Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Low-temperature toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Outdoor electric-insulation modified epoxy resin composition

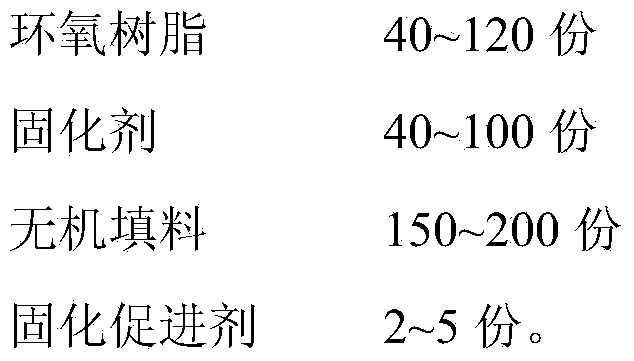

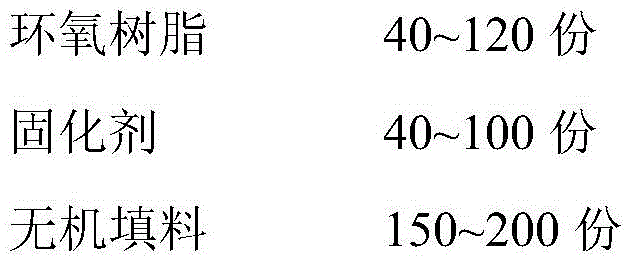

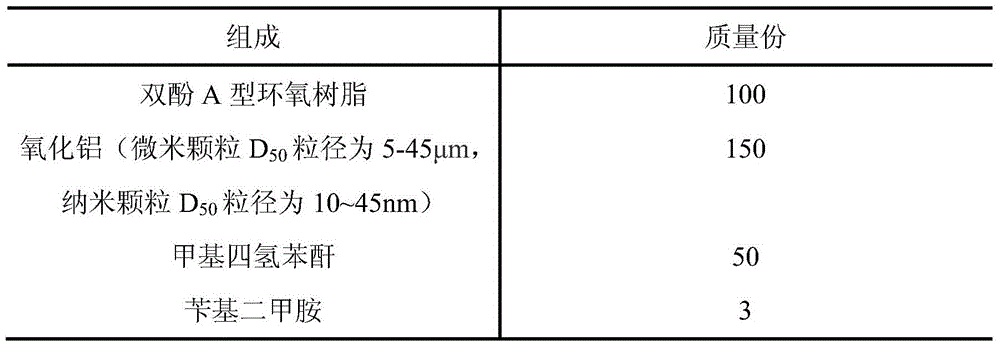

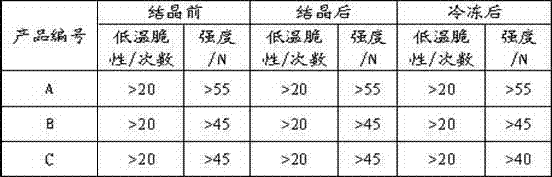

The invention discloses an outdoor electric-insulation modified epoxy resin composition which comprises an epoxy resin, a curing agent, a curing accelerator and an inorganic filler. The outdoor electric-insulation modified epoxy resin composition has the advantages of high weather resistance, favorable hydrophobicity, high volume resistivity, high tracking resistance, high arc resistance, low thermal expansivity and the like, and can be used for manufacturing suspension insulators for alternating current transmission lines as well as umbrella skirts of cross arms and other outdoor insulation parts. Compared with the silicon rubber umbrella skirt, the umbrella skirt prepared from the composition can prevent birds from damage, resist line walking trampling, avoid shipping damage and the like.

Owner:赛思迈(上海)新材料科技有限公司

Wax-containing composition for leather and its product surface coating

ActiveCN1611560AGood miscibilityHigh affinityLiquid surface applicatorsCoatingsSolubilityCarbon chain

The invention relates to a kind of waxy combination for surface coating of leather and its products, which is mainly composed with wax, high molecular polymer cream, long carbon-chain fatty alcohol, fatty amide, surface-active agent, and water, but its components doesn't contain organic solvent, water solubility organic alcohol, and mineral oil. Use fatty amide as cosolvent of coating combination system; fatty amide has fine intersolubility with wax, fatty alcohol, high molecular polymer, and other solid constituents; so it can improve stability of coating combination system, can guarantee continuation and compactness of coating film, and also can avoid the disadvantages of containing mineral oil and low molecular water solubility alcohol in the components. When using for surface coating of leather and its products, it has natural gloss, excellent abilities of water-resistant, antidusting, drying proof, and wet proof, and fine frictional property. So it has convenient usage that is safe, and can decline pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ferritic stainless steel sheet with excellent thermal fatigue properties, and automotive exhaust-gas path member

InactiveUS20080279712A1Reasonable component designIncreased durabilityThermal fatigueLongest Diameter

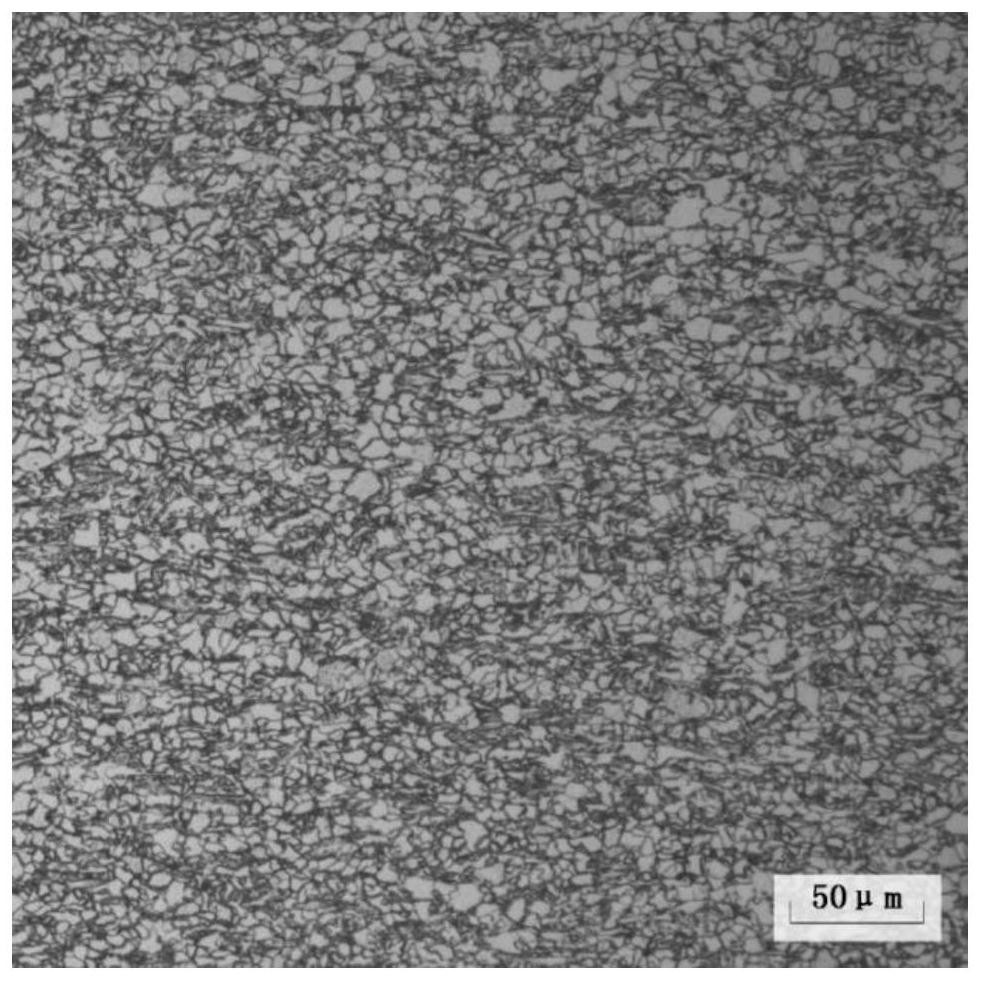

Disclosed is a ferritic stainless steel sheet with excellent thermal fatigue properties, including, by mass %, 0.03% or less of C, 1.0% or less of Si, 1.5% or less of Mn, 0.6% or less of Ni, 10˜20% of Cr, 0.05˜0.30% of Ti, 0.51˜0.65% of Nb, 0˜less than 0.10% of Mo, 0.8˜2.0% of Cu, 0˜0.10% of Al, 0.0005˜0.02% of B, 0˜0.20% of V, and 0.03% or less of N, with the balance being Fe and inevitable impurities, having a composition satisfying the following equations (1) and (2) and having a structure in which ε-Cu phase grains each having a long diameter of 0.5 μm or more are present in a density of 10 or less per 25 μm2: Nb−8(C+N)≧0 . . . (1), 10 Si+20 Mo+30 Cu+20(Ti+V)+160 Nb−(Mn+Ni)≧100 . . . (2). The ferritic stainless steel sheet, having a relatively inexpensive component composition, has excellent thermal fatigue properties, and is suitable for use in an automotive exhaust-gas path member, including an exhaust manifold, a catalyst converter, a front pipe, or a center pipe.

Owner:NISSHIN STEEL CO LTD +1

High tensile strength low carbon bainite thick steel plate and its production method

InactiveCN1786245AReduce carbon contentLow carbon content, low temperature toughnessOther manufacturing equipments/toolsChemical compositionHigh intensity

The invention offers a high tensile strength low carbon bainite coarse plate and its manufacturing method. Its compositions (Wt%) are C 0.052%-0.08%, Si 0.1%-0.5%, Mn1.65%-1.90%, Nb 0.015%-0.060%, Ti 0.005%-0.03%, B 0.0005%-0.003%, Mo 0.25%-0.50%, Cu 0.62%-0.85%, Ni 0.42%-0.80%, Al 0.015%-0.05%, and rest Fe and other inevitable impurity. The invention adopts low cost Mn element as the main additional element, fully applies the changing action of Cu, Mo, Ni, Nb, B to the bainite. The steel has low carbon, good low temperature toughness, welding performance, and forming performance. Its Nb and Ti element is low. And it is fit for large-scale industrialization continuous casting production. The TMCP+ RPC+T technique is adopted to make tensile strength over 900N / mm2 high intensity and tenacity steel. Adopting lower steel blank heating temperature can economize energy and improve steel low temperature toughness. The product can apply in engineering machinery, digging machinery, heavy-duty car, and marine facilities field, and etc.

