Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Reduced casting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

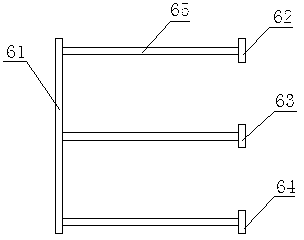

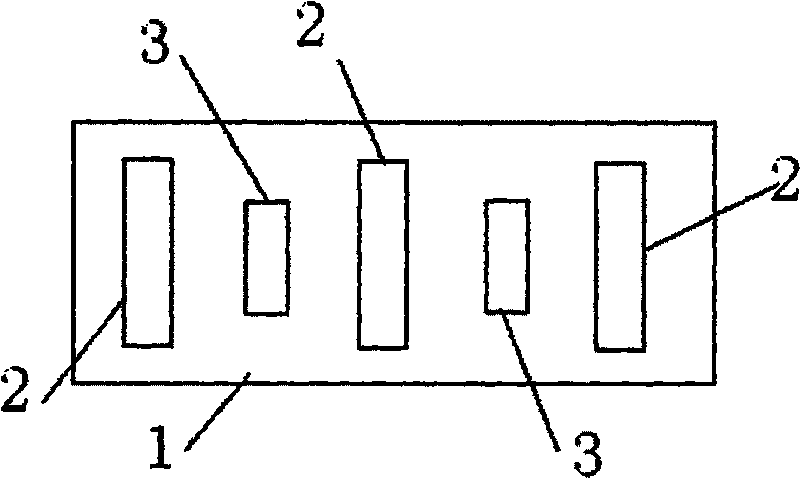

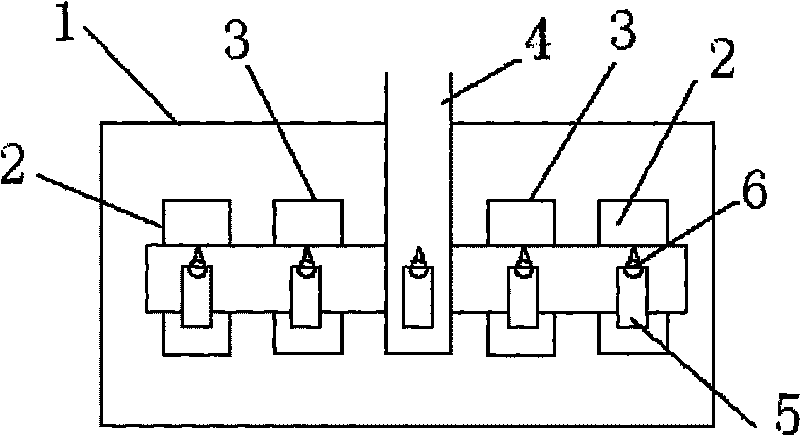

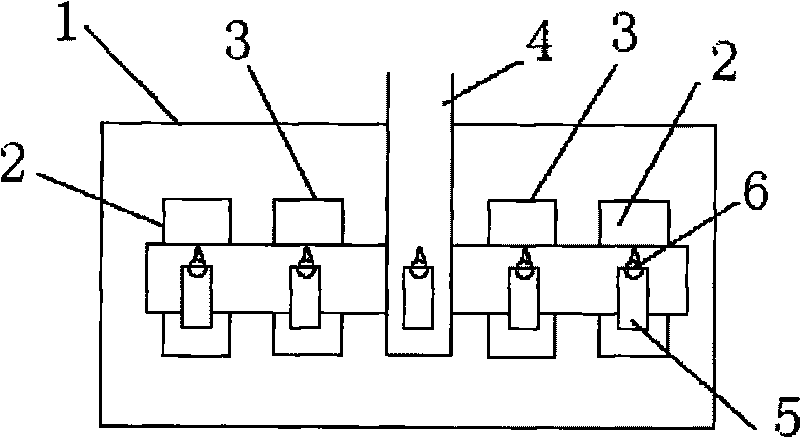

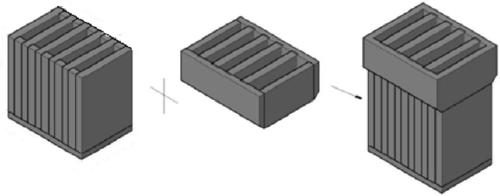

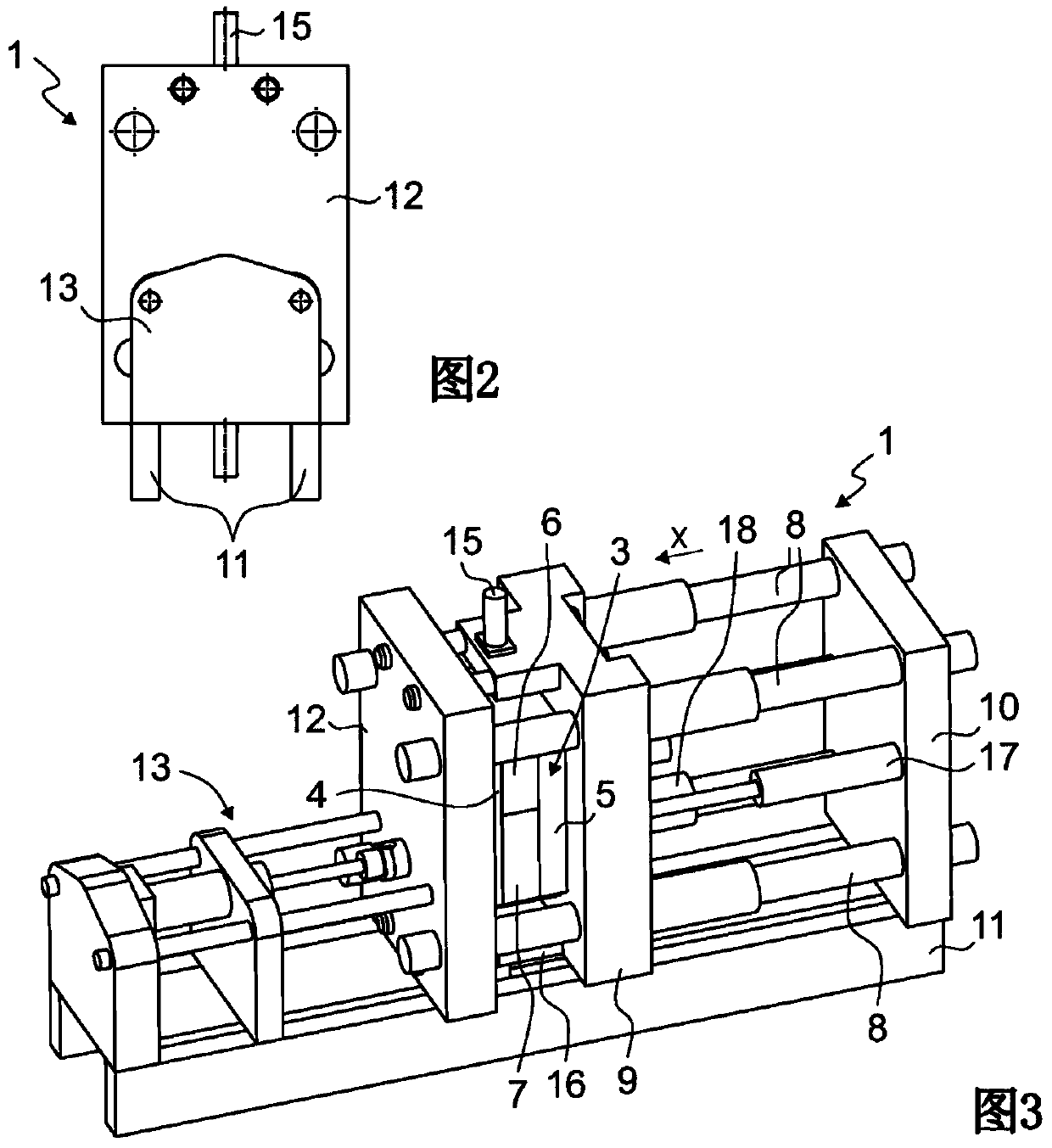

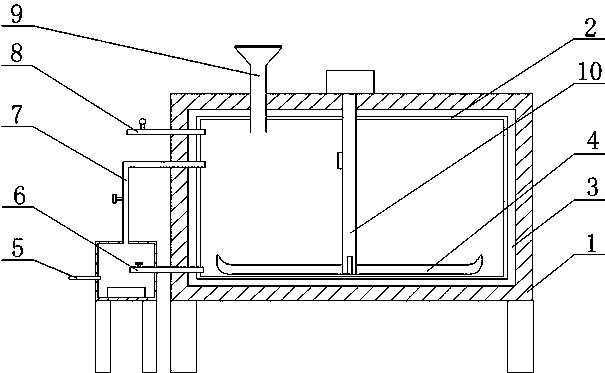

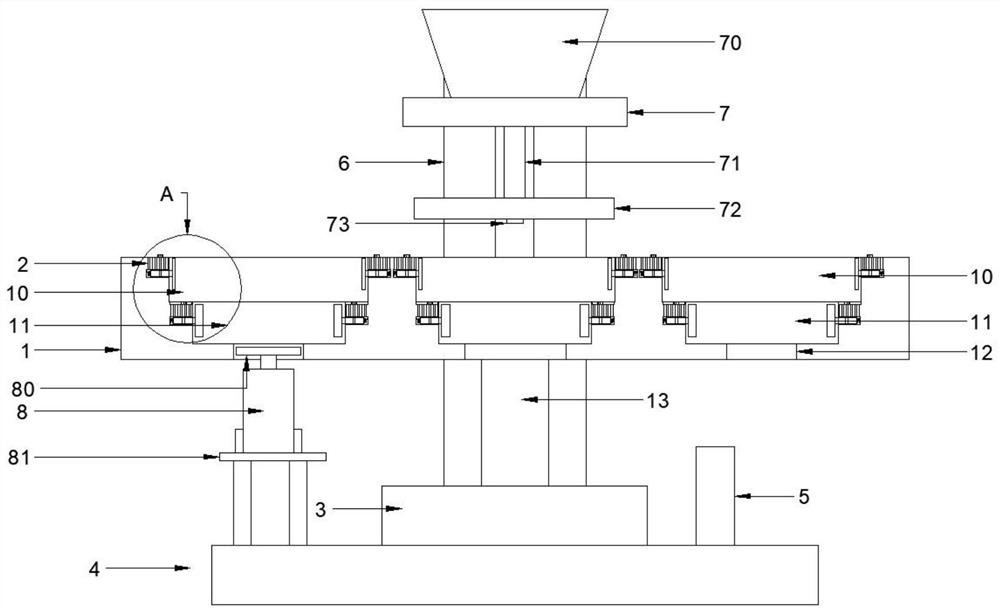

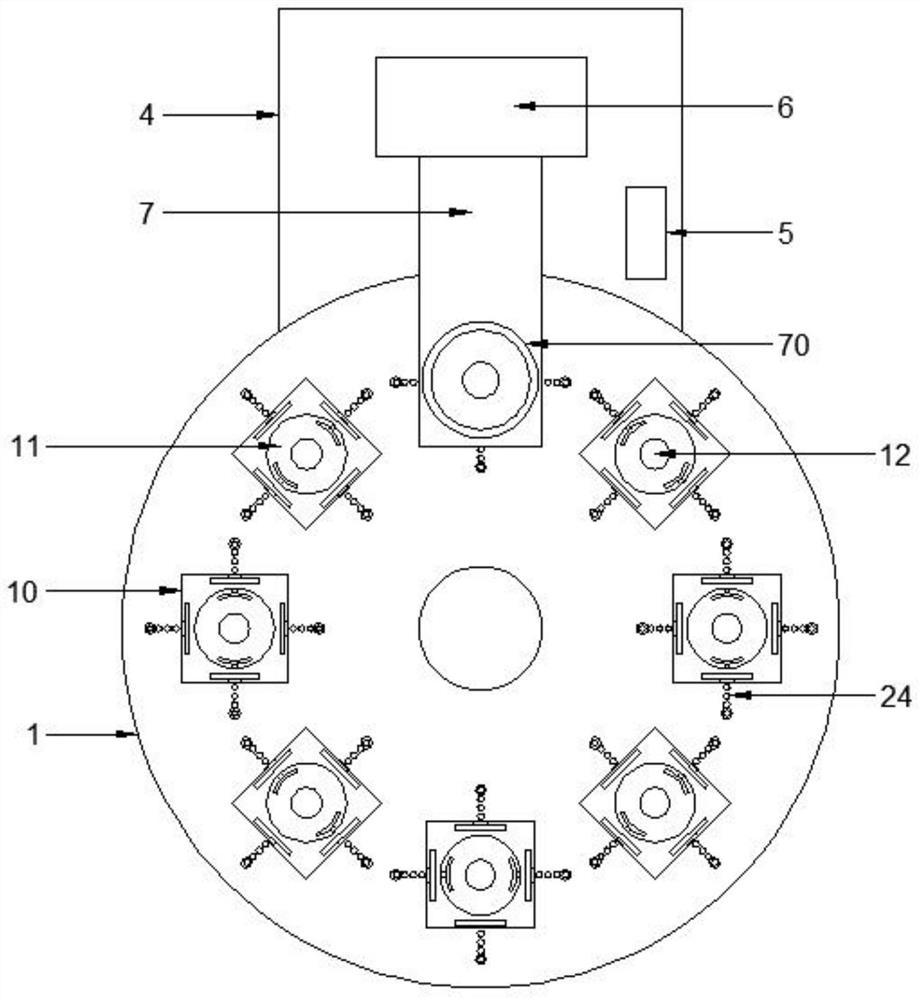

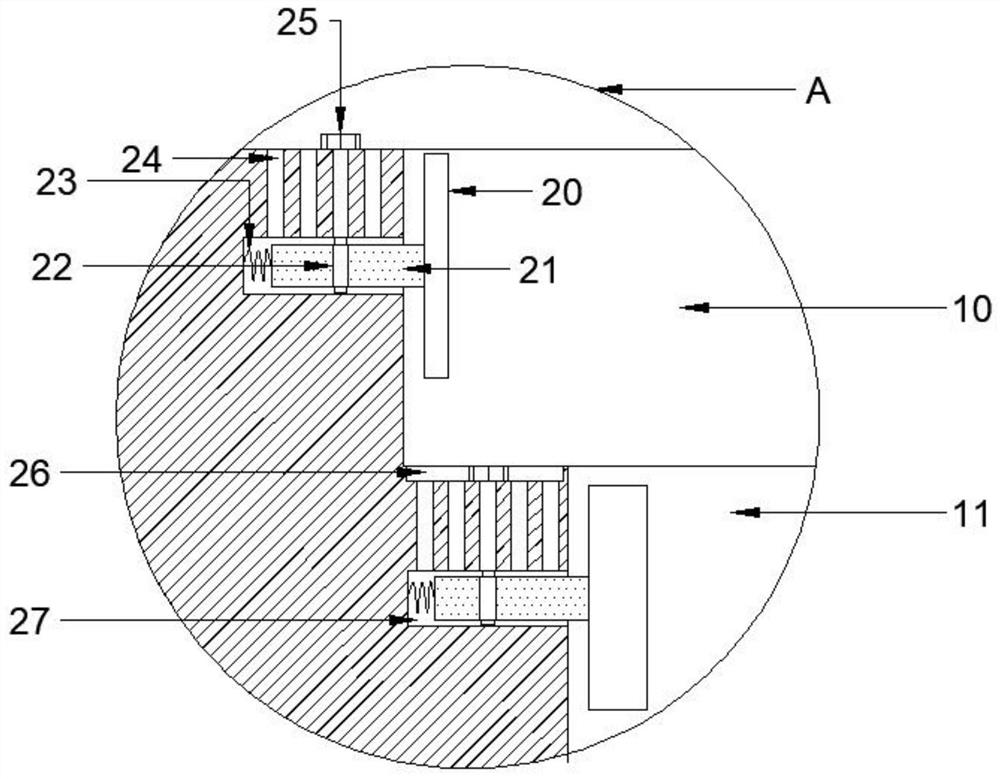

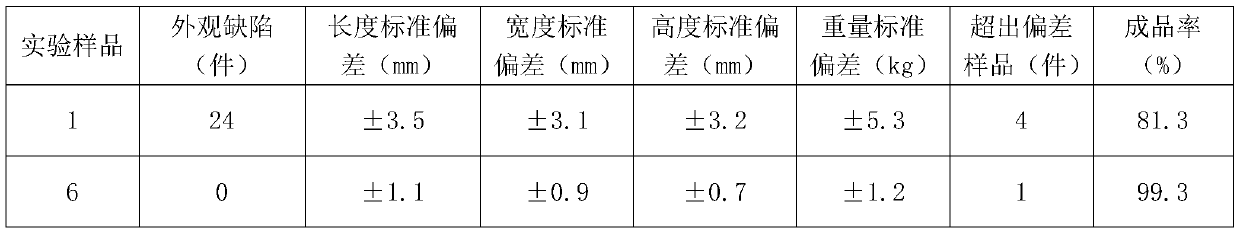

High-pressure grouting molding manufacturing process of toilet bowl, molding die of high-pressure grouting molding manufacturing process and ceramic toilet bowl

