Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Meet high-end needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A corrosion-resistant aluminum alloy profile

ActiveCN104962786BReduce production processShorten the production cycleCorrosion resistantContinuous casting

The invention discloses a production method of a corrosion-resistant aluminum alloy profile. The corrosion-resistant aluminum alloy profile comprises, by mass percent, 3%-8% of Cu, 2%-5% of Fe, 5%-9% of Mn, 1%-2% of Mg, 1%-2% of Zn, 0.3%-0.8% of Si, 0.1% of Ni, 0.05% of Ti and the balance Al. The materials are smelted for 6-8 hours at high temperature to obtain molten aluminum alloy; horizontal continuous casting is carried out on the obtained molten aluminum alloy and cleaning is conducted; the aluminum alloy profile is obtained through continuous extruding and forming; second-stage aging heat treatment is carried out on the obtained aluminum alloy profile, and a finished corrosion-resistant aluminum alloy profile product is obtained. The alloy production process is simplified and the alloy production period is shortened without homogenization and pre-heating treatment, and the energy-saving and environment-friendly production requirements of a short-process technology are completely met. Besides, the manufactured aluminum alloy profile has excellent corrosion resistance and tensile strength and can meet high-end requirements increasing day by day.

Owner:浙江米皇新材股份有限公司

Polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and preparation method

ActiveCN103436167AImprove anti-corrosion and anti-bacterial abilitySpecific performanceAntifouling/underwater paintsFibre treatmentActive agentPolytetrafluoroethylene

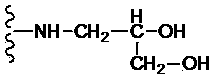

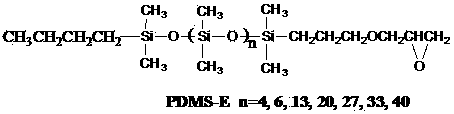

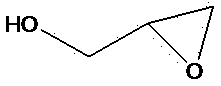

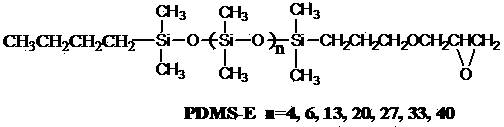

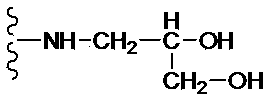

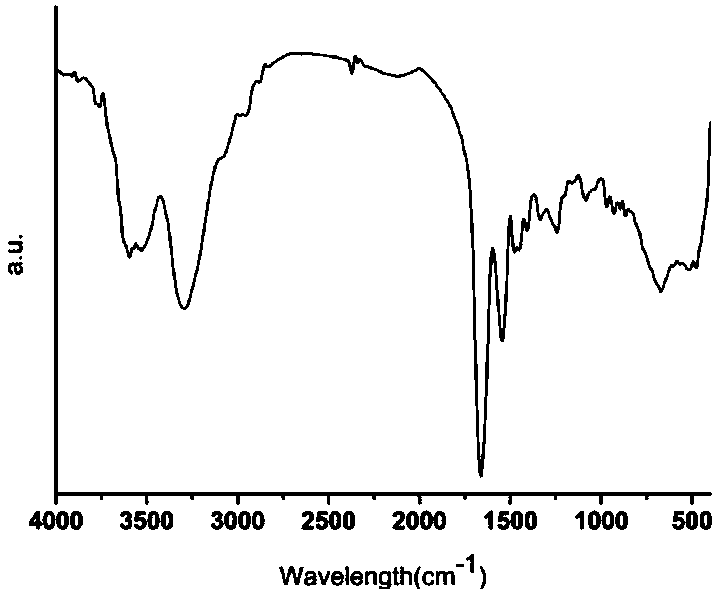

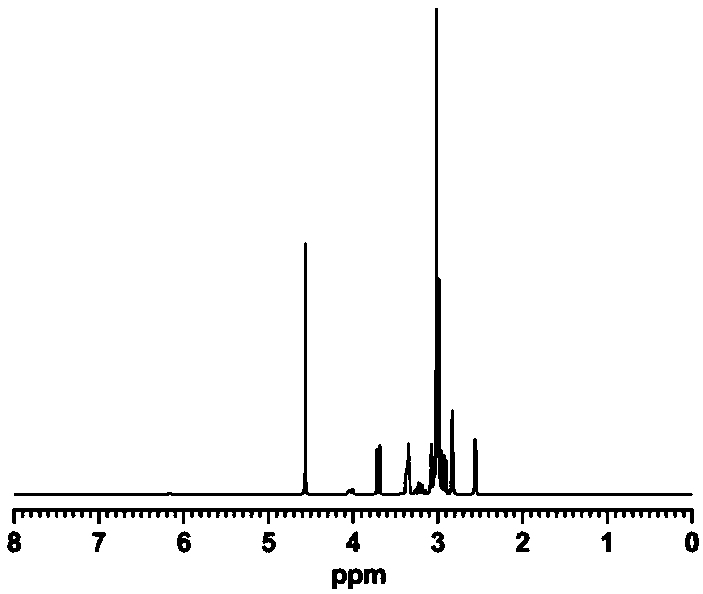

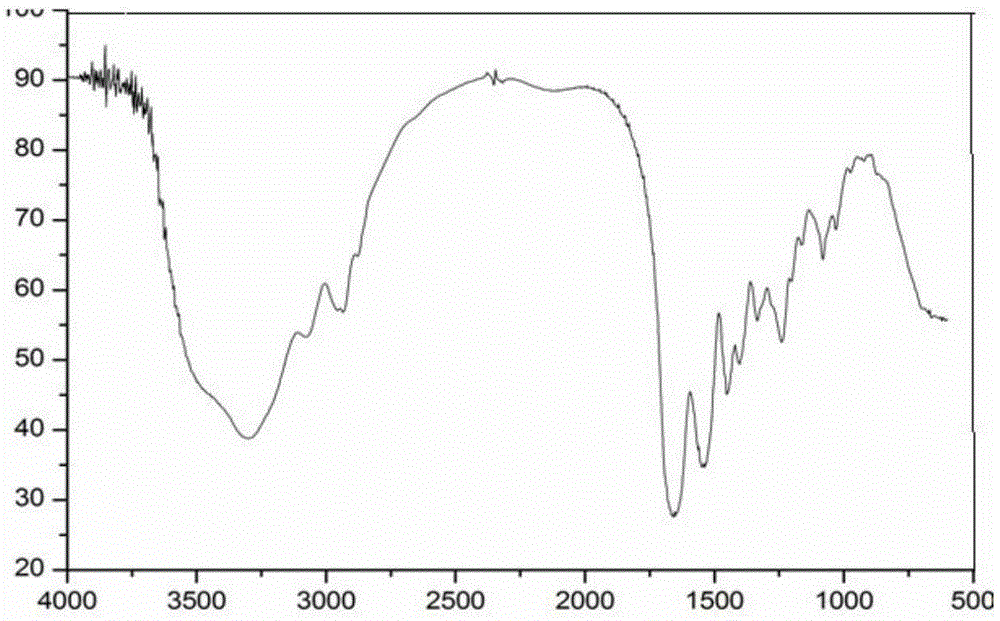

The invention relates to a polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and a preparation method. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding epoxy quaternary ammonium salt into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding glycidol into a second reaction flask to obtain solution 2; adding a surfactant into a third reaction flask, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 3; mixing the solution 1, the solution 2 and the solution 3 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or three or four of ethanol, tetrahydrofuran, acetone and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the multifunctional gelatin leather finishing agent. The finishing agent has the characteristics of strong hydrophobicity, flexible film, antibacterial property, high heat stability, organic solvent resistance, wet scrubbing resistance and the like.

Owner:山东山科美谷科技发展有限公司

Polysiloxane and glycidol-containing strong-hydrophobicity gelatin leather finishing agent and preparation method

ActiveCN103436168APlay a plasticizing roleImprove performanceFibre treatmentProtein coatingsActive agentPolytetrafluoroethylene

The invention relates to a polysiloxane and glycidol-containing strong-hydrophobicity gelatin leather finishing agent and a preparation method. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding glycidol into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding a surfactant into a second reaction flask, continuously stirring, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 2, wherein the using amount of the surfactant is 0.5-20 percent of the mass of the gelatin; mixing the solution 1 and the solution 2 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or two or three of ethanol, tetrahydrofuran and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the gelatin leather finishing agent with a superior function. The finishing agent has the characteristics of strong hydrophobicity, super extensibility, heat resistance, oxidation resistance, wet scrubbing resistance and the like.

