A kind of outdoor electrical insulation modified epoxy resin composition

An epoxy resin and electrical insulation technology, which is applied in the field of modified epoxy resin compositions, can solve problems such as the electrical insulation properties of materials not mentioned, achieve enhanced mechanical properties and electrical insulation properties, excellent hydrophobicity, and avoid sheds damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

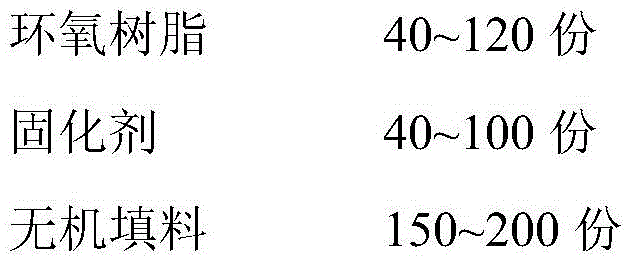

Method used

Image

Examples

Embodiment 1

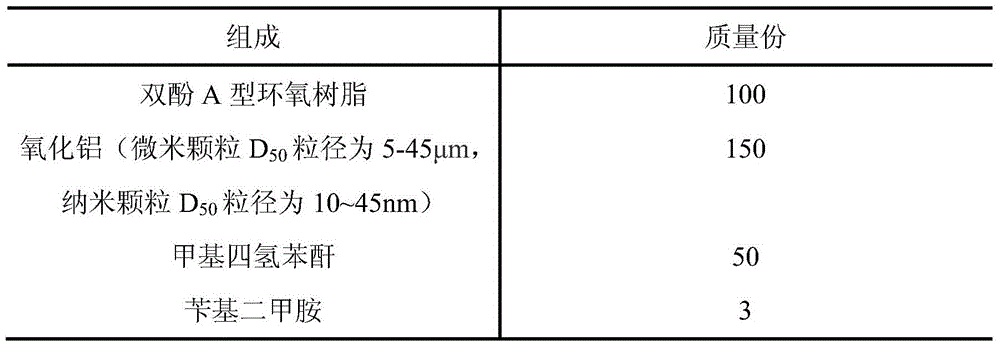

[0037] Embodiment 1 (epoxy resin is not modified with silicone)

[0038] Preparation of epoxy resin composition:

[0039] The formula of epoxy resin composition is as follows:

[0040]

[0041] Preparation method: (1) Add 100 parts by mass of bisphenol A epoxy resin to a high-speed disperser, heat to 65°C, and stir for 60 minutes; (2) Add 75 parts by mass of surface-modified alumina to the above-mentioned In the epoxy resin, carry out high-speed dispersion and vacuum degassing treatment, the dispersion time is 3h, and the vacuum degree is 100Pa; (3) 50 mass parts of curing agent methyltetrahydrophthalic anhydride and 3 mass parts of accelerator benzyldimethylamine are carried out Pre-mixing, the mixing temperature is 45°C, the stirring time is 40min, and then 75 parts by mass of surface-modified alumina are added for high-speed dispersion and vacuum degassing treatment, the dispersion time is 2h, and the vacuum degree is 150Pa; (4) Preheat the mold, apply a mold release a...

Embodiment 2

[0042] Embodiment 2 (epoxy resin is modified by organosilicon)

[0043] Preparation of epoxy resin composition:

[0044] The formula of epoxy resin composition is as follows:

[0045]

[0046]

Embodiment 3

[0047] Embodiment 3 (epoxy resin is modified by organosilicon)

[0048] Preparation of epoxy resin composition:

[0049] The formula of epoxy resin composition is as follows:

[0050]

[0051] Preparation method: (1) Add 100 parts by mass of bisphenol A epoxy resin prepolymer modified by amino-terminated polydimethylsiloxane into a high-speed disperser, heat the system to 85°C, and stir The time is 30min, so that the two are fully mixed evenly; (2) 75 parts by mass of surface-modified alumina are added to the above-mentioned epoxy resin, and high-speed dispersion and vacuum degassing are carried out. The dispersion time is 6h, and the vacuum degree 200Pa; (3) Premix 50 parts by mass of curing agent methyltetrahydrophthalic anhydride and 3 parts by mass of accelerator benzyldimethylamine, the mixing temperature is 55 ° C, the stirring time is 20min, and then add 75 parts by mass through the surface The modified alumina is subjected to high-speed dispersion and vacuum degassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com