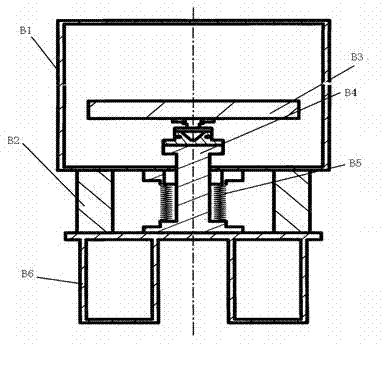

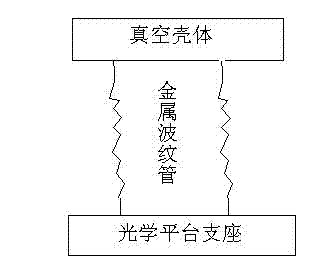

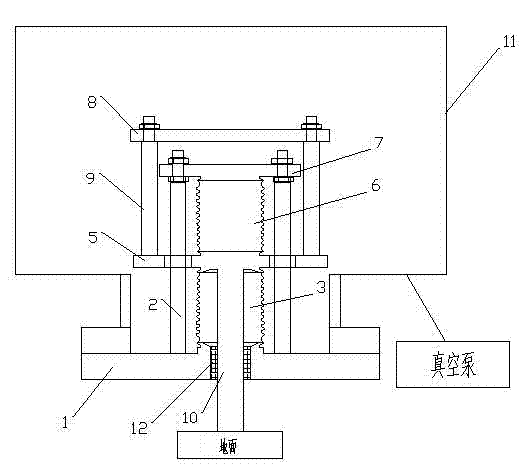

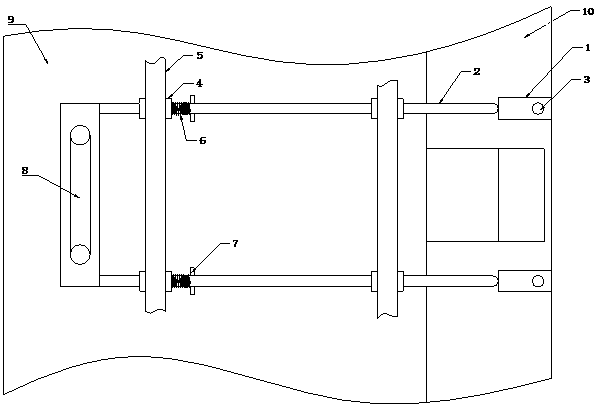

Vacuum operating platform with damping mechanism

ActiveCN102818587AReduce vibrationGuaranteed vacuum environmentMeasurement apparatus for damping movement partsClassical mechanicsEngineering

The invention discloses a vacuum operating platform with a damping mechanism, wherein the vacuum operating platform is fixedly connected with a sealing flange through a vacuum chamber shell; the sealing flange is fixedly connected with a damping flange; an upper corrugated pipe is fixedly connected between a platform supporting plate and the damping flange; and a lower corrugated pipe is fixedly connected between the sealing flange and the platform supporting plate. When vibration is generated, the vacuum chamber shell transfers the vibration to the sealing flange; the sealing flange directly transfers the vibration to the lower corrugated pipe; meanwhile, the vibration of the sealing flange is transferred to the damping flange through an auxiliary supporting part and then transferred to the upper corrugated pipe; the damping flange can be regulated along the axial direction of the auxiliary supporting part so as to regulate deformation of the upper corrugated pipe and the lower corrugated pipe; and therefore, the vibration force of the upper corrugated pipe transferring to the platform supporting plate is opposite to the vibration force of the lower corrugated pipe transferring to the platform supporting plate. As a result, the vibration of the platform supporting plate is effectively reduced.

Owner:KYKY TECH

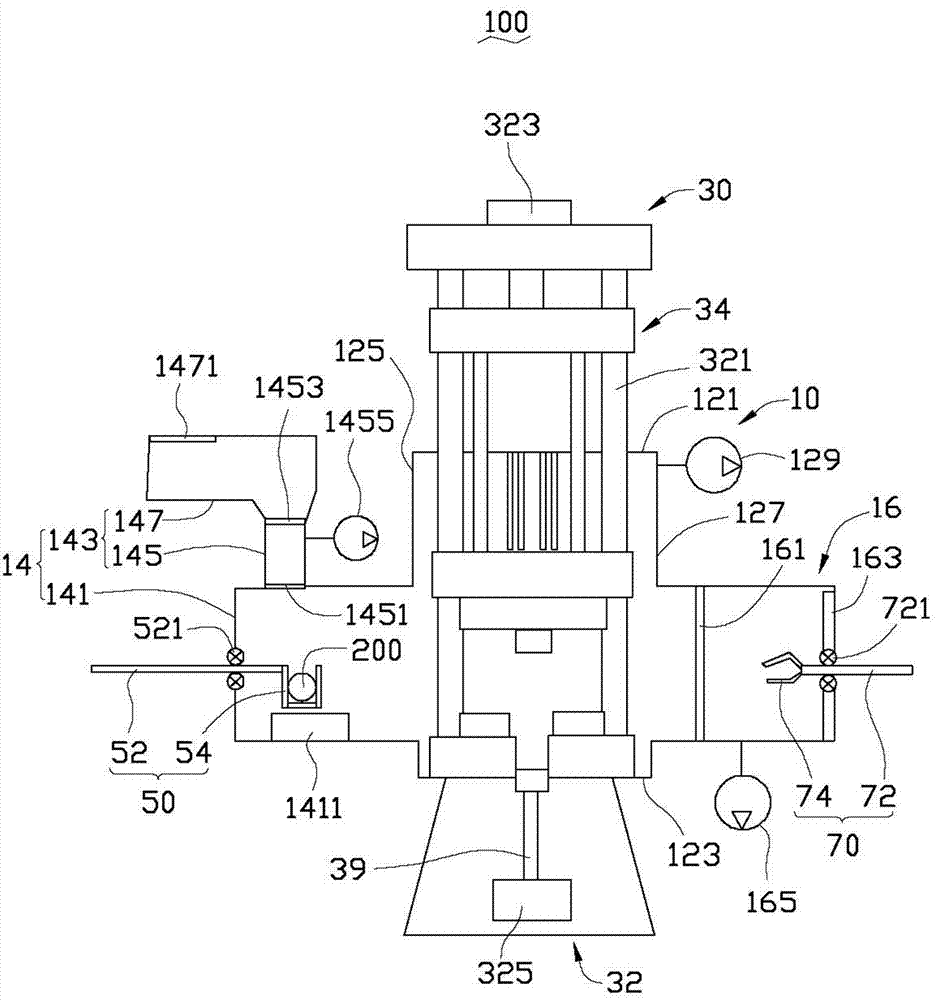

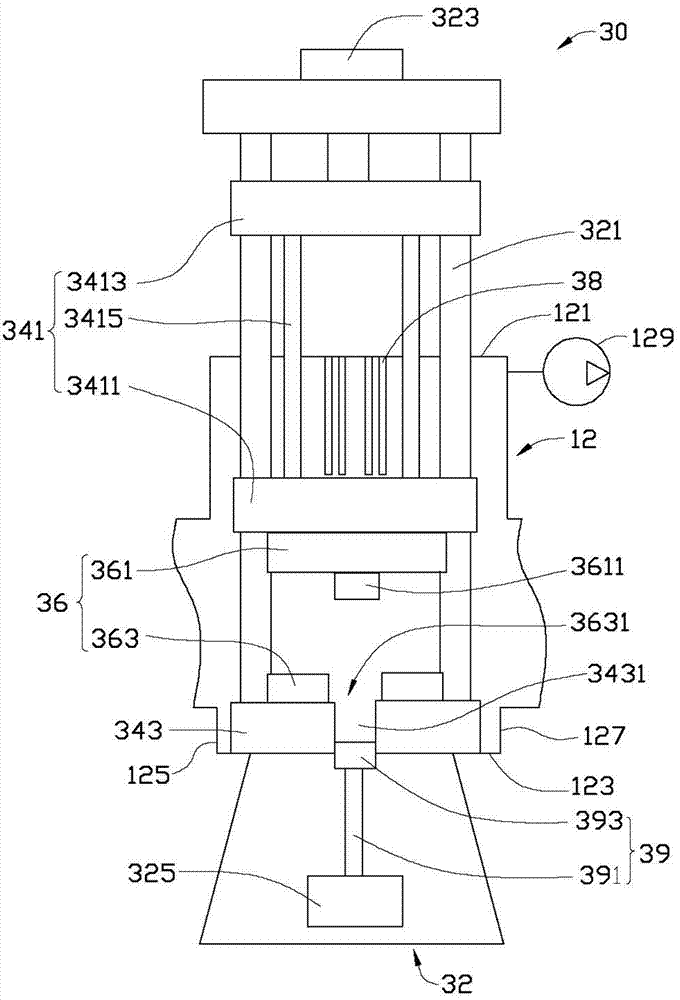

Die casting machine

A pressure casting machine can be configured to mold a molten material into a workpiece. The pressure casting machine can include a vacuum chamber and a pressure casting mechanism coupled to the vacuum chamber. The vacuum chamber can include a processing section having a top wall and a bottom wall opposite to the top wall, a first gate configured to seal the processing section, and a first vacuum pump coupled to the processing section. The pressure casting mechanism can include a first driver positioned adjacent to the top wall, a first core received in the processing section and coupled to the first driver, a second core received in the processing section, and a plurality of pushing members received in the processing section. The second core can be coupled to the bottom wall and opposite to the first core. The pushing members can be coupled to the top wall.

Owner:JIZHUN PRECISION IND HUIZHOU

High-class animal oil refining process

InactiveCN103540403AQuality assuranceGuaranteed stabilityFatty-oils/fats refiningEssential-oils/perfumesOil and greasePhosphoric acid

According to a production technique provided by the invention, medium-temperature soft water washing is adopted and phosphoric acid or citric acid is added to chelate heavy metal ions in the process, so that possibility of grease oxidation is reduced; to ensure the quality of edible oil, the dewatering and the decoloration procedures are carried out in a vacuum environment; the stability of the grease is ensured by adding a certain amount of citric acid in the deacidification and deodorization procedures, and the grease is high in yield and good in quality because of physical deacidification and deodorization in high vacuum; automatic temperature adjustment is adopted, so that the product quality is ensured; vacuum pipelines are arranged, so that the vacuum environment is ensured; and the oil circulation period is shortened by adopting a continuous or semi-continuous production mode.