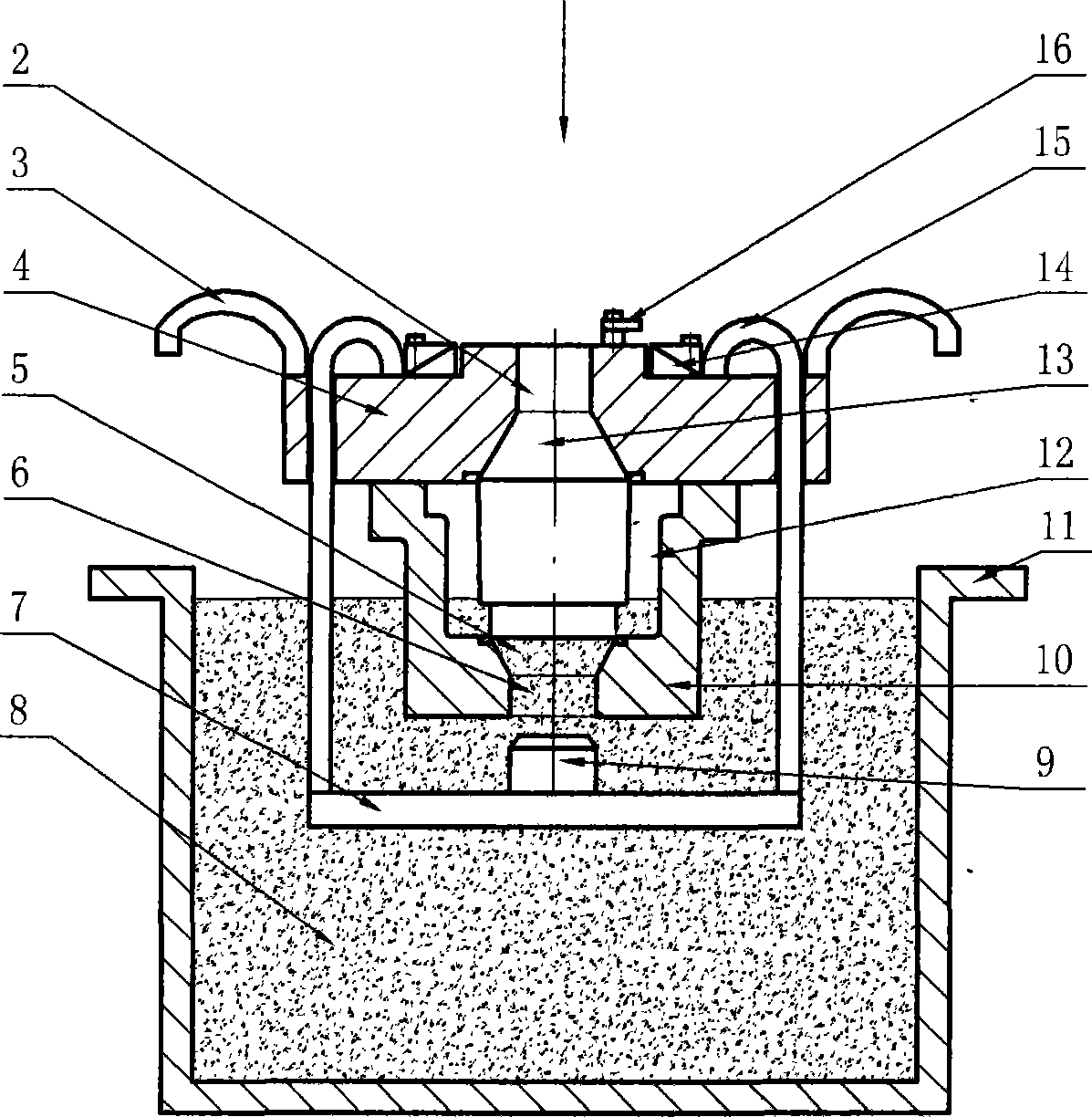

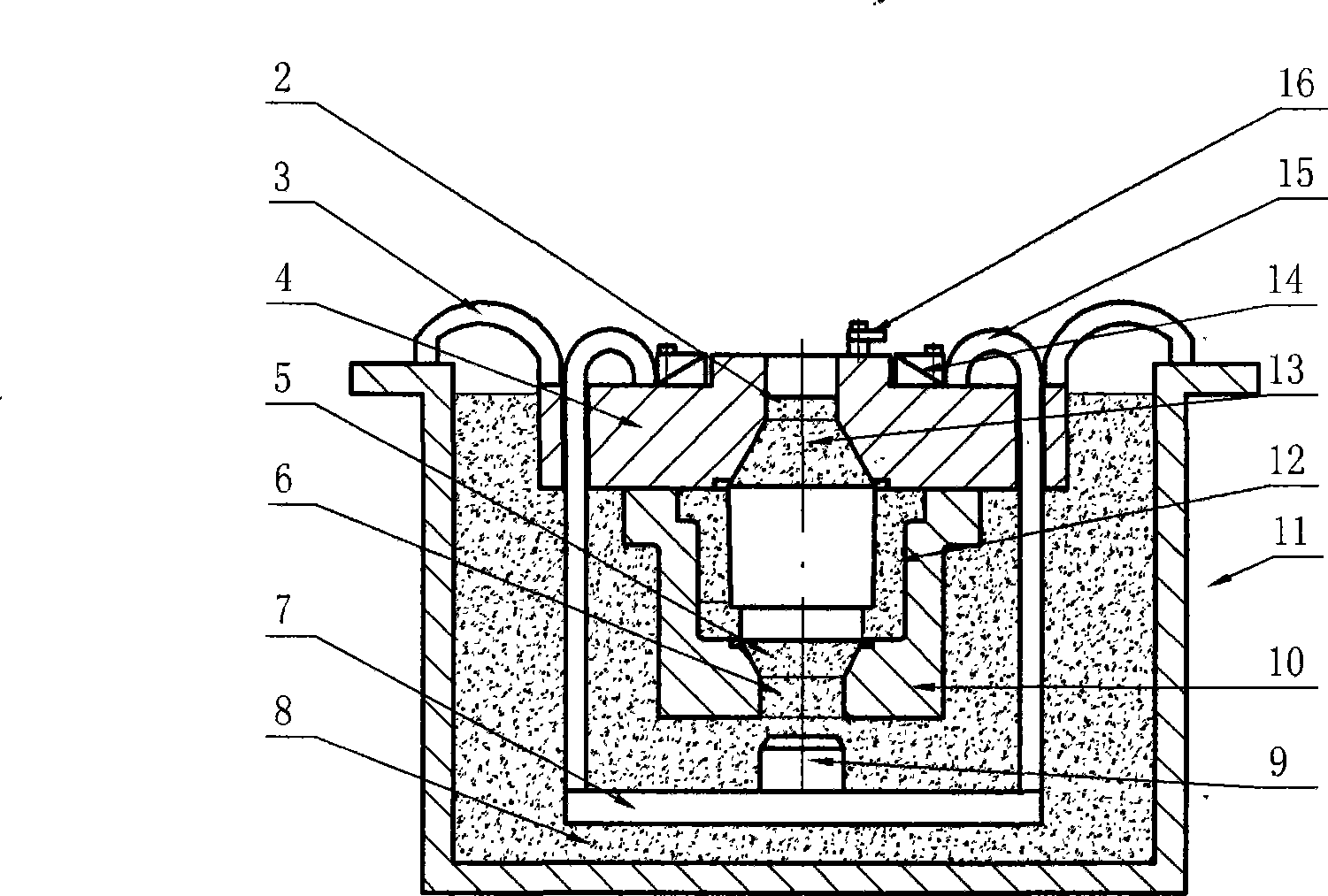

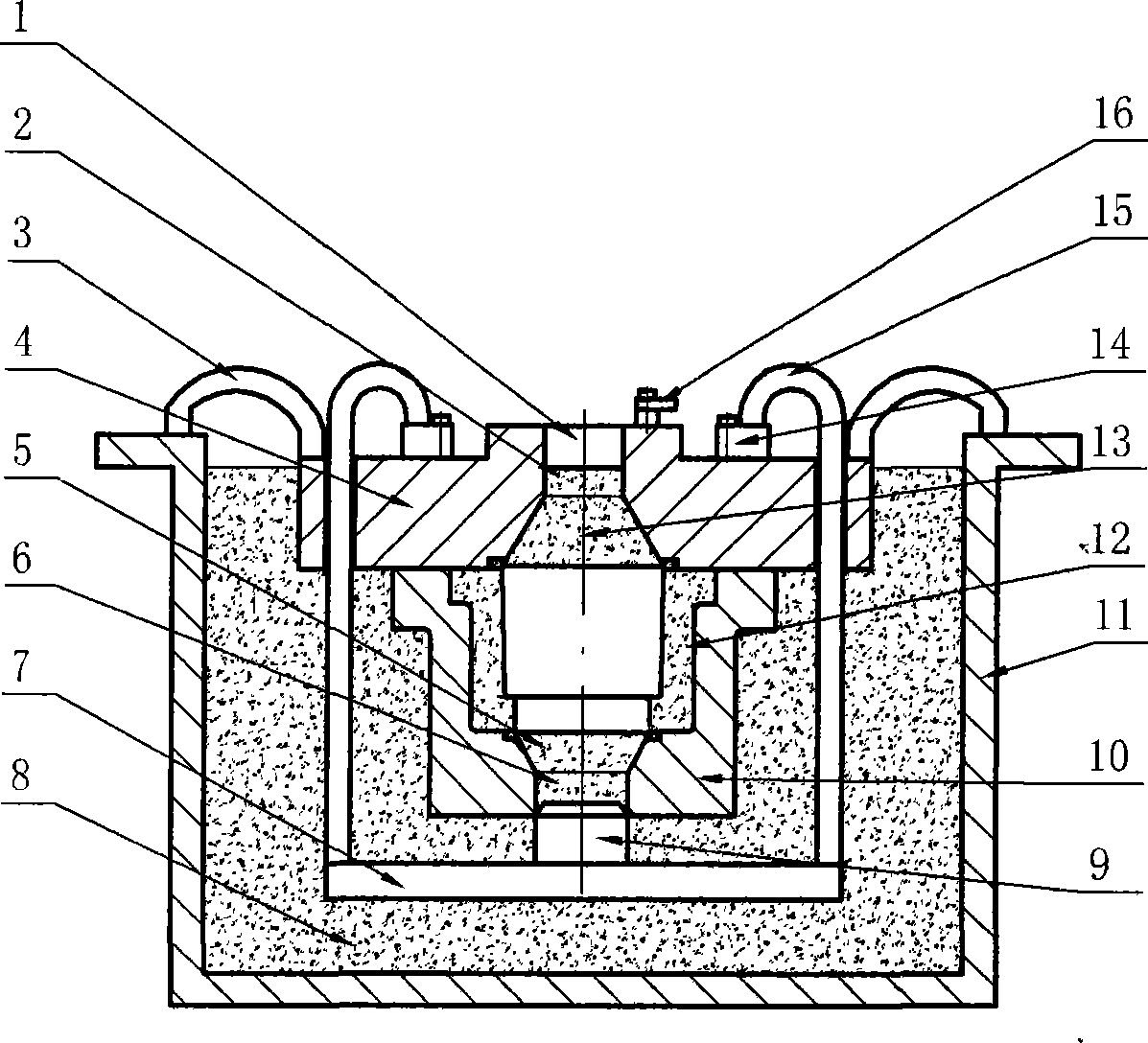

InactiveCN105365030AImprove structural strengthImprove structural qualityWater closetsAuxillary shaping apparatusHigh pressureToilet

The invention relates to the field of manufacturing processes, molding dies and finished products of sanitary ceramic products, and provides a high-pressure grouting molding manufacturing process of a toilet bowl. The high-pressure grouting molding manufacturing process comprises the steps of arranging of horizontal type high-pressure grouting equipment, arranging of a plurality of molding die bodies, die closing, grouting, die opening, die releasing and bonding and molding. Each molding die body comprises two female dies and a male die between the female dies. The molding die bodies are arranged on a bearing system of the horizontal type high-pressure grouting equipment in the horizontal direction. Two half-edge blanks are obtained every time die opening and die releasing are carried out. A complete toilet bowl blank is molded after each step of bonding and molding. Thus, according to the high-pressure grouting molding manufacturing process of the toilet bowl, the grouting molding yield and efficacy can be increased, and equipment cost is reduced; and a double-face grout eating manner can also be adopted so that the product yield and quality can be increased, the grout return manufacturing process is omitted, and the grouting molding time is greatly shortened.

