Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Low casting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for in-situ preparation of polybenzimidazole-based electrolyte membrane and polybenzimidazole-based electrolyte membrane prepared thereby

InactiveUS20120115050A1Promote formationLow viscosityFinal product manufactureSolid electrolyte fuel cellsAlcoholElectrolyte

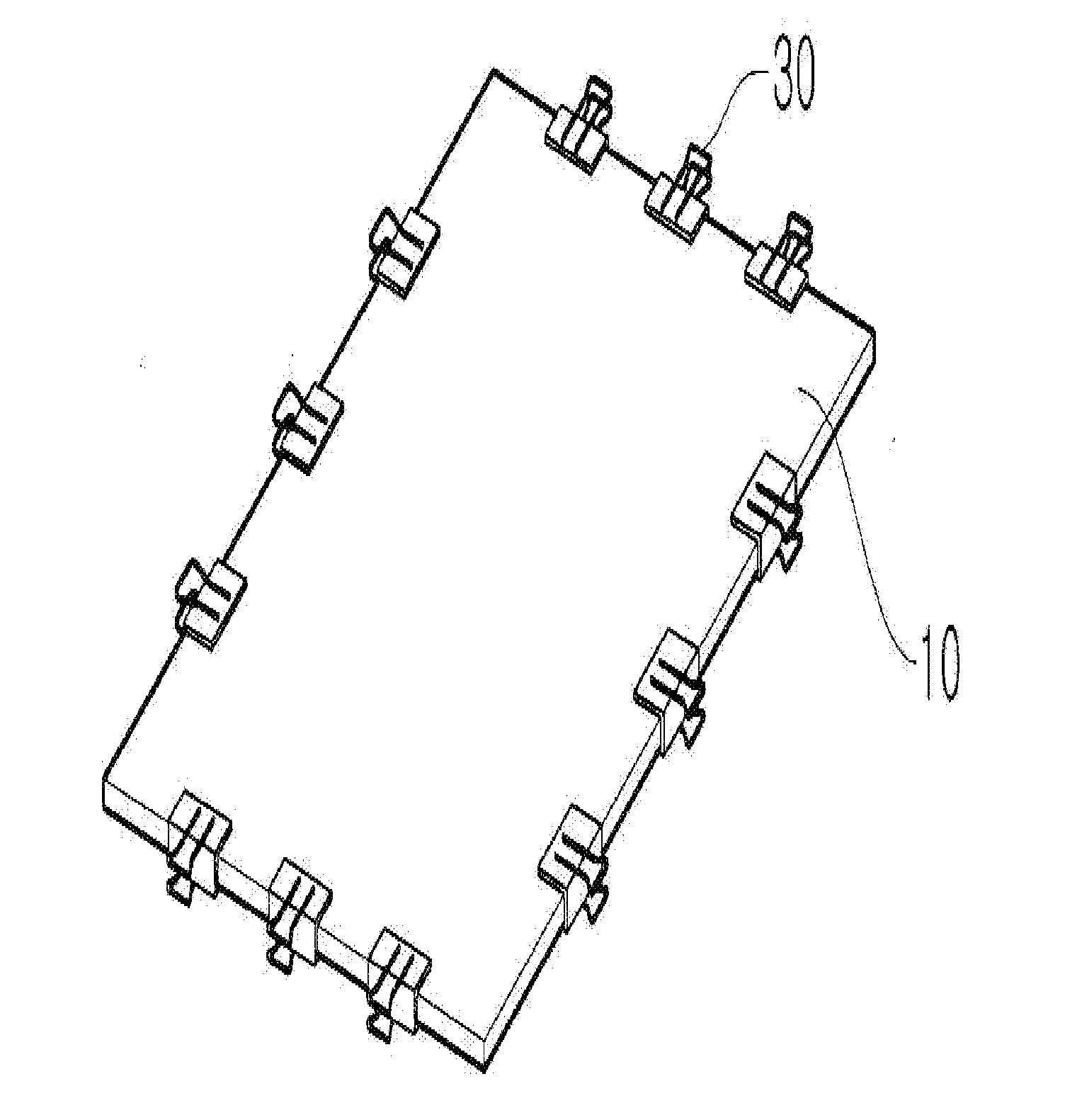

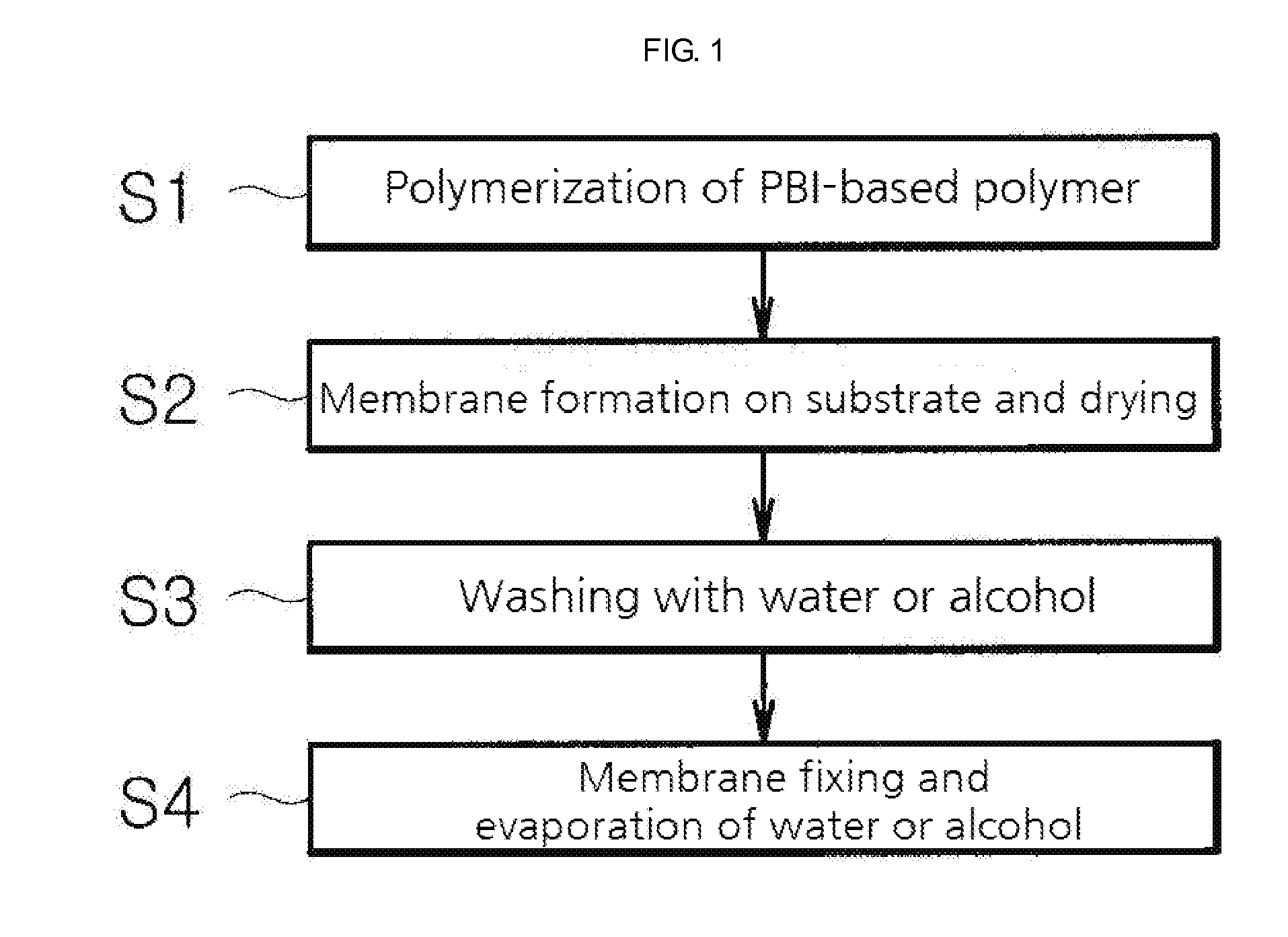

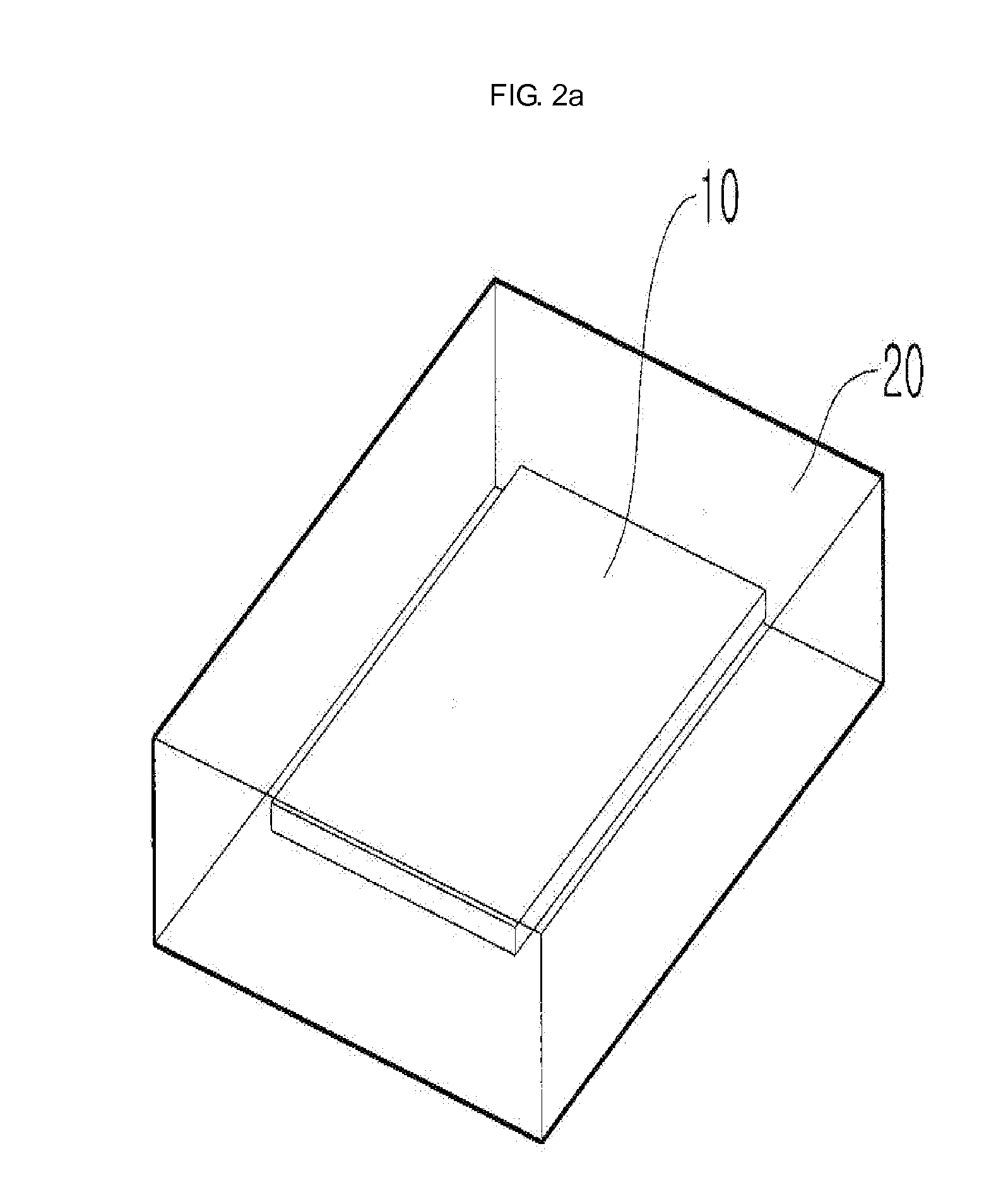

Disclosed is a method for in-situ preparation of a polybenzimidazole-based electrolyte membrane, including: polymerizing a polybenzimidazole polymer in a solution; casting a solution containing the polymerized polymer onto a substrate and drying the solution in air to form a membrane; washing the dried membrane with water or alcohol; and allowing water or alcohol to evaporate from the membrane containing water or alcohol, while maintaining the shape of the membrane. The method for in-situ preparation of a polybenzimidazole-based electrolyte membrane allows easy preparation of a polybenzimidazole-based electrolyte membrane having a desired area without any complicated processes, and thus contributes to simplification of an overall process for fabricating a fuel cell.

