Casting device

A mold and support surface technology, applied in casting equipment, equipment for feeding molten metal into casting molds, metal processing equipment, etc., can solve the problems of unfavorable casting mold cooling, cumbersome casting process, slow cooling process, etc., to save casting Time, convenient demoulding process, good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

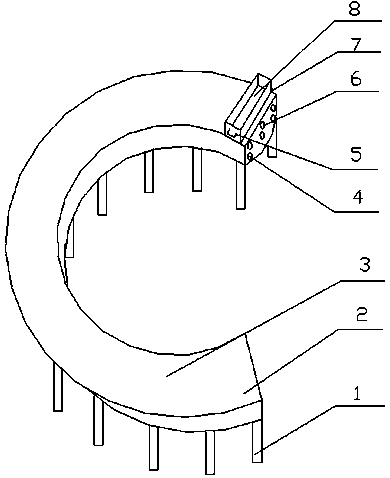

[0019] as attached figure 1 As shown, a casting device includes a casting mold 8 and a bracket 3. The casting mold 8 is placed on the bracket 3. The bracket 3 is an open curved structure. The bracket 3 is welded by the support rod 1 at the lower end and the support surface 2 at the upper end. , the upper surface of the supporting surface 2 is a horizontal structure, a row of water inlet pipes 6 and a water outlet pipe 4 are arranged in the supporting surface 2, the water inlet pipes 6 are above the water outlet pipes 4, and the bottom surface of the casting mold 8 is in complete contact with the supporting surface 2, The tangent at the point of contact between the casting mold 8 and the support surface 2 is perpendicular to the length direction of the casting mold 8, and the bottom surface of one end of the casting mold 8 in the length direction is connected to the side with a larger curvature radius on the support surface 2 in a rotatable manner, and the casting mold 8. The o...

specific Embodiment 2

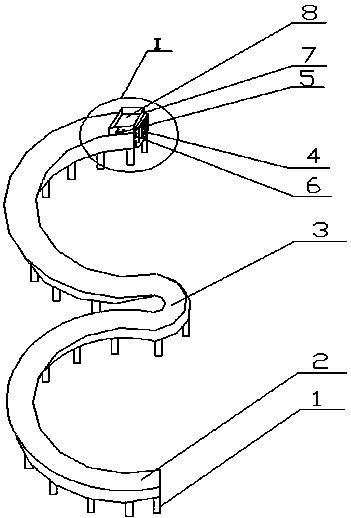

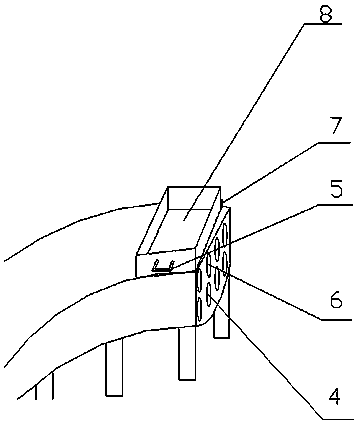

[0024] as attached figure 2 And attached image 3 As shown, a casting device includes a casting mold 8 and a bracket 3. The casting mold 8 is placed on the bracket 3. The bracket 3 is an open curved structure. The bracket 3 is welded by the support rod 1 at the lower end and the support surface 2 at the upper end. , the upper surface of the supporting surface 2 is a horizontal structure, a row of water inlet pipes 6 and a water outlet pipe 4 are arranged in the supporting surface 2, the water inlet pipes 6 are above the water outlet pipes 4, and the bottom surface of the casting mold 8 is in complete contact with the supporting surface 2, The tangent at the point of contact between the casting mold 8 and the support surface 2 is perpendicular to the length direction of the casting mold 8, and the bottom surface of one end of the casting mold 8 in the length direction is connected to the side with a larger curvature radius on the support surface 2 in a rotatable manner, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com