Owner:GLOBE UNION INDAL

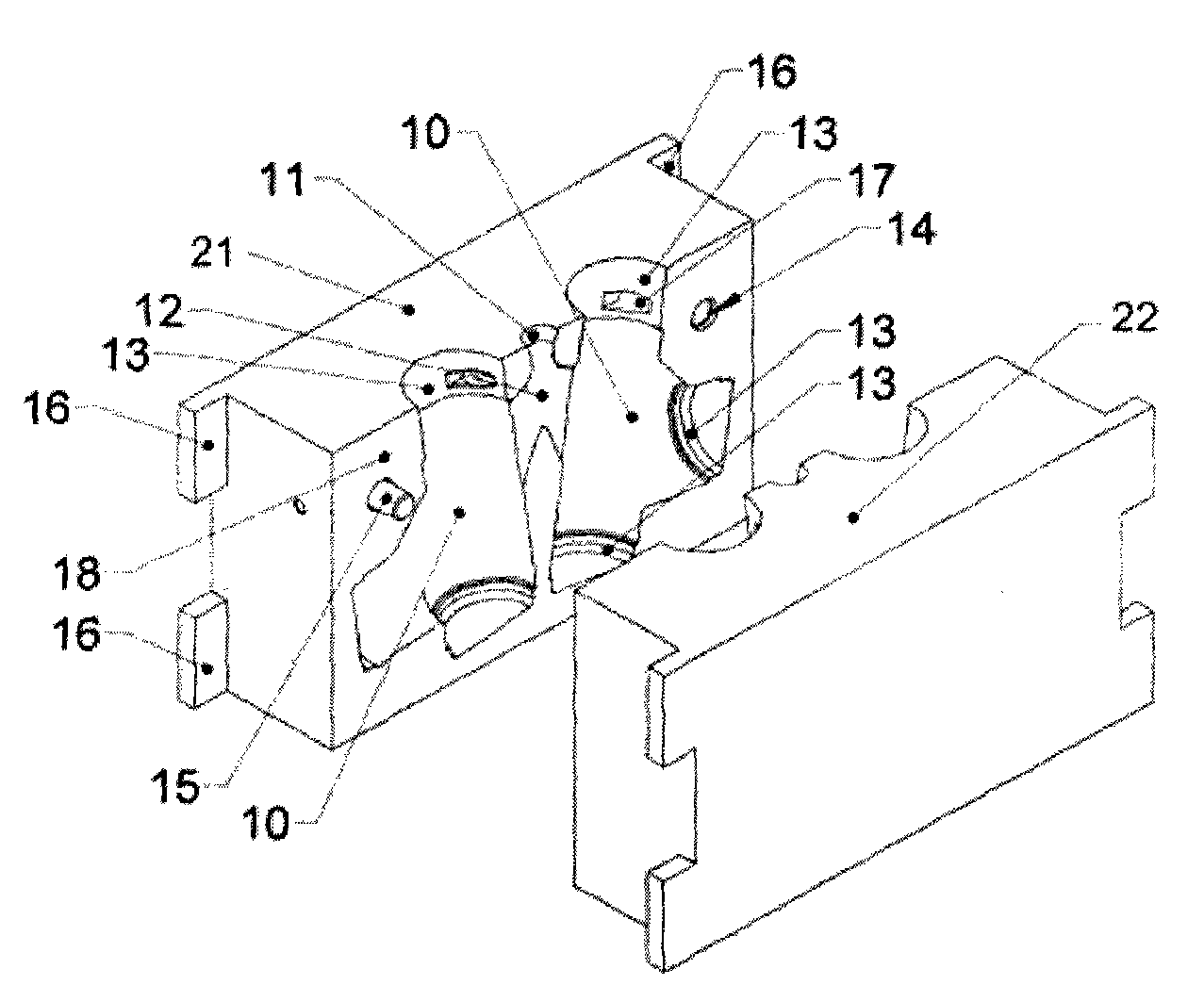

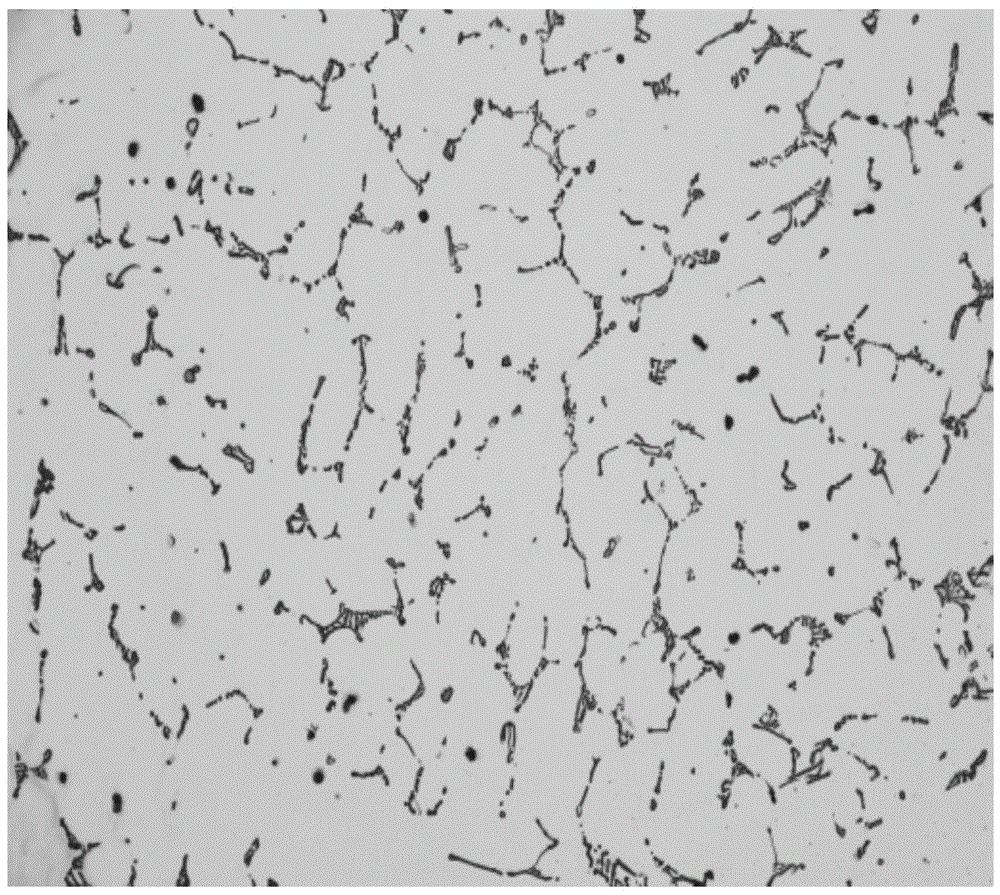

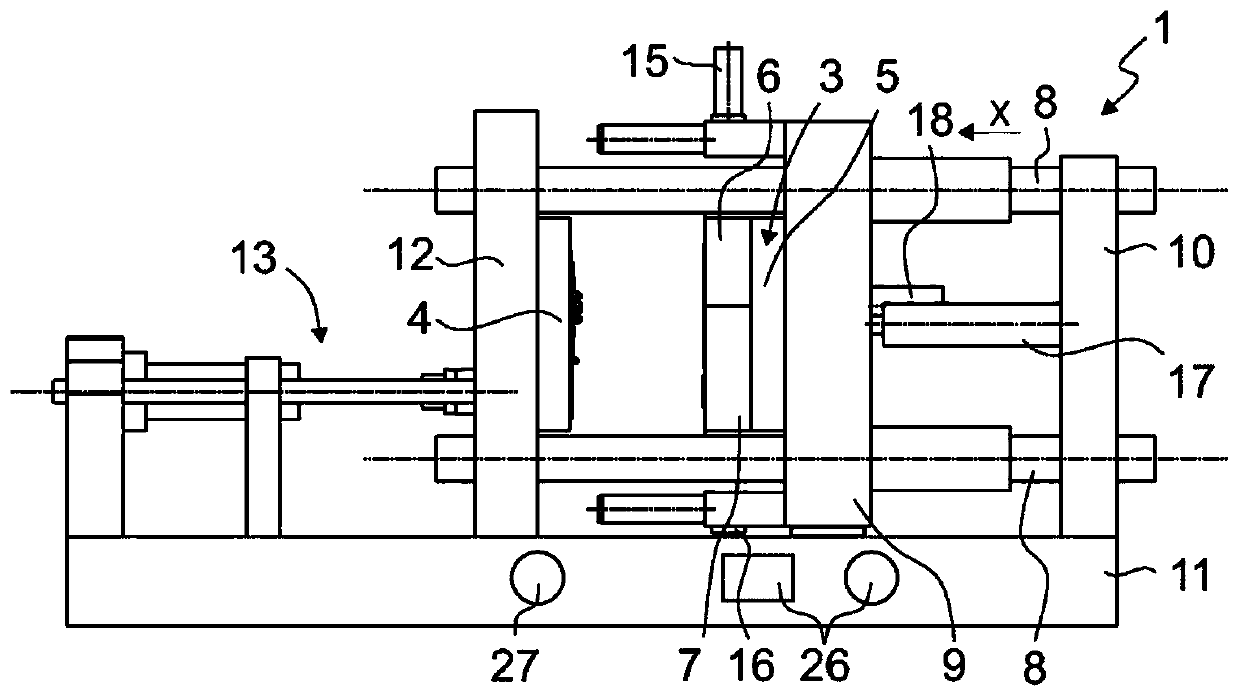

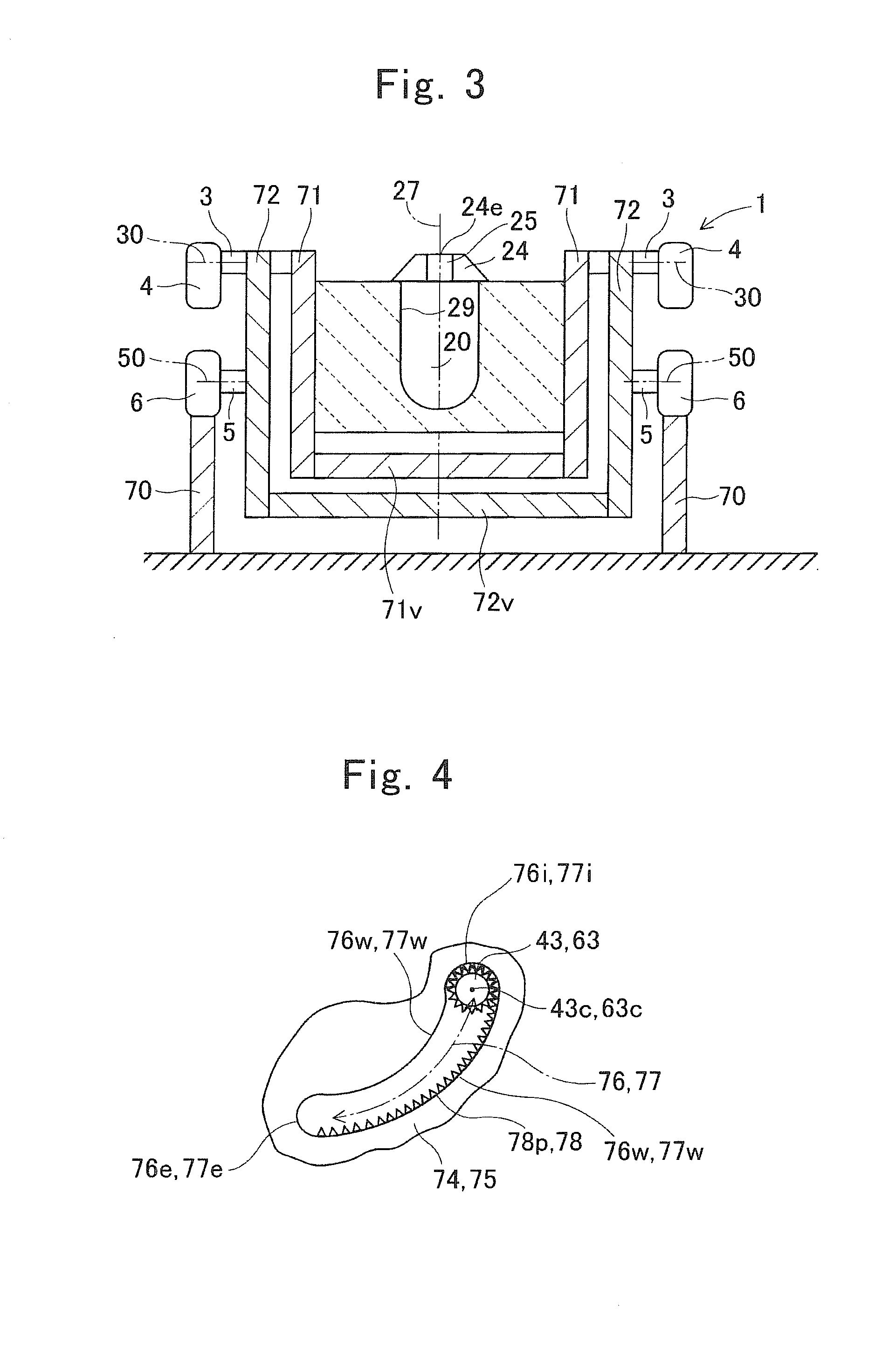

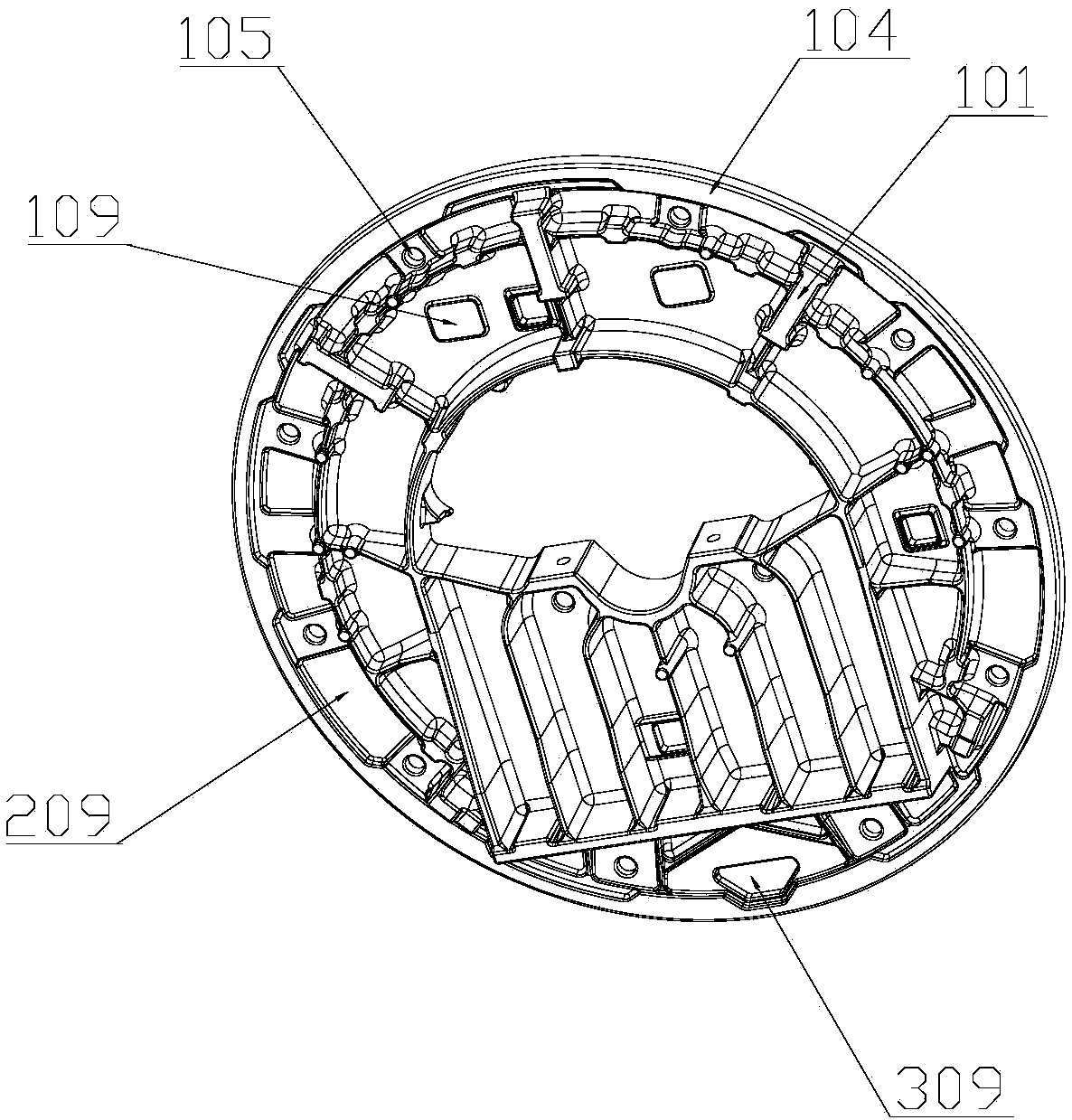

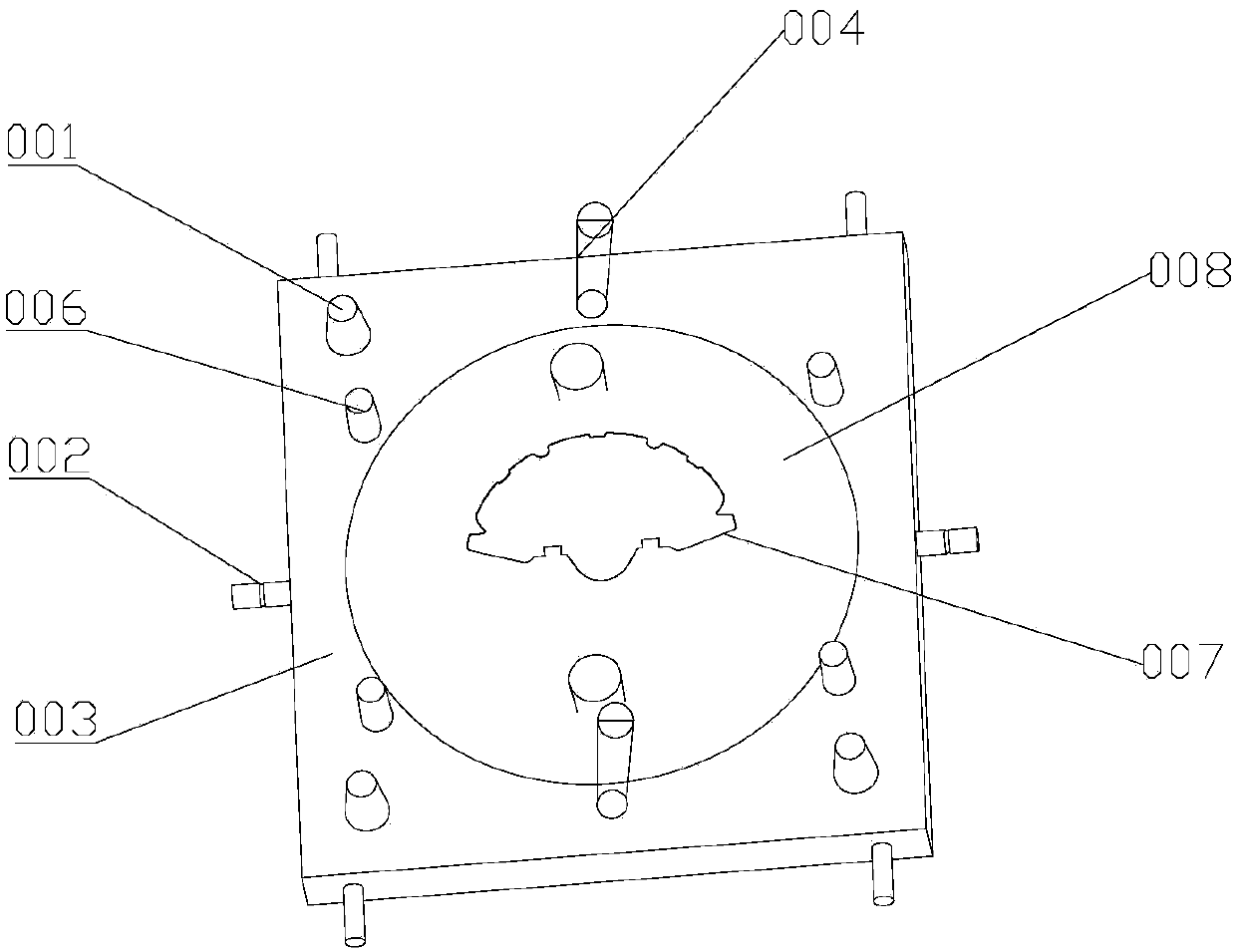

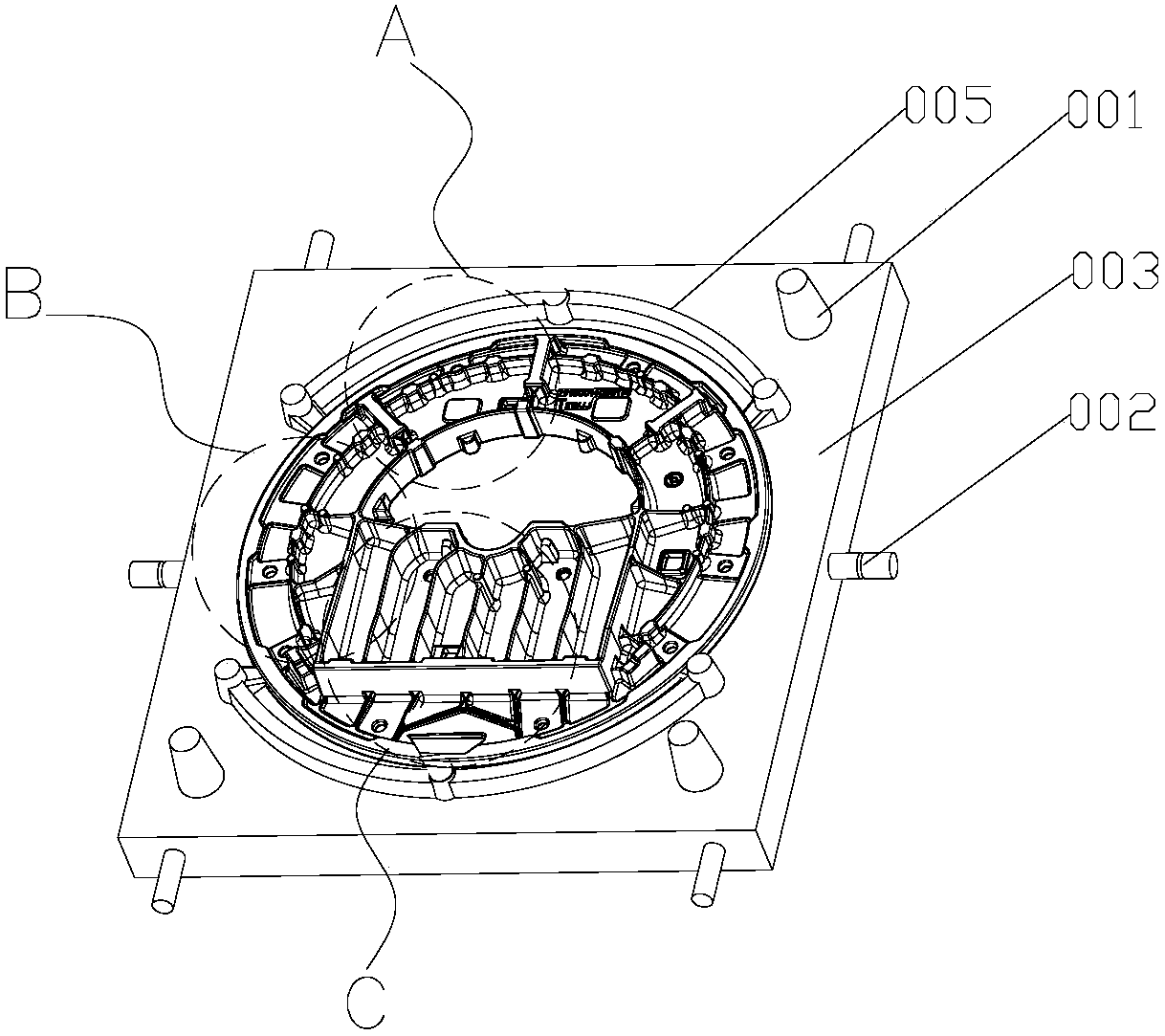

Metal mold and manufacturing method thereof, and metal mold casting apparatus

ActiveCN103521705AAvoid underwateringReduced casting timeFoundry mouldsFoundry coresMetal moldJoint surface

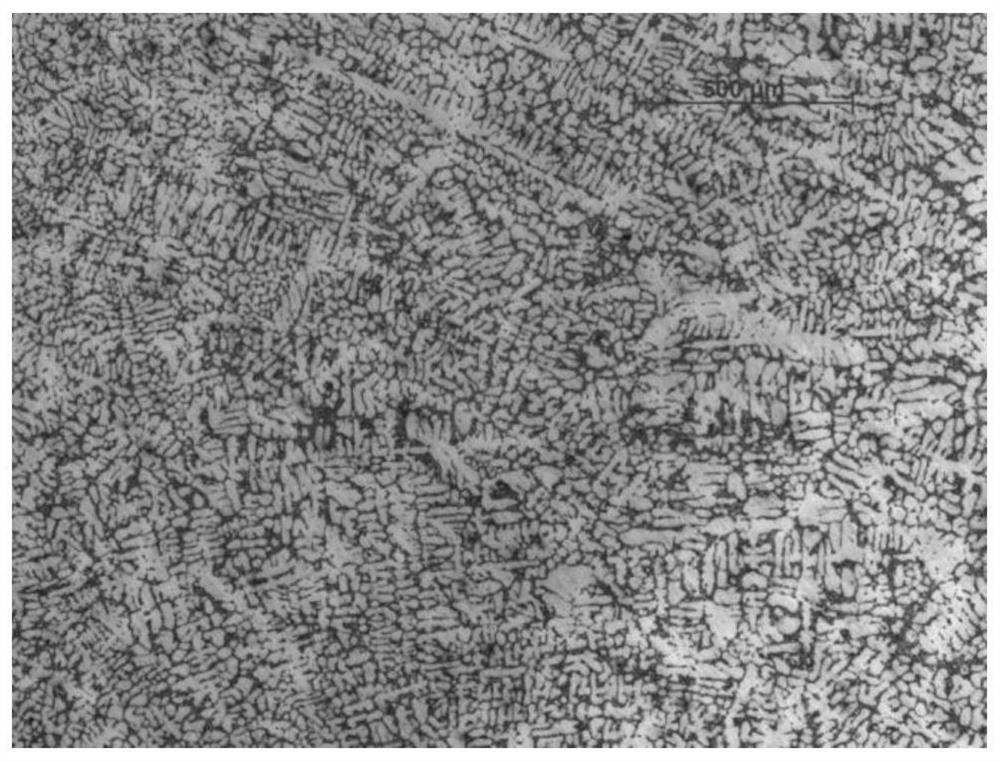

The invention discloses a metal mold and a manufacturing method thereof and a metal mold casting apparatus. The metal mold is arranged on the metal mold casting apparatus and comprises a first half mold and a second half mold which are processed from low-carbon structural steel with a uniform metallic structure. The first half mold and the second half mold are respectively provided with, in correspondence, a cavity used for formation of the shape of a casting during casting, a cast gate, a runner, fixed supporting feet which can be fixedly connected to the metal mold casting apparatus and joint surfaces which fit each other during closing of the first half mold and the second half mold, wherein the cavity is a concave cavity matching with the shape of the external surface of the casting and accommodates a sand core used for defining the interior surface shape and wall thickness of the casting, and a positioning part used for positioning the relative position between the sand core and the cavity is arranged above the cavity. The metal mold prepared by using the manufacturing method provided by the invention can shorten casting time, realizes rapid filling and formation and improves yield.

Owner:XUSHUI XINGHUA CASTING

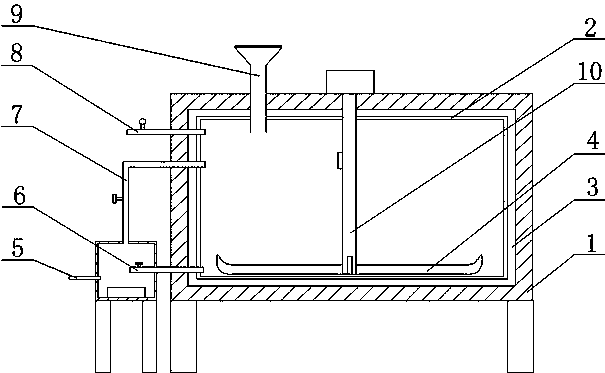

Polycrystalline silicon ingotting furnace and ingotting method thereof

ActiveCN103343387AShorten the running cycleIncrease production capacityPolycrystalline material growthSingle crystal growth detailsTransformerCrystallization

The invention discloses a polycrystalline silicon ingotting furnace and an ingotting method thereof, relating to the technical field of equipment for preparing uniform polycrystalline silicon with a certain structure. The ingotting furnace comprises a furnace body insulating layer, a top heater, a quartz crucible, a heat-dissipation platform, a heat-dissipation window and a bottom heater. The bottom heater is located on the lower side of the heat-dissipation platform. The bottom heater and the top heater are controlled by independent transformers, and are adjusted separately. The rate power of the bottom heater is 5kw-100kw. The bottom heater is started in the heating and smelting period during a running process of the ingotting furnace, and is stopped completely during a crystallization process of silicon liquid, so that the temperature of silicon material at the bottom of the crucible quickly rises by the smelting of the silicon material, thereby reducing the smelting duration of the silicon material and improving the productivity of the ingotting furnace.