Owner:KOREA INST OF SCI & TECH

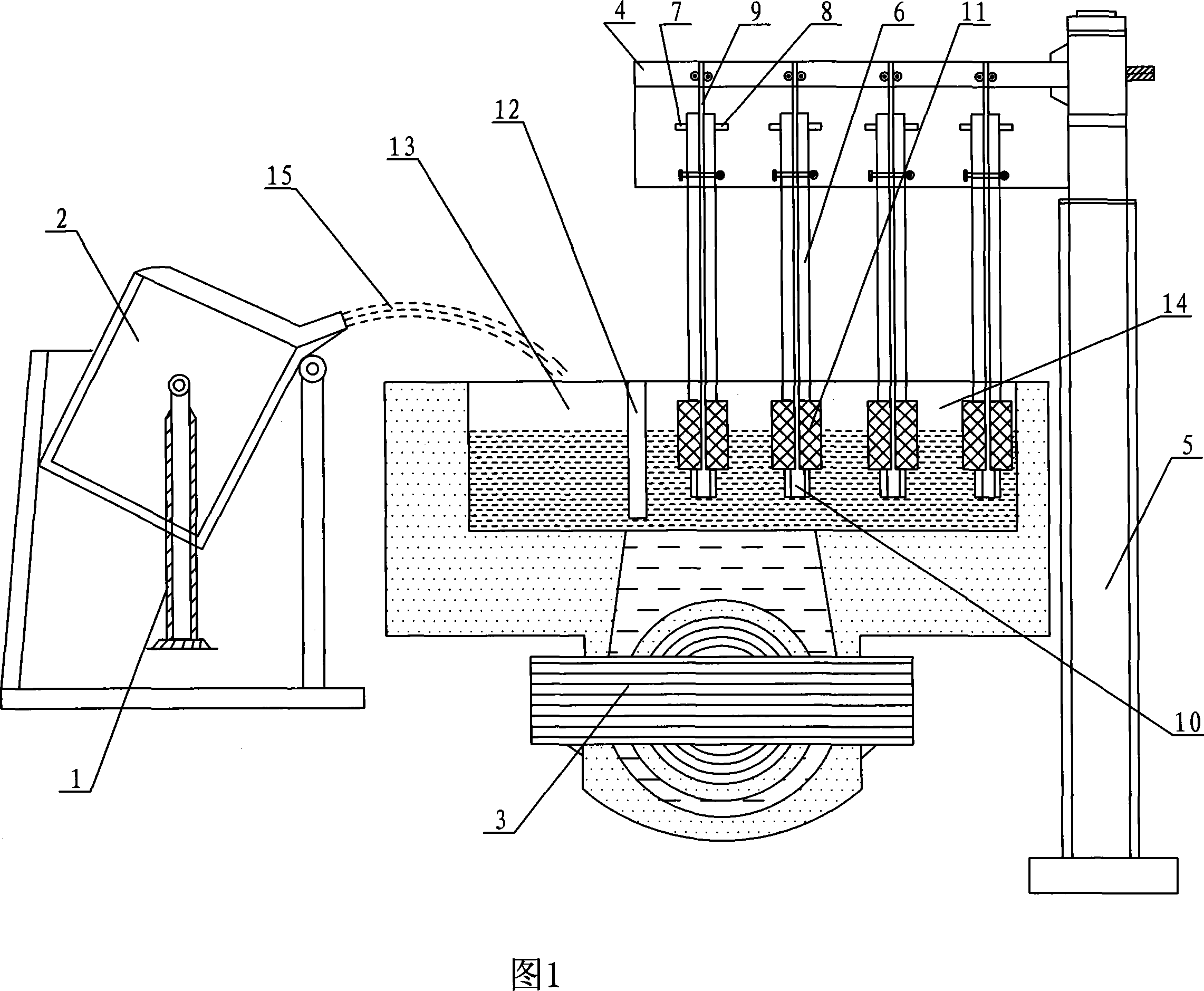

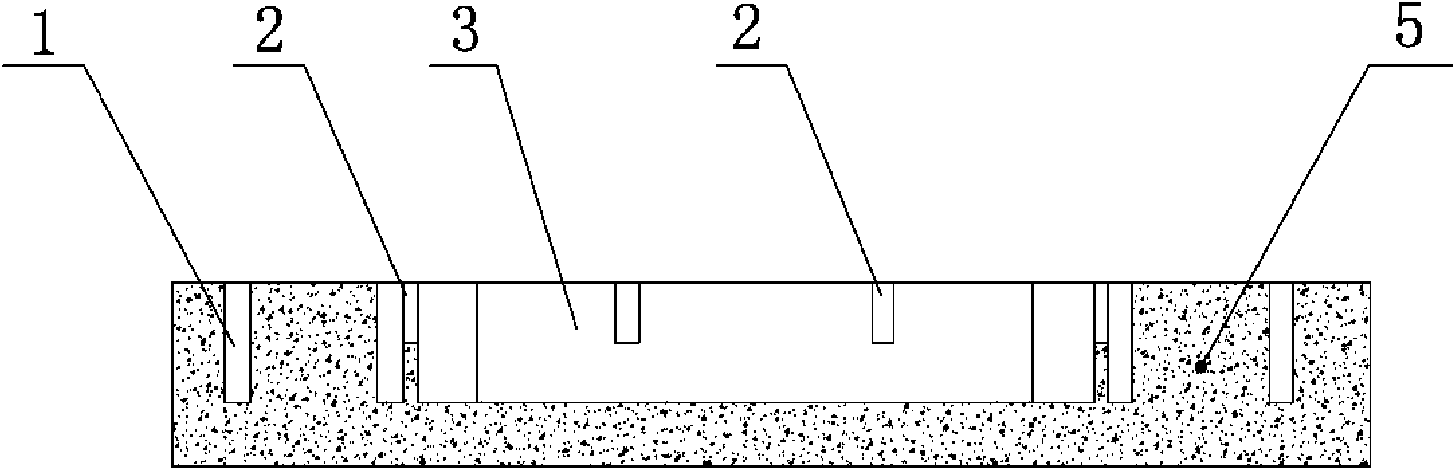

Upper-drawing casting device for the silicon bronze bar blank

The invention discloses an up-drawing casting device for silicon bronze bar billet, comprising a smelter positioned on the landing control device. A side face of the smelter is provided with a power frequency furnace with an iron core, the upper surface of the power frequency furnace with an iron core is provided with a plurality of drawing devices which are positioned on a rolling crane. The drawing devices are provided with a crystallizer, the upper end of which is provided with a water inlet port and a water outlet port respectively. The dummy bars of the drawing devices are arranged through and in the crystallizer. The lower end of the crystallizer is provided with a graphite mould. The outside of the connection of the graphite mould and the crystallizer is provided with graphite protecting jacket. The invention has the advantages that the casting temperature of the up-drawing casting device for silicon bronze bar billet is low, the drawing speed is fast, the productivity effect is high, the grain of silicon bronze bar billet produced by the invention is uniformity and the production safety is good, thereby avoiding the dangerous accidents in operation.

Owner:GAOXIN ZHANGTONG

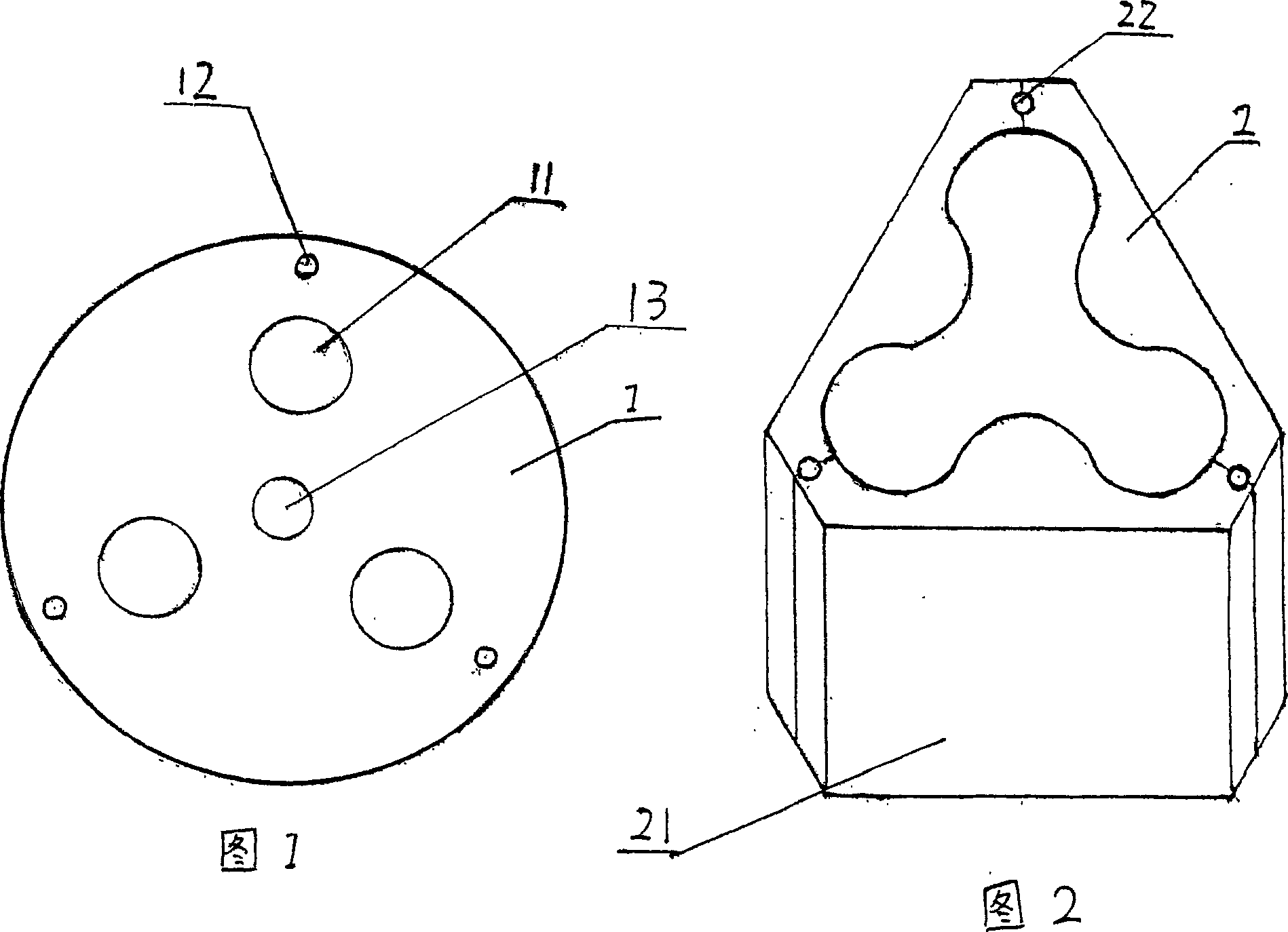

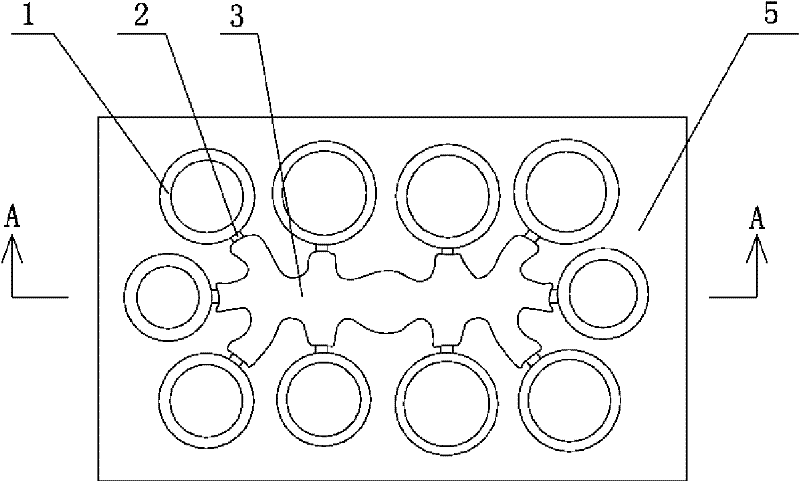

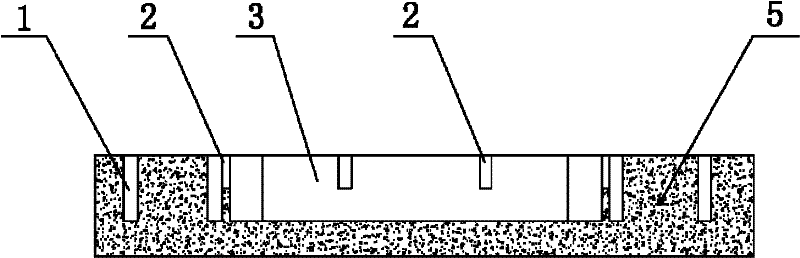

Method and mould for manufacturing valve retainer

InactiveCN101590586AAvoid leaningAvoid deformationFoundry mouldsFurnace typesEnergy consumptionMaterials science

The invention discloses a method for manufacturing a valve retainer, which comprises the following steps: arranging a sprue on a mould; and carrying out smelting, casting, demoulding, heat treatment and ground finishing on metal, wherein the mould is a directly molded mould for the valve retainer. Compared with the prior manufacturing method, the method for manufacturing the valve retainer saves four steps of sliping a head, boring an inner hole, digging up an excircle and cutting off. Therefore, the method simplifies the production steps, saves a large amount of labors, reduces the equipment input and energy consumption, shortens the production cycle and reduces the production cost.

Owner:张永炤 +1

High-uniformity tin-phosphor bronze strip preparation process

The invention belongs to the technical field of bronze strip manufacturing, and particularly relates to a high-uniformity tin-phosphor bronze strip preparation process. The high-uniformity tin-phosphor bronze strip preparation process comprises the following steps of S1, smelting, S2, casting, S3, milling, S4, homogenizing heat treatment, S5, cold rough rolling, S6, intermediate annealing, S7, cold intermediate rolling, S8, cold finish rolling, and S9, finished product annealing. According to the technical scheme, the smelting process can improve the component and structure uniformity of a casting blank, the gas content in melt can be effectively reduced, meanwhile, the components in a smelting furnace are uniformly distributed, and the burnout rate of alloy elements is low; and in the subsequent processing process, microsegregation forms such as intragranular segregation and grain boundary segregation can be eliminated by promoting the high-temperature diffusion process, a recrystallization structure is controlled and residual stress is reduced through a combined deformation heat treatment process, the microsegregation and stress distribution uniformity of the alloy is further improved, so that a tin-phosphor bronze strip with good structure and performance uniformity is obtained.

Owner:中铜华中铜业有限公司

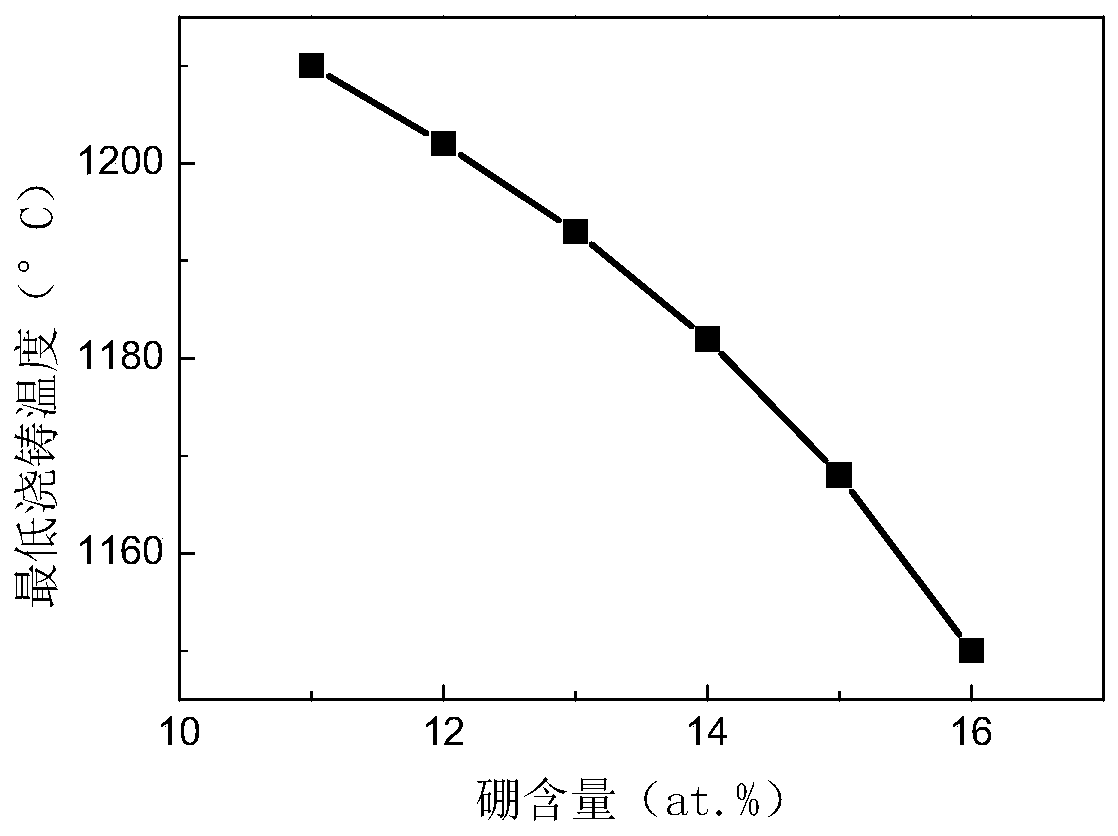

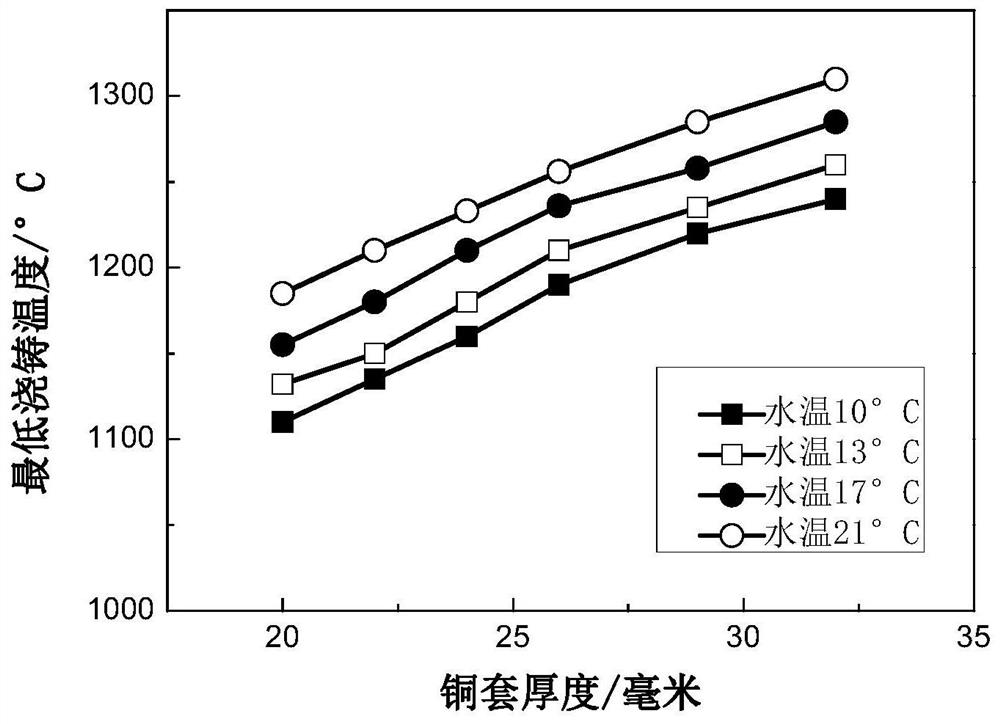

Method for preparing iron-based amorphous alloy strip by reducing casting temperature of melt

The invention relates to a method for preparing an iron-based amorphous alloy strip by reducing casting temperature of melt, in particular to a method for preparing an iron-based amorphous alloy stripby reducing casting temperature of Fe-P-C-Si-B series alloy melt. The casting temperature of the melt is reduced by adjusting and controlling the contents of nonmetal elements Si and B in the Fe76PCSi22-XBX alloy melt, and the value of X ranges from 11 to 16. The process is further adjusted, the casting temperature of the Fe76PCSi22-XBX alloy melt can be adjusted and controlled to the lowest casting temperature, and the lowest casting temperature of the method ranges from 1150 DEG C to 1210 DEG C. The density of the iron-based amorphous alloy strip can be improved, the surface quality can beimproved, and the advantages of low implementation cost, high efficiency, high controllability and repeatability, high in technical reliability and the like are achieved.