Owner:李宁

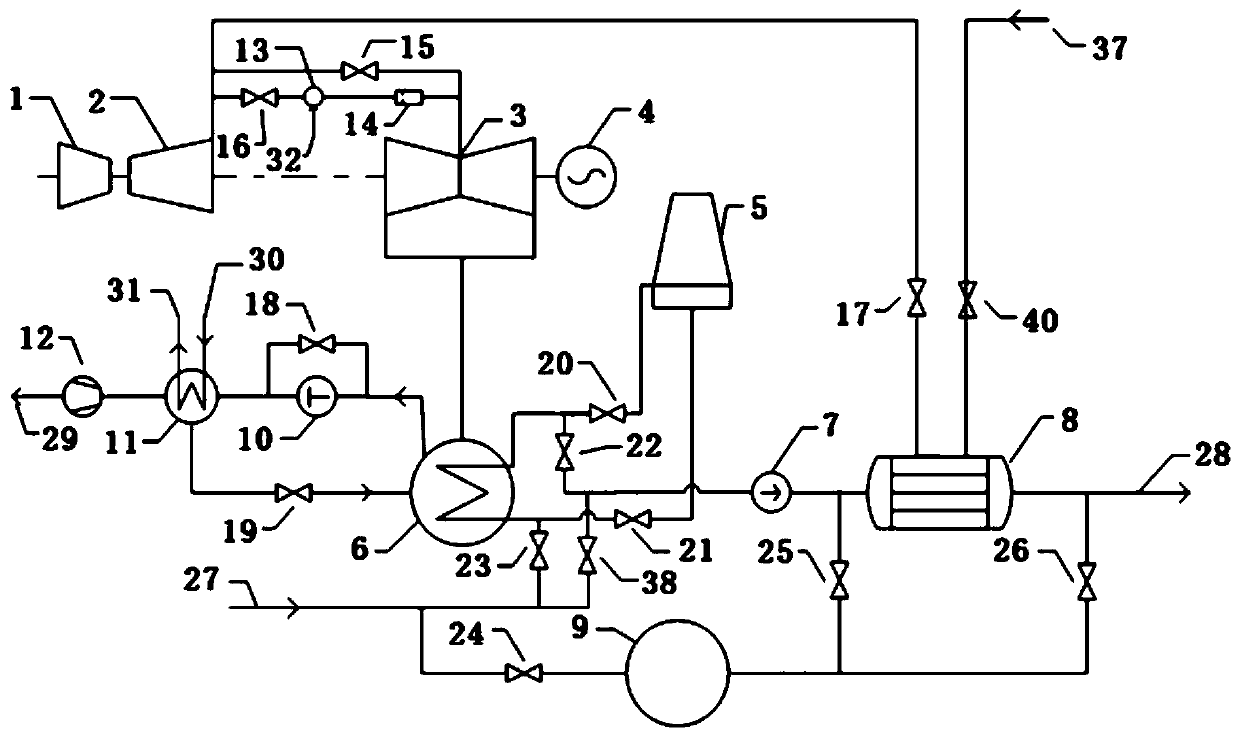

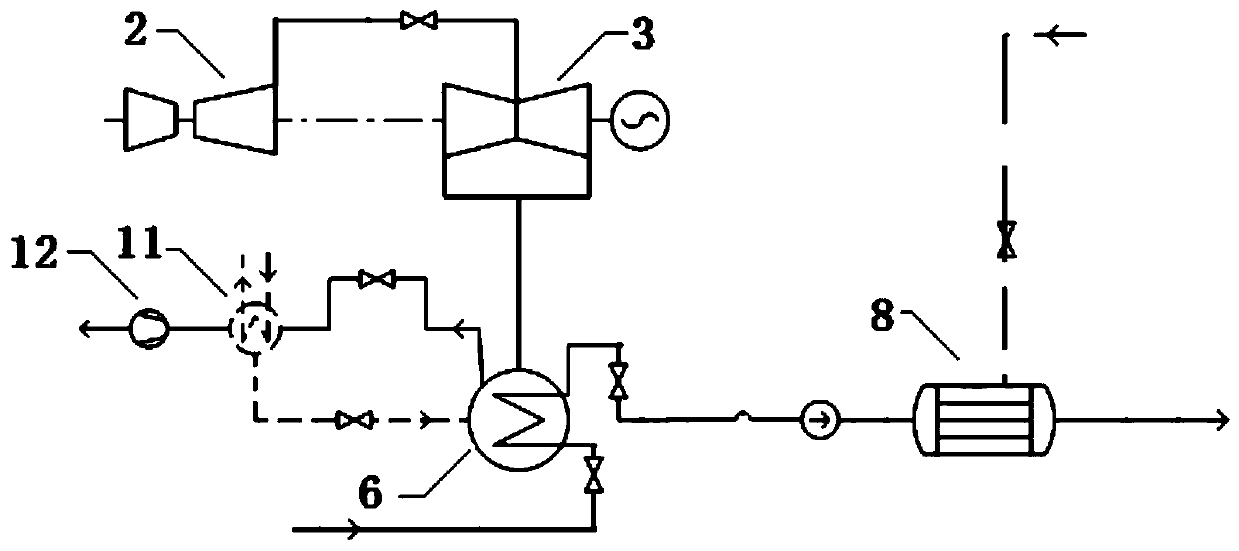

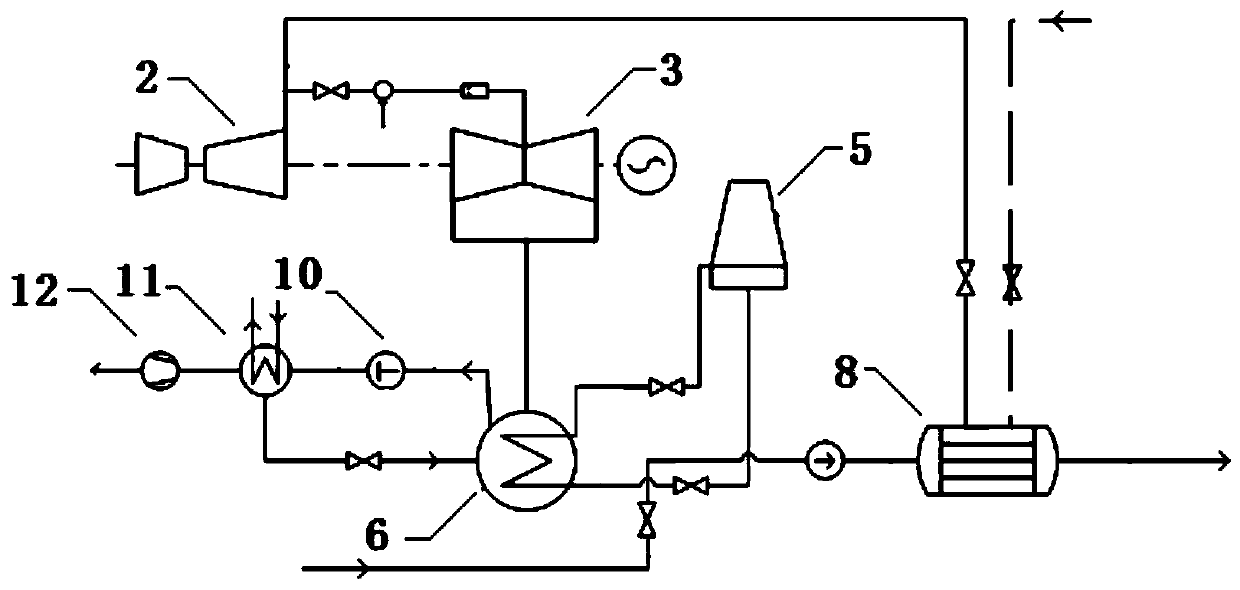

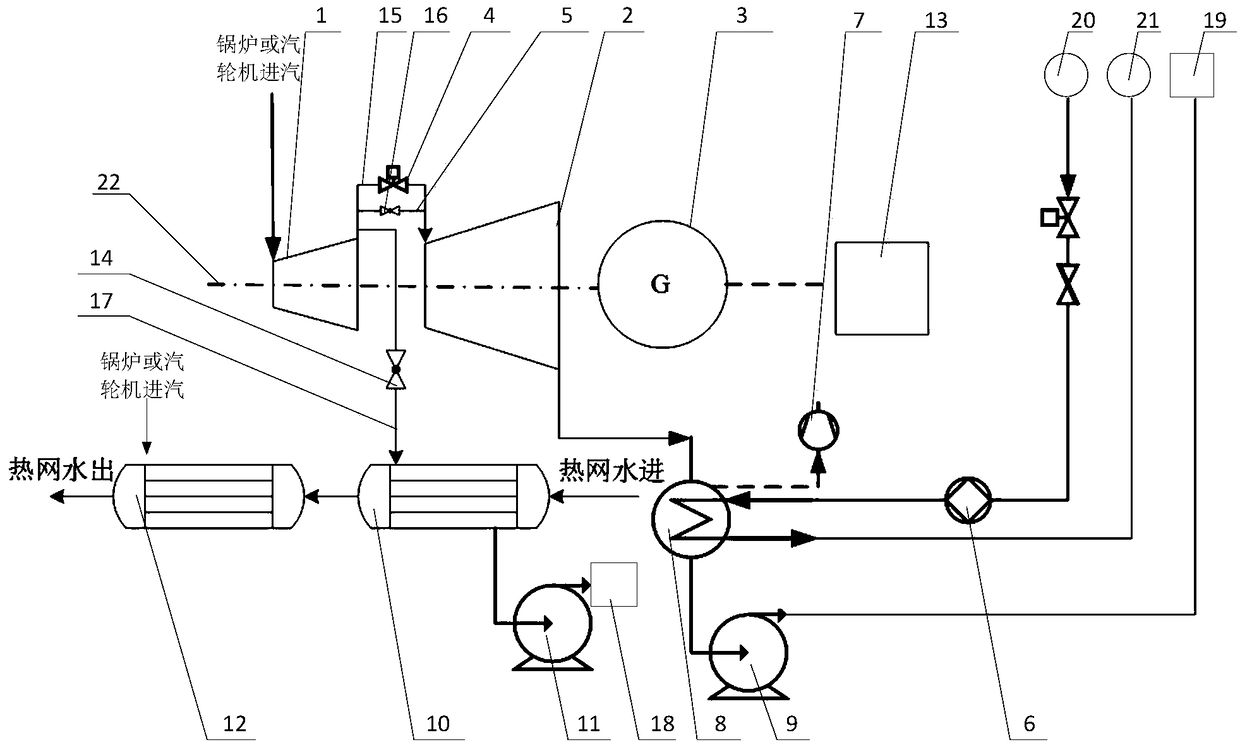

Cogeneration unit heat supply method and heat supply system

ActiveCN111365748AGuaranteed vacuum environmentReduce work stressCentral heating with accumulated heatLighting and heating apparatusCogenerationProcess engineering

The invention relates to the technical field of steam turbine generator units, and particularly provides a cogeneration unit heat supply method and heat supply system which solve the contradiction that the heat load demand and the electrical load peak regulation are difficult to schedule simultaneously in the heat supply period. According to the heat supply method and system, a high-back-pressureheat storage mode can be adopted when the heat load demand is low and the electrical load demand is high, a high-back-pressure heat release mode is adopted when the heat load demand and the electricalload demand are high and the heat load demand is higher than the heat production amount matched with the electricity production amount produced according to the electrical load demand by the unit, alow-pressure cylinder near-zero output heat storage mode is adopted when the electrical load demand and the heat load demand are low, and a low-pressure cylinder near-zero output heat release mode isadopted when the electrical load demand is low, the heat load demand is high and the heat load demand is higher than the heat production amount matched with the electricity production amount producedaccording to the electrical load demand by the unit.

