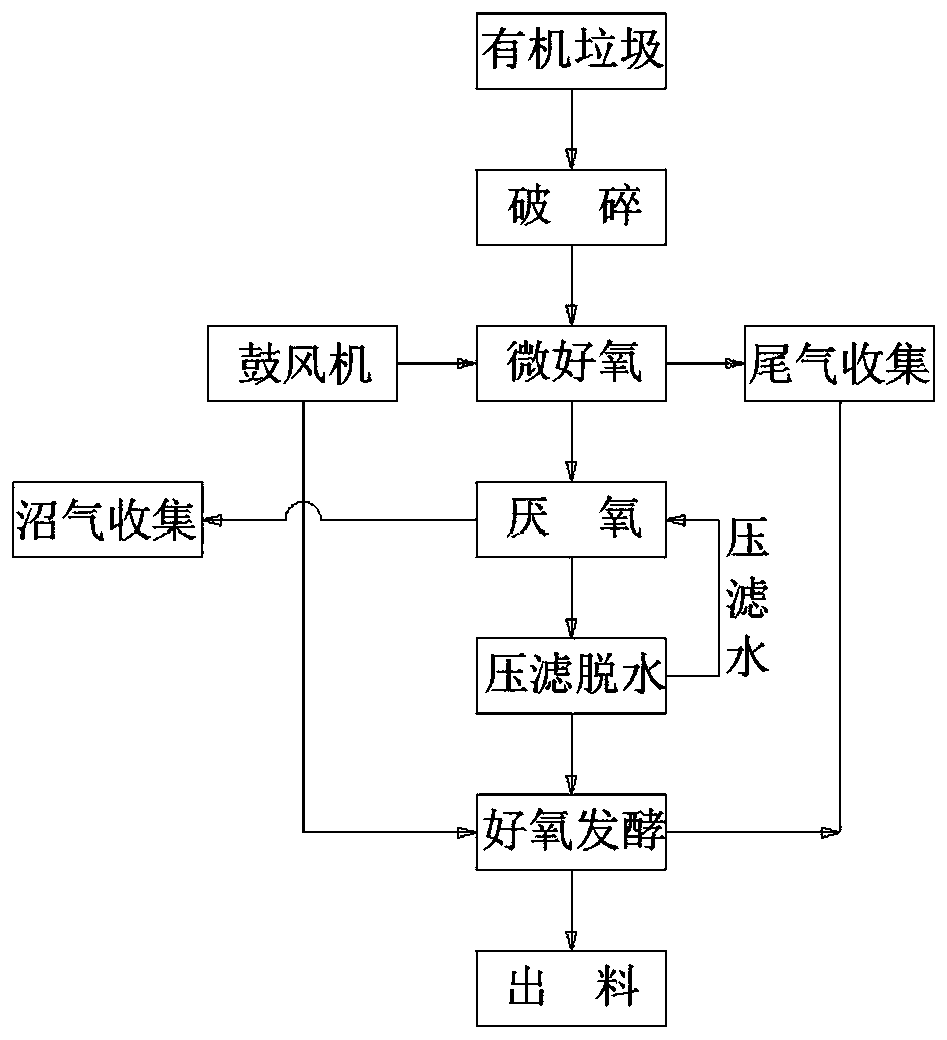

Three-stage integrated treatment system and method for organic biomass garbage

A processing system and biomass technology, applied in the field of organic biomass waste recycling, can solve the problems of easy acidification of dry anaerobic fermentation, affecting the yield of biogas, and no blocking of sorting material transmission, so as to overcome the logistics flow. Poor performance and blockage, strong practicability, and the effect of solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

