A kind of overall quenching and tempering heat treatment method for h13 round steel

A quenching and tempering heat treatment and annealing heat treatment technology, applied in the field of heat treatment, can solve the problems of serious environmental pollution, product scrapping, and fire hazards, and achieve excellent comprehensive performance, reduce processing costs, and avoid pollution and fire hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

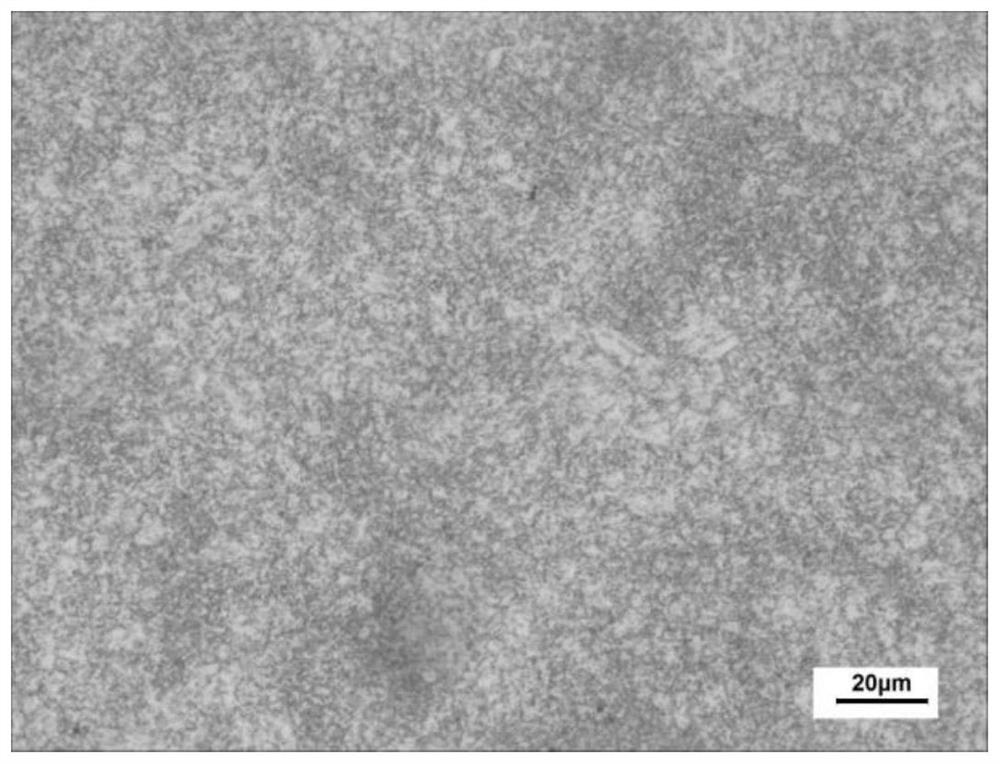

[0062] In this example, the overall quenching and tempering heat treatment is performed on H13 round steel with a specification of Φ45mm, and the hardness range after heat treatment is required by the user to be 27-35HRC. The H13 round steel is obtained by rolling and forming, and the overall quenching and tempering heat treatment method is as follows:

[0063] Quenching and tempering method: induction coil austenitizing temperature 1010℃, quenching water cooling; tempering 670℃, holding time 2h; specific steps are as follows:

[0064] (1) Annealing heat treatment: according to the heat treatment method of H13 section steel in CN201310548794.0, the rolled H13 round steel is subjected to annealing heat treatment;

[0065] (2) Surface finishing: To finish the surface of H13 round steel after annealing and heat treatment, fine cracks can be removed by peeling with grinding wheel, turning and grinding, etc., to prevent quenching cracking caused by unremoved surface defects.

[00...

