Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "No flow marks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

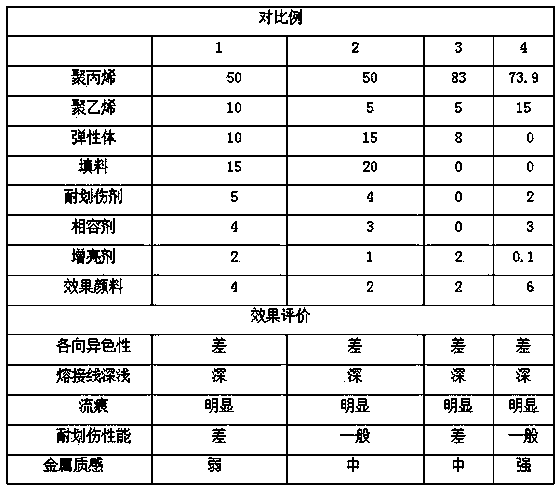

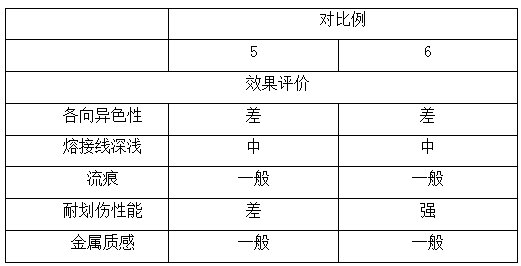

Scratch-resistant high-gloss spraying-free polypropylene composition with aesthetic effect as well as preparation method and application of composition

InactiveCN103910937AImprove scratch resistanceFlow behavior is reduced or even avoidedElastomerPolypropylene

The invention discloses a scratch-resistant high-gloss spraying-free polypropylene composition with aesthetic effect. The composition comprises the following components by weight percent: 40-94wt% of polypropylene, 0-15wt% of polyethylene, 0-20wt% of elastomer, 0-30wt% of filler, 1-6wt% of a scratch resistant agent system, 2-6wt% of effect pigment, 0.1-2wt% of brightener, and 0-4wt% of a compatilizer. Due to the synergistic effect of the scratch resistant agent system and the effect pigment, the spraying-free product is endowed with more excellent scratch resistance, thus having broader application prospect; in addition, the fluidity of the polypropylene composition is also affected, so that in injection molding or extruding, the change of the space position of the metal pigment of certain appearance shape along with melt flow is limited, the orientation of the metal pigment along with melt flow is reduced or even avoided, the defect of heterochromia of traditional spraying-free product is overcome, and the polypropylene composition has excellent metal texture, has no flow marks, and weakens and even eliminates dark appearance caused by a weld line.

Owner:KINGFA SCI & TECH CO LTD

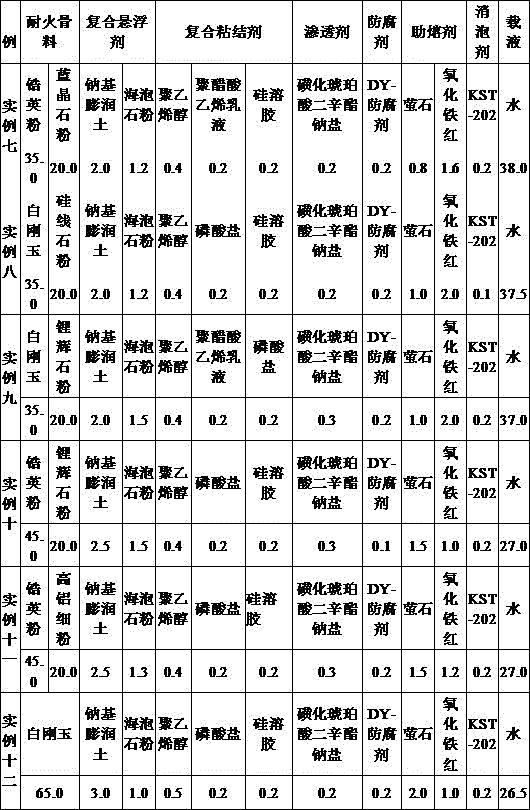

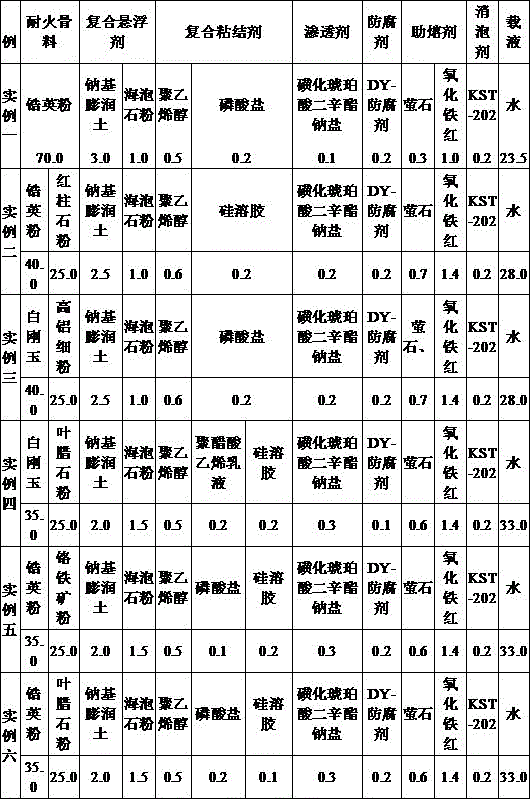

Preparation method of water based flow coating for 3D printing sand mold

ActiveCN105665620ANo pollution in the processImprove securityFoundry mouldsFoundry coresWater basedPyrophyllite

The invention relates to the technical field of 3D printing sand mold casting and in particular to a water based flow coating for a 3D printing sand mold and a preparation method of the water based flow coating. The water based flow coating is prepared from zircon powder, white corundum, high-aluminum fine powder, ferrochrome mineral powder, pyrophyllite powder, sillimanite powder, cyanite powder, andalusite powder, spodumene powder, sodium bentonite, sea-foam stone powder, polyvinyl alcohol, polyvinyl acetate emulsion, phosphate, silica sol, sulfonated dioctyl succinate sodium salt, preservative, a defoaming agent, fluorite, iron oxide red and water. The water based flow coating for the 3D printing sand mold has the advantages of excellent mobility, appropriate permeability, good leveling property, high-efficiency suspension stability, appropriate coating thickness, super strong anti-burn-on property, environment protection, no pollution and high efficiency.

Owner:NINGXIA KOCEL MOLD

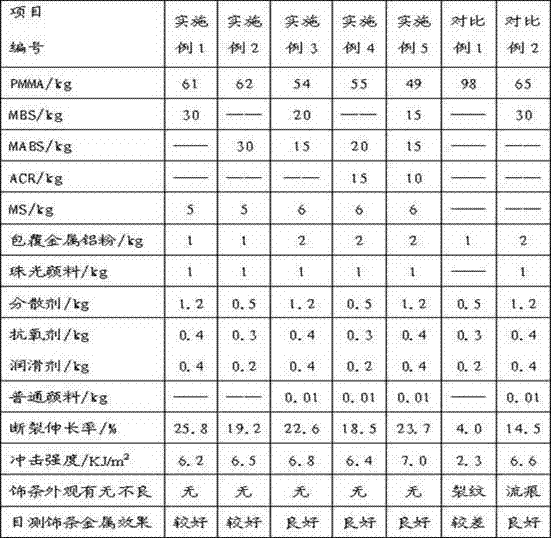

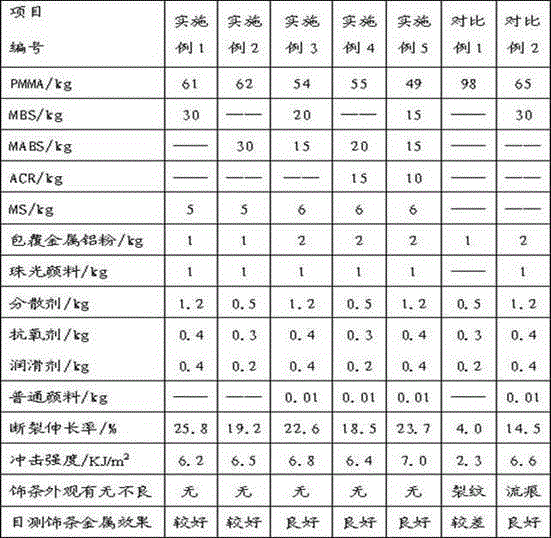

Spraying-free metallic PMMA (polymethyl methacrylate) modified material and preparation method thereof

The invention discloses a spraying-free metallic PMMA (polymethyl methacrylate) modified material and a preparation method thereof. The method comprises the steps that the PMMA is used as a matrix resin raw material, MBS (methyl methacrylate), MABS (methyl methacrylate / acrylonitrile / butadiene / styrene / copolymer) and ACR (acrylate copolymer with core-shell structure) are taken as toughening agents, MS (methyl methacrylate / styrene copolymer) is taken as a processing modifying additive, aluminum powder coated with metals and pearlescent pigments which enable materials to be metallic are added, a certain quantity of dispersing agents, a small quantity of antioxidant agents, a lubricating agent, pigments and the like are supplemented, after the materials are uniformly mixed in the proportion, the materials are milled by a parallel double-screw extrusion machine, and a spraying-free metallic PMMA modified material is formed. The material and PVC (polyvinyl chloride) are subjected to compound co-extrusion, so that the surface of the prepared product has an excellent metallic effect; and compared with traditional spraying products, the spraying-free metallic PMMA modified material has the advantages of low cost, environment friendliness, scratch resistance, recycle and the like, therefore, the spraying-free metallic PMMA modified material is particularly suitable for being processed into lateral trim workpieces of refrigerators.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