Owner:UNIV OF SCI & TECH BEIJING +1

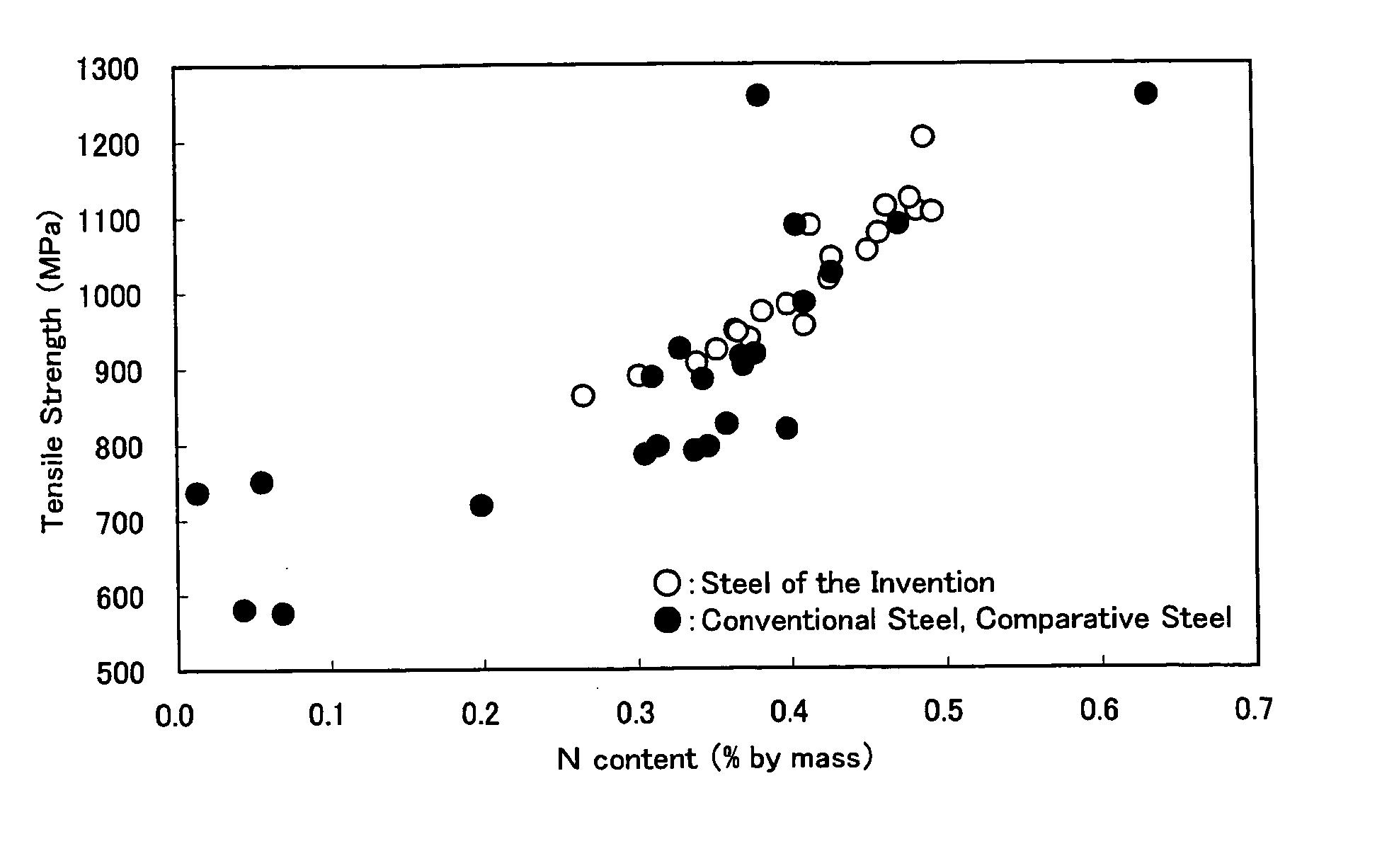

Stainless steel for high-pressure hydrogen gas, and container and device made of same

InactiveUS20050178477A1Superior mechanical property and corrosion resistanceHigh strengthWelding/cutting media/materialsSoldering mediaHigh pressure hydrogenHigh intensity

A high-strength stainless steel, having good mechanical properties and corrosion resistance in a high-pressure hydrogen gas environment, is used as a container or other device for high-pressure hydrogen gas, and consists of, by mass %, C: not more than 0.04%, Si: not more than 1.0%, Mn: 7 to 30%, Cr: 15 to 22%, Ni: 5 to 20%, V: 0.001 to 1.0%, N: 0.20 to 0.50% and Al: not more than 0.10%, and the balance Fe and impurities. Among the impurities, P is not more than 0.030%, S is not more than 0.005%, and Ti, Zr and Hf are not more than 0.01% respectively, and the contents of Cr, Mn and N satisfy the relationship, 2.5Cr+3.4Mn≦300N. The weld metal of the welded joint of the container or other device made of the said stainless steel satisfies the relationship, −11≦Nieq−1.1×Creq≦−8.

Owner:NIPPON STEEL CORP

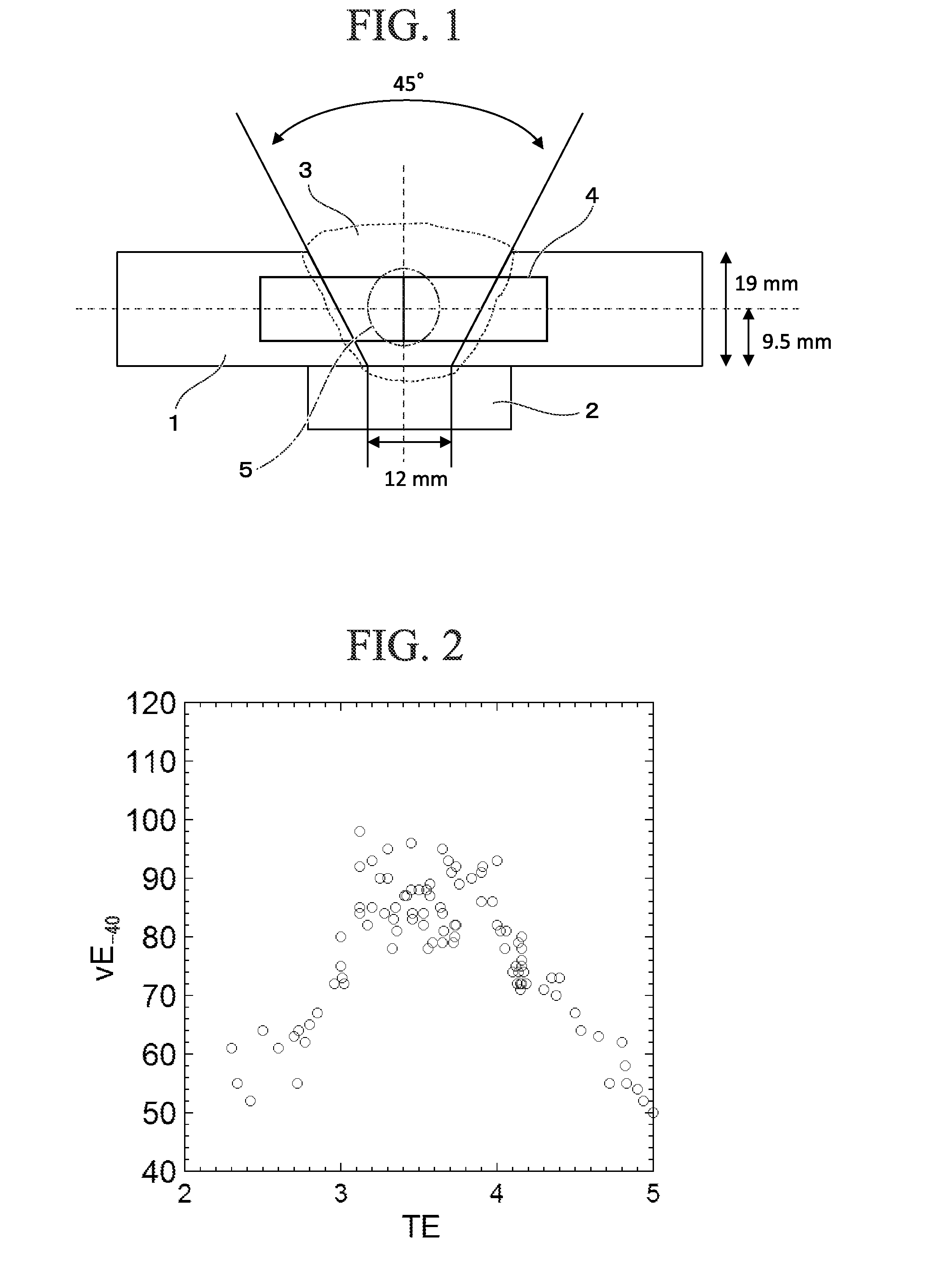

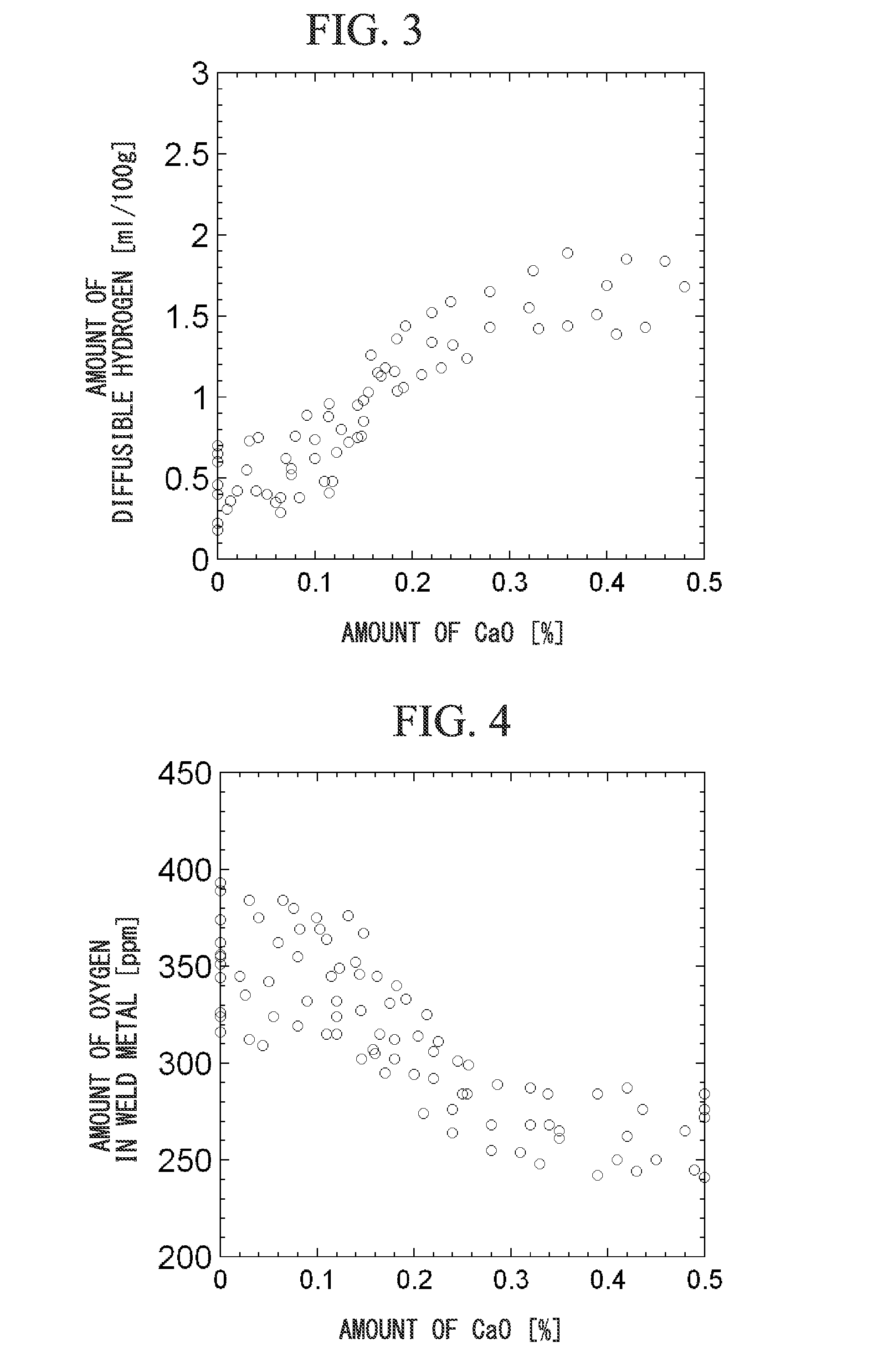

Flux-cored wire, welding method using flux-cored wire, method for manufacturing weld joint using flux-cored wire, and weld joint

ActiveUS20150360327A1Improve toughnessReduce warm-upArc welding apparatusWelding/cutting media/materialsIron powderTi oxides

In a flux-cored wire according to the present invention, CaF2 and the like are included and a total amount thereof α is 3.3 to 6.0% in terms of mass % with respect to a total mass, Ti oxide and the like are included and a total amount thereof β is 0.4 to 1.2% in terms of mass % with respect to the total mass, CaCO3 and the like are included and a total amount thereof is 0.1 to 0.5% in terms of mass % with respect to the total mass, and an amount of an iron powder in the flux is less than 10% in terms of mass % with respect to the total mass.

