Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Overcome mobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

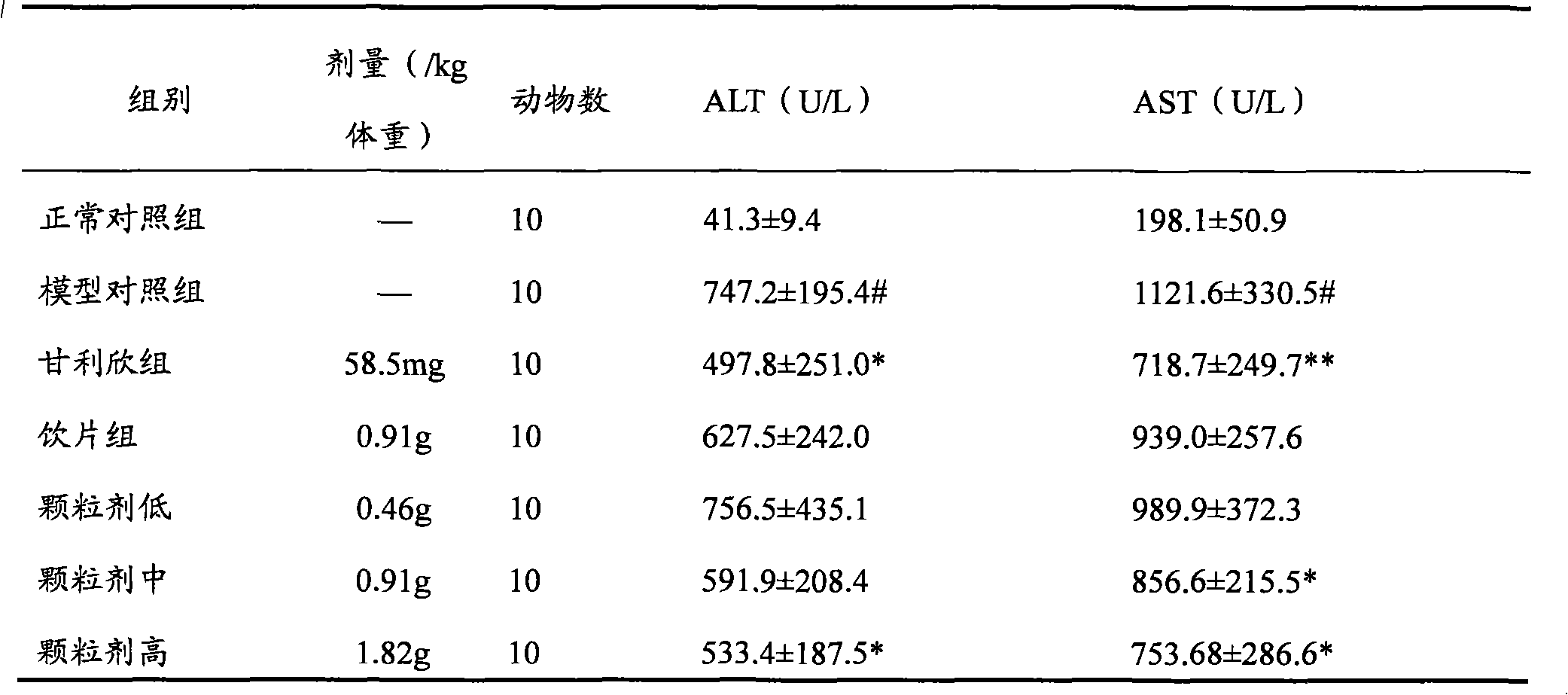

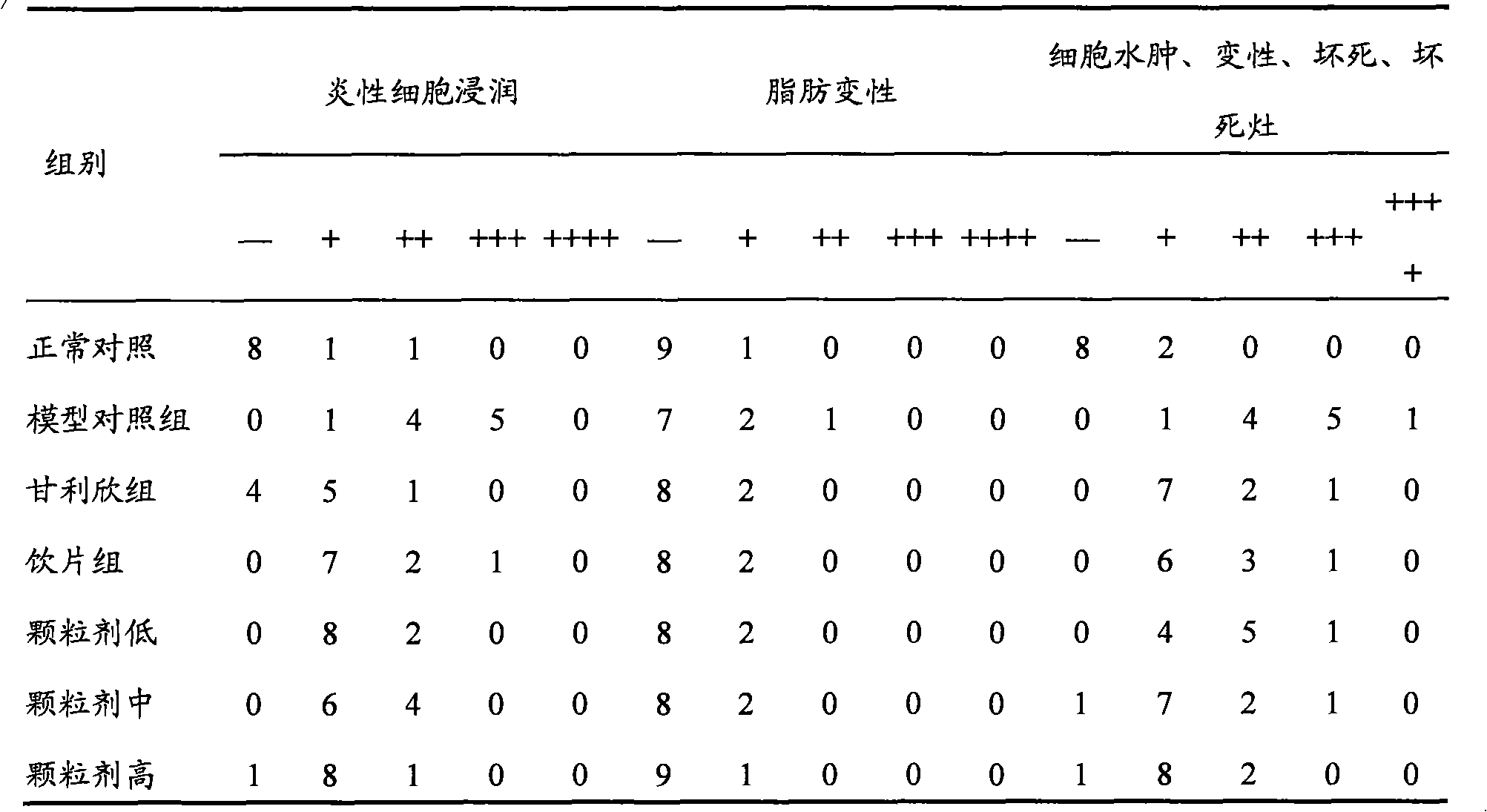

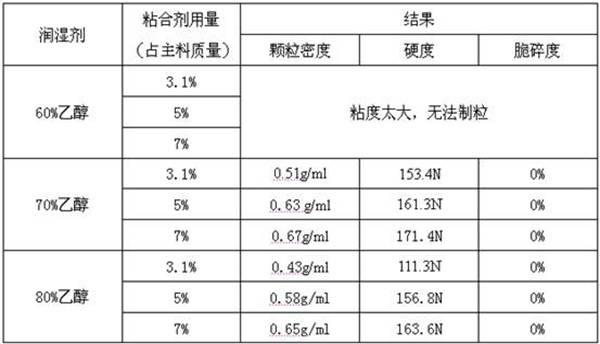

Chinese medicinal composition granules and preparation method thereof

ActiveCN101850066AGood effectSafe to takeAntinoxious agentsGranular deliveryDiseaseSalvia miltiorrhiza

The invention relates to Chinese medicinal composition granules and a preparation method thereof. The Chinese medicinal composition granules comprise the following ruptured powder in part by weight: 3 to 18 parts of American ginseng ruptured powder, 1 to 24 parts of pseudo-ginseng ruptured powder, 6 to 36 parts of dendrobium ruptured powder, and 9 to 45 parts of root of red-rooted salvia ruptured powder, wherein the granularity D90 of the ruptured powder is between 5 and 75 mu m. The invention also provides a method for preparing the Chinese medicinal composition granules. The method comprises the following steps of: uniformly mixing the American ginseng ruptured powder, pseudo-ginseng ruptured powder, dendrobium ruptured powder, and root of red-rooted salvia ruptured powder of which the D90 is between 5 and 75 mu m; preparing a soft material by adopting aqueous ethanol at the concentration of over 20 vol percent; and after granulating by using a granulator with 10 to 30 meshes, drying and finishing the granules to obtain the Chinese medicinal composition granules. The Chinese medicinal composition granules are applied to preventing and regulating human cardiac-cerebral vascular system diseases and sub-health state such as weak immunity and fatigability, have the obvious advantages of high medical effect, high quality uniformity, convenient carrying and administration, safety, reliability, and the like, and can meet the requirement on modern fast-paced lifestyle.

Owner:ZHONGSHAN ZHONGZHI PHARMA GRP +1

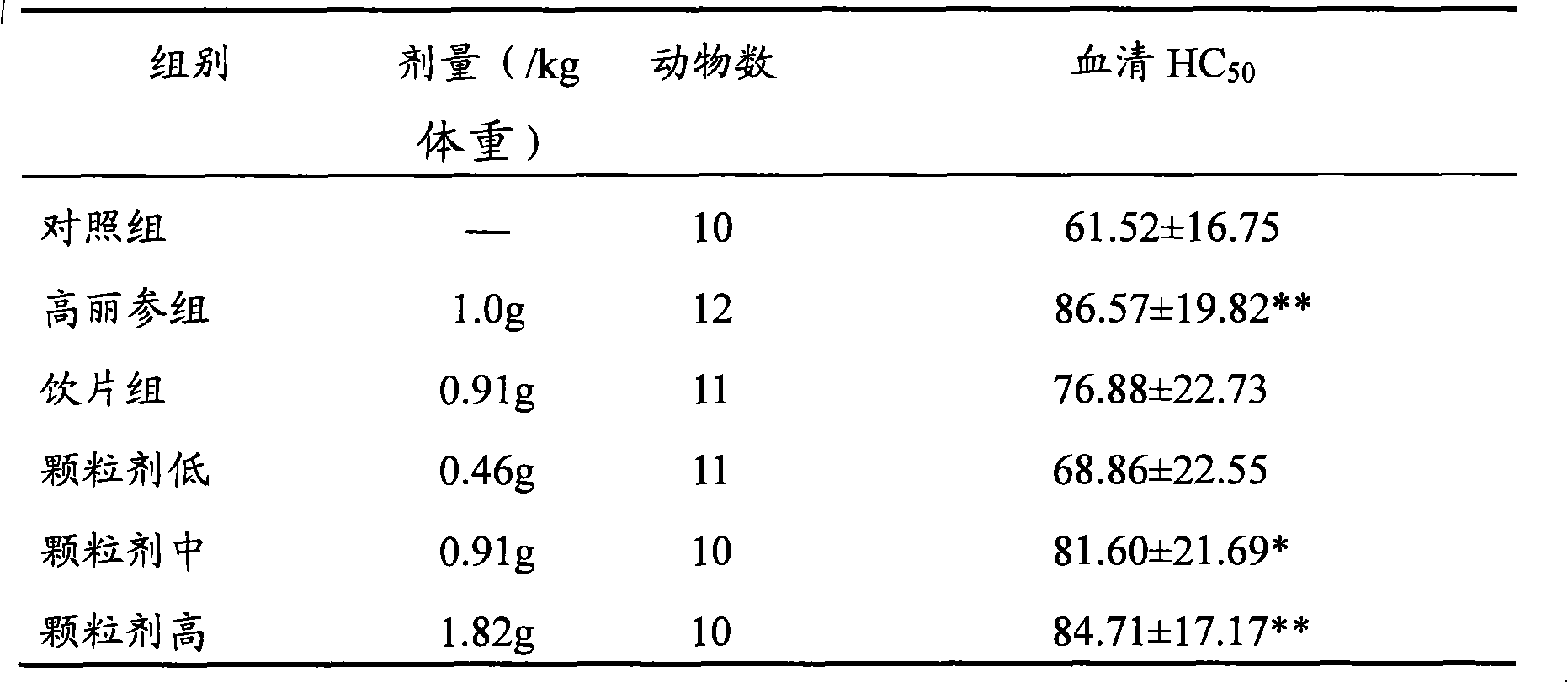

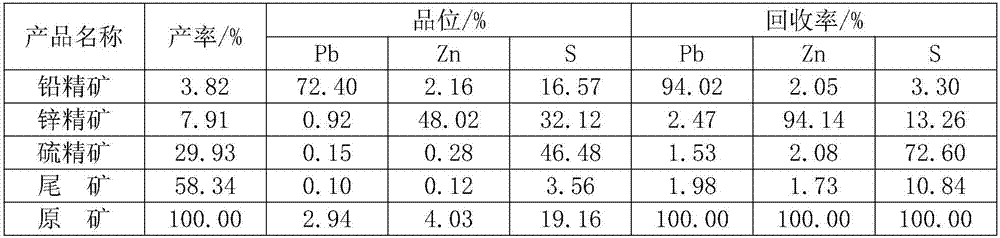

Flotation separation technology for high-sulfur lead-zinc ore in high-concentration environment

ActiveCN107999267AImprove acceleration performanceStrengthen the arching effectFlotationWet separationHigh concentrationSeparation technology

The invention discloses a flotation separation technology for high-sulfur lead-zinc ore in a high-concentration environment. The flotation separation technology aims at high-sulfur lead-zinc sulfide ore containing associated gold and silver, and flotation of lead and associated gold and silver minerals is preferentially carried out in a high-concentration and neutral natural pH flotation environment; and lead-flotation tailings are subjected to two-stage rough flotation so as to realize bulk flotation of zinc-sulfur minerals, the pH value and the potential of ore pulp are regulated and controlled by adopting lime in the zinc-sulfur separation flotation process so as to realize zinc-sulfur separation, and a small amount of activating agents and collecting agents are added to strengthen flotation of zinc minerals difficult to float. According to the flotation separation technology, the defects that in the lead flotation process of high-alkali mediums, the recovery rate of lead, gold andsilver is low, the usage amount of agents is large, the floatation process is not stable, and the like can be overcome; and meanwhile, a zinc-sulfur mineral inhibitor XKK012 and a lead-gold-silver collecting and frothing agent XKY712 are invented, so that the problems that the lead-zinc-sulfur separation efficiency is low, the separation precision is poor, and the hydrophobic capacity of part of lead-gold-silver minerals is weak can be solved, and the technology has the advantages of being energy-saving, environment-friendly, non-toxic, harmless, low in beneficiation cost, high in recovery efficiency and suitable for comprehensive recovery of valuable metal minerals in the high-sulfur silver-lead-zinc-contained ore.

Owner:WESTERN MINING CO LTD +2

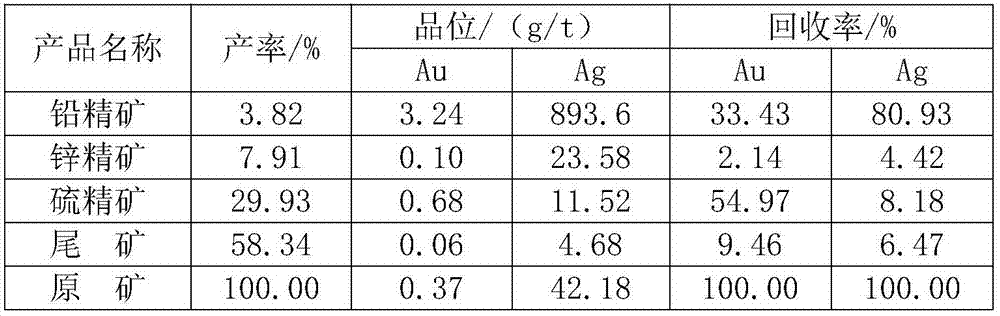

Novel hydraulic pump body mechanism

InactiveCN104131959AReduce volumeOvercoming structural complexityPumpsPositive-displacement liquid enginesHydraulic pumpEngineering

The invention discloses a novel hydraulic pump body mechanism. The top end of a hydraulic pump body is connected with a fixed jaw; an electromagnetic coil is mounted on the outer circle of the hydraulic pump body; a lower cover body is mounted in the lower port part of the hydraulic pump body; a lower cover ball is mounted on the lower cover body; a lower cover spring and a lower gland are mounted on the lower cover ball; a piston is mounted in a hole in the middle of the hydraulic pump body; a piston rolling ball is mounted on the piston; a telescopic spring and a piston gland are mounted on the piston rolling ball; a piston spring is mounted at the upper part of the piston; and an upper cover body is mounted at the upper port part of the hydraulic pump body.