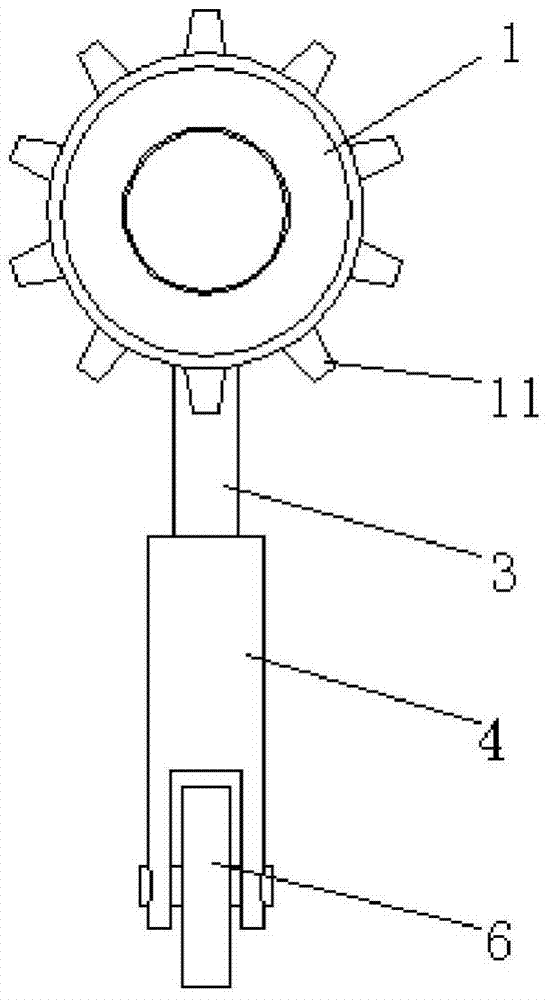

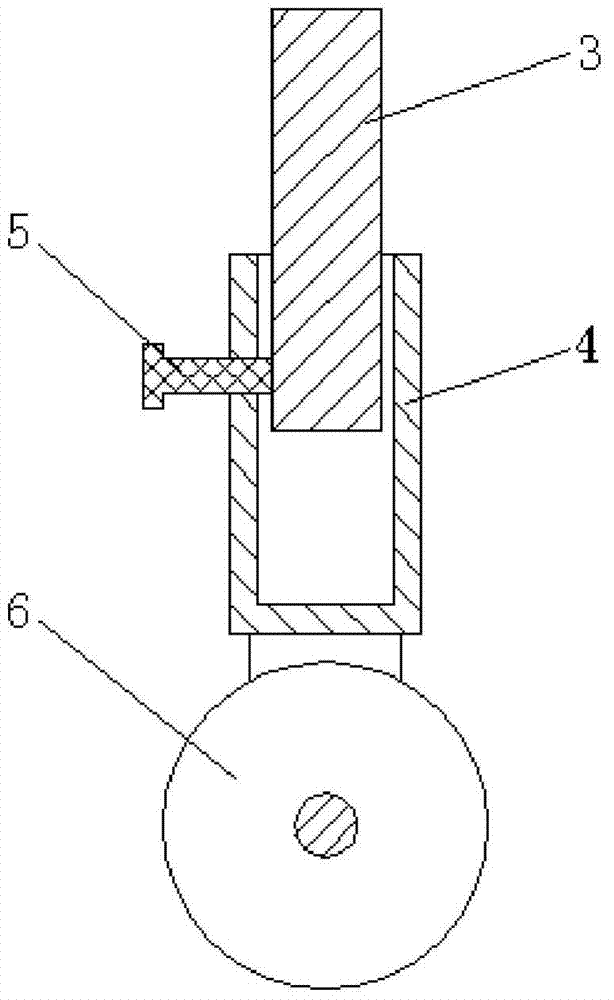

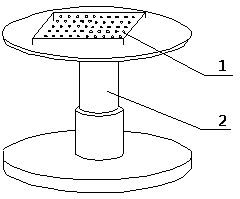

Height-adjustable pipe inner wall spraying equipment

InactiveCN104209214AImprove surface qualitySpray evenlySpraying apparatusEngineeringMechanical engineering

The invention discloses height-adjustable pipe inner wall spraying equipment and belongs to the field of spraying equipment. The height-adjustable pipe inner wall spraying equipment comprises a spraying head, a spraying pipe, a height adjusting device and a walking device, wherein the spraying head is mounted at one end of the spraying pipe and is communicated with the spraying pipe; the height adjusting device comprises a support rod, a connecting bushing and an adjusting screw; the connecting bushing is hollow inside and the side wall of the connecting bushing is provided with a thread hole; one end of the support rod extends into the connecting bushing; the adjusting screw extends into the connecting bushing via the thread hole for propping the support rod on the inner wall of the connecting bushing, and the other end of the support rod is fixedly connected to the part, near the spraying head, of the spraying pipe, and is perpendicular to the spraying pipe; the walking device is mounted at the bottom of the height adjusting device and can drive the spraying pipe to move in the axial direction of a pipe. The spraying equipment has the advantages of stable and reliable operation, good spraying effect, high efficiency and low cost and is suitable for inner walls of various small-diameter pipes, in particular for the inner walls of ultralong small-diameter pipes.

Owner:常州冯士节能环保科技有限公司

Cast iron evaporative pattern coating and preparation method thereof

ActiveCN104353777AGood hangabilityImprove thermal performanceFoundry mouldsFoundry coresCelluloseAdhesive

The invention relates to the technical field of evaporative pattern coatings, and in particular relates to a cast iron evaporative pattern coating and a preparation method thereof. The cast iron evaporative pattern coating comprises the following components in parts by weight: 100 parts of refractory aggregate, 2-4 parts of a suspending agent, 1.2-1.6 parts of an adhesive, 0.4-1 part of a thickening agent, 0.5-1.2 parts of a sintering agent, 0.2-0.6 part of an antioxidant and 0.2-0.5 part of an anti-foaming agent, wherein the thickening agent is one or two of sodium carboxymethyl cellulose and xanthan gum; the sintering agent is sodium tripolyphosphate. The coating is good in coating property, a coated layer is free of flow marks or drain marks and good in thermal property and air permeability and is not infiltrated with a molten metal liquid; a cast piece is smooth in surface and free of sand adhesion defect. The preparation method comprises the following steps: uniformly mixing the powder-like components, pouring water into a stirring bucket, pouring the mixed components into the stirring bucket, and stirring for 30-40 minutes by using a stirring machine, wherein the weight of the water accounts for 80% that of the coating. The coating does not need to be prepared for a second time when be used, thus being convenient to use.

Owner:襄阳聚力新材料科技有限公司

High-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and preparation method thereof

InactiveCN105199294AImprove the lubrication effectImprove wettabilityAntioxidantAcrylonitrile butadiene styrene

The invention relates to the technical field of polymer materials, in particular to a high-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and a preparation method thereof. The composite material comprises, by weight: 70-90 parts of ABS resin, 4.0-10 parts of a compatilizer, 5.0-10 parts of a toughener, 1.0-3.0 parts of white oil, 0.4-0.6 part of a composite antioxidant, 0.5-1.0 part of a lubricant, and 1.0-5 parts of pearl powder. The preparation method is simple, and the prepared ABS composite material has good mechanical properties, low aid emigration rate, significant pearl effect, smooth surface free of flow marks and scratch resistant, and long service life.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

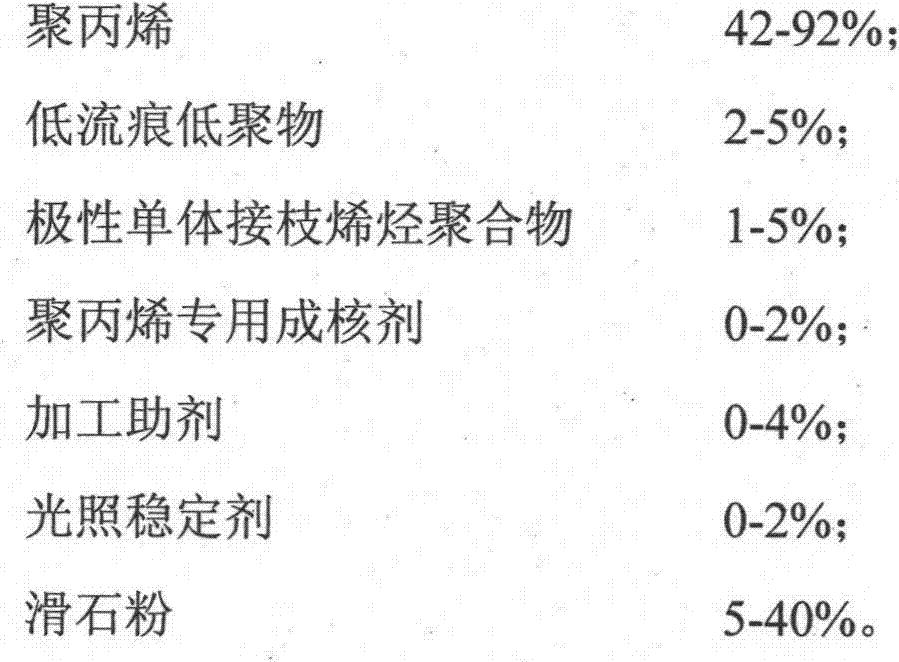

High-rigidity polypropylene composite without flow marks as well as preparation method of polypropylene composite

The invention discloses a polypropylene composite for a fender as well as a preparation method of the polypropylene composite. The polypropylene composite is prepared from 42-92wt% of polypropylene, 2-5wt% of an oligomer with few flow marks, 1-5wt% of a polar monomer graft olefin polymer, 0-2wt% of a special nucleating agent for polypropylene, 0-4wt% of a processing aid, 0-2wt% of a light stabilizer and 5-40wt% of talcum powder. The preparation method comprises the following steps: melting, mixing and dispersing the polypropylene, the oligomer with few flow marks, the polar monomer graft olefin polymer, the special nucleating agent for polypropylene, the processing aid and the light stabilizer in a double-screw extruder; feeding the talcum powder into the double-screw extruder from one side by an agravic metering balance; and extruding and granulating, thereby finally obtaining the product, namely the polypropylene composite. The polypropylene composite has the characteristics of high rigidity, high gloss and no flow marks and meets the requirements of large-sized polypropylene parts on appearance, and polypropylene injection molded parts have no flow marks.

Owner:SHANGHAI KINGFA SCI & TECH

WPU (Water-soluble Polyurethane) coating applied to powder-free PVC (Poly Vinyl Chloride) glove and preparation method thereof

ActiveCN102807810ANo self-adhesionImprove smoothnessPolyurea/polyurethane coatingsEmulsionWater soluble

The invention provides a WPU (Water-soluble Polyurethane) coating applied to a powder-free PVC (Poly Vinyl Chloride) glove. The WPU coating is prepared from the following components in percentage by weight: 15-30 percent of an aqueous polyurethane emulsion, 2-5 percent of flatting silica, 5-10 percent of a substrate wetting agent, 5-10 percent of a thickener, 2-3 percent of a slipping agent and 50-70 percent of deionized water, wherein the sum of the weight percentage of each component is 100 percent. The invention further provides a method for preparing the WPU coating applied to the powder-free PVC glove.