Owner:QILU UNIV OF TECH

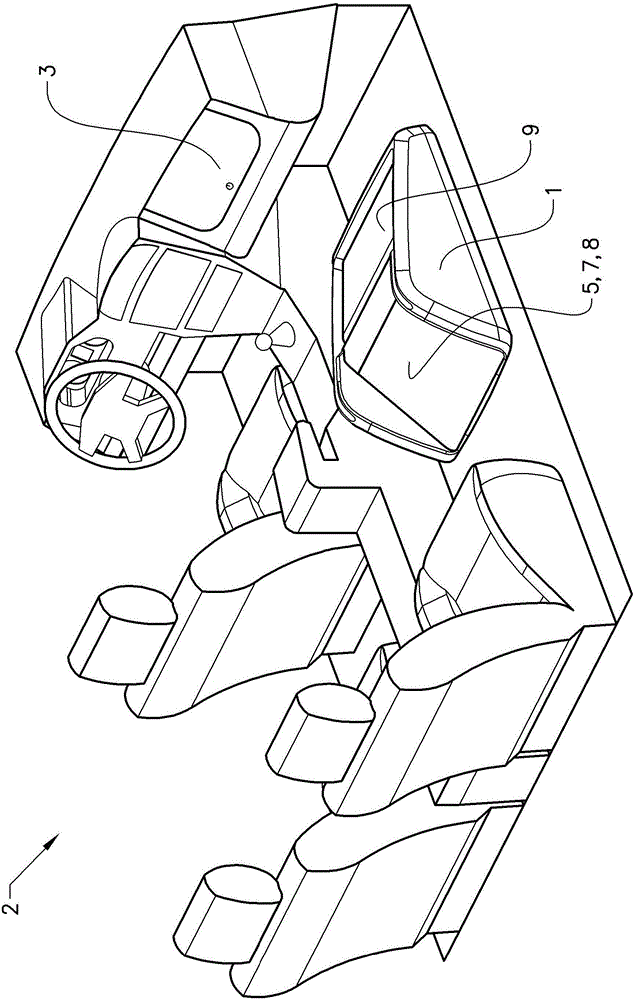

Multi-functional catering module for arrangement in vehicle

The invention relates to a multi-functional catering module (1) for arrangement in a passenger compartment of a vehicle and a vehicle. The catering module (1) is arranged to be mounted to seat rails of the passenger compartment and arranged to be movable along the seat rails between at least a first user position and a stowage position. The catering module (1) comprises at least one service or entertainment option.

Owner:VOLVO CAR CORP

High-weather-resistance aluminum alloy profile

The invention discloses a production method of a high-weather-resistance aluminum alloy profile. The method includes the steps of mixing and smelting, casting, annealing, heat treatment achieved through a two-step method, two-stage aging and air cooling of the aluminum alloy profile, and finally oxidization treatment, wherein in the step of mixing and smelting, mixing is carried out on raw materials, by mass percent, 7-8.8% of Zn, 0.8-1.5% of Cu, 1-4% of Fe, 2-3% of Mn, 2-3% of Mg, 0.2-0.5% of Si, 0.2-0.8% of Cr, 0.08% of Ni, 0.03% of Ti and the balance Al, the materials are smelted for 6-8 hours at high temperature to obtain an aluminum alloy solution; in the step of heat treatment achieved through the two-step method, aluminum alloy cast ingot obtained after treatment is extruded into the aluminum alloy profile through an aluminum alloy profile die. The aluminum alloy profile which is super resistant to weather and corrosion can be manufactured without spraying, energy conservation and environment protection are achieved, and safety performance is high.

Owner:浙江米皇新材股份有限公司

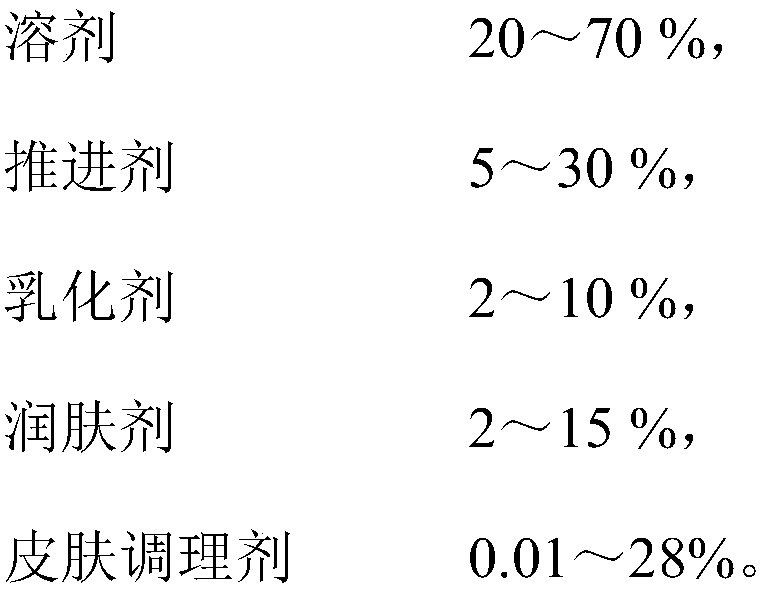

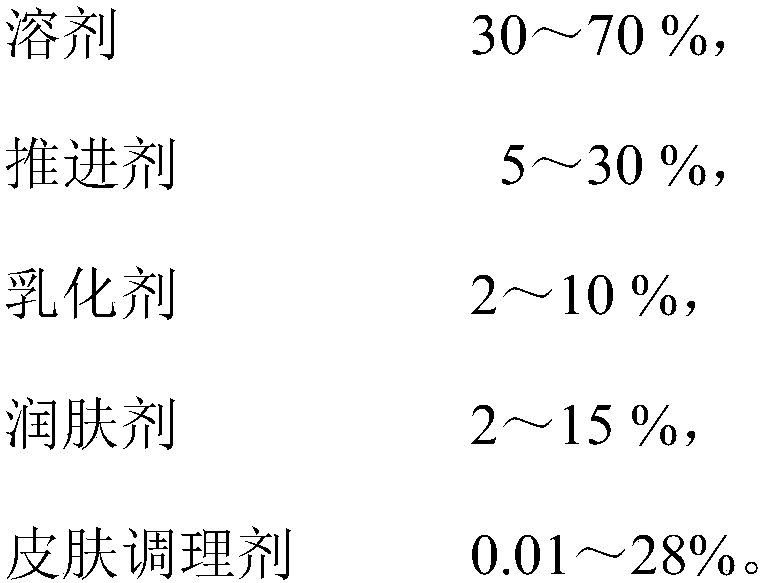

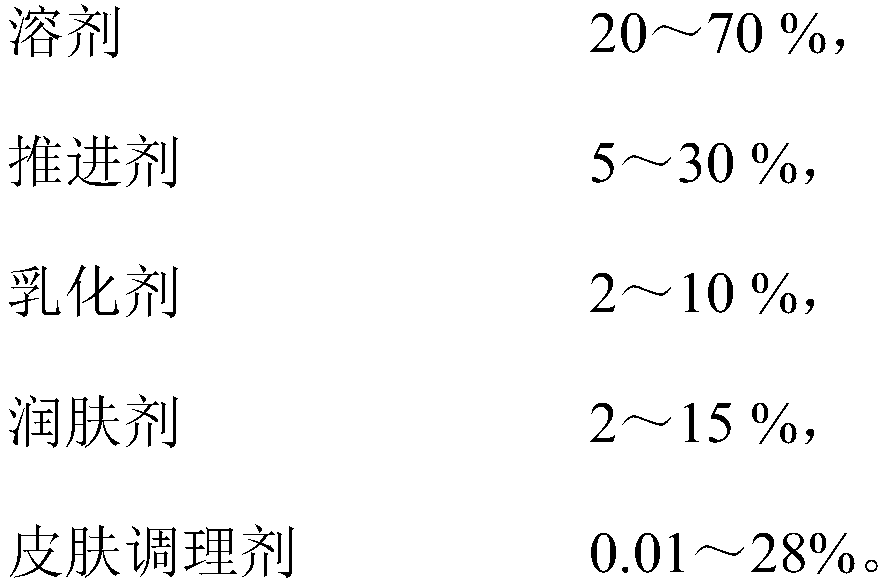

Mild makeup removing mousse and preparation method thereof

The invention discloses mild makeup removing mousse and a preparation method thereof. The mousse is prepared from the following components in percentage by weight: 30 to 70 percent of a solvent, 5 to30 percent of a propellant, 2 to 10 percent of an emulsifier, 2 to 15 percent of a skin moistening agent and 0.01 to 28 percent of a skin conditioning agent. The preparation method comprises the following steps: mixing the solvent with the emulsifier and part of the skin moistening agent and stirring until the materials are uniformly dispersed and dissolved; while stirring, adding the residual skin moistening agent and the skin conditioning agent; uniformly stirring until the materials are completely dispersed and dissolved to form material liquid; packaging the material liquid through an aerosol can and filling with the propellant; detecting that a product is qualified. According to the mild makeup removing mousse disclosed by the invention, a grease raw material is combined with aerosolpackaging and a unique emulsifying system; a material body is shown in a dense and elastic form; the mild makeup removing mousse has the advantages of no additives, easiness for washing and no residues; the dense makeup removing oil mousse can enter pores to dissolve makeup powder in the pores, so that a face is cleansed, and the makeup is more completely removed; the mild makeup removing mousse is convenient to use and easy to carry.

Owner:ZHONGSHAN TIANTU FINE CHEM CO LTD

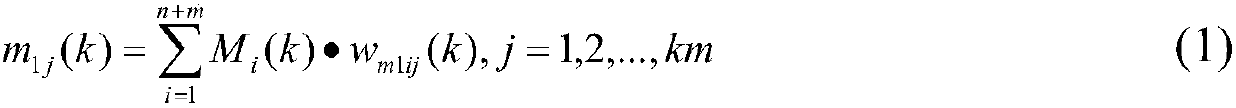

Car active noise reduction method based on heuristic dynamic programming

ActiveCN107791970ARespond effectivelyGood noise reduction in the carSound producing devicesElectric/fluid circuitFrequency spectrumAlgorithm

The invention discloses a car active noise reduction method based on heuristic dynamic programming, and belongs to the field of active noise reduction methods of noise in car rooms. According to the car active noise reduction method, massive data in a large database of noise information in a virtual environment of a cloud server are initiatively fitted, the rule of noise frequency spectrum characteristics in the database is looked for through a model network and an execution network trained by heuristic dynamic programming, the noise data with the similar frequency spectrum characteristics arefitted together, an off-line expert library having the less data size and reduced and generated from a huge database is established, so that optimization of the noise data is achieved, and the optimal control quantity is provided for a system. According to the innovative mode, the method can overcome the drawback that an existing car active noise reduction method needs to conduct one-by-one real-time operation on the massive data, and through practical testing, the method can fully meet requirements of noise reduction of an actual traffic car under a real road condition, so that the car active noise reduction method has great market prospect and potential economic value.