Embodiment 2

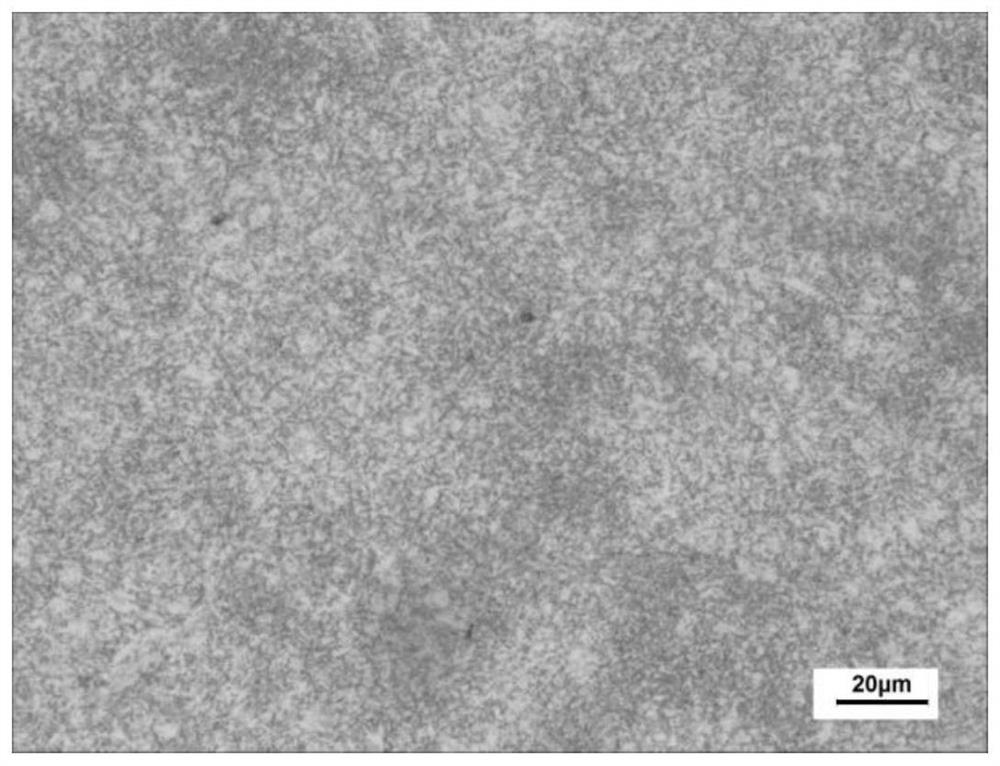

[0070] In this example, the overall quenching and tempering heat treatment is performed on H13 round steel with a specification of Φ60mm, and the hardness range after heat treatment is required by the user to be 27-35HRC. The H13 round steel is obtained by rolling and forming, and the overall quenching and tempering heat treatment method is as follows:

[0071] Quenching and tempering method: induction coil austenitization temperature 1010 ℃, quenching water cooling; tempering 670 ℃, holding time 3h; specific steps are as follows:

[0072] (1) Annealing heat treatment: according to the heat treatment method of H13 section steel in CN201310548794.0, the rolled H13 round steel is subjected to annealing heat treatment;

[0073] (2) Surface finishing: To finish the surface of H13 round steel after annealing and heat treatment, fine cracks can be removed by peeling with grinding wheel, turning and grinding, etc., to prevent quenching cracking caused by unremoved surface defects.

...

Embodiment 3

[0079] In this example, the overall quenching and tempering heat treatment is performed on H13 round steel with a specification of Φ120mm, and the hardness range after heat treatment is required by the user to be 50-56HRC. The H13 round steel is obtained by rolling and forming, and the overall quenching and tempering heat treatment method is as follows:

[0080] Quenching and tempering method: continuous furnace austenitization temperature 1010 ℃, holding time 2h, quenching water cooling; tempering at 540 ℃, holding time 4h. Specific steps are as follows:

[0081] (1) Annealing heat treatment, according to the heat treatment method of H13 section steel in CN201310548794.0, the rolled H13 round steel is subjected to annealing heat treatment;

[0082] (2) Surface finishing: To finish the surface of H13 round steel after annealing and heat treatment, fine cracks can be removed by peeling with grinding wheel, turning and grinding, etc., to prevent quenching cracking caused by unr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com