Owner:GUODIAN LONGYUAN ENERGY SAVING TECH

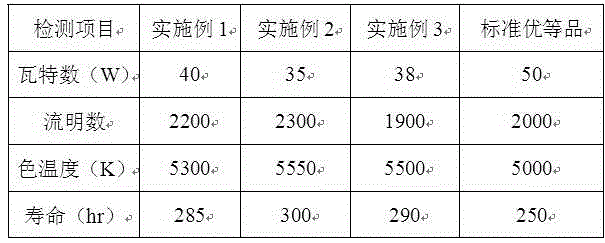

Halogen lamp producing technique

InactiveCN104576299AImprove ObservabilityQuality improvementElectrical apparatusEngineeringChemistry

The invention discloses a halogen lamp producing technique. The halogen lamp producing technique comprises the step of bulb shell production, filament production, wick production, bulb production, and assembly. In the bulb shell manufacturing technique, a quartz tube serves as the raw material, so that the product lumens are effectively improved, and the light is more definite; the quartz tube are sawed twice and repeatedly cleaned, so that the problem of tube breakage in the tube sawing process is solved; through secondary wet hydrogen shaping and hydrogen-annealed shaping after primary shaping, the hydrogen element is increased; certain oxide impurities can be removed during heating in a hydrogen environment; after tungsten filaments are heated in the hydrogen environment, atoms in the tungsten filaments become atoms with more stable lattice structures, so that the tungsten filaments cannot droop during long-term use, and accordingly, the service life of a halogen lamp is prolonged; as nitrogen which has no reaction with the material is added, the vacuum environment of the filaments is guaranteed, the service life is prolonged, and the lumen level is improved.

Owner:DANYANG ZHONGYUAN AUTOMOBILE LIGHT

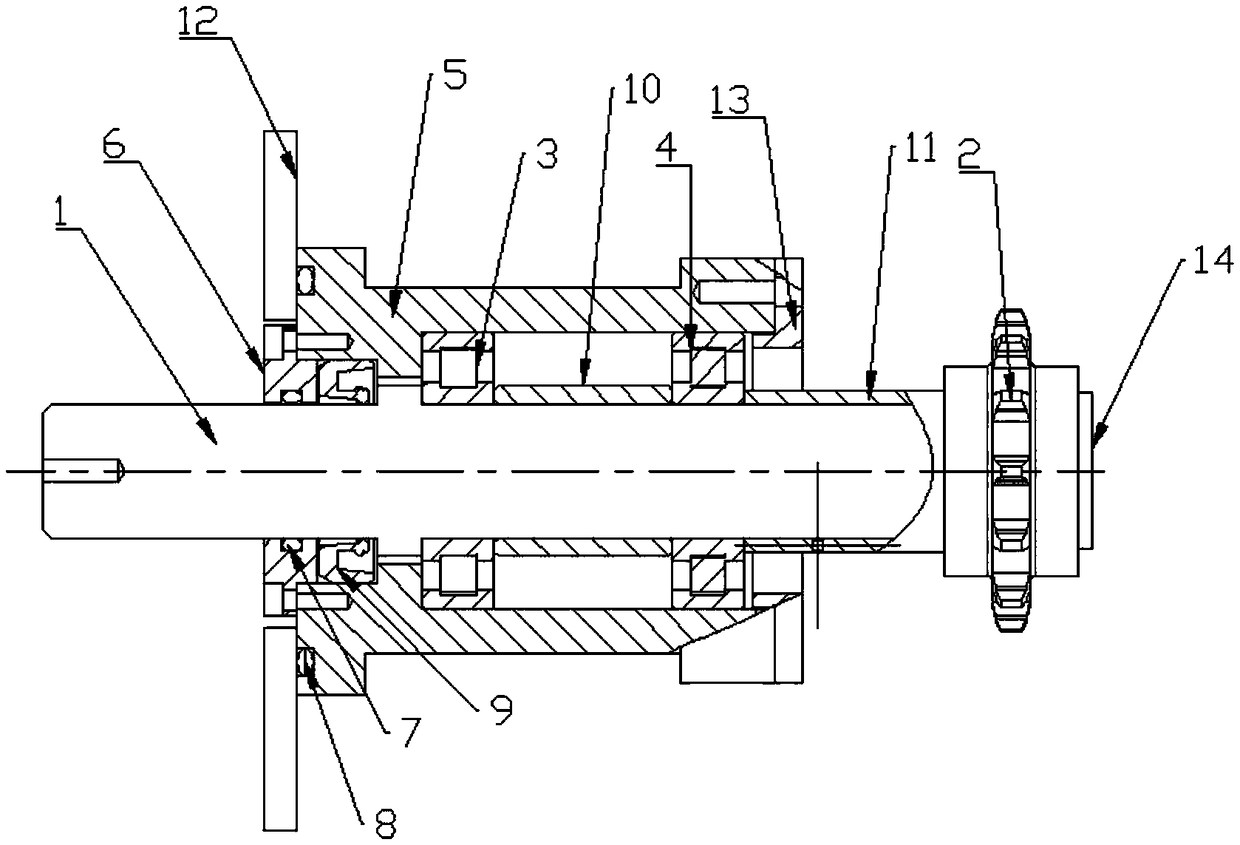

Horizontally-opposite diaphragm type electric vacuum pump

InactiveCN105134567AReduce volumeGuaranteed vacuum environmentPositive displacement pump componentsFlexible member pumpsVacuum assistedEngineering

The invention relates to a vacuum pump providing vacuum assisting power for an automobile braking master pump and aims to provide a horizontally-opposite diaphragm type electric vacuum pump which is small in size, large in exhaust amount and convenient to machine. The horizontally-opposite diaphragm type electric vacuum pump comprises a fixed support, a motor and a pump body. Two eccentric cranks which are horizontally arranged in the left and right direction are installed on a motor shaft in the pump body and connected with connecting rods. The other ends of the connecting rods are connected with diaphragm assemblies which are wrapped in diaphragms. The edges of the diaphragms are fixed to the pump body. End covers are installed at the two ends of the pump body. A sealed work cavity is formed between each diaphragm and the corresponding end cover. Two sets of installing holes are machined in the inner side of each end cover, and each upper installing hole and each lower installing hole are provided with an air inflow valve and an air outflow valve respectively. Each air inflow valve and the corresponding air outflow valve are communicated with an air inflow channel and an air outflow channel respectively. Each air inflow channel is connected with an air outflow pipeline. The air outflow channels are communicated with the interior of the pump body. An exhaust port is formed in the upper portion of the pump body.

Owner:SHIJIAZHUANG JIAXIN AUTOMOTIVE BRAKE SYST

Vacuum continuous coating system for strip material and transition cabin unit used by same

PendingCN109338327ANarrow downReduce difficultyVacuum evaporation coatingSputtering coatingCoating systemMaterials science

The invention discloses a vacuum continuous coating system for a strip material and a transition cabin unit used by the same, belongs to the technical field of vacuum continuous coating, provides a transition cabin unit for vacuum continuous coating of the strip material in order to meet the vacuum requirements needed by the vacuum coating system, and further provides a system capable of conducting continuous vacuum coating on the strip material so as to solve the problem that in an existing coating system, all technological devices and cabins need to be arranged in a full-closed large vacuumcabin body. According to the vacuum continuous coating system for the strip material and the transition cabin unit used by the same, the transition cabin units can be only arranged on the conveying tracks on the two sides of a strip material entrance and exit vacuum coating area, therefore, conveying channels corresponding to the conveying tracks of the strip material can be isolated and sealed, and a vacuum environment formed in the vacuum coating area is effectively guaranteed; and therefore a full-closed large vacuum cabin body does not need to be arranged to contain an unwinding mechanism,a winding mechanism, the vacuum coating area and a whole conveying channel of the strip material in an enclosing mode.

Owner:PANZHIHUA UNIV +1

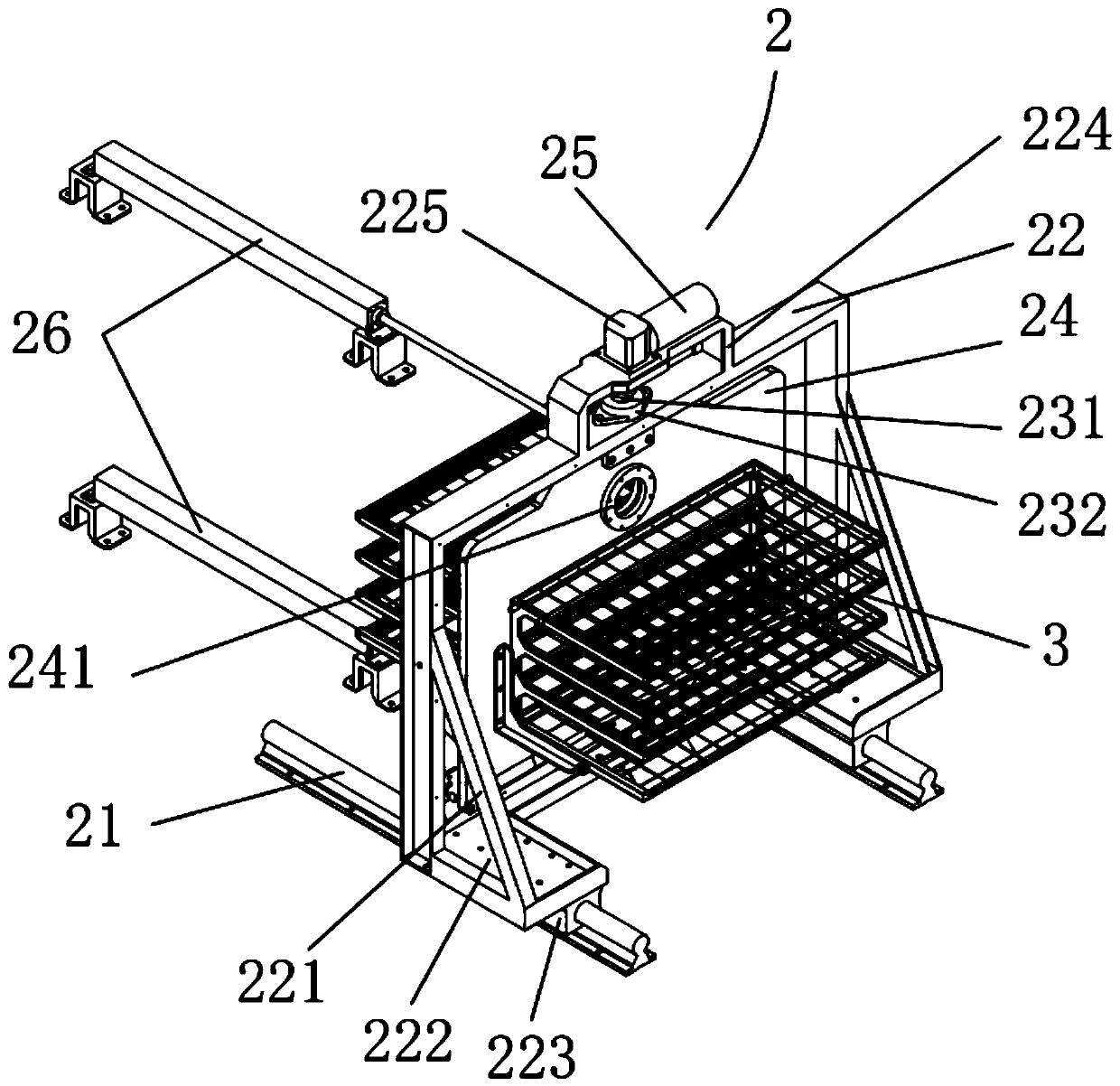

Overturning sliding cavity door structure, plasma vacuum cavity and plasma treatment equipment

PendingCN110184590AAvoid failureGuaranteed vacuum environmentElectric discharge tubesChemical vapor deposition coatingEngineeringMechanical engineering

The invention discloses an overturning sliding cavity door structure, a plasma vacuum cavity and plasma treatment equipment. The cavity door structure comprises a slide rail, a mounting rack slidablymounted on the slide rail and a cavity door rotatably connected in the mounting rack. Material rest trays are arranged on two sides of the cavity door, a vertical rotating shaft is mounted in the middle of the cavity door in a penetrating manner, the vertical rotating shaft is mounted in the mounting rack, and the vertical rotating shaft is driven by a driving mechanism A located on the top of themounting rack, the cavity door under the action of the driving mechanism A rotates in the mounting rack around the vertical rotating shaft, and the mounting rack is driven by an external driving mechanism B to slide; and the plasma vacuum cavity and the plasma treatment equipment adopt the overturning sliding cavity door structure. By arranging the rotary vacuum cavity door, the positions of thematerial rest trays can be exchanged, so that a purpose of changing in-out materials quickly is further achieved.