Owner:长春一汽四环汽车管路有限公司

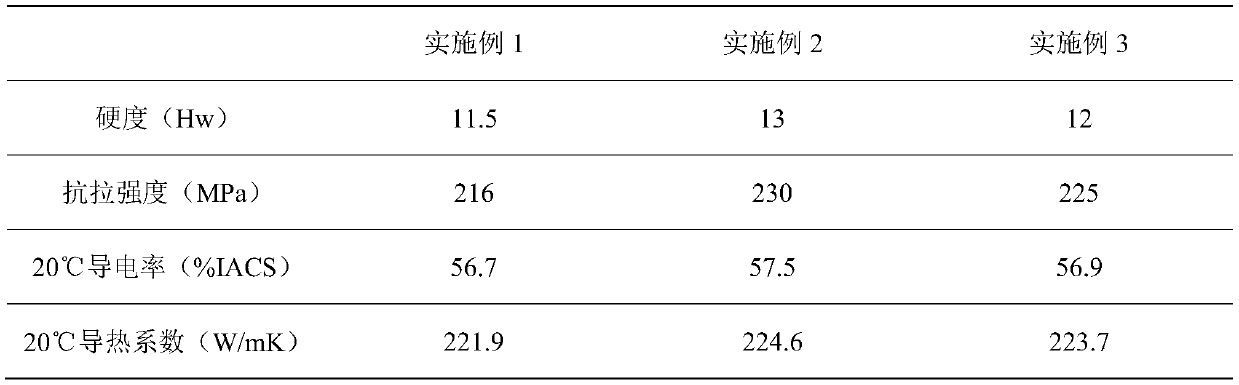

Preparation process of high-thermal-conductivity extruded aluminum alloy profile

ActiveCN110343884ASimple preparation processOptimizing aging process parametersSolution treatmentHardness

The invention discloses a preparation process of a high-thermal-conductivity extruded aluminum alloy profile. The preparation process comprises the following steps of 1) extrusion, 2) refining, 3) extruding, and 4) effectiveness and the like. An online air cooling technology is adopted, the process of solid solution treatment is omitted, so that the production efficiency is improved; and optimization is carried out on various parameters, especially effective parameters in the preparation process so as to obtain an optimal scheme. According to the preparation process, the formula of the aluminum alloy is improved, the content of Mg and Si in the aluminum alloy component is reduced, Mg / Si ratio is controlled, so that the type of the alloy is in a slightly excess type of Si, and the harmful effect of V is eliminated by adding the boron adding element. On the premise of keeping the hardness, the conductivity of the product is improved. Through verification, the vickers hardness of the product can reach more than 11 Hw or above, the tensile strength is higher than 215 Mpa, the electric conductivity at 20 DEG C is higher than 56% IACS, and the heat conductivity coefficient can reach 220W / mK or above, and all technical parameters reach the world leading level.

Owner:JIANGSU WEITENG COPPER CO LTD

Method for preparing diisopropanolamine

ActiveCN101265197AMeet high-end needsLess operating costs for productionOrganic compound preparationAmino-hyroxy compound preparationMonoisopropanolaminePesticide

The invention relates to a method of manufacturing diisopropanolamine. Liquid ammonia and water are mixed to form ammonia water which is fully mixed with propylene oxide; the mixed solution is preheated until the temperature reach 140 to 145 DEG C and then is delivered into a reactor for reacting, the temperature is controlled within 148 to 155 DEG C when in reacting, the pressure is controlled within 16.0 to 18.0MPa, the inputting molar ratio of the ammonia and the propylene oxide is controlled within 5 to 8, and the reaction is fully performed for 1.5 to 3 hours; the mixture products obtained in the reaction are separated to obtain isopropanolamine products, diisopropanolamine products and triisopropanolamine products through flash evaporation and rectification in a stepwise way. In the diisopropanolamine products which are manufactured by adopting the method, the component of 1, 1<1>-nitrousalkyl-dipropyl-2-alcohol accounts for more than 99 percent (hereinafter referred to as mass percent), and the isomeride thereof is less than 1 percent. In addition, the cost of the production operation in the method is less, the production cost is low, the product quality is high, and the high-end requirement of products such as synthetic medicine, farm insecticide, etc. is satisfied.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

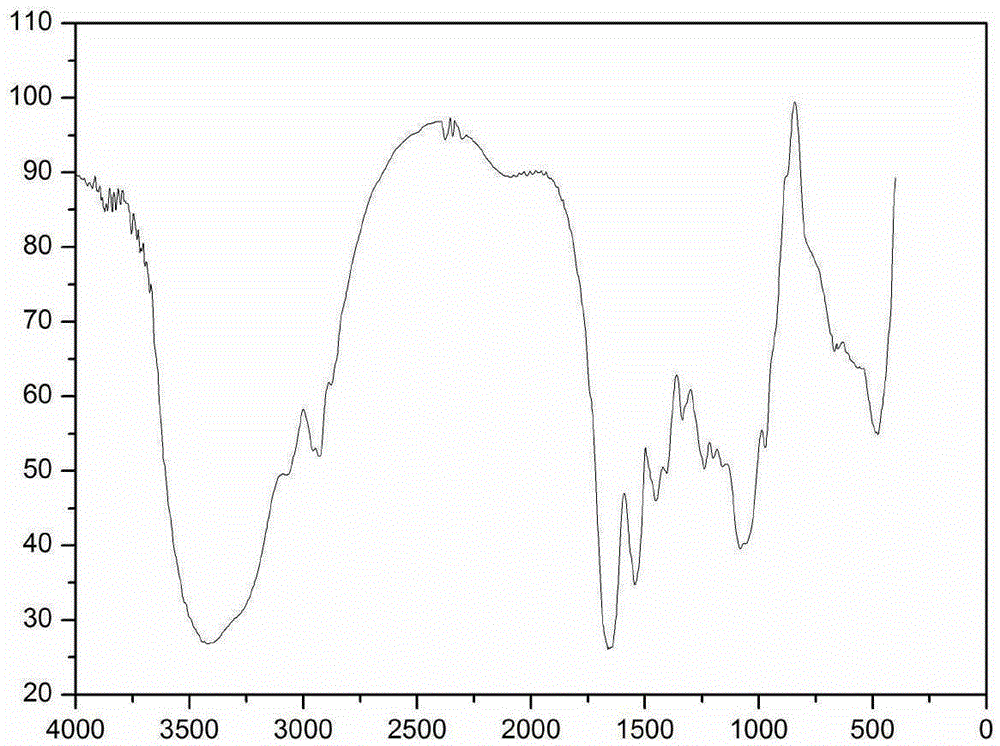

Retanning agent for improving tearing strength of leather and preparation method of retanning agent

InactiveCN108219162AHigh tear strengthImprove antibacterial propertiesTanning treatmentHydrogenHydrogen atom

The invention relates to a retanning agent for improving tearing strength of leather and a preparation method of the retanning agent. The retanning agent is prepared from 2,3-glycidyl ethyl methyl ethylamine chloride grafted gelatin polymer; preparation raw materials of the polymer comprise 2,3-glycidyl ethyl methyl ethylamine chloride and gelatin; for the polymer obtained by addition reaction ofepoxy group of the 2,3-glycidyl ethyl methyl ethylamine chloride and hydrogen atoms of primary amine on gelatin molecules, the breaking elongation is 19mm and the strength is 0.25 to 0.40MPa; the glass transition temperature is 190 to 218 DEG C, the antibacterial rate is 40 to 90 percent, the adsorption dye rate is 60 to 78 percent and the thickening rate is 110 to180 percent. The retanning agentcan significantly improve the tearing strength of the leather, and has the advantages of antibacterial property, adsorption and fixing of dye, bright coating colors and the like.

