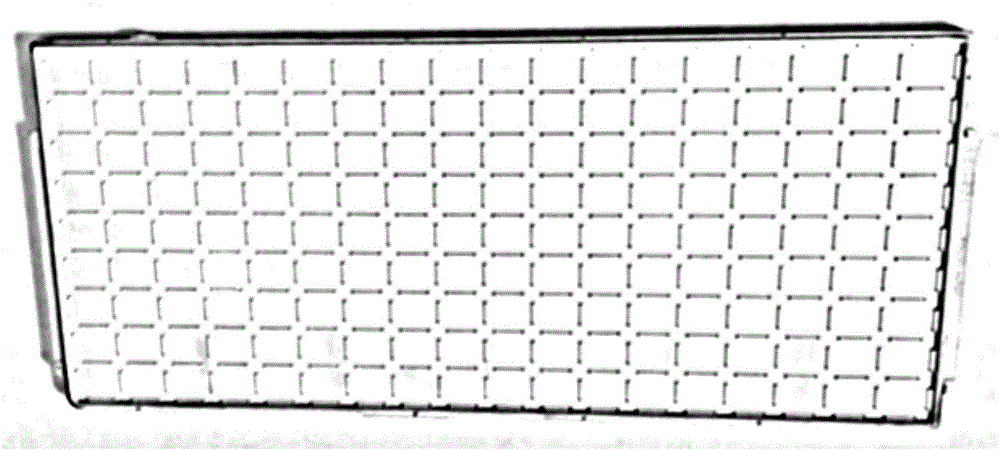

Aluminum alloy electronic chip tray and preparation process thereof

A technology of electronic chip and preparation process, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc. It can solve the problems of high appearance quality and product flatness, poor impact resistance, and short service life of aluminum alloy die-casting parts. problems, to achieve the effect of good appearance quality, small thermal deformation and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