Owner:SUZHOU WEIPENG ELECTRICAL TECH CO LTD

Auxiliary machine integrated power source system with cylinder switching function for supplying heat

PendingCN109306877AImprove thermal economyRealization of cylinder cutting functionSteam useElectricityEngineering

The invention discloses an auxiliary machine integrated power source system with a cylinder switching function for supplying heat. One path of steam output by a high-pressure cylinder leads to a low-pressure cylinder, and the other path is led to a hot-net heater; each steam pipeline is provided with a valve, and the connecting and the disconnecting of the steam pipelines are controlled; the high-pressure cylinder and the low-pressure cylinder are the same power input shaft, the terminal of the power input shaft is connected with a generator, the generator is driven, and the generator drives aload to run; a low-pressure cylinder zero-output technology is applied when heat supply is carried out in winter, the rest of steam both enters the hot-net heater to realize external heat supply; a pure-condensation working condition is maintained to run in a non-heat-supply season, and the high-pressure cylinder and the low-pressure cylinder jointly drive the generator to generate electricity; during heat supply conversion, only the valves on different steam pipelines need to be adjusted, the cylinder switching function can be realized; the reaction is rapid, and the system is simple; the steam exhaust of a small steam turbine in winter is almost all used for the heat supply, the loss of a source is avoided, and the heat economical efficiency is high.

Owner:XIAN XIRE ENERGY SAVING TECH

A method for manufacturing laminated glass based on thermocompression forming process

ActiveCN105365330BAvoid displacementGuaranteed vacuum environmentLamination ancillary operationsLaminationSheet filmCotton cloth

The invention provides a method for manufacturing laminated glass based on a hot-press molding process; during a process of hot-press molding of the laminated glass, glass after laminating is not put in a vacuum bag, but silica gel and other high-temperature-resistant sealing materials are smeared on side faces of the peripheries of two glass plates and an interlayer, so that the sealing materials initially fix the laminated glass for avoiding the glass plates shifting while sealing the interlayer; an aspirating hole is reserved at one position of an adhesive sheet at the middle, and after the interlayer is vacuumized, the reserved aspirating hole is plugged to ensure the vacuum environment of the interlayer. According to the method, a vacuum bag in the prior art is omitted, only cotton cloth, lint or other flexible materials are required to be laid between contact faces of the lower glass plate in a die and a grinding device, and the upper surface of the upper glass plate is not required to be laid with the flexible materials; the upper surfaces of the glass plates do not produce indentation in the hot-press molding process, and only a part contacted with the die is required to be polished during post processing, so that the workload is saved, the rate of finished products is improved, and thus the goods delivery time is shortened.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

A self-operating vacuum interrupter and its self-operating method

InactiveCN107481889BReduce volumeSmall footprintHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum interrupter

The invention discloses an automatic operating vacuum arc extinguish chamber and an automatic operating method thereof. The vacuum arc extinguish chamber comprises a static conductive rod, a movable conductive rod, a static contact, a movable contact, an arc extinguish chamber housing, a shielding cover, a flexible conductor, a main circuit terminal, a gate-opening driving coil, a magnetic repulsion disk, a gate-closing driving coil and a bistable retention structure. The invention discloses an automatic operating method of the automatic operating vacuum arc extinguish chamber. A conventional arc extinguish chamber and an operation mechanism are integrated to greatly reduce the part number and size of the operation mechanism and operation power of the mechanism. A bellows structure of a conventional arc extinguish chamber is eliminated, and the automatic operating vacuum arc extinguish chamber has the advantages of simple structure, compactness, long service lifetime and low cost.

Owner:XI AN JIAOTONG UNIV +3

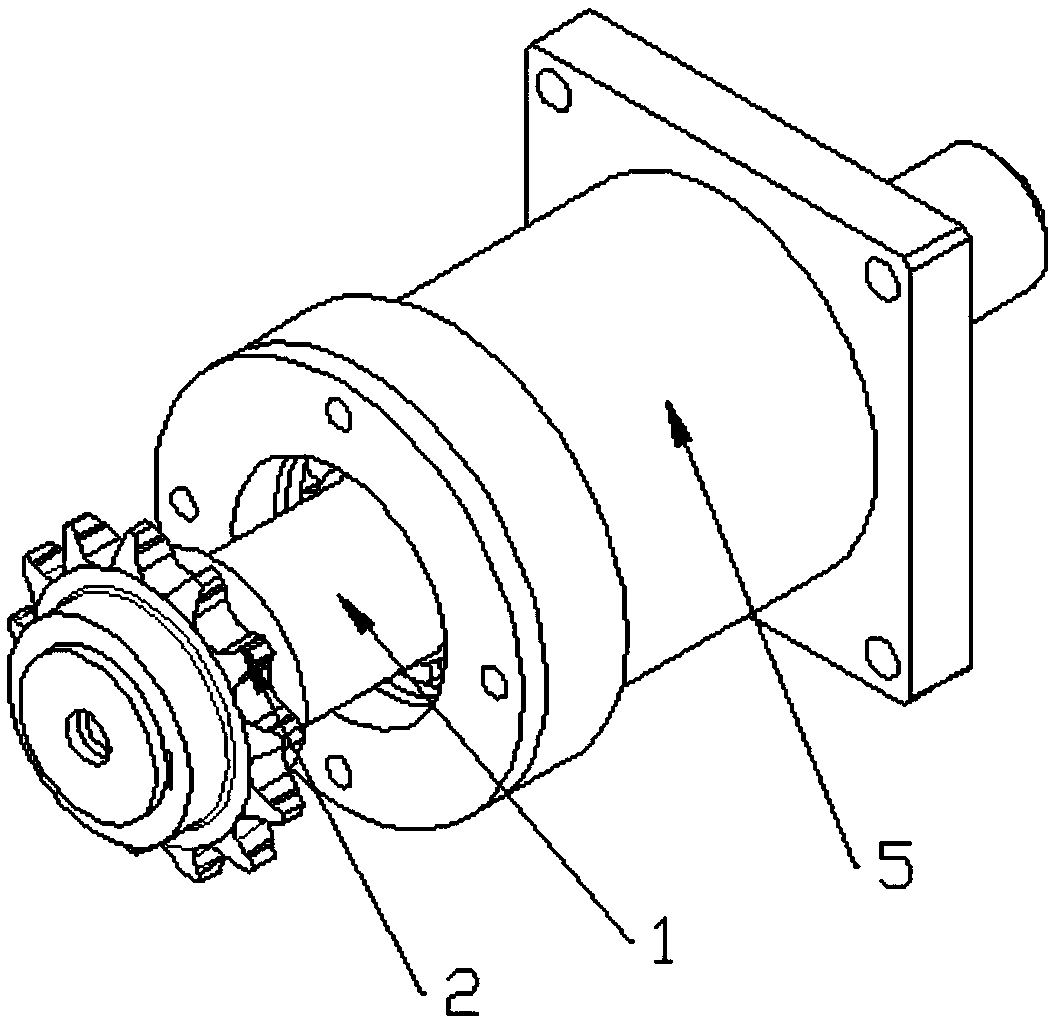

Dynamic seal device of vacuum equipment and vacuum equipment

The invention provides a dynamic seal device of vacuum equipment and the vacuum equipment and relates to the technical field of the vacuum equipment. The dynamic seal device of the vacuum equipment and the vacuum equipment aim to solve the problem of poor sealing performance of existing vacuum equipment caused by displacement of bearings at the two ends of a rotating shaft. The dynamic seal devicecomprises a drive assembly and a seal assembly, wherein the drive assembly is located outside a vacuum chamber and fixedly connected with the wall of the vacuum chamber, the drive assembly is connected with a conveying device, and the seal assembly is used for sealing the junction of the drive assembly and the vacuum chamber. By arranging the drive assembly outside the vacuum chamber and arranging the seal assembly between the drive assembly and the outer wall of the vacuum chamber, seal is reliable and the vacuum environment of the vacuum chamber is kept; and as the drive assembly is arranged outside the vacuum chamber, when operation pressure switching is carried out in the vacuum chamber, the drive assembly is not affected or shift to cause damage and abrasion to the seal assembly, andairtightness of the vacuum chamber is effectively ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Ramp sheet resistance type metallized film evaporation device

InactiveCN112680711AImprove the sticking effectImprove uniformity and stabilityFixed capacitor electrodesThin/thick film capacitorPhysicsSheet resistance

A ramp sheet resistance type metallized film evaporation device comprises a box body, a metal film main body penetrates through the top of the interior of the box body, and the two ends of the metal film main body are connected with traction mechanisms; the side wall of the box body communicates with a vacuum pump; an evaporation mechanism is mounted at the bottom of the interior of the box body, and is horizontally arranged at the bottom of the metal film main body; the evaporation mechanism is used for evaporating a metal agent on the metal film main body; and a first sealing mechanism and a second sealing mechanism are symmetrically arranged at the top of the interior of the box body. According to the ramp sheet resistance type metallized film evaporation device, the metal film can be subjected to dust removal and impurity removal treatment, the attaching effect on the metal film and an evaporation material is improved, and the uniformity and stability of an evaporation layer are improved; and the second sealing mechanism can cool the metal film, so that the evaporated film can be cooled by metal, the conductivity of the metal film can be effectively ensured, and the metal film is prevented from being damaged by heat.

Owner:马鞍山悠思电子科技有限公司

Stirring and sealing device for preparing epoxy-inorganic filler composite material and operation method

According to the stirring and sealing device for preparing the epoxy-inorganic filler composite material and the operation method, by arranging a stirring and sealing mechanism, when a stirrer fixed to a dynamic sealing structure conducts stirring operation, a dynamic sealing spring in the dynamic sealing structure extrudes a dynamic sealing rubber ring upwards under the action of rotating torque, and the sealing effect in the rotating process is achieved; the interior of the constant-temperature drying box is subjected to air extraction through the air extraction pump to generate vacuum, so that air in the epoxy-inorganic filler composite material is continuously extracted in the stirring process, meanwhile, constant-temperature drying in the stirring process is kept, and generation of bubbles in the operation process is reduced and avoided; the stirred epoxy-inorganic filler composite material is directly poured into a mold under the action of gravity in a vacuum environment; the device is integrally arranged, the time of the process of preparing the epoxy-inorganic filler composite material can be greatly shortened, meanwhile, the whole process is sealed in a vacuum mode, and the material preparation yield is high.