Owner:QILU UNIV OF TECH

High-toughness heat-resistant Mg-Gd alloy suitable for gravity casting and preparation method thereof

The invention provides a high-toughness heat-resistant Mg-Gd alloy suitable for gravity casting and a preparation method thereof. The alloy comprises the following chemical components of, in percentage, 4.0-10.0% of Gd, 2.0-6.0% of Zn, 0.5-1.2% of Al, 0.1-0.3% of Mn, 0.01-0.08% of M, and the balance Mg, wherein the M is one or two elements of Ti and B; the preparation method comprises the following steps that (1) burdening is performed according to a Mg-Gd alloy component; (2) an industrial pure magnesium ingot is melted; (3) heating is performed to 700 DEG C, and industrial pure zinc, an Mg-Gd and Mg-Mn intermediate alloy are melted; (4) heating is performed to 730 DEG C, after an industrial pure aluminum ingot, Al-Ti, Al-Ti-B and Al-B intermediate alloys added are all melted, refining isperformed to obtain a magnesium alloy melt; (5) gravity casting is performed; and (6) secondary solid solution and artificial aging treatment are performed. According to the high-toughness heat-resistant Mg-Gd alloy and the preparation method, after the alloy is subjected to the gravity casting, the secondary solid solution treatment and the artificial aging heat treatment, the tensile strength at room temperature is 300 MPa, the elongation percentage is 15%, the high-temperature tensile strength at 200 DEG C is 218 MPa, the elongation percentage is 20%, and the high-end requirement for lightweight development in the industries of aerospace, automobiles, telecommunication and the like is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Corrosion-resistant aluminum alloy profile

ActiveCN104962786AReduce production processShorten the production cycleAlloyUltimate tensile strength

The invention discloses a production method of a corrosion-resistant aluminum alloy profile. The corrosion-resistant aluminum alloy profile comprises, by mass percent, 3%-8% of Cu, 2%-5% of Fe, 5%-9% of Mn, 1%-2% of Mg, 1%-2% of Zn, 0.3%-0.8% of Si, 0.1% of Ni, 0.05% of Ti and the balance Al. The materials are smelted for 6-8 hours at high temperature to obtain molten aluminum alloy; horizontal continuous casting is carried out on the obtained molten aluminum alloy and cleaning is conducted; the aluminum alloy profile is obtained through continuous extruding and forming; second-stage aging heat treatment is carried out on the obtained aluminum alloy profile, and a finished corrosion-resistant aluminum alloy profile product is obtained. The alloy production process is simplified and the alloy production period is shortened without homogenization and pre-heating treatment, and the energy-saving and environment-friendly production requirements of a short-process technology are completely met. Besides, the manufactured aluminum alloy profile has excellent corrosion resistance and tensile strength and can meet high-end requirements increasing day by day.

Owner:浙江米皇新材股份有限公司

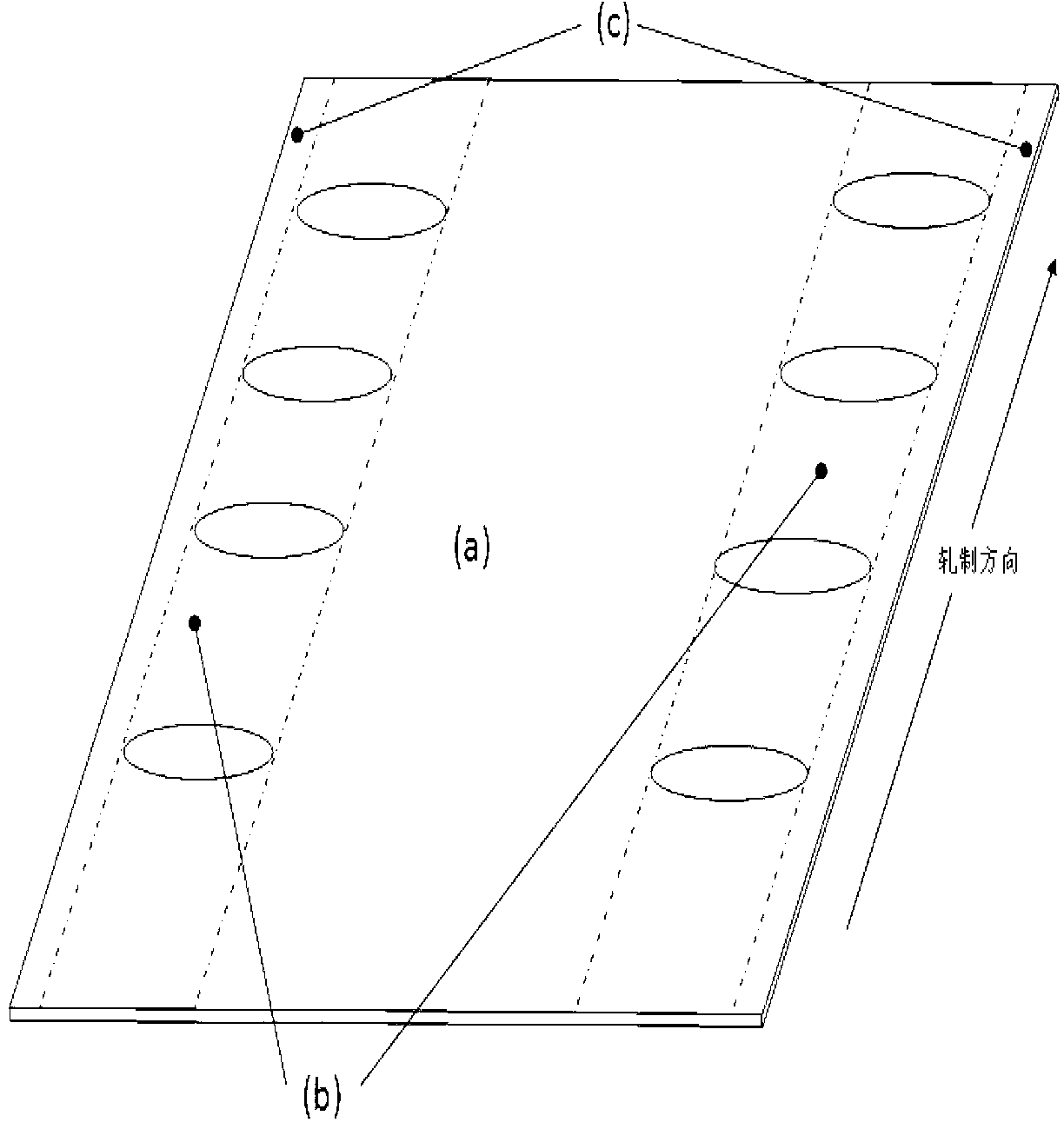

Method for manufacturing civil high-grade anti-theft door plank

ActiveCN103290311ARefined grain structureImprove uniformityBurglary protectionDoor leavesClosed loopHigh surface

The invention relates to a method for manufacturing a civil high-grade anti-theft door plank. The method comprises the steps of (1) obtaining a continuous casting slab by molten iron desulphurization, converter smelting, RH vacuum treatment and continuous casting for forming blanks; heating the continuous casting slab; carrying out high-pressure water descaling, rough rolling, finish rolling, laminar cooling and reeling on the heated slab after discharging from a furnace; and (2) uncoiling, pickling and trimming a hot rolled coil obtained in the step (1), rolling the rolled coil into cold-strip steel by a reversing cold rolling machine with a single frame, carrying out hood annealing treatment after degreasing, and finally carrying out smoothing, finishing and electrostatic oiling to obtain the civil high-grade anti-theft door plank. The method disclosed by the invention is stable to operate, convenient to use, free of new introduction of any production equipment, and free of increase the technological process of production; the production cost is not increased; the defect that a closed-loop vortex wave is generated when the surface of an ultra-low carbon cold-roll steel sheet is close to the edge part of the steel sheet can be effectively overcome; and the demand of the civil high-grade anti-theft door plank on high surface quality is met.

Owner:NINGBO IRON & STEEL

High-toughness heat-resisting pressure casting Mg-Gd alloy and preparation method thereof

The invention provides a high-toughness heat-resisting pressure casting Mg-Gd alloy and a preparation method thereof. The high-toughness heat-resisting pressure casting Mg-Gd alloy comprises components including, by stoichiometric ratio, 4.0%-8.0% of Gd, 1.2%-4.8% of Zn, 0.5%-1.2% of Al, 0.1%-0.3% of Mn, 0.01%-0.08% of M and the balance Mg, wherein M is one or two elements of Ti and B. The preparation method comprises the steps that firstly, materials are prepared according to Mg-Gb alloy components; secondly, industrial pure magnesium ingots are melted; thirdly, the temperature is raised to 720 DEG C, industrial pure zinc, Mg-Gd and Mg-Mn intermediate alloys are added and stirred to be completely melted; fourthly, the temperature is raised to 730 DEG C, after industrial pure aluminum ingots, Al-Ti, Al-Ti-B and Al-B intermediate alloys are sequentially added, magnesium alloy melt is obtained after refining; and fifthly, the magnesium alloy melt is cooled to a pressure casting temperature so as to be subjected to pressure casting, and a pressure casting alloy is obtained. The strength of extension of the alloy in a pressure casting state at the room temperature reaches 318 MPa, thestrength of extension of the alloy at the high temperature of 200 DEG C reaches 218 MPa, the room temperature ductility reaches 12.0%, the high-toughness heat-resisting pressure casting Mg-Gd alloy can be used without aging or solution heat treatment, and the high-end requirement of aerospace and other industries for light weight is met.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

Method of synthesizing monoisopropanolamine

ActiveCN101265196BMeet high-end needsImprove qualityOrganic compound preparationAmino-hyroxy compound preparationDistillationSynthesis methods