Owner:NIPPON STEEL CORP

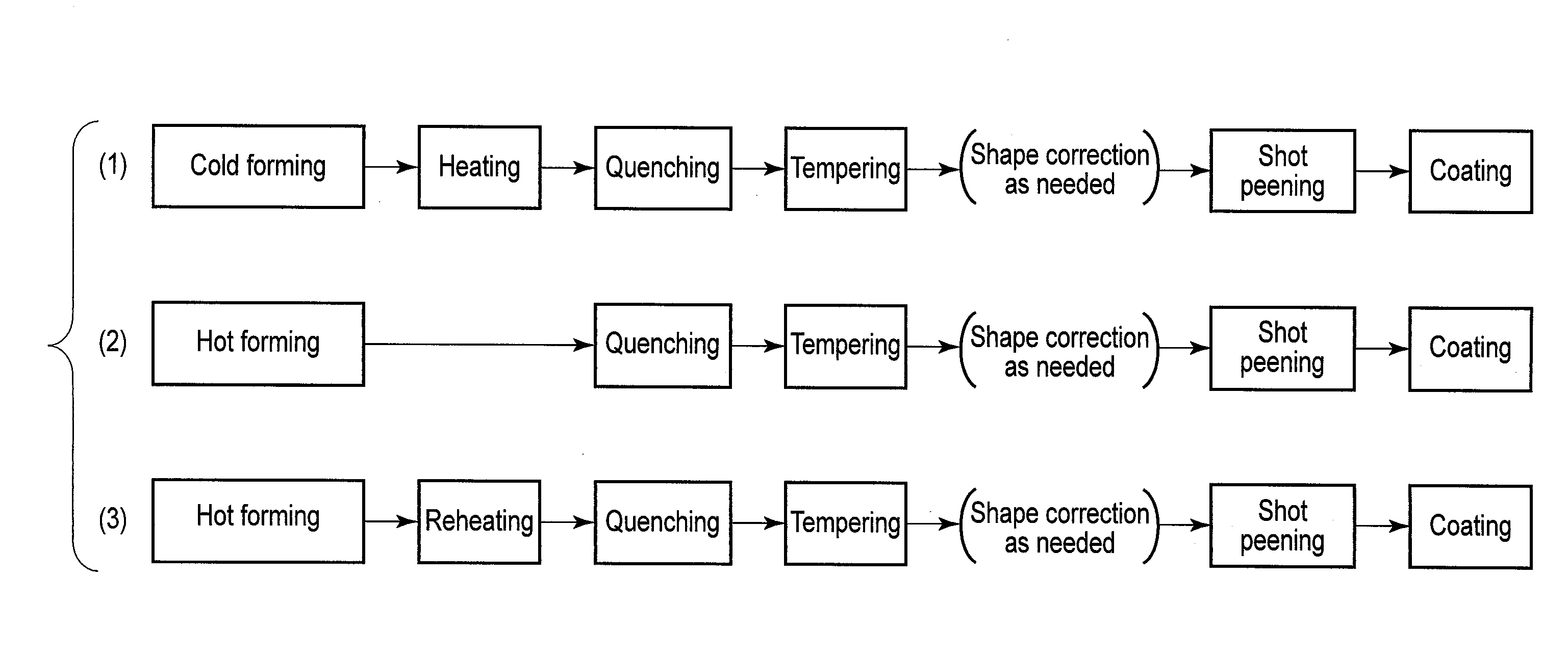

Hot-stamped part and method of manufacturing the same

ActiveUS20160145704A1Excellent low-temperature toughnessExcellent strength toughnessFurnace typesHeat treatment furnacesAustenite grainChemical composition

A hot-stamped part includes a chemical composition represented by, in mass %: C: 0.120% to 0.400%; Si: 0.005% to 2.000%; Mn or Cr, or both thereof: 1.00% to 3.00% in total; Al: 0.005% to 0.100%; B: 0.0003% to 0.0020%; P: not more than 0.030%; S: not more than 0.0100%; O: not more than 0.0070%; N: not more than 0.0070%; Ti: 0% to 0.100%; Nb: 0% to 0.100%; V: 0% to 0.100%; Ni: 0% to 2.00%; Cu: 0% to 2.00%; Mo: 0% to 0.50%; Ca or REM, or both thereof: 0% to 0.0300% in total; and the balance: Fe and impurities, and a structure represented by: an area fraction of martensite or bainite, or both thereof: not less than 95% in total; a coverage factor of prior austenite grain boundary by iron-based carbides: not more than 80%; and a number density of iron-based carbides in prior austenite grains: not less than 45 / μm2.

Owner:NIPPON STEEL CORP

Ferritic Stainless steel material for automobile exhaust gas passage components

InactiveUS20090120536A1Improve low temperature toughnessImprove machinabilitySilencing apparatusMachines/enginesHeat resistanceCopper

To provide a ferritic stainless steel material for automobile exhaust gas passage components usable in a high-temperature range over 900° C. and even over 950° C. The ferritic stainless steel material has excellent heat resistance and low-temperature toughness and has a composition comprising, in terms of % by mass, at most 0.03% of C, at most 1% of Si, from 0.6 to 2% of Mn, at most 3% of Ni, from 10 to 25% of Cr, from 0.3 to 0.7% of Nb, from more than 1 to 2% of Cu, from 1 to 2.5% of Mo, from 1 to 2.5% of W, at most 0.15% of Al, from 0.03 to 0.2% of V, and at most 0.03% of N, and optionally containing any of B, Co, W, Ti, Zr, REM and Ca with a balance of Fe and inevitable impurities, and the composition satisfies restrictive formulae 1.2Nb+5Mo+6Cu≧11.5 and 15Nb+2Mo+0.5Cu≧10.5. The steel material has a texture where the total amount of Nb and Mo existing as a precipitation phase is at most 0.2% by mass.

Owner:NISSHIN STEEL CO LTD

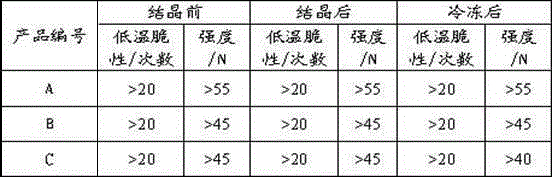

Modified polyester hot melt adhesive and preparation method for adhesive film thereof

ActiveCN105111990AIncrease elasticityGood adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyPolyester

The invention discloses a modified polyester hot melt adhesive and a preparation method for an adhesive film thereof. The modified polyester hot melt adhesive comprises the raw materials in parts by weight: 35-80 parts of a polyester hot melt adhesive, 20-65 parts of a thermoplastic type polyurethane elastomer and 0.5 part of an antioxidant. According to the modified polyester hot melt adhesive disclosed by the invention, the polyester hot melt adhesive is blended and modified by using the polyurethane elastomer, so that the problem of low temperature brittleness of an existing polyester hot melt adhesive product is solved well. The polyester hot melt adhesive product disclosed by the invention has relatively good toughness and is not crispy at (-40) DEG C, can be used for binding metals such as an aluminum sheet and the like with epoxy resin, and is suitable for binding a metal plate and epoxy resin, particularly binding an aluminum plate and an epoxy coating pipeline in a refrigerator.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

High-strength and low-hardness hydrogen sulfide corrosion resistant steel and preparation method thereof

The invention discloses high-strength and low-hardness hydrogen sulfide corrosion resistant steel. The steel comprises the following chemical components in percentage by mass: 0.01-0.05% of C, 0.05-0.35% of Si, 1.10%-1.40% of Mn, less than or equal to 0.006% of P, less than or equal to 0.0005% of S, 0.01%-0.05% of Alt, 0.01%-0.05% of Nb, 0.01%-0.05% of V, 0.005%-0.02% of Ti, 0.00%-0.20% of Ni, 0.00%-0.20% of Cr, 0.00%-0.20% of Cu and the balance of Fe and inevitable impurities, wherein the carbon equivalent CEIIW is 0.30%-0.33%, and the CEPcm is 0.12%-0.14%. The invention further discloses a preparation method, and the prepared steel has high strength, low hardness and excellent hydrogen sulfide corrosion resistance.

Owner:SHOUGANG CORPORATION

Stainless steel for high-pressure hydrogen gas

InactiveUS7749431B2Superior mechanical property and corrosion resistanceHigh strengthWelding/cutting media/materialsSoldering mediaHigh pressure hydrogenHigh intensity

A high-strength stainless steel, having good mechanical properties and corrosion resistance in a high-pressure hydrogen gas environment, is used as a container or other device for high-pressure hydrogen gas, and consists of, by mass %, C: not more than 0.04%, Si: not more than 1.0%, Mn: 7 to 30%, Cr: 15 to 22%, Ni: 5 to 20%, V: 0.001 to 1.0%, N: 0.20 to 0.50% and Al: not more than 0.10%, and the balance Fe and impurities. Among the impurities, P is not more than 0.030%, S is not more than 0.005%, and Ti, Zr and Hf are not more than 0.01% respectively, and the contents of Cr, Mn and N satisfy the relationship, 2.5Cr+3.4Mn≦300N. The weld metal of the welded joint of the container or other device made of the said stainless steel satisfies the relationship, −11≦Nieq−1.1×Creq≦−8.