Owner:江苏中科启航新材料工业研究院有限公司 +3

Steel wire rope head casting method

InactiveCN103372641AConducive to breaking testEffective quality controlGearingCylindersCasting moldAlloy

The invention relates to a steel wire rope head casting method which is characterized in that tin-based bearing alloy is fused, zinc-based complex adhesion promoters are prepared to be used; rope heads at two ends of a steel wire rope are divided into completely divergent broom heads, and the broom heads are washed through steams, blown dry through high pressure wind and placed into the fused bearing alloy for preheating for 40-75s; after preheating, the zinc-based complex adhesion promoters are evenly coated on each steel wire of the broom heads; the broom heads coated with the adhesion promoters are placed into the fused bearing alloy again, evenly stirred and taken out, the broom heads coated with the alloy in advance are placed into a casting mold for casting of conical heads. The steel wire rope head casting method has the advantages of being simple in process, environmentally friendly and fast and convenient to operate, being capable of well ensuring the rope head casting quality and being favorable for overall pulling breaking measurement and detection of the steel wire rope.

Owner:宇宙钢丝绳有限公司

Composite wear-resisting plate

InactiveCN104647814ANo deformationImprove wear resistanceConveyorsSynthetic resin layered productsThermal stateEngineering

The invention belongs to the technical field of wear-resisting plates applied to middle troughs of scraper conveyers of coal mines and particularly relates to a composite wear-resisting plate. The wear-resisting plate comprises a base plate and a wear-resisting layer embedded onto the base plate. The base plate is a wear-resisting plate which is made from polyurethane; an embedding groove is formed in the local part of a work face of the base plate of the wear-resisting plate; and wear-resisting polyurethane is poured into the embedding groove in the form of a thermal state liquid. The composite wear-resisting plate is good in wear-resisting performance, relatively high connection strength between the base plate and the wear-resisting layer is ensured due to the embedding structure, and the manufacturing process is relatively simple.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

Novel mineral material and preparation method and application thereof

The invention provides a novel mineral material. The novel mineral material is prepared from the following raw materials in percentage by weight: 65-90% of stone, 0-5% of carbon fibers, 5-10% of ash powder and 5-20% of epoxy resin and a curing agent. The invention further provides a preparation method and application of the novel mineral material. The mineral material provided by the invention isgood in shock absorption, and particularly 10 times better than cast iron, and brings optimal vibration damping and noise reduction effects. The thermal stability is good, and the influence of temperature change on the dimensional precision of the machine tool hardly exists when the material is used for the numerical control machine tool, precision is high, a casting temperature is low, internal stress is avoided, the precision can be guaranteed, the integration is good, the novel mineral material can be directly injected into a pipeline, a cable, a sensor and the like, the corrosion resistance is good, good corrosion resistance is achieved on oil, cooling liquid and other corrosive liquid, energy is saved, environment is protected, energy consumption is low and is reduced by 80% comparedwith cast iron, and the material can be used as a regenerated material for secondary utilization.

Owner:杭州太普机械科技有限公司

Covering agent applicable to smelting of copper alloy containing easily oxidized alloying elements and application of covering agent

The invention belongs to the technical field of copper alloy machining, and relates to a covering agent applicable to smelting of a copper alloy containing easily oxidized alloying elements, and application of the covering agent. The coving agent consists of the following components in mass percent: 50-80% of sodium borate and 20-50% of cullet, wherein the sodium borate and the cullet are added respectively, and the cullet is added firstly, and then the sodium borate is added with the time interval not less than 10 min. Through the covering agent, vacuum smelting can be replaced by common smelting, the copper alloy containing easily oxidized alloying elements can be smelted by a common electric induction furnace, large-size ingot castings can be easily prepared and continuously cast, and the alloy quality of the copper alloy subjected to smelting is better. The covering agent related to the invention has the characteristics of low cost, environmental protection and energy conservation.

Owner:洛阳双瑞达特铜有限公司

Molten steel cleaning agent

PendingCN111876557AImprove qualityReduce energy consumptionProcess efficiency improvementSlagNon-metallic inclusions

The invention discloses a molten steel cleaning agent which is used for removing suspended non-metallic inclusions in molten steel in a molten state and gas dissolved in a metal solution, improving the quality of the molten steel and reducing the slag hole and pore rate of a casting product. The molten steel cleaning agent comprises 70%-80% of cement and 30%-20% of fluorite powder. By adding the molten steel cleaning agent into a furnace, the quality of molten steel can be improved, the slag hole and pore rate of casting products is reduced, and the percent of pass of the casting finished products is greatly increased. Different from the situation that similar products are limited to slagging in a ladle outside a furnace, extra temperature drop is caused by standing of molten steel, and heat is lost, the in-furnace slagging characteristic of the molten steel cleaning agent can reduce furnace wall slag adhesion, lower the furnace wall thickness, improve the induction heating efficiencyand reduce the energy consumption, the use amount of the molten steel cleaning agent is smaller than that of similar products on the market, the capacity of removing gas and inclusions in molten steelis better, the economic benefit is higher, and the molten steel cleaning agent is suitable for wide application and popularization.

Owner:姚玉美

Control method for center segregation of casting blank

The invention relates to the field of steel and iron metallurgy, particularly to a control method for center segregation of a casting blank. The method specifically comprises the following steps: (1)manufacturing an alloy steel wire having the same type as a target casting steel type; (2) calculating a thermal enthalpy value of medium steel ladle liquid according to an actual temperature of the medium steel ladle liquid; (3) calculating the heat consumed to reach thermal balance according to a target temperature of the medium steel ladle liquid; and (4) feeding the alloy steel wire in step (1) in the medium steel ladle liquid to supply the heat. The control method improves the problem of center segregation by effectively lowering the casting temperature of the medium steel ladle liquid inthe continuous casting production process, so that the homogeneity of the casting blank is improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Single crystal copper fixed anode target for X-ray tube and preparing method thereof

InactiveCN110303141AImprove high temperature performanceHigh bonding strengthX-ray tube electrodesRheniumX-ray

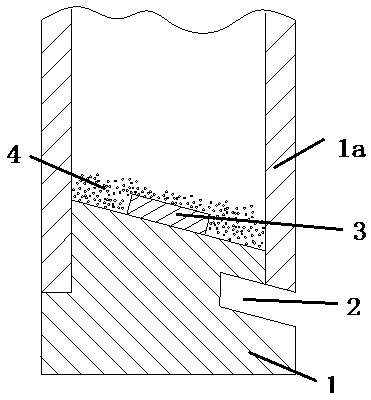

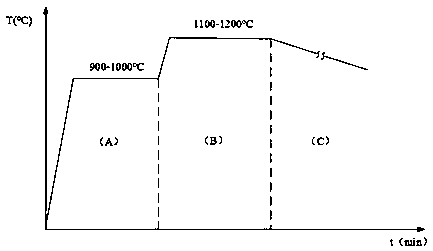

The invention provides a single crystal copper fixed anode target for an X-ray tube. The single crystal copper fixed anode target comprises a copper base and a tungsten-rhenium alloy sheet target surface. A preparing method for preparing the single crystal copper fixed anode target for the X-ray tube comprises the steps that a tungsten-rhenium alloy sheet and a high-purity copper powder are addedinto a mold, and slow cooling is carried out after two-stage temperature rising and heating are carried out. Through design of the mold and the process temperature, the prepared fixed anode target base copper is of a single crystal structure. Because no thermal expansion coefficient and thermal conductivity anisotropy caused by grain boundaries exists, the problem of grain boundary cracking causedby the thermal stress effect in work of the X-ray fixed anode target is solved, the heat dissipation performance is higher, and the service life is longer.