Owner:XUZHOU KAILONG MINING SCI & TECH DEV

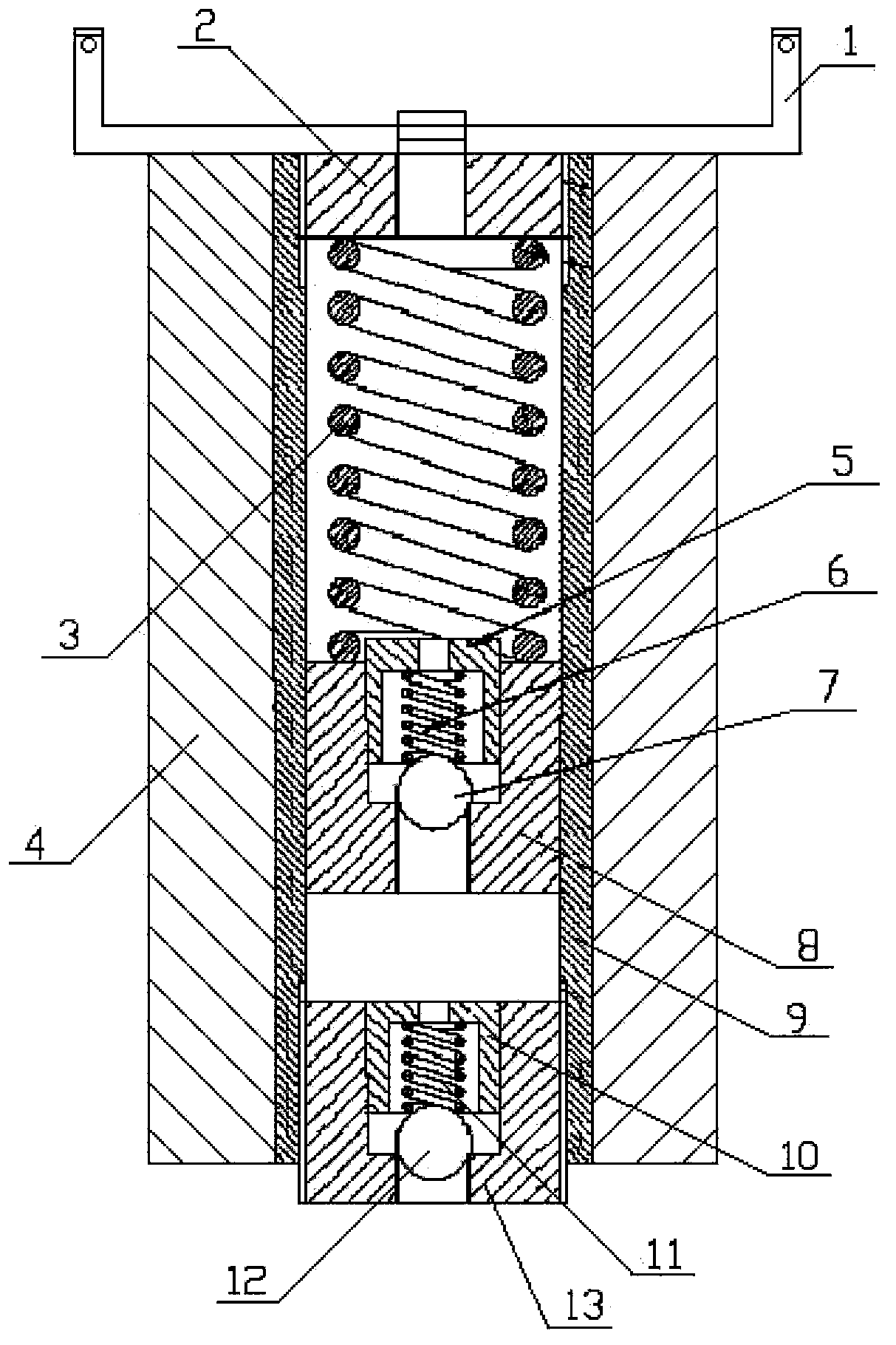

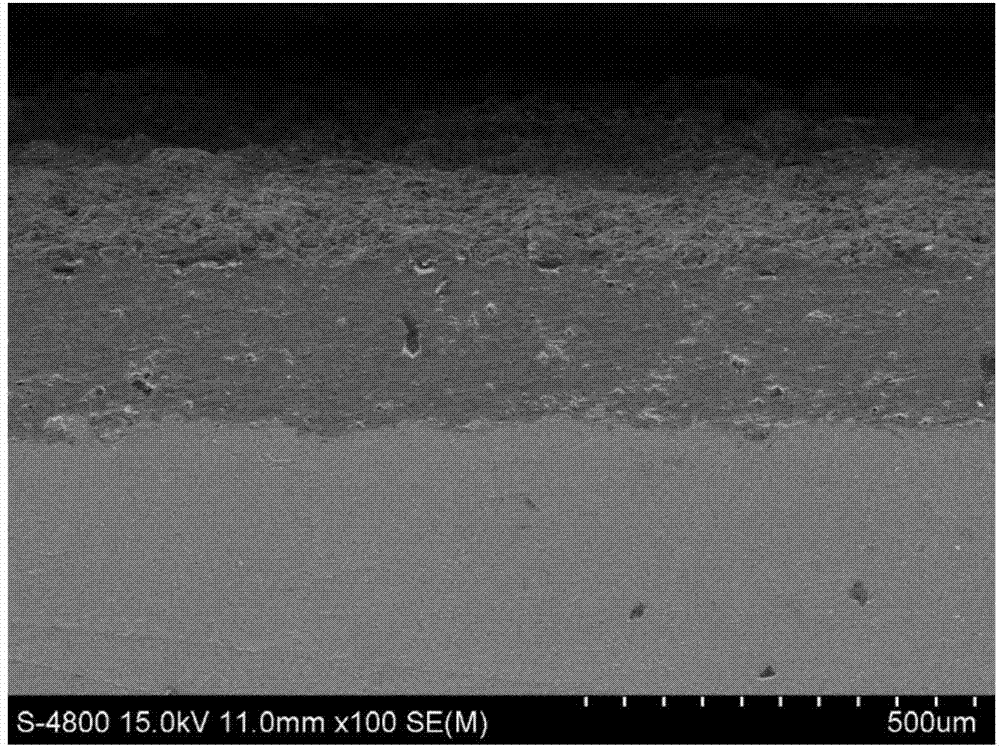

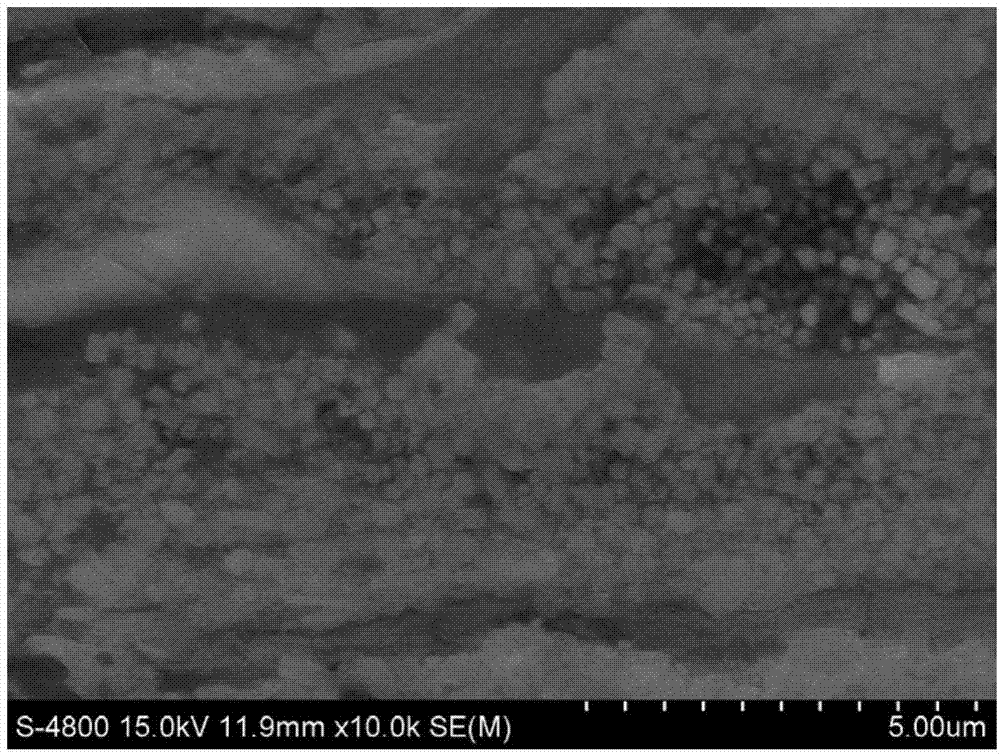

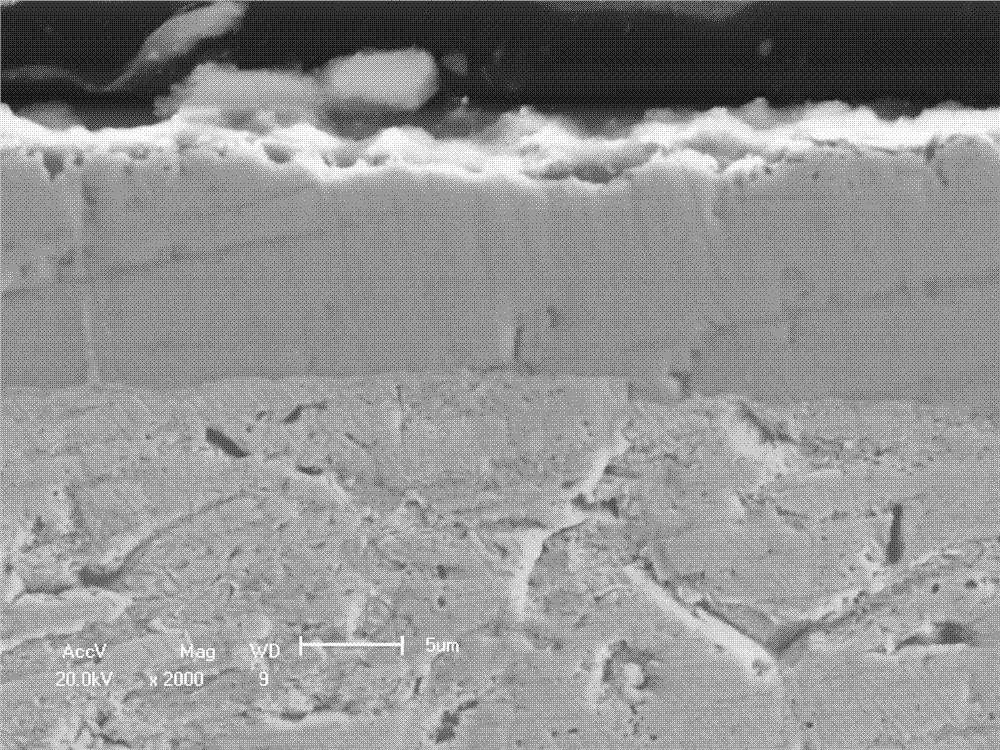

Preparation method of titanium boride based inorganic composite coating

Relating to plating of metal materials, the invention provides a preparation method of a titanium boride based inorganic composite coating. The mixed powder of micron-sized metal Al powder, micron-sized, submicron-sized or nano-sized TiO2 powder, and micron-sized, submicron-sized or nano-sized B4C powder is taken as a raw material, the mixed powder is sprayed on the alloy underlayer surface of a metal or alloy workpiece surface by thermal spraying. During thermal spraying, the Al, TiO2 and B4C in the mixed powder react with nitrogen in a powder feeding gas to synthesize the titanium boride based inorganic composite coating in situ. The method provided in the invention overcomes the defects of high raw material cost, complicated preparation process, high energy consumption, low efficiency, difficult control of coating processing precision, low coating density, poor coating uniformity, weak binding force between the coating and a substrate, low coating toughness, easy coating cracking, and unsuitability for application in large-scale industrial production existing in the prior art for preparation of titanium boride based composite coatings.