Owner:NIPPON STEEL CORP

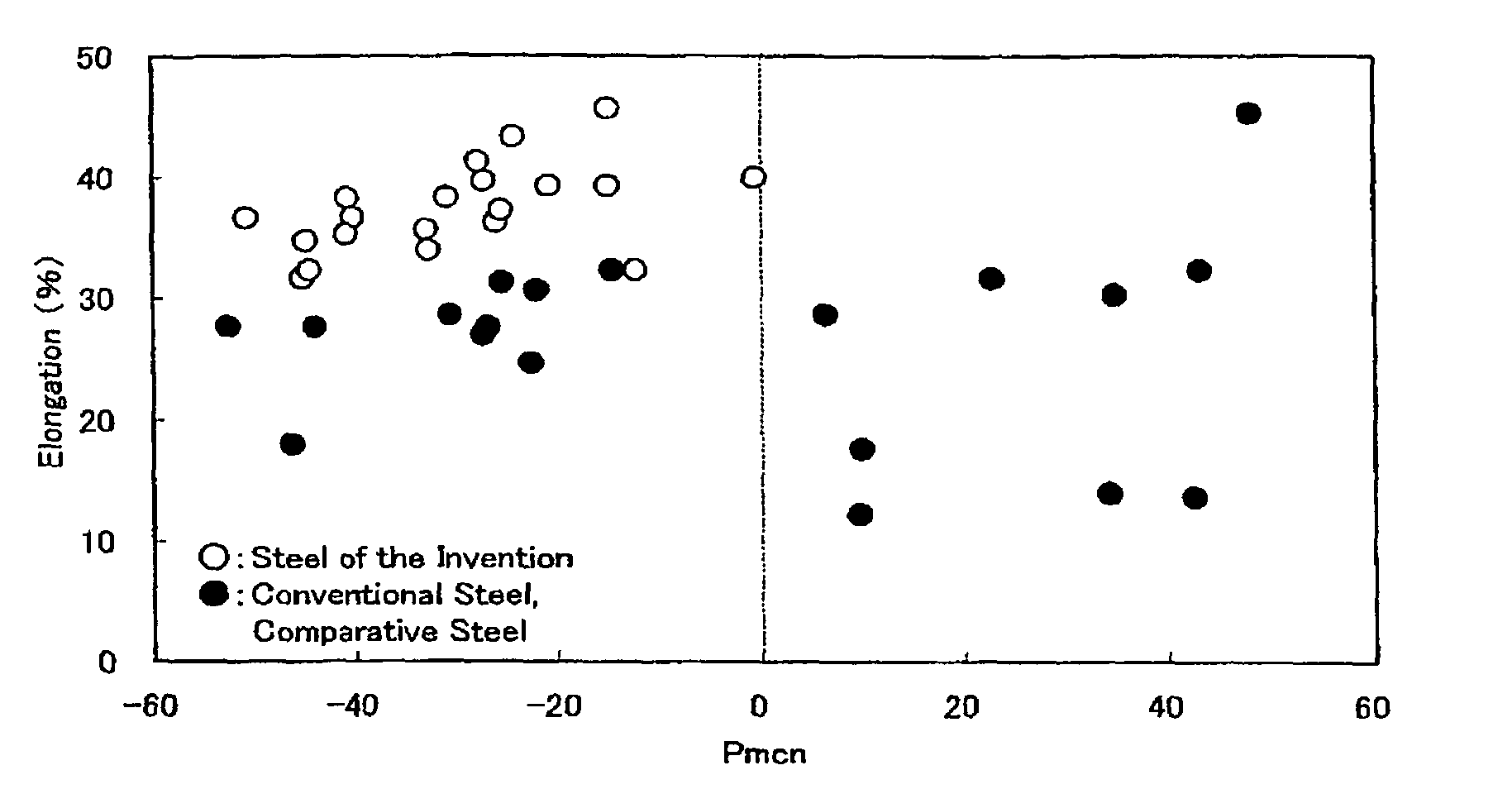

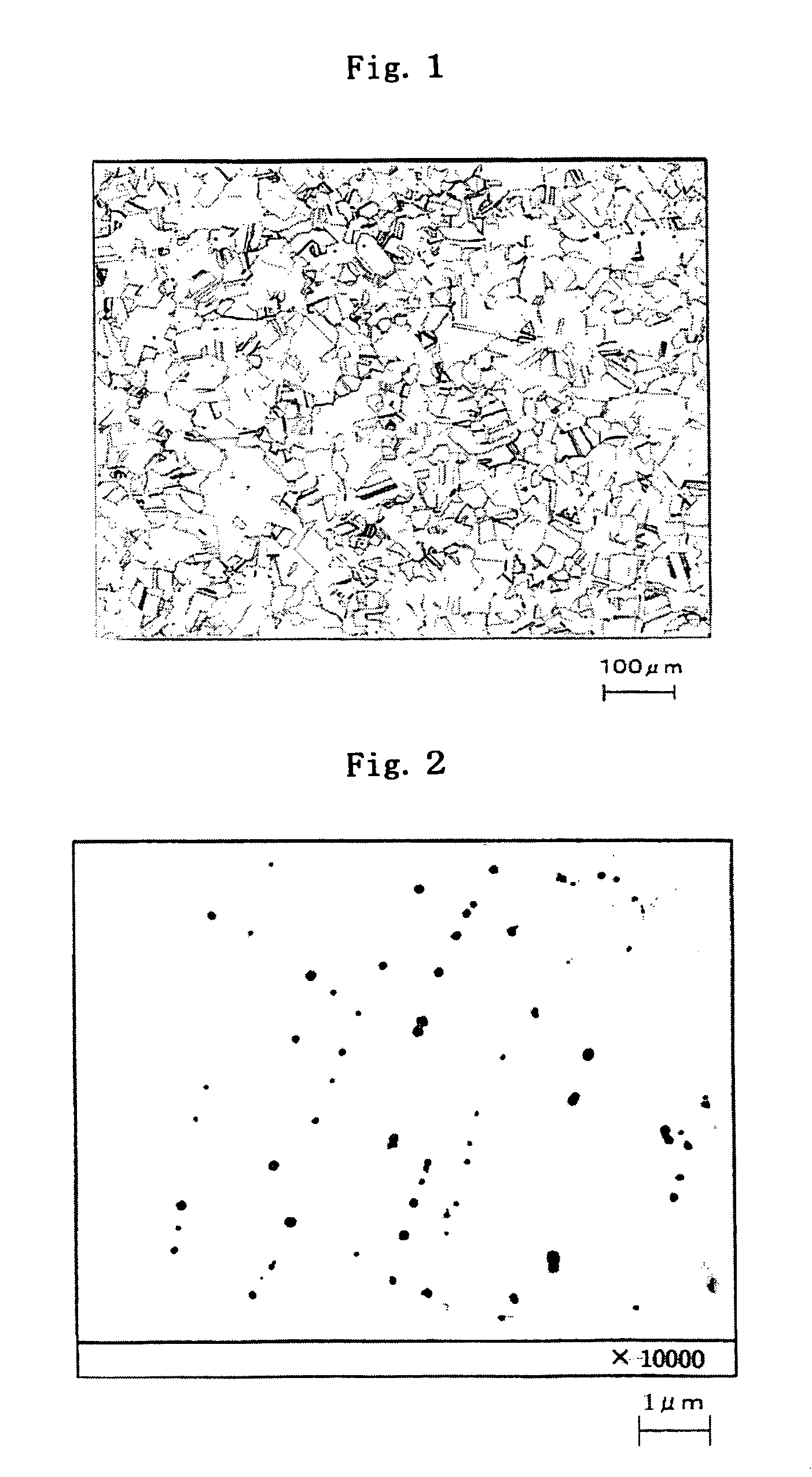

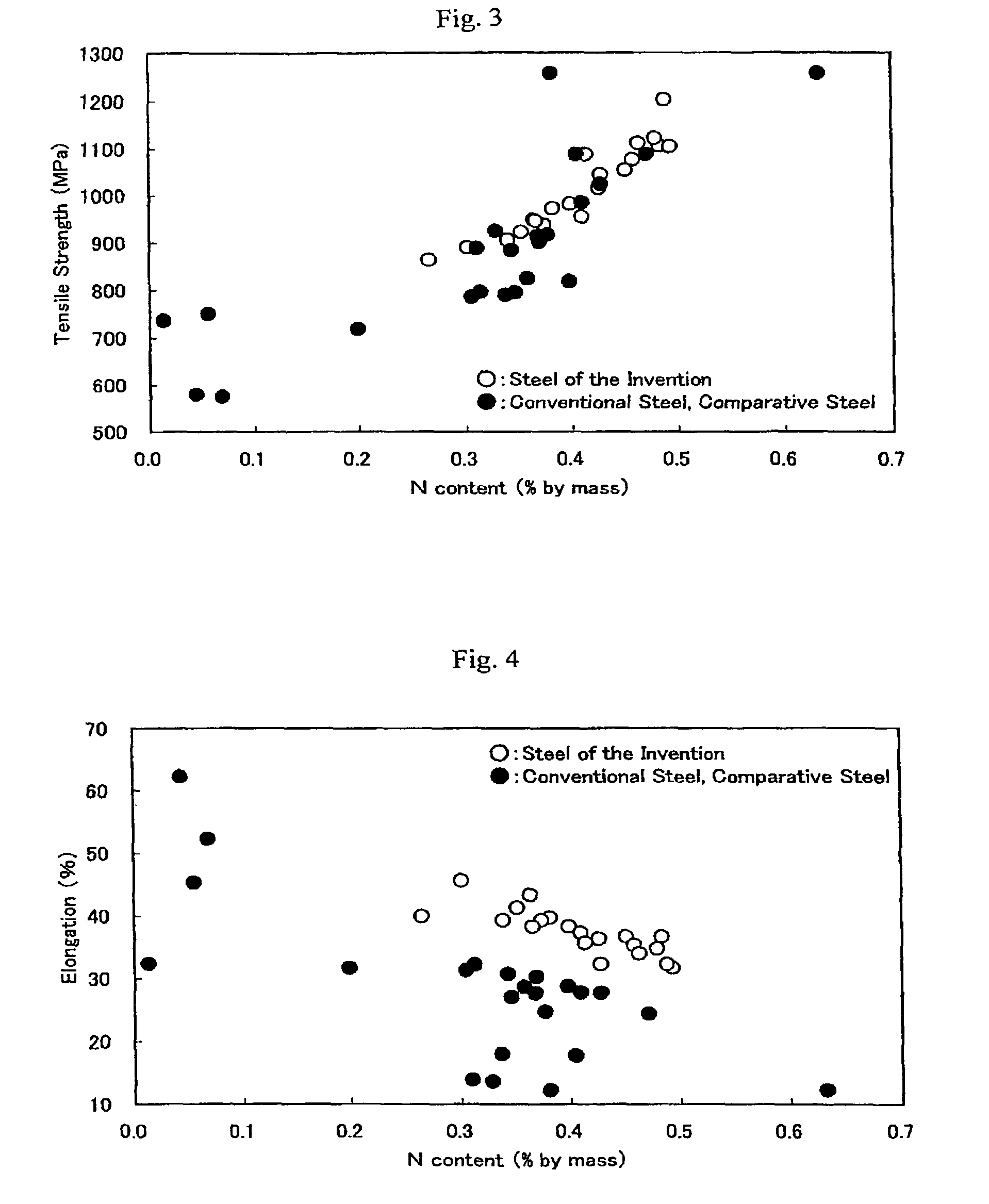

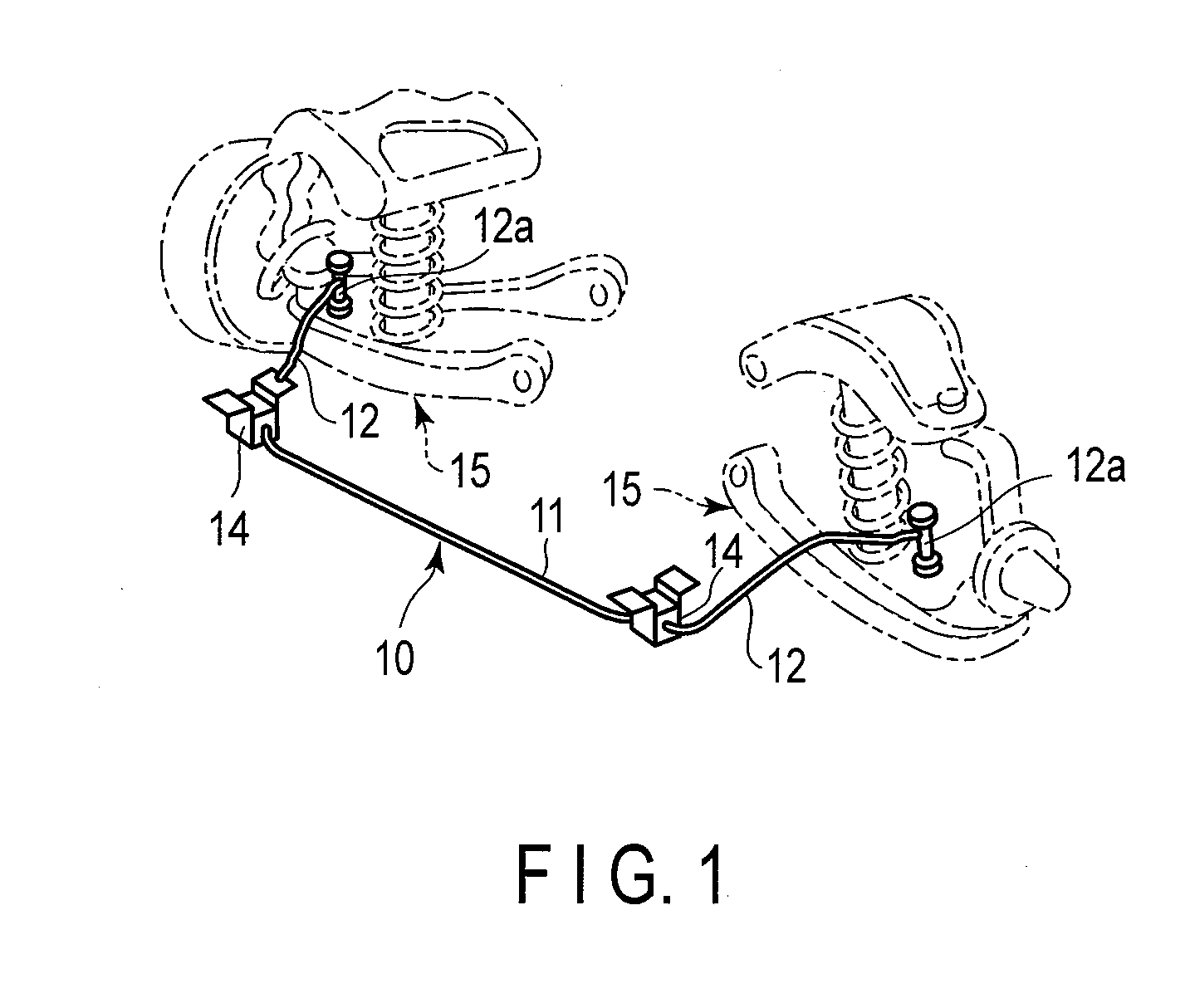

Steel for vehicle suspension spring part, vehicle suspension spring part, and method of fabricating the same

InactiveUS20170021691A1Improve corrosion resistanceImprove low temperature toughnessSpringsIncreasing energy efficiencyAustenite grainToughness

A steel, having a high corrosion resistance and low-temperature toughness, for a vehicle suspension spring part, the steel includes 0.21 to 0.35% by mass of C, more than 0.6% by mass but 1.5% by mass or less of Si, 1 to 3% by mass of Mn, 0.3 to 0.8% by mass of Cr, 0.005 to 0.080% by mass of sol. Al, 0.005 to 0.060% by mass of Ti, 0.005 to 0.060% by mass of Nb, not more than 150 ppm of N, not more than 0.035% by mass of P, not more than 0.035% by mass of S, 0.01 to 1.00% by mass of Cu, and 0.01 to 1.00% by mass of Ni, the balance being Fe and unavoidable impurities, with Ti+Nb≦0.07% by mass, wherein crystal grains of the steel after hardening have a prior austenite grain size number of 7.5 to 10.5, and the steel having a tensile strength of not less than 1,300 MPa.

Owner:NHK SPRING CO LTD +1

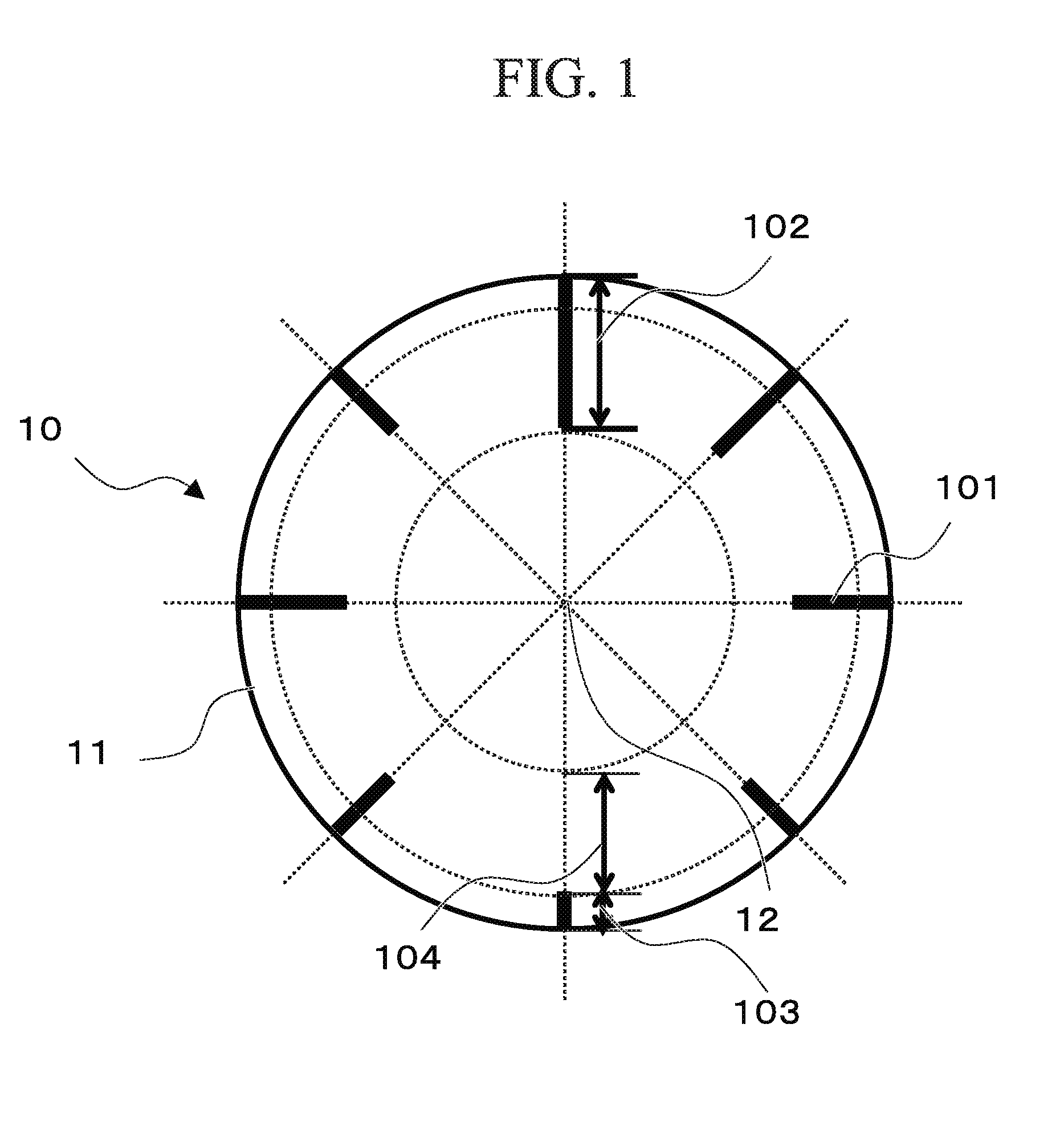

Steel bar

InactiveUS20160273067A1High propertyLow temperature toughnessFurnace typesHeat treatment furnacesCrystalliteChemical composition

A steel bar according to one embodiment of the present invention includes predetermined chemical composition, wherein a quenching deflection in a cross section is 1.5 mm or less, wherein Δmax and Δmin is 1.5 mm or less, wherein a structure in a surface layer area includes 10 area % or less of ferrite and a remainder including one or more selected from