Owner:XI AN JIAOTONG UNIV +1

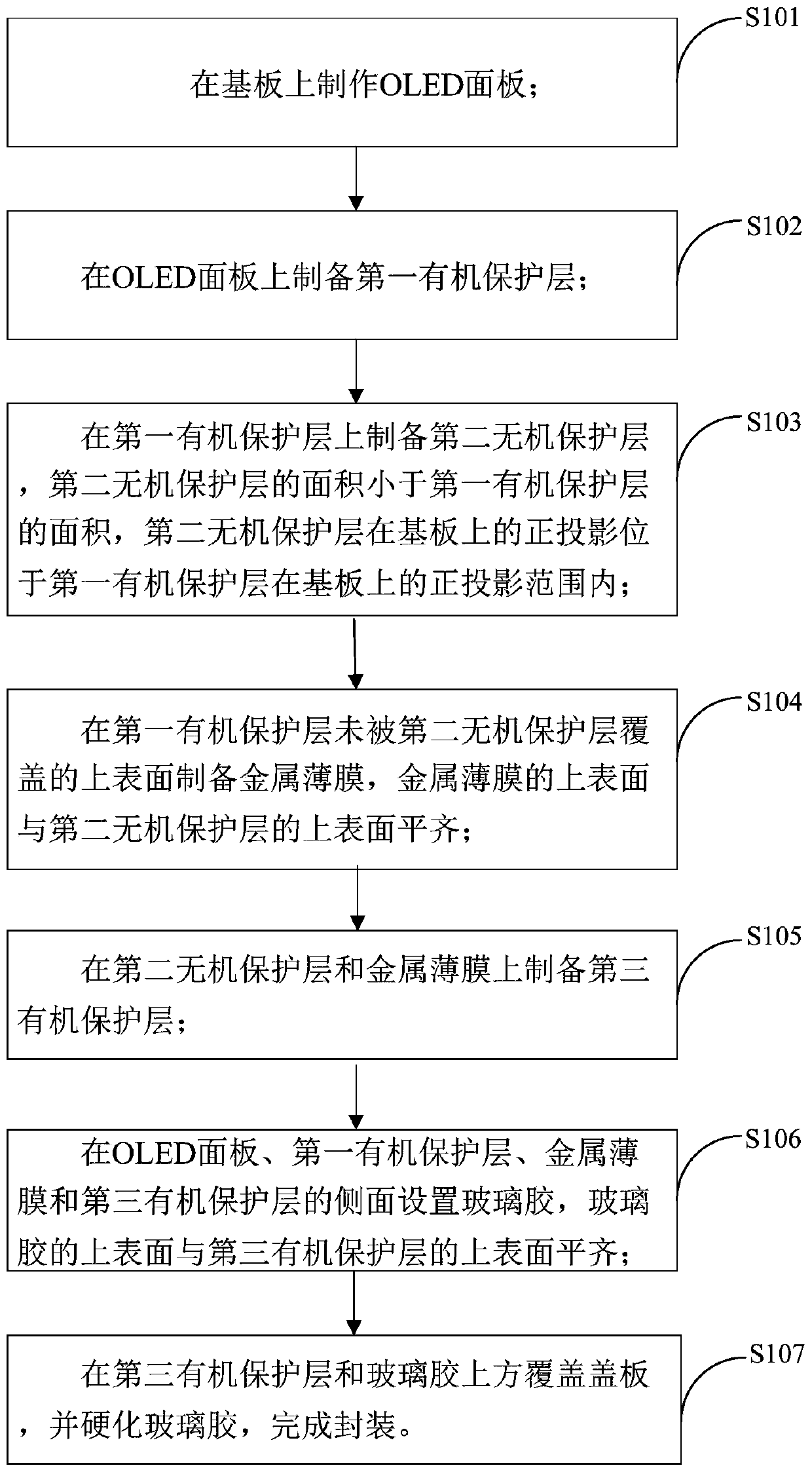

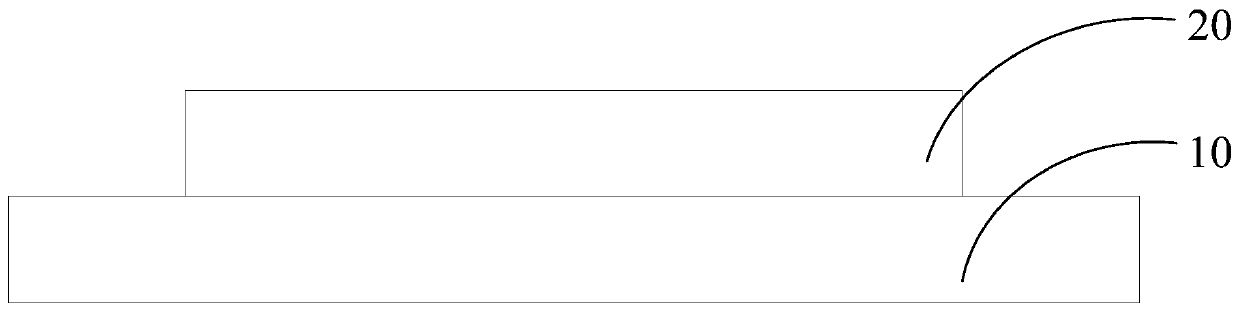

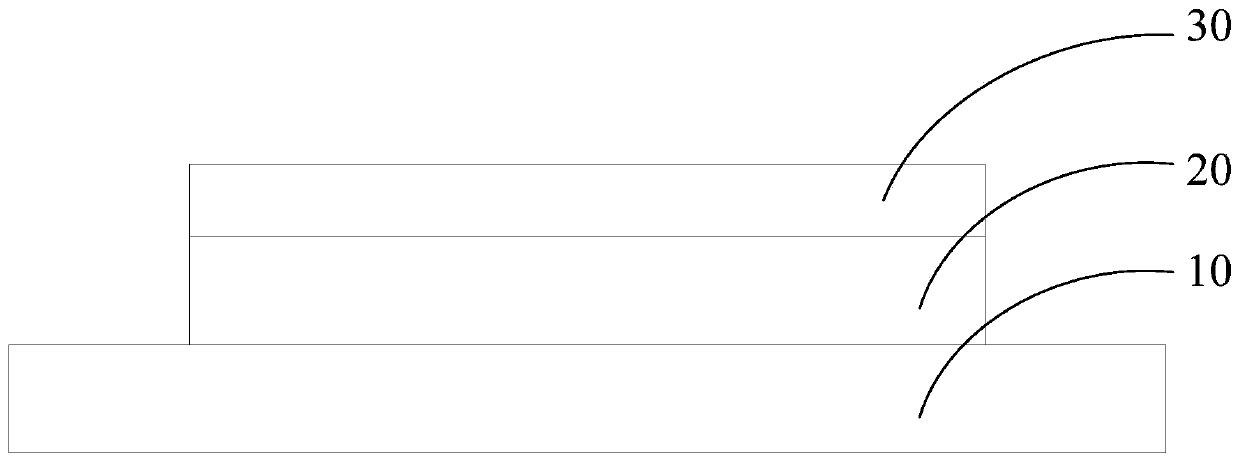

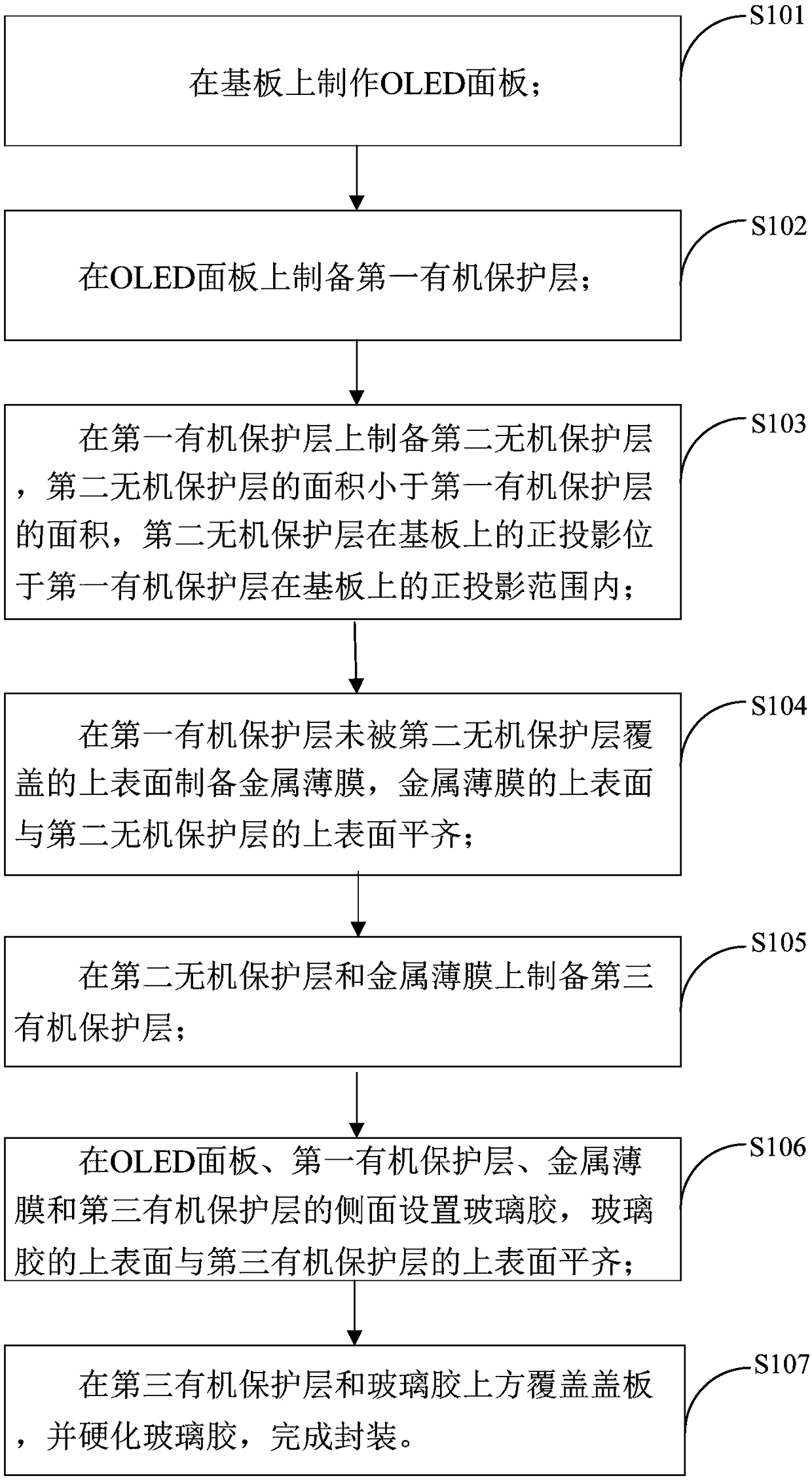

Packaging method of oled display device and oled display device

ActiveCN109285969BImprove waterproof performanceImprove sealingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The invention relates to the field of display technology, and provides a packaging method of an OLED display device and an OLED display device. The packaging method includes: manufacturing an OLED panel on a substrate; sequentially preparing a first organic protective layer and a second inorganic protective layer on the OLED panel; Prepare a metal thin film on the side of the second inorganic protective layer, and the metal thin film is flush with the upper surface of the second inorganic protective layer; prepare the third organic protective layer on the second inorganic protective layer and the metal thin film; Protective layer, metal film and the side of the third organic protective layer are provided with glass glue, and the upper surface of the glass glue is flush with the third organic protective layer; Cover the cover plate above the third organic protective layer and the glass glue, harden the glass glue, and complete encapsulation. The OLED device is encapsulated by a multi-layer thin film combination combined with a metal thin film and glass glue, which increases the thermal conductivity, sealing performance and structural strength of the device. The method has simple process, is beneficial to cost control, and is applicable to industrial production.