Owner:YINGLI ENERGY CHINA

Equipment and process for casting multi-branch steel ingot with vacuum spill method and liquid steel

InactiveCN101342586AReduced casting timeSimple installationMolten metal pouring equipmentsTundishLiquid steel

The present invention relates to a device and a process adopting the liquid steel vacuum overflow method to cast a plurality of ingots, which belongs to the technical field of the vacuum casting ingot, and aims at overcoming the weaknesses that the liquid steel is secondarily oxidized when the liquid steel is poured into the pouring box in vacuum pouring way, and the pouring time is long, the device is large, etc. The desaeration slide gate nozzle steel ladle is adopted for direct pouring, and after the liquid steel is poured to a specified height at a primary mould cap port: proposal A and proposal B, the liquid steel flows into the next or the next two moulds through one or two single-way overflow grooves so as to pour all steel ingots. Proposal C, the liquid steel pours all steel ingots through the primary or a plurality of balancing overflow grooves with the same height of the bottom marker. Proposal D, the liquid steel pours all steel ingots through a plurality of single-way overflow grooves on the primary cap and a plurality of balancing overflow grooves with the same height of the bottom marker among the rest caps. Adopting each proposal, the height of the cap port of the ingot is basically the same. The process of the present invention has short general pouring time, and is safe and smooth, and has good quality of the steel ingot, and has simple device and less invenatment, and can save the energy. The process of the present invention is applicable to vacuum pouring a plurality of quality steel ingots that are used for rolling and forging in the special steel and heavy machine industries.

Owner:冬燕

Casting process of aluminum alloy slab ingot

The invention relates to a casting process of a aluminum alloy slab ingot, which is particularly suitable for co-casting the aluminum alloy slab ingot with different specifications and belongs to the production technical field of aluminum processing industry. The casting process comprises the following steps of: 1, establishing casting process parameters; 2, simulating casting; 3, confirming fusant temperature in a heat preserving furnace; 4, laying out a crystallizer; 5, casting; 6, sampling from final components; and 7, cooling aluminum liquid. The casting process of aluminum alloy slab ingot is capable of casting the aluminum alloy slab ingot with two or more than two specifications at one step, and has high production safety, low investment cost and easy operation.