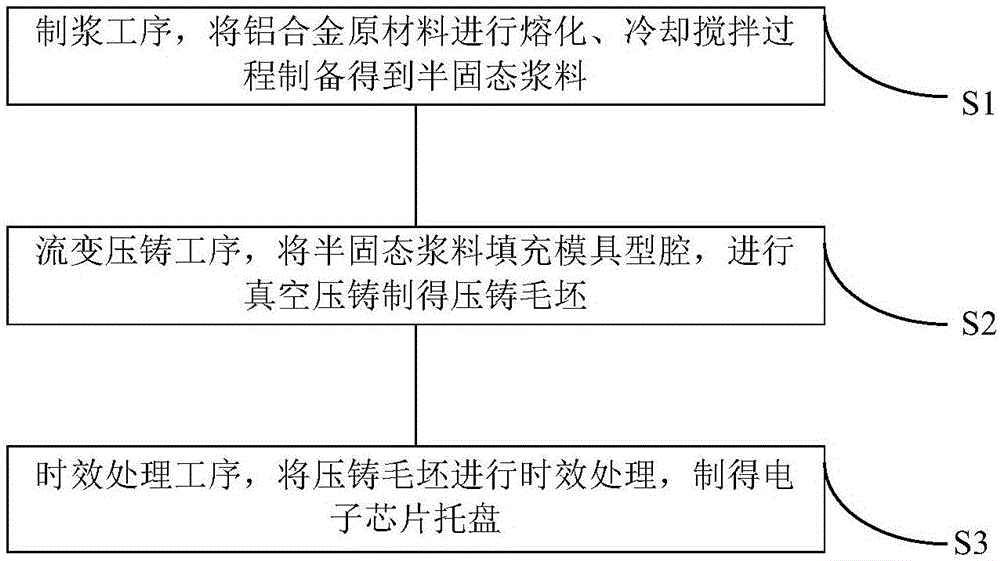

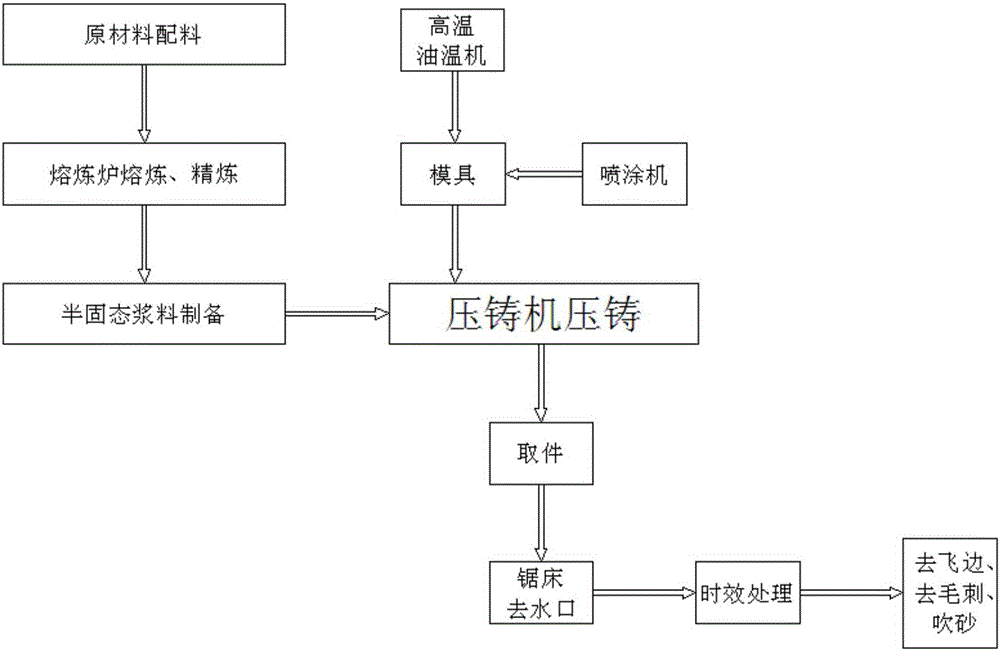

Method used

Image

Examples

Embodiment 1

[0053] In the pulping process, the ADC12 aluminum alloy material is selected for the preparation of semi-solid slurry. The aluminum alloy raw material is smelted in a smelting furnace, refined and degassed, and then a liquid alloy is obtained. As a pulping equipment, the liquid alloy in the spoon is mechanically stirred during the cooling process, and the mechanical stirring speed is 1200 rpm to obtain a semi-solid slurry with spherical crystals; the temperature of the semi-solid slurry is 595 ℃, and the solid phase ratio Is 43%;

[0054] In the rheological die-casting process, the above semi-solid slurry is filled into the mold cavity under the action of the die-casting machine. The mold cavity roughness Ra is 1.8μm; the matching gap of the mold parting surface is 0.02mm. After the filling is completed, increase the pressure, and Vacuum die-casting is performed to obtain a die-casting blank; wherein the cavity vacuum is 60mbar, the pumping time is 0.5s, and the boost pressure is...

Embodiment 2

[0057] In the pulping process, the ADC12 aluminum alloy material is selected for the preparation of semi-solid slurry. The aluminum alloy raw material is smelted in a smelting furnace, refined and degassed, and then a liquid alloy is obtained. As a pulping equipment, the liquid alloy in the spoon is mechanically stirred during the cooling process. The mechanical stirring speed is 1200 rpm to prepare a semi-solid slurry with spherical crystals; the temperature of the semi-solid slurry is 600 ℃, and the solid phase The rate is 42%;

[0058] In the rheological die-casting process, the semi-solid slurry is filled into the mold cavity under the pressure of the die-casting machine. The mold cavity roughness Ra is 1.8μm; the matching gap of the mold parting surface is 0.02mm. Increase the pressure after the filling is completed, and Vacuum die-casting is performed to obtain a die-casting blank; wherein the cavity vacuum is 60mbar, the pumping time is 0.5s, and the boost pressure is 240M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com