Owner:株洲未铼新材料科技有限公司

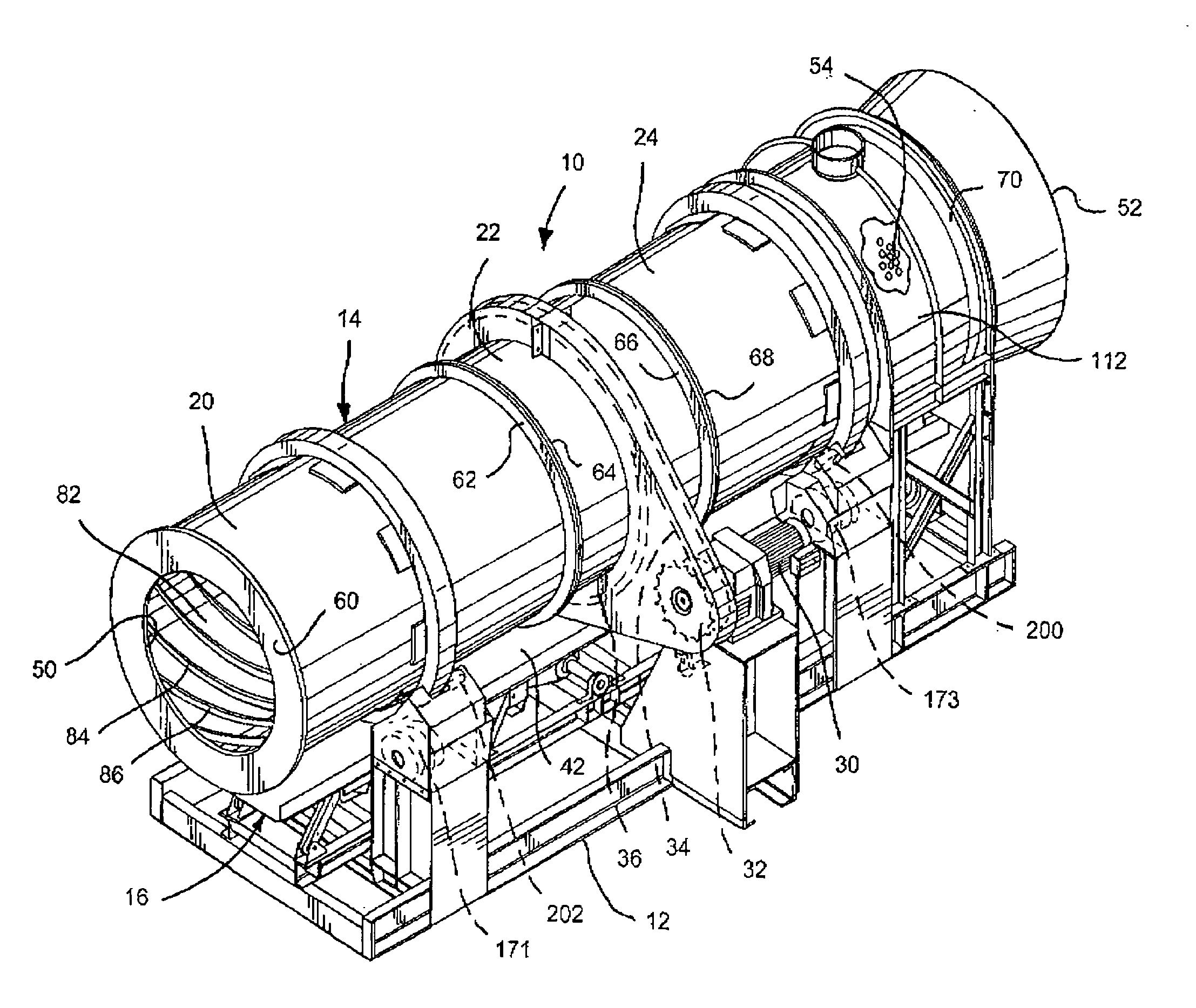

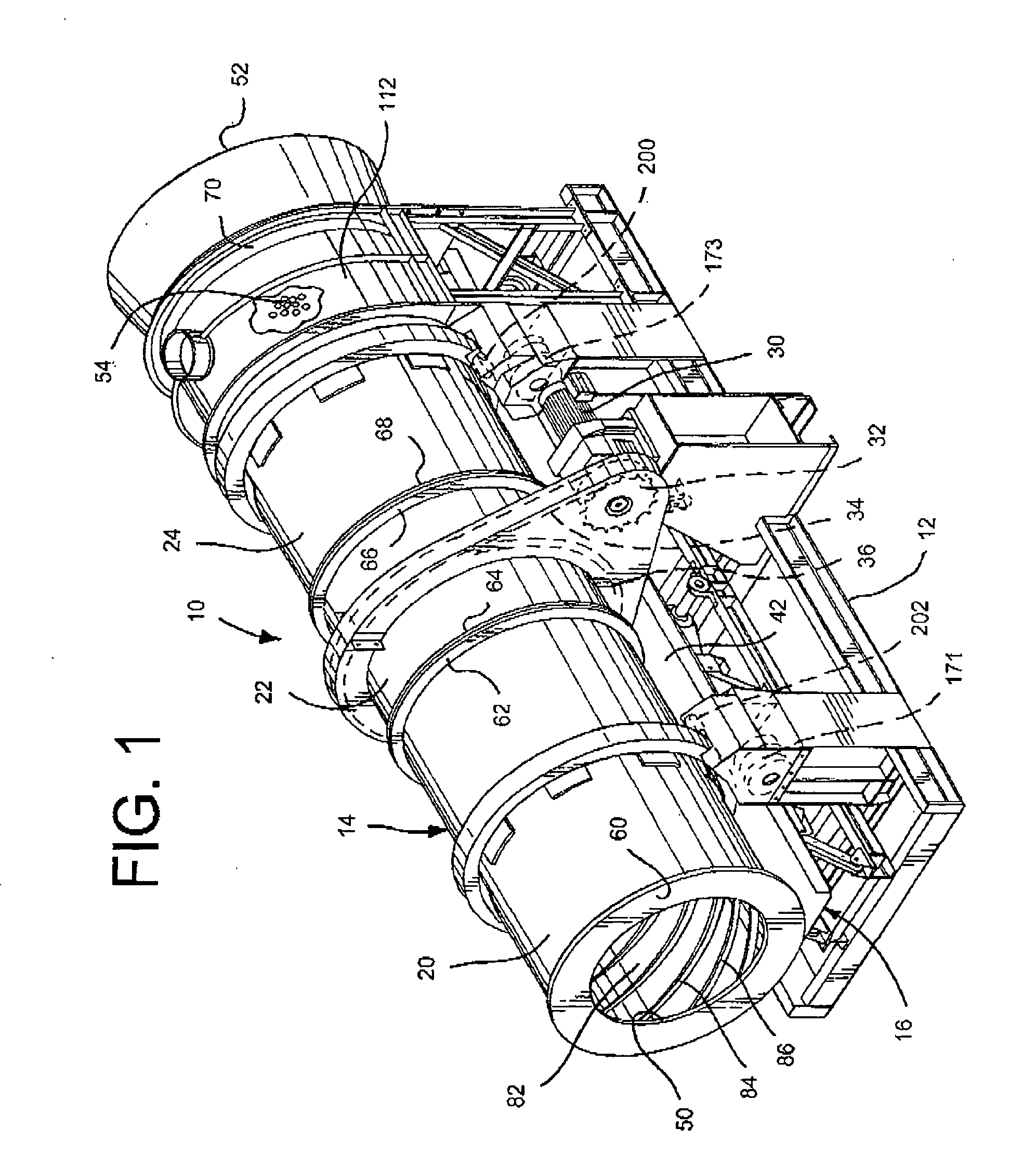

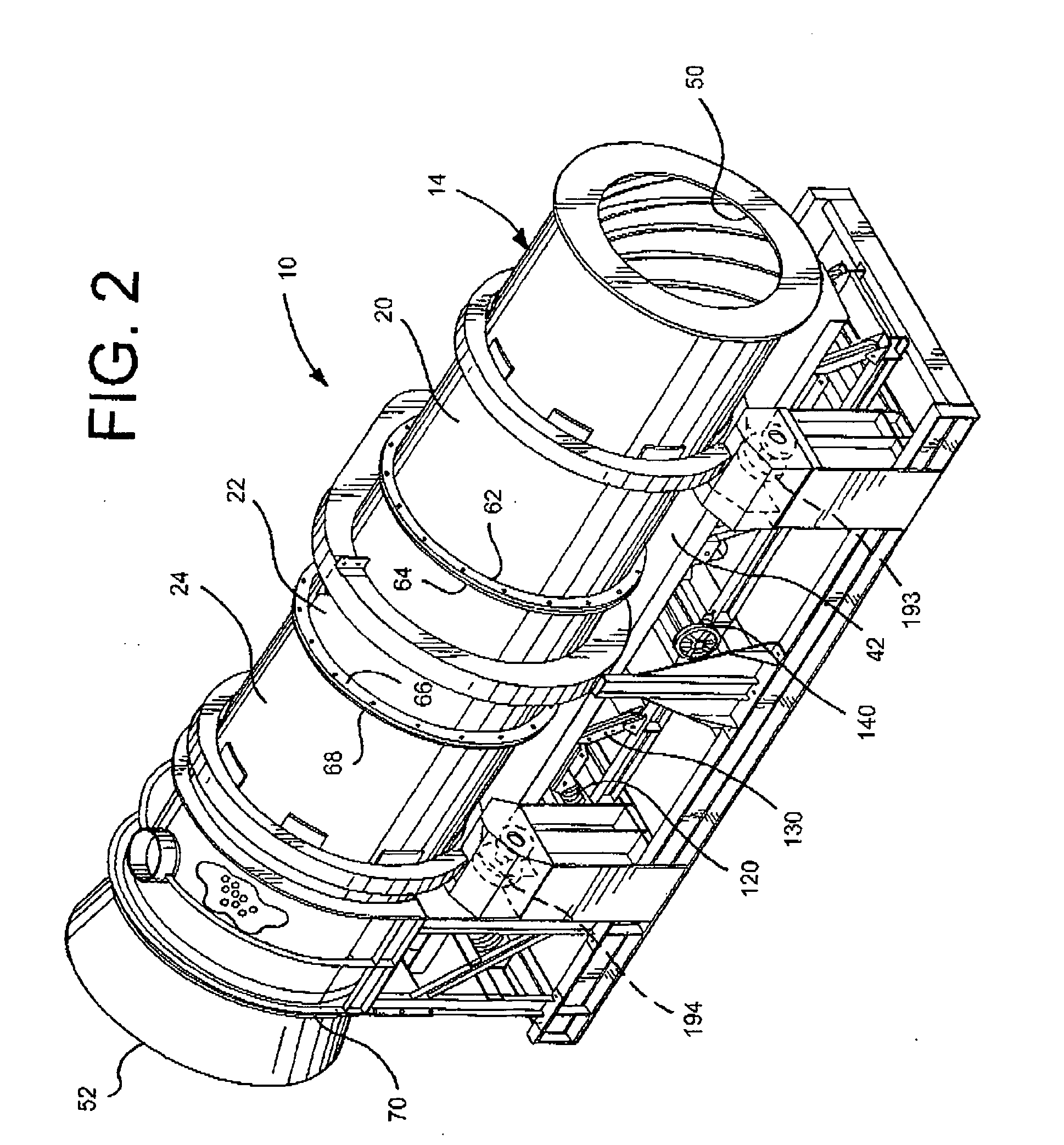

Rotary Drum and vibratory conveyor system

InactiveUS20090283237A1Easy to disassemblePromote exchangeMould handling/dressing devicesEngineeringMaterial Perforation

A rotary drum and vibratory conveyor system including a single walled rotary drum positioned above a vibratory conveyor assembly. The rotary drum may be segmented with each segment having end flanges that are connected to an adjoining segment with bolts. A section or sections of the rotary drum have perforations covered by a dust hood that allow sand and media to fall from the drum through a funnel structure onto the conveyor assembly. The vibratory conveyor assembly includes upper and lower conveyors, where the upper conveyor collects the media falling from the drum and passes the sand to the lower conveyor. The media may be redirected back to the drum inlet to be reused.

Owner:GENERAL KINEMATICS CORP

Impellers (rotor)of Root's blower manufacturing method

The invention discloses a manufacturing method of a Roots blower impeller or rotor. The manufacturing method is to preheat the template, cavity and core of the mold to 180-200°C, apply a release agent after heating, then fix the cavity on the lower template, load the core, and cover it. Formwork, fix the pouring sleeve, pour the alloy smelted according to the general method into the mold, the casting temperature is 450°C, after hardening, open the mold and take out the finished product, the casting is quenched at 180°C and placed at room temperature for 48 hours; the mold after mold opening Apply release agent, close the mold for secondary casting, and the mold does not need to be reheated. The alloy of the invention has low smelting temperature, simple casting process, is convenient for recycling and back casting, and better realizes resource reuse.

Owner:王绍全

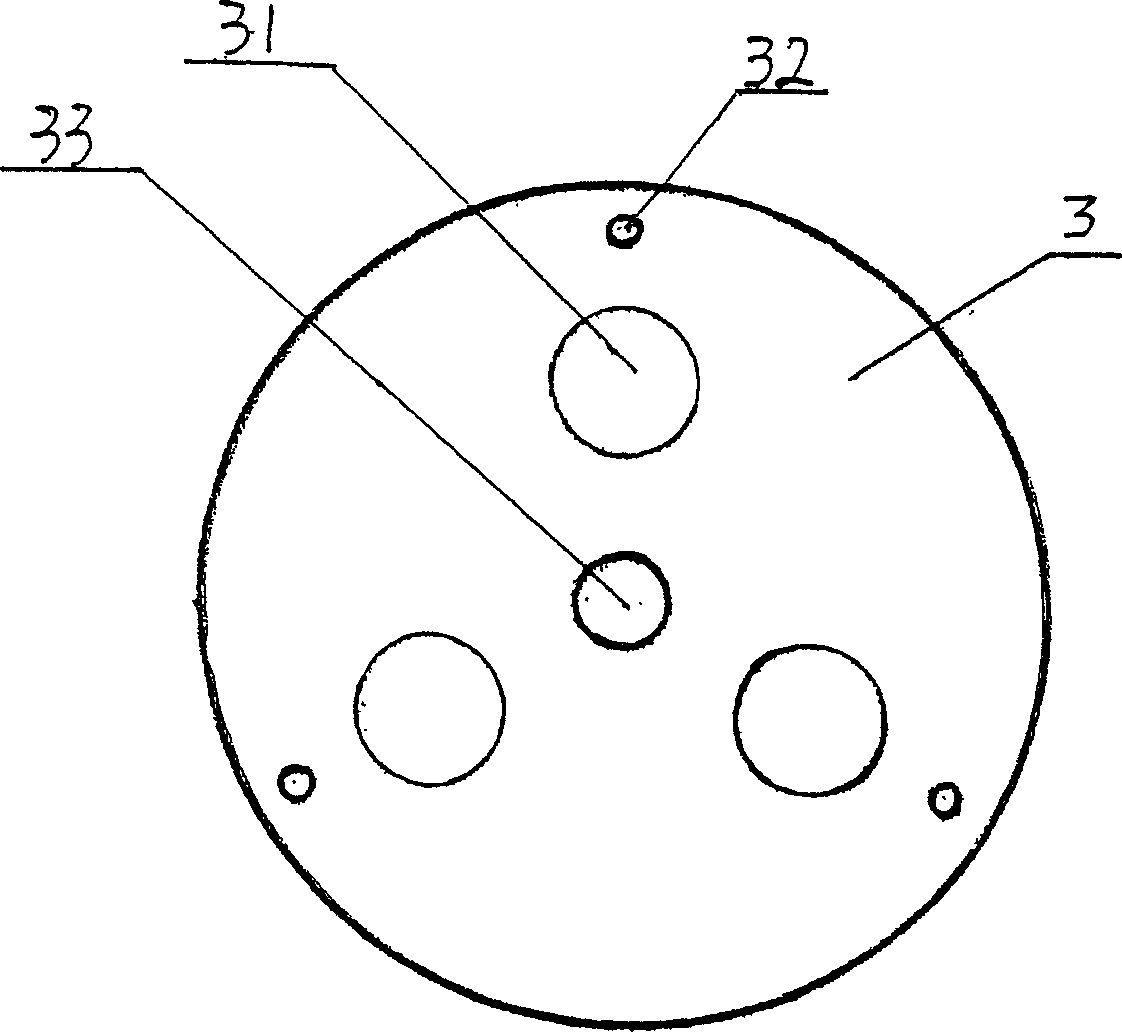

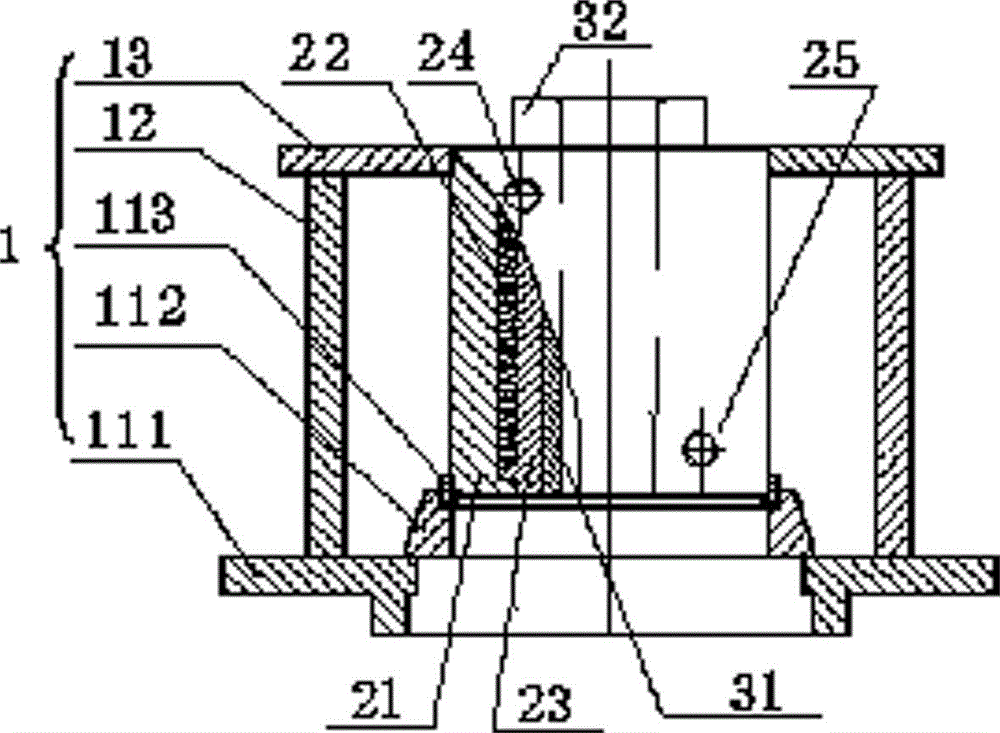

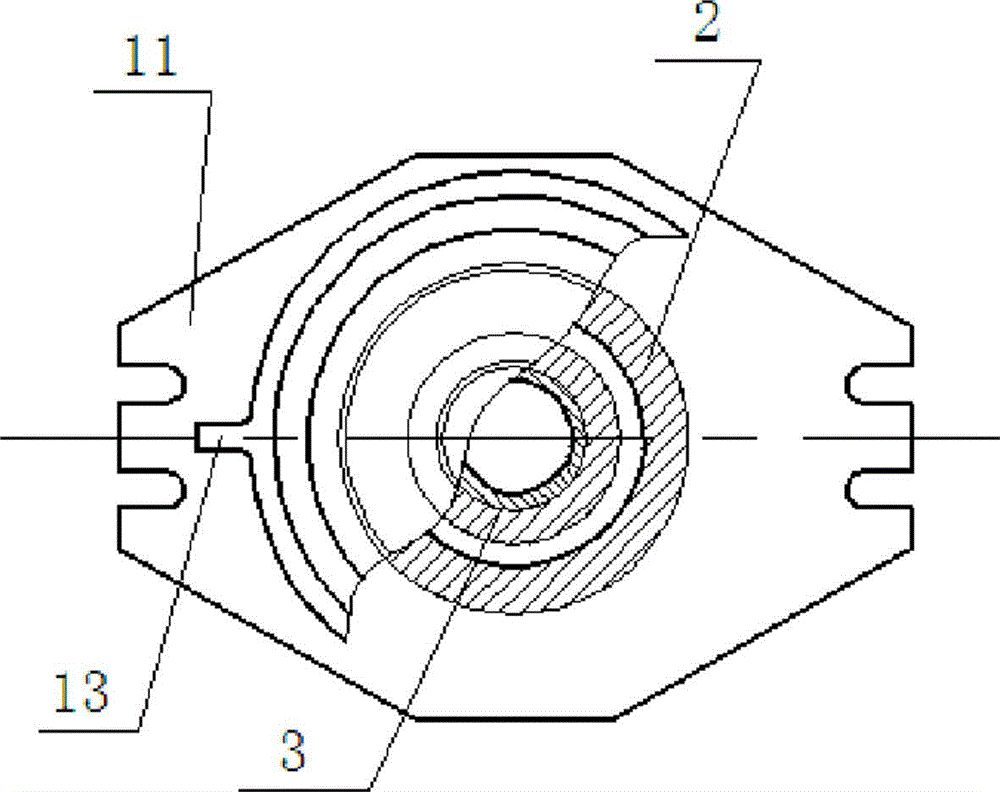

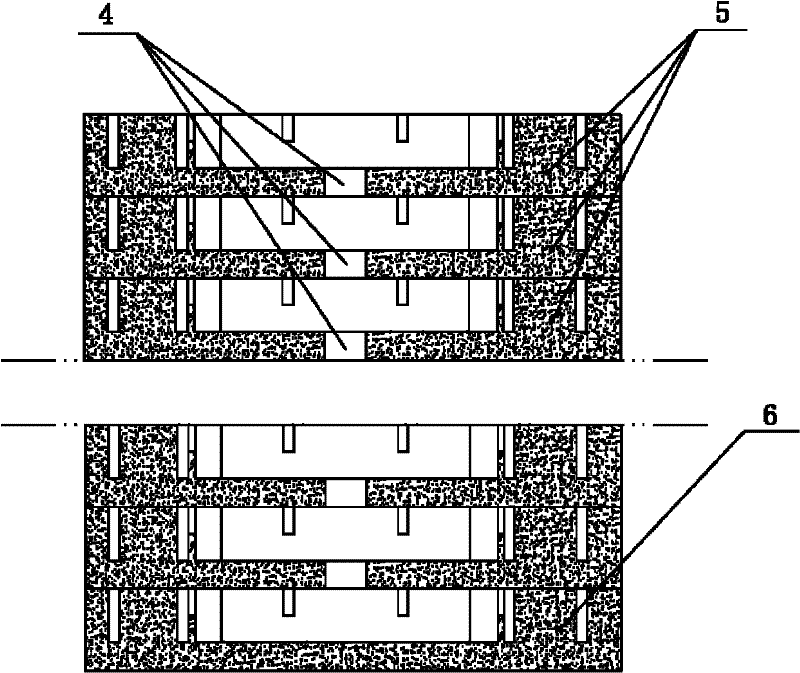

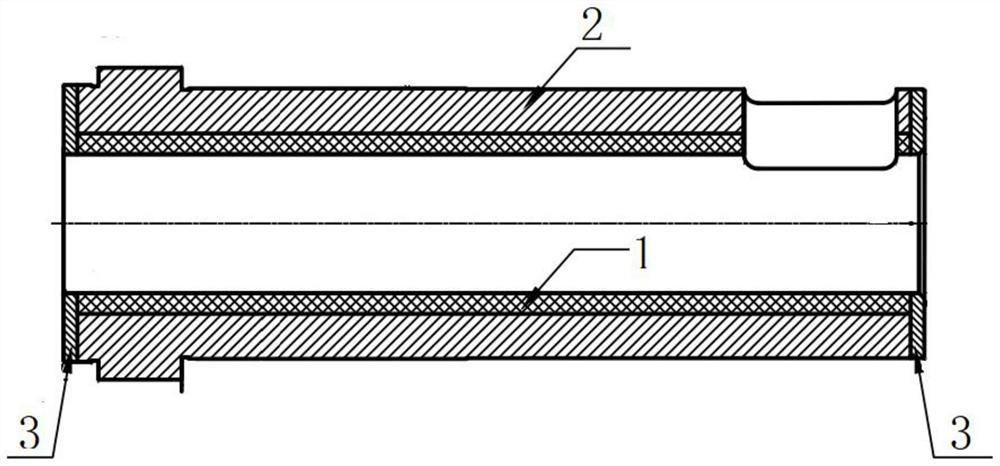

Horizontal continuous casting crystallizer

The invention belongs to the technical field of horizontal continuous casting of copper alloy, and provides a horizontal continuous casting crystallizer, which comprises a cooler, a graphite die and a fixed frame, wherein the cooler comprises an inner tube and an outer tube; a dentate cooling channel is formed between the inner tube and the outer tube, and the inner wall of the inner tube is in close contact with the outer wall of the graphite die; the graphite die is arranged in the cooler which is arranged in the fixed frame. According to the horizontal continuous casting crystallizer, provided by the invention, one time of water cooling can complete rapid cooling of a casting blank, the horizontal continuous casting crystallizer is suitable for mass production, the average speed of casting reaches 300kg / h, the casting defects such as segregation, shrinkage cavity, shrinkage porosity and the like of the casting blank are overcome, the microstructure is uniform, the performance is stable, the service life of the graphite die is greatly improved, and the production cost is reduced.