Owner:优美特(北京)环境材料科技股份公司

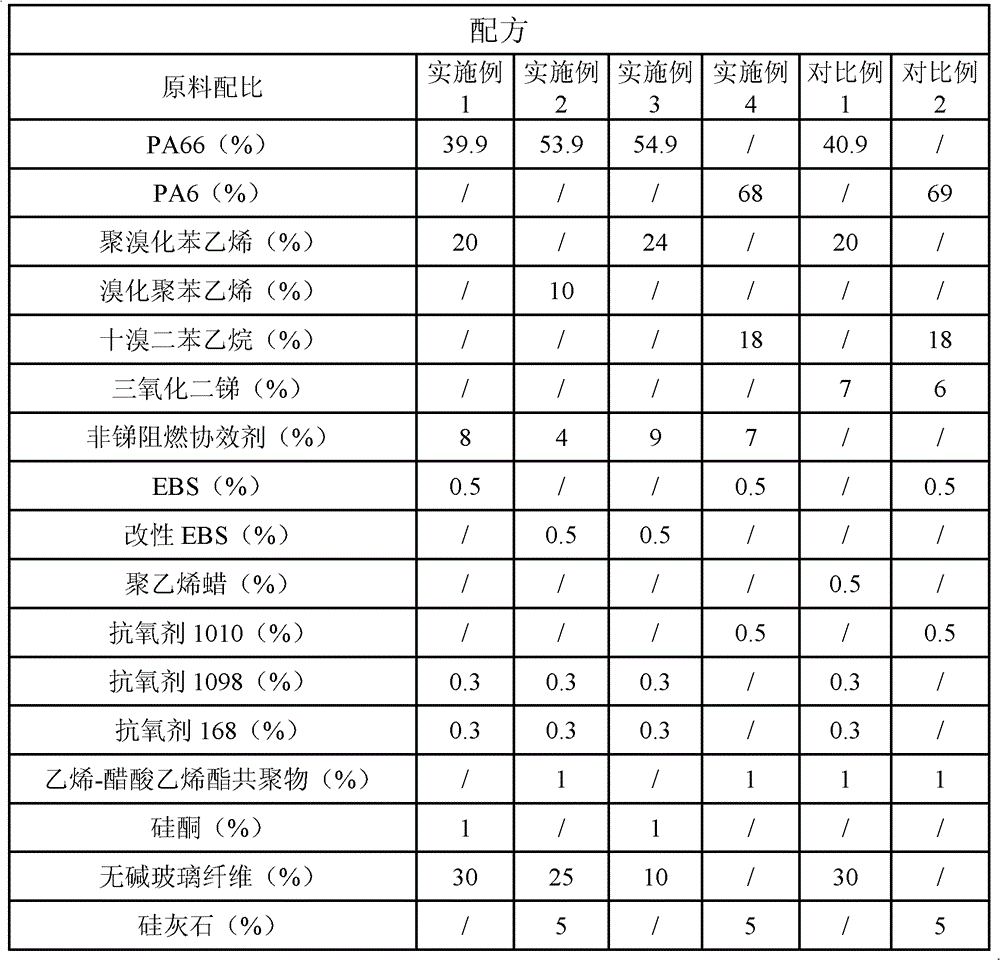

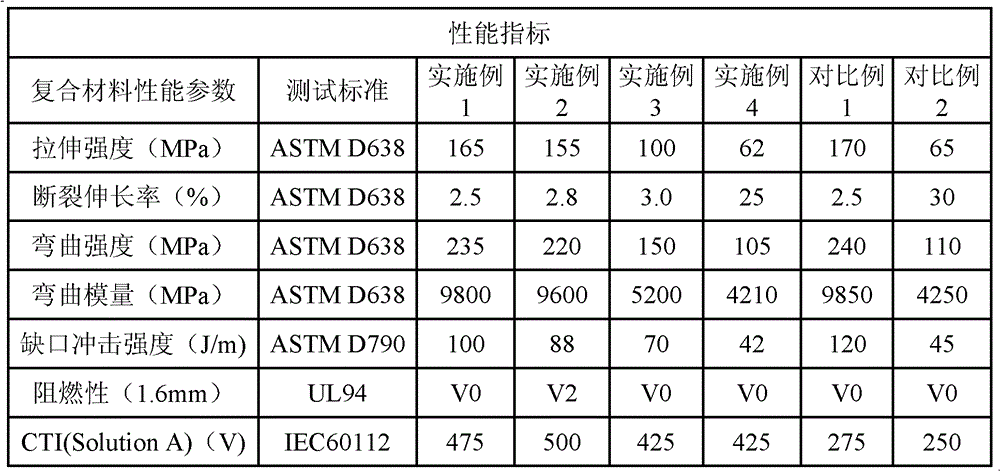

Non-antimony flame-retardant polyamide composite material and preparation method and application thereof

The invention provides a non-antimony flame-retardant polyamide composite material, which comprises the following raw materials in percentage by weight: 20 to 90 percent of polyamide, 5 to 25 percent of halogen flame retardant, 2 to 10 percent of non-antimony flame-retardant synergist, 0.1 to 3 percent of lubricant, 0.1 to 1 percent of antioxidant, 0.3 to 3 percent of surface modifying agent and 1 to 40 percent of enhancement modifying agent, wherein the non-antimony flame-retardant synergist comprises magnesium oxide, silicon dioxide and tin dioxide in a molar ratio of (2-3):(1-2):1. The invention also provides a preparation method for the non-antimony flame-retardant polyamide composite material and application of the non-antimony flame-retardant polyamide composite material. According to the non-antimony flame-retardant polyamide composite material, a comparative tracking index (CTI) value is improved to more than 400 V under the condition of no antimony sesquioxide and zinc borate, the phenomenon of flow marks is avoided, and the production cost is reduced. The non-antimony flame-retardant polyamide composite material can be prepared by the conventional equipment and the conventional method, manufacturing equipment is not needed to be transformed, and industrial production is easy to realize.

Owner:上海耐特复合材料制品有限公司

Preparation method of soft-touch polypropylene composite material

The invention relates to a preparation method of a soft-touch polypropylene composite material. The preparation method comprises the steps of preparation of a foaming composition, preparation of polyurethane master batch, preparation of polypropylene resin master batch, mixing of the polyurethane master batch and the polypropylene resin master batch and the like. The foaming agent foams in polyurethane during injection molding so that more elastic holes are formed in the material, and the polypropylene material is endowed with good soft touch due to the elasticity of the polyurethane elastomer; meanwhile, the surface of the injection molding part made of the polypropylene material prepared by the method has no phenomena such as air marks, flow marks and welding marks.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

