Stirring and sealing device for preparing epoxy-inorganic filler composite material and operation method

A technology for inorganic fillers and composite materials, which is applied in the field of stirring and sealing devices for the preparation of epoxy-inorganic filler composite materials, which can solve problems such as difficult removal of material bubbles, generation of pores or shrinkage cavities, and increase in material viscosity, achieving high yields , easy to achieve, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings.

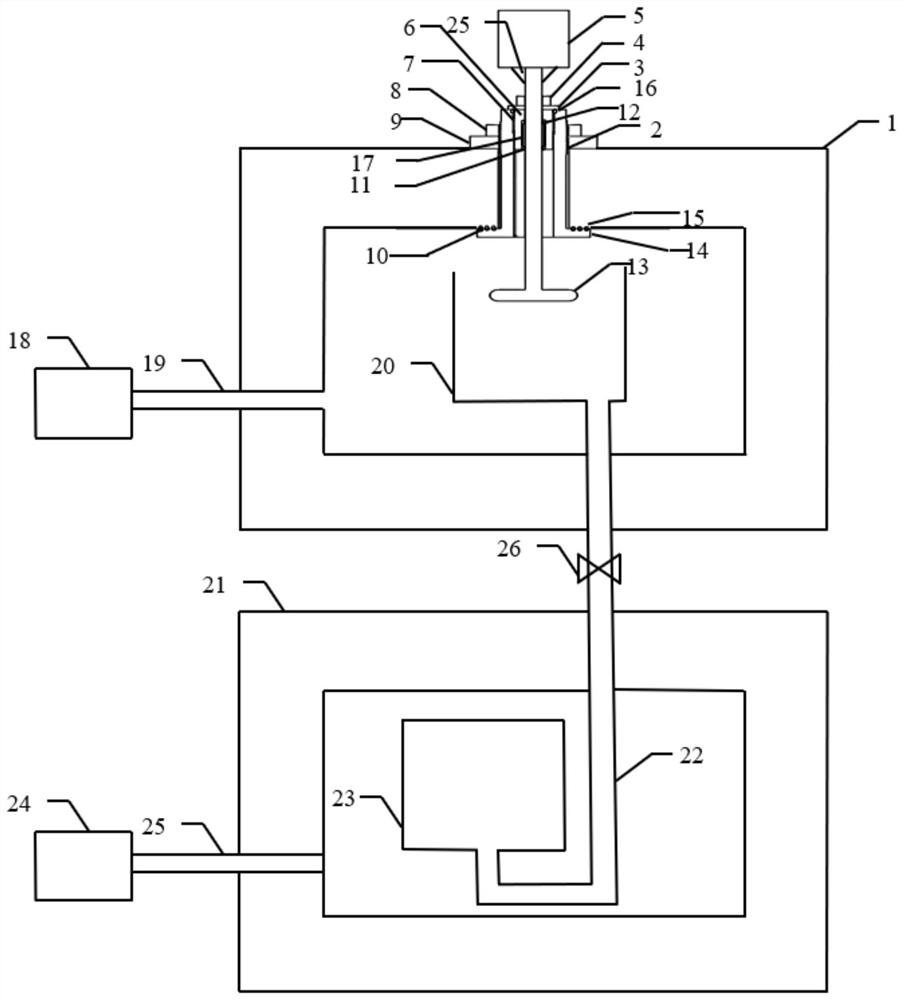

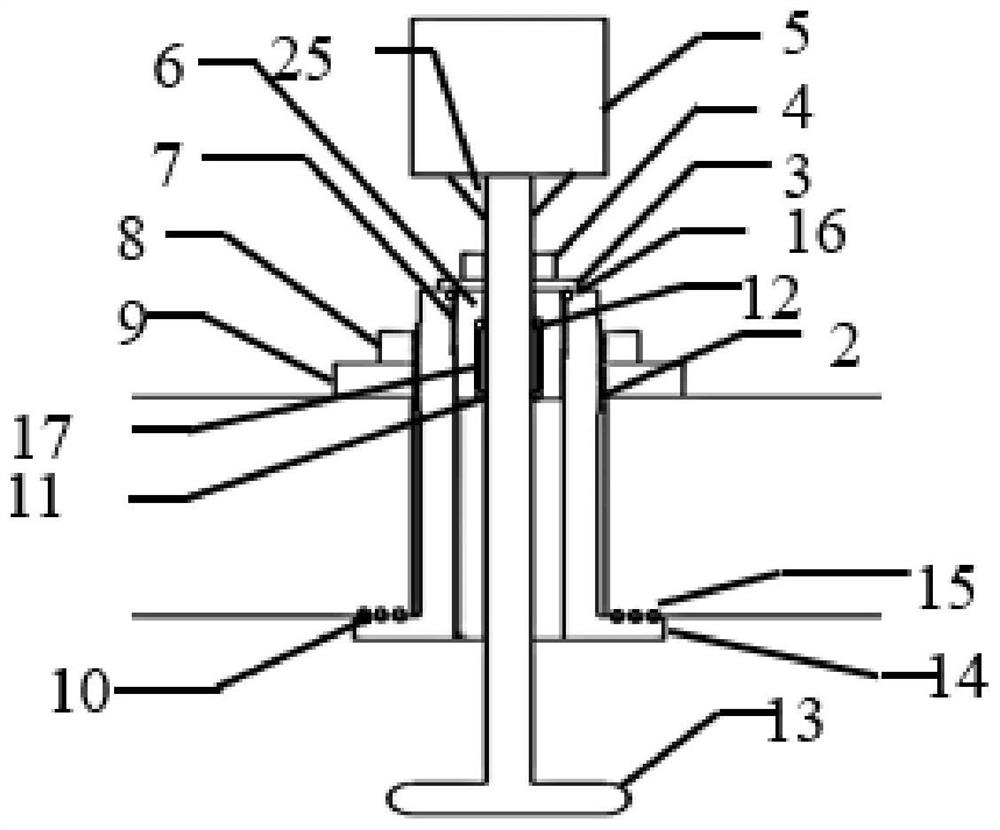

[0032] See figure 1 , An epoxy-inorganic filler composite material for preparing a sealing mixing device, including a first constant temperature drying tank 1 and a second constant temperature drying oven 21, the first constant temperature drying oven 1, is provided with a stirred container 20 The first thermostatic drying case 1 side is connected to the first pumping pump 18 through the first pumping pump 18, and the first constant temperature drying case 1 is provided with a sealing mixing mechanism, and the mixing container 20 is passed below. The casting conduit 22 is perpendicular to the top wall of the first constant temperature drying case 1 and the second constant temperature drying oven 21, respectively, in the bottom of the mold 23 provided in the second constant temperature drying case 21, and within the second constant temperature drying case 2 1 On one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com