Rust-removing and spot-removing method for synchronizer gear ring

A synchronizer gear ring and freckle removal technology, which is applied to the coating process of metal materials, can solve the problems of manufacturers' economic and reputation loss, waste of metal materials, etc., and achieve the effect of small investment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] HAl61-4-3-1 is a multi-component complex brass, composed of Cu, Zn, Al, Si, Ni, Co six elements. Chemical composition ratio: Cu60-62%, Al3.5-4.5%, Si0.5-1.5%, Ni2.5-4.0%, Fe0.5-1.3%, Co0.5-1.0Zn balance. Because of its excellent strength, hardness, corrosion resistance and wear resistance, it is widely used in the field of wear-resistant materials and is the preferred material for the synchronizer ring of trucks.

[0032] The derusting and freckle removal process of the synchronizer gear ring is as follows:

[0033] 1) Degreasing; soak with metal cleaning agent and water at room temperature until there are no oil droplets on the surface; the mass percentage of metal cleaning agent is: 80±2%;

[0034] 2) Carry out rust and spot removal treatment on rusted and speckled gear rings with rust and spot removal solution: rust and spot removal solution: CrO 3 50-100g / L, H 2 SO 4 30-50ml / L, brightener 1-3g / L, metal active agent 1-3g / L; the time of rust and spot removal depen...

Embodiment 2

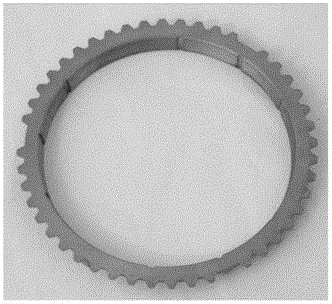

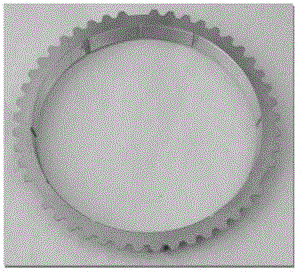

[0042] HMn62-3-3-0.7 is a multi-component complex brass, composed of Cu, Zn, Al, Mn, Si five elements. Chemical composition ratio: Cu61-63%, Mn2.7-3.7%, Al2.4-3.4%, Si0.5-1.0%Zn balance. Because of its excellent strength, hardness, corrosion resistance and wear resistance, it is widely used in the field of wear-resistant materials, and is the preferred material for synchronizer rings of cars, light vehicles and miniature vehicles. Pictures of corroded synchronizer rings before and after treatment image 3 with Figure 4 .

Embodiment 3

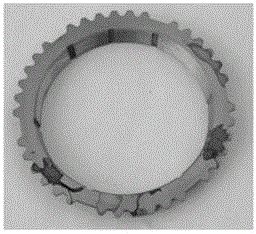

[0044] MBA-2 is a multi-component complex brass, composed of Cu, Zn, Mn, Al, Si, Ni, Cr seven elements. Chemical composition ratio: Cu59-65%, Al1.7-3.7%, Mn2.2-3.8%, Si0.5-1.3%, Ni0.2-0.6%, Cr0.07-0.27Zn balance. Because of its excellent strength, hardness, corrosion resistance and wear resistance, it is widely used in the field of wear-resistant materials. It is the preferred synchronizer ring material for Japanese cars, light cars and mini cars. Pictures of corroded synchronizer rings before and after treatment Figure 5 with Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com