a group consisting of a bainite and a martensite, wherein an average value of the grain size of a bcc phase in the surface layer area is 1.0 to 10.0 μm, wherein an average value of the grain size of the bcc phase in a center area is 1.0 to 15.0 μm, wherein a hardness of a region of which a depth from the surface is 50 μm is Hv200 to Hv500, and wherein a total decarburized layer thickness DM-T is 0.20 mm or less.

Owner:NIPPON STEEL CORP

Nylon 11/polylactic acid biological base high molecular alloy and preparation method and application thereof

The invention discloses a nylon 11 / polylactic acid biological base high molecular alloy, which comprises the following substances in parts by weight: 30-70 parts of nylon 11, 30-70 parts of polylacticacid, 1-8 parts of a compatilizer and 0.1-0.6 part of a stabilizer. A preparation method of the nylon 11 / polylactic acid biological base high molecular alloy comprises the following steps: vacuum-drying a PA11 matrix resin, a PLA resin, the compatilizer and the heat stabilizer; uniformly mixing the materials through a high speed mixer; then extruding the mixture through a twin-screw extruder, anduniformly granulating the mixture; and finally, drying the mixture in a vacuum oven to remove water. The primary raw material of the nylon 11 / polylactic acid biological base high molecular alloy is the biological base material, so that the demand on a petroleum-based high molecular material is lowered. The nylon 11 / polylactic acid biological base high molecular alloy material has great tensile strength, high modulus, high impact performance, good heat stability and low price, and the production process technology thereof has low demand on equipment, and the alloy is suitable for industrial production on a large scale.