Owner:武汉泛洲中越合金有限公司

Die-cast zinc alloy with high flowability and preparation method thereof

The invention discloses die-cast zinc alloy with high flowability and a preparation method thereof. The alloy comprises the components by weight percent: 4.51-6.0% of Al, 0.01-0.08% of Mg, 0.5-0.7% of Cu, 0.01-0.02% of Li, 0-0.1% of Ti, 0-0.02% of B, less than 0.02% of inevitable impurity elements such as Pb, Cd, Fe, Sn in total, and the balance of Zn. The preparation method comprises the steps of: firstly, putting an Al ingot into a smelting furnace, heating to 680-720 DEG C; adding a covering agent after a part of molten aluminum appears; cooling to 650-680 DEG C after the Al ingot is completely melted; adding a Zn ingot, Al-Mg, Al-Cu and Zn-Li middle alloy, refining and drossing; adding B and Ti elements, agitating, drossing and cooling to 420-560 DEG C; and stewing, drossing and casting. Compared with common die-cast zinc alloy, the flowability of the die-cast zinc alloy provided by the invention can be improved by over 70%; the grain size of the die-cast zinc alloy is effectively refined; the comprehensive mechanic performance of the alloy is improved.

Owner:CENT SOUTH UNIV +1

Production process of high-temperature structural ceramic/metal composite material tube for aluminum alloy die casting machine

ActiveCN113649772AExtended service lifeSimple production processFurnace typesHeat treatment furnacesDie castingCeramic metal

The invention relates to a production process of a high-temperature structural ceramic / metal composite material tube for an aluminum alloy die casting machine. The composite material tube comprises a ceramic lining, a metal jacket and an end cover. The production process of the composite material tube comprises the steps of machining the ceramic lining, machining the metal jacket and the end cover, and assembling and matching the ceramic lining, the metal jacket and the end cover. A ceramic lining machining process comprises the steps of raw material preparation, grinding and pulping, workpiece forming, green body drying, high-temperature firing and inner and outer circle machining. A metal jacket and end cover machining process comprises the steps of metal tube and end cover cutting and blanking, metal tube and end cover inner and outer circle rough machining, heat treatment and metal tube and end cover inner and outer circle finish machining. A ceramic lining, metal jacket and end cover assembling and matching process includes the steps of measurement inspection, combined assembly and thermal adaptation testing. A metal tube and a ceramic tube are compounded, so that the alloy melt corrosion resistance and the wear resistance of the material tube are greatly improved, and the service life is long; the composite material tube is low in heat conductivity coefficient, and energy consumption is reduced; and strength and toughness are good, the manufacturing cost is low, and production period is short.

Owner:江苏三条鱼新材料科技有限公司 +1

Casting method of thermal insulation pipeline

InactiveCN107030251AIncrease temperatureReduced casting timeFoundry mouldsFoundry coresHigh volume manufacturingThermal insulation

The invention provides a casting method of a thermal insulation pipeline. The casting method comprises the following steps: 1, taking and fully mixing silicon powder, attapulgite and crosslinking polyvingypyrrolidone (PVPP) uniformly to obtain a granular material, performing low temperature drying on the granular material to obtain a mixture I; 2, taking aggregate, a heating material, a thermal insulation material and a binder, mixing for 10-25 min to obtain a slurry; 3, filling a pipeline die with the mixture I and the slurry by using a core shooter for forming, and demolding, wherein the pipeline wall thickness is 6-10 mm; 4, placing the pipeline material after forming and demolding into a continuous drying kiln, drying for 30-40 min at the rate of 1-2 cm / s and at the temperature of 320-450 DEG C, solidifying, drying, and clearing the corners of the pipeline, so as to obtain the finished product. According to the casting method of the thermal insulation pipeline, the pipeline casting time is shortened, the pipeline casting temperature is reduced, and the overall thermal insulation effect of the pipeline is obviously improved; besides, the process is simple, complex and dangerous operation steps are avoided, the material cost is low, the production efficiency is high, and the industrial mass production is facilitated.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

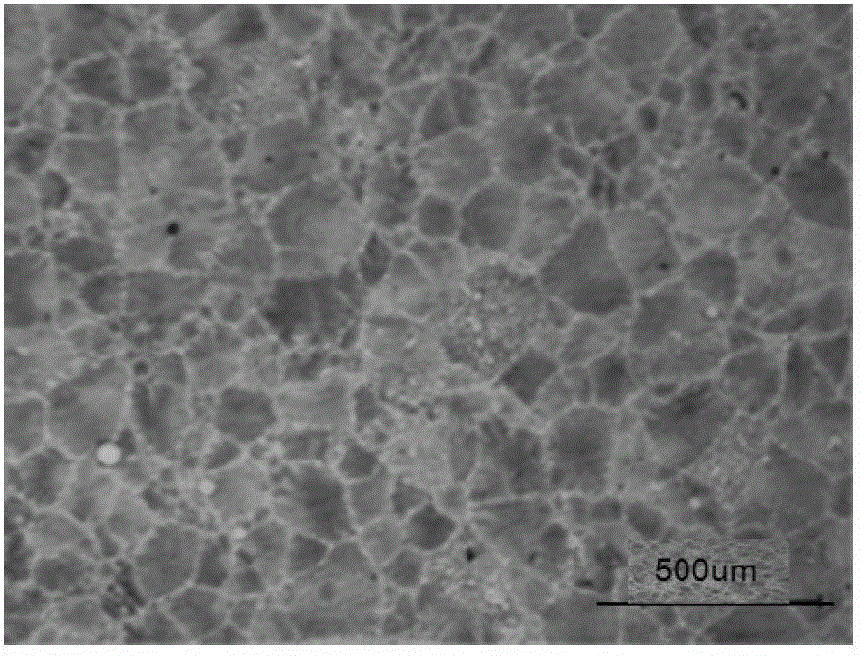

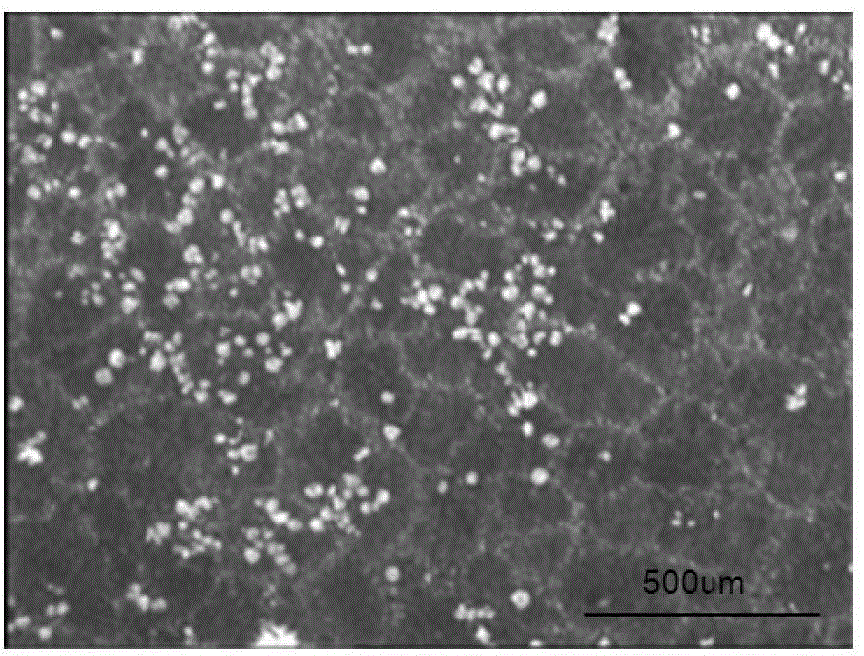

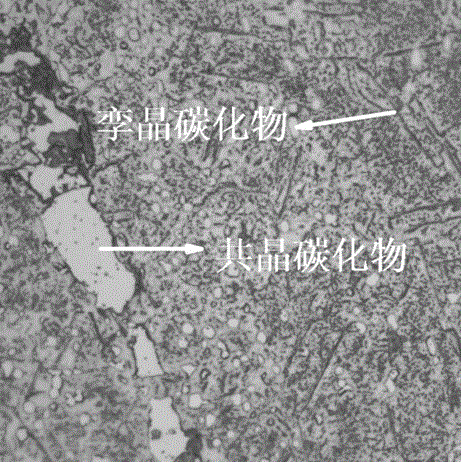

A high carbon and high chromium 9cr18 martensitic stainless steel shaft forging preparation process

ActiveCN104259361BImprove segregationLow casting temperatureMetal-working apparatusTemperature controlChemical composition

The invention relates to a high-carbon and high-chromium 9Cr18 martensite stainless steel shaft forging preparation technology. During smelting, the weight percentage of carbon in stainless steel is controlled to be 0.90-0.92%, and the weight percentages of other ingredients are as follows: 17.0-17.5% of Cr, 0.50-0.55% of Si and 0.40-0.45% of Mn; the casting temperature is controlled to be 1450-1480 DEG C; 10.5 ton of electroslag ingots are adopted for forging, the electroslag ingots are hot-charged and heated up, the heating temperature is 1140-1180 DEG C, the initial forging temperature is 1000-1120 DEG C, the finish forging temperature is higher than or equal to 950 DEG C, and the returning heating-up time cannot exceed 2 hours; after forging, normalizing and isothermal annealing are conducted, the normalizing temperature is 850-950 DEG C, and air cooling is conducted to obtain the temeprature of 650-750 DEG C for isothermal annealing. The high-carbon and high-chromium 9Cr18 martensite stainless steel shaft forging preparation technology provided by the invention controls the chemical compositions, the forging heating, the initial forging temperature, the finish forging temperature, the deformation mode, the deflection and the after-forging heat treatment temperature of steel to enable twin-crystal carbides in the steel to be moved or improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