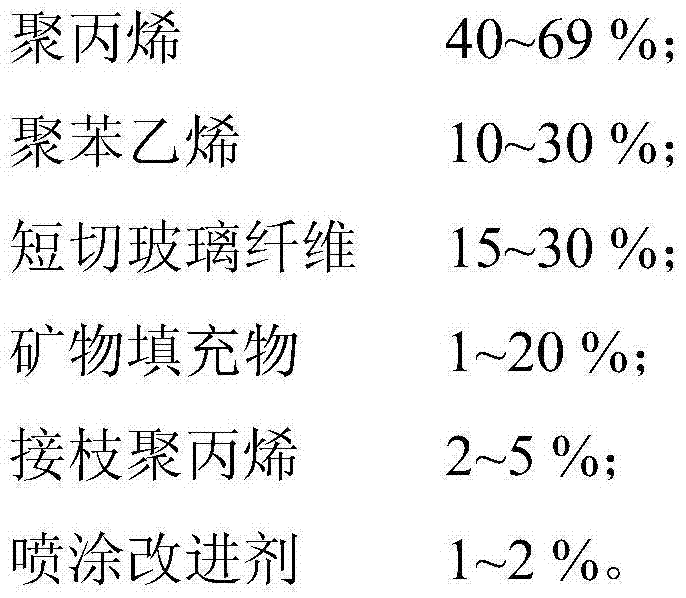

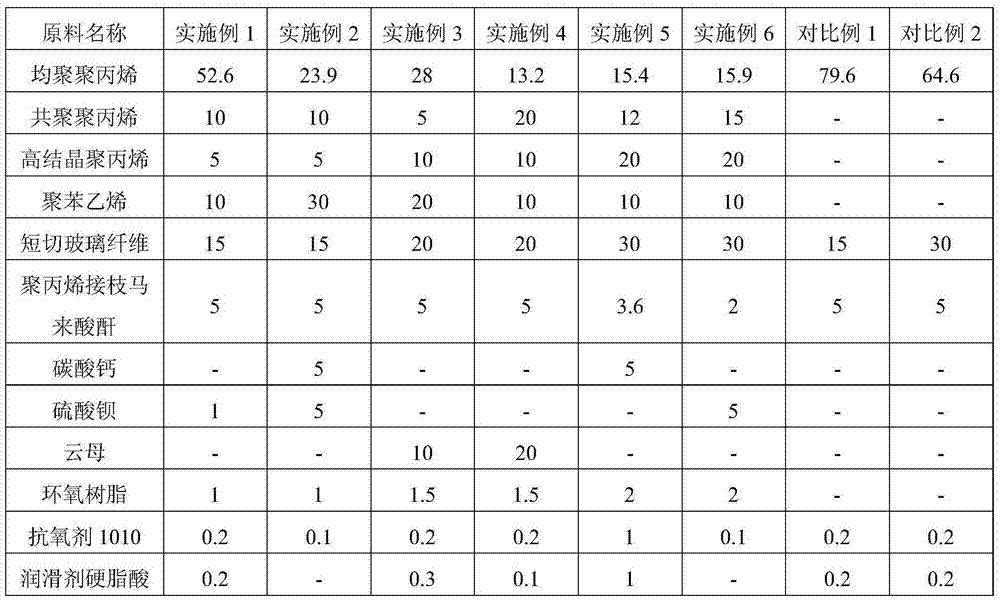

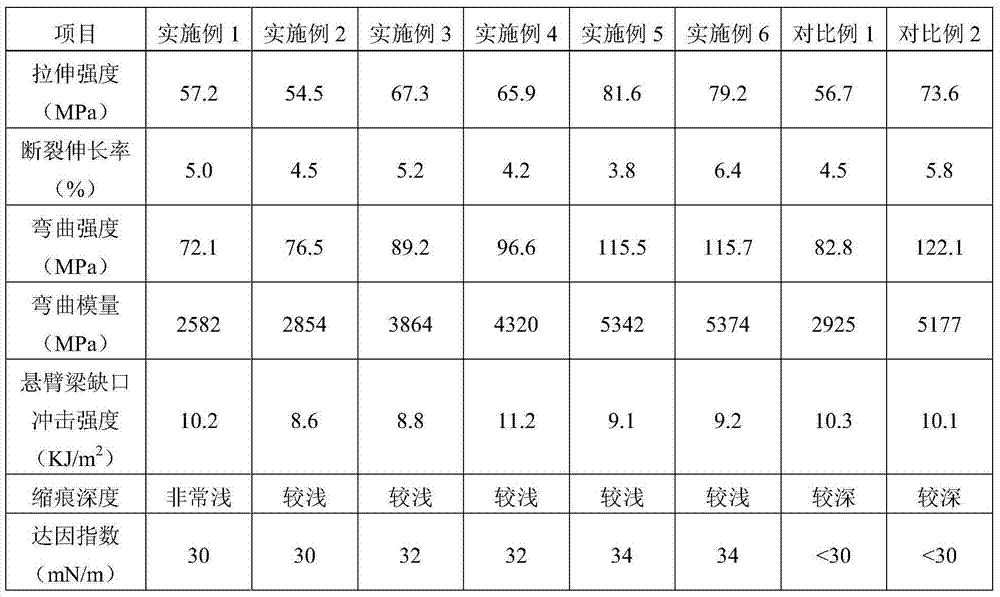

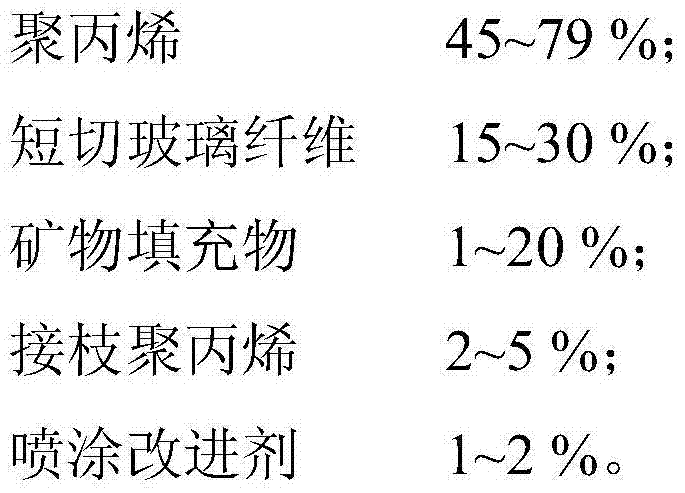

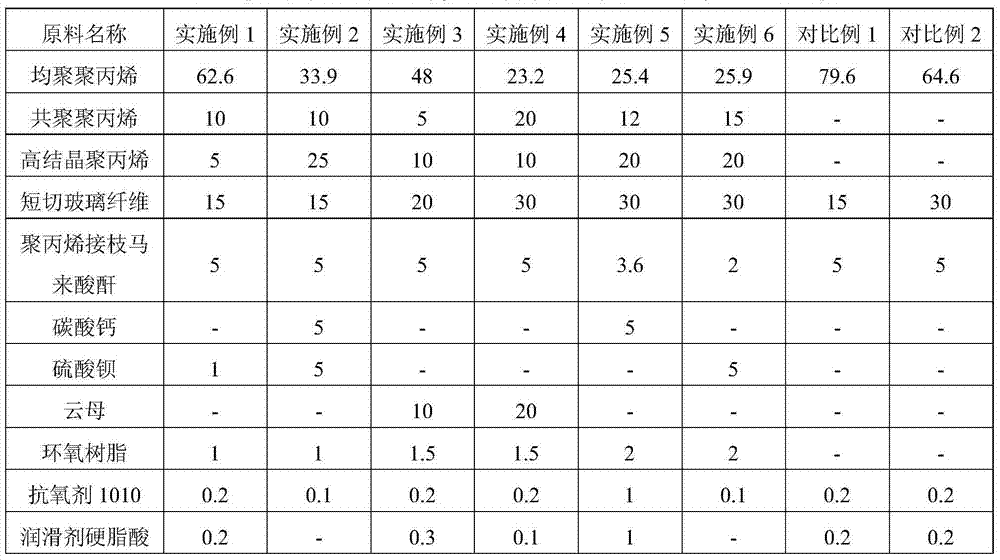

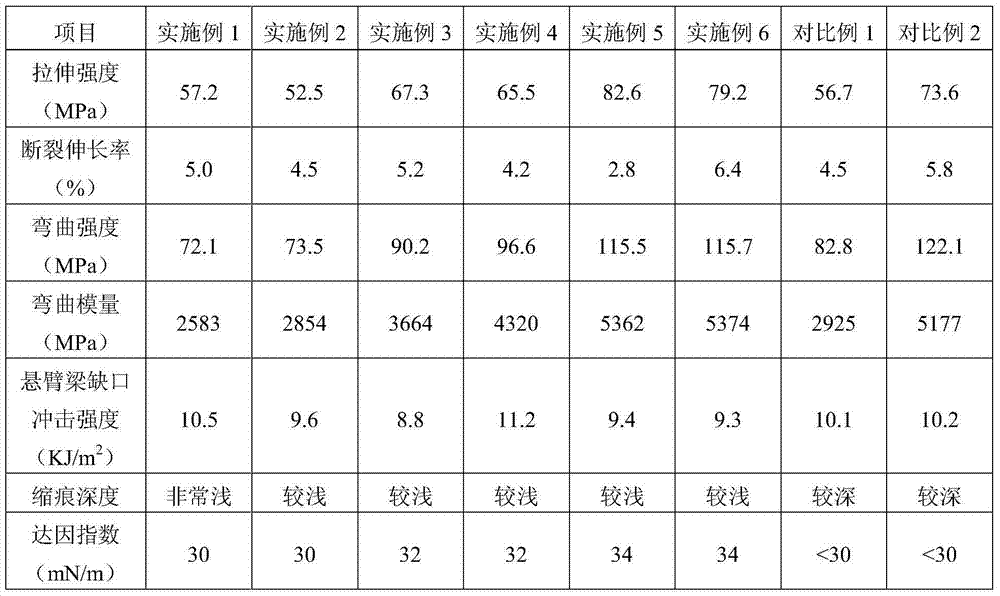

Glass fiber reinforced polypropylene/polystyrene alloy composite material and its preparation and application thereof

The invention belongs to the technical field of modified plastics and discloses a glass fiber reinforced polypropylene / polystyrene alloy composite material which is easy to spray and has shallow shrink mark and a preparation method and an application thereof. The alloy composite material includes the following ingredients: by weight, 40-69% of polypropylene, 10-30% of polystyrene, 15-30% of short-cut glass fiber, 1-20% of a mineral filler, 2-5% of graft polypropylene and 1-2% of a spray improver. By the adoption of high-crystallinity polypropylene, cooling and solidification speed during the injection molding process is raised effectively, and the surface of a finished product has characteristics of shallow shrink mark, low warpage and high surface glossiness. In addition, dyne index is high, and printing-ink wellability is good. With the addition of short-cut glass fiber and the mineral filler, the composite material has better mechanical property. The composite material is applied to household appliances and automobile industry, can be used to replace engineering plastics, and also meets requirements of products which highly require dimensional stability, warpage and mechanical properties.

Owner:TIANJIN KINGFA NEW MATERIAL +1

Zinc-based multi-element alloy for hot dipping and preparation method thereof

InactiveCN101818316AGood value for moneyReduce consumptionHot-dipping/immersion processesRare-earth elementDip-coating

The invention provides a zinc-based multi-element alloy for hot dipping and a preparation method thereof. The zinc-based multi-element alloy comprises the following components in percentage by mass: 2 to 3 percent of Al, 0.1 to 0.2 percent of RE(LA, Ce and PR mixed rare earth), 0.02 to 0.03 percent of Ni, 0.01 to 0.02 percent of Si, 0.01 to 0.02 percent of Mg, 0.005 to 0.01 percent of Cu and the balance of Zn. The zinc-based multi-element alloy has the advantages that: (1) in the alloy, the Al, Ni, Si, Cu and other elements are reasonably mixed, so the corrosion resistance of a hot-dip coating is obviously improved by over 20 percent than that of a pure zinc coating, meanwhile, the aluminium content is controlled within 3 percent so as to ensure that the alloy has good dip plating performance; and (2) in the alloy, La, Ce, Pr and other rare-earth elements and Mg element are reasonably mixed, so the fluidity and wetting performance of alloy plating solution are further improved, the surface quality of the coating is good, and the metal consumption is reduced by over 20 percent than that of the traditional galvanization. The zinc-based multi-element alloy and the preparation method thereof have obvious advantages in the aspects such as improving performance quality of hot-dip galvanized products, reducing metal consumption and reducing production cost.

Owner:KUNMING UNIV OF SCI & TECH

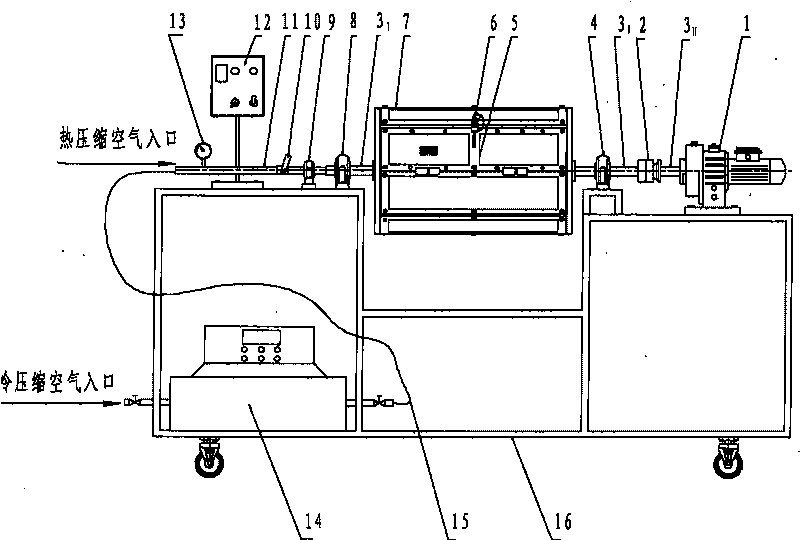

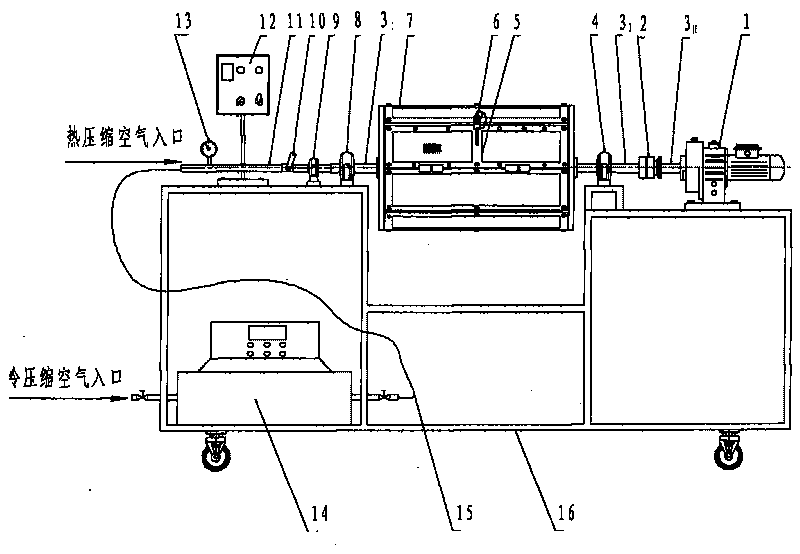

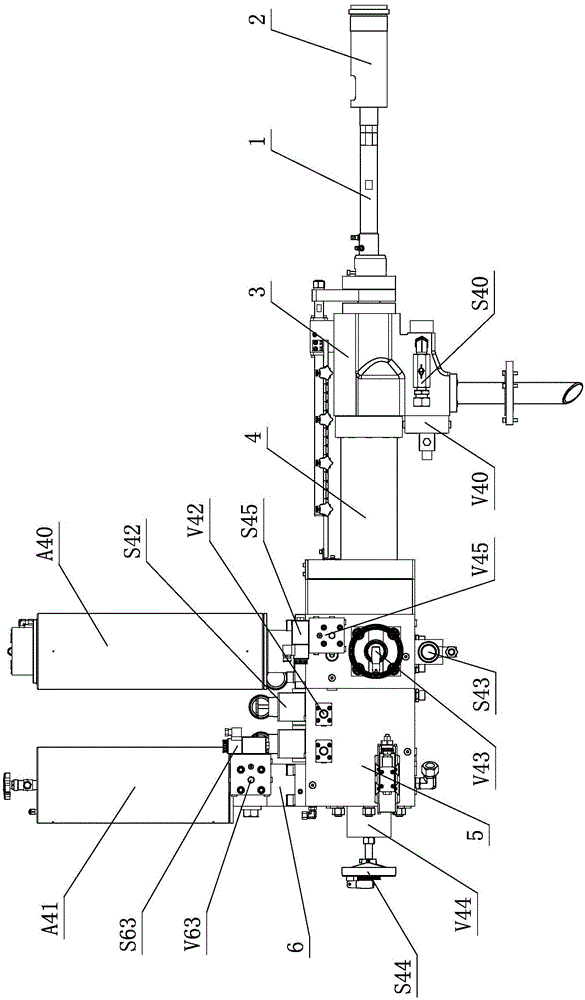

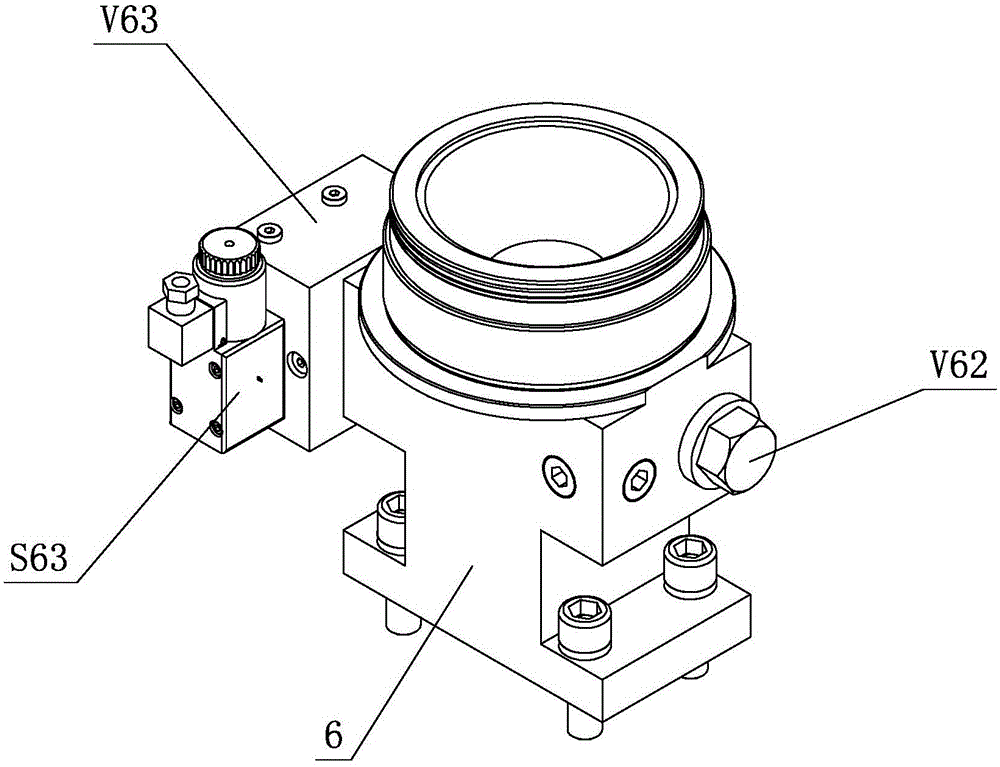

Method and equipment for coating dry-film lubricant

The invention provides a method and equipment for coating a dry-film lubricant, which is used for bolts with the bar diameter phi not greater than 10, threaded fasteners with the thread less than M10 and small parts. The method particularly comprises the following steps: pouring parts which are dipped and coated with liquid-state dry-film lubricant paint into the coating equipment for rolling and leveling, pouring out the parts on a mesh screen after a certain time, spreading, transferring into a baking oven, drying and solidifying. The problems of flow marks, knots and uneven thickness of a film layer on the surface of a coating caused by a spraying or dip coating process method are solved.