Owner:ZHONGBEI UNIV

High tensile strength low carbon bainite thick steel plate and its production method

InactiveCN100350065CLow temperature toughnessLow heating temperatureOther manufacturing equipments/toolsChemical compositionHigh intensity

The invention offers a high tensile strength low carbon bainite coarse plate and its manufacturing method. Its compositions (Wt%) are C 0.052%-0.08%, Si 0.1%-0.5%, Mn1.65%-1.90%, Nb 0.015%-0.060%, Ti 0.005%-0.03%, B 0.0005%-0.003%, Mo 0.25%-0.50%, Cu 0.62%-0.85%, Ni 0.42%-0.80%, Al 0.015%-0.05%, and rest Fe and other inevitable impurity. The invention adopts low cost Mn element as the main additional element, fully applies the changing action of Cu, Mo, Ni, Nb, B to the bainite. The steel has low carbon, good low temperature toughness, welding performance, and forming performance. Its Nb and Ti element is low. And it is fit for large-scale industrialization continuous casting production. The TMCP+ RPC+T technique is adopted to make tensile strength over 900N / mm2 high intensity and tenacity steel. Adopting lower steel blank heating temperature can economize energy and improve steel low temperature toughness. The product can apply in engineering machinery, digging machinery, heavy-duty car, and marine facilities field, and etc.

Owner:UNIV OF SCI & TECH BEIJING +1

High-strength low-temperature resistant material for turnover box

The invention discloses a high-strength low-temperature resistant material for a turnover box, The high-strength low-temperature resistant material is prepared from the following components in parts by weight: 89 to 137 parts of polypropylene, 57 to 84 parts of high-density polyethylene, 17 to 33 parts of SEBS, 3 to 11 parts of alumina, 5 to 13 parts of aluminum-doped zinc oxide whisker, 4 to 17 parts of hollow glass microspheres, 5 to 19 parts of nano attapulgite, 5 to 13 parts of organic modified montmorillonite, 4 to 16 parts of wollastonite powder, 0.1 to 2 parts of an antioxidant, 0.5 to3 parts of a compatibilizer, 0.1 to 4 parts of naphthenic oil, and 0.1 to 3 parts of EBS; the raw materials are subjected to the steps of mixing, extruding, water cooling, pulling for strip forming, pelletizing and the like. The high-strength low-temperature resistant material disclosed by the invention has high mechanical strength and excellent anti-aging performance and antistatic performance, can meet the application requirements of the turnover box under low temperature use conditions, has high impact strength, and is resistant to throw and impact, and the material disclosed by the invention can be widely used in low temperature climate outdoor turnover boxes and other fields.