The invention relates to a synthesis method of isopropanolamine. The synthesis method comprises the following steps: (1) liquid ammonia and water are mixed to form ammonia water which is mixed with propylene oxide; mixed solution is preheated until the temperature reaches 120 to 125 DEG C, and the inputting molar ratio of the ammonia and the propylene oxide is controlled within 10 to 15; (2) the materiel after preheating is delivered into a reactor, the reaction temperature ranges from 128 to 138 DEG C, the pressure ranges from 12.6 to 13.8MPa, and the reaction time ranges from 1.5 to 3 hours; (3) the surplus unreacted ammonia is separated from the obtained mixture after the reaction by using a flash distillation column, the pressure in the flash distillation column ranges from 0.6 to 1.6MPa, and the temperature of a column kettle ranges from 140 to 160 DEG C; (4) the mixture which is separated through the flash distillation column is delivered into a leading tower for rectification dehydration, the pressure in the leading tower ranges from minus 0.080 to minus 0.085MPa, the temperature at the top of the leading tower is 45 to 55 DEG C, and the temperature at the bottom in a towerkettle ranges from 110 to 130 DEG C; (5) the mixture after dehydration is delivered into a rectification column for rectification, the pressure in the rectification column ranges from minus 0.095 to minus 0.099MPa, the temperature in the column kettle ranges from 135 to 160 DEG C, the temperature at the top of the rectification column ranges from 60 to 70 DEG C, isopropanolamine products are obtained at the top of the rectification column, and the mixture composed of diisopropanolamine and triisopropanolamine is obtained in the column kettle. The synthesis method has simple production procedure, little equipment investment, and high product quality.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

Treating technology for all-cotton yarn leather skin-feel coating

The invention relates to the field of textile processing and specifically relates to a treating technology for an all-cotton yarn leather skin-feel coating. The treating technology comprises the following steps: S1) pre-treating: turning and unwinding a gray cloth, sewing and singeing; S2) primarily treating: unwinding, scouring and bleaching the pretreated gray cloth and then continuously polishing; S3) continuously dyeing the gray cloth; S4) settling, sizing and preshrinking the dyed gray cloth; S5) checking the end product; S6) finishing the coating. The invention has the beneficial effectsthat the gray cloth reaching the standard is selected, the weft and warp tear resistance and fastness of cotton yarn both can reach up to above 15N and the coating can meet the high-end requirementsof the market after the all-cotton yarn leather skin-feel coating is treated according to the treating technology provided by the invention, the treated fabric is a leather skin-feel coating, the overall style has a velvet feel and leather effect, the overall style has elasticity and vertical feel after water washing, the quality and style are guaranteed while the comfort and filling power are guaranteed.

Owner:无锡佳纺面料有限公司

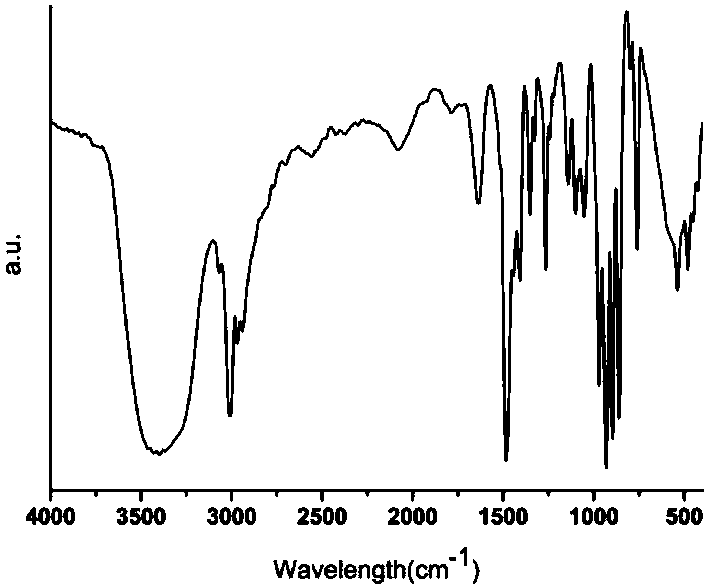

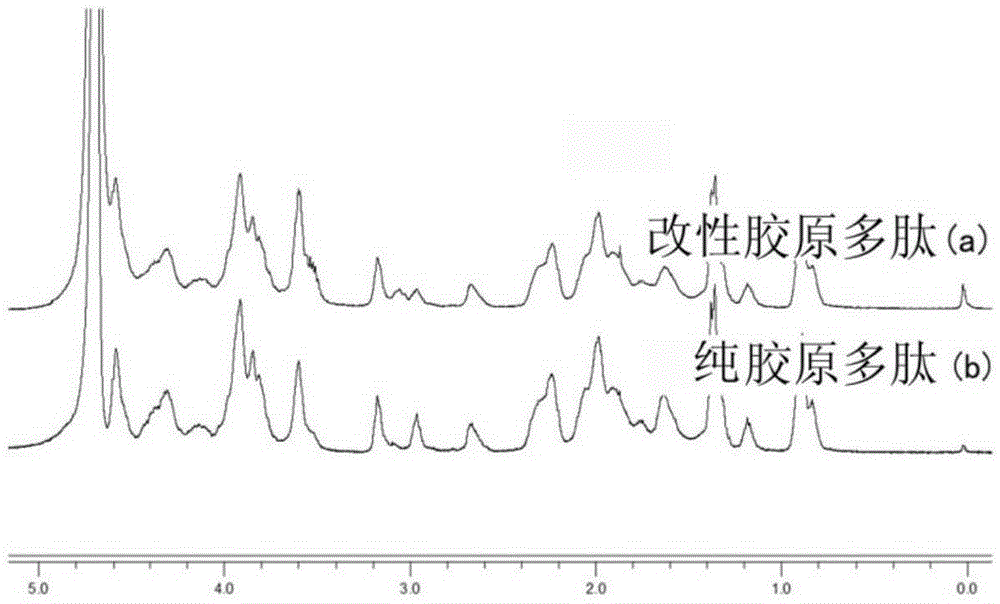

Preparation of mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane by freeze-drying method

The present invention relates to preparation of a mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane by a freeze-drying method. Surfactant sodium alkyl sulfate is dissolved in water and formulated into an aqueous solution, the aqueous solution is stirred for 1-2h at 40-60 DEG C under the condition of pH of 8 to 11, gelatin is added, stirring is performed for 4-8h, and mono-epoxy-terminated polysiloxane with the molecular weight of 500 is added to obtain a mono-epoxy-terminated polysiloxane-modified gelatin solution. The mono-epoxy-terminated polysiloxane-modified gelatin solution is centrifuged at a low temperature, after layering, water is added into an intermediate layer for even mixing, ethanol is added, after even mixing, 0.5-0.8ml of the mixture is measured and dropwise added into a gelatin substrate, standing is performed for 12-18h, liquid nitrogen is used for freezing, and the freeze-drying method is used for drying to obtain the mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane. The mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane has the characteristics that component concentration change is gradient in longitudinal section, and the mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane is high in tensile strength, good in hydrophobicity and soft, and so on.

Owner:山东山科美谷科技发展有限公司

Method for protecting color and improving stability for non-concentration reduction pear juice

PendingCN110692876ARich in nutritional valueObvious browning inhibition effectFood ingredient as taste affecting agentFood ingredient as flavour affecting agentBiotechnologyBrowning

The invention provides a processing method to solve the problem of brown stain of non-concentration reduction pear juice and improving stability. Kiwi fruit pulp is added, and high-pressure homogenizing treatment is combined. The processing method specially comprises the following steps of selecting raw materials of pears and kiwi fruits, performing cleaning, performing cutting, performing squeezing to obtain juice, performing enzymolysis, performing filtration, performing high-pressure homogenizing, performing deaeration and performing sterilization. The kiwi fruit pulp is combined with the high-pressure homogenizing treatment, so that the particle size of the pear juice can be reduced, the stickiness and the yield stress of a system can be improved, and the system stability of the pear juice can be improved. Besides, the kiwi fruit pulp is rich in vitamin C, so that the brown stain of the pear juice can be effectively avoided. The obtained non-concentration reduction pear juice is completely blended from the kiwi fruit pulp, is attractive in color, outstanding in flavor, unique in mouth feel and rich in nutrients, and can meet high-end requirements of consumers.

