A method for manufacturing laminated glass based on thermocompression forming process

A technology of laminated glass and thermoforming, which is applied in the direction of chemical instruments and methods, lamination, and lamination devices, can solve problems such as poor product performance, difficult polishing work, and inapplicability to mass production, so as to improve the yield rate and shorten the Effects of delivery time and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The method for manufacturing laminated glass based on the thermocompression forming process of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

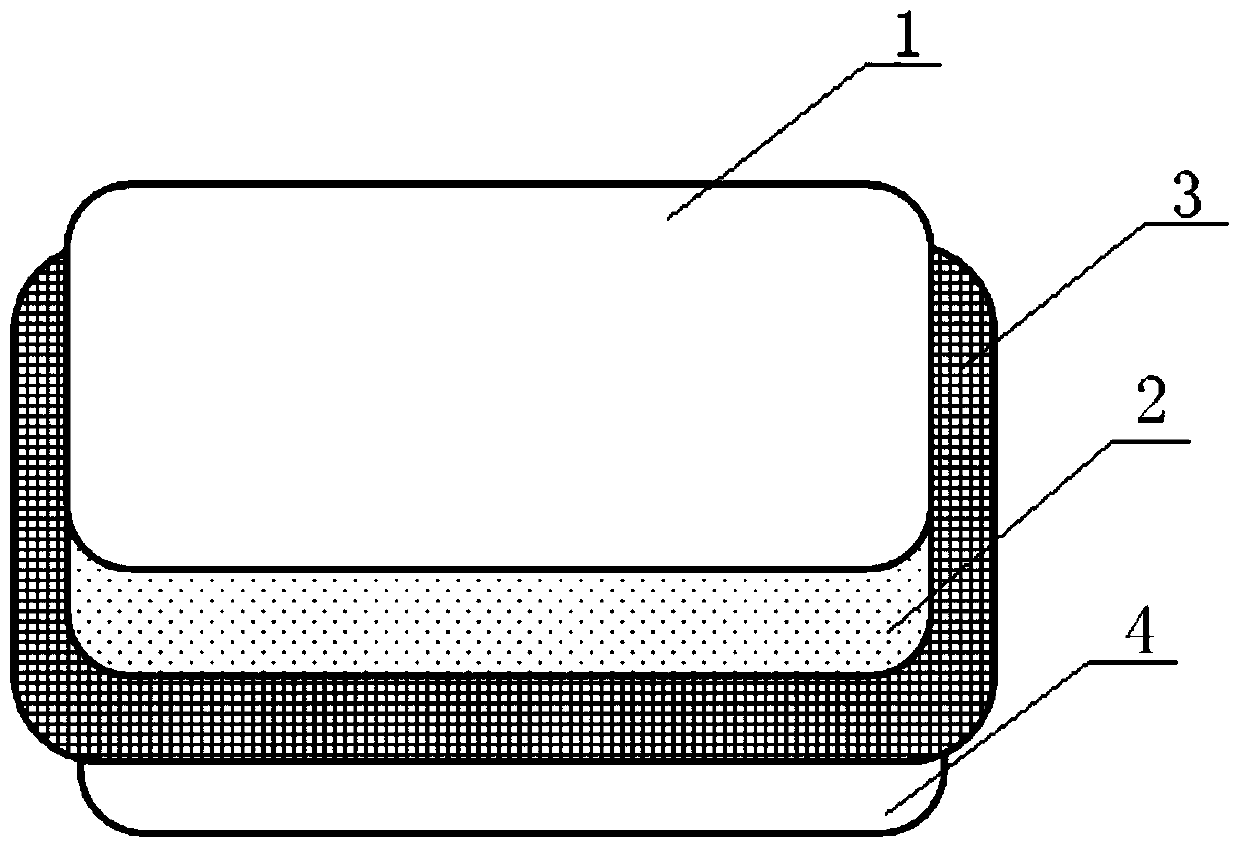

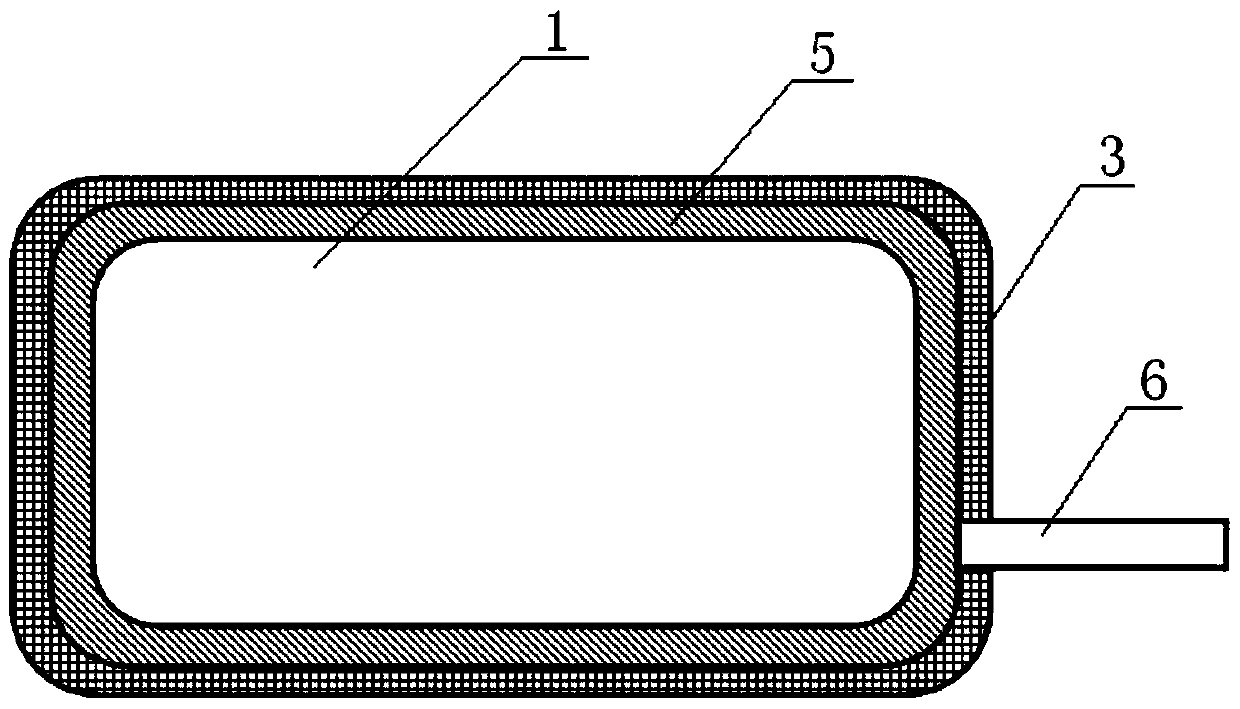

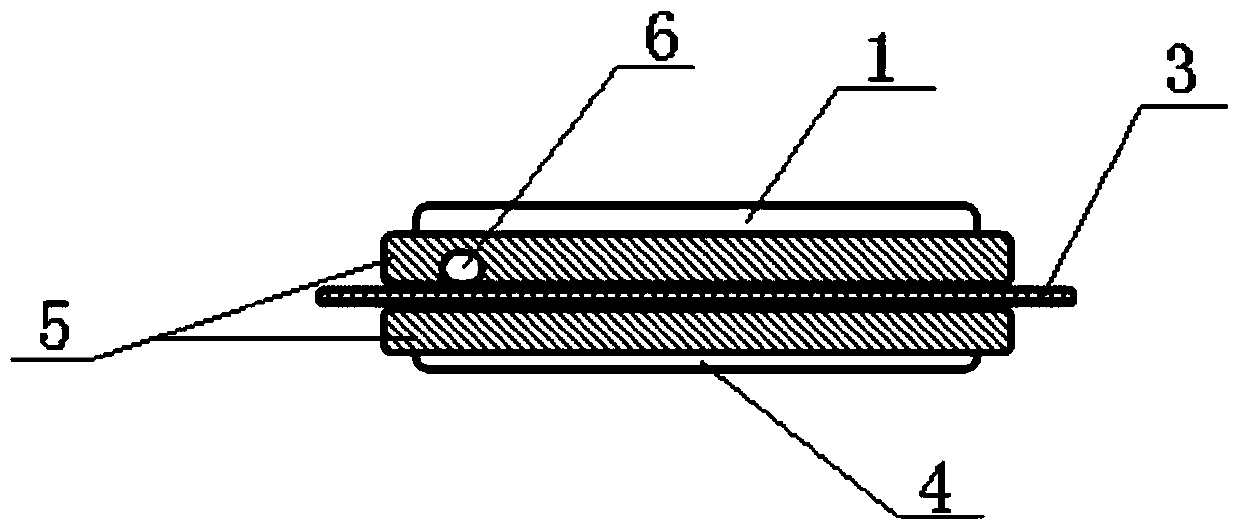

[0038] figure 1 The structure of the processed material of the laminated glass manufactured by the manufacturing method of the present invention is shown, such as figure 1 As shown, the processing material includes upper and lower two glass plates 1, 4 and an interlayer between the two glass plates, the interlayer is composed of a silk screen 3 and an intermediate film 2 placed thereon; figure 2 It is a top view of the overall structure of the glass after assembling, image 3 It is a side view of the side where the air extraction hole is reserved in the overall structure of the glass after assembling, such as figure 2 and image 3 shown in figure 1 On the basis of gluing, apply sealing material 5 on the surrounding sides of the glass plate and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com