Split type carbonization furnace set

A carbonization furnace, split technology, applied in the field of split carbonization furnace group, can solve the problems of unstable product quality, long production cycle, long operation time, etc., to improve equipment production efficiency, reduce work intensity, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

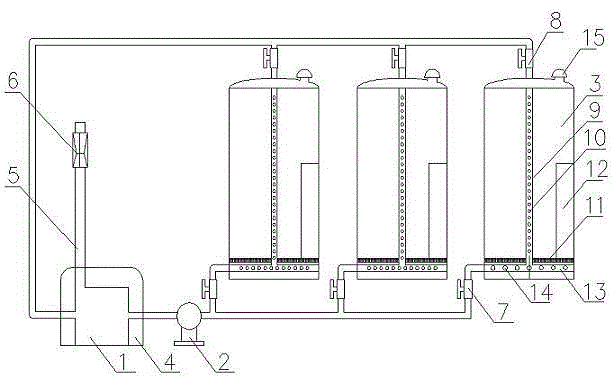

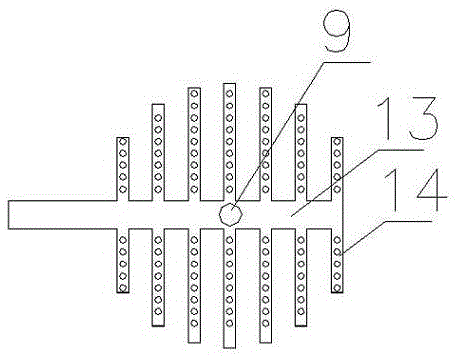

[0014] see figure 1 , figure 2 , a split type carbonization furnace group, which is composed of a combustion furnace 1, a heat pump 2 and a carbonization furnace 3, the combustion furnace 1, heat pump 2 and carbonization furnace 3 are connected in sequence through pipelines, the combustion furnace 1 and carbonization The furnaces 3 are separated, and there are three or more than three carbonization furnaces 3, and the way that the carbonization furnaces 3 are connected to the overall process is connected in parallel. The combustion furnace 1 is provided with an insulating layer 4, the combustion furnace 1 is provided with a chimney 5, and the top of the chimney 5 is provided with a flue gas filter 6. The bottom of the carbonization furnace 3 is provided with a bottom hot gas main pipe 13, and the bottom hot gas main pipe 13 is tiled along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com