Owner:BOHAI UNIV

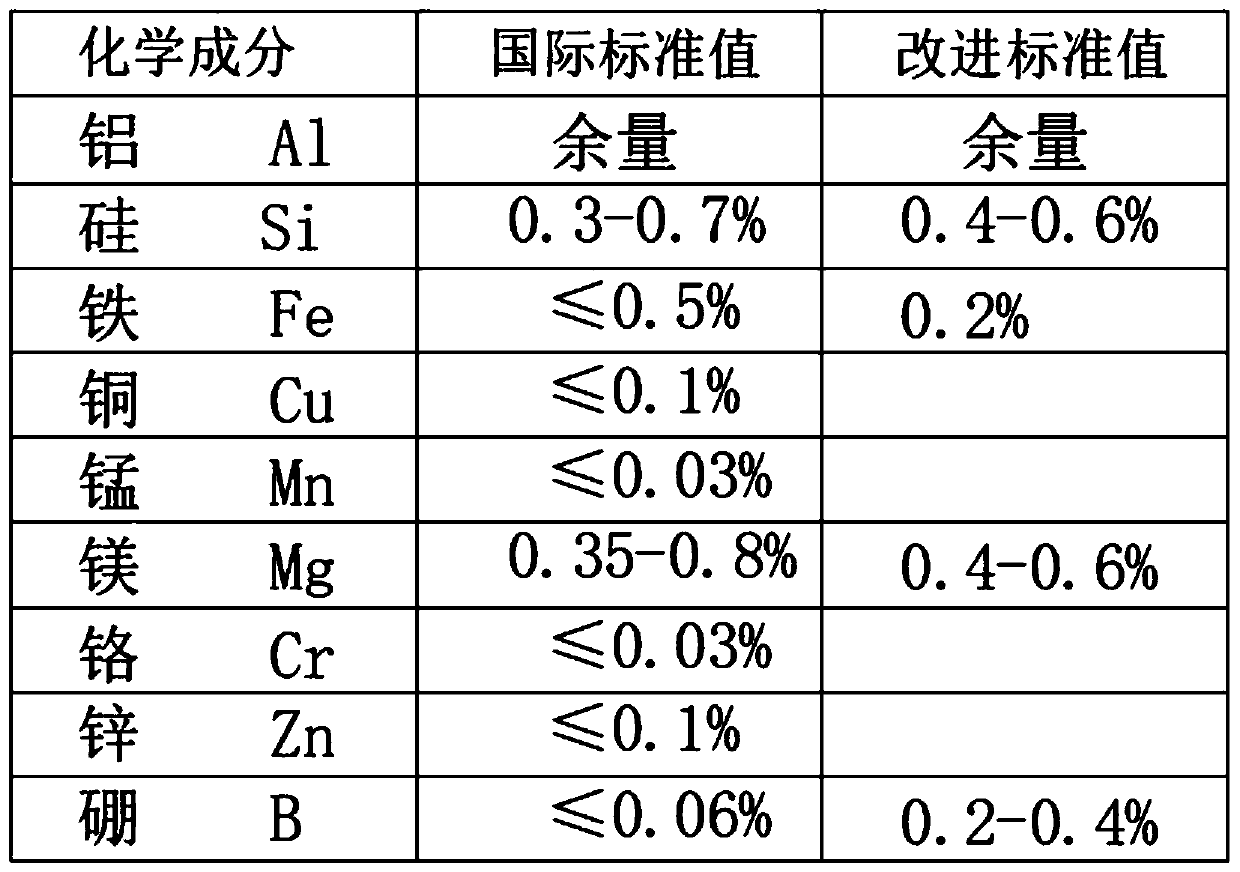

Aluminum alloy conducting material

InactiveCN110453116AAdjust heat treatment processImprove practicalitySurface reaction electrolytic coatingElectrophoretic coatingsMetallurgyHeat treated

The invention discloses an aluminum alloy conducting material. The aluminum alloy conducting material comprises the main ingredients including, by mass, not larger than 0.1% of Zn, not larger than 0.03% of Mn, 0.4%-0.6% of Mg, 0.4%-0.6% of Si, 0.2% of Fe, not larger than 0.1% of Cu, not larger than 0.03% of Cr, 0.2%-0.4% of B and the balance Al. Six steps are included. The mark of the developed new product is 6101-T7, the alloy ingredients of an aluminum alloy are changed, and the stability of molecules in the aluminum alloy is improved; the overall ingredients and texture are more stable, thehigh-end needs of domestic electric products and the conducting needs of users are effectively met, an aluminum alloy heat treatment process is adjusted, it is guaranteed that the overall conductingproperty is more stable, and it is ensured that the aluminum alloy reaches the index requirement that the conductivity is larger than or equal to 32% IACS; and the practical performance of the aluminum alloy is improved, the practicality and superiority of the process of the aluminum alloy conducting material are guaranteed so that the aluminum alloy conducting material can be popularized and applied early at the later stage.

Owner:昆山山鑫铝业有限公司

Aluminum alloy door frame

InactiveCN107035271AHigh strengthImprove mechanical propertiesMolten spray coatingWindow/door framesManganeseMethylbenzoprim

The invention provides an aluminum alloy door frame. The aluminum alloy door frame comprises an aluminum alloy base material and a functional coating with which the surface of the aluminum alloy base material is coated. The aluminum alloy base material is prepared from, by weight, 5-8 parts of silicon, 6-10 parts of nickel, 5-8 parts of chromium, 1-2 parts of copper, 0.5-1 part of iron, 1-2 parts of manganese, 1-2 parts of magnesium, 1-2 parts of zinc, 0.5-1 part of titanium, smaller than or equal to 200 ppm of calcium, 0-0.2 part of lead, 0-0.05 part of cadmium and the balance aluminum. The functional coating is prepared from 20-50 parts of butadiene rubber, 20-50 parts of filler, 8-10 parts of plasticize and 3-10 parts of coupling agent. The filler is prepared from, by mass, 30-60% of aluminum oxide-titanium dioxide composite, 20-40% of manganese dioxide and 10-40% of silicon dioxide. The lubricating agent is organic silicon oil, the coupling agent is isopropyl trioleate trioleate, and the plasticizer is diethylene glycol dimethyl benzoate. The aluminum alloy door frame is high in surface strength, good in corrosion resistance and scraping resistance and attractive in appearance.