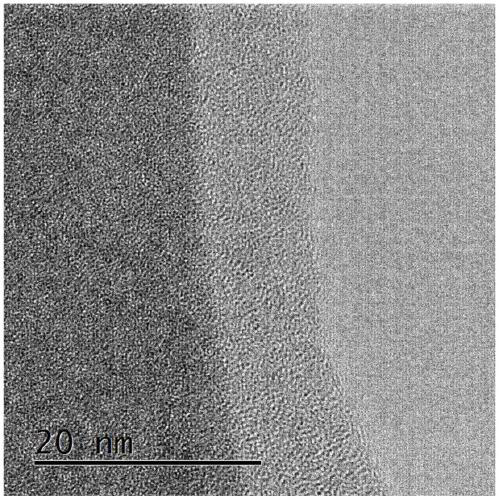

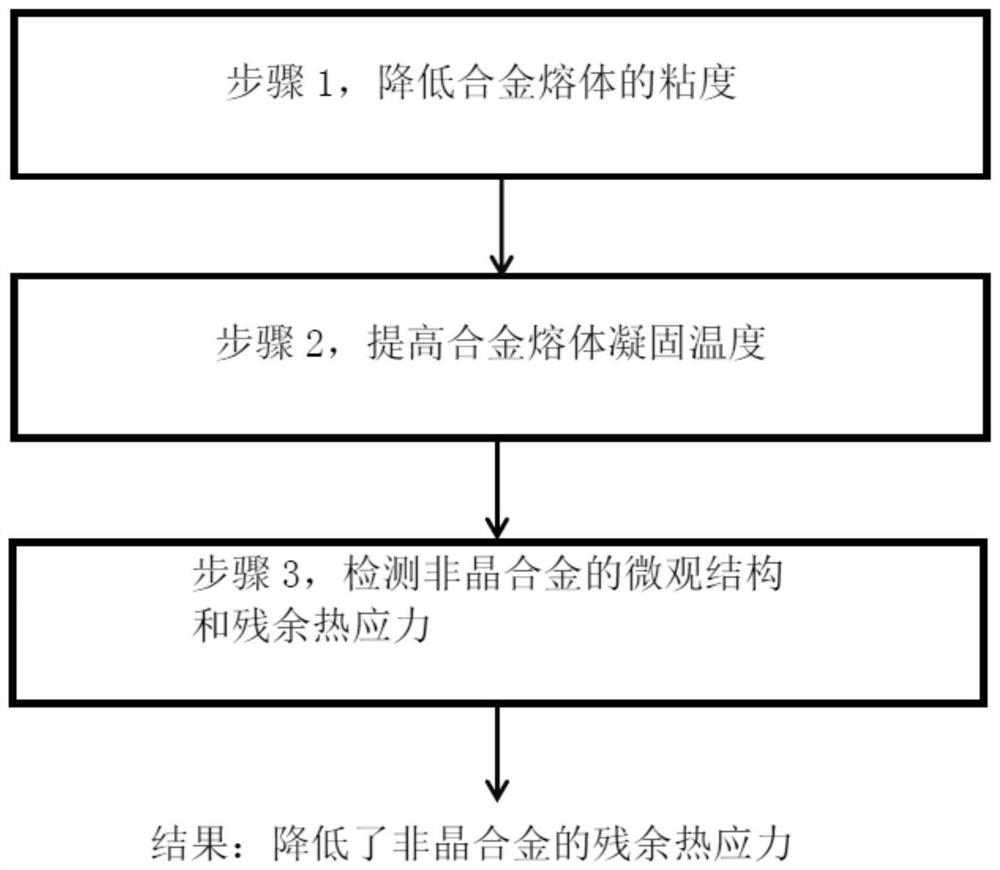

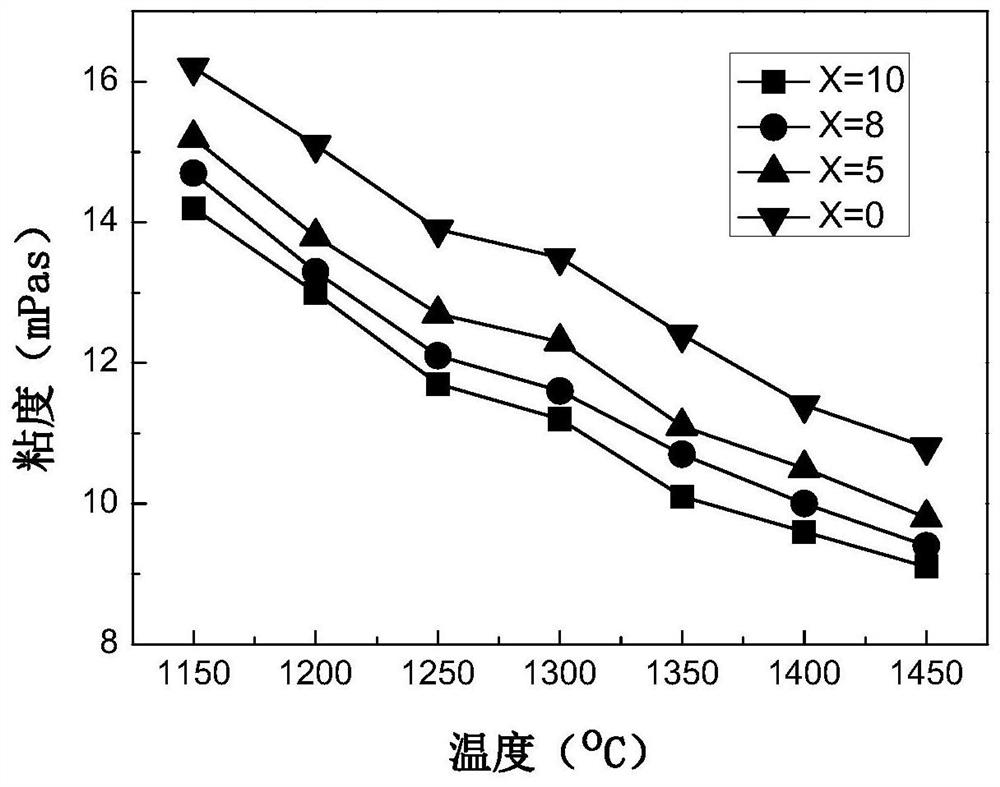

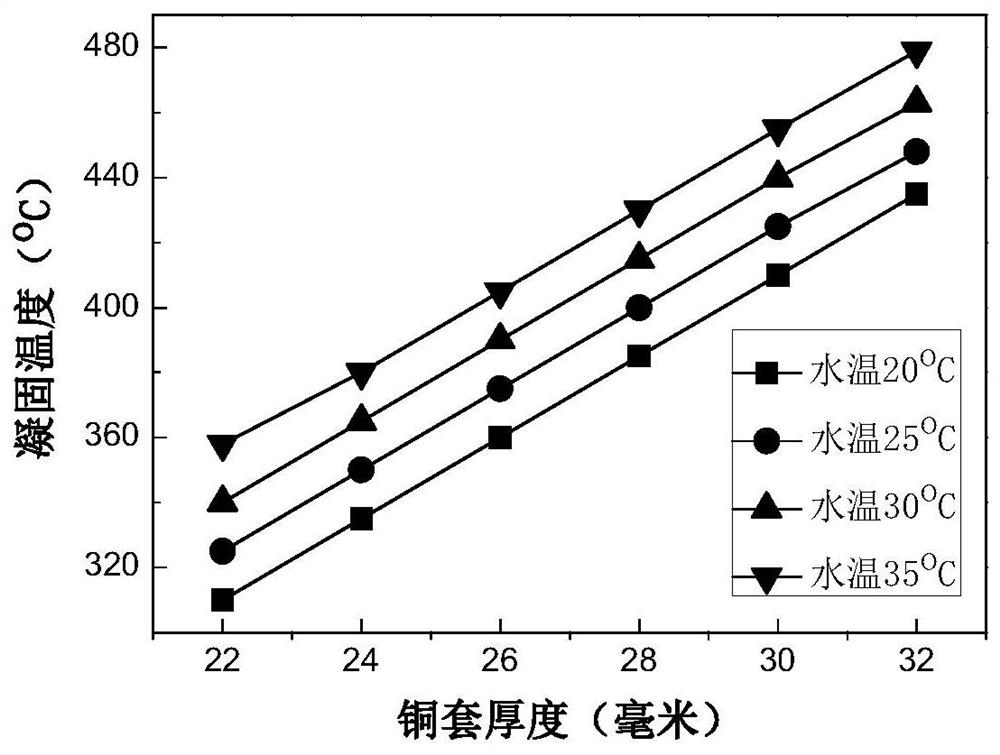

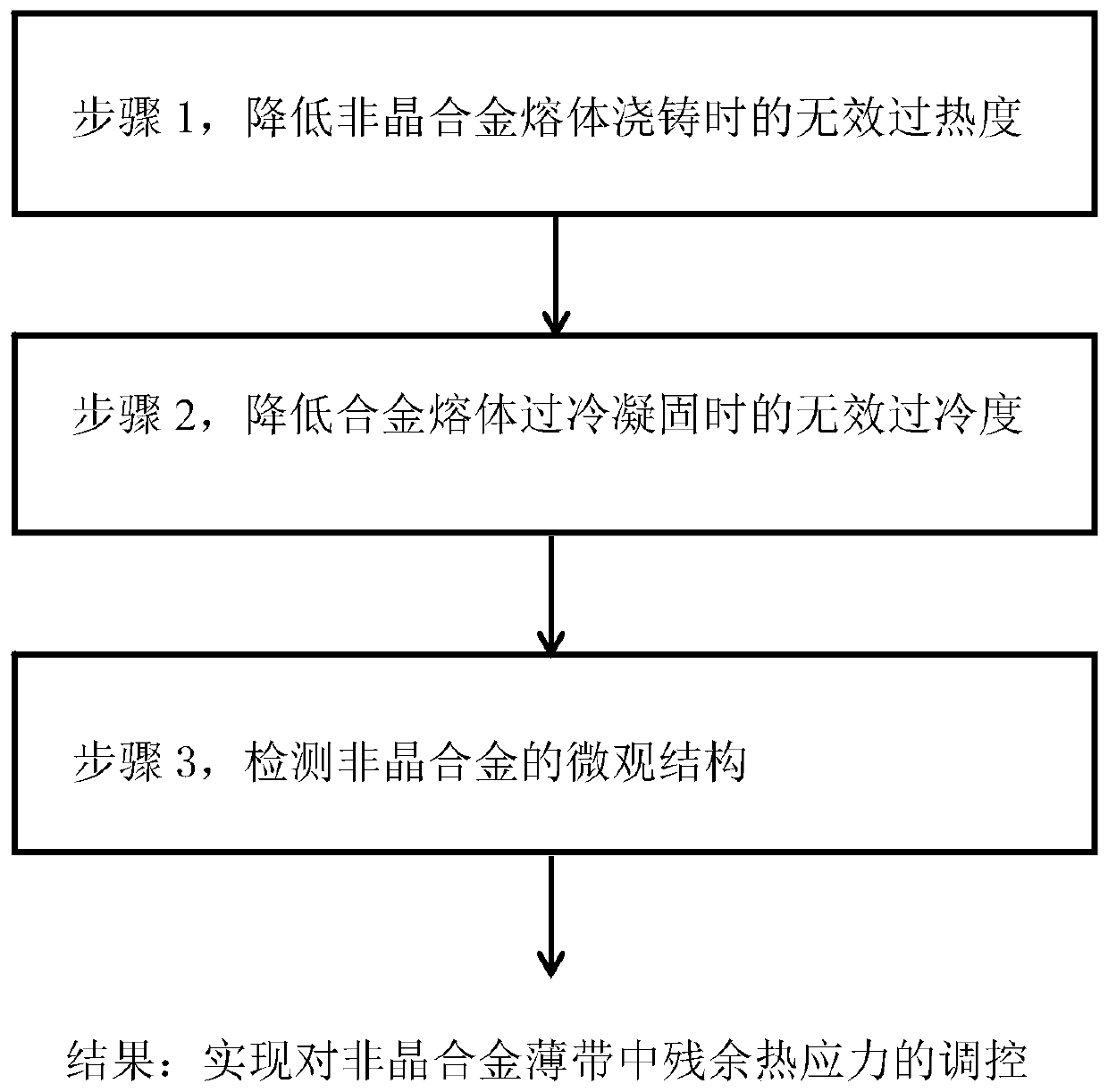

A process for preparing low residual thermal stress amorphous alloy

The invention provides a process method for preparing a low residual thermal stress amorphous alloy, comprising: step S1, select a reference alloy, and use a non-metallic element that forms a low-melting point alloy with a metal element to partially replace the non-metallic element that forms a high-melting point alloy with a metal element. Form a series of alloys with different components by means of metal elements, and measure their viscosity at different casting temperatures to establish the relationship between viscosity-casting temperature-composition; step S2, measure different cooling conditions for the series of alloy melts at different casting temperatures Set up the relationship of cooling condition-solidification temperature-casting temperature-composition; step S3, at first, according to the relationship obtained in step S1, select the alloy composition of low viscosity and set the casting temperature according to the viscosity standard; then, according to the selection The alloy composition, the set casting temperature and the relationship obtained in step S2, select the cooling conditions corresponding to the increase of the supercooled solidification temperature; finally, an amorphous alloy is obtained.