Owner:SHANDONG NANSHAN ALUMINUM

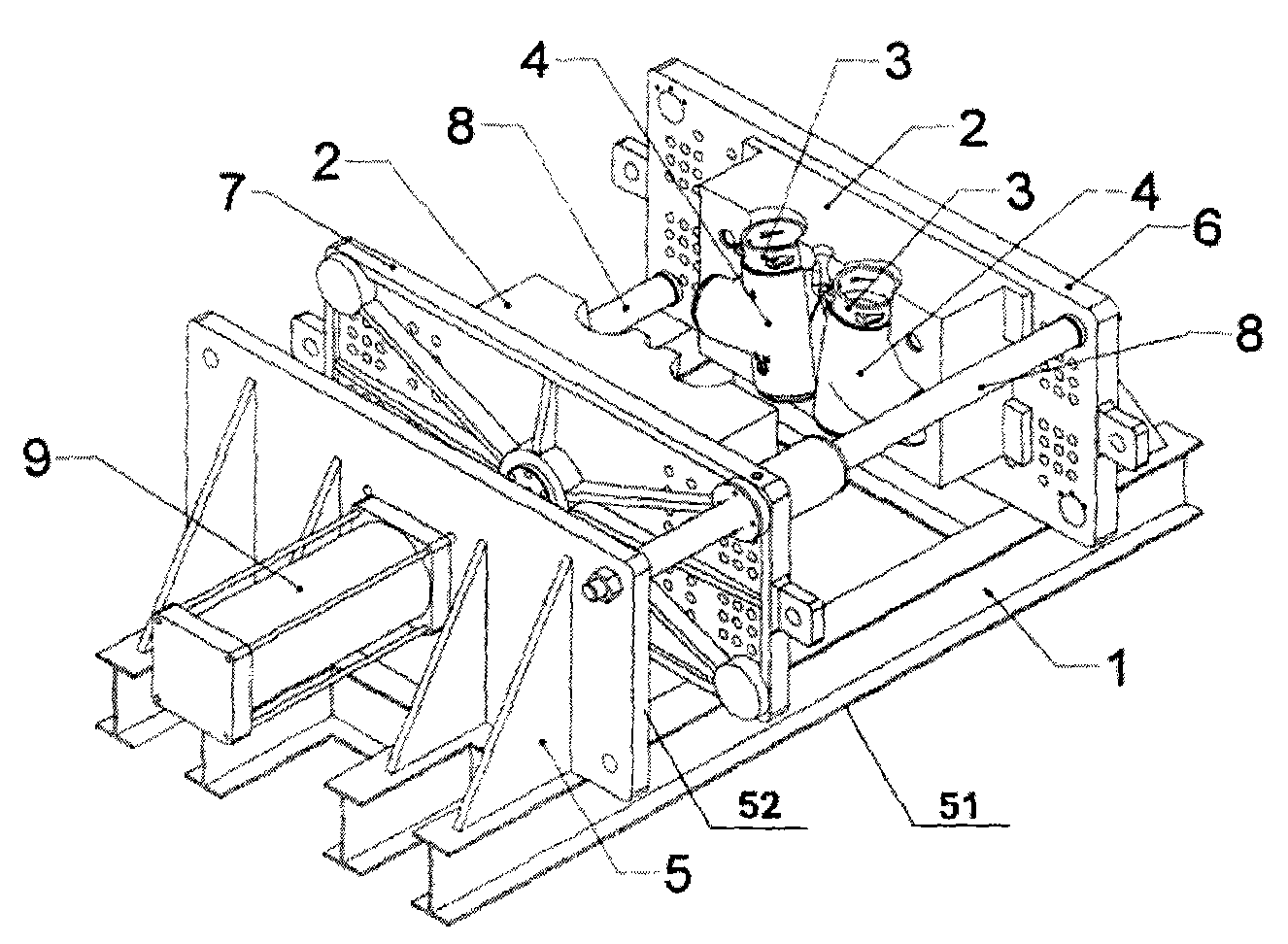

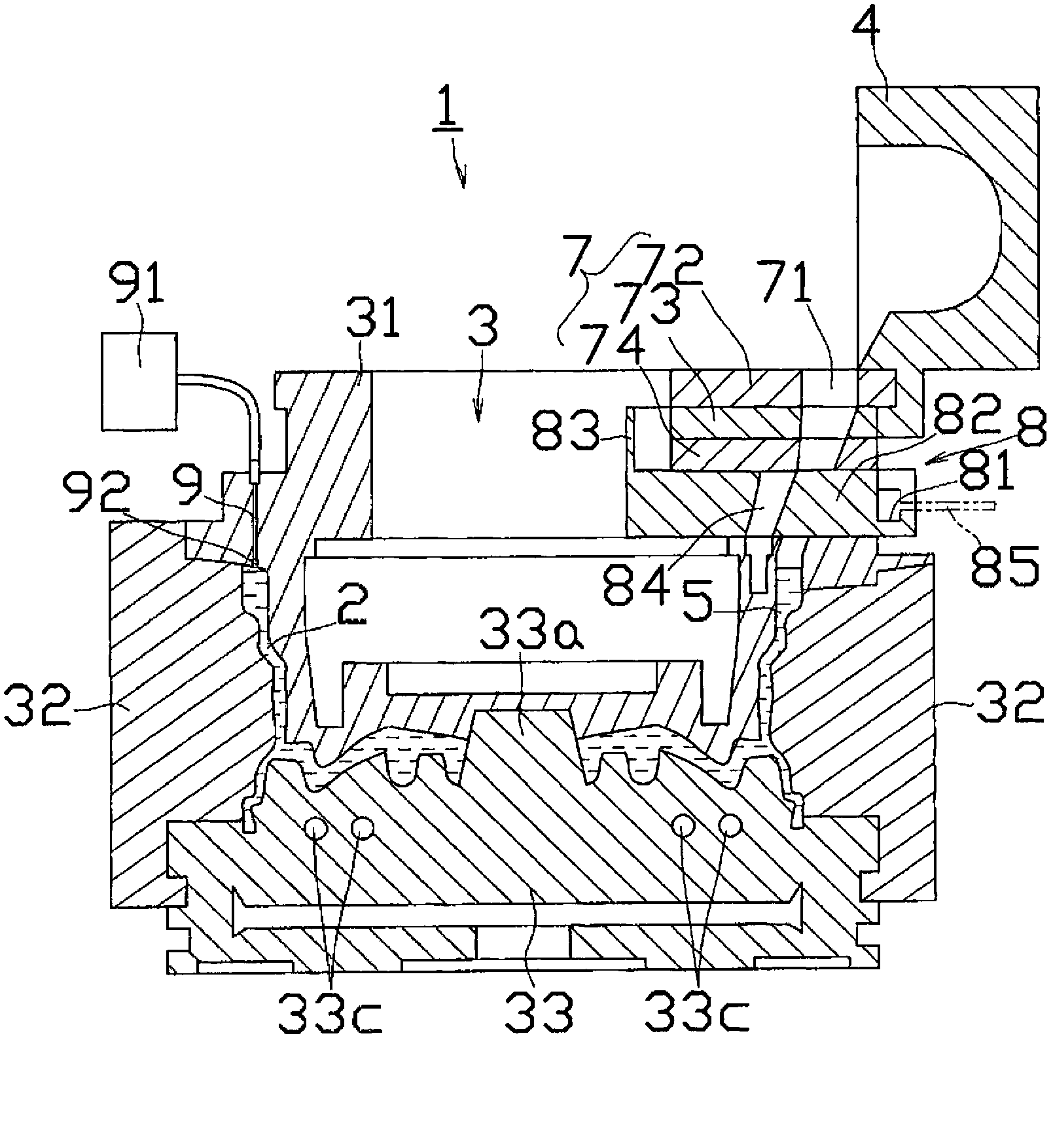

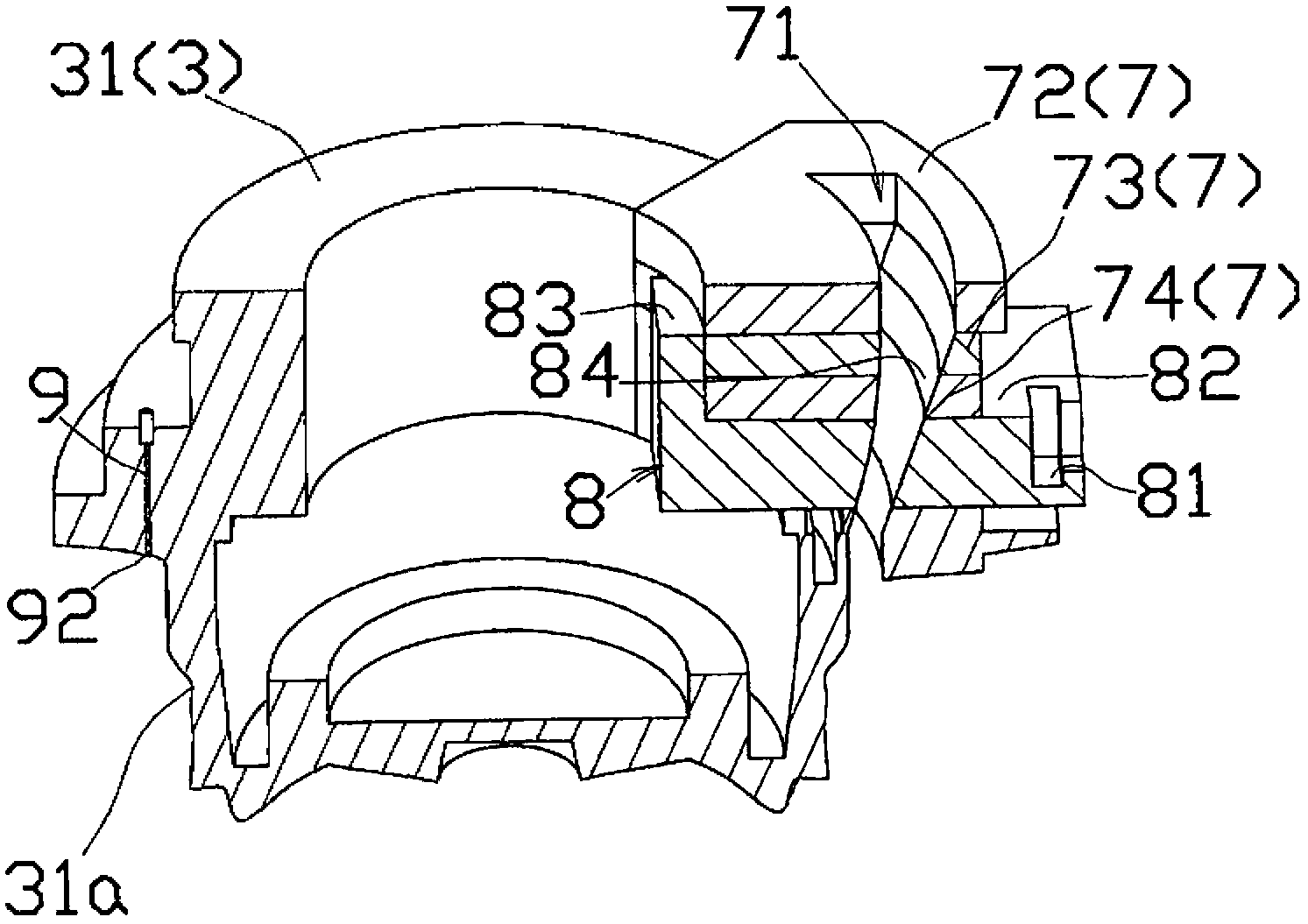

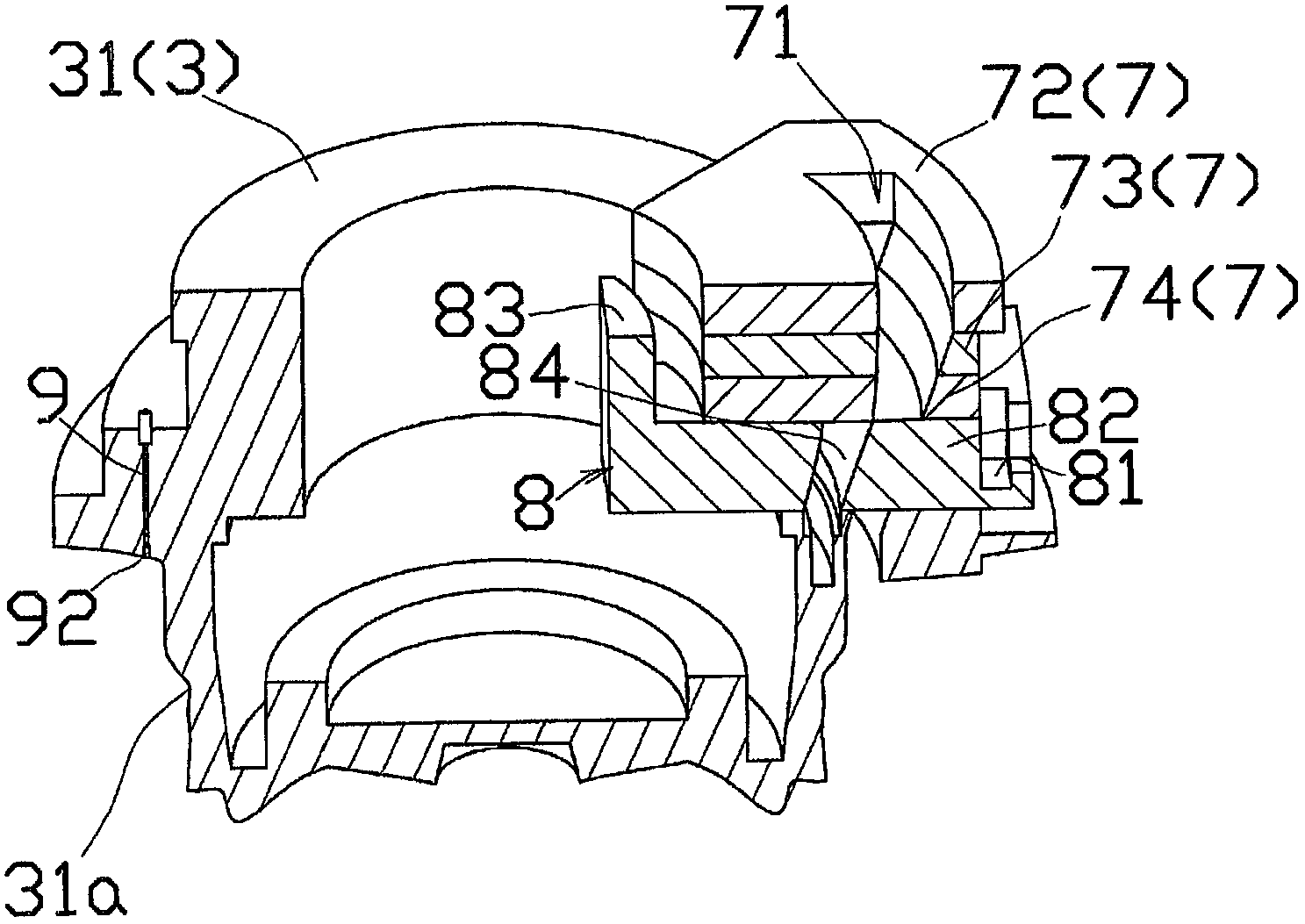

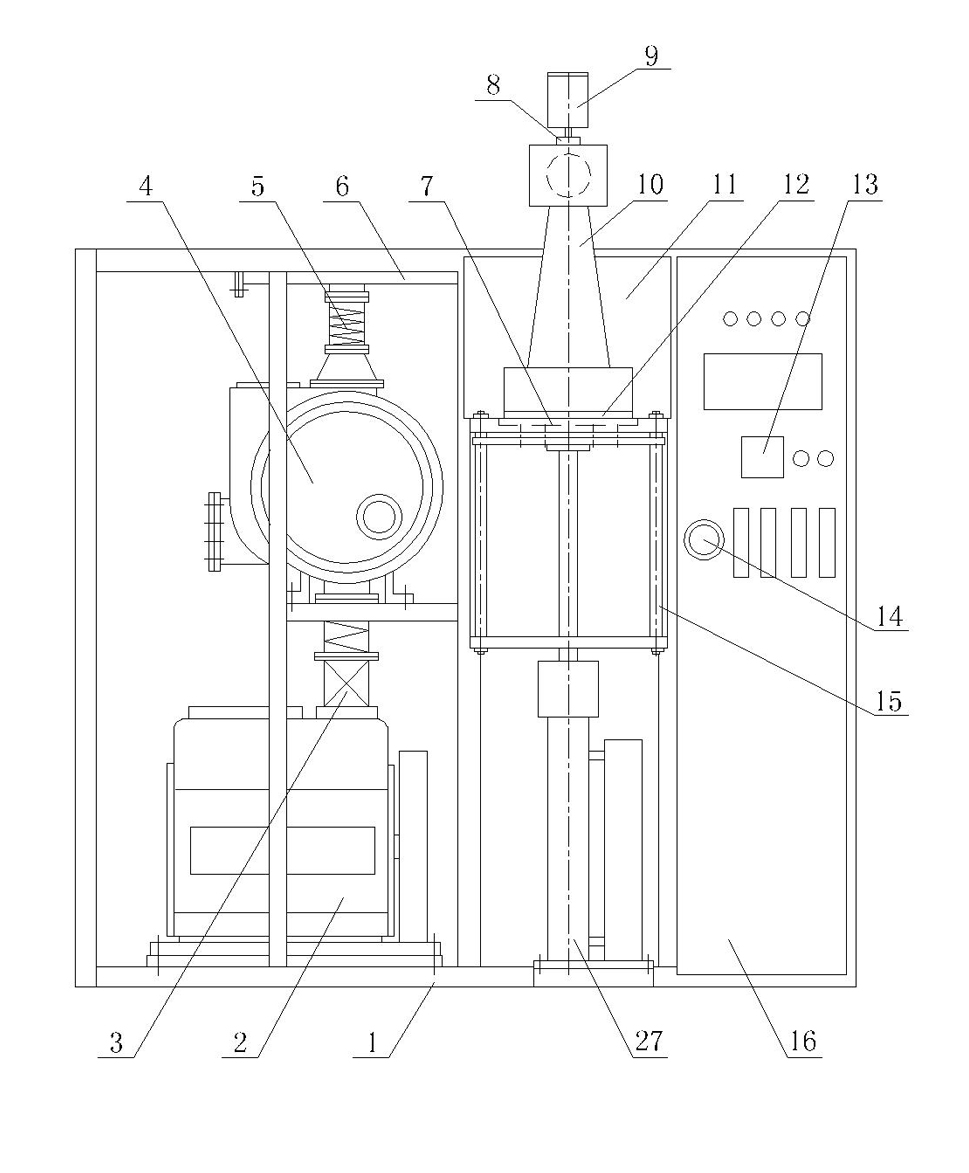

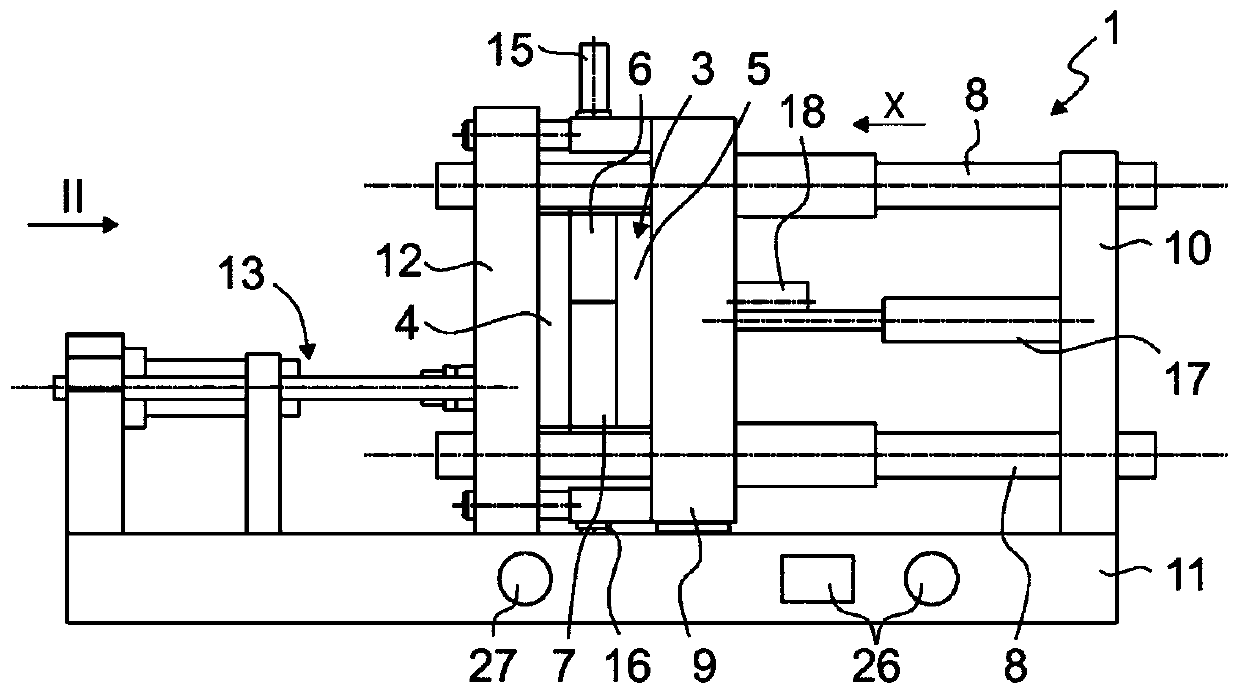

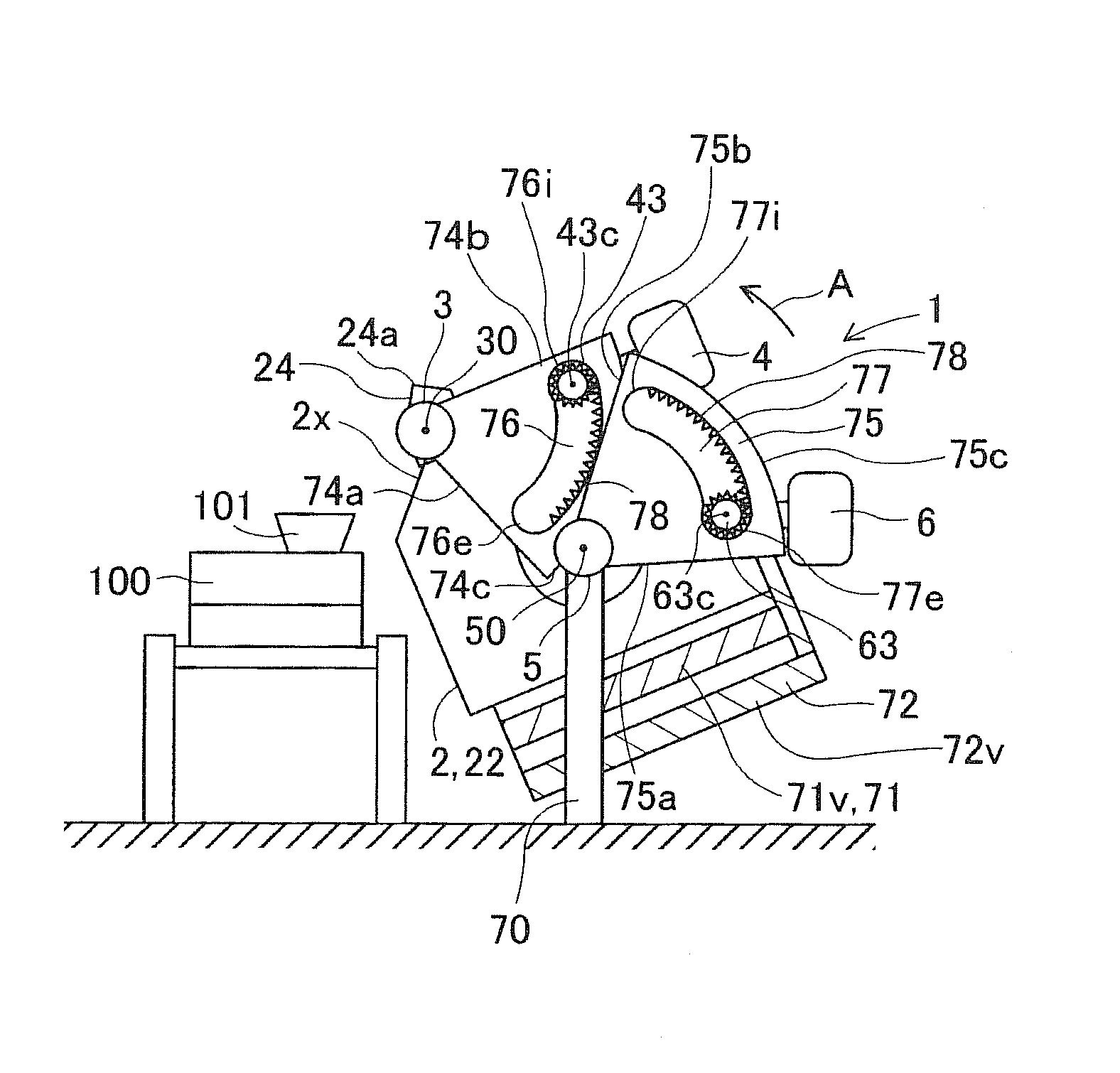

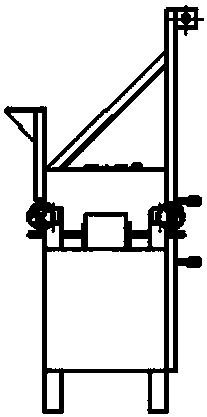

Tilt type gravity molding device

InactiveCN102712041AReduce the amount of timeReduce manufacturing costFoundry mouldsFoundry coresMetallurgyStanding Positions

A tilt type gravity molding device comprises: a mold (3) which can tilt between a fallen position and a standing position raised approximately 90 degrees from the fallen position; a pouring mold (7) in which a pouring gate (71) for guiding molten metal to the cavity (2) for forming a molded article is formed; and a bowl-like member (4) which contains the molten metal and pours the molten metal into the pouring gate (71) as the mold (3) tilts. In order to eliminate the need for a feeder head and for a reduction in the tilt speed and to enable the molten metal within the mold to be appropriately pressurized by gas, the tilt type gravity molding device also comprises: a blocking means (8) which is provided between the pouring gate (71) and the cavity (2) and which can open and close the pouring gate (71); a gas opening (9) which is provided at the upper part of the mold (3) in the standing position, prevents the molten metal from flowing to the outside of the mold (3), and permits only gas to pass therethough; and a gas supply means (91) which can supply a high-pressure gas to the gas opening (9).

Owner:MORIKAWA KANAGATA

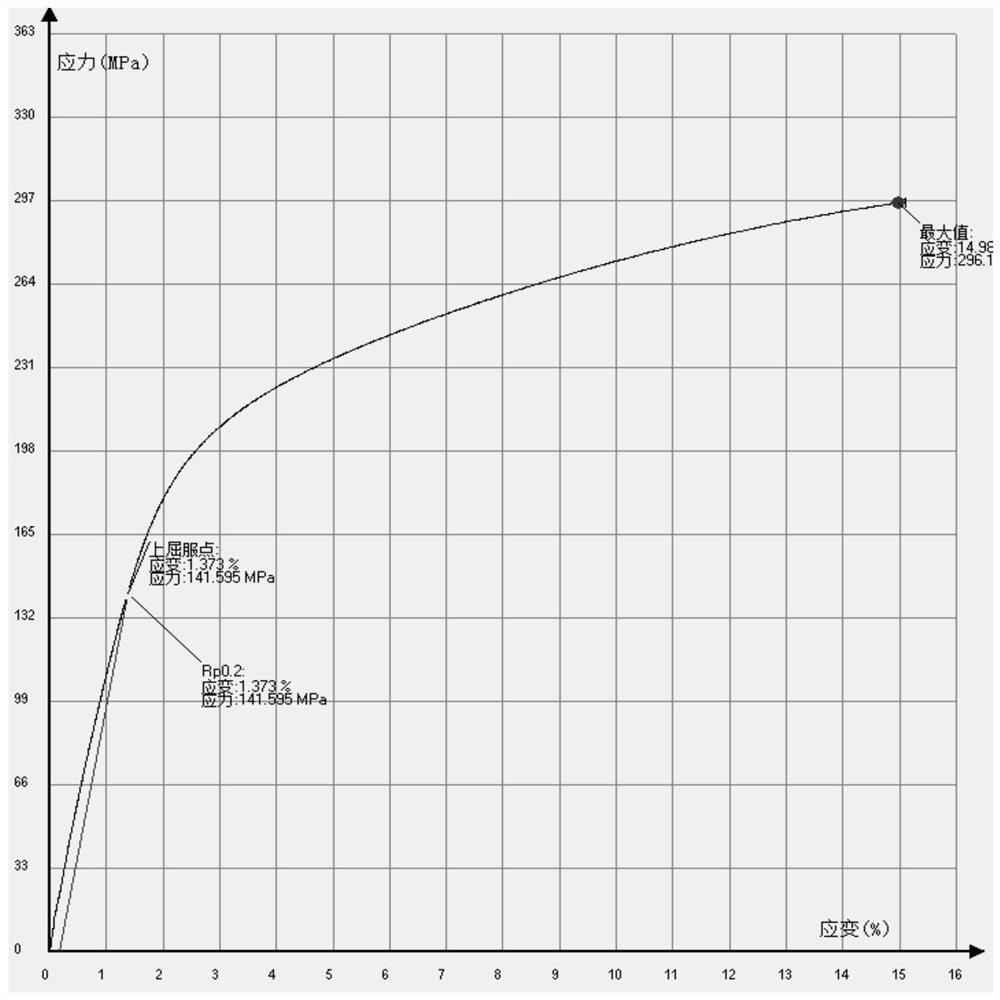

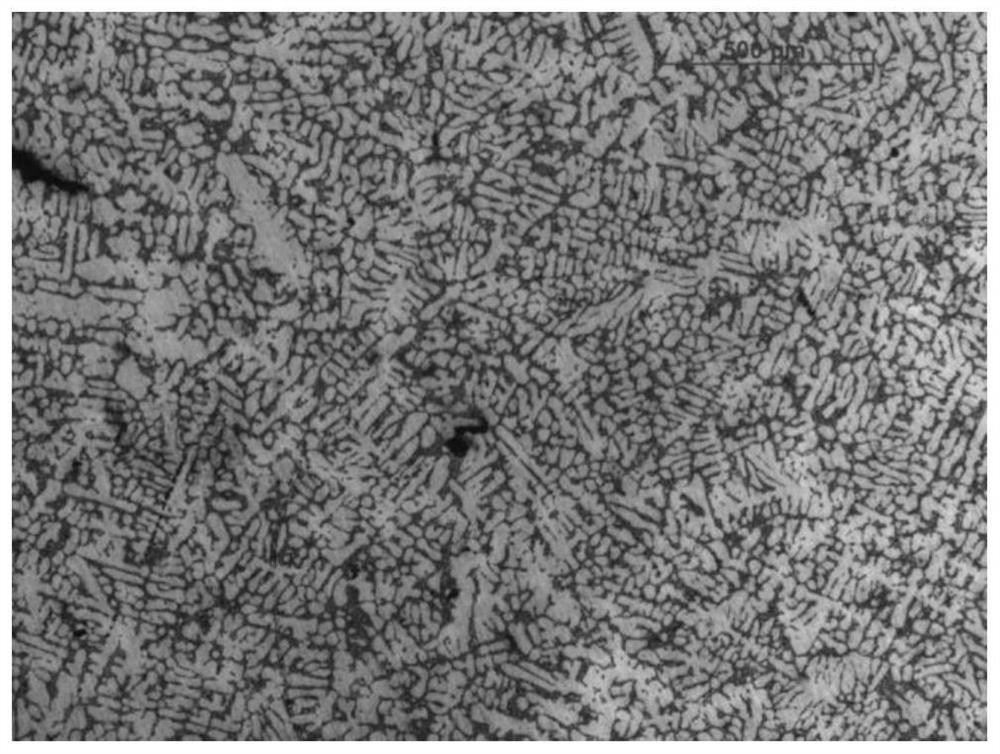

Non-heat-treatment reinforced high-toughness pressure-casting aluminum alloy material for new energy automobile battery box

