Wood-grain-imitating master batch applicable to PVC (Polyvinyl Chloride) and preparation method thereof

A technology of imitating wood grain and masterbatch, applied in the field of color masterbatch, can solve the problems of poor wear resistance, uneven distribution of anti-wood grain plastic pigments, rough surface, etc., to achieve enhanced wear resistance, smooth and natural surface, and clear lines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

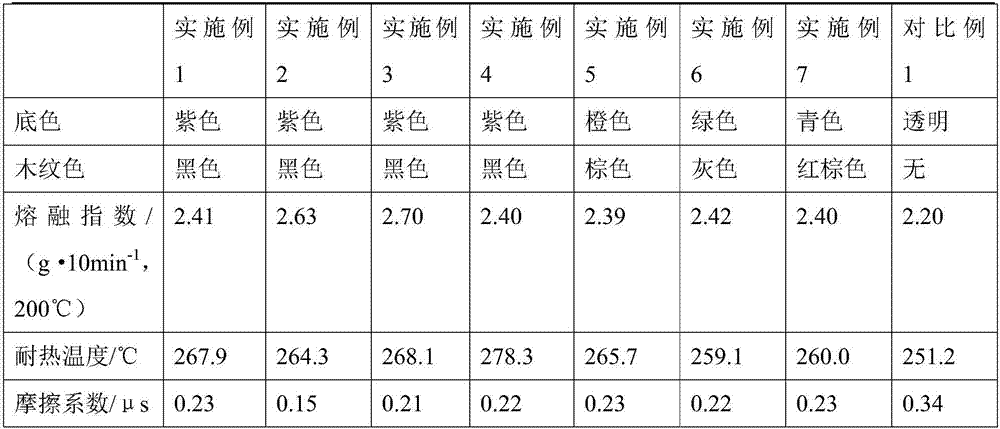

Examples

Embodiment 1

[0032] An imitation wood grain masterbatch suitable for PVC, prepared from the following raw materials by weight percentage:

[0033] Phthalocyanine red 0.1%, phthalocyanine blue 0.1%, PVC 19.8%, carbon black 0.1%, PVC 18.9%, PET 41%, modified polytetrafluoroethylene powder wax 5%, oxidized polyethylene wax 12%, diphenylamine 2 %, sulfite 0.7%, silicone oil 0.3%.

Embodiment 2

[0035] An imitation wood grain masterbatch suitable for PVC, prepared from the following raw materials by weight percentage:

[0036] Phthalocyanine red 0.1%, phthalocyanine blue 0.1%, PVC 25.8%, carbon black 0.1%, PVC 18.9%, PET 35%, modified polytetrafluoroethylene powder wax 5%, oxidized polyethylene wax 12%, diphenylamine 2 %, sulfite 0.7%, silicone oil 0.3%.

Embodiment 3

[0038] An imitation wood grain masterbatch suitable for PVC, prepared from the following raw materials by weight percentage:

[0039] Phthalocyanine red 0.1%, phthalocyanine blue 0.1%, PVC 22.8%, carbon black 0.1%, PVC 15.9%, PET 33%, modified polytetrafluoroethylene powder wax 10%, oxidized polyethylene wax 15%, diphenylamine 2 %, sulfite 0.7%, silicone oil 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com