Owner:HEBEI UNIV OF TECH

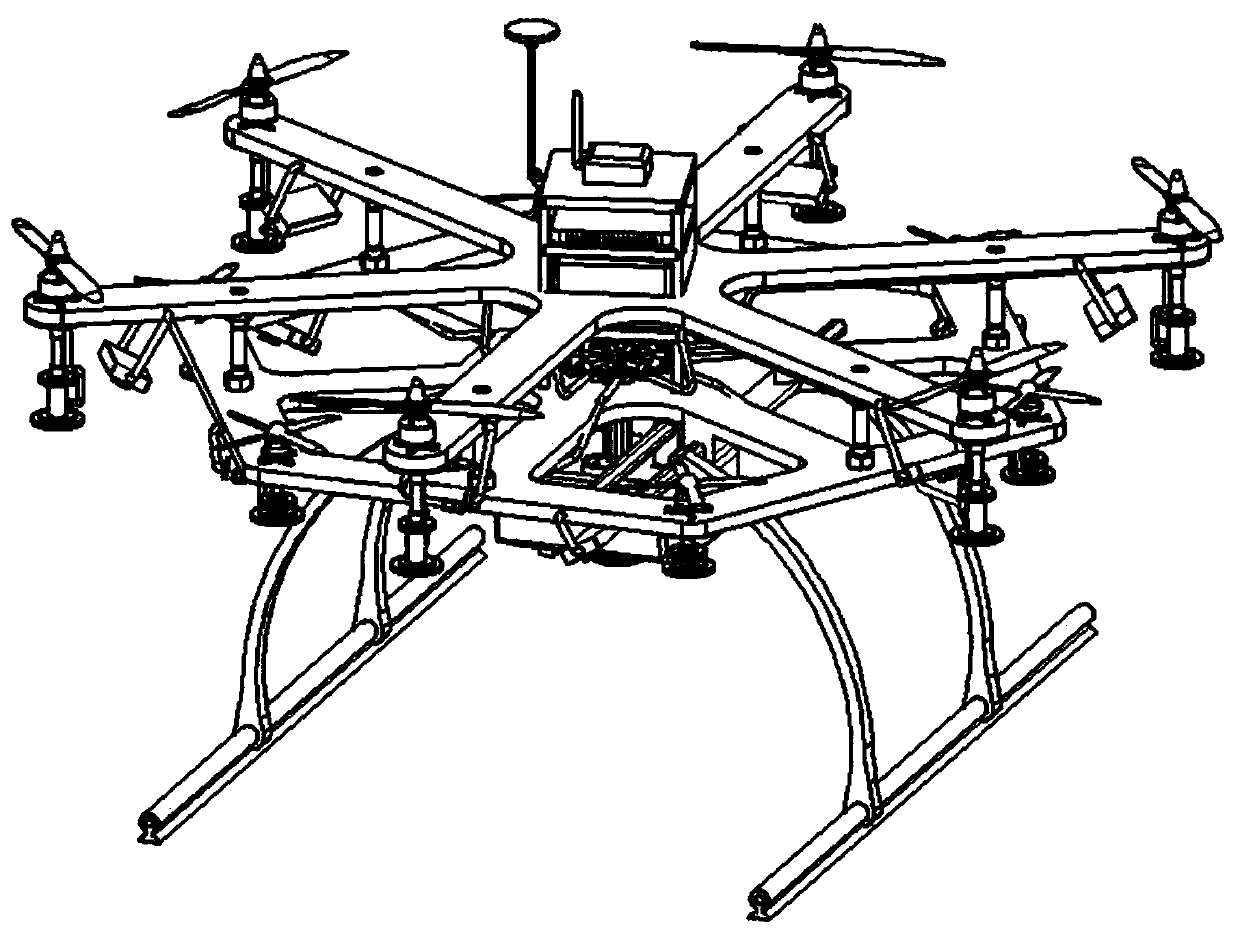

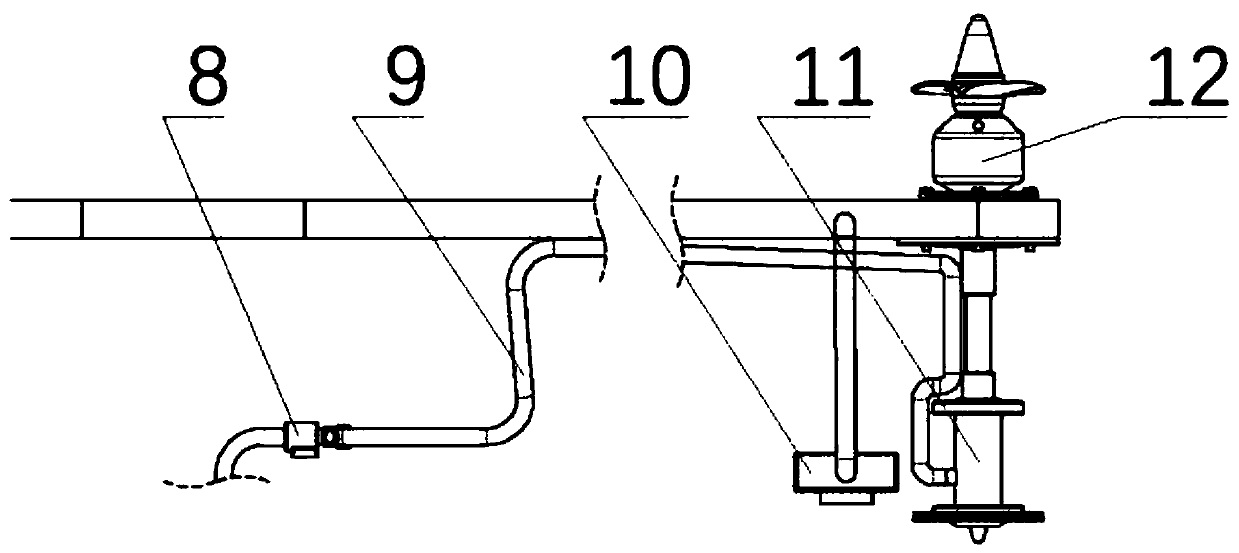

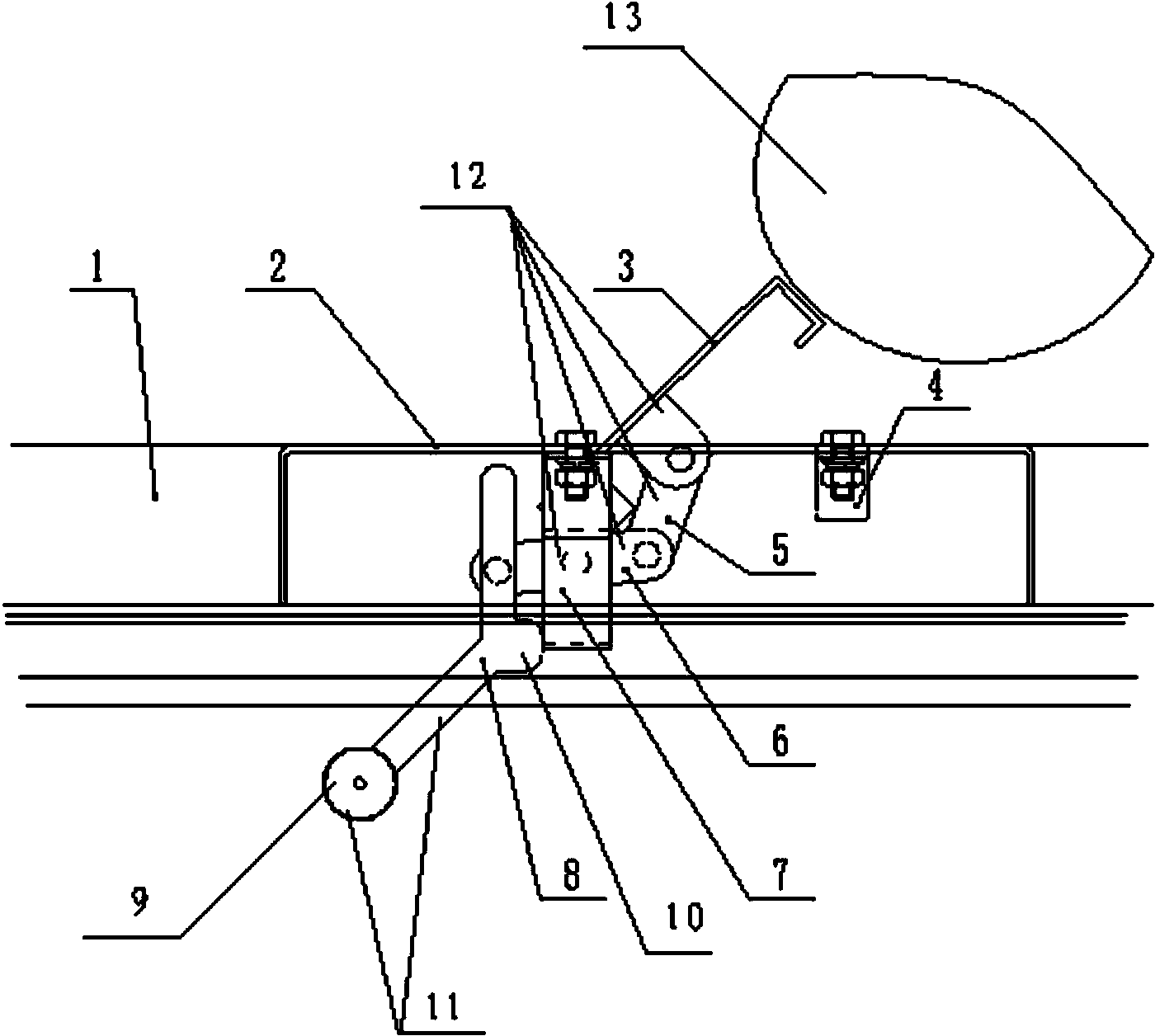

Unmanned aerial vehicle variable-quantity accurate pesticide applying system and method

PendingCN109720578AOvercome the disadvantages of being easily limited by the natural environmentOvercome carryingAircraft componentsInsect catchers and killersLaser rangingControl system

The invention discloses an unmanned aerial vehicle variable-quantity accurate pesticide applying system and method. The system comprises an unmanned aerial vehicle, a tree crown detection system, a pesticide liquid conveying system and a control system. The tree crown detection system is composed of an image acquisition device and a two-dimensional laser ranging scanning device. The pesticide liquid conveying system is composed of a pesticide box, water pumps, connecting pipes and nozzles. The control system is composed of a flight control module and a pesticide application control module. Thevariable-quantity accurate pesticide applying system is finished through the tree crown detection system, the pesticide liquid conveying system and the control system. By the adoption of the variable-quantity accurate pesticide applying method, the unmanned aerial vehicle can be controlled to hover over the center of a tree crown, the relative height of the unmanned aerial vehicle is adjusted, the flow of each water pump is controlled through the pesticide application control module, pesticide is sprayed at multiple points at the same time, so that the accuracy and comprehensiveness of pesticide application are guaranteed, and the state of an illness of a tree is effectively controlled.

Owner:NANJING FORESTRY UNIV

Water-soluble composite containing thermoplastic PVA (polyvinyl alcohol) and preparation method of water-soluble composite containing thermoplastic PVA

ActiveCN107266838AReduce crystallinityExcellent melt processing fluidityThermoplasticPolyvinyl alcohol

A water-soluble composite containing thermoplastic PVA (polyvinyl alcohol) is finely particulate, the particle size is 0.0015-2.0 mm, and the composite is prepared from thermoplastic PVA resin and a linear random polymer in a weight ratio of (80-99.9): (0.1-20). The water-soluble composite containing thermoplastic PVA is characterized in that the melt index is 8-35 g / 10 min, the melt temperature is 120-280 DEG C, and the water solution temperature is 20-80 DEG C. The water-soluble composite has lower crystallinity and excellent melt processing fluidity, overcomes defects of high crystallinity and poor melt flowability of existing blended modified PVA resin, and a preparation method is simple and easy to implement.

Owner:CHINA PETROCHEMICAL CORP +1

Method for smelting non-oriented silicon steel by using molten iron containing vanadium and titanium

ActiveCN104988424AOvercome mobilityOvercoming poor desulfurization effectManufacturing convertersSteelmakingCastability

The invention relates to a method for smelting non-oriented silicon steel by using molten iron containing vanadium and titanium, and belongs to the technical field of metallurgy. The method comprises the steps of converter vanadium extraction of the molten iron containing vanadium and titanium, desulphurization, converter steelmaking, RH refining and slab continuous casting in order to obtain the non-oriented silicon steel. The method fully overcomes the disadvantages of poor top slag fluidity, poor desulphurization effect and many residual elements of the molten iron containing vanadium and titanium, reduces entrance of vanadium, titanium and other residual elements to the molten steel, and improves the purity of the molten steel; and the method adopting a double station RH refinery and continuous caster matching production mode guarantees the smelting cycle in a range of 35-40min. The technology has the characteristics of high purity of the molten steel, high castability of the molten steel, and short production cycle.

Owner:HEBEI IRON AND STEEL

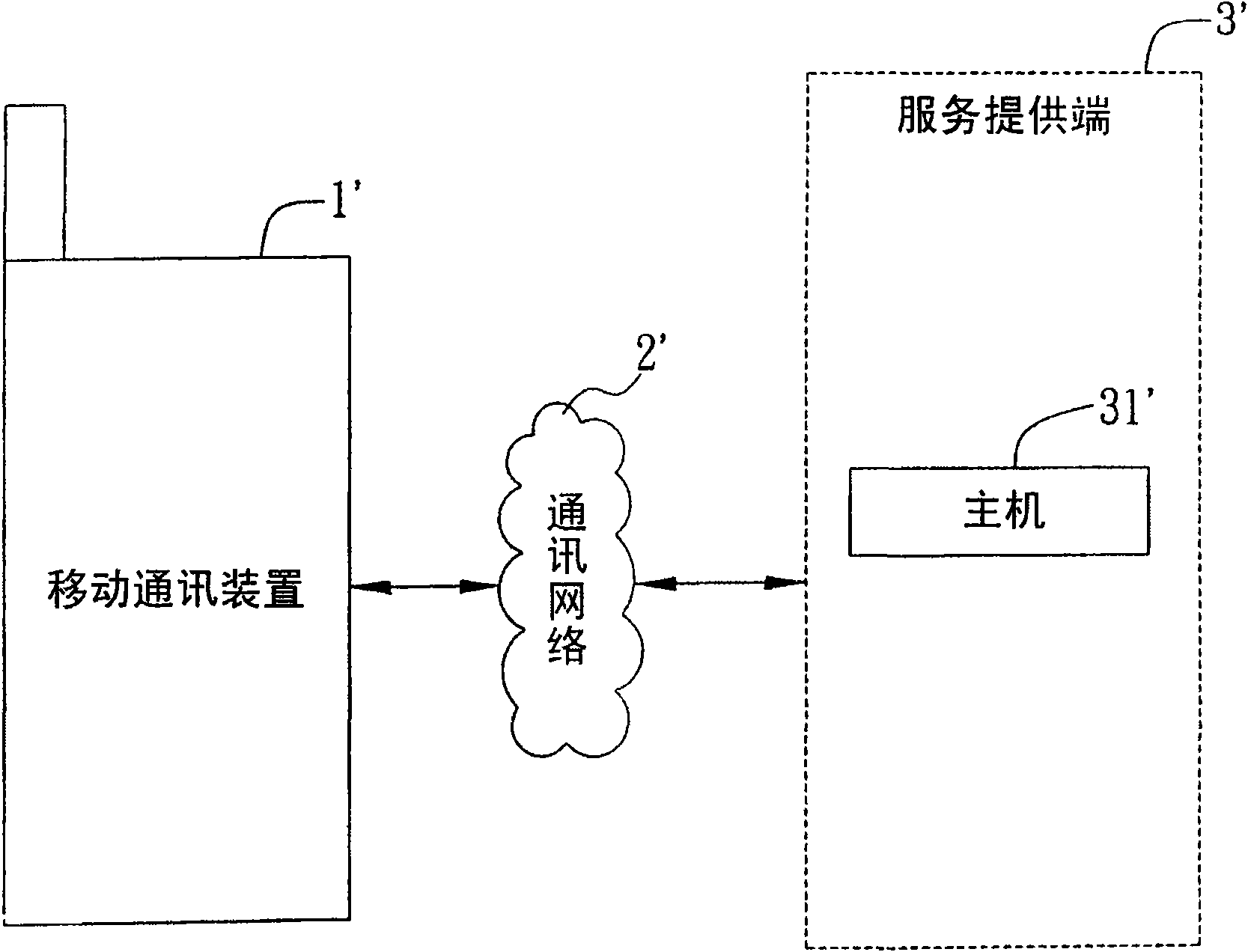

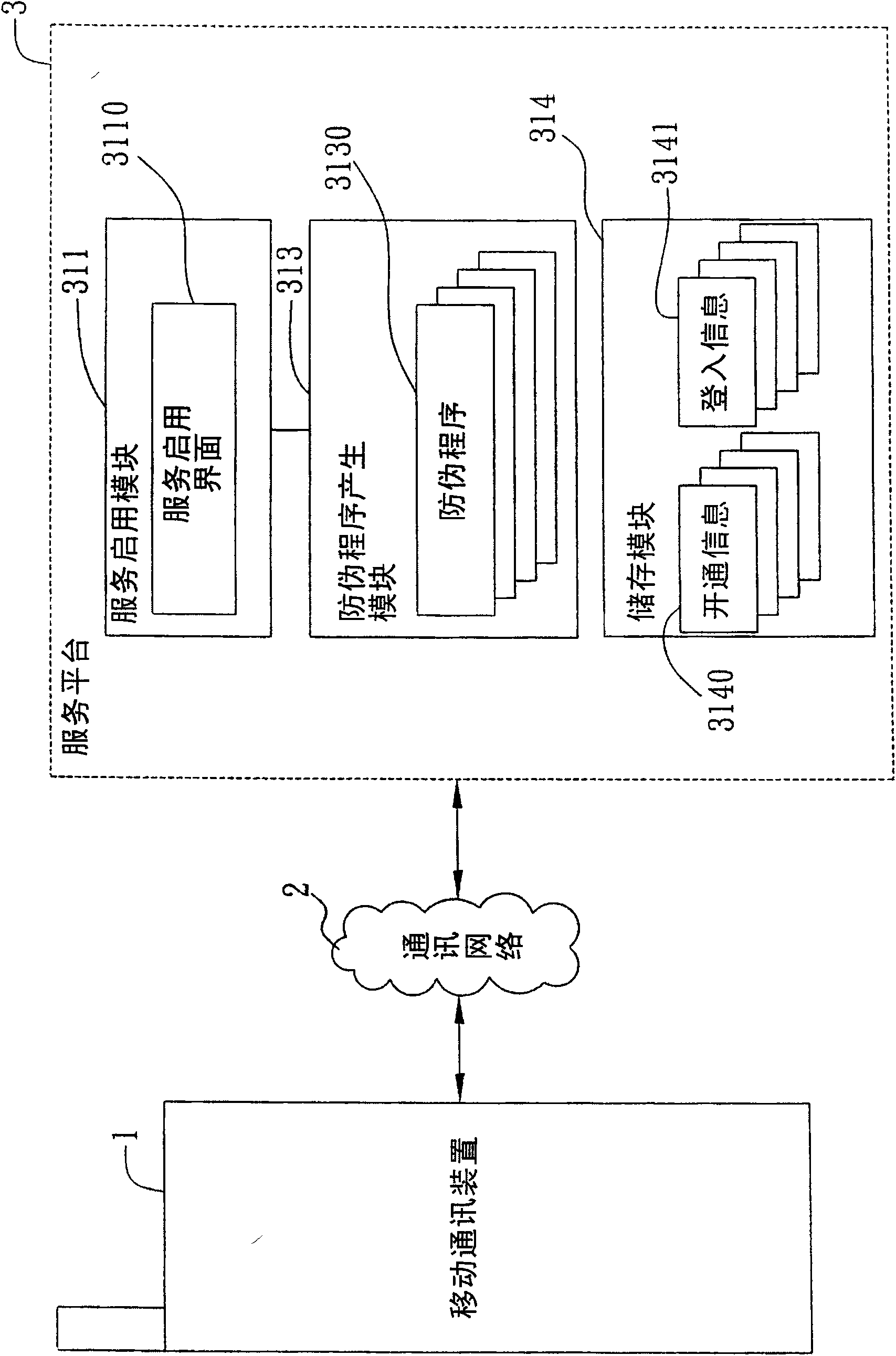

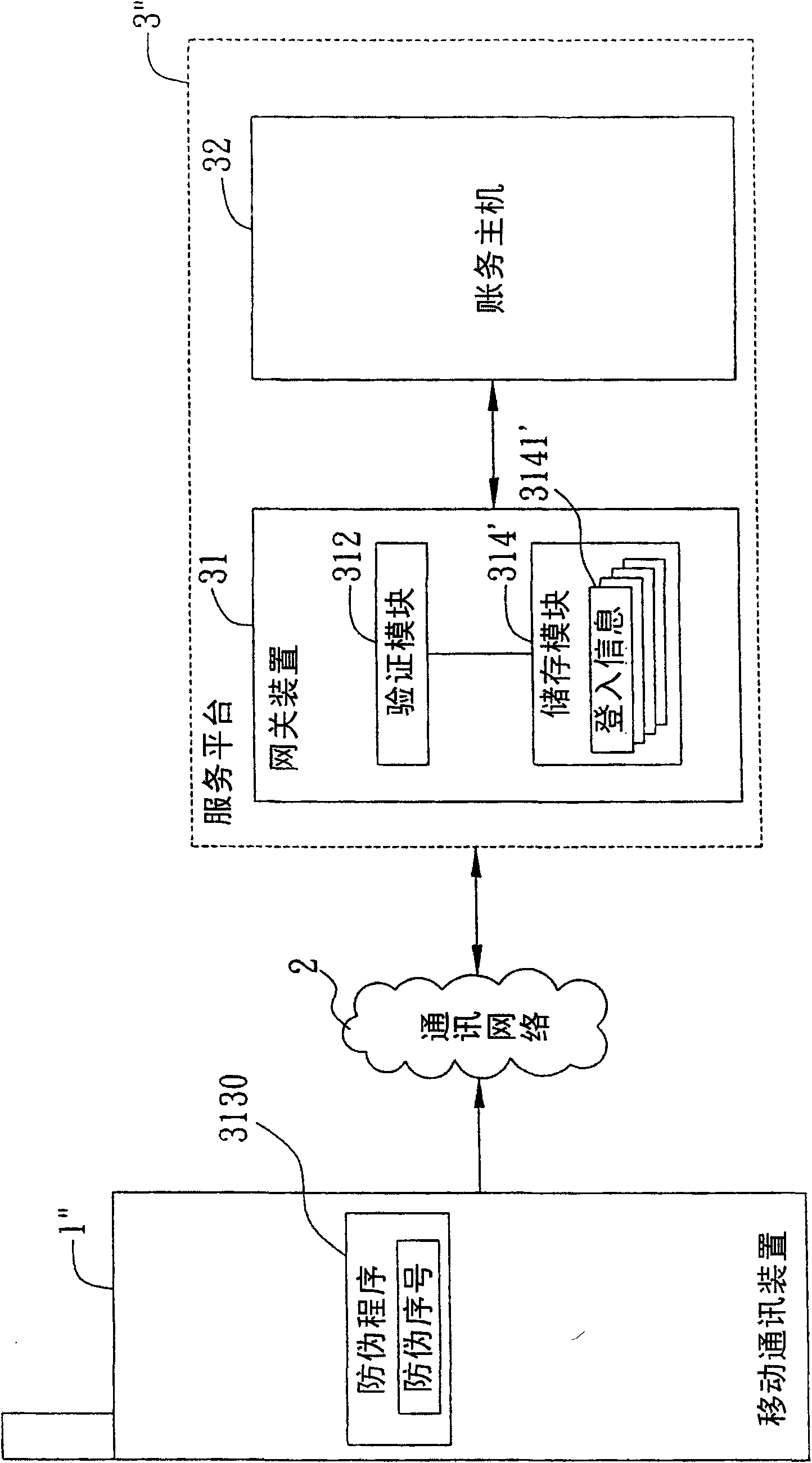

Login authentication system and method

InactiveCN101854627ALow costReduce the cost of protectionSecurity arrangementPasswordNetworked system

The invention discloses login authentication system and method. The login authentication system is a safety login mechanism for a client to login a service platform through a network system by using a mobile communication device. The service platform demands the mobile communication device to input an account number and a password to carry out opening authentication. After the mobile communication device is subjected to the opening authentication of the service platform, the service platform automatically generates an anti-counterfeiting program with a software serial number and returns the anti-counterfeiting program to the mobile communication device to write in the mobile communication device so that the mobile communication device logins the service platform by using the anti-counterfeiting program with the software serial number.

