Die casting machine

A die-casting machine and die-casting molding technology, applied in the field of die-casting machines, can solve the problems of destroying the vacuum environment of the mold cavity, complex mold structure, affecting the quality of die-casting parts, etc., and achieve the effect of ensuring the vacuum die-casting environment, simplifying the mold structure, and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

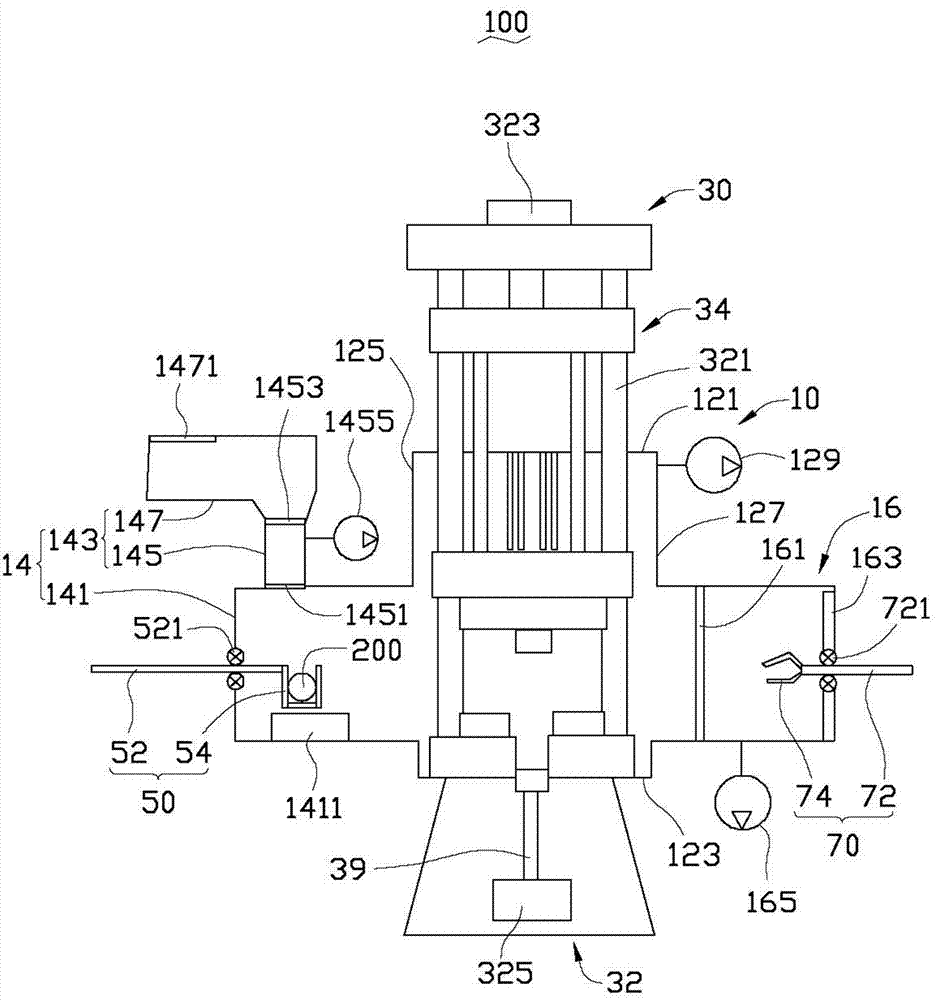

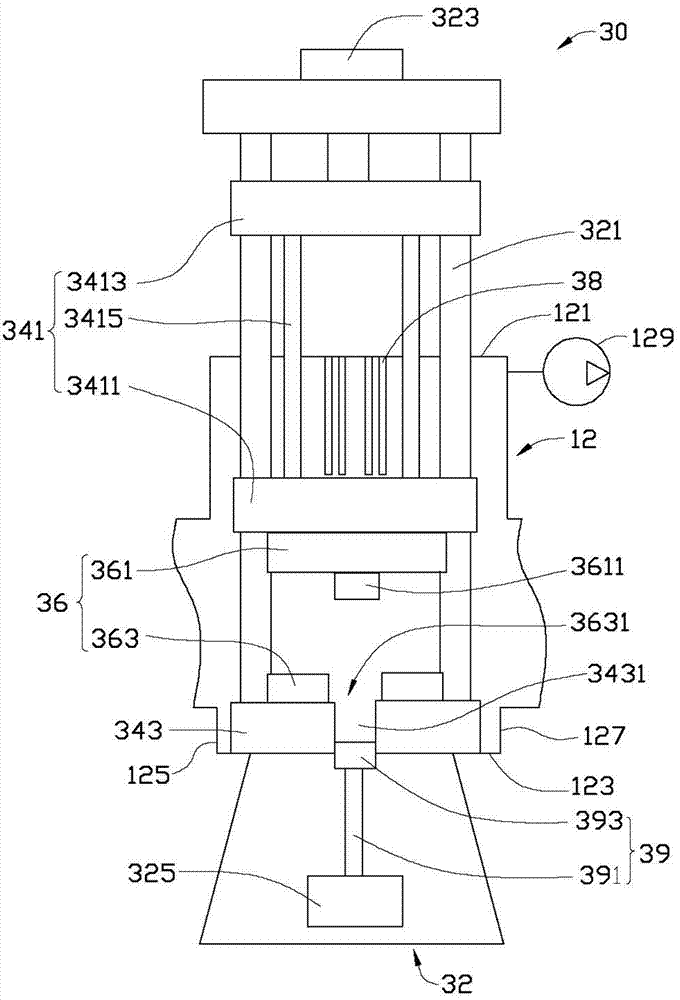

[0011] see figure 1 , the die casting machine 100 according to the embodiment of the present invention is used to realize the vacuum die casting of the molten material 200 . In this embodiment, the molten material 200 is an amorphous alloy material. The die-casting machine 100 is a vertical die-casting machine, which includes a vacuum chamber 10 and a die-casting mechanism 30 , a feeding mechanism 50 and a retrieving mechanism 70 partially accommodated in the vacuum chamber 10 .

[0012] The vacuum chamber 10 is an airtight chamber, which includes a processing room 12 and a feeding room 14 and a material taking room 16 respectively arranged on both sides of the processing room 12 . The processing room 12 is used for partially accommodating the die-casting mechanism 30 to allow the die-casting mechanism 30 to work in a sealed vacuum environment. The processing room 12 includes opposite top walls 121 and bottom walls 123 , and opposite first side walls 125 and second side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com