Owner:创明(韶关)绿色能源材料技术研究院有限公司

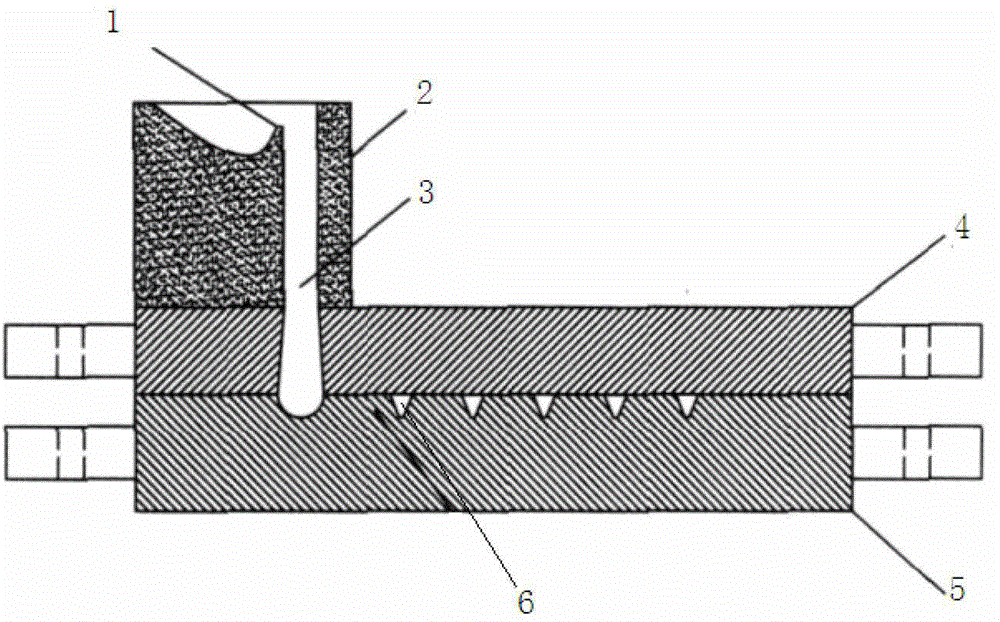

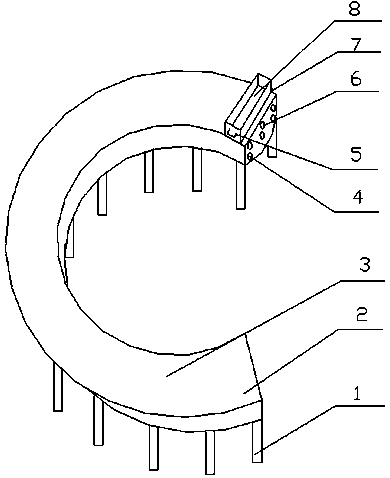

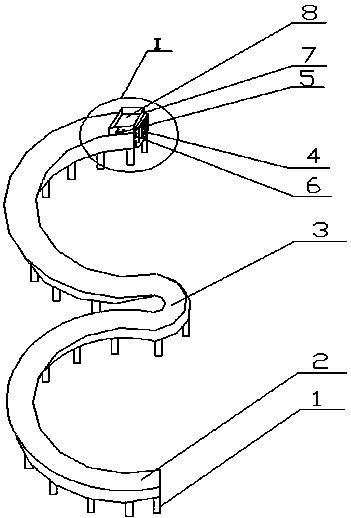

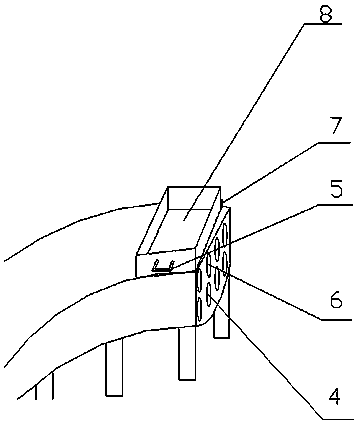

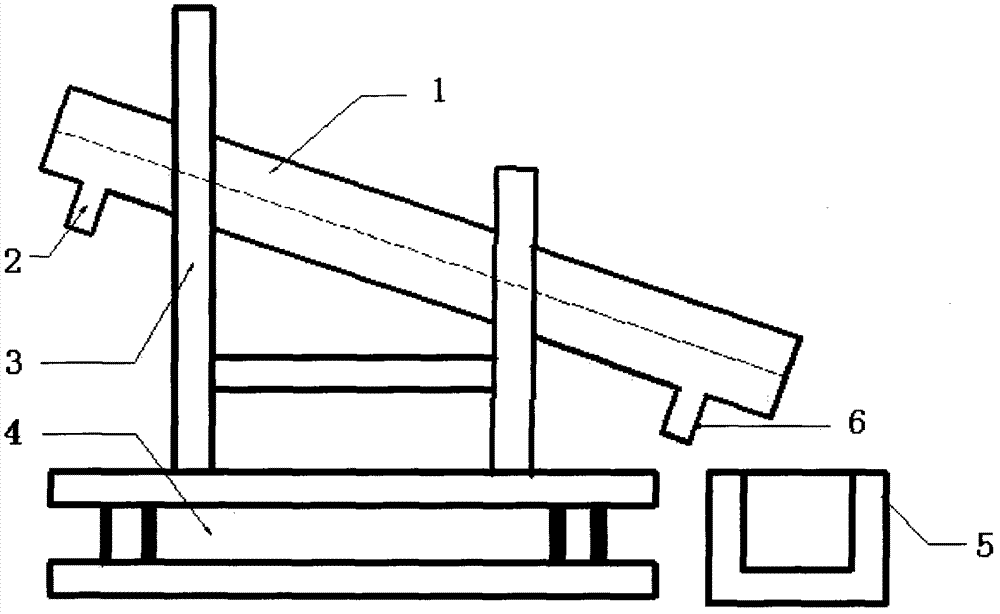

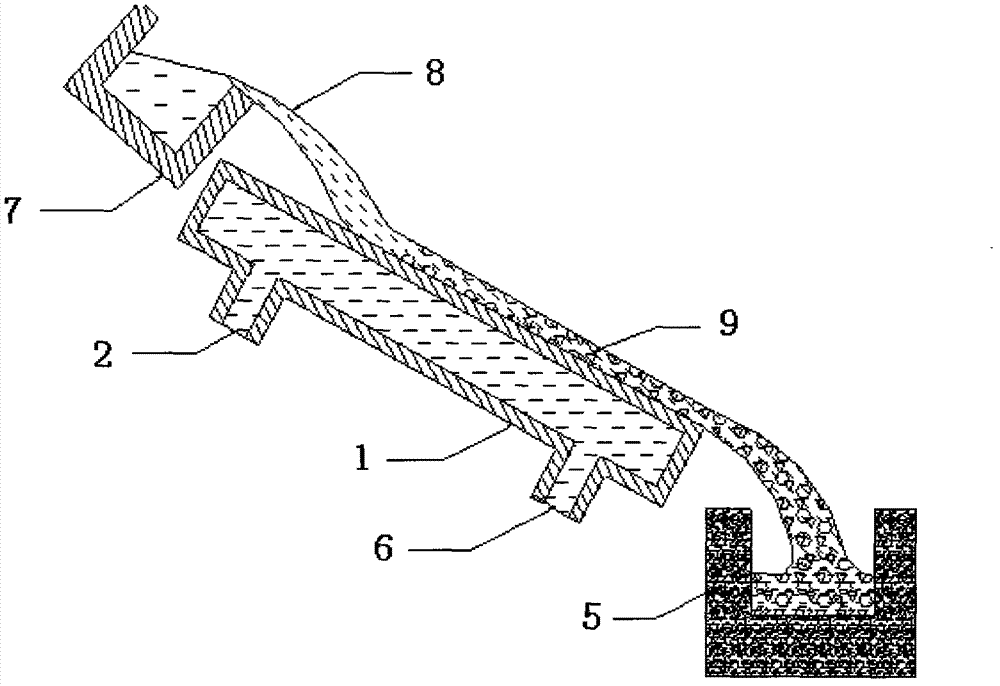

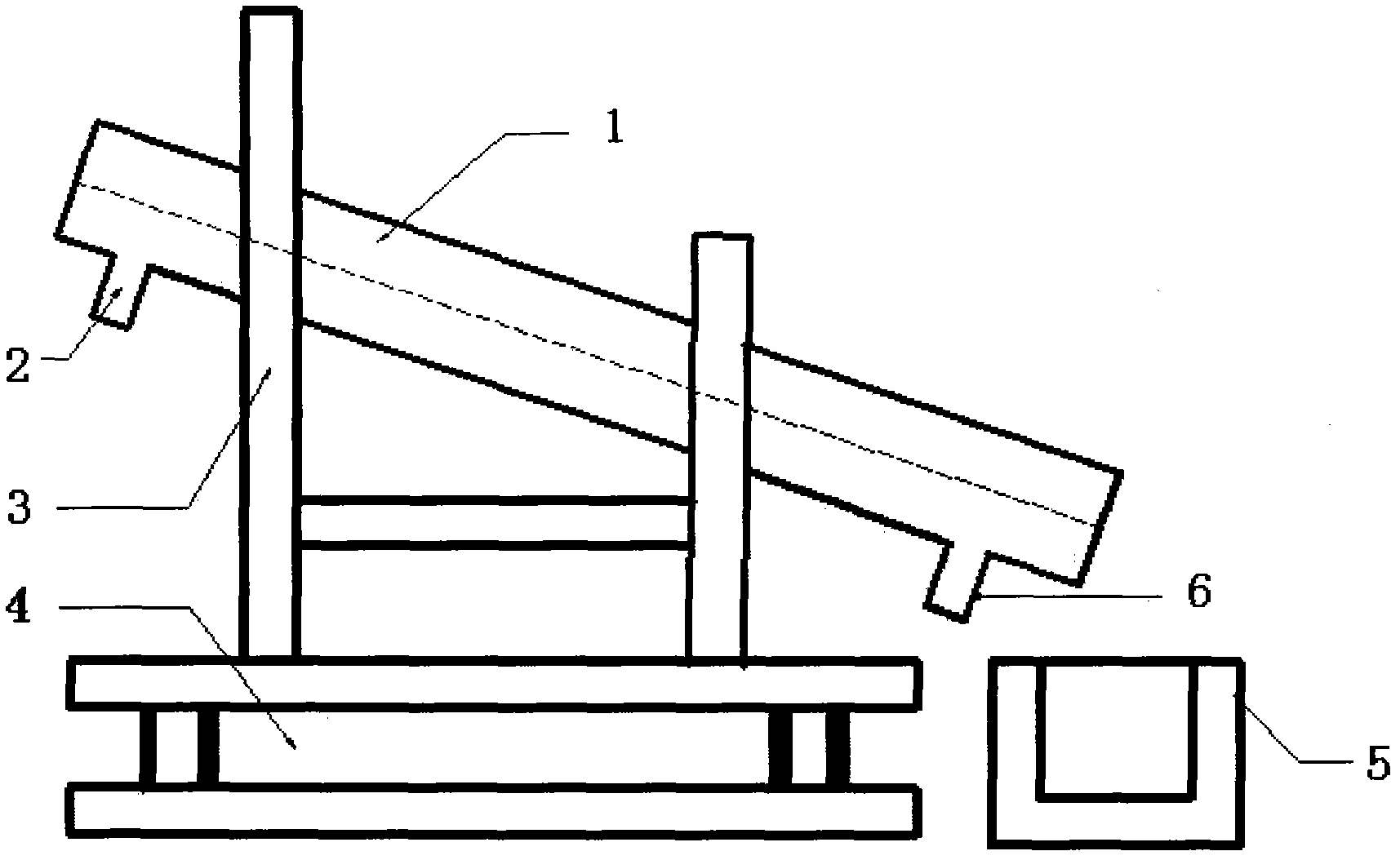

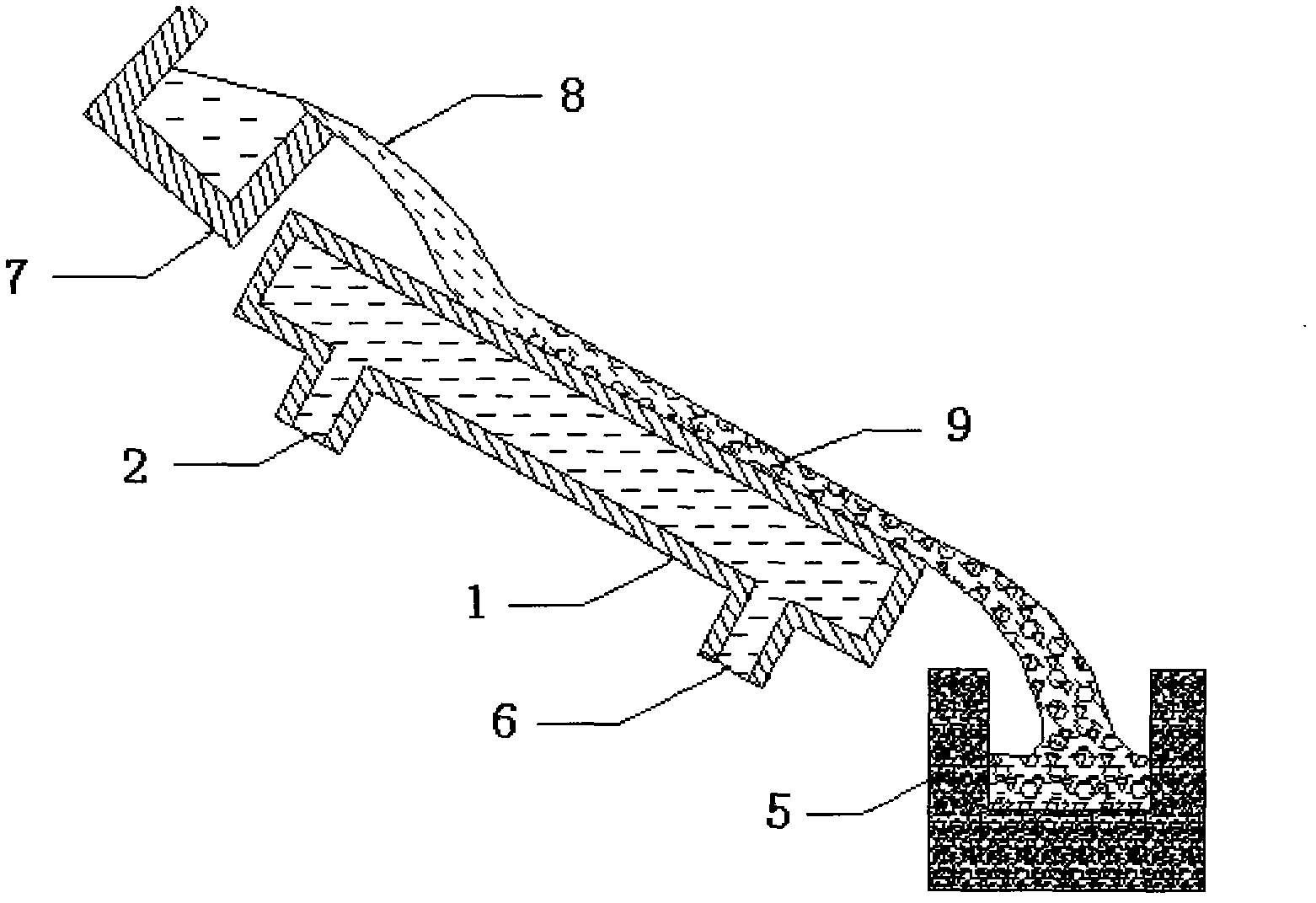

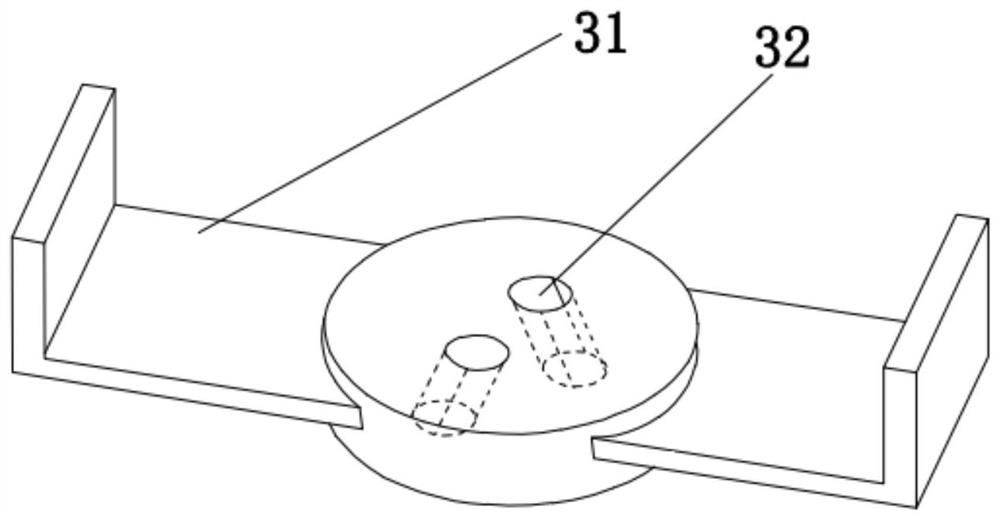

Casting device

InactiveCN104384484ALow casting temperatureImprove casting qualityMolten metal conveying equipmentsEngineeringSupport surface

The invention relates to a casting device, which comprises a casing die and a bracket, wherein the casting die is arranged on the bracket, the bracket is of an opened curve structure, and is formed by welding lower support rods and an upper support surface, the upper surface of the support surface is of a horizontal structure, a row of water inlet pipes and a row of water outlet pipes are arranged in the support surface, the water inlet pipes are positioned above the water outlet pipes, the lower bottom surface of the casting die is in full contact with the support surface, the tangential line of the contact point of the casting die and the support surface is vertical to the length direction of the casting die, the bottom surface of one end of the casting die along the length direction is rotationally connected with one large-curvature radius side of the support surface, and the side surface of the other end of the casting die along the length direction is provided with a lifting handle. The casting device has the advantage that the bracket with a cooling system is adopted, identical casting dies are sequentially arranged on the bracket, and a plurality of casting dies are cooled when each casting die is cast along the bracket, so the casting efficiency and casting quality are simultaneously improved.

Owner:耒阳市诚松有色金属再生有限公司

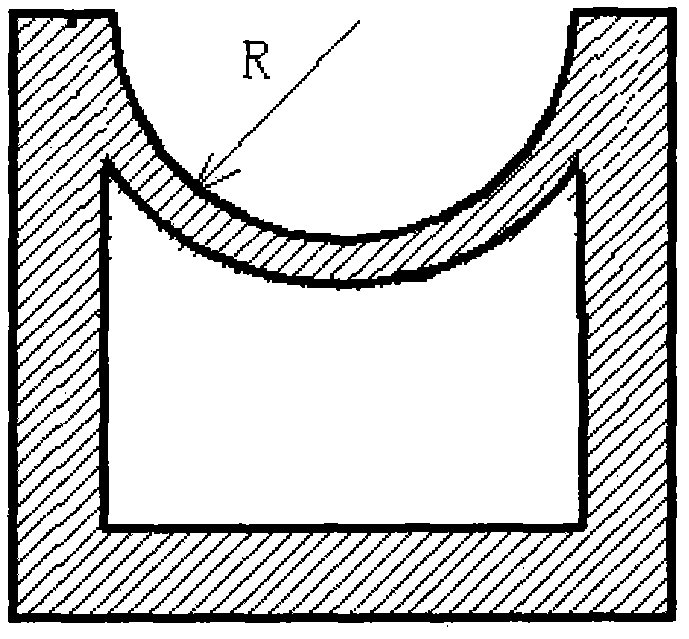

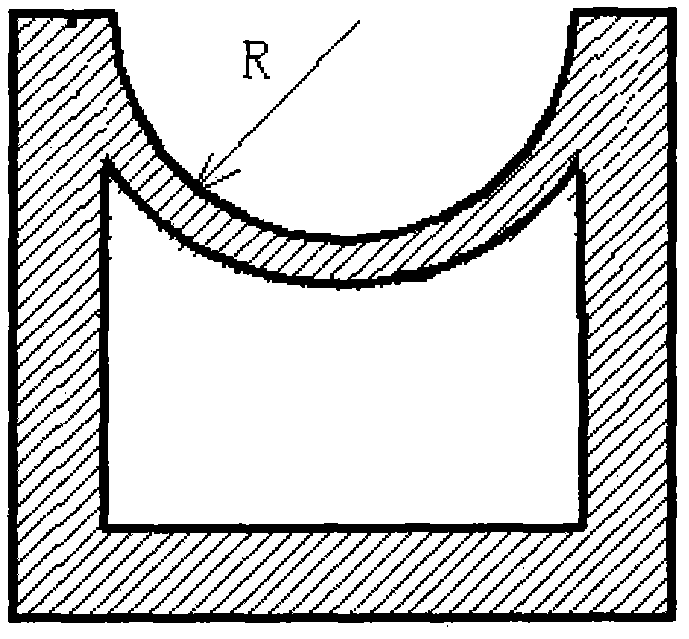

Method for controlling large-scale nodular iron cast coagulation tissue

The invention relates to a method for controlling a large-scale nodular iron cast coagulation tissue. The method comprises the following steps of: placing a cooling body manufactured by graphite, gray cast iron and copper on a bracket; controlling nodular iron liquid flow and temperature reduction by adjusting an inclined angle to the horizontal direction and the overflow length and controlling the number of iron liquid crystal nucleuses after treatment, wherein the surface of the cooling body is a semicircular concave surface with the curvature radius of 200 to 500 mm and is coated with fireproof coating, the cooling body is hollow and cooling water can be introduced into the cooling body; allowing the nodular iron liquid subjected to nodulizing inoculation to flow through the cooling body and then enter a casting cavity; and properly reducing the casting temperature of the nodular iron liquid and generating a large number of crystal nucleuses through chilling action of the cooling body so as to refine the large-scale nodular iron cast coagulation tissue and prevent graphite distortion.

Owner:KUNMING UNIV OF SCI & TECH

The control method of slab center segregation

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method and mould for manufacturing valve retainer

InactiveCN101590586BAvoid leaningAvoid deformationFoundry mouldsFurnace typesEnergy consumptionMold removal

The invention discloses a method for manufacturing a valve retainer, which comprises the following steps: arranging a sprue on a mould; and carrying out smelting, casting, demoulding, heat treatment and ground finishing on metal, wherein the mould is a directly molded mould for the valve retainer. Compared with the prior manufacturing method, the method for manufacturing the valve retainer saves four steps of sliping a head, boring an inner hole, digging up an excircle and cutting off. Therefore, the method simplifies the production steps, saves a large amount of labors, reduces the equipmentinput and energy consumption, shortens the production cycle and reduces the production cost.