Owner:邱宏达

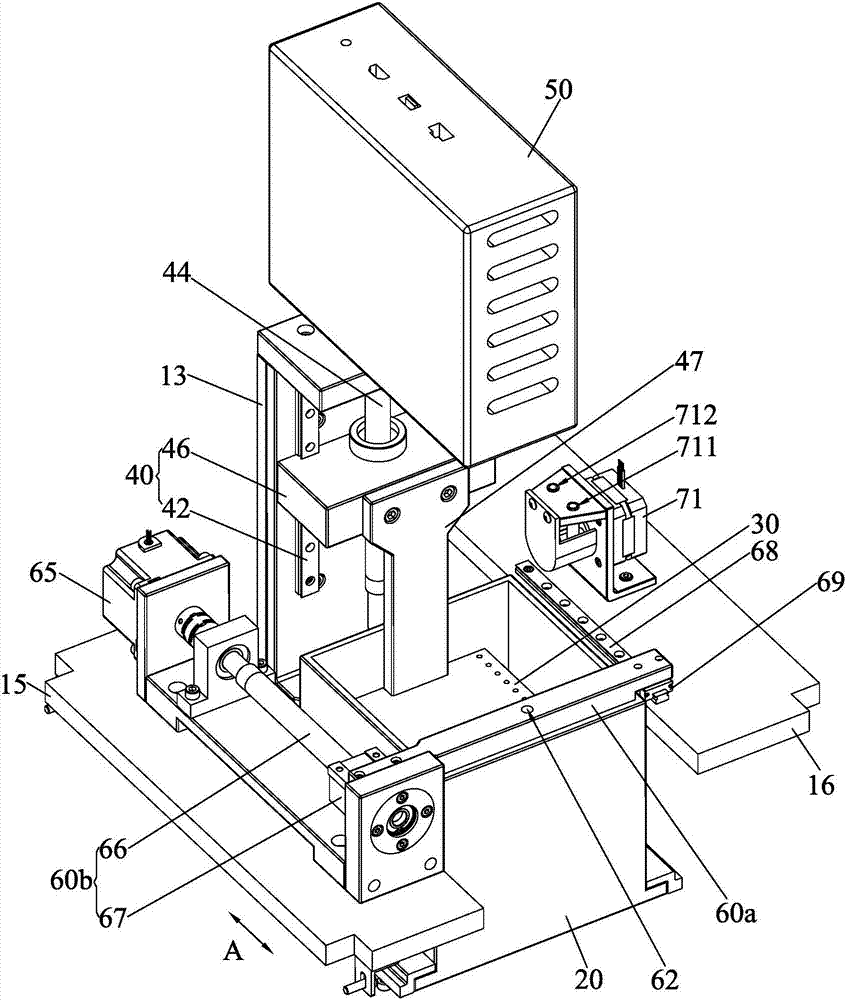

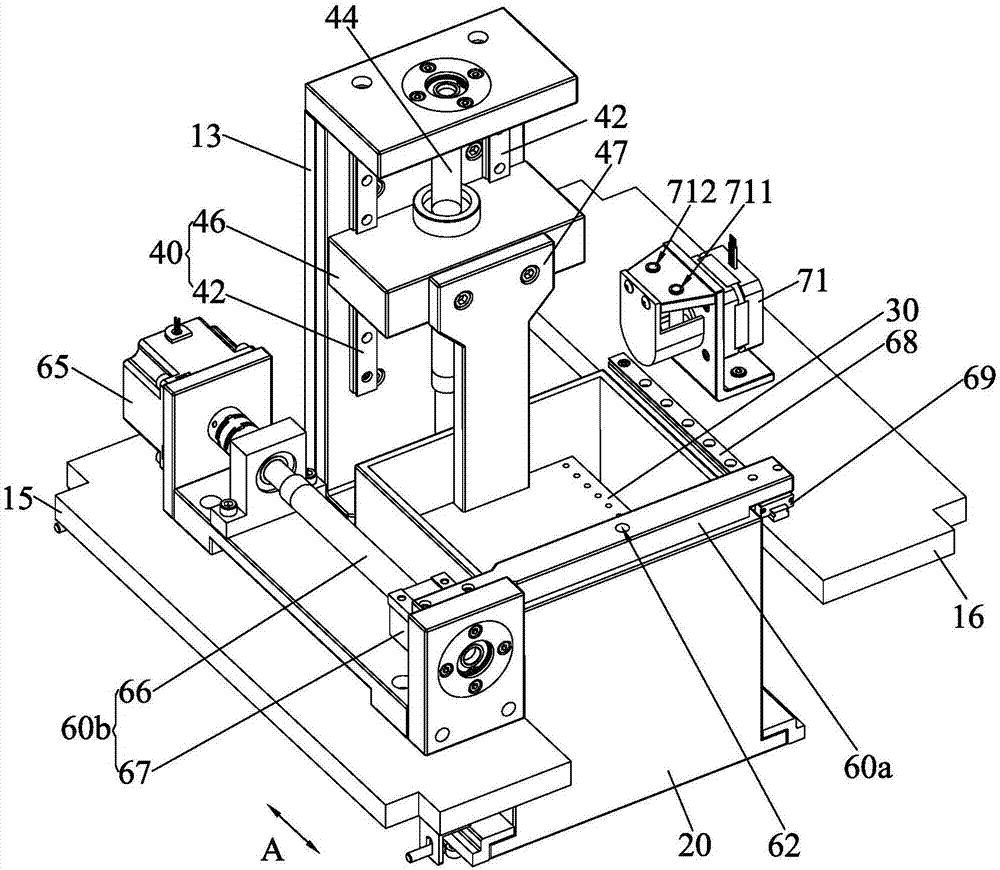

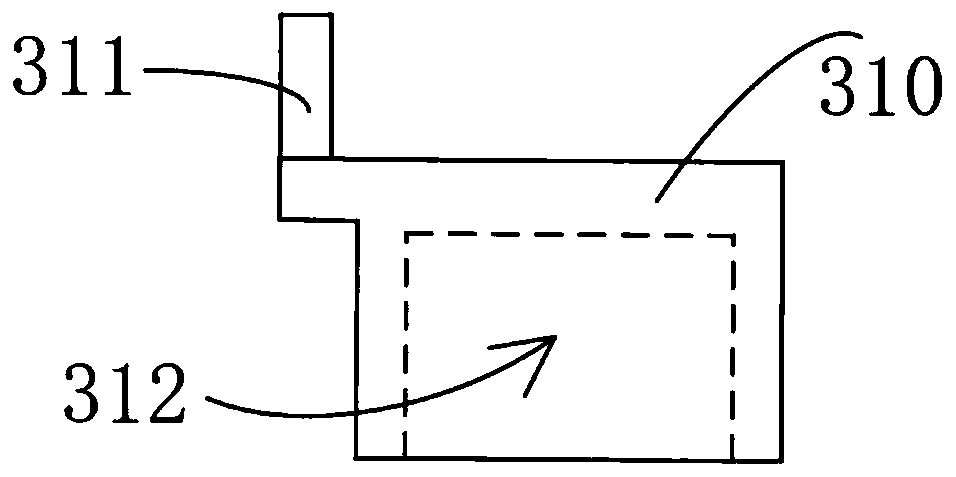

Upward exposure type ceramic photocuring 3D printing equipment and manufacture method thereof

InactiveCN107020744AGuaranteed reliabilityEvenly distributedAdditive manufacturing apparatus3D object support structuresEngineeringMaterial supply

The invention discloses upward exposure type ceramic photocuring 3D printing equipment and a manufacture method thereof. The upward exposure type ceramic photocuring 3D printing equipment comprises a machine table, a scraper mechanism, a material supply mechanism, a material trough, a molding platform, a lifting mechanism and a projector, wherein the lifting mechanism is used for driving the molding platform to go upwards and downwards relative to the material trough; the projector is located above the material trough; the scraper mechanism comprises a scraper arranged above the material trough in a spanning manner and a driving assembly used for driving the scraper to slide; a liquid flow channel, a feeding opening and a discharging opening are formed in the scraper, and the discharging opening is arranged in the spanning direction of the scraper; and the material supply mechanism comprises a circulating pump, a recycling hose and an output hose, the recycling hose is connected between an inlet of the circulating pump and the material trough, and the output hose is connected between an outlet of the circulating pump and the feeding opening. The circulating pump pumps photocuring liquid in the material trough and conveys the photocuring liquid into the liquid flow channel of the scraper, and the photocuring liquid flows into the material trough from the discharging opening. A three-dimensional model is easier to separate from the material trough, and the forming reliability of the three-dimensional model is prevented from being affected by the sedimentation of the photocuring liquid.

Owner:DONGGUAN UNIV OF TECH

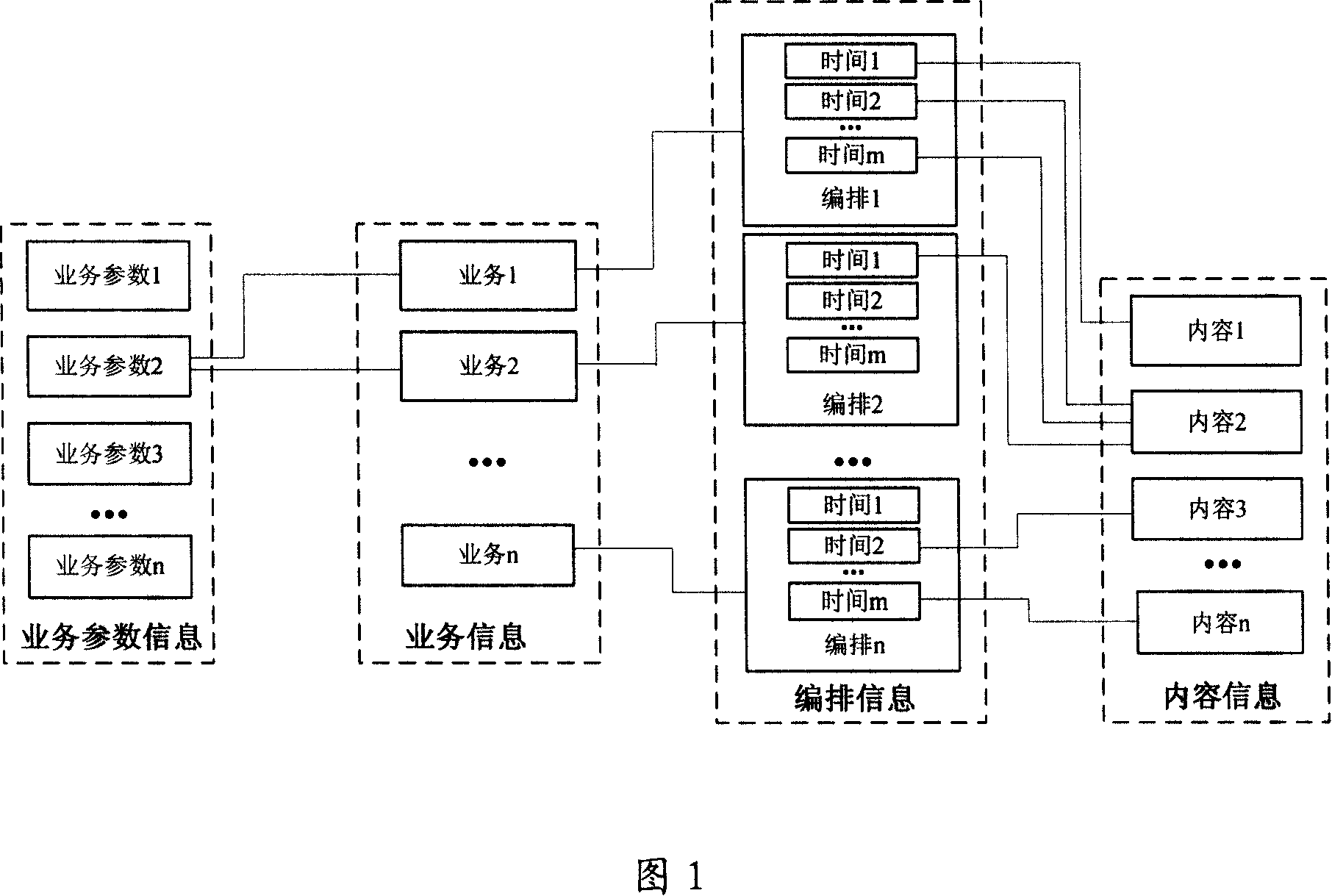

Transmission method for data information of electronic service directory

InactiveCN101047847AOvercoming narrow bandwidthOvercome mobilityTelevision system detailsBroadcast with distributionData informationTransfer procedure

This invention discloses a transmission method for data information of electronic service directory including: dividing data information into one or several kinds of service information, arranging information, content information and operation parameter information by a data kind identification field, segmenting the sorted data information in terms of blocks by a data block identification field, segmenting the data block into several sections by a section sequence number field, and the data sections are corresponding to the data units of complex sub-frames, which are transmitted in the service logic channels of an electronic service directory.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

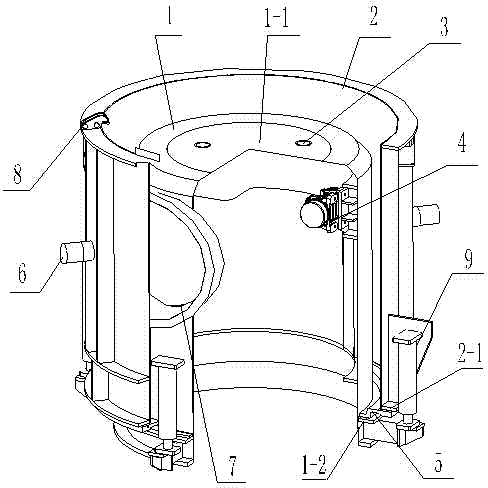

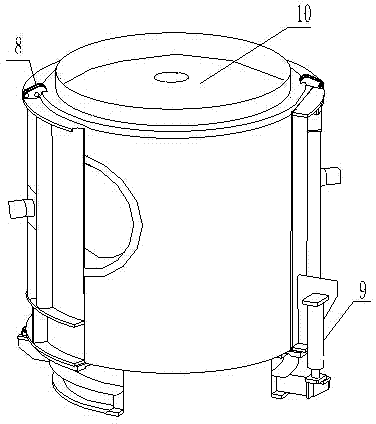

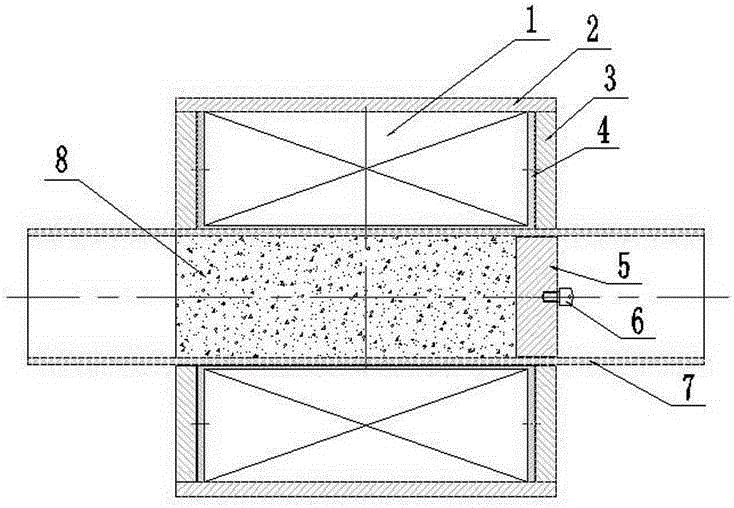

Concrete inspection well molding mould with base

ActiveCN104742250AOvercome mobilityOvercome the problem that it is not easy to inject into the inner cavity of the moldMouldsCeramic shaping coresLocking mechanismMaterials science

The invention provides a concrete inspection well molding mould with a base. The concrete inspection well molding mould comprises a cylindrical inner die and an outer die; one end of the inner die is provided with a bottom part, and an inspection well molding space forms between the inner die and the outer die; a faucet disk used for supporting concrete material filled in the molding space is arranged between one end of the inner die without the bottom part and corresponding end of the outer die; the faucet disk is fixedly connected with the inner die or the outer die, and one end of the inner die without the bottom part is connected with the outer die through a jacking mechanism. The concrete inspection well molding mould further comprises a bottom tray for pressing the concrete material filled in the molding space and a locking mechanism used for locking the bottom tray on the mould. By adopting the concrete inspection well molding mould, the molding efficiency and production quality of the inspection well are obviously improved.

