Production device for synthesizing small-molecular-weight polyphenyl ether

A production equipment and small molecular weight technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low heat transfer efficiency, complicated product purification process, poor mass transfer effect, etc., and achieve the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

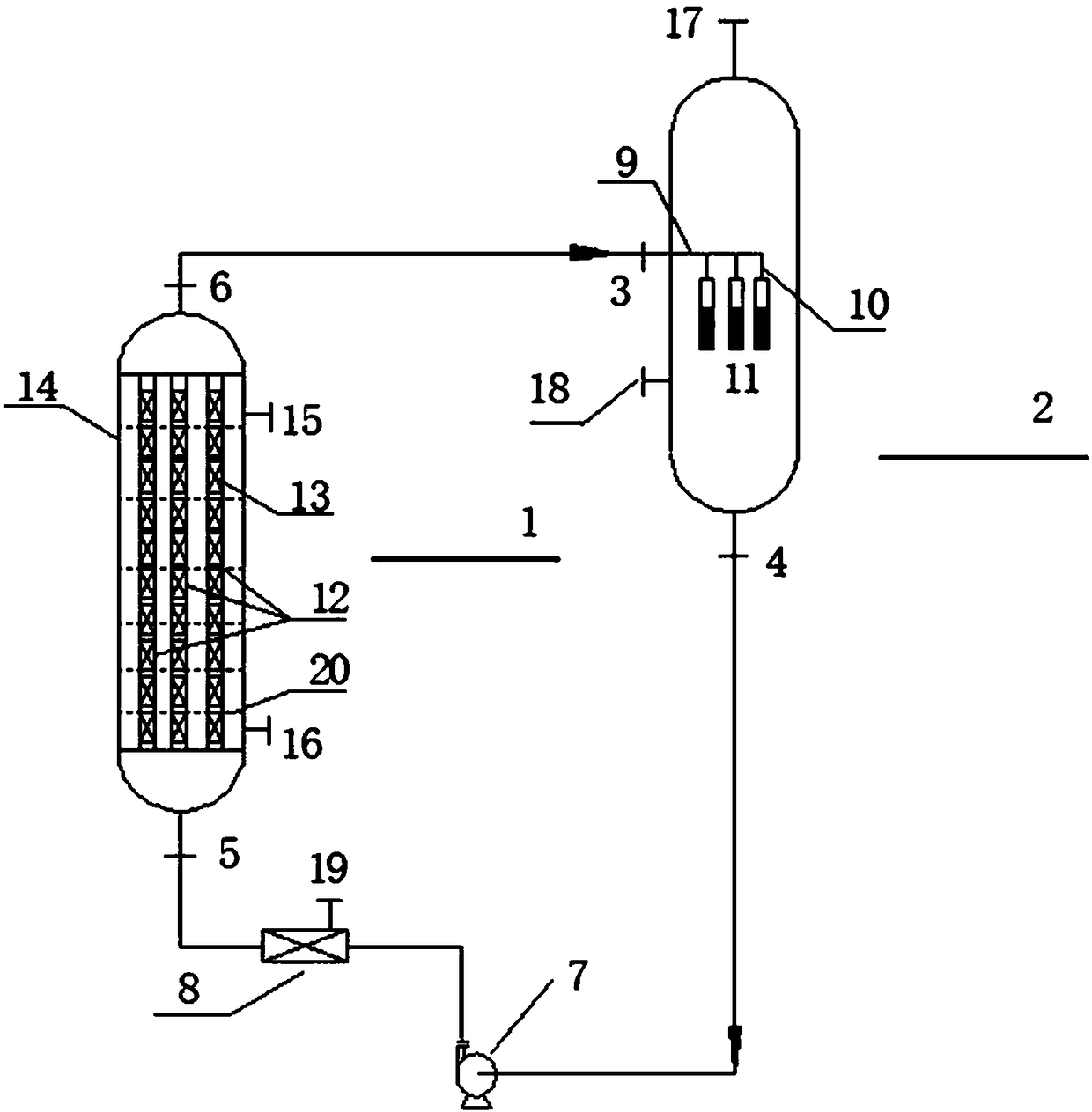

[0068] use figure 1 Shown equipment, first reactor (1) structure:

[0069] Shell side of the first reactor: the height of the cylinder is 1000mm, the diameter is 50mm, the distance between the baffles is 100mm, and the quantity is 8 pieces;

[0070] The first reactor tube pass: the number of tube bundles is 1, the length is 1000mm, the diameter of the tube bundle is 20mm, the number of dispersed components in the tube bundle is 10, and the specific surface area is 500m 2 / m 3 , the porosity is 0.05%; the length is 100mm;

[0071] use figure 1 The equipment shown, the second reactor structure:

[0072] The second reactor cylinder has a height of 1500mm and a diameter of 150mm;

[0073] Inside the barrel of the second reactor,

[0074] The diameter of the main pipe is 20mm; the length is 120mm;

[0075] The diameter of the branch pipe is 10mm; the number is 6;

[0076] There are distribution caps on the branch pipes: the number is 12; metal sintered wire mesh hollow cyli...

Embodiment 2

[0086] use figure 1 Shown equipment, first reactor (1) structure:

[0087] Shell side of the first reactor: the height of the cylinder is 10000mm, the diameter is 500mm, the distance between the baffles is 180mm, and the quantity is 50 pieces;

[0088] The first reactor tube pass: the number of tube bundles is 1000, the length is 10000mm, the diameter of the tube bundle is 5mm, the number of dispersed components in the tube bundle is 10, and the specific surface area is 500m 2 / m 3 , the porosity is 0.05%; the length is 100mm;

[0089] use figure 1 The equipment shown, the second reactor structure:

[0090] The height of the second reactor cylinder is 10000mm, and the diameter is 5000mm;

[0091] Inside the barrel of the second reactor,

[0092] The diameter of the main pipe is 300mm; the length is 5000mm;

[0093] The diameter of the branch pipe is 20mm; the quantity is 200;

[0094] There are distribution caps on the branch pipes: the quantity is 400; metal sintered ...

Embodiment 3

[0104] use figure 1 Shown equipment, first reactor (1) structure:

[0105] Shell side of the first reactor: the height of the cylinder is 500mm, the diameter is 25mm, the distance between the baffles is 10mm, and the quantity is 45 pieces;

[0106] The first reactor tube pass: the number of tube bundles is 3, the length is 500mm, the diameter of the tube bundle is 5mm, the number of dispersed components in the tube bundle is 40, and the specific surface area is 1000m 2 / m 3 , the porosity is 0.1%; the length is 10mm;

[0107] use figure 1 The equipment shown, the second reactor structure:

[0108] The second reactor cylinder has a height of 500mm and a diameter of 50mm;

[0109] Inside the barrel of the second reactor,

[0110] The diameter of the main pipe is 20mm; the length is 50mm;

[0111] The diameter of the branch pipe is 5mm; the number is 8;

[0112] There are distribution caps on the branch pipes: the number is 16; metal sintered wire mesh hollow cylinder, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com