Owner:AVIC STANDARD PARTS MFG

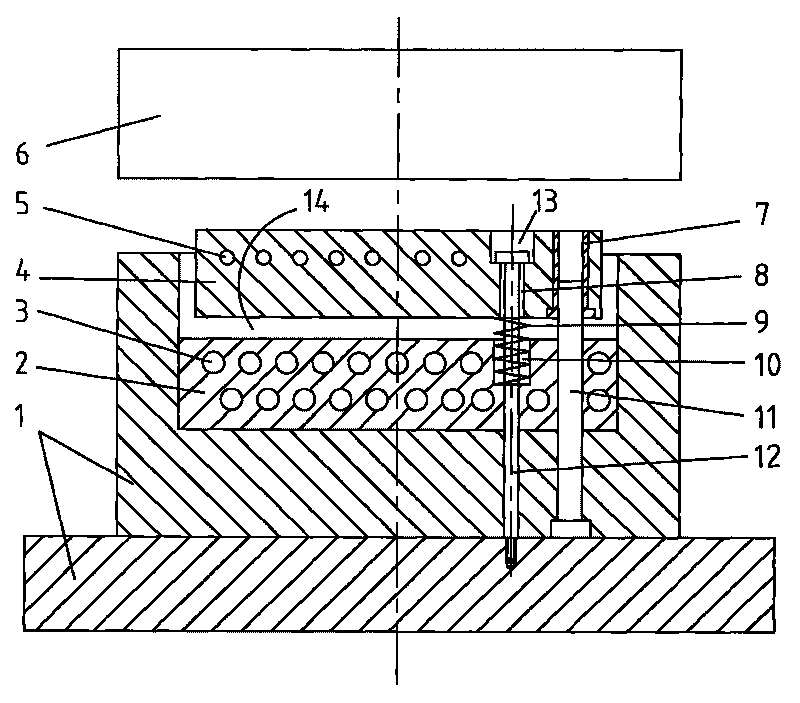

Quick heating and quick cooling highlight molding die

Owner:CHINA HUALU PANASONIC AVC NETWORKS

Glass fiber reinforced polypropylene composite material and its preparation method and application thereof

InactiveCN103589061AImprove mechanical propertiesEvenly distributedGlass fiberPolypropylene composites

The invention belongs to the technical field of modified plastics and discloses a glass fiber reinforced polypropylene composite material which is easy to spray and has shallow shrink mark and a preparation method and an application thereof. The composite material includes the following components: by weight, 45-79% of polypropylene, 15-30% of short-cut glass fiber, 1-20% of a mineral filler, 2-5% of graft polypropylene and 1-2% of a spray improver. With the addition of short-cut glass fiber and the mineral filler, the obtained glass fiber reinforced polypropylene composite material has better mechanical property. The composite material is applied to household appliances and automobile industry, can be used to replace engineering plastics. By the adoption of high-crystallinity polypropylene, cooling and solidification speed during the injection molding process of the material is raised effectively, and the surface of a finished product has characteristics of shallow shrink mark, low warpage and high surface glossiness. In addition, the product has advantages of high bending strength and flexural modulus, good processability, low cost, high dyne index and good printing-ink wellability.

Owner:TIANJIN KINGFA NEW MATERIAL +1

Spraying method of small part

InactiveCN103623982AFree rotationReduce wastePretreated surfacesCoatingsEngineeringMaterials processing

The invention discloses a spraying method of a small part. The method comprises the steps of a, clamping the part; b, primary spraying: spraying one side of the part, enabling a tooling to rotate slowly at the speed of 2-3r / min, adopting a small spray gun, and spraying along the direction of an included angle within the range of 150-450 degrees, at the interval of the straight-line distance of 10-30mm and under the compressed air pressure of 0.35-0.5MPa; c, low-temperature baking: after the spraying, transferring a fixture and the part in parallel into a hot air device with a function of low-temperature baking function, controlling the temperature to be 20-30 DEG C, and pre-baking the fixture and the part for 25-35min until the sprayed surface of the part is dried; d, secondary spraying: after low-temperature baking, overturning the part, spraying the other side of the part which is not sprayed according to the step b, and then carrying out low-temperature baking according to the step c; e, treating by curing. The spraying method of the small part has the characteristics of being high in spraying quality, material-saving, simple and convenient in processing and low in cost.

Owner:AVIC STANDARD PARTS MFG

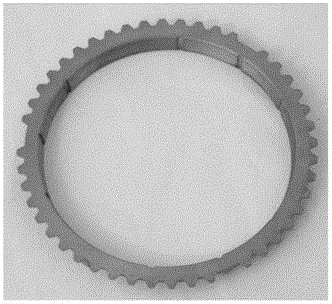

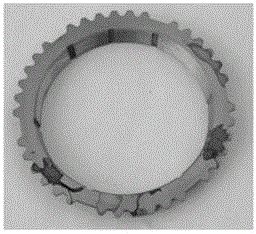

Rust-removing and spot-removing method for synchronizer gear ring

InactiveCN103602998ANo flow marksNo re-corrosionMetallic material coating processesSoap solutionEngineering

The invention discloses a rust-removing and spot-removing method for a synchronizer gear ring. The method comprises steps of removing oil; performing rust-removing and spot-removing treatment by using a rust-removing and spot-removing aqueous solution; rinsing the treated synchronizer gear ring in clear water; dipping the rinsed synchronizer gear ring in an aqueous soap solution; passivating the dipped synchronizer gear ring in a passivation solution; dipping the passivated synchronizer gear ring in water having a temperature of 60-80 DEG C; and drying. The method is simple in operation and low in investment. By the method, the synchronizer gear ring can regain a surface coating with high quality. The synchronizer gear ring treated by the steps is uniform and glossy and free from flow marks and environment pollution, and is passivated without the chromate. The synchronizer gear ring treated by the method cannot be corroded again in a storing process.

Owner:长春永新汽车同步器有限公司

A kind of topcoat for building curtain wall aluminum veneer and preparation method thereof

The invention relates to a finish for a building curtain wall aluminum veneer, and a preparation method thereof. The finish comprises 60 to 70% of FEVE fluorocarbon resin, 5 to 10% of an organic silicon resin, 0.05 to 0.1% of an acrylic acid levelling agent, 0.1 to 0.3% of an organosilicon levelling agent, 0.3 to 0.8% of benzotriazole ultraviolet absorbent, 0.3 to 0.8% of hindered amine light stabilizer, 0.1 to 0.3% of an organotin catalyst, 10 to 15% of butyl acetate, 10 to 15% of dimethylbenzene and 9 to 13% of an aliphatic isocyanate curing agent, wherein the aliphatic isocyanate curing agent needs to be individually packaged and stored and is added into a formula prior to construction for use. The FEVE fluorocarbon resin and the organic silicon resin are utilized as film-forming substances of the finish and the finish can be cured at normal temperature, and thus energy and labor are saved. Through a fluorine-silicon interpenetrating network structure, film surface tension is reduced and a water contact angle is reduced, and thus film anti-contamination properties are improved greatly. Through introduction of silicon atoms, film toughness is improved, and thus a film surface isnot easy to craze and temperature tolerance and endurance are further improved. In addition, the finish has the advantages of simple preparation method and low cost.

Owner:苏州金近幕墙有限公司

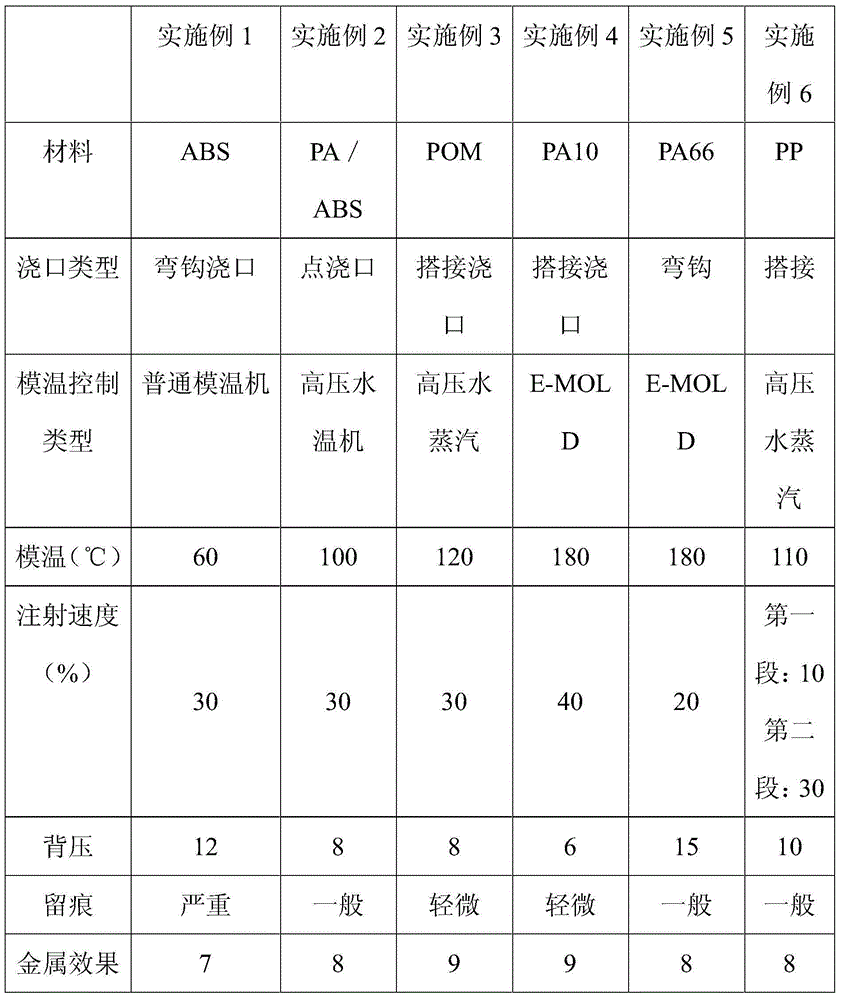

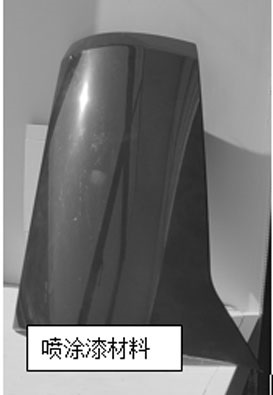

Free-spraying metallic-luster injection molding process for car interior trim parts and exterior parts

The invention discloses a free-spraying metallic-luster injection molding process for car interior trim parts and exterior parts. The free-spraying metallic-luster injection molding process comprises the following steps: adding metal powder into a raw material which is a plastic base material, and arranging a random water path close to a mould cavity of an injection mould with the high surface quality and the small thermal deformation to enable the surface temperature of the mould to be uniform; pouring the mould by adopting a hooked pouring gate, a pin-point gate and a side pouring gate; controlling the temperature of the surface of the mould in an injection-molding process; and pouring by adopting one or more pouring gates by adopting a high-pressure low-speed injection molding technique, a low-pressure high-speed injection molding technique or a normal-pressure normal-speed injection molding technique, and a sequential injection molding process, wherein the pouring gates adopt a needle valve type pouring gates. The parts produced by adopting the free-spraying metallic-luster injection molding process have no flow marks and solution marks on surfaces, have the good metallic luster and can be used for car interior trim parts and exterior parts.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

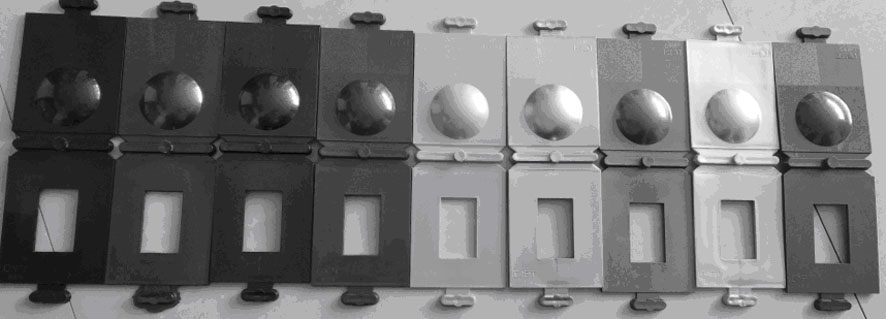

Strip-shaped aluminum pigment with smooth surface and few flow marks

The invention discloses a strip-shaped aluminum pigment with a smooth surface and few flow marks. The pigment is prepared from, by weight, 70-75 parts of sheet aluminum powder, 14-15 parts of methacryloxy propyl trimethoxyl silane, an appropriate amount of absolute ethyl alcohol, 28-30 parts of trimethylolpropane triacrylate, 1.1-1.2 parts of crylic acid, 0.09-0.1 part of azodiisobutyronitrile, 1.75-1.9 parts of polyvinylpyrrolidone, 4-4.5 parts of ethylene bistearic amide, 19-20 parts of polyethylene, 2-3 parts of hydrotalcite, 2-3 parts of polytetrafluoroethylene particles, 2-3 parts of organobentonite, 0.8-1 part of silicone oil, an appropriate amount of deionized water and 0.8-1 part of polyvinyl alcohol. The prepared product has the smooth surface and has no flow mark, the defect that flow marks are produced in the plastic part molding process is reduced, the plastic part performance is improved, industrial control over the whole technological process is convenient, the pigment is safe, and no solvent is adopted.