Owner:苏州科星混凝土水泥制品装备有限公司

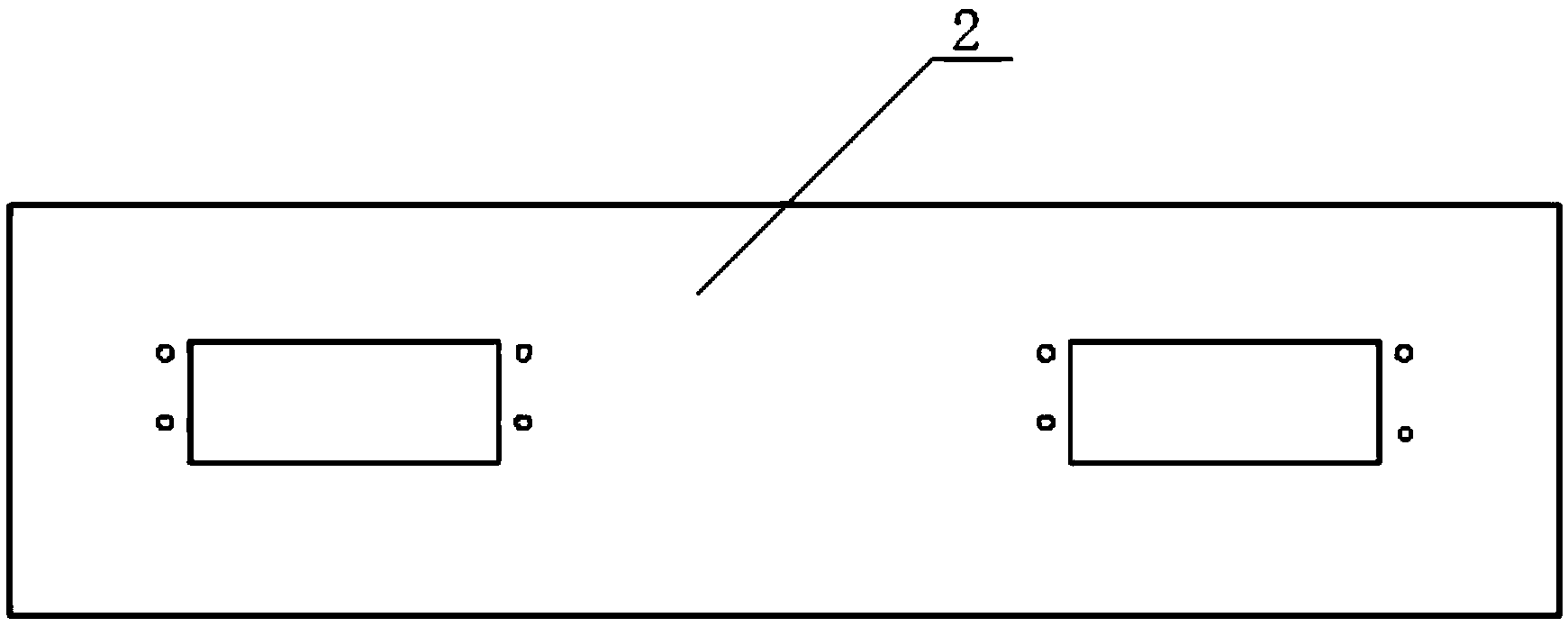

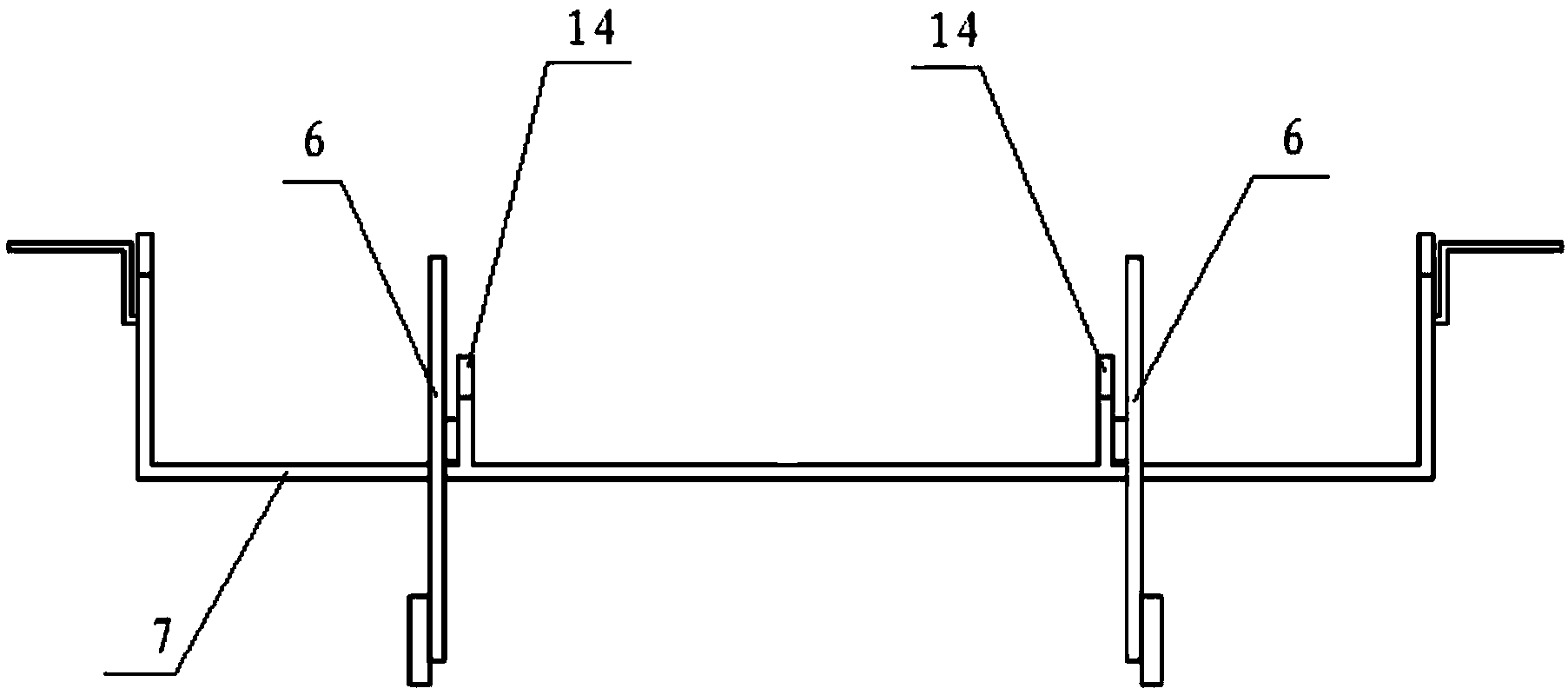

Automobile front baffle device for vehicle-loading tray

ActiveCN103556859AOvercome mobilityOvercoming the defect of falling from the vehicle palletParkingsEngineeringMechanical engineering

The invention relates to an automobile front baffle device for a vehicle-loading tray, in particular to an automobile front baffle device for a stereo garage lifting vehicle-loading tray. The automobile front baffle device comprises a vehicle-loading plate, a movable baffle group, a bearing plate and a baffle locking connecting rod group for driving the movable baffle group to move and be locked. The movable baffle group is fixedly installed on the vehicle-loading plate, the bearing plate is fixed on the vehicle-loading plate, and the baffle locking connecting rod group is movably connected with the movable baffle group. The automobile front baffle device has the advantages that by utilizing the simple structure, the shortcoming that automobiles move easily on the vehicle-loading tray in the transportation process, so that the automobiles falls off the vehicle-loading tray is overcome, and the automobiles are stopped stably and safely.

Owner:王忠利

Aluminizing agent and method for preparing Si-B-Y coating on surface of tantalum and tantalum alloy

InactiveCN107267915AEnhanced resistance to peelingImprove liquiditySolid state diffusion coatingOxidation resistantPre treatment

The invention belongs to the technical field of high-temperature coatings and particularly relates to an aluminizing agent and method for preparing a Si-B-Y coating on the surface of tantalum and tantalum alloy. The aluminizing agent disclosed by the invention comprises, by weight, 12%-17% of aluminized element Si (with the purity greater than or equal to 99%), 1.0%-2.0% of aluminized element Y2O3 (with the purity greater than or equal to 99%), 1.0%-2.0% of aluminized element B (with the purity greater than or equal to 98%), 5%-8% of catalyst NaF (analytically pure), and the balance fillers Al2O3. The invention further discloses the preparation method of the coating. The preparation method comprises the steps of (1) conducting surface pretreating on a sample; (2) conducting ball milling and refining on the prepared aluminizing agent; (3) putting the sample and the aluminizing agent into an aluminizing tank and sealing the aluminizing tank; (4) conducting heating, heat preservation and cooling on the aluminizing tank put in a high-temperature furnace; and (5) finally, taking out the sample and then cleaning and drying the sample. The obtained coating is uniform and compact in structure, can be well bonded to a matrix and can remarkably improve the thermal protection properties of matrix alloy and resist the high temperature of 1000 DEG C for 100 h or more, and the thermal protection properties mainly include the high-temperature antioxidation property, the anti-corrosion property and the anti-wear property. Equipment required by the method is simple, and the method is reliable in process, low in cost and suitable for production and application.

Owner:BEIFANG UNIV OF NATITIES

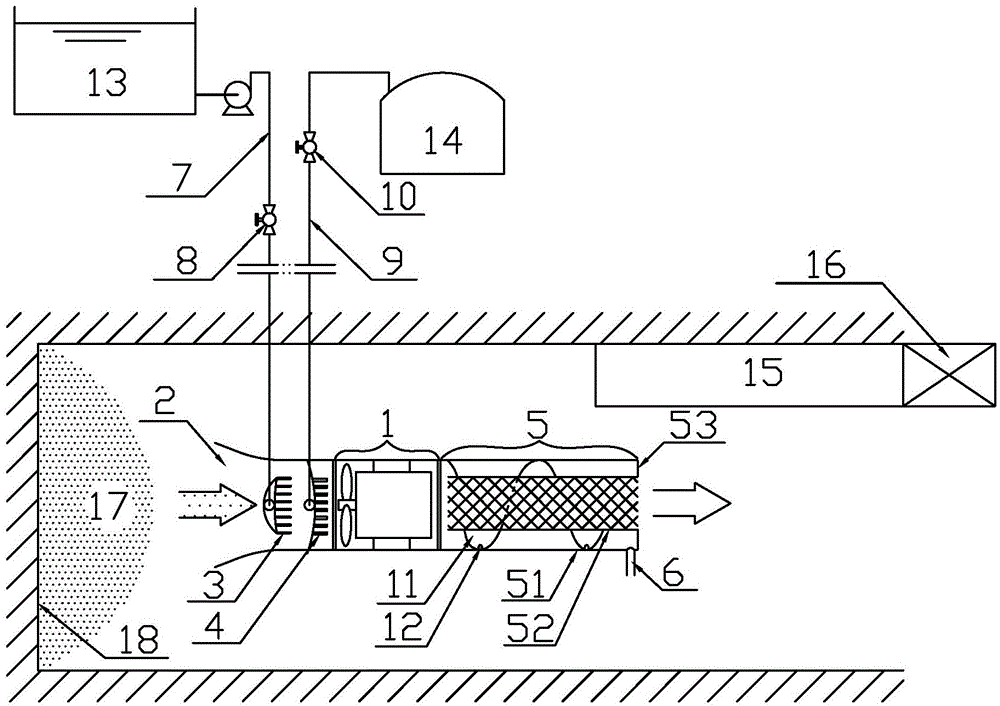

Method for improving underground coal mine negative pressure suction dust removal technology

The invention relates to a method for improving an underground coal mine negative pressure suction dust removal technology. According to the method, a horn opening, high-pressure water jet pumps and high-pressure gas jet pumps are additionally arranged in front of an air inlet of an axial flow fan, and a water film dust removal barrel is additionally arranged at an air outlet of the axial flow fan; water, dust and fog are fully mixed through the high-pressure water jet pumps, the high-pressure gas jet pumps and the axial flow fan, and then the water, dust and fog are separated out by the water film dust removal barrel. The method for improving the underground coal mine negative pressure suction dust removal technology has the advantages of being small in investment, fast to take effect, obvious in dust removal effect and suitable for coal mine driving face dust removal.

Owner:兖矿能源集团股份有限公司

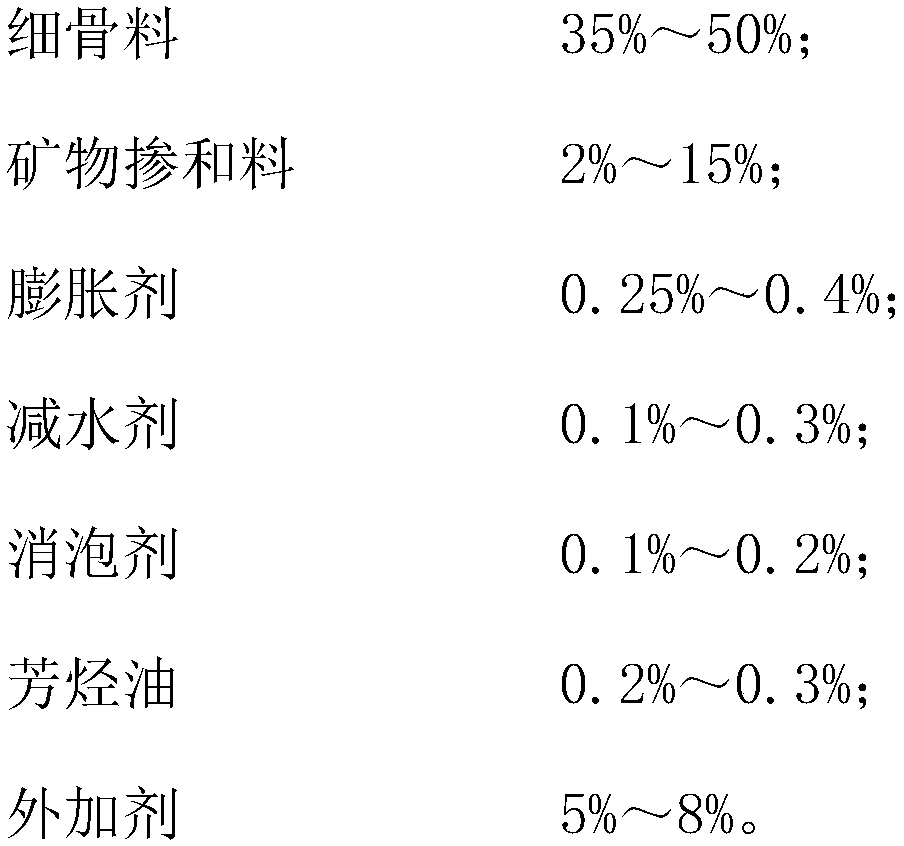

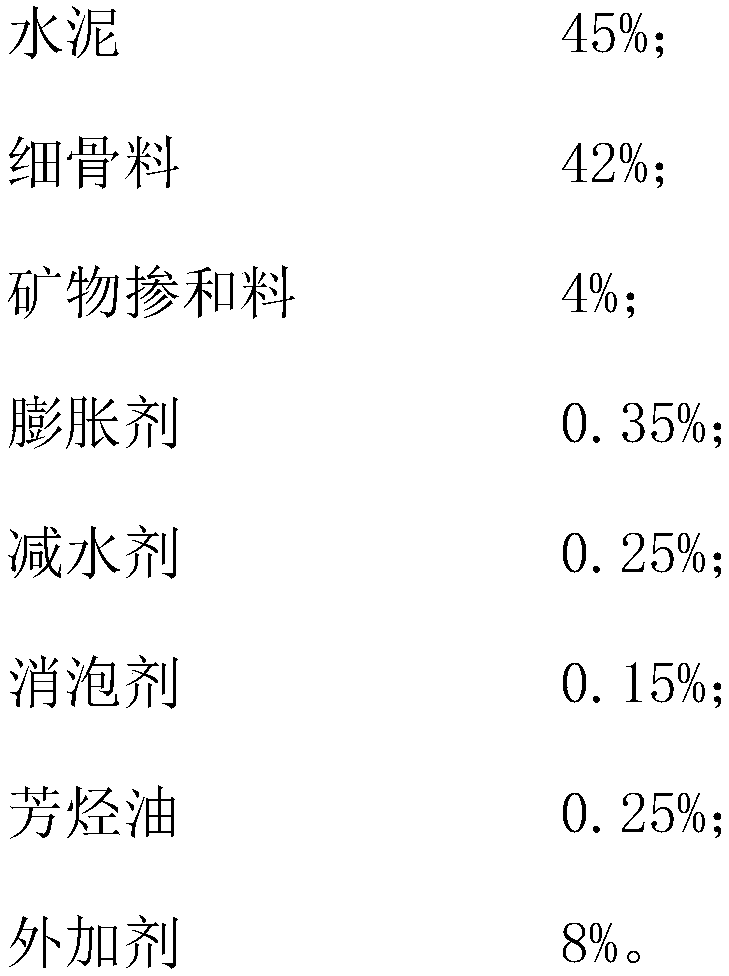

High-fluidity sleeve grouting material for rebar connection and preparation method thereof

The invention provides a high-fluidity sleeve grouting material for rebar connection and a preparation method thereof. The high-fluidity sleeve grouting material for rebar connection is made from, byweight, 45-55% of cement, 35-50% of fine aggregate, 2-15% of mineral mixture, 0.25-0.4% of an expanding agent, 0.1-0.3% of a water reducer, 0.1-0.2% of a defoaming agent, 0.2-0.3% of aromatic hydrocarbon oil and 5-8% of an admixture. The sleeve grouting material for rebar connection prepared herein has high fluidity; the problem is solved that an existing sleeve grouting material for rebar connection has insufficient initial fluidity in actual engineering application or is poorer than regular materials in initial fluidity, and has poor fluidity retaining capacity; with certain fluidity of thegrouting material ensured, the problem of inadaptation to production and construction due to too high fluidity of the grouting material is solved; fluidity of grout is improved, and service performance of the grouting material is improved.