Owner:合肥市旺友门窗有限公司

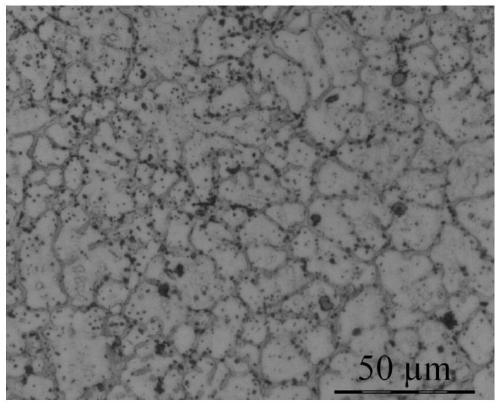

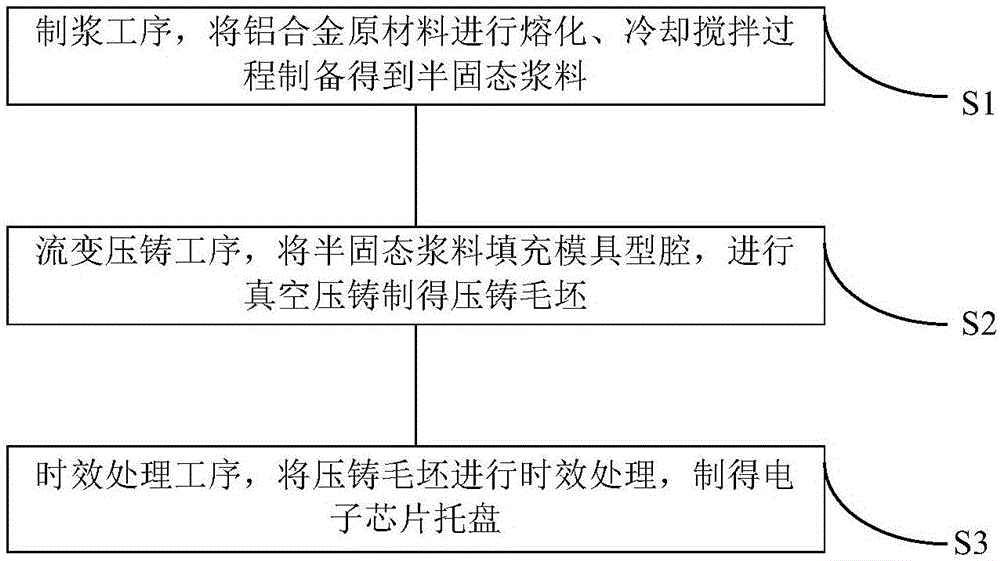

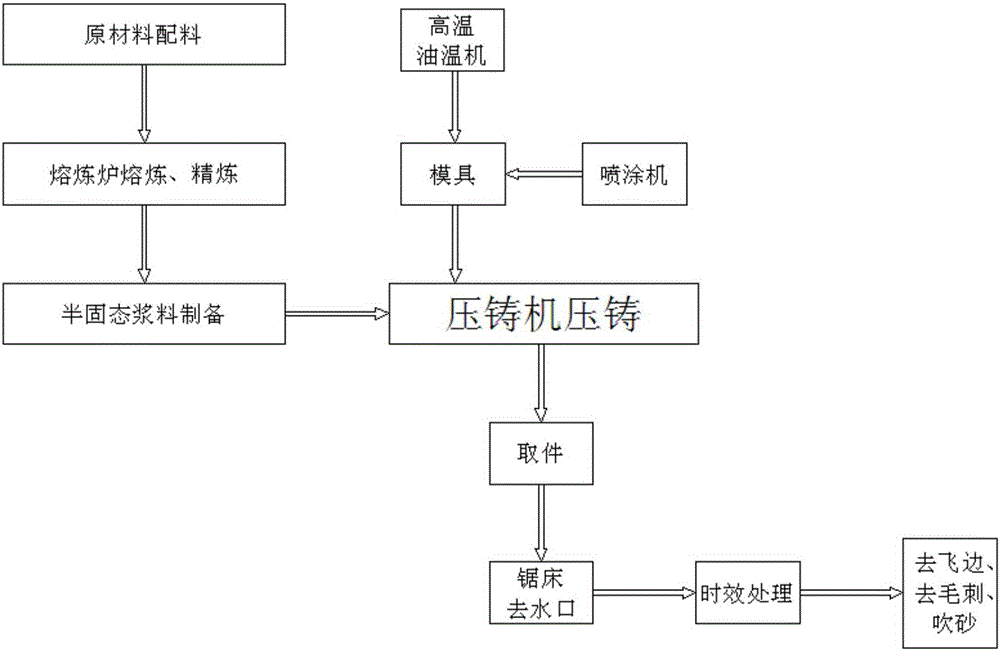

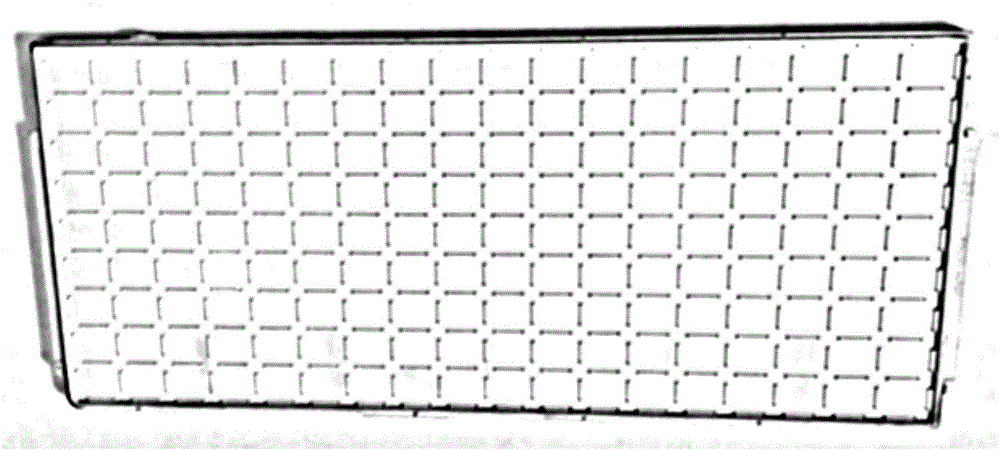

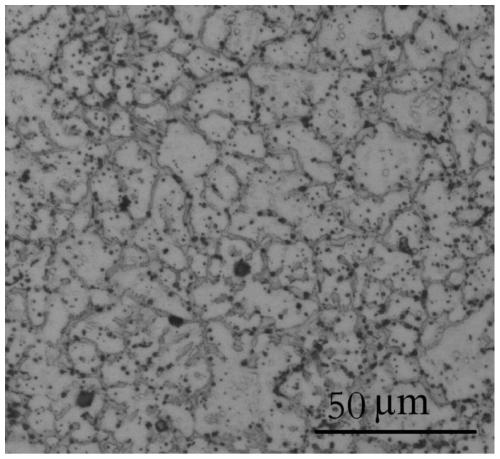

Aluminum alloy electronic chip tray and preparation process thereof

ActiveCN107520419AMeet the design requirementsMeet high-end needsSemiconductor/solid-state device manufacturingSemi solidDie casting

The invention provides a preparation process of an aluminum alloy electronic chip tray. The electronic chip tray is produced through a semi-solid rheo-diecasting process. The production process specifically comprises a pulping procedure, a rheo-diecasting procedure and an aging treatment procedure. Vacuum die casting is adopted as a die casting manner. The aluminum alloy electronic chip tray prepared through the preparation process has the excellent performance of an aluminum material, effectively overcomes the technical problem that an aluminum alloy material is prone to deforming when heated, is small in heat deformation and has excellent appearance quality and anti-static performance; the market application of the electronic chip tray is opened up; the application field of die castings is expanded; and the aluminum alloy electronic chip tray produced through the preparation process is further requested to be protected.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

Modified gelatin gradient film prepared from mixed glycidol and single-epoxy-terminated polysiloxane

The invention relates to a modified gelatin gradient film prepared from mixed glycidol and single-epoxy-terminated polysiloxane. A method for preparing the modified gelatin gradient film includes dissolving surfactants in water to prepare aqueous solution; adding gelatin into the aqueous solution under the conditions of the temperatures of 40-60 DEG C and the pH (potential of hydrogen) of 8-11; stirring the gelatin and the aqueous solution for 4-8 h and then adding the single-epoxy-terminated polysiloxane into the gelatin and the aqueous solution continuously or in batches to obtain mixtures; carrying out reaction for 12-30 h and then adding glycidol into the mixtures; continuing to carry out reaction at the temperatures of 40-60 DEG C for 6-12 h to obtain milk white turbid liquid; adding ethyl alcohol into the milk white turbid liquid and uniformly mixing the ethyl alcohol with the milk white turbid liquid to obtain mixed liquid; dripping 0.5-0.8 ml of the measured mixed liquid on gelatin substrates; allowing the gelatin substrates to stand still for 12-18 h and then freezing the gelatin substrates by the aid of liquid nitrogen; drying the gelatin substrates by the aid of a freeze dryer to obtain the gradient film. The dosage of the gelatin is 1-10% of the mass of the aqueous solution. The dosage of the single-epoxy-terminated polysiloxane is 0.2-1.0 times the molar weight of the gelatin. The dosage of the glycidol is 0-1 times the mass of the single-epoxy-terminated polysiloxane. A volume ratio of the ethyl alcohol to reaction liquid is (3-5):1. The modified gelatin gradient film has the advantages that the concentration of components of the modified gelatin gradient film changes in longitudinal sections in a gradient manner, the modified gelatin gradient film is high in tensile strength and good in hydrophobic property and is soft, and the like.

Owner:山东山科美谷科技发展有限公司

Pressure casting Mg-Er alloy with high strength, high toughness and heat resistance and preparation method thereof

The invention provides a pressure casting Mg-Er alloy with high strength, high toughness and heat resistance and a preparation method thereof. The alloy is composed of, by mass, 4.0-8.5% of Er, 1.2-5.1% of Zn, 0.5-1.2% of Al, 0.1-0.3% of Mn, 0.01-0.08% of M, and the balance Mg, wherein the M is one or two elements of Ti and B. The preparation method comprises the following steps of (1), proportioning according to the composition of the Mg-Er alloy; (2), melting industrial pure magnesium ingots; (3), heating up to 720 DEG C, adding industrial pure zinc, Mg-Er and Mg-Mn master alloys, and stirring to melt completely; (4), heating up to 730 DEG C, and totally melting the industrial pure aluminum ingots, Al-Ti, Al-Ti-B and Al-B master alloys added in sequence to obtain a magnesium alloy melt;and (5) cooling the magnesium alloy melt to pressure casting temperature to carry out pressure casting to obtain the pressure casting alloy. After the die casting of the alloy, the tensile strength ofthe pressure casting alloy reaches 302 MPa at room temperature, the tensile strength reaches 205 MPa at the high temperature of 200 DEG C, the room temperature elongation reaches 15.0%, and the alloycan be used without aging and solid solution heat treatment to meet the high-end requirement of lightweight in aerospace and other industries.

Owner:FENGYANG L S NET FORMING CO LTD

Shower gel

InactiveCN105520866AReduce contentMeet high-end needsCosmetic preparationsToilet preparationsShower gelChemical preparation

The invention discloses a shower gel. In terms of the total mass, each kilogram of the shower gel consists of 50-80g of a shower gel surfactant, 30-50g of a pearl concentrate, 20-50g of thickening powder, 1-1.5g of plant essential oil and the balance of water, wherein preferably, the water is selected from purified water, activated water or ionized water. The shower gel disclosed by the invention can solve the problem of the prior art which, although being high in quality and inexpensive, is not exquisite enough; and the shower gel can reduce the content of chemical preparations to the greatest extent and achieve exquisite appearance and delicate fragrance, so as to meet the high-grade demands of some families.

Owner:SHAANXI JINHAOYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

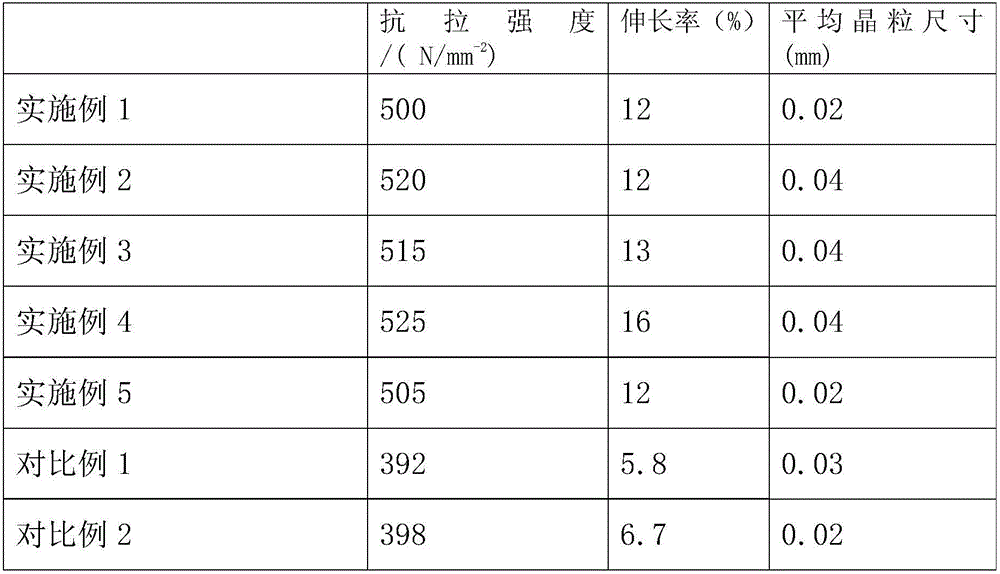

A kind of production technology of environment-friendly high-toughness duralumin alloy profile

ActiveCN104975213BReduce production processShorten the production cycleDuraluminUltimate tensile strength

The invention discloses an environment-friendly high-toughness hard aluminum alloy profile production process. The production process comprises burdening and smelting; the burdening is performed for the following component in percentage by mass: 5-5.5% of Cu, 2-4.5% of Fe, 0.1-0.3% of Mn, 0.5-3% of Mg, 1.1-1.5% of Zn, 0.1-1% of Si, 0.1% of Ni, 0.2% of Ti, and the balance of Al; the smelting is performed for 6-8 h under high temperature to obtain aluminum alloy molten liquid; and then, the horizontal continuous casting, the continuous extrusion and the three-stage ageing heat treatment are performed. The process shortens the alloy production process and period without needing the homogenization and the preheating treatment, and totally accords with the production requirements of energy conservation and greenness of a short-flow process; and a prepared aluminum alloy profile has excellent toughness and tensile strength, and can satisfy the gradually increasing high-end demands.