Owner:HEFEI SUNRISE PIGMENTS

Vehicle spraying-free composite material and preparation method thereof

The invention relates to a vehicle spraying-free composite material. The vehicle spraying-free composite material comprises the following raw materials: polypropylene resin, fillers, metal powder, straight-chain alkyl acid salt, cyclopentadiene and an antioxidant, wherein the metal powder adopts double-layer wrapping; the inner layer is wrapped with thermosetting resin; and the outer layer is wrapped with silicon dioxide nanopowder. Meanwhile, the invention also relates to a method for preparing the method. Aluminum powder is wrapped by double layers; the inner is used for reducing the heat conductivity coefficient of the metal powder, so that occurrence of a welding line is reduced; and the outer layer of silicon dioxide nanopowder can prevent physical or chemical change of the metal powder and the inner layer during high-temperature treatment. Due to addition of the straight-chain alkyl acid salt, the compatibility of the powder and the polypropylene base material is improved and occurrence of current ripple is reduced; and due to addition of the cyclopentadiene, crosslinking effect can be achieved and the integral hardness of the material is increased; meanwhile, due to the high-temperature depolymerization characteristic of the cyclopentadiene, the high-temperature processing property of the polypropylene resin is not influenced.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

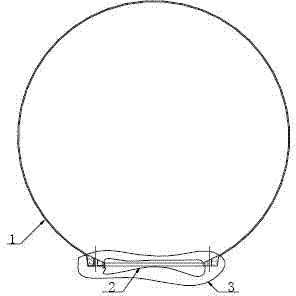

Manufacturing method for seamless ball screen

The invention discloses a manufacturing method for a seamless ball screen. The manufacturing method includes that needed resin mixture is prepared, the resin mixture is coated and distributed on the surface of a spherical die in a spray coating mode, coating operation is repeated after the resin mixture is totally solidified until the required coating thickness is achieved, then, a flange is sleeved on a ball opening of the spherical die after being coated, demolding process is carried out, a seamless ball is obtained, an imaging layer is coated on the surface of the seamless ball and the seamless ball screen is obtained. The manufacturing method for the seamless ball screen has the advantages that the inner surface and the outer surface of a ball body are smooth, no polishing process is needed, meanwhile, the die can be made very thin, demolding is quite easy, a resin thin film solidifies quickly, efficiency is largely improved, quality of the coated transparent ball is good, qualified rate is extremely high (more than 95%), the coated imaging layer is even, rill marks or other flaws can not occur, and aging effect of ultraviolet rays can be effectively prevented.

Owner:WUXI XIKE NETWORK TECH

Spraying-free metal-texture high-gloss high-weather-resistance PMMA/ASA alloy material and preparation method thereof

The invention discloses a spraying-free metal-texture high-gloss high-weather-resistance PMMA / ASA alloy material and a preparation method thereof. AS resin, PMMA resin, ASA rubber powder, glass powder, a pigment and auxiliary agents are mixed and then added into a screw extruder, and the spraying-free metal-texture high-gloss high-weather-resistance PMMA / ASA alloy material is obtained through extrusion. The metal-texture high-gloss high-weather-resistance PMMA / ASA alloy material provided by the invention is a material which can realize a colorful appearance effect without paint spraying treatment, with direct injection molding and without spraying, so that the cost is reduced, the environment is protected, the production process is simple, the product yield is improved, the application prospect is wide, and the PMMA / ASA alloy material has a good use value.

