Scratch-resistant high-gloss spraying-free polypropylene composition with aesthetic effect as well as preparation method and application of composition

A polypropylene composition and spray-free technology, applied in the field of modified plastics, can solve problems such as differences in scratch resistance, achieve excellent scratch resistance, solve anisotropy defects, and eliminate the effect of dark appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

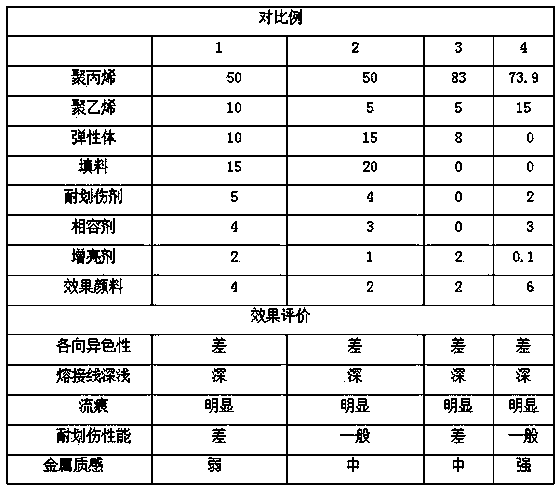

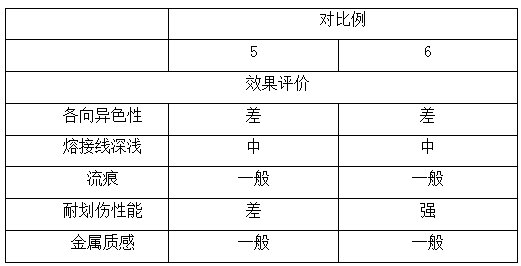

Examples

Embodiment 1

[0039] Weigh each component according to the formula in Table 1, polypropylene, polyethylene, elastomer, scratch-resistant agent system, compatibilizer, brightener

[0040] Mix in the high mixer for 1~3 minutes, then add talcum powder and effect pigments and mix in the high mixer for 1~3 minutes at a speed of 1000~2000 rpm to obtain a premix; the premix is extruded by a twin-screw Extrusion machine is melted and extruded, the temperature of each zone of the screw is 190~230°C, and vacuum granulated to produce polypropylene with scratch resistance and high gloss without spraying aesthetic effect.

[0041] Wherein, polypropylene is copolymerized polypropylene;

[0042] Polyethylene is high-density polyethylene HDPE;

[0043] The elastomer is ethylene-hexene copolymer;

[0044] The anti-scratch agent system is a mixture of 90% dimethyl polysiloxane and 10% glycidyl ether epoxy resin;

[0045] The compatibilizer is ethylene maleic anhydride copolymer;

[0046] The brightener i...

Embodiment 2

[0049] Each component is weighed according to the formula in Table 1, and its preparation method is the same as in Example 1.

[0050] Wherein, polypropylene is copolymerized polypropylene;

[0051] Polyethylene is low density polyethylene LDPE;

[0052] The elastomer is a mixture of 20% ethylene-propylene copolymer and 80% ethylene-octene copolymer;

[0053] The anti-scratch agent system is a mixture of 90% erucamide and 10% glycidyl ester epoxy resin;

[0054] The compatibilizer is propylene maleic anhydride copolymer;

[0055] The brightener is N,N-higher fatty acid group-ethylene bisstearamide;

[0056] The effect pigment is 50μm flake aluminum powder;

Embodiment 3

[0058] Each component is weighed according to the formula in Table 1, and its preparation method is the same as in Example 1.

[0059] Wherein, polypropylene is homopolypropylene;

[0060] Polyethylene is linear low density polyethylene LDPE;

[0061] The elastomer is a mixture of 50% ethylene-hexene copolymer and 50% ethylene-butene copolymer;

[0062] The anti-scratch agent system is a mixture of 90% oleic acid amide and 10% glycidyl amine epoxy resin;

[0063] The brightener is N,N-ethylenebisstearamide;

[0064] The effect pigments are 80 μm silica-coated flake aluminum powder and 50 μm silica-coated pearlescent pigment, the ratio of the two is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com