Owner:含山县胜发塑料制品有限公司

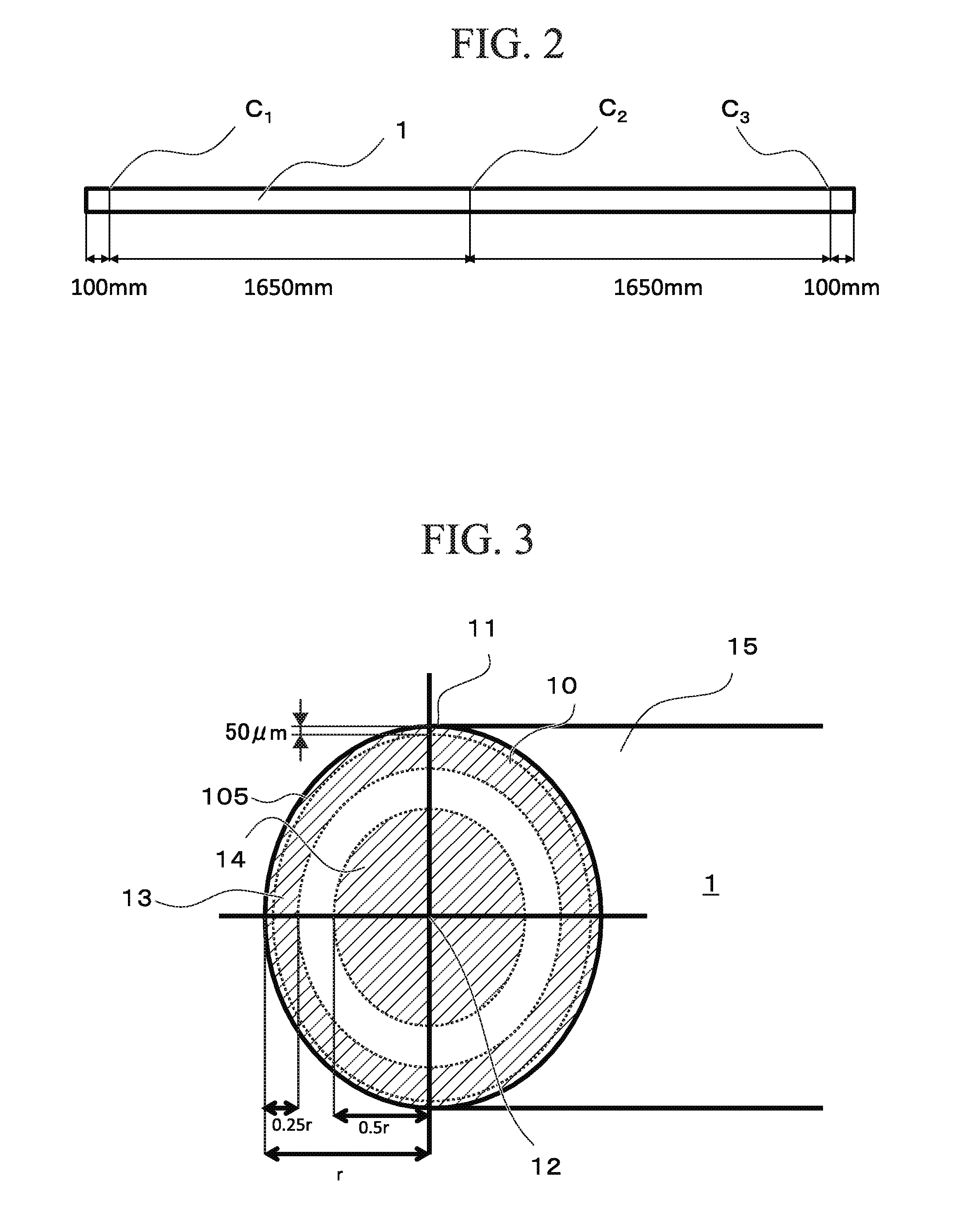

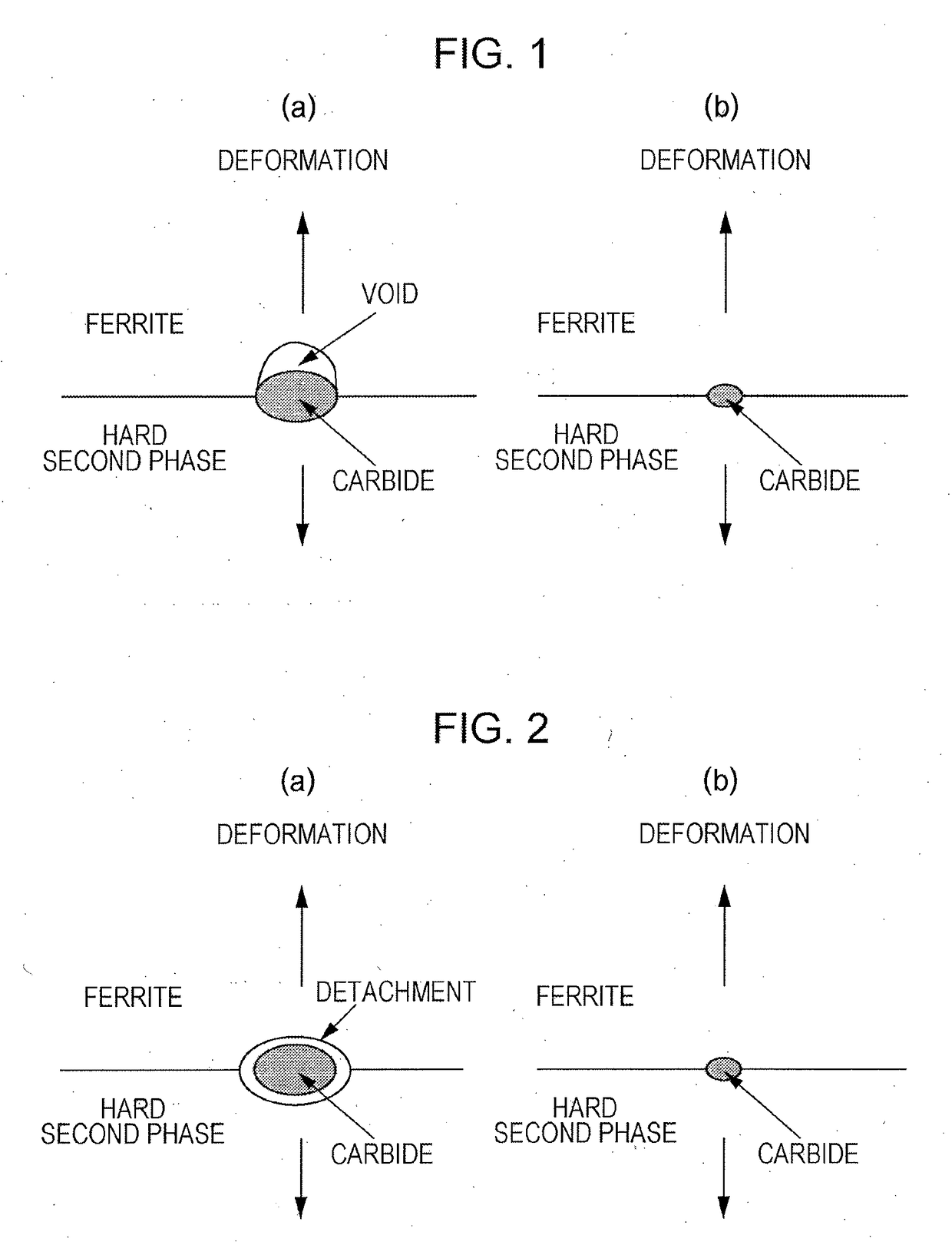

High strength steel sheet and method for producing the same

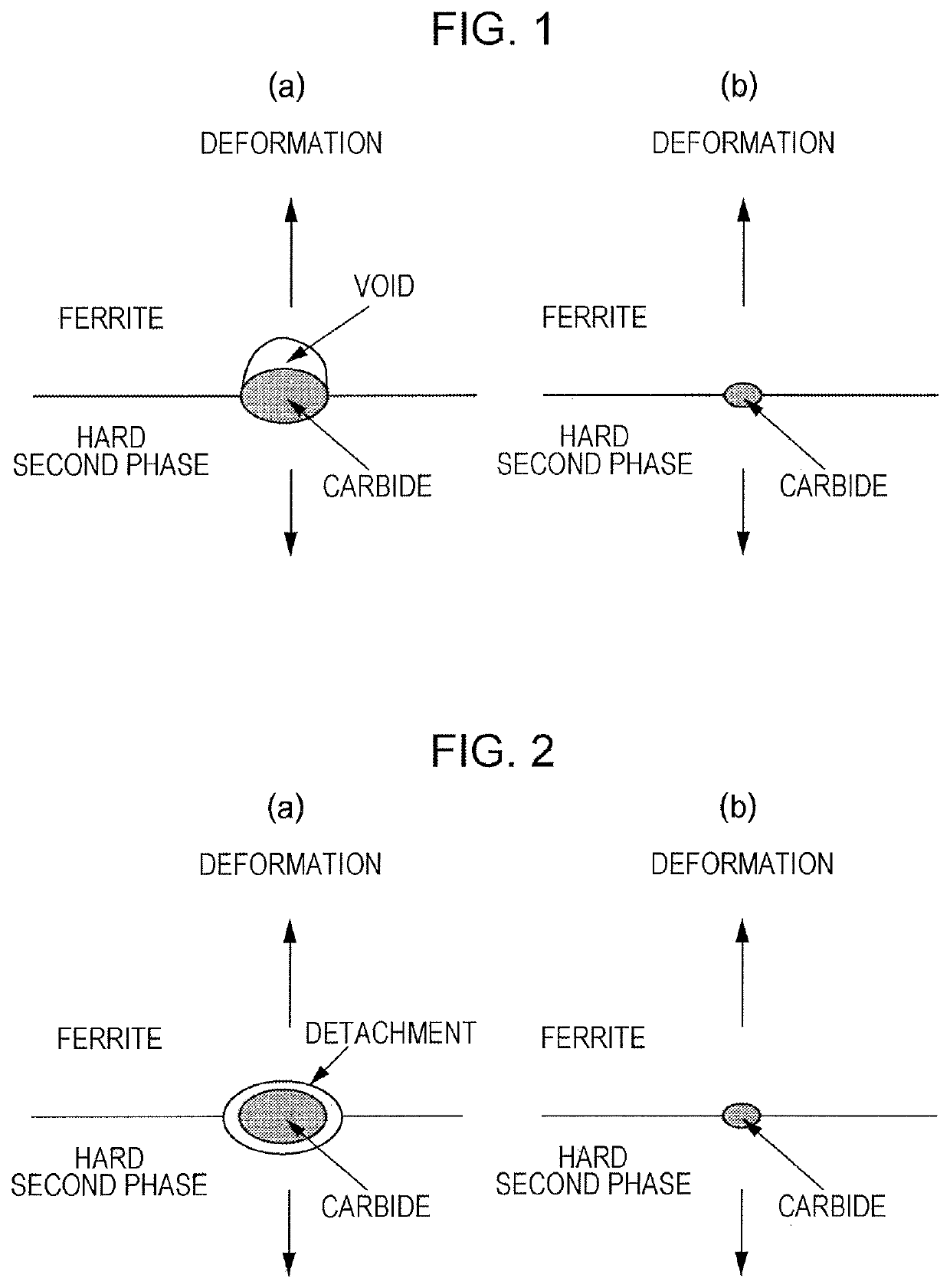

ActiveUS20190032186A1Improve ductilityImprove toughnessHot-dipping/immersion processesFurnace typesCarbideUltimate tensile strength

High strength steel sheets that have excellent ductility and low-temperature toughness and methods for producing such high strength steel sheets. A high strength steel sheet includes a composition containing, on a mass % basis, C: 0.05% to 0.30%, Si: 0.5% to 2.5%, Mn: 0.5% to 3.5%, P: 0.003% to 0.100%, S: 0.02% or less, Al: 0.010% to 1.5%, and N: 0.01% or less, the balance being Fe and unavoidable impurities, and a steel microstructure including a ferrite phase with an area fraction of 10% to 70%, a hard second phase with an area fraction of 30% to 90%, and a carbide that is at an interface between a ferrite phase and a hard second phase and that has an average equivalent-circle diameter of 200 nm or less.

Owner:JFE STEEL CORP

A kind of outdoor electrical insulation modified epoxy resin composition

The invention discloses an outdoor electrical insulation modified epoxy resin composition, which comprises epoxy resin, curing agent, curing accelerator and inorganic filler. The outdoor electrical insulation modified epoxy resin composition has excellent properties such as high weather resistance, excellent hydrophobicity, high volume resistivity, high resistance to tracking, high arc resistance, and low thermal expansion, and can be used to make AC transmission Compared with silicone rubber sheds, sheds for suspension insulators, crossarms and other outdoor insulation parts for lines can prevent bird pecks, resist trampling on inspection lines, and avoid transportation damage.

Owner:赛思迈(上海)新材料科技有限公司

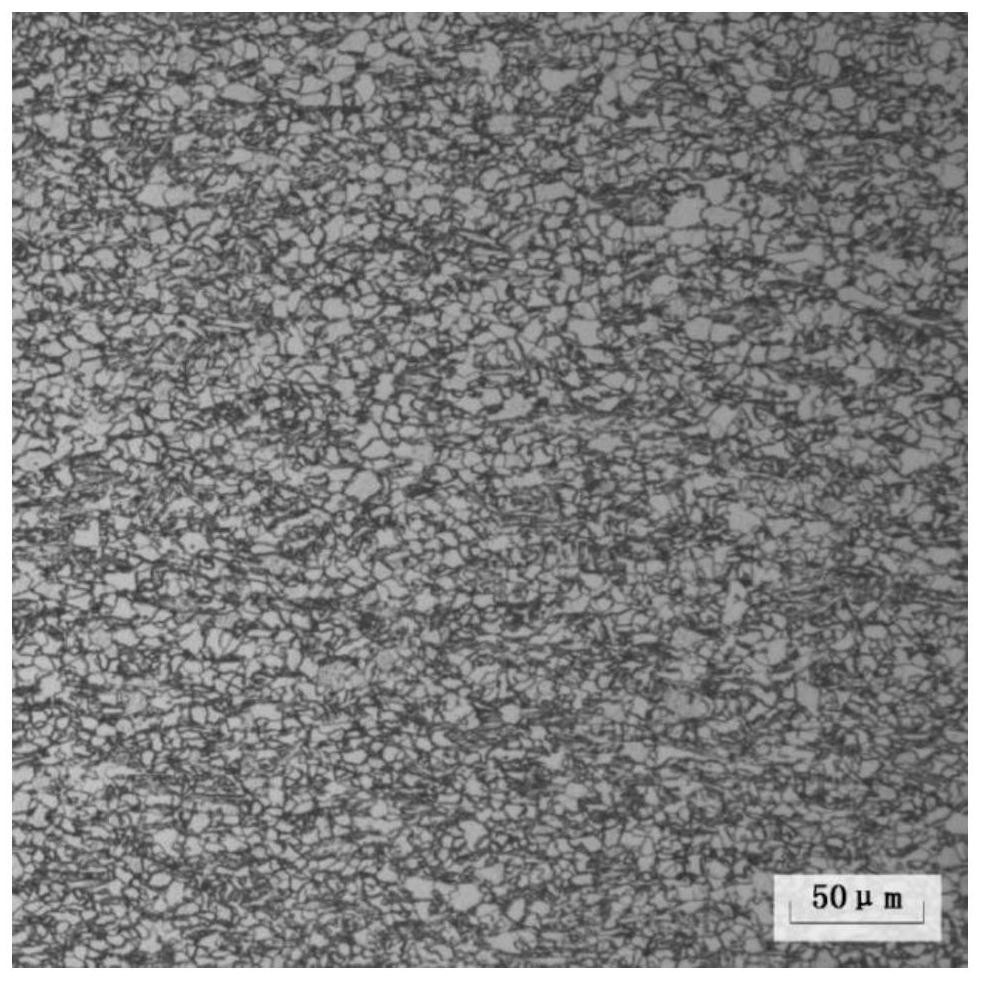

Austenite-type stainless steel hot-rolling steel material with excellent corrosion resistance, proof-stress, and low-temperature toughness and production method thereof

ActiveUS20100230011A1Improve corrosion resistanceGood seawater resistanceRoom temperatureSS - Stainless steel

An austenitic stainless steel hot-rolled steel material can be provided which has sea-water resistance and strength superior to conventional steel. Low-temperature toughness can be maintained, which is preferable in a structural member of speedy craft. The steel material can include an austenitic stainless steel hot-rolled steel material which excels in the properties of corrosion resistance, proof stress, and low-temperature toughness. In such austenitic stainless steel hot-rolling steel material, e.g., PI [=Cr+3.3(Mo+0.5W)+16N] ranges from 35 to 40, δ cal [=2.9(Cr+0.3Si+Mo+0.5W)−2.6(Ni+0.3Mn+0.25Cu+35C+20N)−18] ranges from −6 to +2, and a 0.2% proof stress at room temperature is not less than 550 MPa, Charpy impact value measured using a V-notch test piece at −40° C. is not less than 100 J / cm2, and the pitting potential measured in a deaerated aqueous solution of 10% NaCl at 50° C. (Vc'100) is not less than 500 mV (as it relates to saturated Ag / AgCl).

Owner:NIPPON STEEL STAINLESS STEEL CORP +1

Steel plate for high-strength and high-toughness steel pipes and method for producing steel plate

ActiveUS20190040488A1High strengthImprove toughnessFurnace typesHeat treatment furnacesChemical compositionHigh intensity

A steel plate for high-strength and high-toughness steel pipes has a chemical composition containing, by mass %, C: 0.03% or more and 0.08% or less, Si: more than 0.05% and 0.50% or less, Mn: 1.5% or more and 2.5% or less, P: 0.001% or more and 0.010% or less, S: 0.0030% or less, Al: 0.01% or more and 0.08% or less, Nb: 0.010% or more and 0.080% or less, Ti: 0.005% or more and 0.025% or less, and N: 0.001% or more and 0.006% or less, and further containing, by mass %, at least one selected from Cu: 0.01% or more and 1.00% or less, Ni: 0.01% or more and 1.00% or less, Cr: 0.01% or more and 1.00% or less, Mo: 0.01% or more and 1.00% or less, V: 0.01% or more and 0.10% or less, and B: 0.0005% or more and 0.0030% or less, with the balance being Fe and inevitable impurities. The steel plate has a microstructure in which an area fraction of ferrite at a ½ position of a thickness of the steel plate is 20% or more and 80% or less and deformed ferrite constitutes 50% or more and 100% or less of the ferrite.

Owner:JFE STEEL CORP

High-strength hot rolled steel sheet and method for manufacturing same

PendingUS20210140007A1Reduce environmental loadReduce weightHot-dipping/immersion processesFurnace typesChemical compositionToughness

Provided is a high-strength hot rolled steel sheet that has excellent stretch flange formability, bendability, and low-temperature toughness while maintaining high strength of a tensile strength TS of 1180 MPa or more, and a method for manufacturing the high-strength hot rolled steel sheet.The high-strength hot rolled steel sheet includes a specific chemical composition, and a steel structure in which a lower bainite phase and / or a tempered martensite phase at 90% or more in terms of a total area fraction is contained as a dominant phase, an average grain size of the dominant phase is 10.0 μm or less, and an amount of Fe in Fe-based precipitates is 0.70% or less in mass %, in which an arithmetic average roughness (Ra) of a surface is 2.50 μm or less, and a tensile strength TS is 1180 MPa or more.