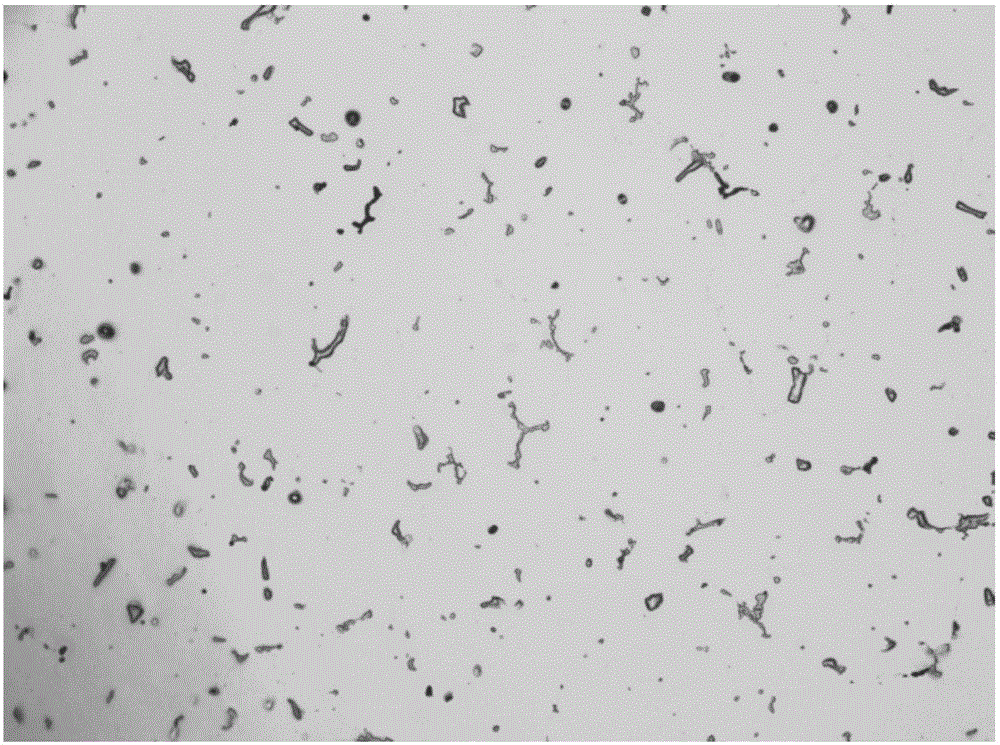

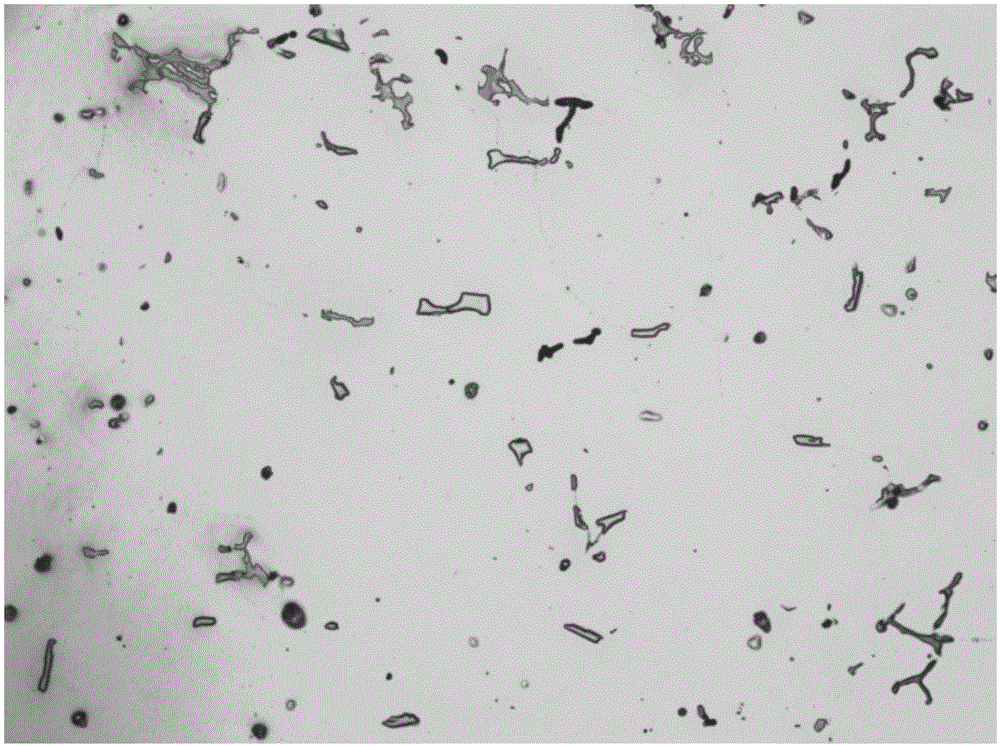

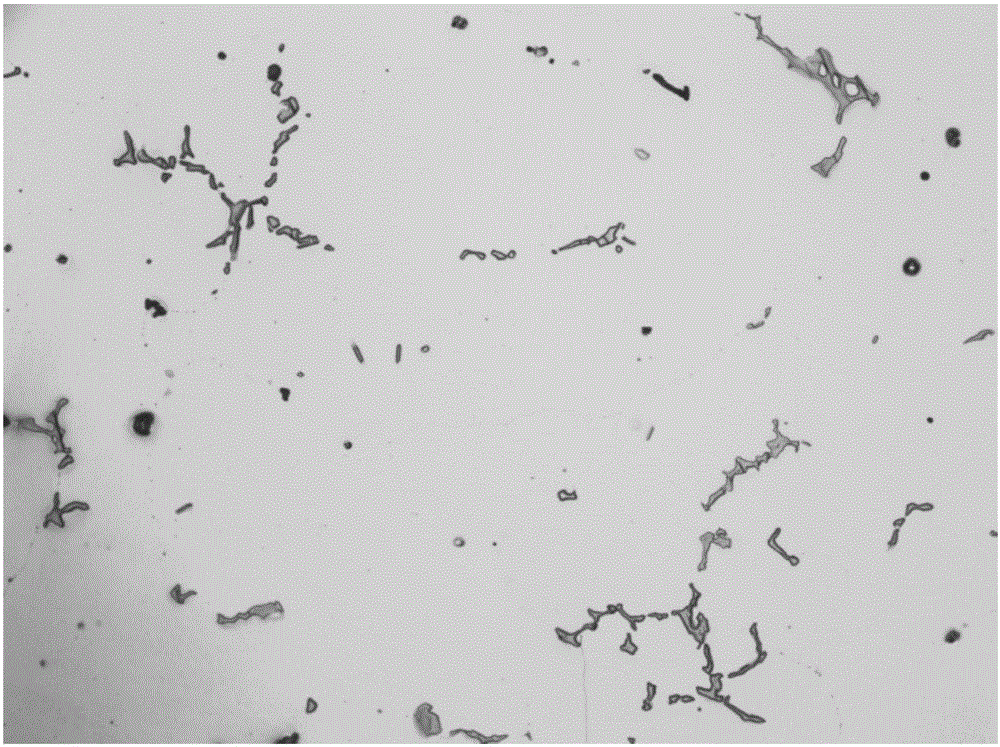

The invention discloses a non-heat-treatment reinforced high-toughness pressure-casting aluminum alloy material for a new energy automobile battery box. The alloy material comprises 7wt%-9wt% of Si, 0.6wt%-1.0wt% of Mg, 0.2wt%-0.8wt% of Mn, smaller than 0.5% of Cu, smaller than 0.7wt% of Fe, smaller than 0.5.0wt% of Zn, smaller than 1wt% of La, smaller than 2wt% of Ce, smaller than 1wt% of Al-Ti-C-Sr and the balance Al, and the sum of the weight percentages of the rest of impurities is controlled to be 0.5wt% or below. The non-heat-treatment reinforced high-toughness pressure-casting aluminum alloy material is obtained by adopting a nanoscale refiner for auxiliary strengthening of rare earth elements, meanwhile, a double-charging-barrel integrated casting mode is introduced into the high-pressure cast new energy battery box, the casting filling time of the battery box in a mold can be shortened, the casting defects such as cold shut shrinkage porosity and the like are avoided, and the product yield is improved.

Owner:苏州慧驰轻合金精密成型科技有限公司

Casting method for casting stainless steel workpiece through evanescent mold

InactiveCN107598087AImprove processing qualityComplex structureFoundry mouldsFoundry coresHigh volume manufacturingLiquid metal

The invention provides a casting method for casting a stainless steel workpiece through an evanescent mold applied to the technical field of evanescent mold casting. The casting method for casting thestainless steel workpiece through the evanescent mold comprises the casting steps that firstly, bake drying is carried out on a mold shell (2), and then the mold shell (2) is put into a sand mold (1); secondly, the sand mold (1) and the mold shell (2) are heated, and the mold shell (2) is disappeared in a liquidation manner; thirdly, the sand mold (1) is put into a sealed molding box (3), and airin the molding box (3) is extracted till the molding box (3) is extracted to a negative pressure state; and fourthly, a liquid metal raw material is poured into a workpiece cavity. By means of the casting method for casting the stainless steel workpiece through the evanescent mold, the machining quality of the stainless steel workpiece can be improved, the production efficiency of the stainless steel workpiece is improved, the large batch production requirement of the stainless steel product is met, meanwhile, the environmental friendly and energy saving effects can be obviously improved, andthe stainless steel workpiece with a complex structure and surface quality superior to that of a traditional process is manufactured.

Owner:ANHUI WEIGONG MACHINERY TECH

Method for manufacturing aluminum alloy large-sized flat ingot for ship body

The invention provides a method for manufacturing an aluminum alloy large-sized flat ingot for a ship body, relates to a manufacturing method for the aluminum alloy large-sized flat ingot, and aims to solve the problem that an aluminum alloy large-sized flat ingot which is prepared according to a conventional preparation method and used for the ship body is poor in mechanical strength and corrosion resistance, and short in service life. The aluminum alloy large-sized flat ingot provided by the invention is prepared from the following raw materials for smelting in percentage by weight: 0.7-1.1% of Mn, 5.5-6.5% of Mg, 0.03-0.15% of Zr, 0.10-0.30% of Er and the balance of Al. The preparation method provided by the invention comprises the following steps: 1, weighing certain amount of such five elements of Mn, Mg, Zr, Er and Al; 2, preparing an aluminum alloy melt; and 3, carrying out semi-continuous casting to obtain the aluminum alloy large-sized flat ingot. The aluminum alloy large-sized flat ingot is applicable to the ship body.

Owner:NORTHEAST LIGHT ALLOY CO LTD

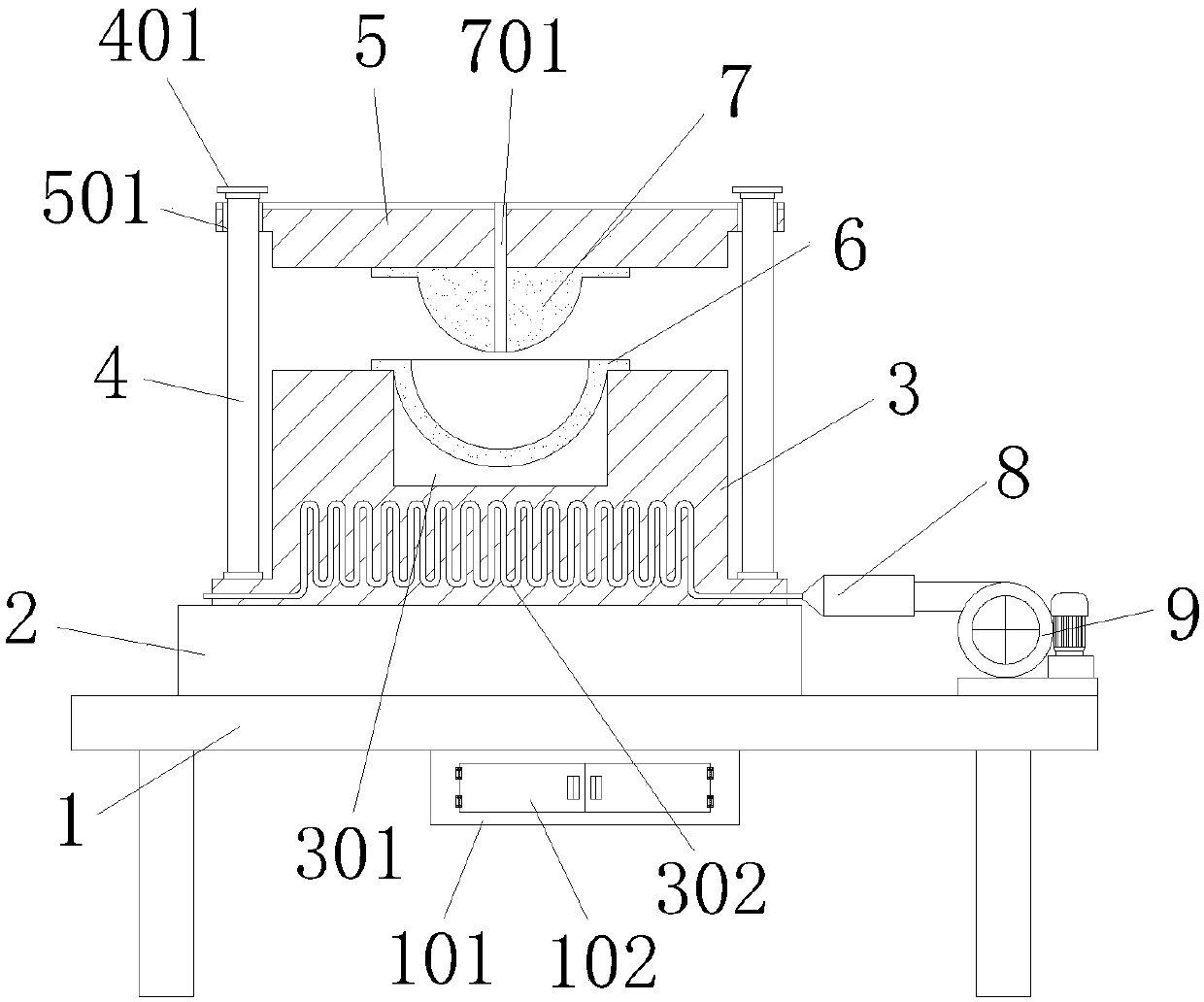

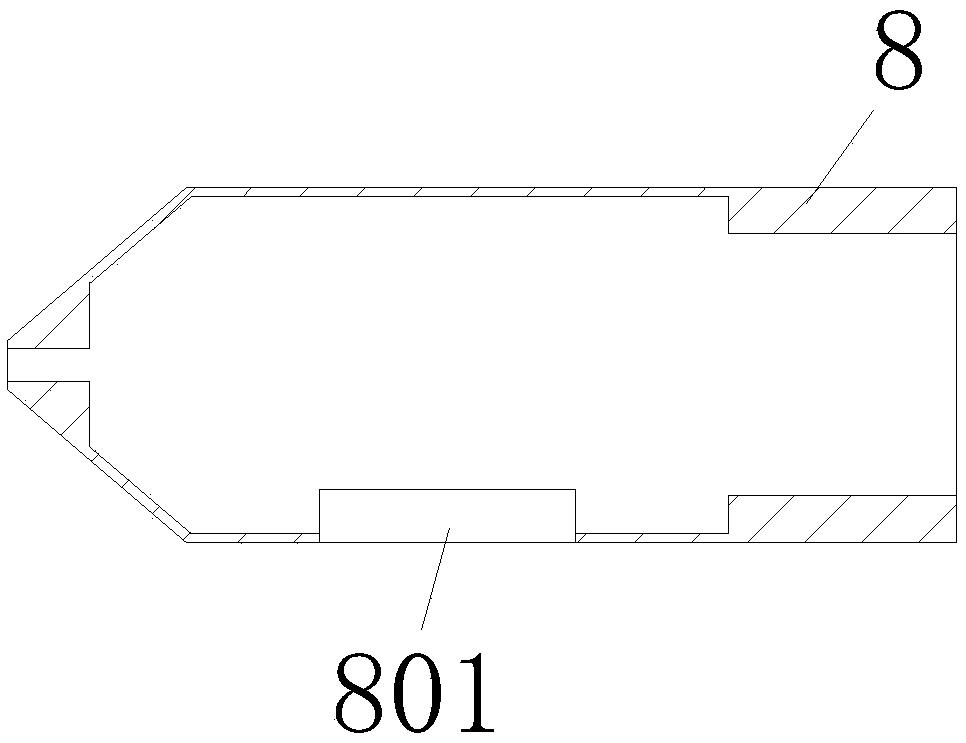

Metal casting mold

PendingCN109530619AReduce the temperatureReduced casting timeFoundry mouldsFoundry coresCold airInjection port

The invention belongs to the technical field of molds, in particular to a metal casting mold. The mold comprises a machine table, a block, a concave die seat, an opening, a heat dissipation tube, a guide column, a limiting piece, a convex die seat, a sliding mouth, a concave die, a convex die, an injection port, a cold air tube, a semiconductor refrigerating sheet and a fan. The semiconductor refrigerating sheet can reduce the temperature inside the cold air tube, cooperate with the fan to blow the cold air in the cold air tube into the heat dissipation tube, reduce the temperature of the convex die seat through the heat transfer effect between the heat dissipation tube and the punch die, thereby reducing the temperature inside an opening, and facilitate the accelerating of metal cooling in the process of casting a metal, thereby shortening the casting time; the concave die and the convex die are fixed by bolts at the bottom and top of the convex die seat and the concave die seat, whena forged metal appearance is changed according to demands, processing can be conducted by replacing the concave die and the convex die, and the mold has a simple structure, is convenient to use, andis suitable for popularization.

Owner:陈孝

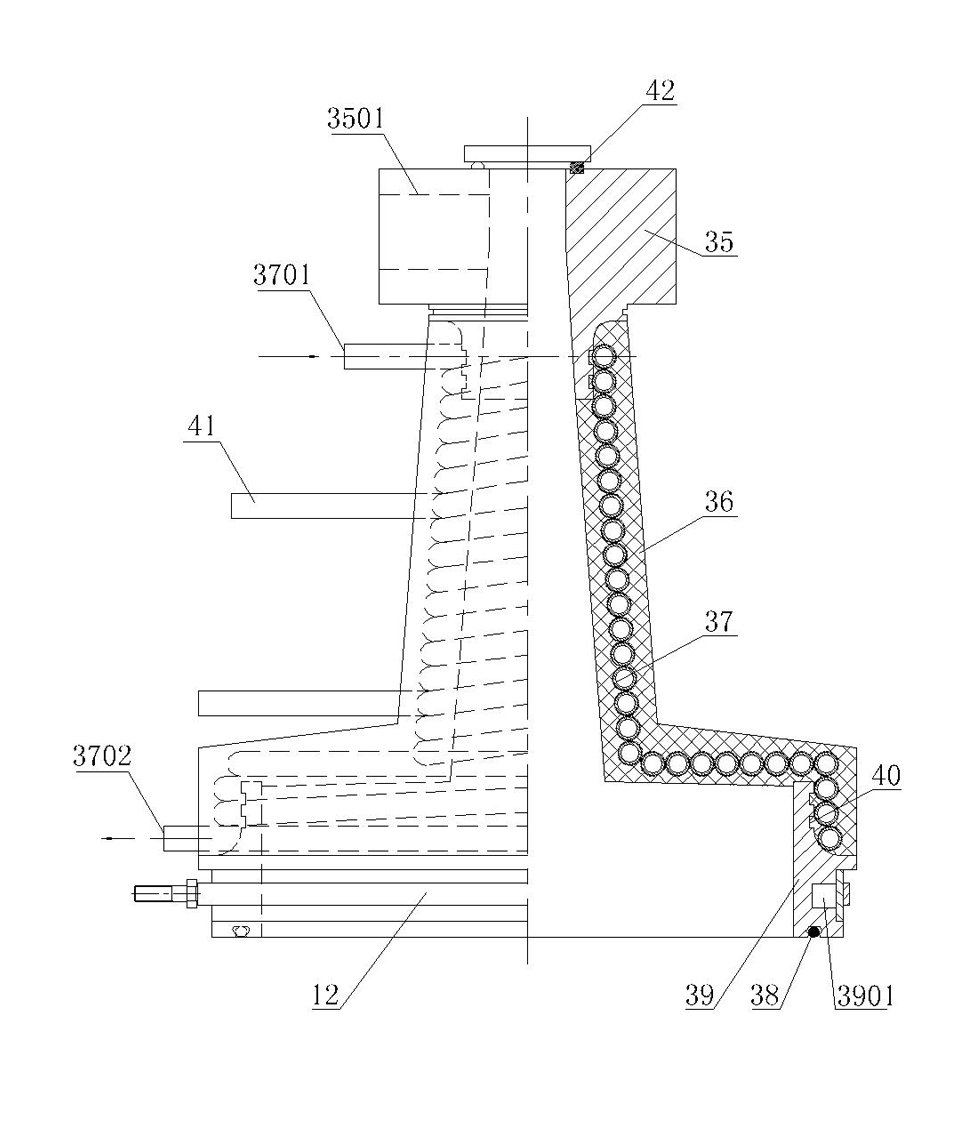

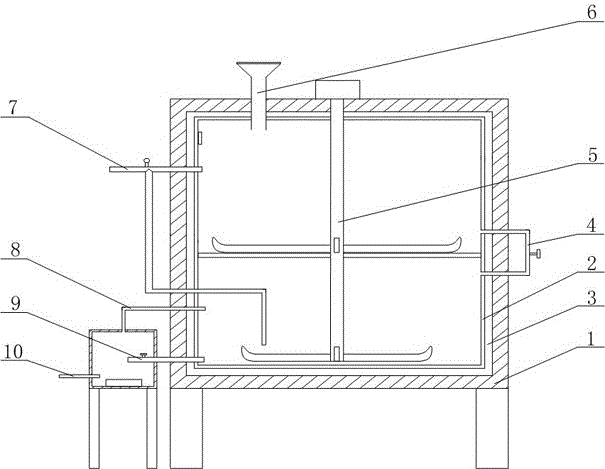

Rapid vacuum induction casting electric furnace

InactiveCN102042755AAvoid Vibration InterferenceReduce heat lossMaintainance of heating chambersCrucible furnacesElectric arc furnaceMedium frequency

The invention discloses a rapid vacuum induction casting electric furnace comprising a rack, wherein a vacuumizing system, a water cooling system and a medium frequency power supply are arranged on the rack. The electric furnace is characterized in that the rack is provided with a casting furnace, wherein the casting furnace is composed of an inspection microscope base, a base, an insulated furnace tube and an inductor copper pipe which is helically preinstalled in the insulated furnace tube; the inspection microscope base is hermetically connected with a vacuum pipeline of the vacuumizing system; the inspection microscope base is provided with an inspection microscope; the two ends of the inductor copper pipe are provided with a water inlet and a water outlet respectively and are respectively led out via the insulated furnace tube; the section, corresponding to the middle part of the casting furnace, of the inductor copper pipe is electrically connected with the medium frequency power supply; a reciprocating hoisting mechanism is arranged below the casting furnace on the rack; and the upper end of the reciprocating hoisting mechanism is provided with a tray. The electric furnace has the following advantages: smelting and casting can be carried out simultaneously, the yield of cast products is high and the product percent of pass can reach more than 85%, so the electric furnace is especially applicable to casting products with complex shapes; the casting time is short and the production efficiency is high; and the product density is high and the product quality is good.

