Method for purifying silicon through semi-continuous crystallization in silicon alloy melt

A silicon alloy, semi-continuous technology, applied in the field of silicon purification, can solve the problems of difficult operation, slow growth rate, slow growth rate of Si crystal, etc., to achieve the effect of simple equipment operation and process, increased growth rate and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

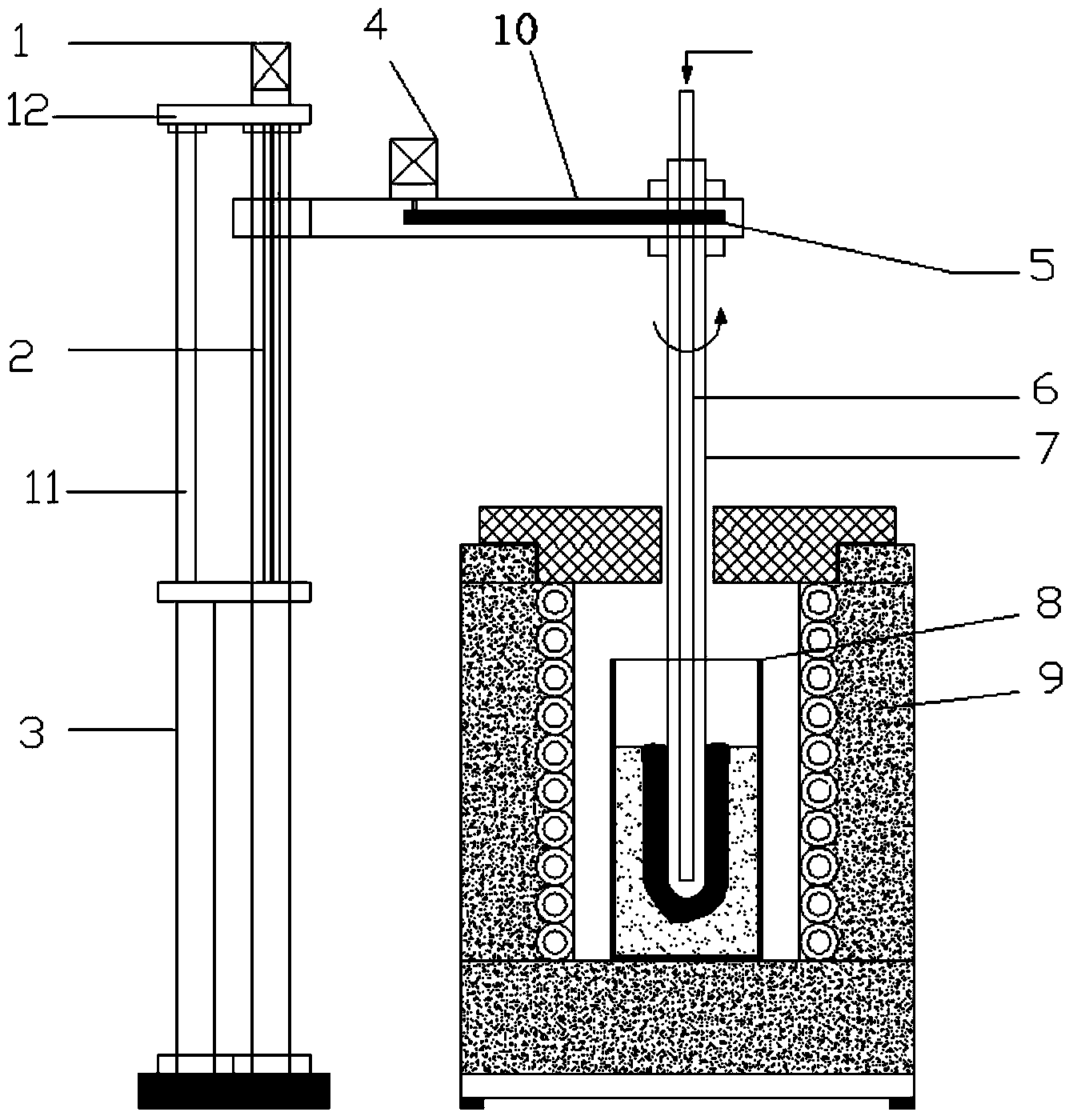

specific Embodiment 1

[0042] Mix 358.7g of metallurgical silicon (grade 3303) as a raw material with 1076.1g of metallic aluminum (purity 96.5%). The typical impurity content of silicon and aluminum is shown in Table 1. Heat the mixture to 950°C to melt and keep it for half an hour, then use a quartz rod Stir the melt and insert it into the crystallization rod after it is completely mixed. Use a stainless steel tube with a diameter of 25.4mm as the crystallization rod with a rotation speed of 130r / min. m 3 / hr, at the same time, reduce the furnace temperature, the cooling rate is 1.7°C / min, cool to 616°C, lift the crystallization rod out of the melt, the surface of the crystallization rod is attached with growing silicon crystals, and use a hammer to separate the silicon crystals from the crystallization rod , Obtain 90.84g of silicon crystals. After the silicon crystal was soaked in dilute hydrochloric acid to remove the attached Al, the ICP-OES test was performed, and the results are shown in Ta...

specific Embodiment 2

[0047] Mix 622.5g of metallurgical silicon (grade 3303) as a raw material with 1228g of metallic aluminum (purity 96.5%). The typical impurity content of silicon and aluminum is shown in Table 1. Heat the mixture to 1050°C to melt and hold it for half an hour, then stir it with a quartz rod Insert the crystallization rod after the melt is completely mixed, use a stainless steel tube with a diameter of 25.4mm as the crystallization rod, and use a stainless steel tube with a diameter of 8mm as a cooling air pipe to feed air at room temperature into the crystallization rod at a ventilation rate of 0.1m 3 / hr, at the same time, reduce the furnace temperature, the cooling rate is 0.12°C / min, cool to 602°C, lift the crystallization rod out of the melt, the surface of the crystallization rod is attached with growing silicon crystals, and use a hammer to separate the silicon crystals from the crystallization rod , to obtain 78.4g of silicon crystals. After the silicon crystal was soak...

specific Embodiment 3

[0050] Mix 642.8g of metallurgical silicon (grade 3303) as a raw material with 1499.8g of metallic aluminum (purity 96.5%). The typical impurity content of silicon and aluminum is shown in Table 1. Heat the mixture to 1050°C to melt and keep it for half an hour, then use a quartz rod Stir the melt and insert it into the crystallization rod after it is completely mixed. Use an alumina tube with a diameter of 25.4mm as the crystallization rod with a rotation speed of 25r / min. 0.1m 3 / hr, at the same time, reduce the furnace temperature, the cooling rate is 0.2°C / min, cool to 600°C, lift the crystallization rod out of the melt, the surface of the crystallization rod is attached with growing silicon crystals, and use a hammer to separate the silicon crystals from the crystallization rod , Obtain 186g of silicon crystals. After the silicon crystal was soaked in dilute hydrochloric acid to remove the attached Al, the ICP-OES test was performed, and the results are shown in Table 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com