Owner:JFE STEEL CORP

A kind of preparation method of modified polyester hot melt adhesive and adhesive film thereof

ActiveCN105111990BIncrease elasticityGood adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterPolyurethane elastomer

The invention discloses a modified polyester hot melt adhesive and a preparation method for an adhesive film thereof. The modified polyester hot melt adhesive comprises the raw materials in parts by weight: 35-80 parts of a polyester hot melt adhesive, 20-65 parts of a thermoplastic type polyurethane elastomer and 0.5 part of an antioxidant. According to the modified polyester hot melt adhesive disclosed by the invention, the polyester hot melt adhesive is blended and modified by using the polyurethane elastomer, so that the problem of low temperature brittleness of an existing polyester hot melt adhesive product is solved well. The polyester hot melt adhesive product disclosed by the invention has relatively good toughness and is not crispy at (-40) DEG C, can be used for binding metals such as an aluminum sheet and the like with epoxy resin, and is suitable for binding a metal plate and epoxy resin, particularly binding an aluminum plate and an epoxy coating pipeline in a refrigerator.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

Steel plate for high-strength and high-toughness steel pipes and method for producing steel plate

ActiveUS11236405B2Improve energy absorptionLow-temperature toughnessFurnace typesHeat treatment furnacesChemical compositionPipe

A steel plate for high-strength and high-toughness steel pipes has a chemical composition containing, by mass %, C: 0.03% or more and 0.08% or less, Si: more than 0.05% and 0.50% or less, Mn: 1.5% or more and 2.5% or less, P: 0.001% or more and 0.010% or less, S: 0.0030% or less, Al: 0.01% or more and 0.08% or less, Nb: 0.010% or more and 0.080% or less, Ti: 0.005% or more and 0.025% or less, and N: 0.001% or more and 0.006% or less, and further containing, by mass %, at least one selected from Cu: 0.01% or more and 1.00% or less, Ni: 0.01% or more and 1.00% or less, Cr: 0.01% or more and 1.00% or less, Mo: 0.01% or more and 1.00% or less, V: 0.01% or more and 0.10% or less, and B: 0.0005% or more and 0.0030% or less, with the balance being Fe and inevitable impurities. The steel plate has a microstructure in which an area fraction of ferrite at a ½ position of a thickness of the steel plate is 20% or more and 80% or less and deformed ferrite constitutes 50% or more and 100% or less of the ferrite.

Owner:JFE STEEL CORP

High-strength steel sheet having excellent ductility and low-temperature toughness and method for manufacturing thereof

PendingUS20220042132A1Improve low temperature toughnessHigh strengthFurnace typesHeat treatment furnacesMechanical engineeringToughness

The present invention relates to a structural steel sheet suitable for ships or steel structures and, more particularly, to a high-strength steel sheet having excellent ductility and low-temperature toughness and a method for manufacturing same.

Owner:POHANG IRON & STEEL CO LTD

A kind of high-strength low-hardness hydrogen sulfide corrosion-resistant steel and its preparation method

Owner:SHOUGANG CORPORATION

High-strength hot-rolled steel sheet having excellent bendability and low-temperature and method for manufacturing same

ActiveUS20210164077A1Small thickness-dependent hardness deviationImprove bendabilityFurnace typesHeat treatment furnacesVehicle frameMetallurgy

The present disclosure relates to a hot-rolled steel sheet utilized as material for heavy machinery, vehicle frames, and the like, and more specifically to a high-strength hot-rolled steel sheet having excellent bendability and low-temperature toughness and a method for manufacturing same.

Owner:POHANG IRON & STEEL CO LTD

A 1500mpa grade ultra-high-strength steel non-copper-coated solid core welding wire for gas shielded welding

InactiveCN105234587BImprove purityHigh impact energyWelding/cutting media/materialsWelding/soldering/cutting articlesCopper platingWelding defect

Owner:SHANDONG IRON & STEEL CO LTD

High-strength steel sheet excellent in resistance to stress-relief annealing and in low-temperature joint toughness

InactiveUS8394209B2Improve the immunityImprove low temperature toughnessFurnace typesHeat treatment furnacesChemical elementStress relief

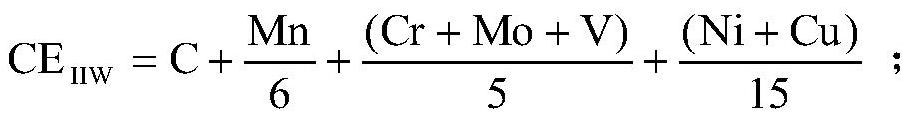

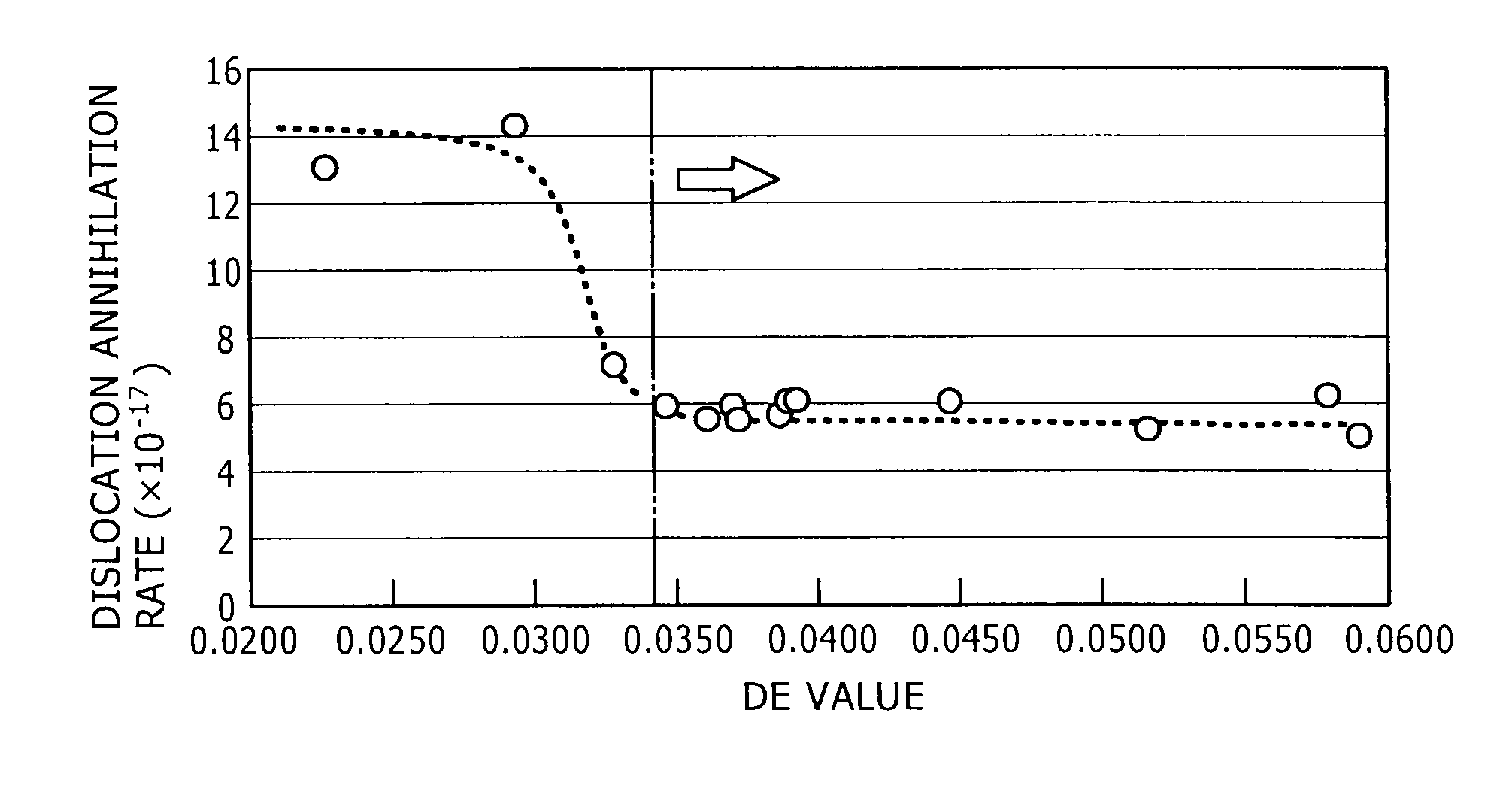

A high-strength steel sheet according to the present invention not only is suitably adjusted in its chemical elements composition, but also has a DE value defined by the following Equation (1) of 0.0340% or more, and a carbon equivalent Ceq defined by the following Equation (2) of 0.45% or less:DE value=[Ti]+[Nb]+0.3[V]+0.0075[Cr] (1)where, [Ti], [Nb], [V], and [Cr] represent contents (mass %) of Ti, Nb, V, and Cr, respectively;Ceq=[C]+[Mn] / 6+([Cr]+[Mo]+[V]) / 5+([Cu]+[Ni]) / 15 (2)where, [C], [Mn], [Cr], [Mo], [V], [Cu], and [Ni] represent contents (mass %) of C, Mn, Cr, Mo, V, Cu, and Ni, respectively. A high-strength steel sheet resistant to strength reduction and good in low-temperature toughness of HAZ even when subjected for a long time to a stress-relief annealing process after being processed by welding, is provided.

Owner:KOBE STEEL LTD

Steel material for high heat input welding

ActiveUS11326238B2Reduce the amount requiredReduce formationWelding/cutting media/materialsWelding/soldering/cutting articlesHeat-affected zoneToughness

Provided is a steel material for high heat input welding having excellent welding heat affected zone low-temperature toughness at −55° C. in the case that the steel material is welded by high heat input welding with a heat input of more than 80 kJ / cm. The steel material may be used in low-temperature storage tanks, for example. The steel material for high heat input welding includes, in mass %, C: 0.04 to 0.09%, Si: 0.15 to 0.25%, Mn: 1.40 to 2.00%, P: 0.015% or less, S: 0.0005 to 0.0040%, Al: 0.030 to 0.080%, Ti: 0.005 to 0.025%, B: 0.0003 to 0.0020%, Ca: 0.0005 to 0.0030%, N: 0.0030 to 0.0060%, O: 0.0040% or less, Nb: 0.005% or less, and Mo: 0.005% or less, the balance being Fe and incidental impurities.

Owner:JFE STEEL CORP

High strength steel sheet and method for producing the same

ActiveUS10941476B2Improve ductilityImprove toughnessHot-dipping/immersion processesFurnace typesCemented carbideToughness

High strength steel sheets that have excellent ductility and low-temperature toughness and methods for producing such high strength steel sheets. A high strength steel sheet includes a composition containing, on a mass % basis, C: 0.05% to 0.30%, Si: 0.5% to 2.5%, Mn: 0.5% to 3.5%, P: 0.003% to 0.100%, S: 0.02% or less, Al: 0.010% to 1.5%, and N: 0.01% or less, the balance being Fe and unavoidable impurities, and a steel microstructure including a ferrite phase with an area fraction of 10% to 70%, a hard second phase with an area fraction of 30% to 90%, and a carbide that is at an interface between a ferrite phase and a hard second phase and that has an average equivalent-circle diameter of 200 nm or less.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com