Owner:JINZHOU GUXING TECH

Steel wire rope head casting method

InactiveCN103372641AConducive to breaking testEffective quality controlGearingCylindersCasting moldAlloy

The invention relates to a steel wire rope head casting method which is characterized in that tin-based bearing alloy is fused, zinc-based complex adhesion promoters are prepared to be used; rope heads at two ends of a steel wire rope are divided into completely divergent broom heads, and the broom heads are washed through steams, blown dry through high pressure wind and placed into the fused bearing alloy for preheating for 40-75s; after preheating, the zinc-based complex adhesion promoters are evenly coated on each steel wire of the broom heads; the broom heads coated with the adhesion promoters are placed into the fused bearing alloy again, evenly stirred and taken out, the broom heads coated with the alloy in advance are placed into a casting mold for casting of conical heads. The steel wire rope head casting method has the advantages of being simple in process, environmentally friendly and fast and convenient to operate, being capable of well ensuring the rope head casting quality and being favorable for overall pulling breaking measurement and detection of the steel wire rope.

Owner:宇宙钢丝绳有限公司

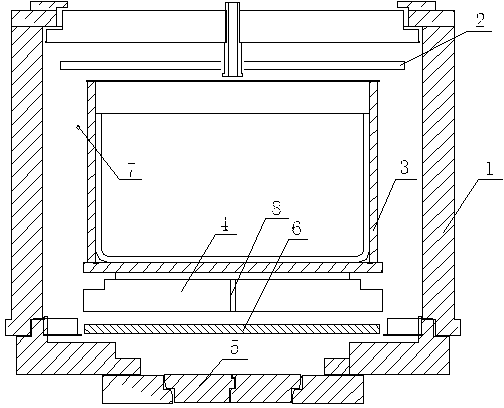

Novel casting method and mould

InactiveCN101367126AMaster the pouring situationLower pouring temperatureMechanical propertyMolten metal

The invention discloses a novel casting method and a casting mould thereof. The method comprises the following steps: the casting mould is immersed in molten metal(8) for casting, an upper pressure device and a lower pressure device are driven to be pressurized by utilizing the lifting force and the gravity of the casting mould, the molten metal is subjected to cavity fill, compensation shrinkage, solidification and crystallization in a mould cavity(12) at the needed pressure, and the casting mould is immersed in water for chilling, thereby improving the mechanical property of a cast. The mould is characterized in that an upper mould(4) is provided with the upper pressure device, a lower mould(10) is provided with the lower pressure device, an upper and a lower pressure plugs(1 and 9) pressurize the molten metal in the mould cavity(12) from the upper part and the lower part of the casting mould respectively, and an upper and a lower compensation shrinkage cavities(5 and 13) replenish the molten metal to the cast for eliminating shrinkage cavity and dispersed shrinkage phenomena. The novel casting method and the casting mould thereof can be used to cast various complicated thin wall aluminum alloy casts such as a cylinder cover of an engine and wheel hub of a vehicle and large-sized thin wall aluminum alloy casts such as a cabin body of a large-sized cruise missile, quickly cast a cast aluminum rotor of a motor with high quality and replace the prior casting method in large scale.