Owner:浙江科普特新材料有限公司

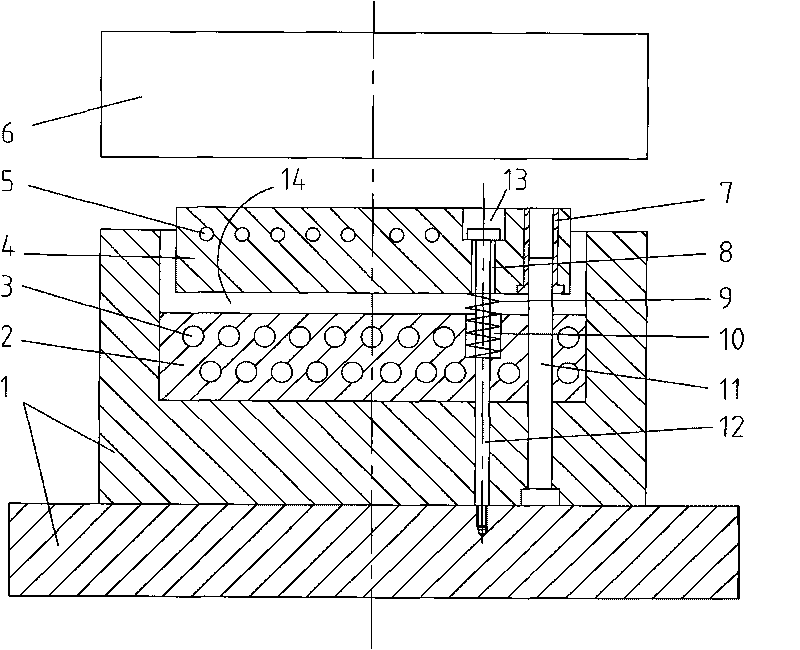

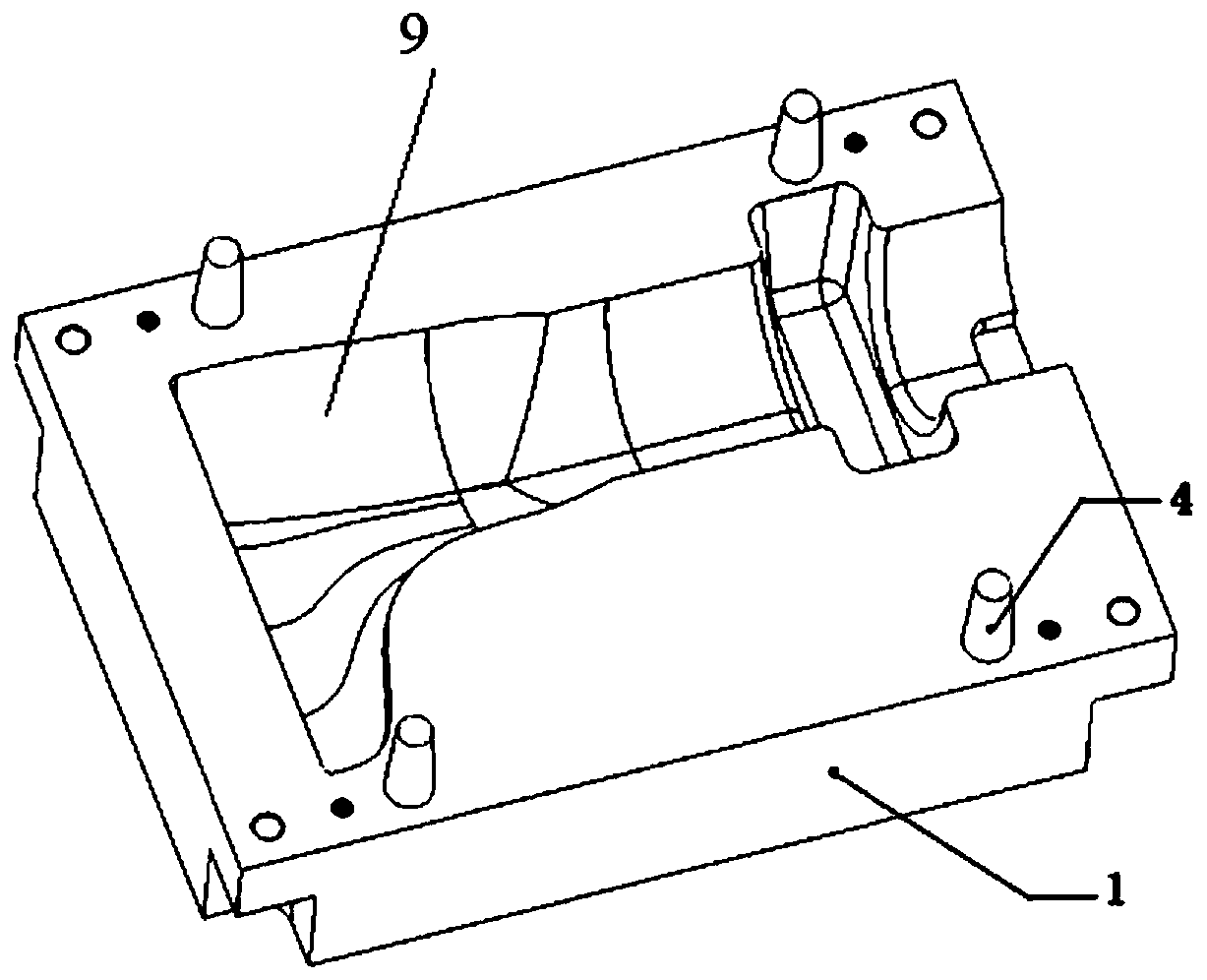

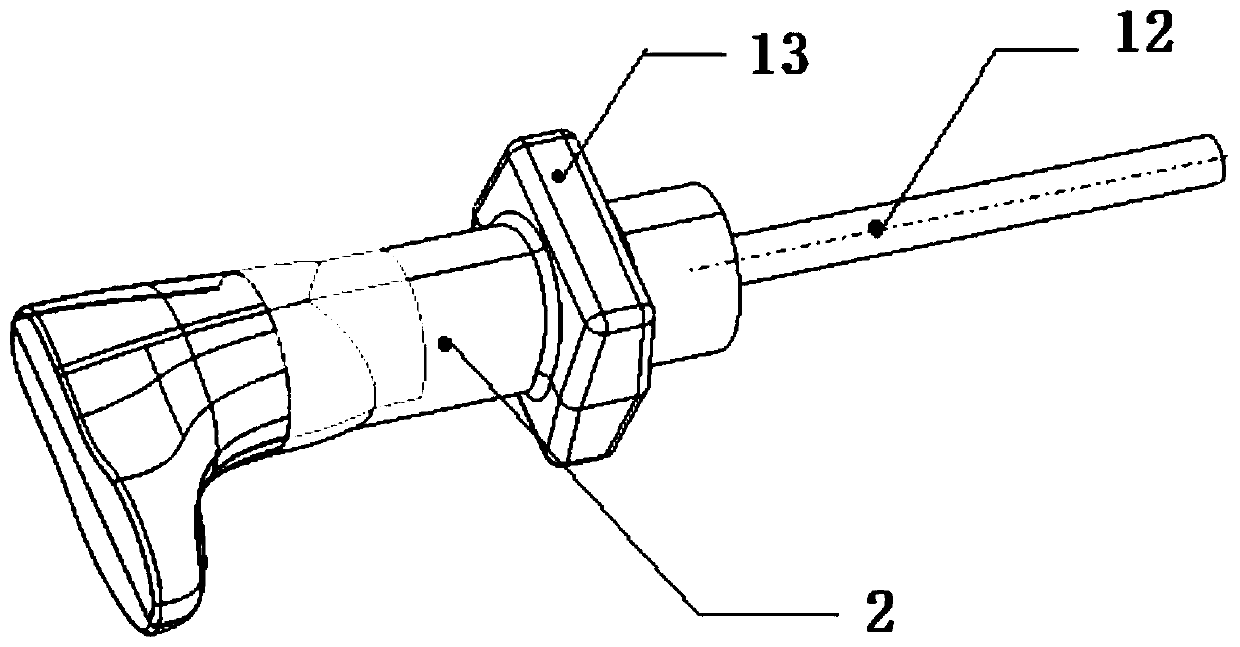

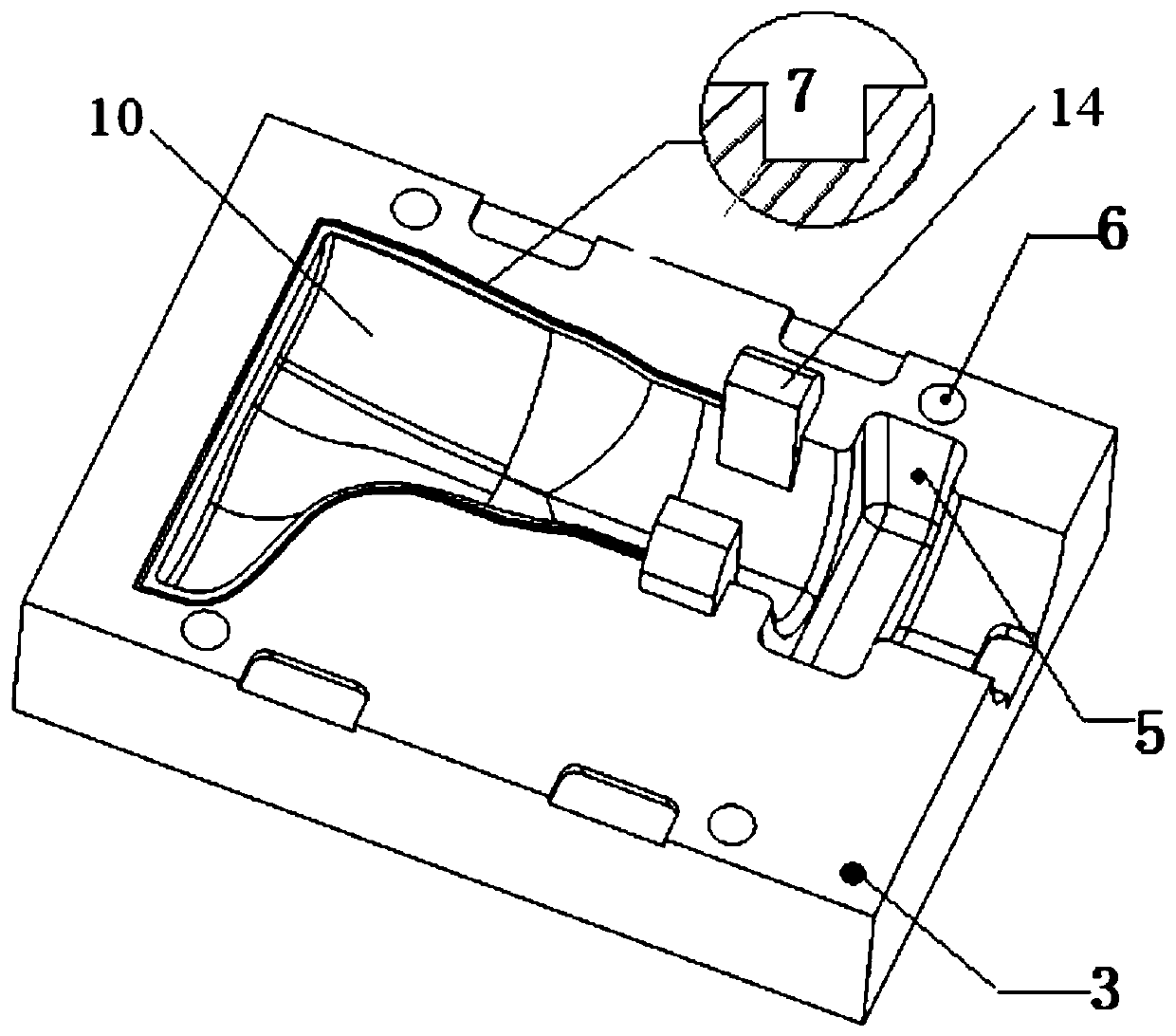

Die for thermoplastic polyurethane elastomer compression molding

InactiveCN109702948AImprove performanceThe surface of the product is smoothCoatingsCompression moldingThermoplastic elastomer

The invention provides a die for thermoplastic polyurethane elastomer compression molding. The die comprises an upper die body (1), a die core (2), and a lower die body (3), wherein the die core (2) comprises a molding body structure, a rectangle positioning block (13) and a handle (12); the upper die body (1) comprises a first molding cavity (9), a positioning groove (5), and positioning post (4); the lower die body (3) comprises a second molding cavity (10), a positioning groove (5), a positioning hole (6), a sealing groove (7), a sealing joint strip (8) and a positioning clip (14); and whenthe upper die body (1) and the lower die body (3) complete molding closing, the inner surfaces of the first molding cavity (9) and the second molding cavity (10) are in consistence with the outline of the molding body structure, and the positioning grooves (5) of the upper die body (1) and the lower die body (3) are in consistence with the outline of the rectangle positioning block (13). The technical problems of difficulty in demolding and cracking of the mold closing line are solved by means of the die for thermoplastic polyurethane elastomer compression molding; and stripping is easy, andthe die for thermoplastic polyurethane elastomer compression molding is suitable for compression molding of thermoplastic elastomer material.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

A kind of spray-free metal texture PMMA modified material and preparation method thereof

The invention discloses a spraying-free metallic PMMA (polymethyl methacrylate) modified material and a preparation method thereof. The method comprises the steps that the PMMA is used as a matrix resin raw material, MBS (methyl methacrylate), MABS (methyl methacrylate / acrylonitrile / butadiene / styrene / copolymer) and ACR (acrylate copolymer with core-shell structure) are taken as toughening agents, MS (methyl methacrylate / styrene copolymer) is taken as a processing modifying additive, aluminum powder coated with metals and pearlescent pigments which enable materials to be metallic are added, a certain quantity of dispersing agents, a small quantity of antioxidant agents, a lubricating agent, pigments and the like are supplemented, after the materials are uniformly mixed in the proportion, the materials are milled by a parallel double-screw extrusion machine, and a spraying-free metallic PMMA modified material is formed. The material and PVC (polyvinyl chloride) are subjected to compound co-extrusion, so that the surface of the prepared product has an excellent metallic effect; and compared with traditional spraying products, the spraying-free metallic PMMA modified material has the advantages of low cost, environment friendliness, scratch resistance, recycle and the like, therefore, the spraying-free metallic PMMA modified material is particularly suitable for being processed into lateral trim workpieces of refrigerators.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