Owner:SHANGHAI HENGFU SCI TECH DEV

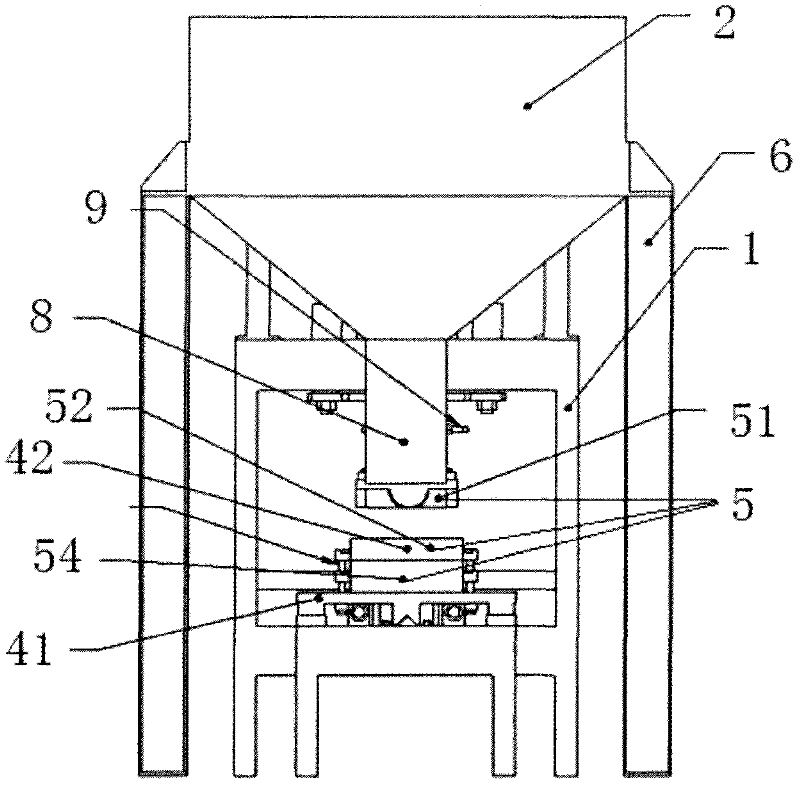

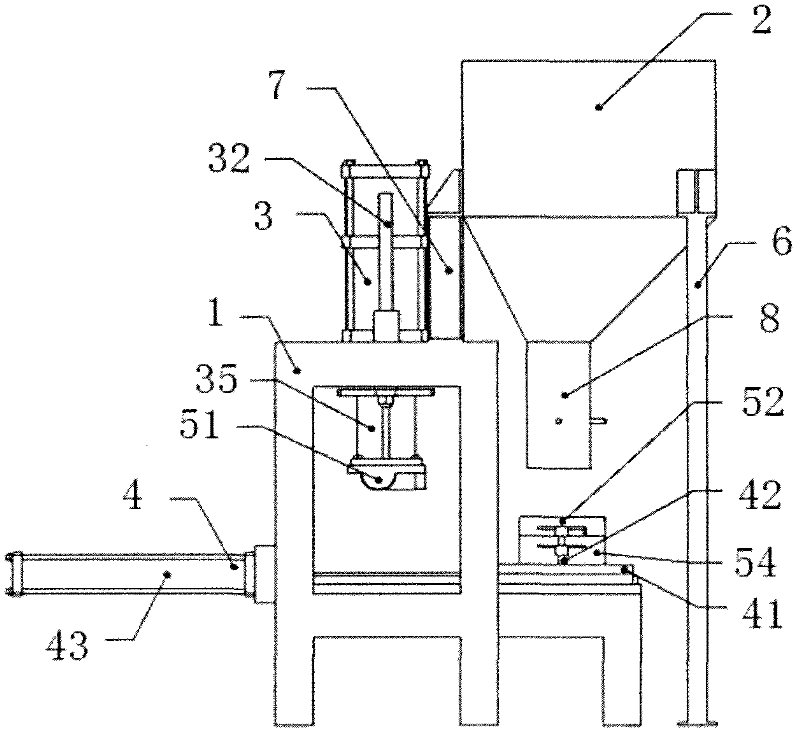

Clay sand molding equipment and method

InactiveCN102416445AEasy to moveUniform hardnessMoulding machine componentsProduction lineProject area

The invention provides clay sand molding equipment and method, relating to the field of casting. In the clay sand molding equipment and method, a planker moving device is adopted, and a quantitative sand box and a molding sand box can be moved conveniently between a sand filling station and a compacting station, so that the defects of incapability of moving the sand box, the requirement of manual sand filling and high labor intensity existing in the conventional molding equipment are overcome; a molding mold body is arranged above, and structures with molding and compacting functions are arranged, so that the surface hardness of a sand mold is uniform; the quantitative sand box is adopted for filling sand, so that each box of sand mold has consistent sand mold density and compactness; a sand mold compacting device is adopted, so that the defects of overlarge size of a cylinder, insufficient compacting pressure and limitation on the molding projecting area existing in the conventional molding equipment are overcome; and a sand hopper structure is arranged above the sand filling station, so that manual sand filling is replaced, the labor intensity of workers is lowered, and convenience is brought to combination of a production line sand conveying system.

Owner:XUSHUI XINGHUA CASTING

Preparation method of polypyrrole/metal-modified Sn3O4 nano composite photocatalytic material

InactiveCN109107614AEnhanced Broad Spectrum Light AbsorptionImprove photocatalytic performanceGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsHeterojunctionPhotocatalytic reaction

The invention discloses a preparation method of a polypyrrole / metal-modified Sn3O4 nano composite photocatalytic material. The nano composite material is a composite photocatalyst material obtained byloading and dispersing metal-modified Sn3O4 semiconductor heterojunction on polypyrrole in a chemical bond complexing form; and the metal-modified Sn3O4 is obtained by separately loading metal nano particles of a single-component metal or multi-component alloy of Pt, Au, Ag, Cu and the like having a plasma resonant effect onto Sn3O4. The photo-induced electron-hole separation rate in the photocatalytic reaction can be sufficiently improved by utilizing the visible light photocatalytic oxidation and reduction characteristics of Sn3O4, the plasma resonant effect of metal nano particles, photo conduction and conductivity of polypyrrole as well as the chemical bond heterojunction structure among different components, so that the performance for degrading pollutants in a photocatalytic oxidation and reduction manner and generating hydrogen by photocatalytic and decomposition of water can be improved. The easy-to-mold characteristic of polypyrrole can effectively avoid the recycling difficulty of the powder material.

Owner:PINGDINGSHAN UNIVERSITY

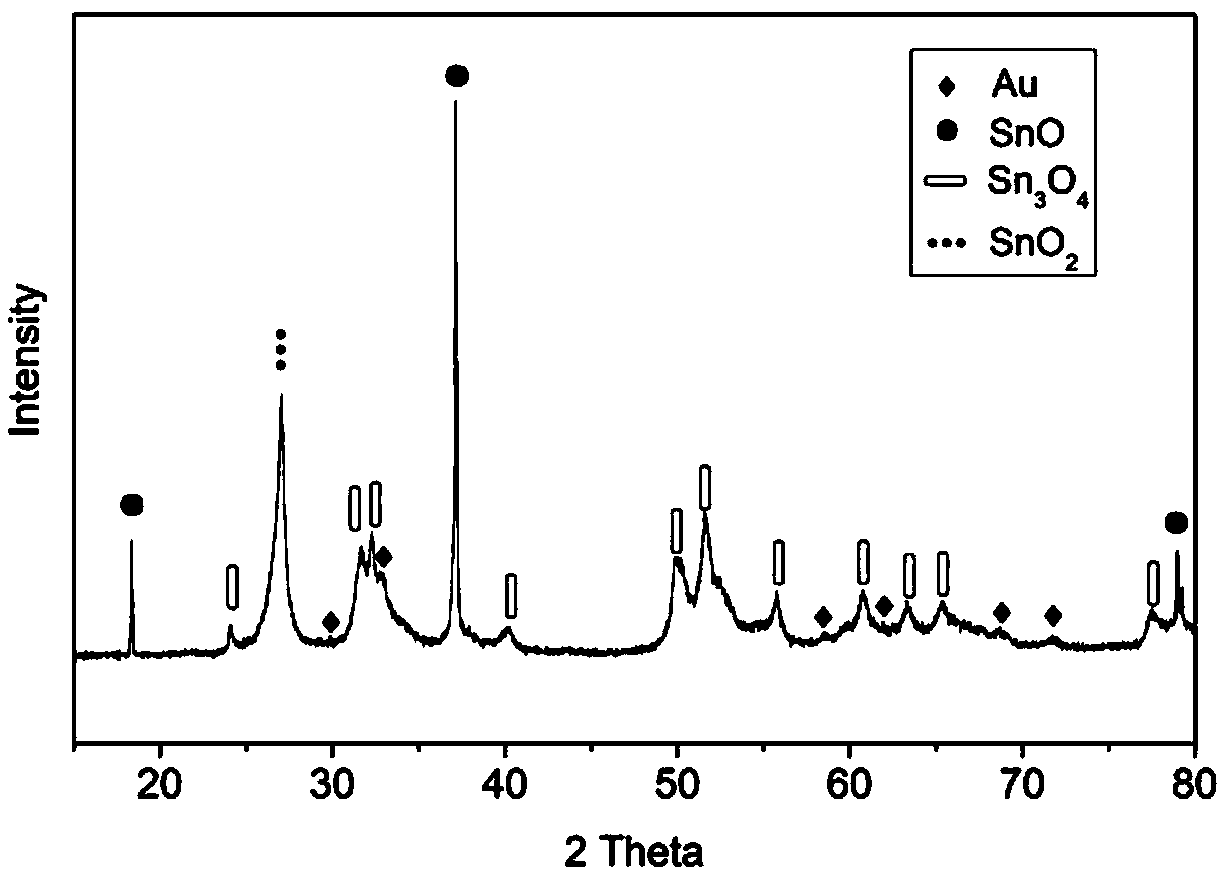

Preparation method of Au modified SnO/Sn3O4/SnO2 nano composite photocatalytic material

InactiveCN109092307AEnhanced light absorptionEasy to separateHydrogen productionHydrogen/synthetic gas productionHeterojunctionPhotocatalytic water splitting

The invention relates to a preparation method of an Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material. The nano composite material is obtained by placing chloroauric acid and a tin source into a solvent, a surfactant and a reducing agent and forming chemical bond complexing among composite ingredients of the materials according to an ice salt bath and solvent combined hot wet chemical in-situ synthesis method. The composite material prepared by the invention utilizes a plasma resonance effect of Au metal nanoparticles, an excellent energy level matching heterojunction structureamong composite components of a tin oxide material and excellent electron conduction of Au metal nanoparticles, and implements rapid electron-hole separation in the process of cooperating photocatalytic oxidation and reduction degradation of pollutants with photocatalytic water splitting hydrogen production, thereby improving efficiency of photocatalytic water splitting and photocatalytic rhodamine B degradation of the Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material.

Owner:PINGDINGSHAN UNIVERSITY

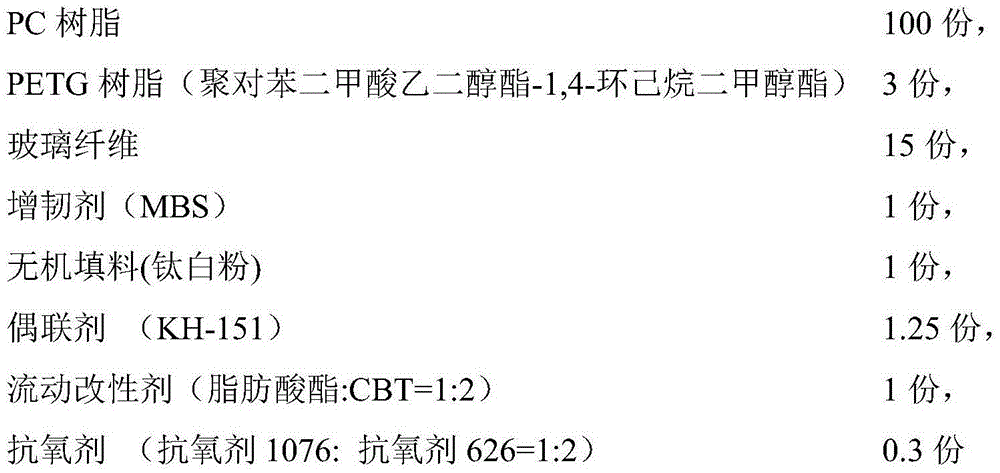

Glass fiber reinforced polycarbonate (PC) composite material and preparation method thereof

The invention discloses a glass fiber reinforced polycarbonate (PC) composite material with high gloss and high flowability. The glass fiber reinforced PC composite material is prepared from the following components in parts by weight: 100 parts of PC resin, 3-20 parts of polyethylene terephthalate glycol (PETG) resin, 15-50 parts of glass fiber, 1-8 parts of toughening agents, 1-5 parts of organic fillers, 0.5-2 parts of coupling agents, 1.0-4.0 parts of flow modifiers and 0.3-1.0 part of antioxidants. A preparation method comprises the following steps: uniformly mixing 100 parts of PC resin, 3-20 parts of PETG resin, 1-8 parts of toughening agents, 1-5 parts of organic fillers, 0.5-2 parts of coupling agents, 1.0-4.0 parts of flow modifiers and 0.3-1.0 part of antioxidants, then adding the obtained mixed materials and 15-50 parts of glass fiber to a screw extruder and carrying out extrusion pelletizing and carrying out stranding pelletizing to prepare the glass fiber reinforced PC composite material. The material has the advantages of easiness in forming, good processing flowability and good surface quality.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for pouring concrete based on magnetic drive

InactiveCN105587125ARealize the purpose of pouringSpeed up the flowSolid waste managementBuilding material handlingElectromagnetic shieldingElectromagnetic field

The invention provides a method for pouring concrete based on magnetic drive. The method is based on the principle that a magnetic substance is attracted by electromagnetic force at an electromagnetic field, concrete containing ferromagnetic aggregates is blended in a proper proportion, and the concrete is driven by a magnetic field erected outside to flow evenly in a member, so that dense pouring is achieved. By means of the pouring method, gravity constraint can be avoided, and omnibearing concrete pouring is achieved. The pouring quality is greatly improved, university is high, and the pouring method can be widely applied to various pouring construction schemes.

Owner:ZHEJIANG UNIV

Tap-hole filling material and filling method thereof

The invention discloses a tap-hole filling material, main raw materials of which are quartz sand, sintered magnesia clinker and waste and old magnesia-chromite bricks and auxiliary materials of which are a carburant and a sintering aid. The raw materials contain, by weight, 25-45% of quartz sand, 30-60% of sintered magnesia clinker, 10-35% of waste and old magnesia-chromite bricks, 0-2% of the carburant and 0-11% of the sintering aid. A filling method of the tap-hole filling material comprises the following step: more than one tap-hole filling material with different ratios undergoes layered filling according to contents of the carburant and the sintering aid from low gradient to high gradient, and the contents of the carburant and the sintering aid at the bottom layer are the lowest. Through compounding of the main raw materials and the auxiliary materials and layered gradient filling, fluidity, sintering property and pouring rate of the filling materials are raised, limitations such as poor fluidity, low free-opening rate and the like of existing tap-hole filling materials are overcome, and technological requirements of converter tapping are met. In addition, cost is low.

Owner:武汉钢铁有限公司

Liquid cooling device and electronic equipment

ActiveCN111194161AOvercome mobilityOvercoming coolingCooling/ventilation/heating modificationsEngineeringCooling pipe

The invention discloses a liquid cooling device and electronic equipment. The liquid cooling device comprises a cooling medium, a liquid cooling pipe, a driving mechanism and a stirring mechanism; thecooling medium is arranged in the pipe cavity of the liquid cooling pipe; the liquid cooling pipe is provided with a guide through hole, and the guide through hole is communicated with a pipe cavityof the liquid cooling pipe; the stirring mechanism comprises a stirring rod; and the stirring rod is provided with a first end and a second end, the first end of the stirring rod is located in a pipecavity of the liquid cooling pipe, the second end of the stirring rod penetrates through the guide through hole and is connected with the driving mechanism, and the driving mechanism drives the stirring rod to move relative to the pipe cavity of the liquid cooling pipe. According to the scheme, the problem that the improvement of the heat dissipation effect of an existing liquid cooling pipe is restricted due to the contradiction between the liquidity of a cooling medium and the filling amount of the cooling medium can be solved.

Owner:维沃移动通信(重庆)有限公司

Modified PPA composite material, preparation method and application thereof

The invention relates to the technical field of a high polymer material and specifically relates to a modified PPA composite material, a preparation method and an application thereof. The modified PPA composite material comprises PPA resin, reinforced modifier, antioxidant, lubricant, nucleating agent, high-fluidity modifier and high-concentration black master batch. The modified PPA composite material has the advantages of high fluidity, high strength and low thermal expansion factor. The preparation method comprises the steps of pretreatment, mixing and fusing pelletizing and has the advantages of simple process and low production cost. Besides, the modified PPA composite material can be applied to the preparation of an LED bead bracket and can promote the miniaturization development of the LED bead.

