Aluminum alloy conducting material

A conductive material, aluminum alloy technology, applied in the direction of electrolytic coating, electrophoretic plating, surface reaction electrolytic coating, etc., can solve the problems of inability to meet the requirements of electrical conduction, and can not better meet the operation requirements of power products, so as to ensure the practicality The effect of fineness, separation, stable texture, and stable conductive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

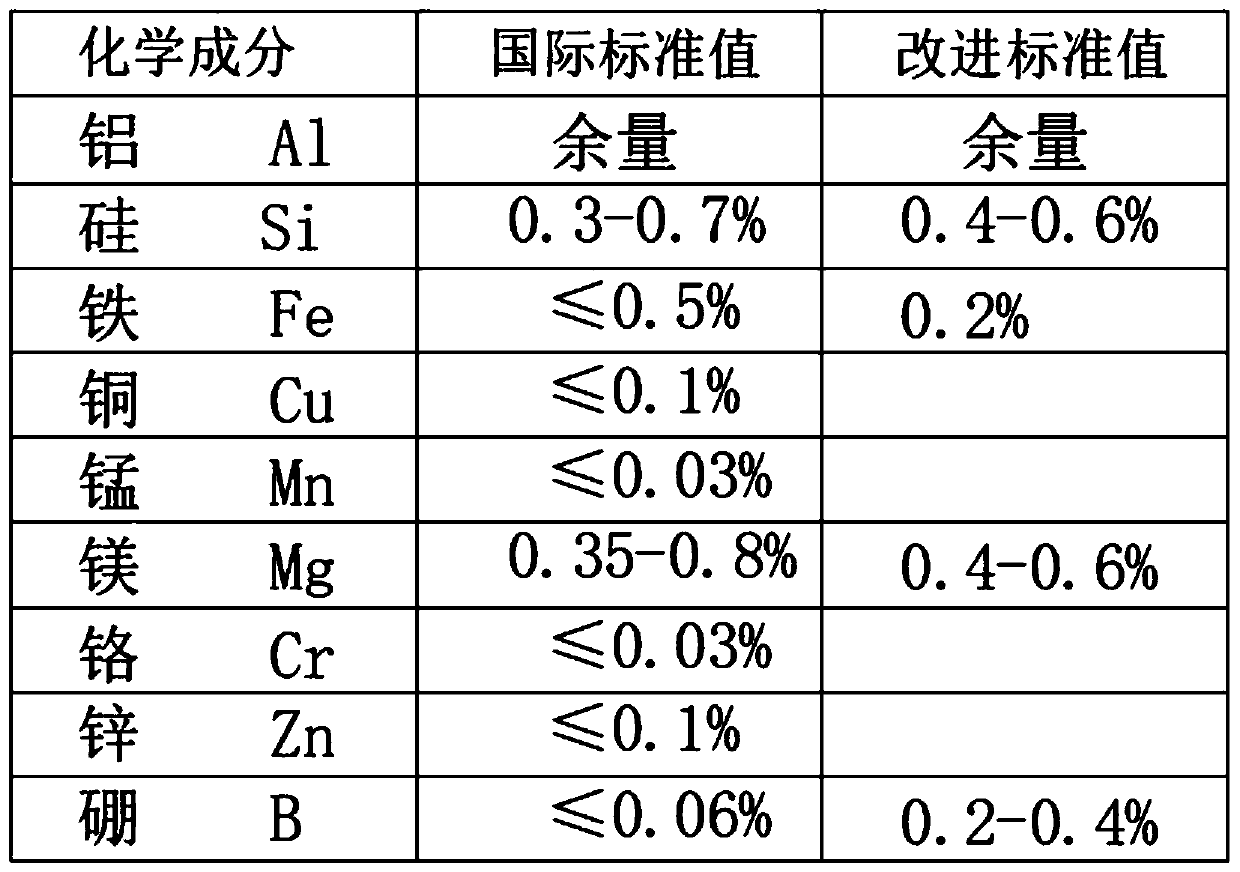

[0023] see figure 1 , the embodiment provided by the present invention: an aluminum alloy conductive material, its main components and mass content are: Zn: ≦0.1%, Mn: ≦0.03%, Mg: 0.4%-0.6%, Si: 0.4%-0.6% , Fe: 0.2%, Cu: ≦0.1%, Cr: ≦0.03%, B: 0.2%-0.4%, and the remainder is AI, which is characterized in that it includes the following six steps:

[0024] Step 1: Prepare raw materials such as aluminum ingots and intermediate alloys according to the corresponding ratio, put the aluminum ingots into the melting furnace, use natural gas to burn and melt the aluminum ingots, stir to make the composition and temperature more uniform, and raise the temperature of the molten aluminum for composition adjustment and refining , to generate molten aluminum;

[0025] Step 2: Adjust the composition ratio of molten aluminum according to alloy requirements, heat the furnace at 740-765°C for refining, and then add zinc, iron additives, copper, manganese, chromium, silicon and boron into the fu...

Embodiment 2

[0035] 1. Production process of casting aluminum alloy:

[0036] Cast aluminum alloy is a kind of aluminum alloy material that is widely used at present. Its production process mainly includes alloy melting, casting forming, heat treatment and surface treatment.

[0037] 1. Melting of cast aluminum alloy

[0038] 1.1 Refining of cast aluminum alloy

[0039] Since the furnace charge and aluminum alloy liquid absorb gas during smelting, transportation and pouring, inclusions are produced, which reduces the purity of the alloy liquid and deteriorates its fluidity. After pouring, various casting defects will occur in the casting (ingot). It affects its mechanical and processing properties, as well as corrosion resistance, air tightness, anodic oxidation performance and appearance quality, etc., so it must be refined before pouring to achieve the purpose of removing gases and inclusions, so that the alloy liquid The purity of the aluminum alloy has been improved. At present, many...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com