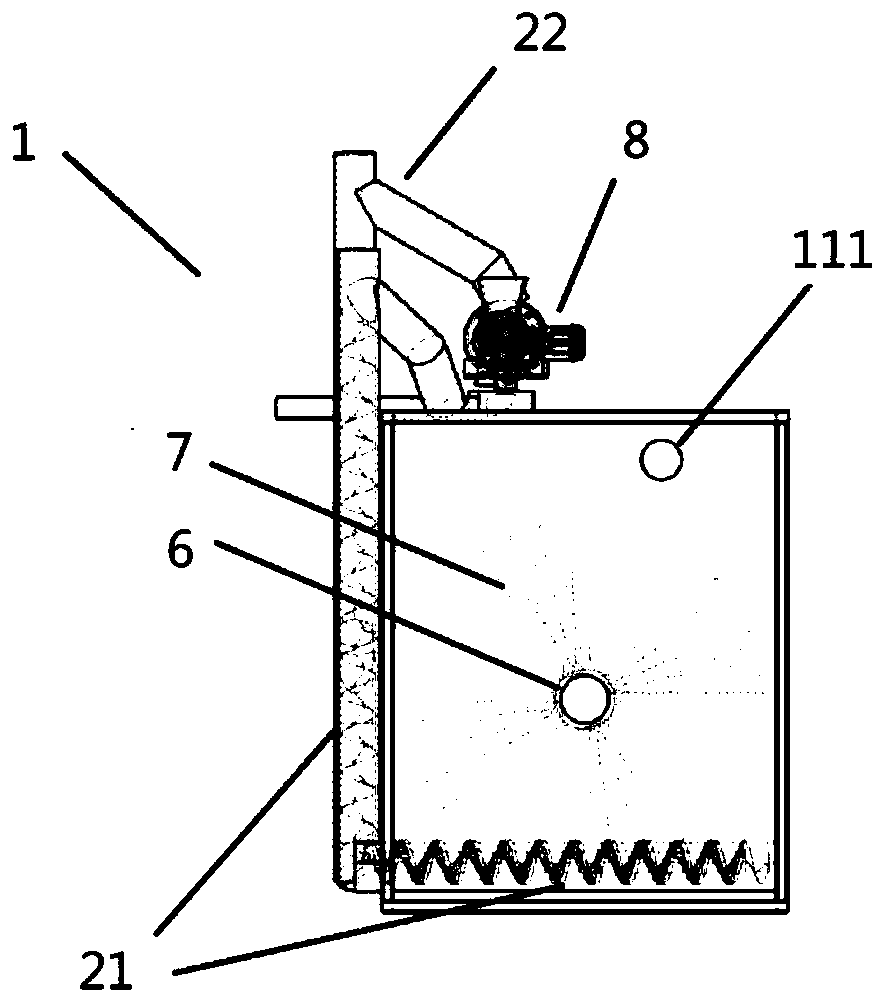

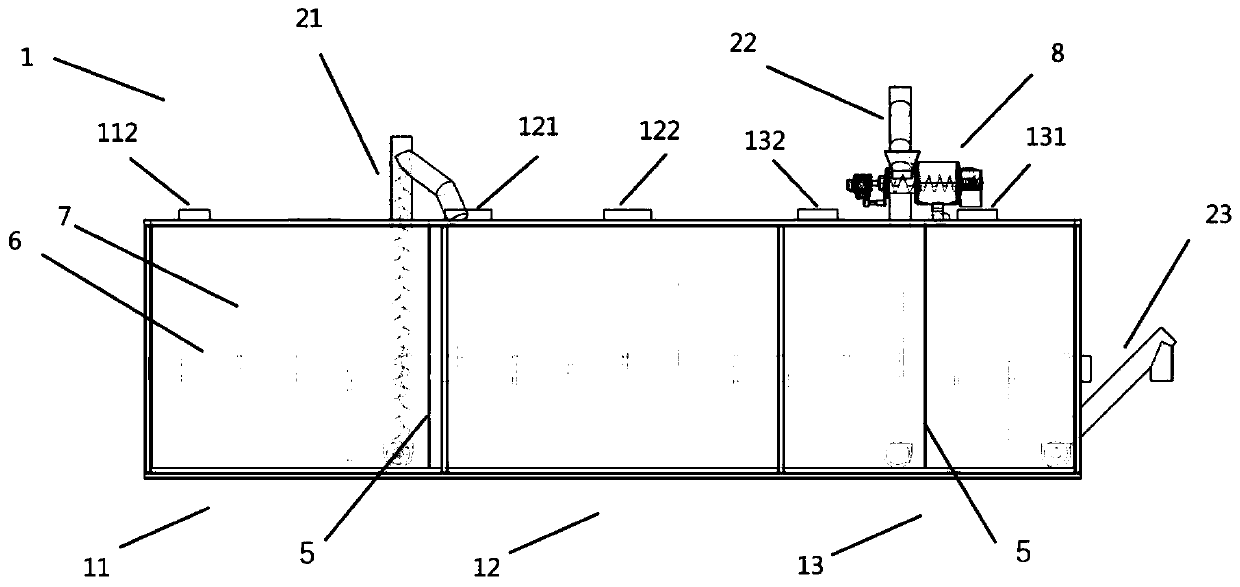

[0090] A three-stage integrated treatment system and treatment method for organic biomass waste,

[0091] Wherein, the treatment system includes: a three-stage fermentation reactor, a screw feeding and discharging device, an external circulation coil and a deodorizing device, etc. The three-stage fermentation reactor is divided into the first microaerobic area, the second anaerobic area and the third aerobic area, which are separated from each other by partitions and connected to form an integral structure. The overall size of the equipment is 30×6× 6m, effective volume 1080m 3 , wherein the volumes of the first microaerobic zone and the third aerobic zone are each 180m 3 , the volume of the second anaerobic zone is 720m 3 . The three-stage fermentation reactor also has a coaxial central stirring shaft running through the first microaerobic zone, the second anaerobic zone and the third aerobic zone, forming a push flow structure in the horizontal flow direction, and using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com