Owner:MLS

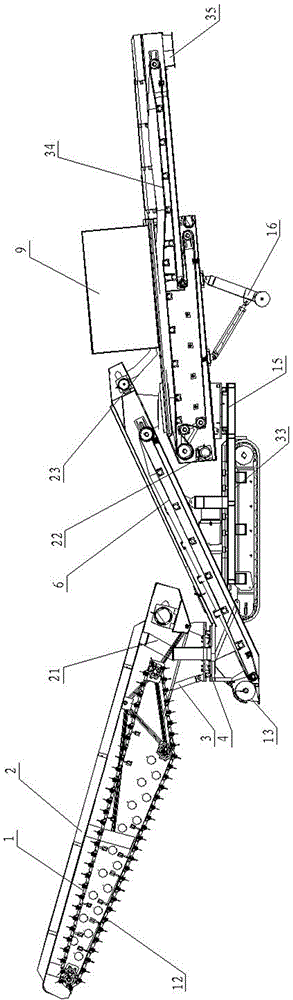

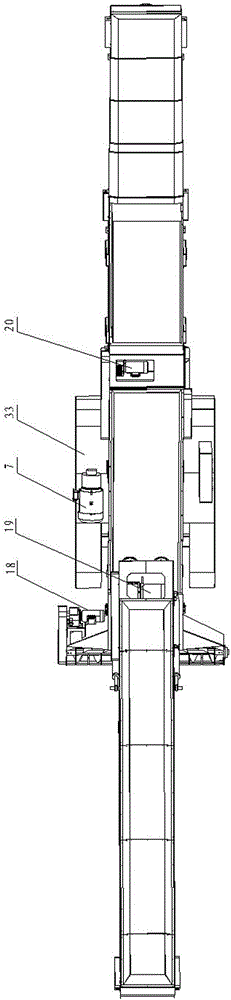

Remote-control bin discharger

InactiveCN105645120AOvercome mobilityOvercome the problem that the person no longer slides freely to the feeding port of the two-way screw auger feeding mechanismLoading/unloadingHydraulic cylinderAir volume

The invention discloses a remote-control bin discharger. The remote-control bin discharger comprises a frame, a scraper conveyer, a telescopic conveyer, a slope conveyer and a feeding device; a central rotary table capable of rotating horizontally is arranged between the lower end part of the scraper conveyer and the frame; a hydraulic cylinder is arranged between the scraper conveyer and the central rotary table. According to the remote-control bin discharger disclosed by the invention, by arranging the scraper conveyer which is used for scraping a material, the material at the top of a material stack can be scraped to a feeding auger; the central rotary table and a rear rotary table are both capable of rotating horizontally in order to respectively adjusting the scraping angle of the scraper conveyer and the position of a discharging hole of the telescopic conveyer; an air hood of the scraper conveyer is communicated with that of the slope conveyer in order to realize classified air suction and dust collection; dust can be concentrated together and can be collected and treated by a single draught fan, so convenient and rapid collection of the dust is realized; an air suction adjusting mechanism for adjusting the air amount is arranged on the air hood of the slope conveyer and is capable of adjusting start and stop of air suction of the air hood of the scraper conveyer and the air hood of the slope conveyer so as to select the optimum dust collection demand.

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

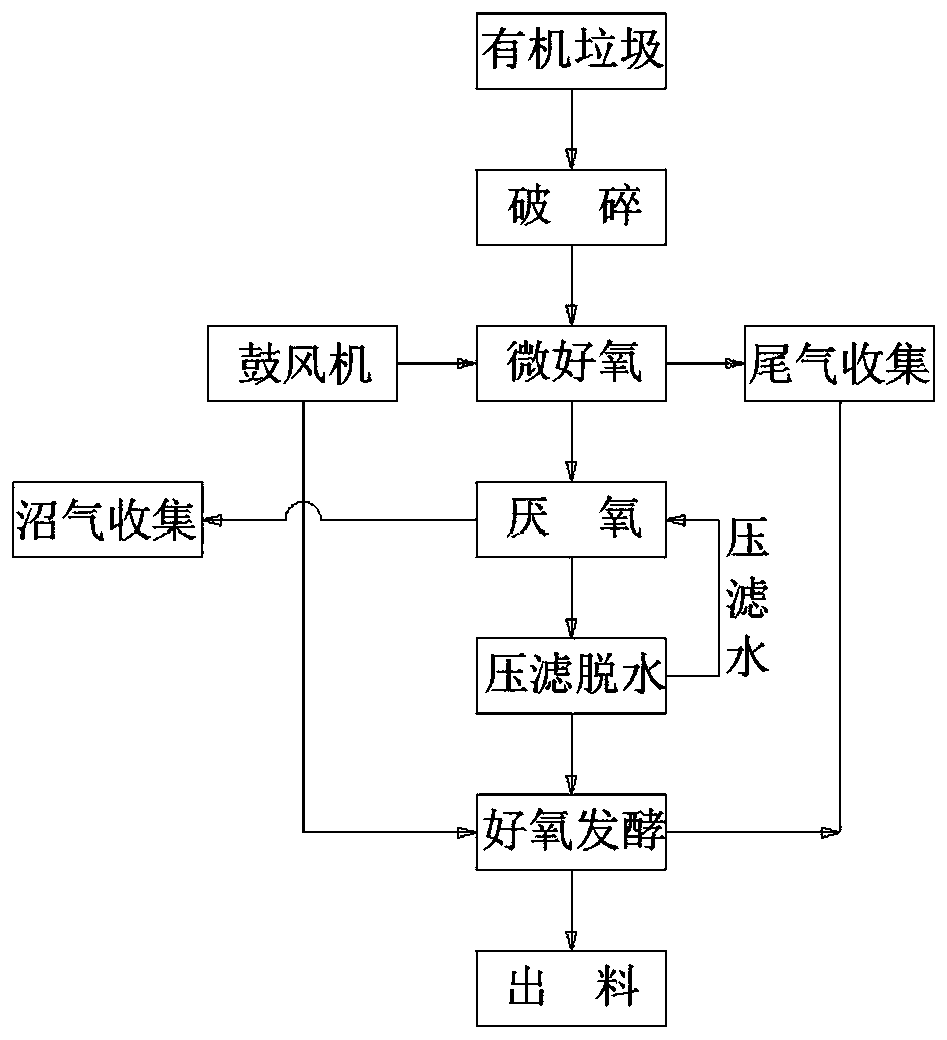

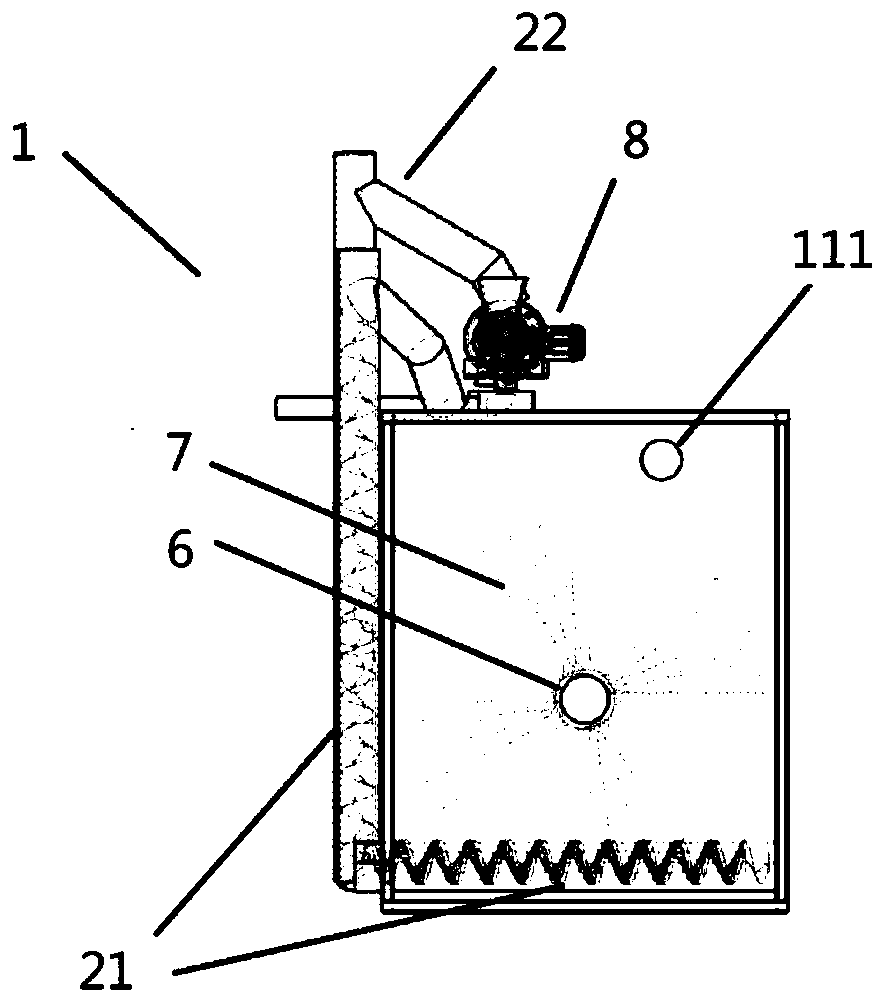

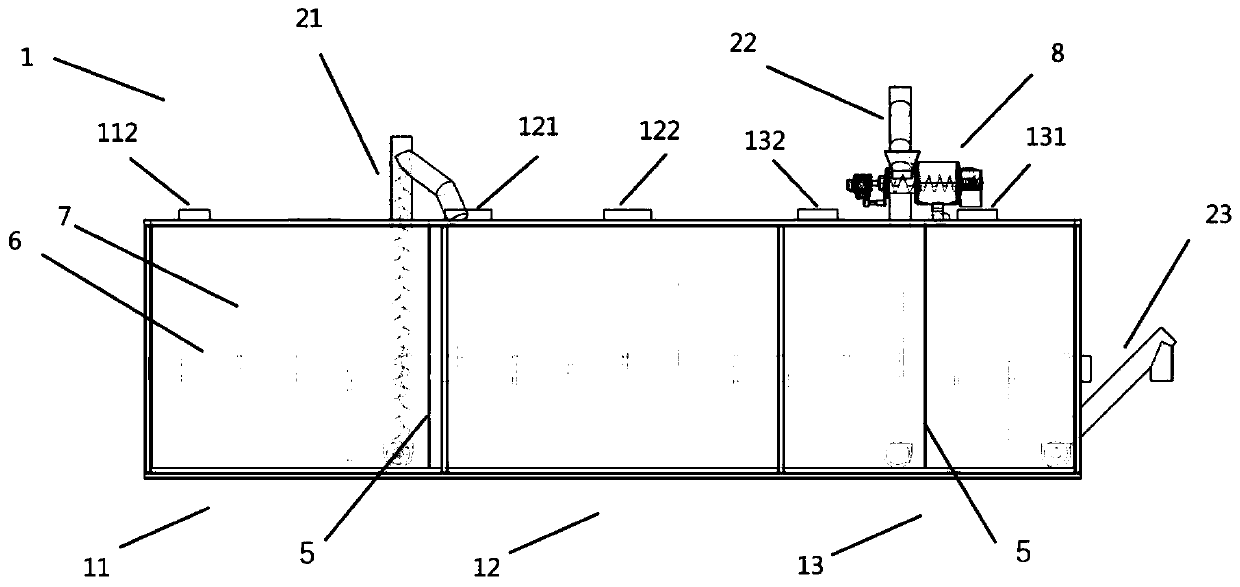

Three-stage integrated treatment system and method for organic biomass garbage

InactiveCN111215432AOvercome mobilityOvercome the clogging problemSolid waste disposalTransportation and packagingProcess engineeringEnvironmental engineering

The invention discloses a three-stage integrated treatment system for organic biomass garbage and a treatment method for the organic biomass garbage. The treatment system involves a three-stage fermentation reactor, a spiral feeding and discharging device, an external circulating coil and a deodorization device. According to the system, the kitchen garbage is subjected to micro-aerobic pretreatment by integrating a micro-aerobic process, an anaerobic process and an aerobic process, so that the problem of unstable operation caused by acidification in the anaerobic process is avoided; secondly,a horizontal plug flow mode and an integrated slow stirring mode are adopted, so that the mass transfer efficiency and the heat transfer efficiency in the anaerobic process are improved; and thirdly,the materials are conveyed on line in the micro-aerobic, anaerobic and aerobic processes in a multi-stage spiral conveying mode, and the problems of poor flowability and blockage of the material floware solved. The process is high in practicability, continuous and efficient, well solves the environmental problem caused by the urban kitchen garbage, comprehensively utilizes the wastes in a recycling manner, and is suitable for environment-friendly treatment of easily biodegradable organic wastes.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

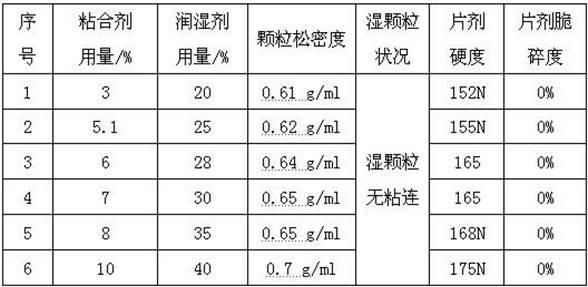

DC (Directly compressible)-xylitol and preparation method thereof

InactiveCN102429885AQuality assuranceHigh densitySenses disorderHydroxy compound active ingredientsCelluloseHigh concentration

The invention discloses DC (Directly compressible)-xylitol, which mainly comprises xylitol, sodium carboxymethylcellulose adhesive and 70% (w / w) ethanol solution wetting agent, wherein sodium carboxymethylcellulose accounts for 3-10% the weight of a mother batch and the ethanol solution accounts for 20-40% the weight of the mother batch. The invention also discloses a preparation method of DC-xylitol. In the preparation method disclosed by the invention, high-concentration ethanol is used as a wetting agent, so as to reduce the viscosity during granulating; and the adhesive is added in an internal addition manner, the problem that granulation is not easy due to over-high use amount and ultrahigh viscosity of the adhesive is overcome. Through the matching of the adhesive and wetting agent,the prepared DC-xylitol is directly compressible, the bulk density of the obtained particle is maximally up to 0.7 g / mL, the hardness of the tablet is more than 140 N, and the friability of the tablet is reduced to 0%.