Owner:浙江米皇新材股份有限公司

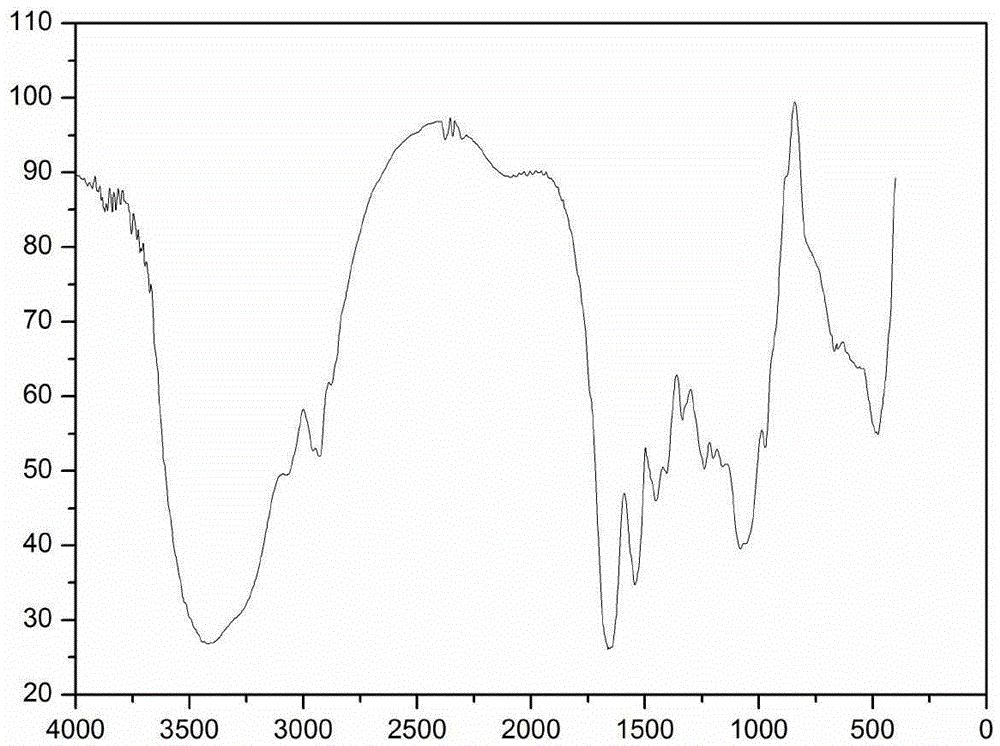

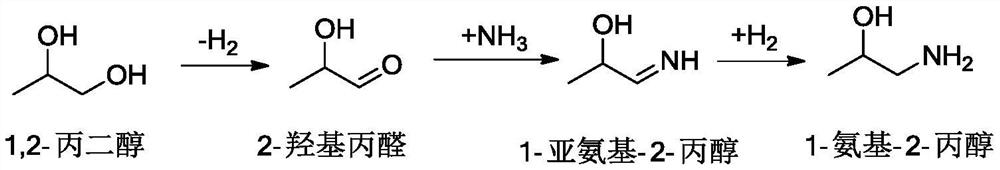

Method for preparing monoisopropanolamine

ActiveCN112125814AAvoid flammable and explosiveMeet high-end needsOrganic compound preparationPreparation by dehydrogenationPtru catalystMonoisopropanolamine

The invention discloses a method for preparing monoisopropanolamine. The method comprises the steps of (a) reacting 1,2-propylene glycol under the action of a dehydrogenation catalyst to obtain 2-hydroxy propionaldehyde; and (b) reacting the 2-hydroxy propionaldehyde obtained in the step (1) with liquid ammonia and hydrogen under the action of a hydrogenation catalyst to prepare monoisopropanolamine. The dehydrogenation catalyst is prepared from a modified gamma-Al2O3 carrier and active components of CuO, PdO, Bi2O3 and In2O3. The hydrogenation catalyst comprises a modified gamma-Al2O3 carrierand active components NiO, V2O5 and Y2O3. Different catalysts and two-step reaction processes are adopted, and the reaction processes of dehydrogenation, imidization and hydrogenation of 1,2-propanediol are controlled to inhibit the generation of by-products such as hydroxyacetone in the dehydrogenation process and by-products such as secondary amine in the amination process, thereby greatly enhancing the yield and selectivity of the monoisopropyl alcohol product.

Owner:WANHUA CHEM GRP CO LTD

Press molding technology for petroleum coke

InactiveCN108101017ATo achieve the purpose of secondary granulationEase of embedding - de-embeddingCell electrodesSecondary cellsLithiumCrucible

The invention discloses a press molding technology for petroleum coke. The technology comprises steps as follows: air-drying, drying, grinding, preheating, stirring, prepressing and pressure maintaining. According to the technology, the petroleum coke is subjected to grinding and extrusion molding, the purpose of secondary granulation of an anode material is achieved, more holes and channels can be formed in the anode material after secondary granulation, embedding-disembedding of lithium in the anode material is facilitated; meanwhile, after the petroleum coke is subjected to grinding and press molding, a molded sheet product can be directly placed in a graphitizing furnace for graphitizing treatment, so that a crucible used in the production process of anode powder can be omitted, then production cost is saved, degree of graphitization of the petroleum coke can be remarkably increased and is increased to 93 or higher from 90, quality of the anode material is improved, and electric capacity of the product is improved. The morphology of the anode material obtained after grinding and press molding is better than an anode material without being subjected to grinding and press molding, and the high-end demand of the market for the anode material is met.

Owner:吉林市松江炭素有限责任公司

High-toughness heat-resistant Mg-Y-Er alloy suitable for low-pressure casting and preparation method thereof

ActiveCN109943757AThe freezing interval is smallImproving Die Casting Process PerformanceRoom temperatureElement composition

The invention provides a high-toughness heat-resistant Mg-Y-Er alloy suitable for low-pressure casting and a preparation method thereof. The high-toughness heat-resistant Mg-Y-Er alloy suitable for low-pressure casting is prepared from the following elements in percentage by mass: 3.0-7.0% of RE, 1.2-4.2% of Zn, 0.5-1.2% of Al, 0.1-0.3% of Mn, 0.01-0.08% of M, and the balance of Mg and other inevitable impurities, wherein RE is a element composition of Y and Er, and M is at least one element of Ti and B. After being subjected to low-pressure casting, secondary solid solution treatment and manual ageing thermal treatment, the high-toughness heat-resistant Mg-Y-Er alloy suitable for low-pressure casting has room-temperature tensile strength of 304 MPa, has ductility of 19%, has high-temperature tensile strength of 209 MPa at a temperature of 200 DEG C, has ductility of 24%, and has high-end needs, on lightweight development, of industries such as aerospace, war industry and cars.

Owner:SHANGHAI JIAO TONG UNIV

Nylon BCF (bulk continuous filament) low-crimp fibers and preparation method thereof

The invention discloses a preparation method of nylon BCF (bulk continuous filament) low-crimp fibers, which comprises the steps of carrying out melt extrusion on chips, spinning, cooling, oiling, drafting, deforming, cooling, intermingling and winding, wherein the temperature of a first drafting roller in the drafting process is 50-68 DEG C, the temperature of a second drafting roller is 170-200DEG C, air pressure of an interlacer is controlled to (4-6) KG in the intermingling process, and deformation air pressure is controlled to (4.5-5.5) KG in the deformation process. The preparation method disclosed by the invention ensures the stability of pressure in the deformation process, the continuous and stable production process is ensured, qualified yarns with high strength, high elasticity, low crimp and low intermingling degree can be produced, the high-end requirements of the market can be met, and the domestication of like products is achieved.

Owner:SHEN MA INDUSTRY CO LTD

Method for preparing diisopropanolamine

ActiveCN101265197BMeet high-end needsLess operating costs for productionOrganic compound preparationAmino-hyroxy compound preparationAlcoholMonoisopropanolamine

The invention relates to a method of manufacturing diisopropanolamine. Liquid ammonia and water are mixed to form ammonia water which is fully mixed with propylene oxide; the mixed solution is preheated until the temperature reach 140 to 145 DEG C and then is delivered into a reactor for reacting, the temperature is controlled within 148 to 155 DEG C when in reacting, the pressure is controlled within 16.0 to 18.0MPa, the inputting molar ratio of the ammonia and the propylene oxide is controlled within 5 to 8, and the reaction is fully performed for 1.5 to 3 hours; the mixture products obtained in the reaction are separated to obtain isopropanolamine products, diisopropanolamine products and triisopropanolamine products through flash evaporation and rectification in a stepwise way. In thediisopropanolamine products which are manufactured by adopting the method, the component of 1, 1<1>-nitrousalkyl-dipropyl-2-alcohol accounts for more than 99 percent (hereinafter referred to as mass percent), and the isomeride thereof is less than 1 percent. In addition, the cost of the production operation in the method is less, the production cost is low, the product quality is high, and the high-end requirement of products such as synthetic medicine, farm insecticide, etc. is satisfied.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com