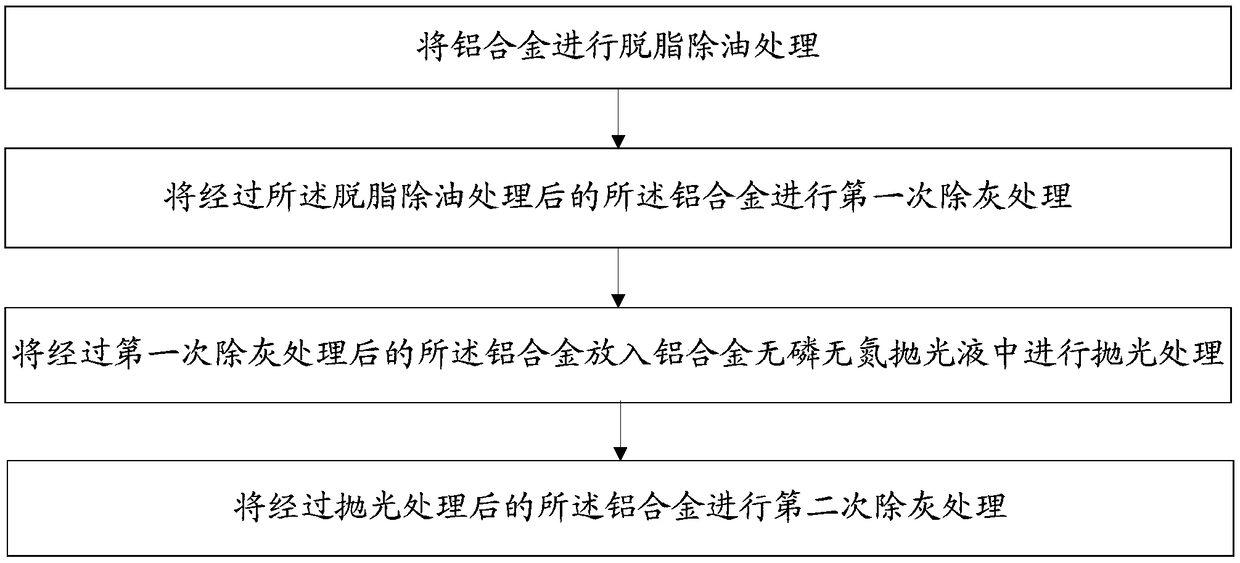

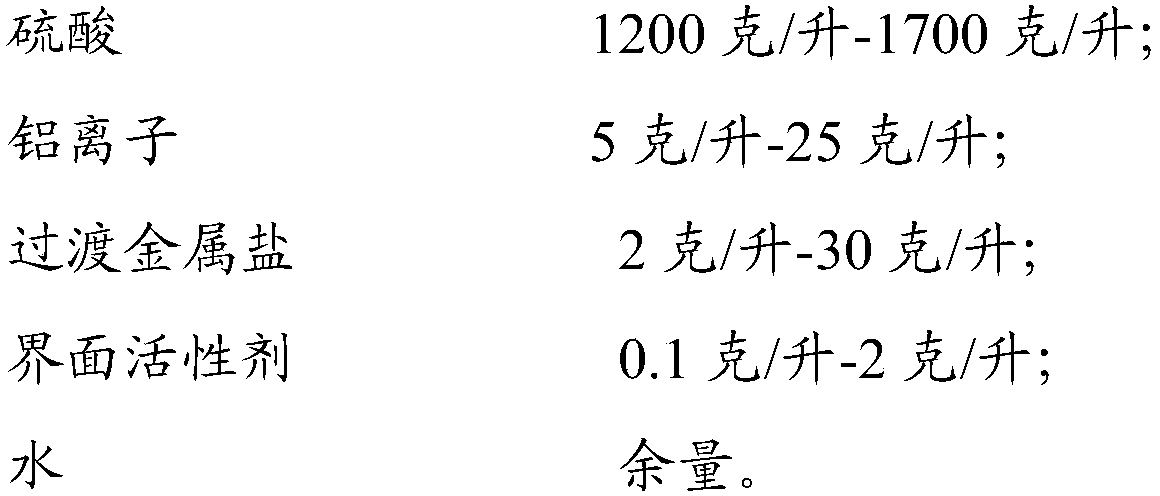

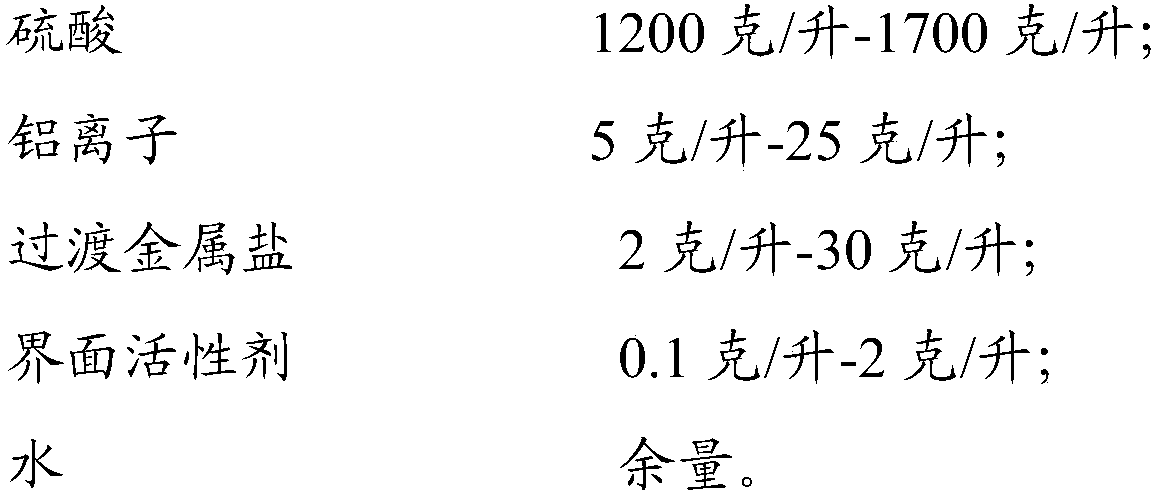

Aluminum alloy non-phosphorus nitrogen-free polishing solution and aluminum alloy surface treatment method

Provided is an aluminum alloy non-phosphorus nitrogen-free polishing solution and an aluminum alloy surface treatment method. The aluminum alloy non-phosphorus nitrogen-free polishing solution is prepared from, by mass concentration, 1200 g / L-1700 g / L sulfuric acid, 5 g / L-25 g / L aluminum ions, 2 g / L-30 g / L metal salt, a 0.1 g / L-2 g / L interfacial agent and the balance water. According to the aluminum alloy non-phosphorus nitrogen-free polishing solution, phosphoric acid and nitric acid are not adopted, phosphorus and nitrogen are not included, pollution related to phosphorus and nitrogen is notcaused to the environment, and therefore the environmental protection property is good. In addition, after an aluminum alloy is polished with the aluminum alloy non-phosphorus nitrogen-free polishingsolution, the brightness of the aluminum alloy can be improved well.

Owner:广东东明新材科技有限公司

3D printing sand mold water-based dip coating and preparation method thereof

InactiveCN108971419AImprove corrosion resistanceIncrease impactFoundry mouldsFoundry coresWater basedPreservative

The invention relates to the technical field of 3D printing sand casting, in particular to a 3D printing sand mold water-based dip coating and a preparation method thereof. The 3D printing sand mold water-based dip coating is prepared from the following components in percentage by weight: 50 to 75% of composite refractory aggregate, 3 to 6% of composite suspending agent, 0.8 to 1.2% of composite binder, 0.1 to 0.5% of penetrant, 0.2 to 0.6% of leveling agent, 0.05 to 0.2% of DL-T201 preservative, 2 to 5% of flux, 0.1 to 0.3% of defoamer, and 25 to 38% of water. The invention also discloses a preparation method of the 3D printing sand mold water-based dip coating. The coating has excellent performance, excellent coating property, proper permeability, good leveling property, high suspensionstability, suitable coating thickness, good sintering peeling property and superior anti-sticking property. Compared with conventional coatings, the coating can be applied only once by dip coating. The penetration depth and coating thickness can meet the requirements. After drying, the coating strength is very high. No flow mark, no dripping, and no accumulation exist.

Owner:贵阳灵峰铸造材料有限公司

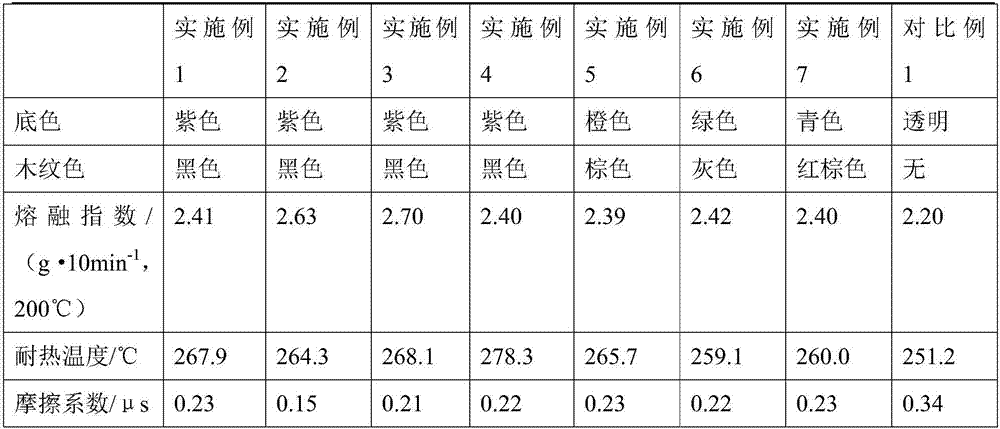

Wood-grain-imitating master batch applicable to PVC (Polyvinyl Chloride) and preparation method thereof

InactiveCN107987424AClear imitation wood grainFlat surfacePolyethylene terephthalate glycolAntioxidant

The invention provides wood-grain-imitating master batch applicable to PVC (Polyvinyl Chloride) and a preparation method thereof. The wood-grain-imitating master batch is prepared from the following raw materials in percentage by weight: 20 to 60 percent of a background color component, 30 to 60 percent of a wood grain component, 5 to 25 percent of compound higher molecular weight wax, 1 to 5 percent of an antioxidant, 0.5 to 1 percent of a thermal stabilizer and 0.1 to 0.5 percent of a lubricant; the background color component is prepared from the following components in percentage by weight:0.1 to 5 percent of background color pigment powder and 95 to 99.5 percent of the PVC; the wood grain component is prepared from the following components in percentage by weight: 0.1 to 5 percent ofwood grain pigment powder, 30 to 60 percent of the PVC and 40 to 70 percent of PET (Polyethylene Terephthalate); the compound higher molecular weight wax is prepared from the following components in percentage by weight: 30 to 70 percent of modified polytetrafluoroethylene micro-powder wax and 30 to 70 percent of oxidized polyethylene wax. According to the wood-grain-imitating master batch provided by the invention, the compound higher molecular weight wax is added; the wear resistance of PVC plastic is enhanced under the synergistic effect of the modified polytetrafluoroethylene micro-powderwax and the oxidized polyethylene wax and the utilization performance of the plastic is improved.

Owner:广东荣晟智造有限公司

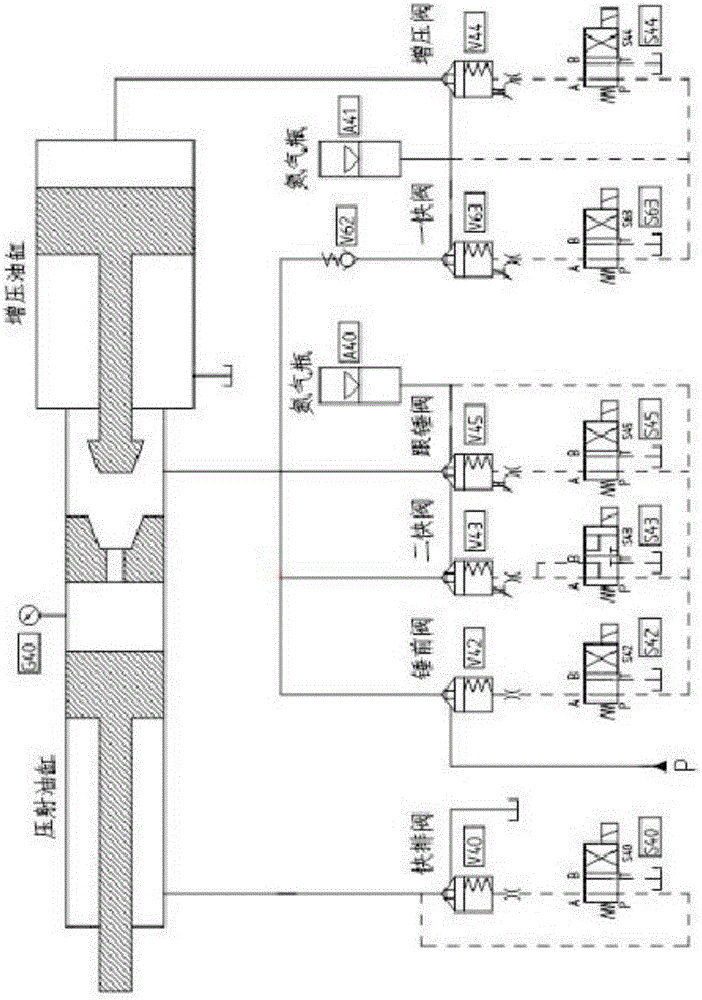

Injection pressure-boosting and speed-increasing structure of die casting machine

The invention discloses an injection pressure-boosting and speed-increasing structure of a die casting machine. The injection pressure-boosting and speed-increasing structure comprises an injection punch, wherein an injection part is arranged at one side of the injection punch; an injection oil cylinder, an injection piston rod and a pressure-boosting oil cylinder are sequentially arranged at the other side of the injection punch; a pressure-boosting cavity is formed between the injection piston rod and the pressure-boosting oil cylinder; and a primarily quick oil path block assembly and a secondarily quick oil path block assembly are arranged on the pressure-boosting oil cylinder. According to the injection pressure-boosting and speed-increasing structure, the speed of the primarily quick action and the secondarily quick action is increased by a design method and a control mode which are combined with a practical production process, so that requirements of producing thin-wall parts such as a magnesium alloy mobile phone middle plate and the like are met, and a common horizontal type cold chamber die casting machine is transformed into a special die casting machine for thin-wall parts represented by the die-cast magnesium alloy mobile phone middle plate; the modified die casting machine can realize that cast pieces are full, less in shrinkage cavities, smooth in surface, good in smoothness, free of flow marks, less in flanges, free of air bubbles and flaws and high in practicability, and meet processing requirements.

Owner:佛山联升压铸科技有限公司

Multi-station powder coating machine for inner wall of spiral lamp tube

InactiveCN103077871AAdjust the blowing angleAchieve powder coatingLuminescent coatings applicationMechanical engineeringPowder coating

The invention discloses a multi-station powder coating machine for the inner wall of a spiral lamp tube. The multi-station powder coating machine comprises a turntable and a drying channel which are along the circumference; a plurality of station devices are uniformly distributed on the turntable; the multi-station powder coating machine is characterized in that air collection boxes are arranged on the station devices; the air collection boxes are connected with air inlet pipes; a row of corrugated pipes are arranged on the air collection boxes; a rotating shaft is arranged on each station device; a workpiece seat is arranged on each rotating shaft; and each workpiece seat is aligned with the outlet of each corrugated pipe. By the multi-station powder coating machine, air can be blown to a spiral lamp tube workpiece which is subjected to powder coating by the corrugated pipes which can be bent at random angles; powder is coated on the inner wall of the lamp tube uniformly without accumulated powder or flow mark; the powder coating quality of the inner wall of the lamp tube and the light efficiency of the lamp tube are improved; and the continuous automatic operation of powder coating and drying of the spiral lamp tube can be realized.

Owner:浙江力胜电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com