Nylon BCF (bulk continuous filament) low-crimp fibers and preparation method thereof

A technology for crimping fiber and nylon is applied in the field of nylon BCF low-crimp fiber and its preparation. Production process, uniform linear density, and the effect of localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of nylon BCF low crimp fiber, the method comprises the following steps:

[0028] (1) Spinning: The dried nylon chips are melted and extruded through a screw extruder, and the melt reaches the spinning box and is metered by a metering pump. The melt is mixed, heated and filtered in the spinning assembly, and passed through the spinneret spit out to form a tow;

[0029] (2) Cooling and cooling: In the cold air chamber, the tow obtained in step (1) is cooled and cooled by side blowing; in this process, the temperature of the cold air is controlled to be 18~20°C, the wind pressure is 420~450Pa, and the wind speed is (0.5-0.55 )m / s; in this process, the temperature and pressure of the cold air are precisely controlled by the automatic control program to avoid fluctuations in the temperature and pressure of the cold air, so as not to have a great impact on the yarn, and can better ensure that the yarn has a good effect Stab...

Embodiment 1

[0050] A preparation method of nylon BCF low crimp fiber, the method may further comprise the steps:

[0051] (1) Spinning:

[0052] The dried nylon chips are melted and extruded through a screw extruder, and the melt reaches the spinning box and is metered by a metering pump. The melt is mixed, heated and filtered in the spinning assembly, and is extruded through the spinneret to form a tow;

[0053] (2) cooling down:

[0054] In the cold air chamber, the tow obtained in step (1) is cooled by side blowing; in this process, the temperature of the controlled cold air is 20 ℃, the wind pressure is 450Pa, and the wind speed is 0.5m / s; Precisely control the temperature and pressure of the cold air to avoid fluctuations in the temperature and pressure of the cold air, so as not to have a greater impact on the yarn, which can better ensure that the yarn effect is good and stable, and ensure that the primary fiber has low orientation and low crystallization, which is beneficial to t...

Embodiment 2

[0071] A preparation method of nylon BCF low crimp fiber, the method may further comprise the steps:

[0072] (1) Spinning:

[0073] The dried nylon chips are melted and extruded through a screw extruder, and the melt reaches the spinning box and is metered by a metering pump. The melt is mixed, heated and filtered in the spinning assembly, and is extruded through the spinneret to form a tow;

[0074] (2) cooling down:

[0075] In the cold air chamber, the tow obtained in step (1) is cooled by side blowing; in this process, the temperature of the cold air is controlled to be 18°C, the wind pressure is 420Pa, and the wind speed is 0.55m / s;

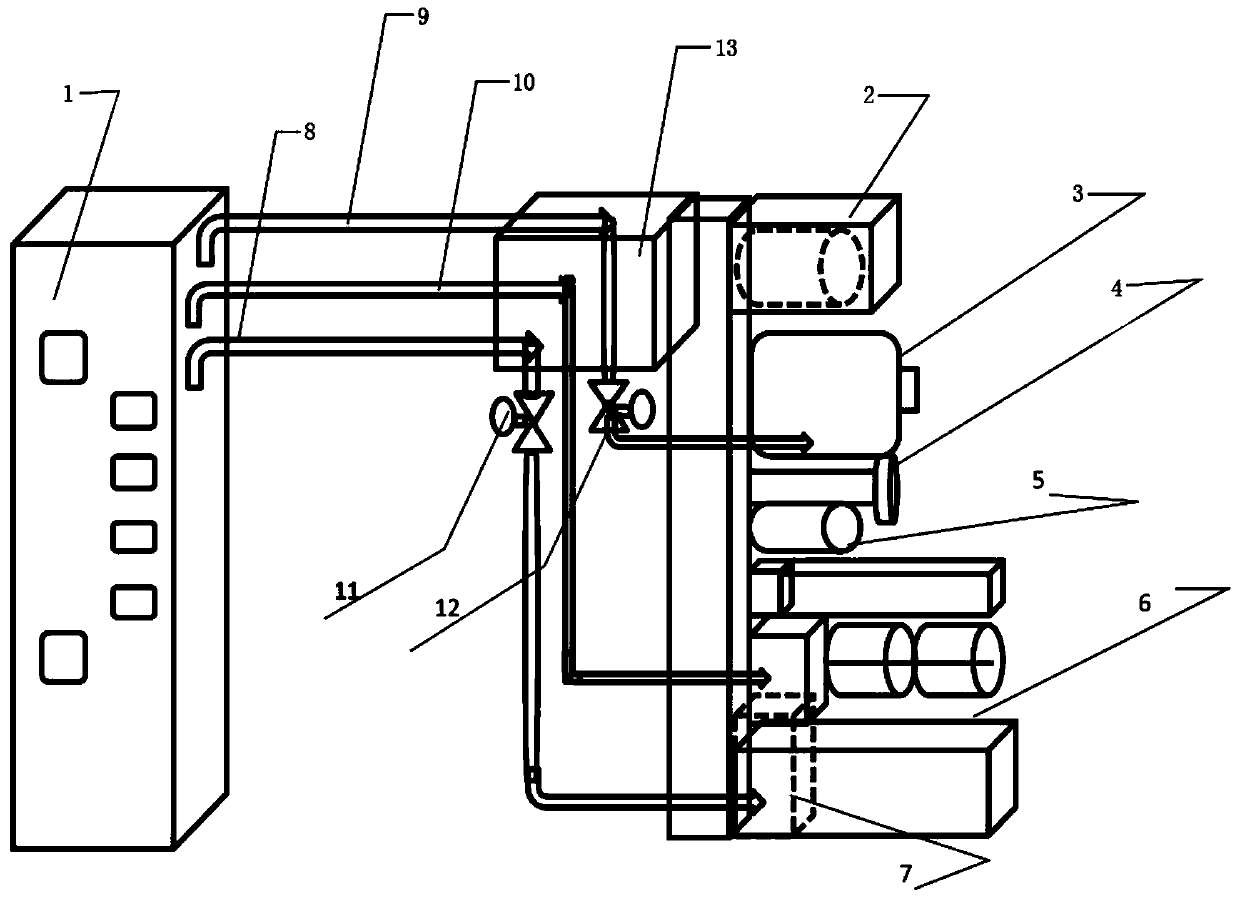

[0076] The tow after cooling is drawn to figure 1 Subsequent processing was carried out in the apparatus shown, as follows:

[0077] (3) Oiling:

[0078] Step (2) the tow after cooling is oiled through the oil nozzle in the device to ensure that the adhesion of the oil is 1.0%;

[0079] (4) Drafting:

[0080] The tow after oiling is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com