Owner:张永炤 +1

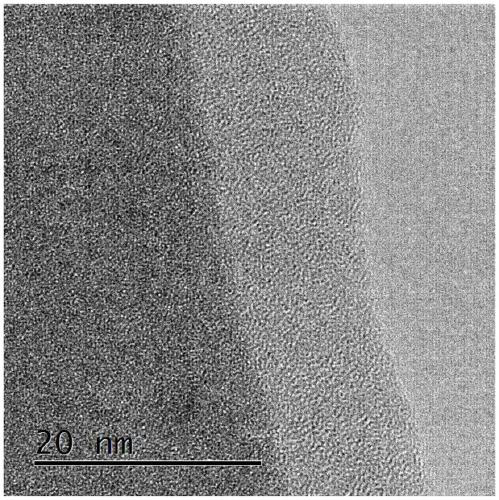

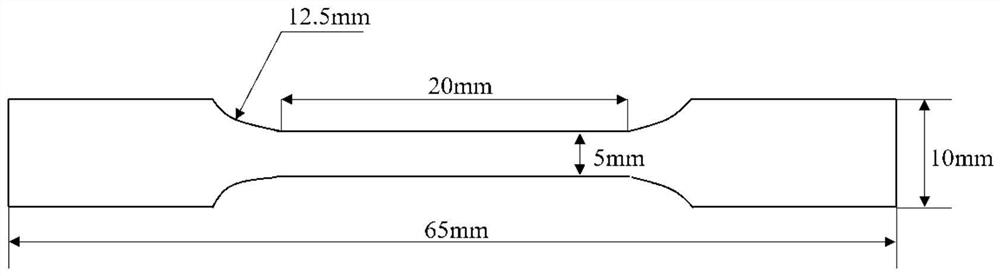

Amorphous alloy thin strip preparation method capable of reducing residual thermal stress

ActiveCN110976796AReduce inactive superheatReduce residual thermal stressCasting parameters measurement/indication devicesAlloyCooling capacity

The invention provides an amorphous alloy thin strip preparation method capable of reducing residual thermal stress. The method comprises the following steps of reducing the ineffective superheat degree of an alloy melt during casting; firstly, obtaining the lowest casting temperature of the alloy melt; selecting the intermediate temperature between the lowest casting temperature and the normal casting temperature as the second casting temperature; reducing the ineffective supercooling degree of the alloy melt during casting; gradually reducing the cooling capacity of a cooling roller at the certain specific second casting temperature, preparing a second amorphous alloy thin strip, and in-situ measuring the solidification temperature of the alloy melt; when a crystal phase is started to begenerated in the second amorphous alloy thin strip, taking the above-mentioned solidification temperature generated when fully amorphous alloy can be obtained as the highest solidification temperature; then obtaining the correlation relationship between the second casting temperature as well as the highest solidification temperature and the cooling capacity; and preparing a target product, specifically, according to the correlation relationship, selecting and setting the casting temperature and setting the cooling capacity, and preparing the target product. The method can reduce the residualthermal stress in the amorphous alloy structure.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

Method for controlling large-scale nodular iron cast coagulation tissue

The invention relates to a method for controlling a large-scale nodular iron cast coagulation tissue. The method comprises the following steps of: placing a cooling body manufactured by graphite, gray cast iron and copper on a bracket; controlling nodular iron liquid flow and temperature reduction by adjusting an inclined angle to the horizontal direction and the overflow length and controlling the number of iron liquid crystal nucleuses after treatment, wherein the surface of the cooling body is a semicircular concave surface with the curvature radius of 200 to 500 mm and is coated with fireproof coating, the cooling body is hollow and cooling water can be introduced into the cooling body; allowing the nodular iron liquid subjected to nodulizing inoculation to flow through the cooling body and then enter a casting cavity; and properly reducing the casting temperature of the nodular iron liquid and generating a large number of crystal nucleuses through chilling action of the cooling body so as to refine the large-scale nodular iron cast coagulation tissue and prevent graphite distortion.

Owner:KUNMING UNIV OF SCI & TECH

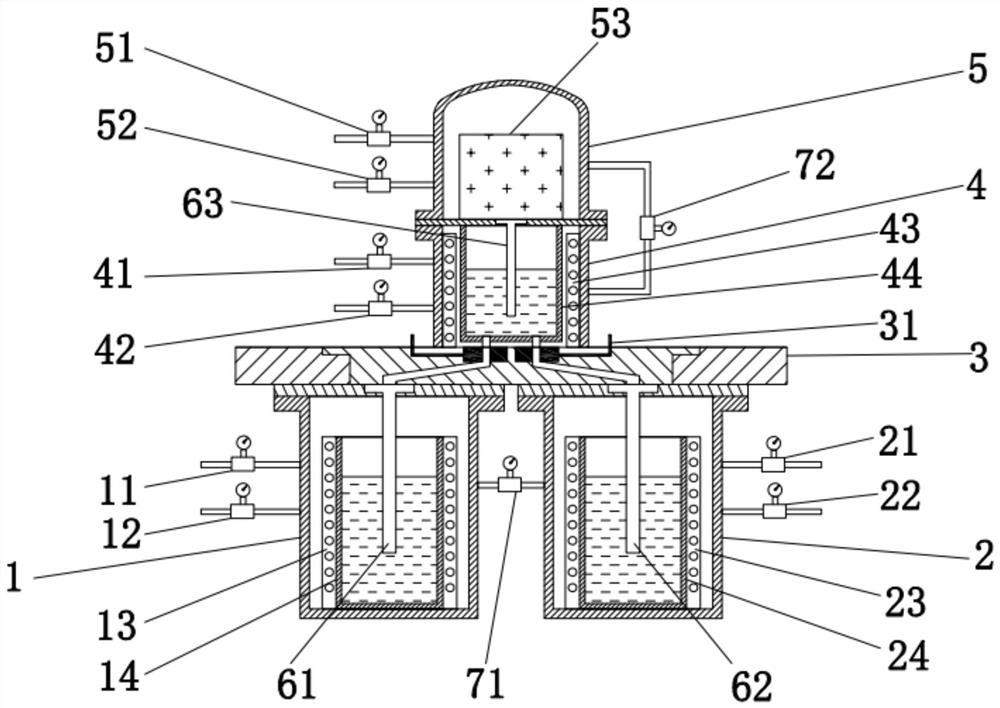

A method and device for near-liquidus differential pressure casting of large complex magnesium alloy components

The invention provides a large-scale complex magnesium alloy component near liquidus pressure difference casting method, belonging to the field of magnesium alloy casting, based on the principle of controlled diffusion solidification, by mixing two kinds of alloy mother liquids with different components and different temperatures to obtain a near liquid phase Magnesium alloy casting liquid with linear temperature and high fluidity, based on the anti-gravity casting method, uses pressure to drive magnesium alloy casting liquid to fill the sand mold from bottom to top, and cools and solidifies at a pressure higher than the environment to complete the casting. The present invention also provides a casting device applied to the above casting method, including a first lower tank and a second lower tank for holding two kinds of mother liquors, a middle tank for mixing mother liquors, an upper tank for filling mold tank, a deflector is provided between the lower tank and the middle tank, the lower tank and the middle tank are connected through a riser pipe, and the middle tank and the upper tank are connected through a riser pipe. The invention can effectively reduce the casting temperature of the magnesium alloy, and avoid burning caused by high temperature during resin sand mold differential pressure casting.

Owner:JIANGSU UNIV

Process and device for producing medium-high manganese steel plate strip

ActiveCN112322866AAvoid inclusionsAvoid formingProcess efficiency improvementSteelmakingMolten metal

The invention discloses a process and a device for producing a medium-high manganese steel plate strip, belongs to the technical field of steelmaking smelting control, and solves the problem that thequality of steel is influenced by macrosegregation of inclusions and manganese elements in the traditional preparation process. The process comprises the following steps that firstly, molten metal isdirectly subjected to continuous casting to form a thin strip with the thickness being 2-4 mm; secondly, the thin strip is heated to 1413 K to 1420 K; thirdly, the heated thin strip is fed into a controllable atmosphere decarburization furnace to be subjected to solid-state decarburization; wherein the temperature in the controllable atmosphere decarburization furnace is 1413-1420 K, a decarburization atmosphere is arranged in the controllable atmosphere decarburization furnace, the component of the decarburization atmosphere is Ar-H2-H2O, the pressure in the controllable atmosphere decarburization furnace is 0.2-1 MPa, and the PH2O / PH2 is controlled to be 0.30-0.55; fourthly, after decarburization is finished, the thin strip is rolled; and fifthly, the thin strip is rolled and then subjected to heat treatment, and the medium-high manganese steel plate strip is prepared. The process and the device are suitable for preparing the medium-high manganese steel plate strip.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

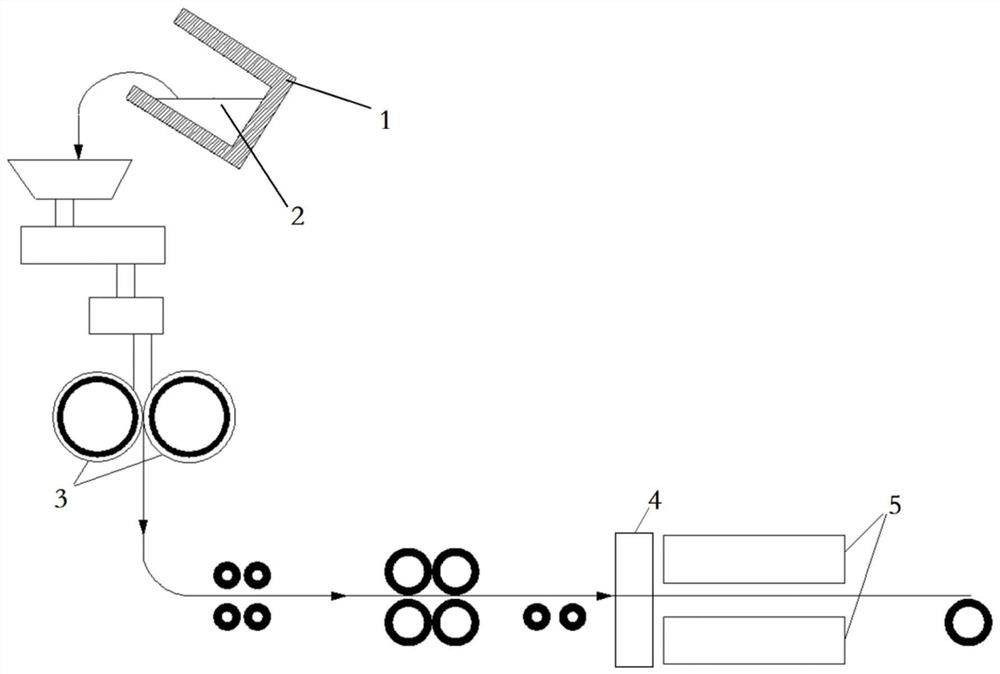

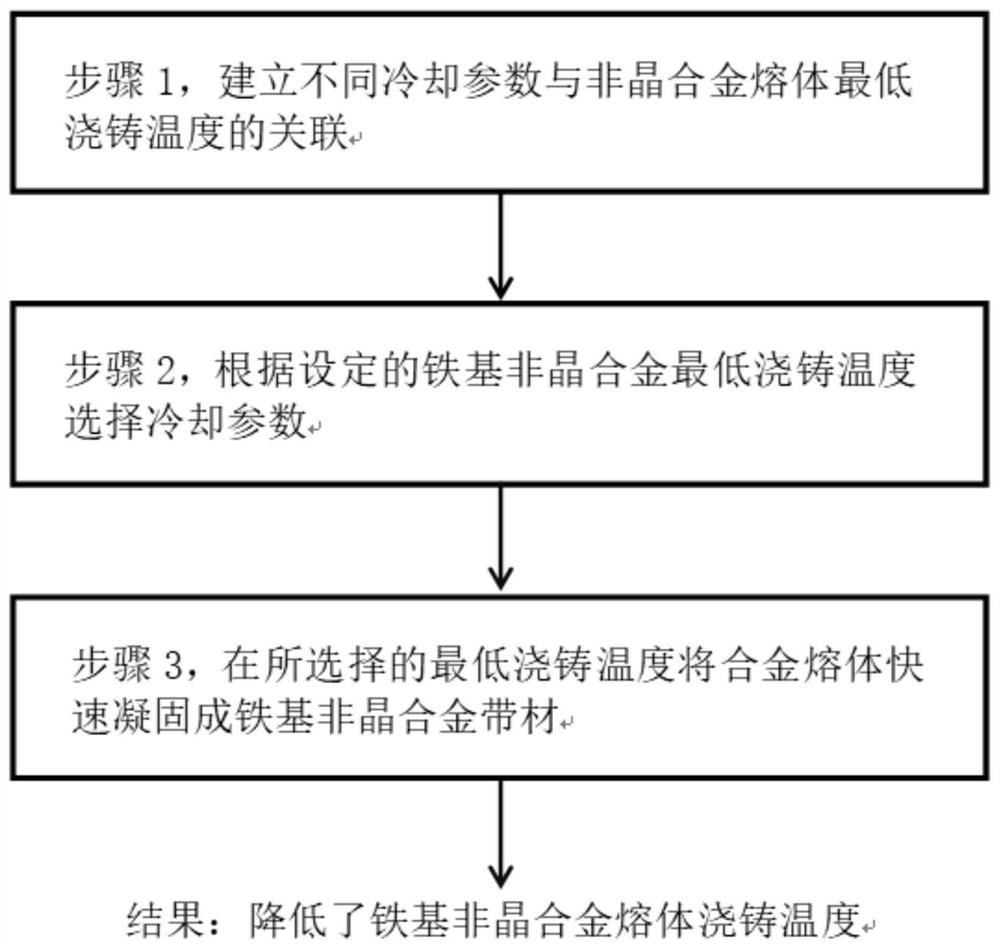

A process method for controlling the casting temperature of amorphous alloy melt

The invention belongs to the technical field of metal functional material preparation, and particularly relates to a process method for regulating and controlling casting temperature of an amorphous alloy melt. The method comprises the following steps that S1, association relationships between different cooling parameters and the lowest casting temperature of the amorphous alloy melt are established; S2, according to the association relationships in the step S1, the lowest casting temperature and the related cooling parameters are selected; and S3, under the conditions of the set lowest casting temperature and the selected cooling parameters, the amorphous alloy melt is rapidly solidified into an amorphous alloy thin strip. According to the provided process method for regulating and controlling the casting temperature of the amorphous alloy melt, the method is suitable for preparing an amorphous alloy material from an alloy melt through a rapid cooling method and is particularly suitable for preparing an iron-based amorphous alloy; and particularly, the method can reduce the casting temperature of the amorphous alloy melt by improving the cooling capacity of a cooling roller underthe condition that components of the iron-based alloy melt greatly fluctuate, and then the performance of the amorphous alloy is improved.

Owner:创明(韶关)绿色能源材料技术研究院有限公司

Production process of high-temperature structural ceramic/metal composite pipe for aluminum alloy die-casting machine

ActiveCN113649772BExtended service lifeSimple production processFurnace typesHeat treatment furnacesHeat treatedHigh heat

The invention relates to a production process of a high-temperature structural ceramic / metal composite pipe for an aluminum alloy die-casting machine. The composite pipe includes a ceramic inner lining, a metal jacket and an end cap; the production process of the composite pipe includes ceramic lining processing, a metal jacket and an end cap Processing, ceramic lining, metal jacket and end cap assembly and adaptation; ceramic lining processing technology includes raw material preparation, grinding and pulping, workpiece molding, green body drying, high temperature firing, inner and outer circle processing; metal jacket and end cap processing technology Including cutting and blanking of metal pipes and end caps, rough machining of inner and outer circles of metal pipes and end caps, heat treatment, finishing machining of inner and outer circles of metal pipes and end caps; assembly and adaptation process of ceramic linings and metal jackets, end caps including measurement inspection, combination Assembly, thermal adaptation test. Through the composite of metal tube and ceramic tube, the corrosion resistance and wear resistance of the material tube are greatly improved, and the service life is long; the thermal conductivity of the composite material tube is low, and the energy consumption is reduced; the strength and toughness are good, and the manufacturing cost is low. The production cycle is short.

Owner:江苏三条鱼新材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com