Owner:TCL CORPORATION

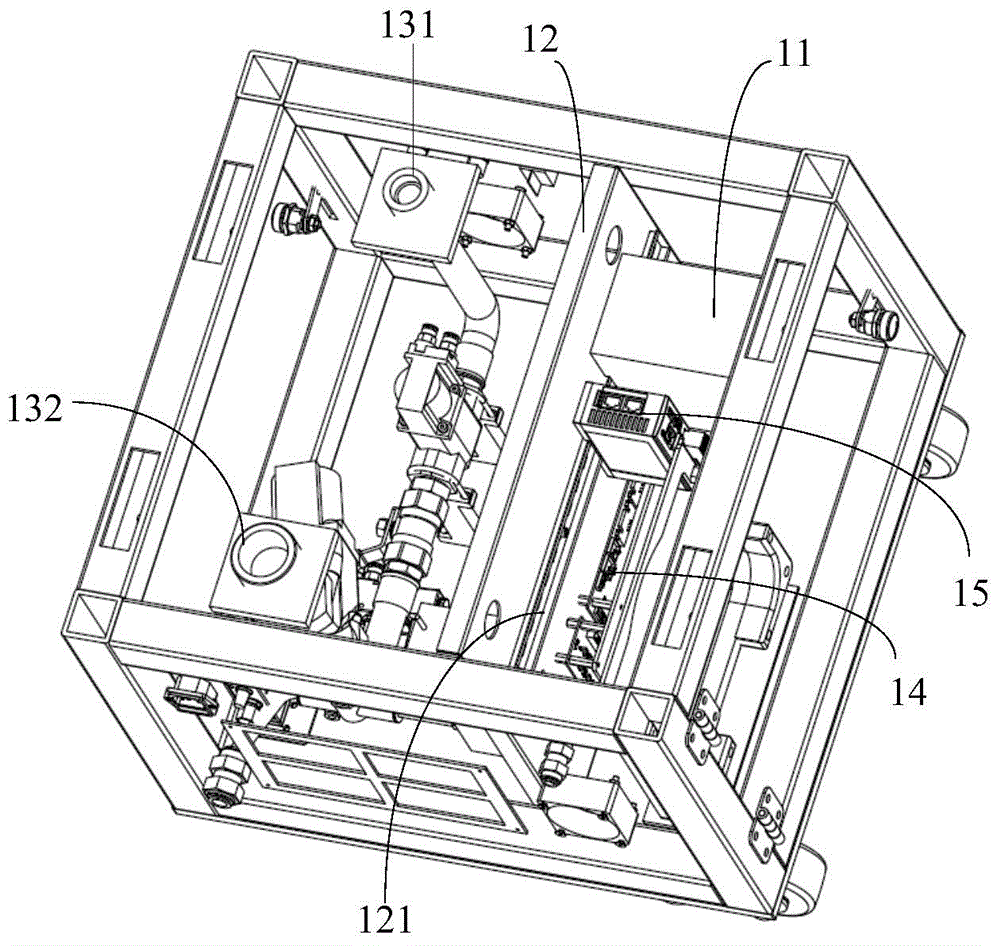

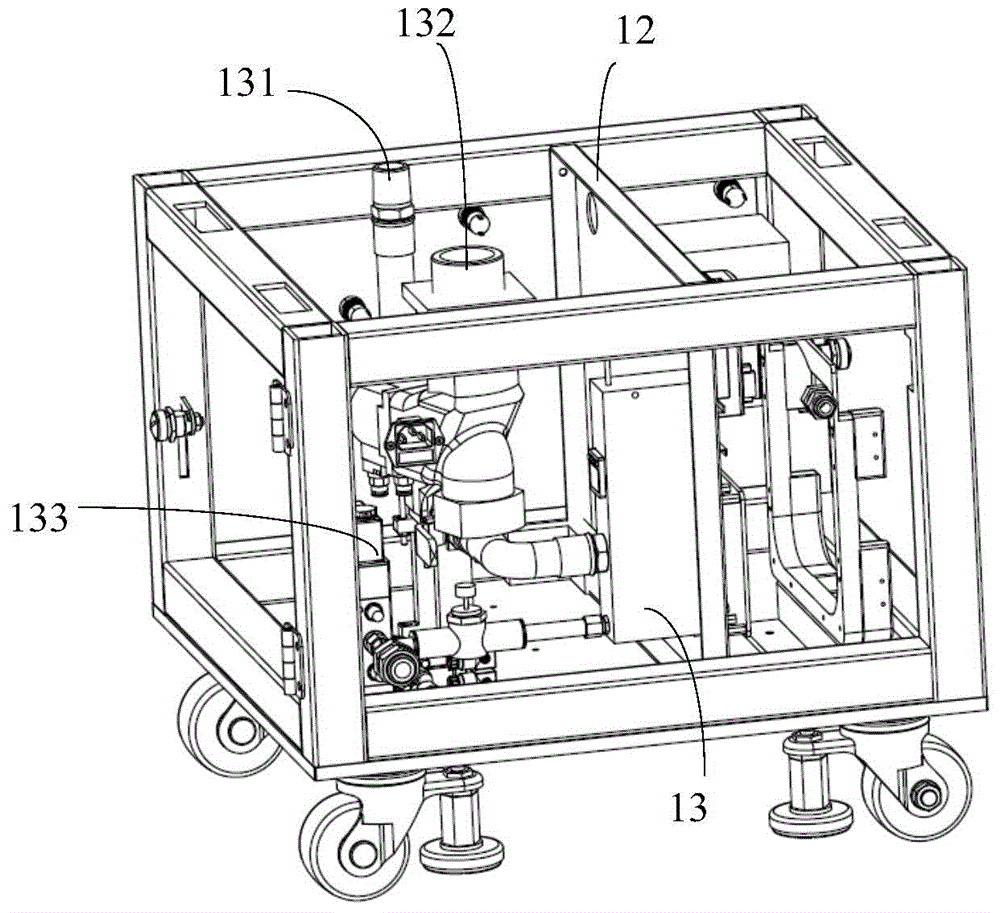

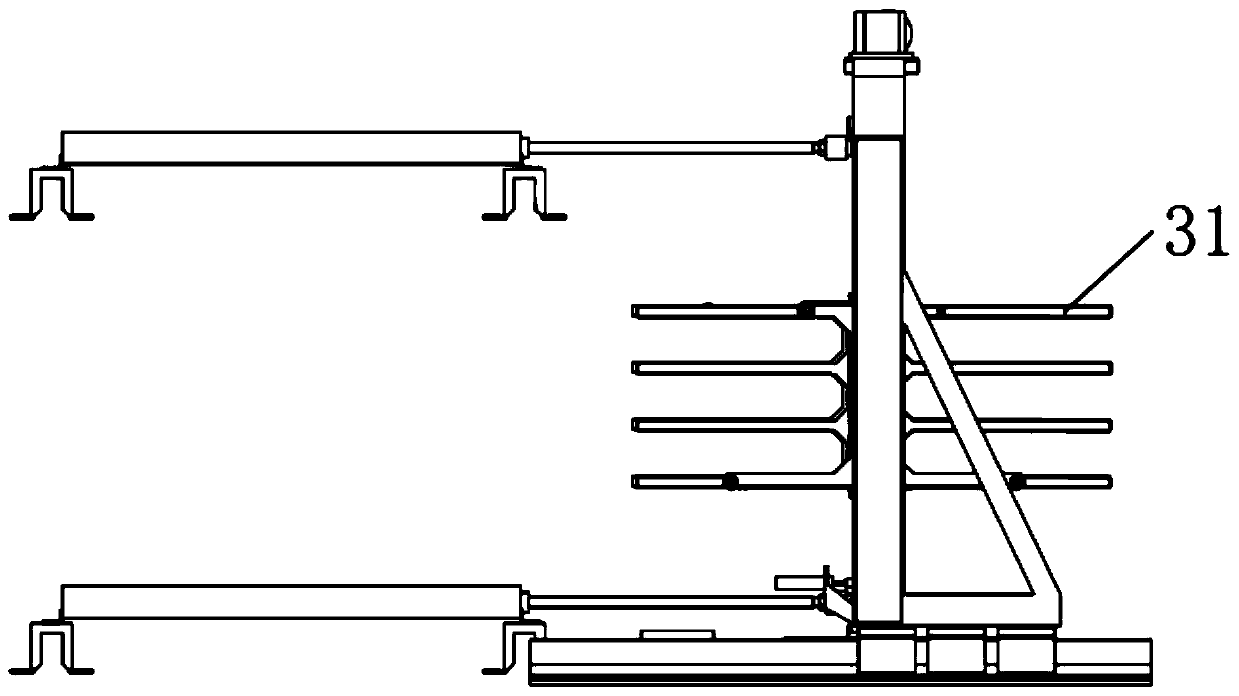

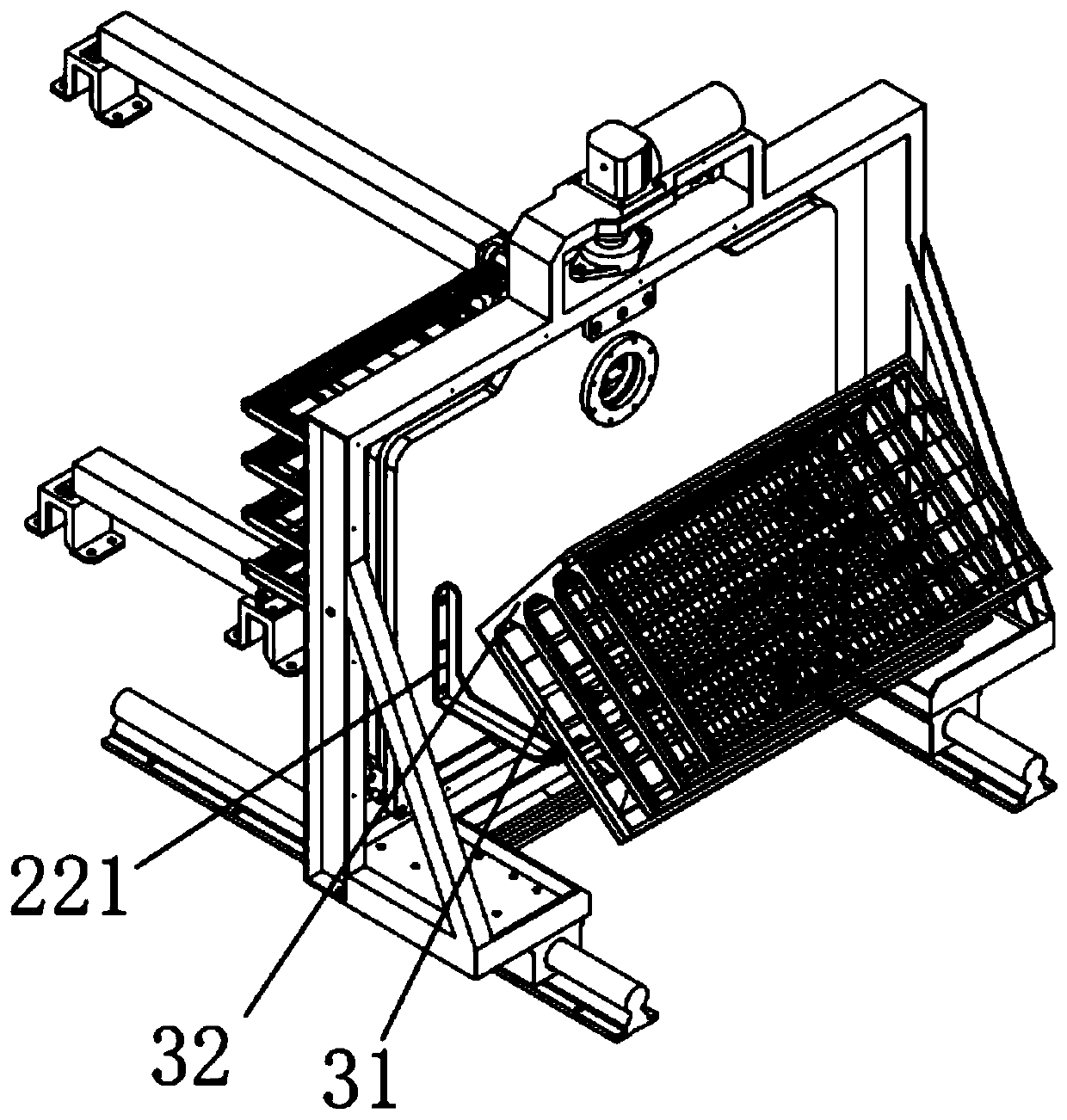

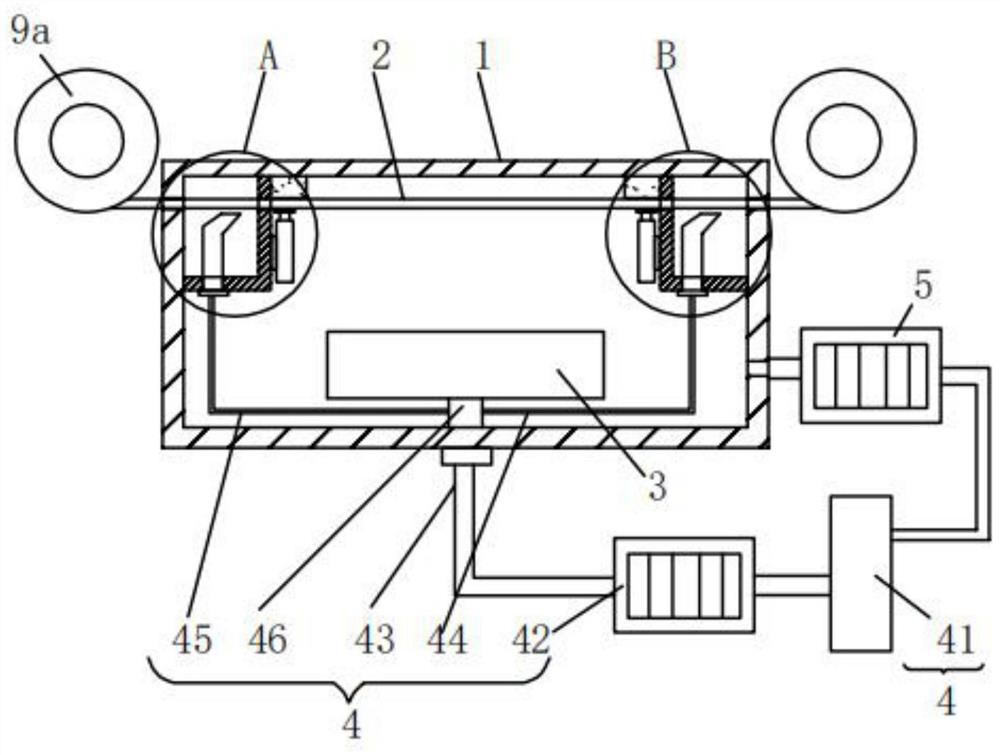

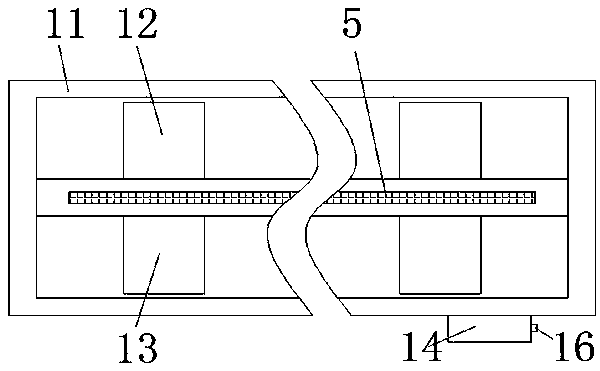

Online monitoring device for sheet resistance of metallized film

InactiveCN108827164AQuality improvementReal-time insight into uniformityUsing optical meansVertical planeHuman–machine interface

The invention discloses an online monitoring device for the sheet resistance of a metallized film, and the device comprises a measurement and control main unit (1) disposed in a vacuum evaporation chamber, a man-machine interface (2) installed outside the vacuum evaporation chamber, and a vacuum electrode flange (3) which is electrically connected with the interior and exterior of the vacuum evaporation chamber. The measurement and control main unit (1) comprises a rack (11), a controller which is fixedly disposed on a vertical plane of the rack (11), and at least one pair of light source emitter (12) and light source receiver (13) which are fixedly disposed on a horizontal plane of the rack (11). The man-machine interface (2) is fixedly disposed on a control box operation plane outside the evaporation chamber, and the vacuum electrode flange (3) is fixedly disposed on a side wall hole (4) of the vacuum evaporation chamber. The device does not need to make contact with a metal coatinglayer on the metallized film, can reflect the uniformity of the coating layer in real time, and facilitates the improvement of the quality of the coating layer.

Owner:钱立文

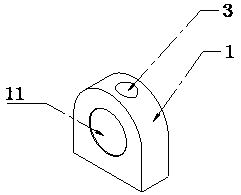

Locking device and vacuum equipment