Owner:SHANDONG LINUO KEFENG PHARMA

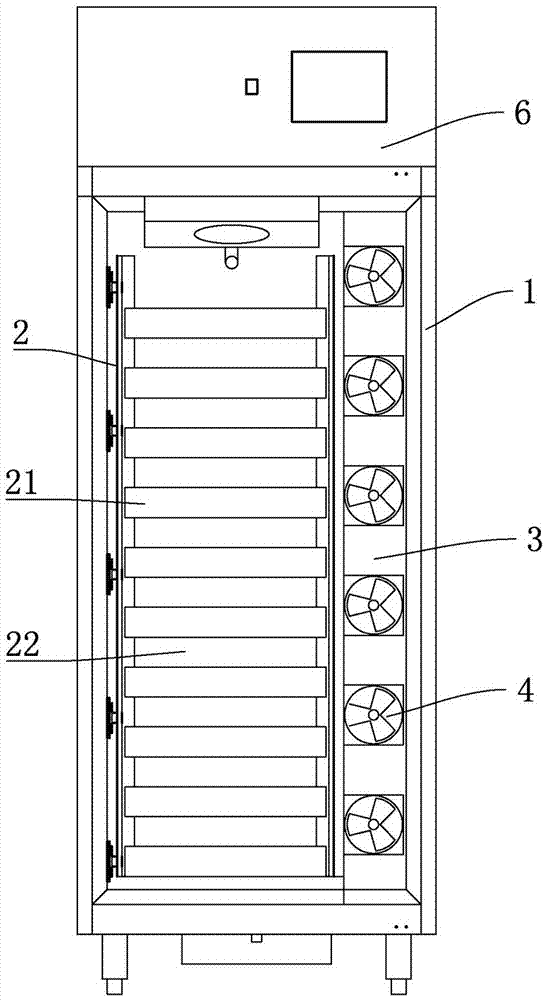

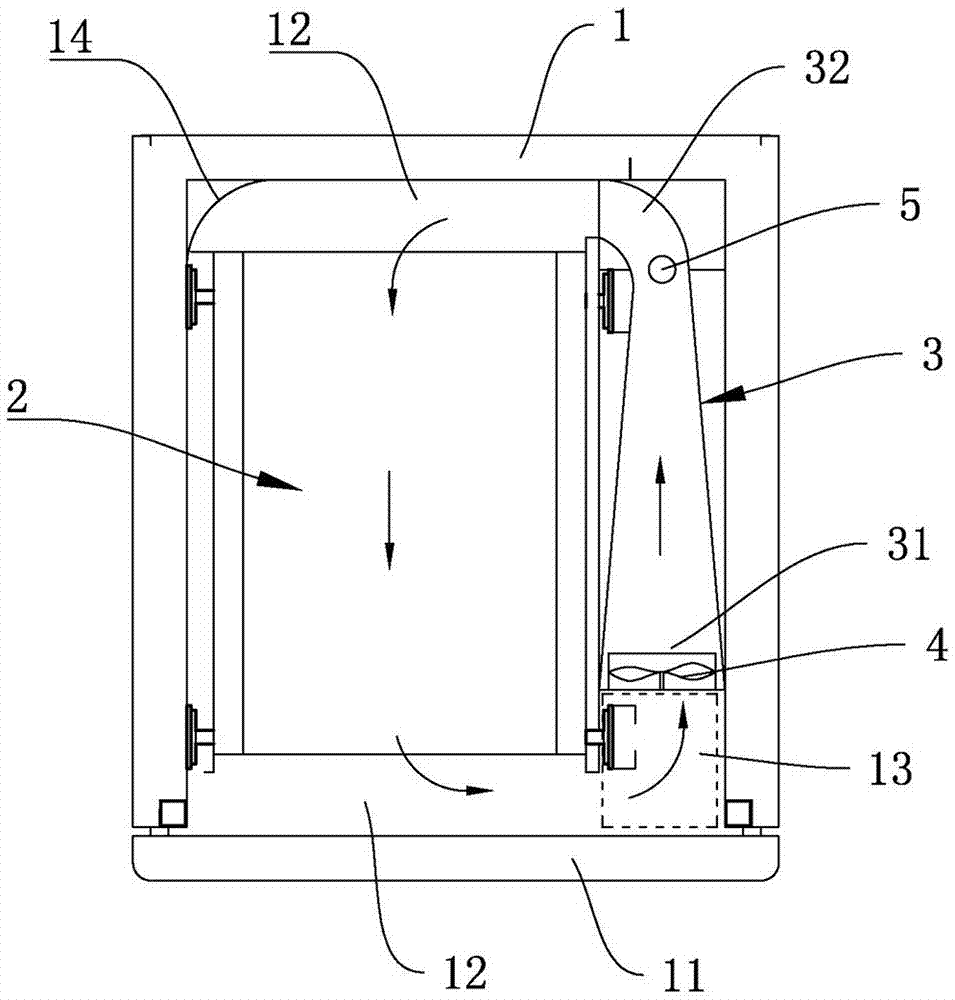

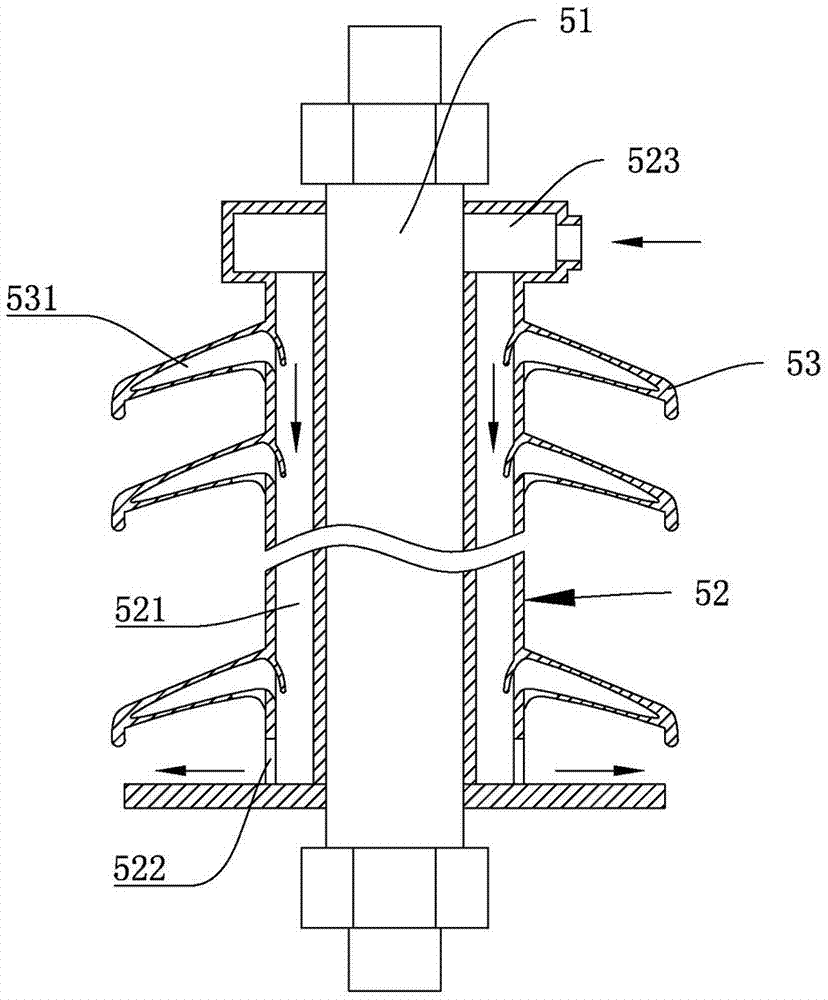

Electrostatic thawing refrigerator

PendingCN107246756AOvercome the problem of large wind resistance area in the direction of air flowOvercome mobilityLighting and heating apparatusDomestic refrigeratorsTemperature controlEngineering

The invention relates to the technical field of thawing refrigerators, in particular to an electrostatic thawing refrigerator. The electrostatic thawing refrigerator comprises a refrigerator body, a thawing shelf, an electrostatic induction device and a temperature control device. The thawing shelf comprises a plurality of thawing plates which are stacked up and down. Every two adjacent upper and lower thawing plates are arranged in a spaced mode, and the position between every two adjacent upper and lower thawing plates forms a spacing region. Air guide regions are formed between the front and rear sides of the thawing shelf and the front and rear sides of the refrigerator body. The spacing regions communicate with the air guide regions on the front side and the rear side. A flow guide groove is formed in the refrigerator body and communicates with the air guide regions on the front side and the rear side, a heating assembly is disposed at one end of the flow guide groove, and a blowing assembly is disposed at the other end of the flow guide groove. By means of the electrostatic thawing refrigerator, the problems that the air resistance area of the thawing shelf in the air flowing direction is large, circulation flow of air flow in the refrigerator body is not smooth, and temperature difference occurs due to non-uniform heat dissipation are solved, the thawing time difference of upper frozen food and lower frozen food is reduced, and the situation that the temperature control device is repeatedly started for temperature controlling due to inconsistent temperature of the upper portion and lower portion is avoided.

Owner:老娘舅餐饮股份有限公司

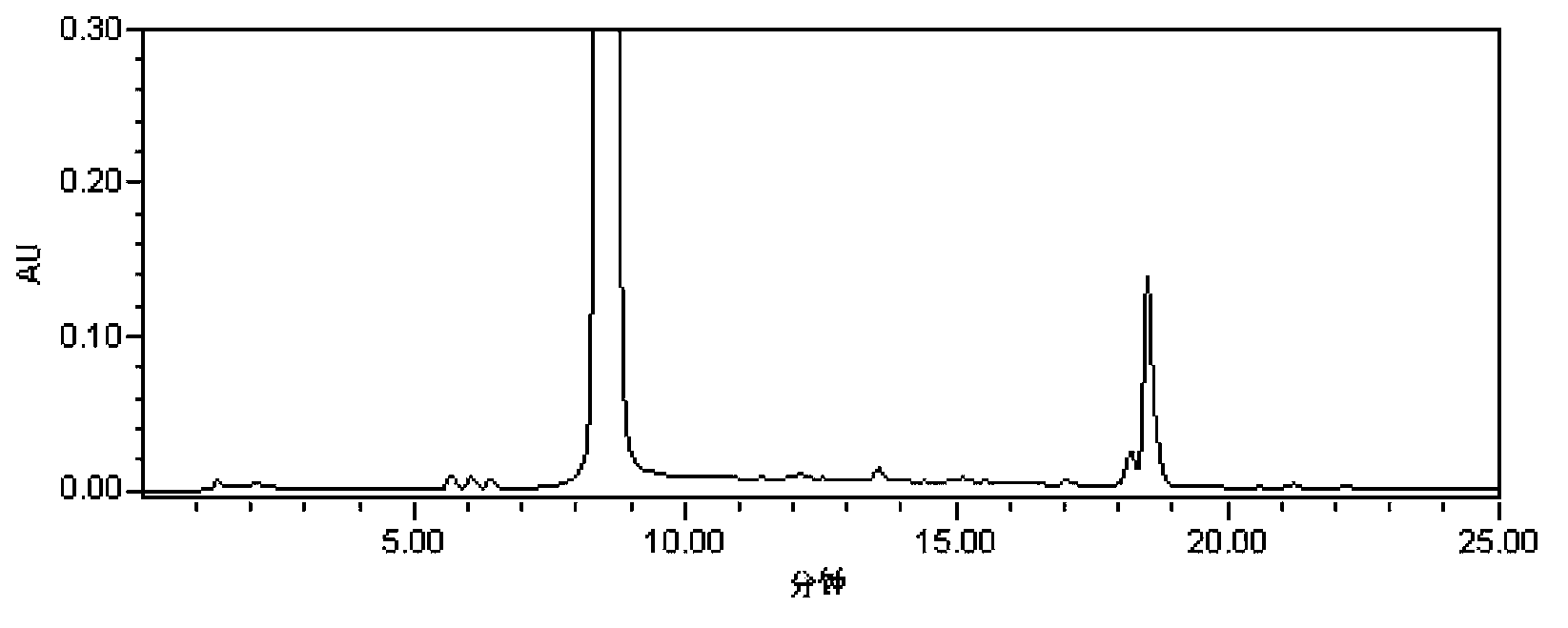

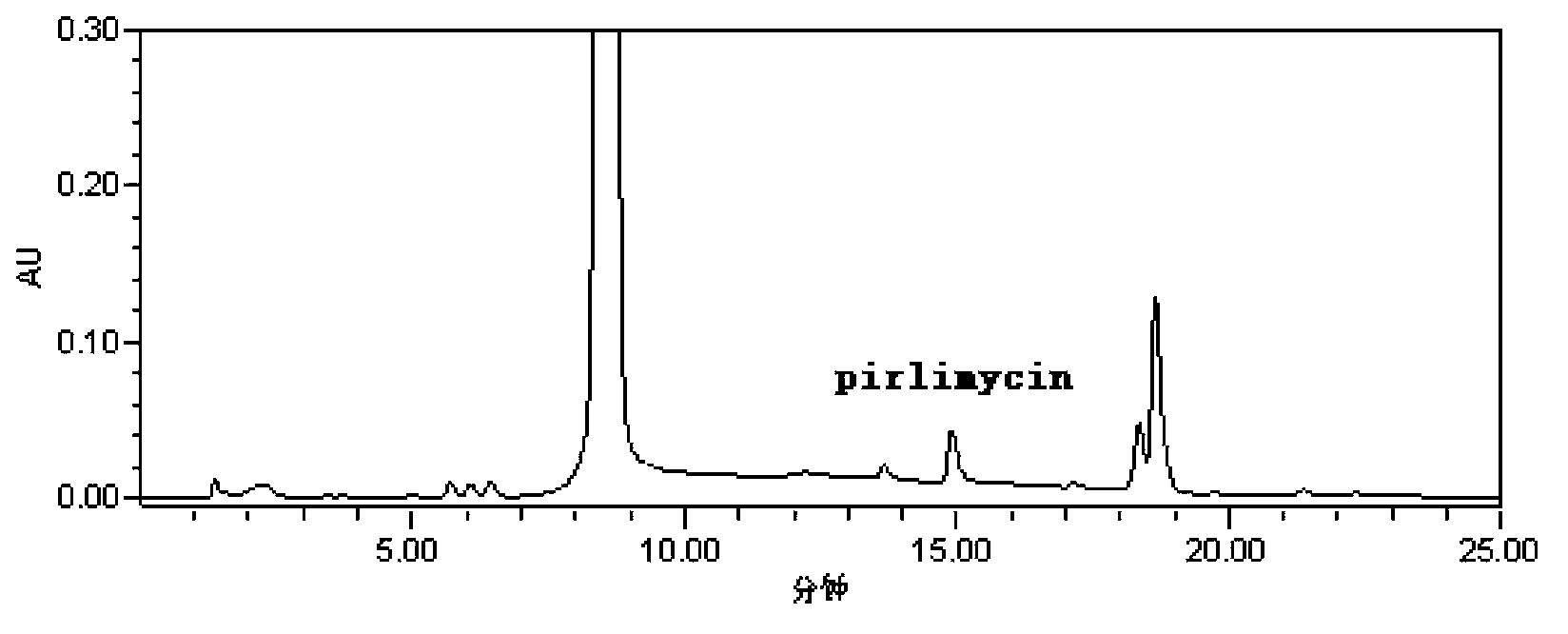

Pirlimycin residue analysis method

InactiveCN103424478AHigh fluorescence activityHigh UV absorption strengthComponent separationUltravioletChloroformic acid

The invention belongs to the field of veterinary drug residue analysis and relates to a pirlimycin residue analysis method. According to the invention, a high-performance liquid chromatograph pre-column derivatization reaction analysis is adopted for a hydrogen substitution reaction of a secondary amine compound. At the room temperature, the concentration of a derivatization reagent, chloroformic acid-9-fluorenylmethyl ester, is 10-2 mol / L, a pH value of a borate buffer solution of 0.1 mol / L is regulated to 9, the reaction is an instant reaction, as only one secondary amine is used as a single reaction site, no reaction terminator is required to be added to achieve the purpose of derivatization, and the derivation product is stable. The derivation product is subject to high performance liquid chromatograph detection, has the maximum ultraviolet strength when the ultraviolet detection wavelength is 266 nm, has the minimum detectable amount of 5 mug / L, is in linear response to the peak area within the range of 20-4000 [mu]g / L, is good in reproducibility of results, and has three concentrations, and the variable coefficient of 3 concentrations and 15 repetitions is smaller than 8%.

Owner:HUAZHONG AGRI UNIV

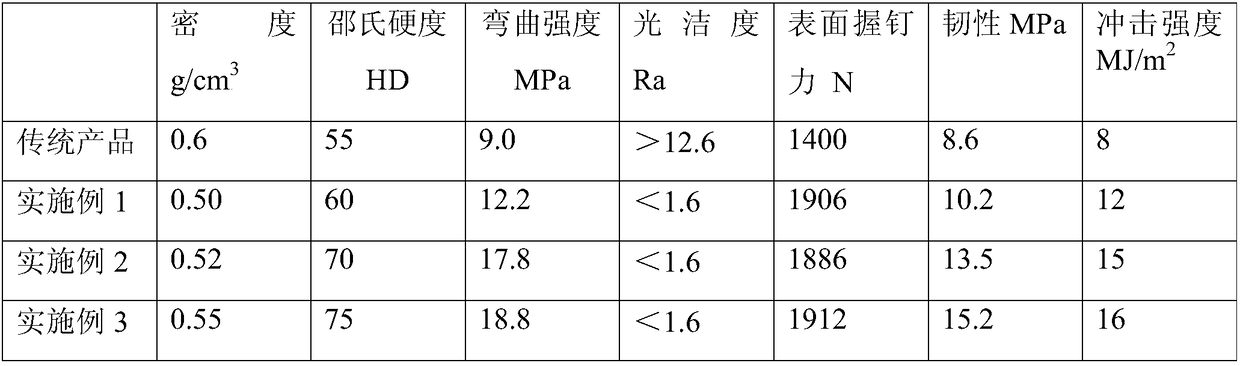

PVC (Polyvinyl Chloride) sanding wood-like decorative plate and preparation method thereof

The invention discloses PVC (Polyvinyl Chloride) sanding wood-like decorative plate and a preparation method thereof, belongs to the technical field of PVC plates and solves the problems of large density and high production cost of existing products. The PVC sanding wood-like decorative plate is prepared from 60 to 80 parts of PVC SG8 type resin, 50 to 70 parts of triple superphosphate, 50 to 70 parts of wood-like reclaimed materials, 3 to 4 parts of foaming regulator p90, 1 to 2 parts of foaming regulator HL-100, 2.9 to 3.2 parts of calcium-zinc stabilizer, 0.5 to 0.7 part of an internal lubricant sp-60, 0.2 to 0.3 part of polyethylene wax, 0.3 to 0.4 part of micronized polyethylene wax N-14P, 0.5 to 0.7 part of plasticizer OA6, 14 to 16 parts of wood flour, 1 to 2 parts of a toughener CPE and a foaming agent. The preparation method comprises the following steps: sequentially putting the materials in a hot blending pot, rapidly cooling after rising the temperature, and carrying out extrusion molding after plasticizing, thus obtaining a finished product. The PVC sanding wood-like decorative plate disclosed by the invention can be used as a wood-like decorative plate.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

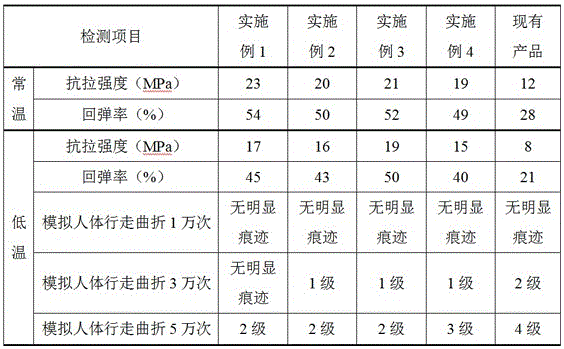

High-strength low-temperature-resistant material for shoes and preparation method of high-strength low-temperature-resistant material

The invention discloses a high-strength low-temperature-resistant material for shoes and a preparation method of the high-strength low-temperature-resistant material.The material is prepared from, by weight, 50-80 parts of butadiene-acrylonitrile rubber, 10-60 parts of natural rubber, 1-3 parts of a vulcanizing agent, 3-8 parts of an activating agent, 1-5 parts of accelerant, 1-3 parts of an anti-aging agent, 5-20 parts of polyvinyl chloride powder and 1-5 parts of plasticizer.The prepared high-strength low-temperature-resistant material for shoes can overcome the defects that cold resistance is poor, the flowing property is low and the like when only polyvinyl chloride is used and can give full play to the advantages of butadiene-acrylonitrile rubber, such as high strength and good processing properties.The prepared material is low in price, easy to obtain, simple in preparation process and high in strength, the tensile strength of the material at the normal temperature is 19-23 MPa, the tensile strength of the material at the low temperature is 15-19 MPa, cold resistance and processing properties are excellent, wear resistance at the low temperature is remarkable, almost no trace is left when human body walking bending is simulated for ten thousand cycles or more, and the high-strength low-temperature-resistant material can be used for producing low-temperature-resistant shoe soles and other cold-resistant auxiliary materials.

Owner:泉州盛达轻工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com