PendingCN108425924ASimple structureEasy to operateFastening meansEngineeringElectrical and Electronics engineering

Owner:SHENZHEN YUANSU OPTOELECTRONICS TECH CO LTD

OLED (Organic Light-Emitting Diode) display device packaging method and OLED display device

ActiveCN109285969AGood water and oxygen isolationGood thermal conductivitySolid-state devicesSemiconductor/solid-state device manufacturingThermal conductivitySurface plate

The invention relates to the field of display technologies, and provides an OLED (Organic Light-Emitting Diode) display device packaging method and an OLED display device. The packaging method comprises the steps of fabricating an OLED panel on a substrate; sequentially preparing a first organic protection layer and a second inorganic protection layer on the OLED panel; preparing a metal film on the side surface of the second inorganic protection layer, wherein the metal film is flush with the upper surface of the second inorganic protection layer; preparing a third organic protection layer onthe second inorganic protection layer and the metal film; arranging glass cement on the side surfaces of the OLED panel, the first organic protection layer, the metal film and the third organic protection layer, wherein the glass cement is flush with the upper surface of the third organic protection layer; and covering the third organic protection layer and the glass cement with a cover plate above, and hardening the glass cement so as to complete the packaging. The OLED device is packaged by combining the combination of multiple films, the metal film and the glass cement, and the thermal conductivity, sealing performance and structural strength of the device are increased. The method is simple in process, conducive to cost control and capable of being applied to industrial production.

Owner:TCL CORPORATION

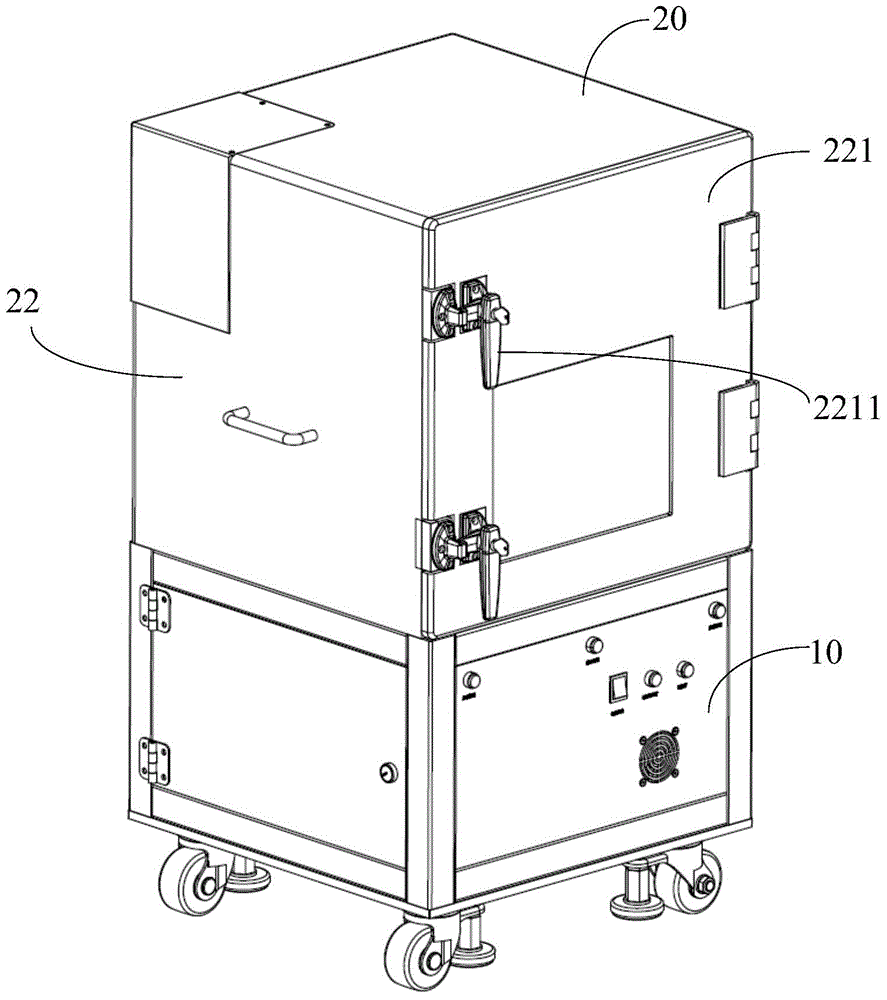

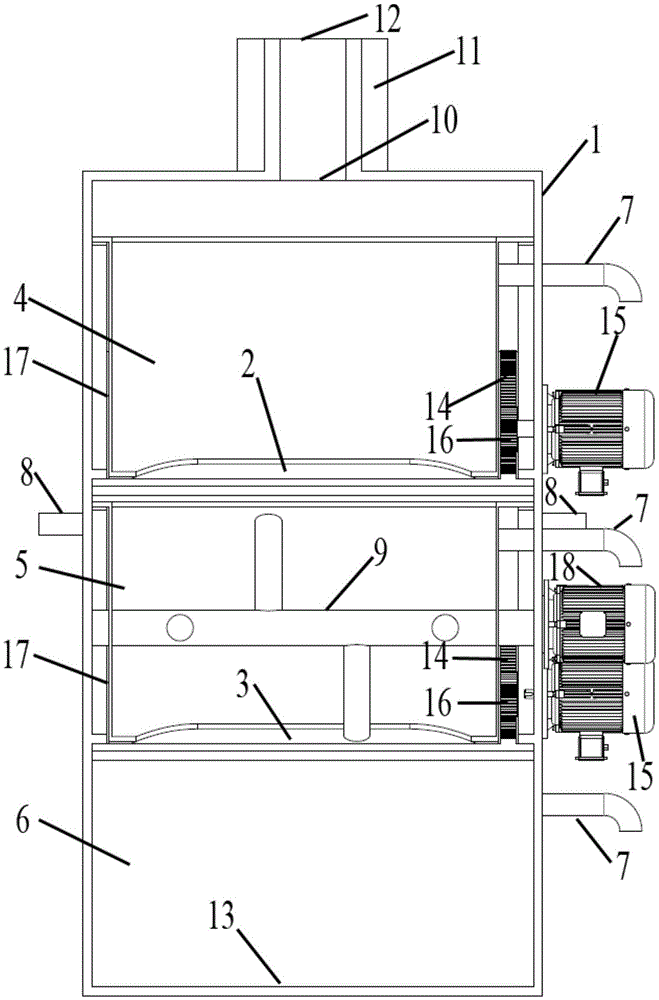

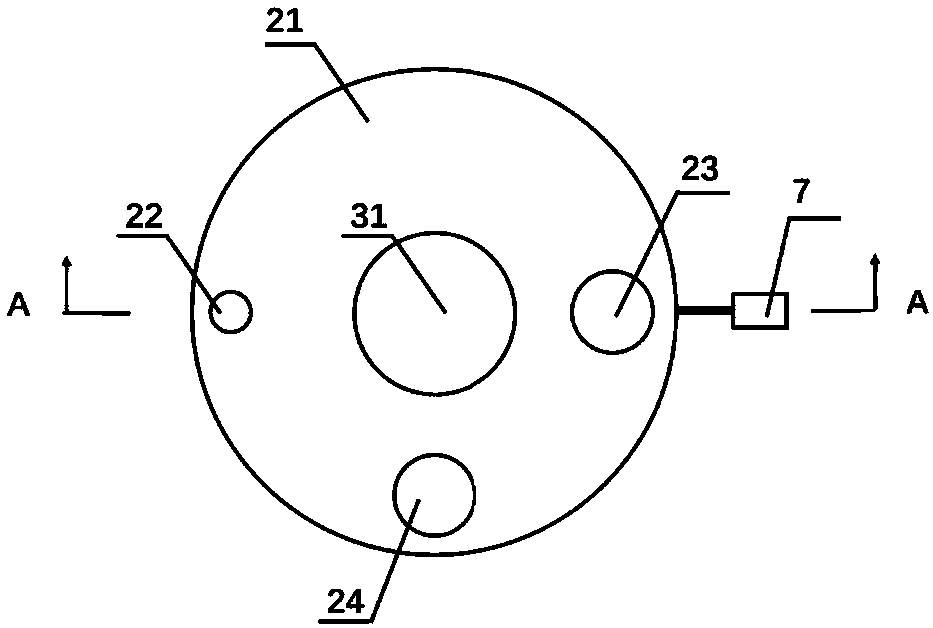

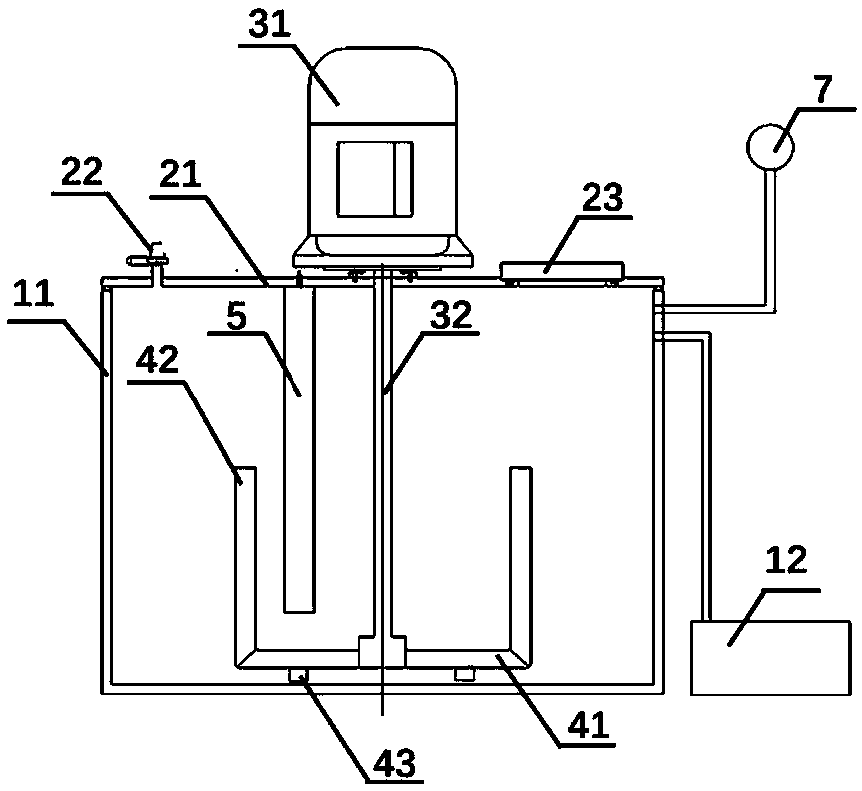

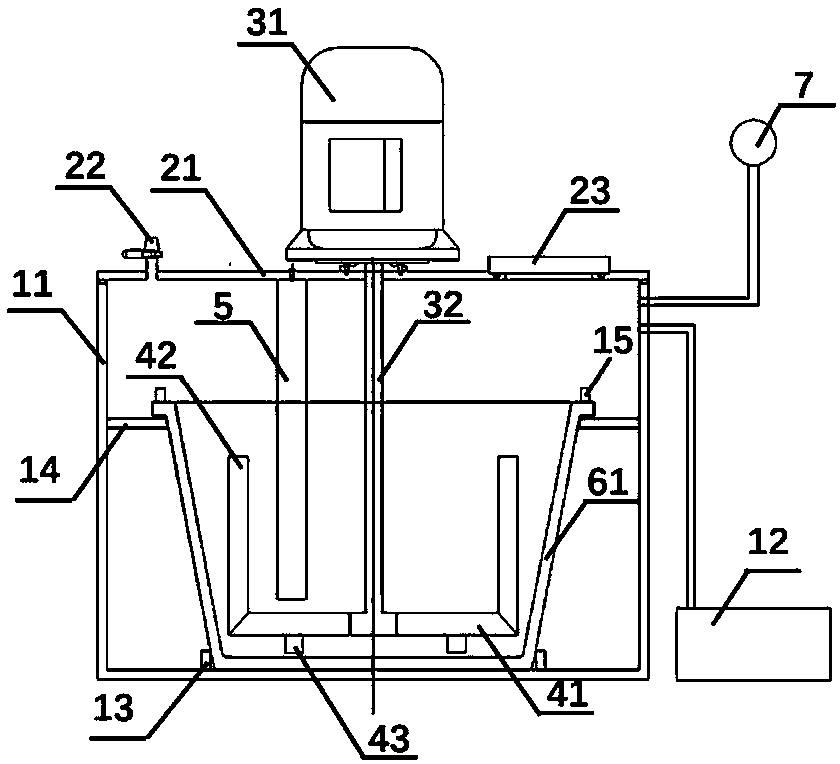

Continuous type vacuum dough mixer and using method thereof

ActiveCN105454342AQuality improvementSimple structureMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsContinuous productionEngineering

The invention provides a continuous type vacuum dough mixer. The continuous type vacuum dough mixer comprises a shell and a vacuumizing device, wherein the inner part of the shell is divided into three continuous sealing working chambers by openable first and second doors, the three continuous sealing working chambers are respectively a flour containing chamber, a dough kneading chamber and a dough containing chamber; the vacuumizing device is communicated with the three continuous sealing working chambers through pipes, so as to perform a selective vacuumizing operation on the three continuous sealing working chambers in the process of feeding, dough kneading and dough discharging. The invention also provides a method for continuous dough kneading by using the continuous type vacuum dough mixer. Through the continuous type vacuum dough mixer provided by the invention, continuous dough kneading can be realized, the subsequent continuous production of noodles in a processing plant is facilitated, a dough kneaded by using the continuous type vacuum dough mixer has the advantages that the surface is loose, the inner part is uniform, gluten value of the dough is high, the elasticity is good, and the processed flour food is smooth in taste, high in transparency and good in elasticity.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Vacuum preparing device and application method

PendingCN108514834AGuaranteed vacuum environmentPlay a blocking roleRotary stirring mixersTransportation and packagingPulp and paper industryVacuum pump

The invention discloses a vacuum preparing device and an application method. The vacuum preparing device comprises a cylinder body and a cylinder cover, a sealing piece is arranged on the contact facebetween the cylinder body and the cylinder cover, one side of the cylinder body is connected with a vacuum pump, and the mode is used for achieving the vacuum environment of the preparing device. A motor is arranged on the cylinder cover, a rotating shaft of the motor penetrates through the cylinder cover, extends into a cavity, and is connected with a stirring paddle, and the stirring paddle extends in the direction of the side edge of the cylinder body and is used for stirring raw materials. A stirring stopping part is also arranged on the cylinder cover, and the stirring evenness of raw materials is improved. The application method of the vacuum preparing device includes the following steps that 1, the motor is started; 2, the raw materials are put into the preparing device; 3, the cylinder cover covers the cylinder body, and the vacuum pump is started; 4, the raw materials are fully stirred; 5, the motor is stopped; 6, a valve is started; 7, the prepared raw materials are taken out.

Owner:SUZHOU AONITE SILICON CARBIDE CERAMIC TECH CO LTD

Encapsulation method for reducing vacuum leakage in composite material formation

The invention belongs to the technical field of composite material formation, and relates to an encapsulation method for reducing vacuum leakage in composite material formation in an autoclave composite material forming process. An inner ring sealing rubber strip and an outer ring sealing rubber strip are arranged in the method, a first sealing space is formed between a prepreg and an inner ring sealing ring, and a second sealing space is formed between the inner ring sealing ring and an outer ring sealing ring. When the outer ring encapsulation material leaks, the second sealing space is communicated with the external space; and because the first sealing space is isolated with the second sealing space, the air of the external space can only enter the second sealing space, and vacuum environment of the first sealing space is kept. By adopting the encapsulation method, two sealing spaces are formed around a workpiece, so that the problem of vacuum leakage in solidifying formation of a composite material at a high temperature and under a high pressure can be effectively solved; and tests prove that the probability of vacuum leakage in the solidification process is reduced from original over 90 percent to below 20 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com