Owner:曾奇中

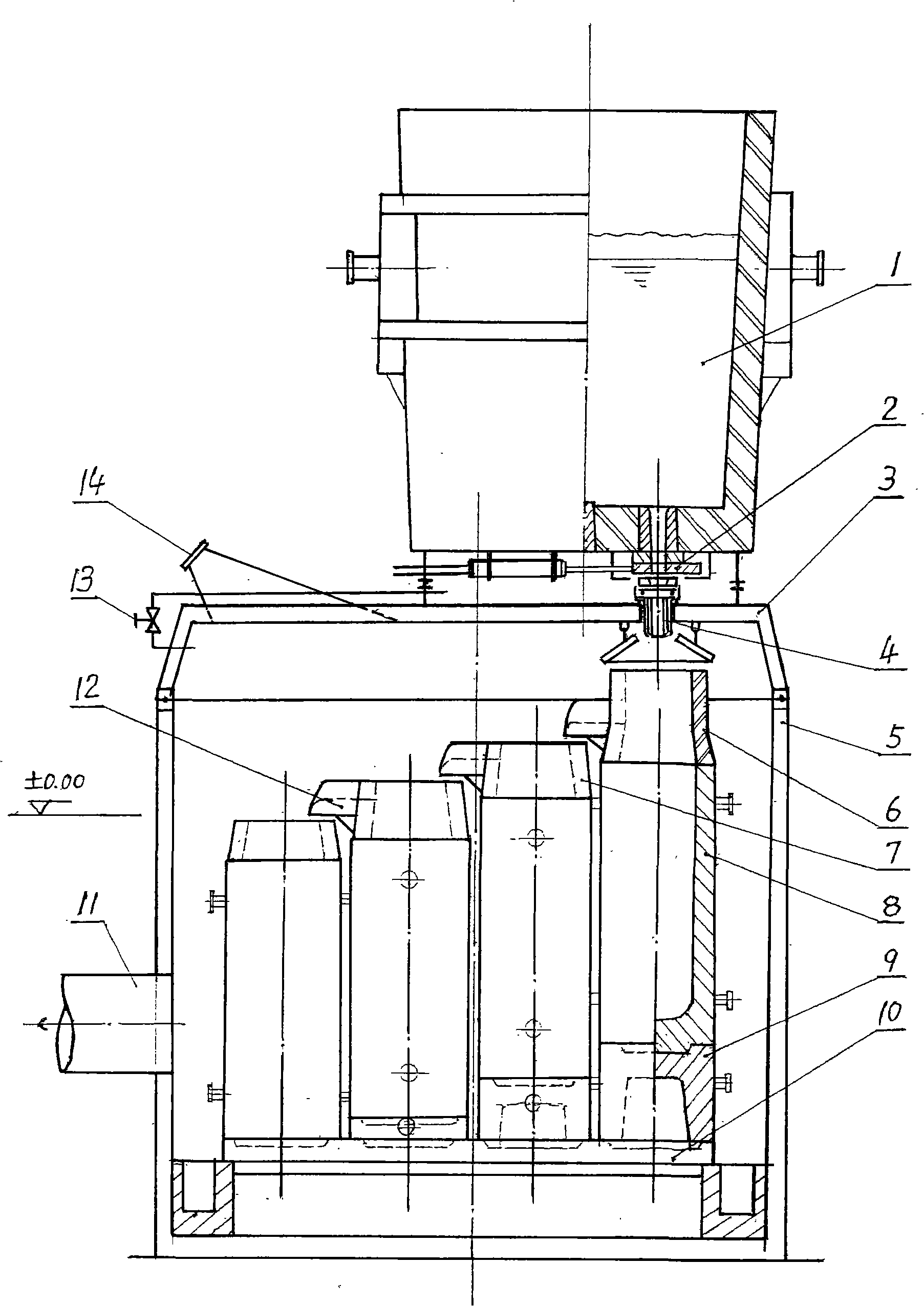

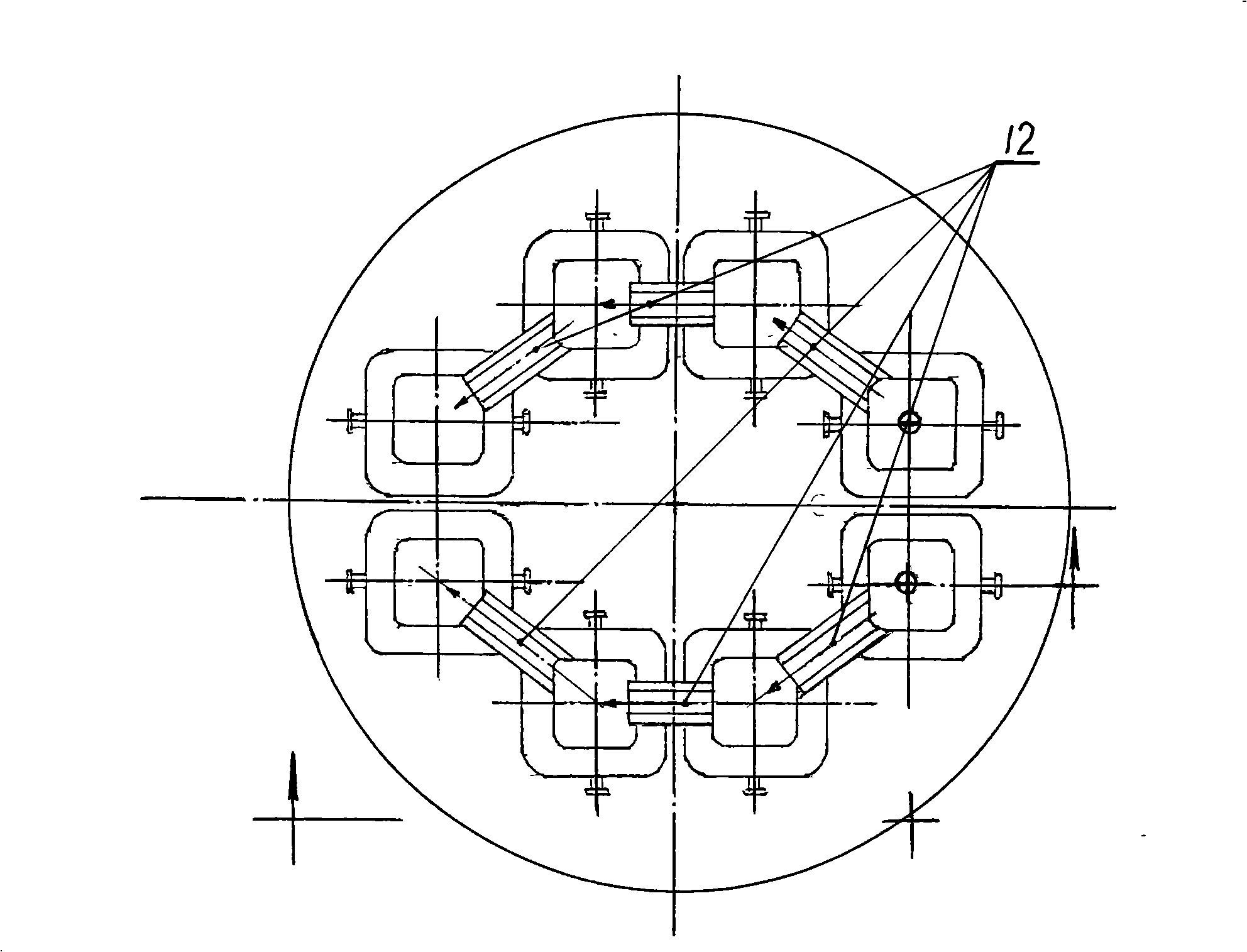

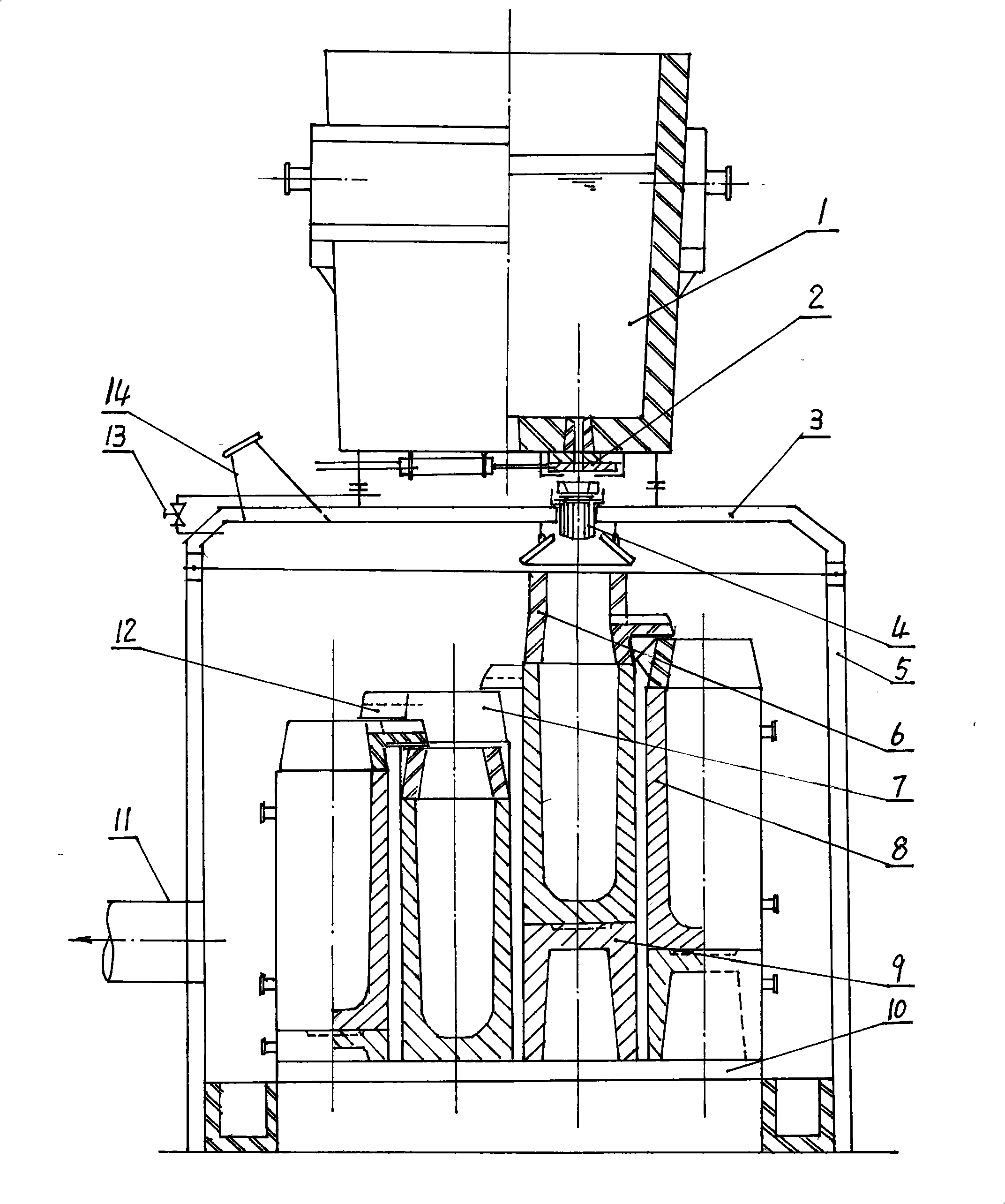

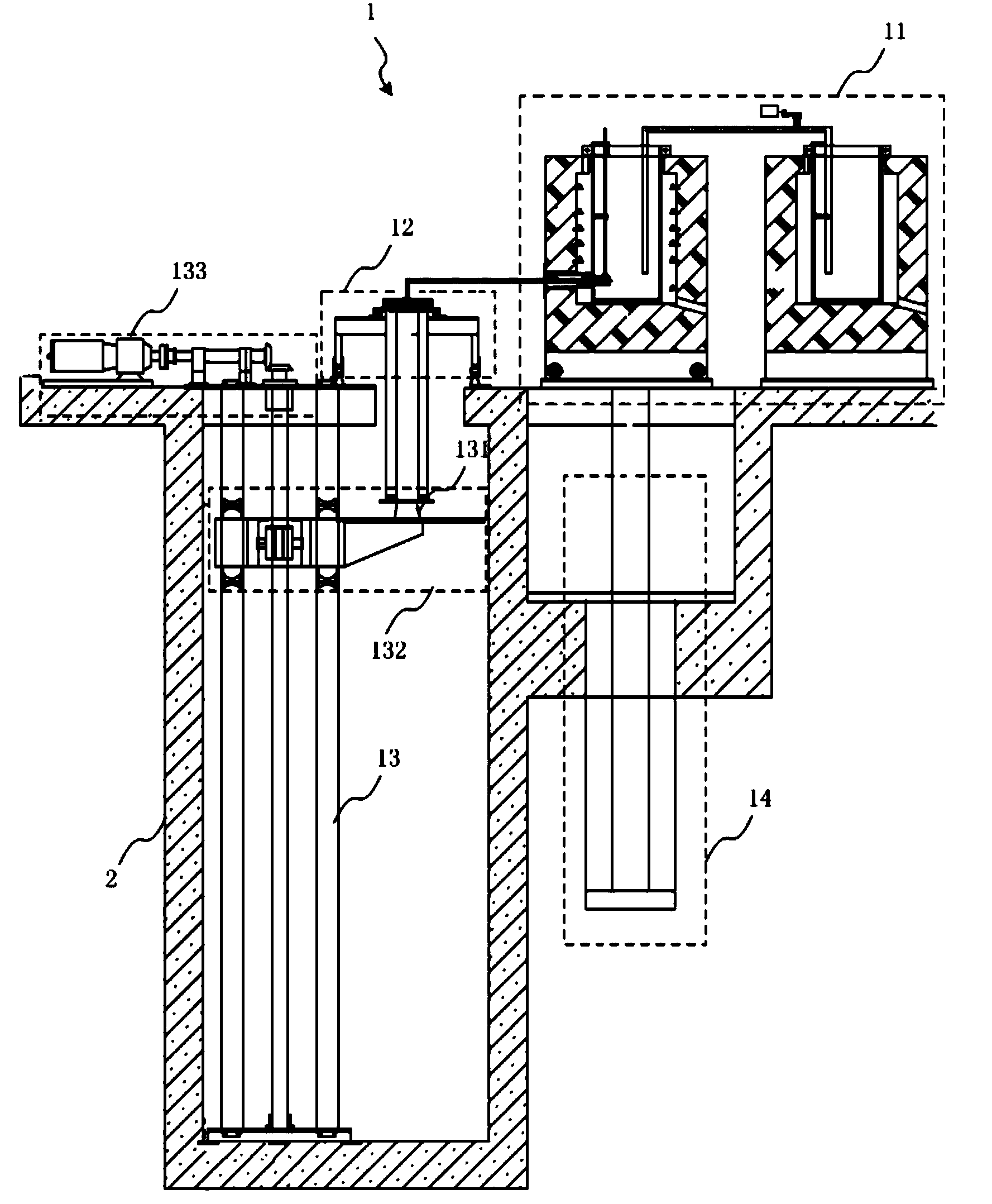

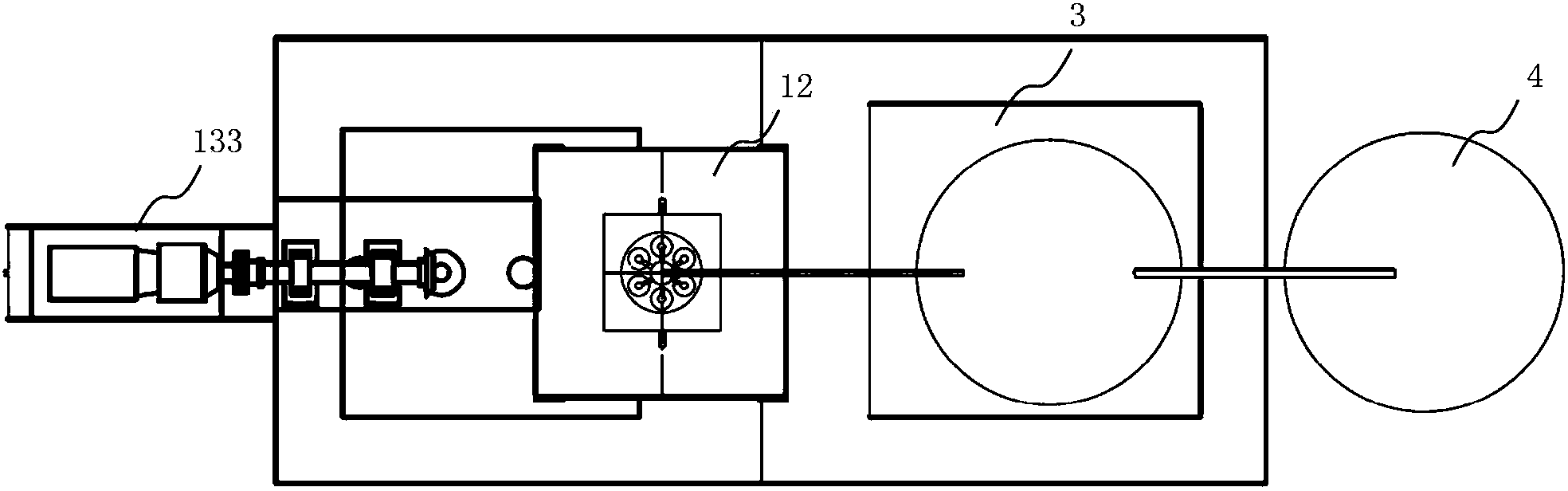

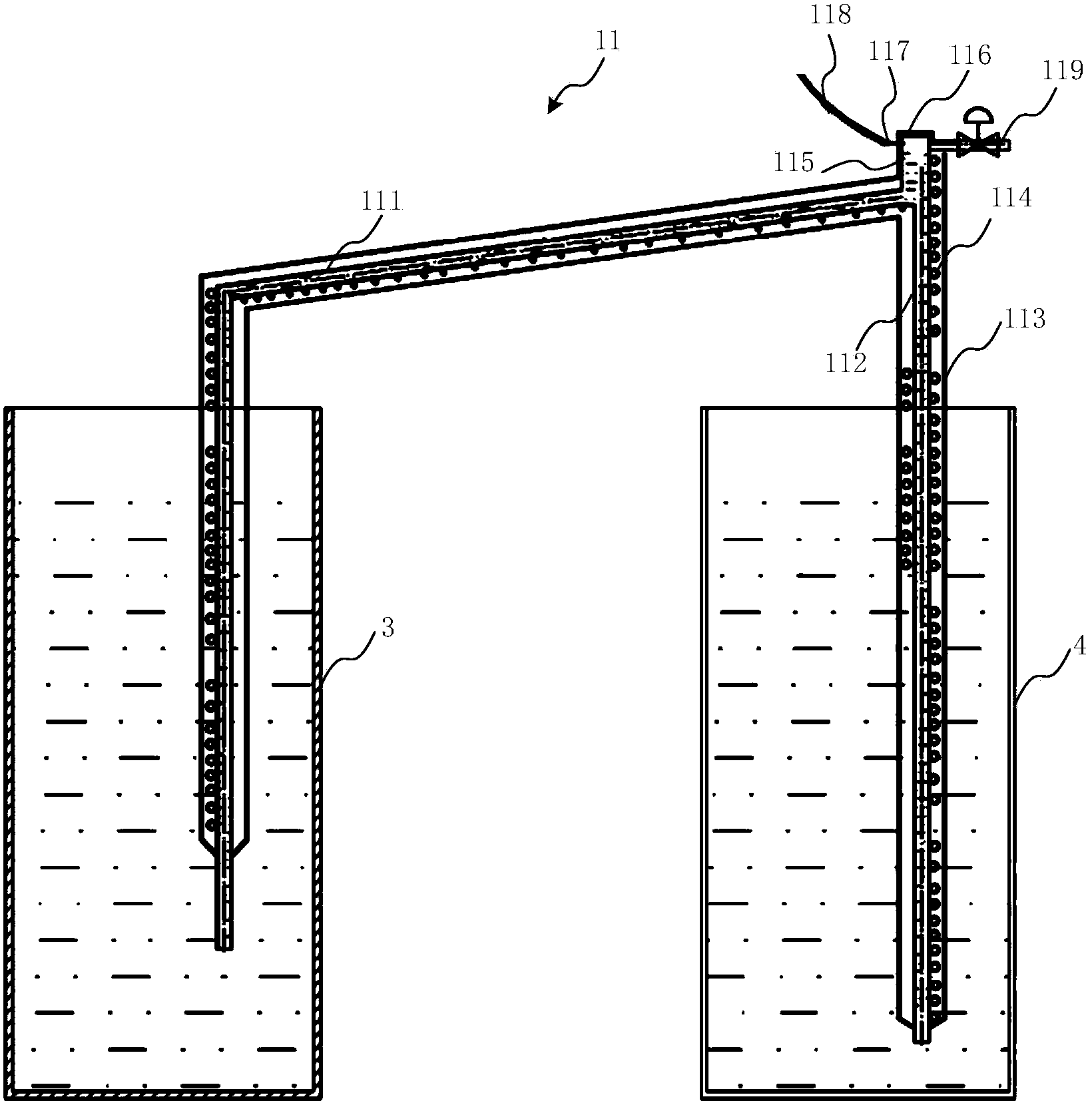

Vertical type direct water cooling semicontinuous multi-ingot casting system

ActiveCN104014752AIncrease productivityReduced casting timeIngot casting plantsElectricityIngot casting

The invention provides a vertical type direct water cooling semicontinuous multi-ingot casting system which comprises a casting well, a casting machine and a casting machine transmission device. The vertical type direct water cooling semicontinuous multi-ingot casting system further comprises a melt transferring device used for transferring melt for casting ingots to a casting furnace from a melting furnace through siphoning and a casting platform allowing the multiple ingots to be cast simultaneously. The melt transferring device comprises a liquid guide pipe, a gas extracting cavity, an electric vacuum source, electric heating wires and the like. The casting platform comprises a crystallizer provided with a plurality of ingot cavities, a flow dividing tray, a funnel flow channel, a borer plug, a heat preservation cap, a liquid level controller, a cooling water tank and the like. The casting machine pulls condensed ingots out of the crystallizer through a dummy ingot bracket. According to the vertical type direct water cooling semicontinuous multi-ingot casting system, due to the fact that the structure of the crystallizer provided with the ingot cavities and the matched flow dividing tray, the matched heat preservation cap and the like is adopted, the six to eight ingots can be cast simultaneously, the production efficiency of the ingots is effectively improved, the casting time of the ingots is shortened, corresponding manpower, electric power and material resources can be greatly saved, and thus production cost is lowered.

Owner:福建镁孚科技有限公司 +3

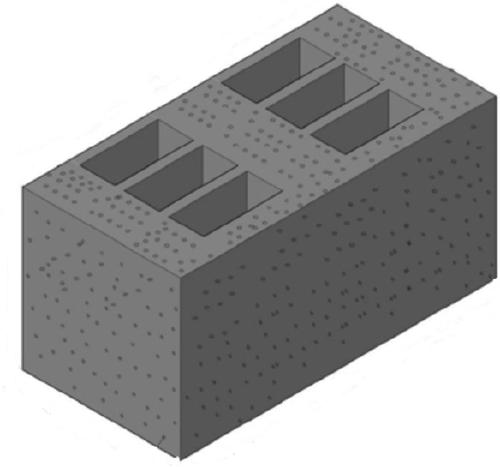

Paving bricks for glass kiln and production process thereof

ActiveCN109095902AGood high temperature resistance, corrosion resistanceImproved thermal shock stabilityGlass furnace apparatusGlass productionSodium carbonateTitanium dioxide

The invention provides paving bricks for a glass kiln and a production process thereof. The paving bricks are prepared from the following raw materials in parts by weight: 30-50 parts of natural zircon sand, 30-50 parts of aluminum oxide powder, 1-3 parts of sodium carbonate, 1-5 parts of fluorite powder, 2-8 parts of silica powder and 8-16 parts of titanium dioxide. By controlling the proportionof the components reasonably and selecting an insulating material reasonably, the prepared paving bricks have excellent performance. In the embodiment process, the sand form of the prepared sand is improved. 15 paving bricks can be produced at one time in one insulating oven after the sand form is improved. The paving bricks are good in quality and high in percent of pass. In the production process, the paving bricks need not to be melted frequently, so that scattering of a feed liquid is reduced, the casting time is shortened and the production efficiency is improved.

Owner:江苏徐耐新材料科技股份有限公司

Recovery system of aluminum alloy door and window waste

InactiveCN107782131AAvoid quality lossAvoid contactCharge composition/stateCrucible furnacesWater vaporFeeding tube

The invention discloses a recycling system for aluminum alloy door and window waste, which comprises a furnace shell, a furnace inner shell is arranged inside the furnace shell, the inner space of the furnace inner shell forms a melting chamber, and a feeding pipe is arranged above the furnace shell, and the feeding pipe It runs through the furnace shell and communicates with the melting chamber. A discharge pipe is arranged inside the furnace inner shell, and a casting box is also included. The discharge pipe communicates with the melting chamber and the casting box. An exhaust pipe and a gas delivery pipe are arranged outside the casting box. The exhaust pipe communicates with the casting box and the outer space, the gas delivery pipe communicates with the casting box and the melting chamber, an air inlet pipe is arranged on the furnace shell, and the air inlet pipe communicates with the outer space and the melting chamber, and an electric heating layer is arranged between the furnace outer shell and the furnace inner shell. The invention prevents castings from being in contact with air during melting and casting by setting protective gas and casting boxes, and solves the problem of low casting quality caused by castings being oxidized and in contact with water vapor.

Owner:张宗发

High-frequency welded tube cast ingot and manufacturing method thereof

The invention provides a high-frequency welded tube cast ingot and a manufacturing method thereof. The high-frequency welded tube cast ingot and the manufacturing method aim at solving the problems that aluminum alloy tubes manufactured through an existing method and subjected to seaming brazing or seamless tubes are poor in corrosion resistance and short in service life. The high-frequency welded tube cast ingot is prepared from Si, Fe, Cu, Mn, Ti and the balance Al. The method includes the first step of weighing, the second step of alloy melt preparation and the third step of semi-continuous casting. The high-frequency welded tube cast ingot and the manufacturing method are used.

Owner:NORTHEAST LIGHT ALLOY CO LTD

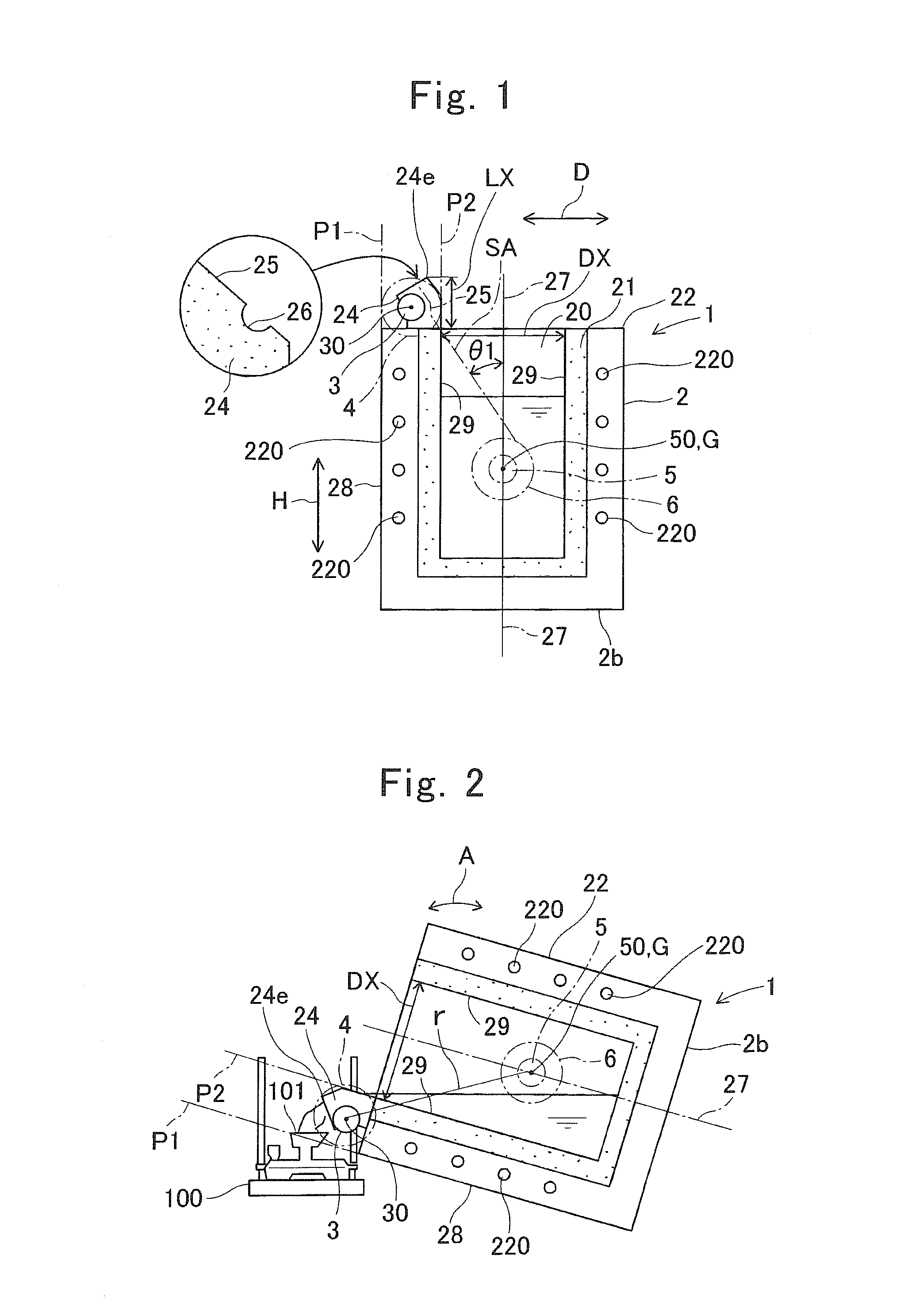

Method, casting mold and device for producing a vehicle wheel

PendingCN111344089AAvoid separationAvoid uneven heatingFoundry mouldsFoundry coresAutomotive engineeringManufacturing engineering

The invention relates to a method for producing a vehicle wheel (2) from a light metal material, in which the light metal material is introduced in liquid form into a mold cavity (14) of a casting mold (3). The vehicle wheel (2) is produced by means of pressurized casting, wherein the casting mold (3) is temperature-controlled in different regions to different temperatures.

Owner:恩泰科斯特拉康有限责任公司 +2

Cast-steel pouring apparatus

InactiveUS20140015174A1Reduce volatilityEfficient dischargeMelt-holding vesselsCasting moldMolten steel

A cast-steel pouring apparatus is provided, cast-steel pouring apparatus which can contribute to shortening a casting time for casting molten steel of cast steel into a sprue of casting mold. A first axial line of a first pivot shaft is positioned on a more diametrically inner side than is a first imaginary extension line of an outer-circumference wall face in a furnace-body main body, and is positioned on a more diametrically outer side than is a second imaginary extension line of an inner-circumference wall face in a fire-retardant lining material that the furnace-body main body has. As a steel-outing trough unit protrudes from a furnace body upward or upward and outward obliquely, a steel-outing leading end of the steel-outing trough unit is positioned on a more diametrically inner side than is the first imaginary extension line of the outer-circumference wall face in the furnace-body main body, and is positioned on a more diametrically outer side than is the second imaginary extension line of the inner-circumference wall race in the fire-retardant lining material that the furnace-body main body has.

Owner:AISIN TAKAOKA CO LTD +2

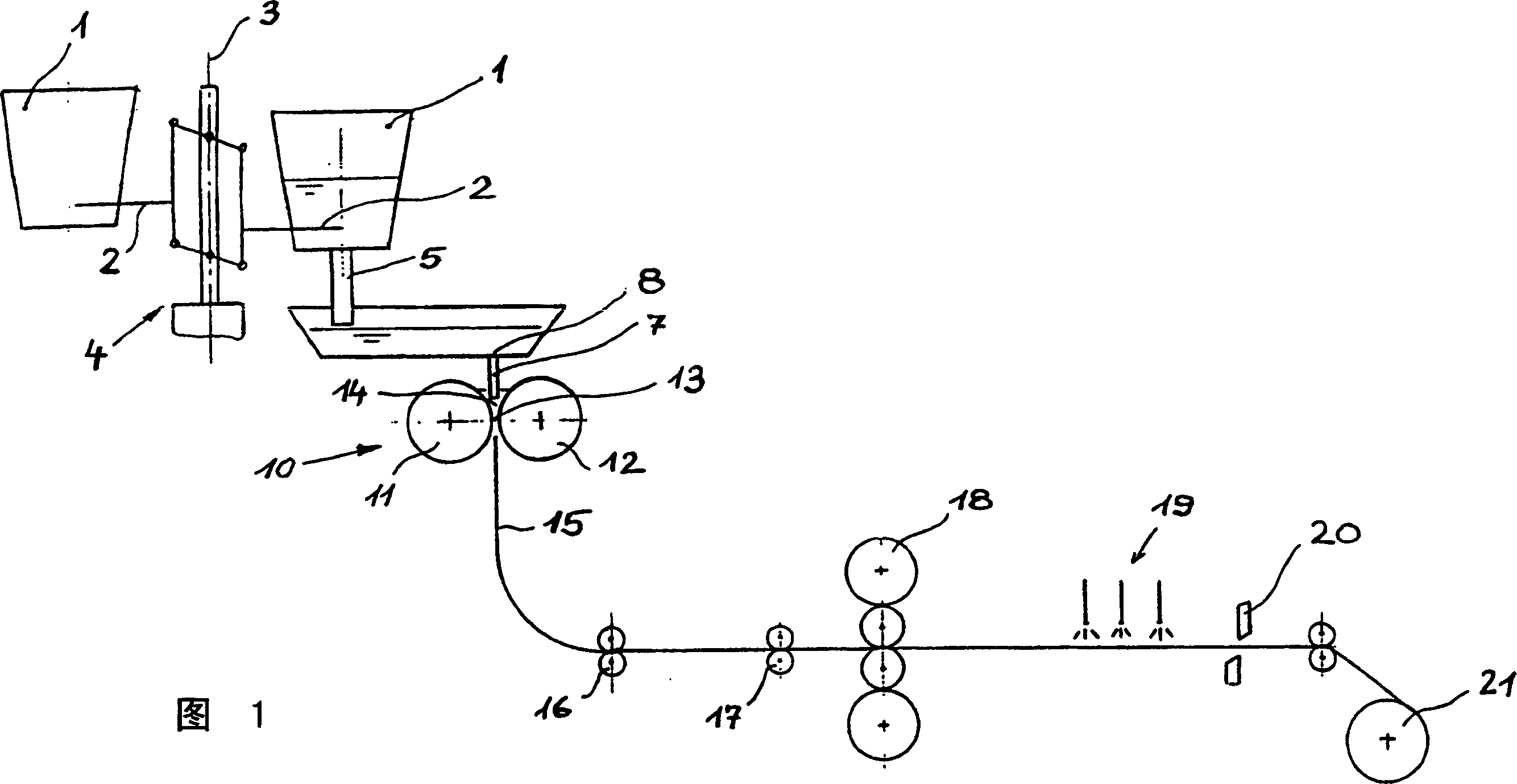

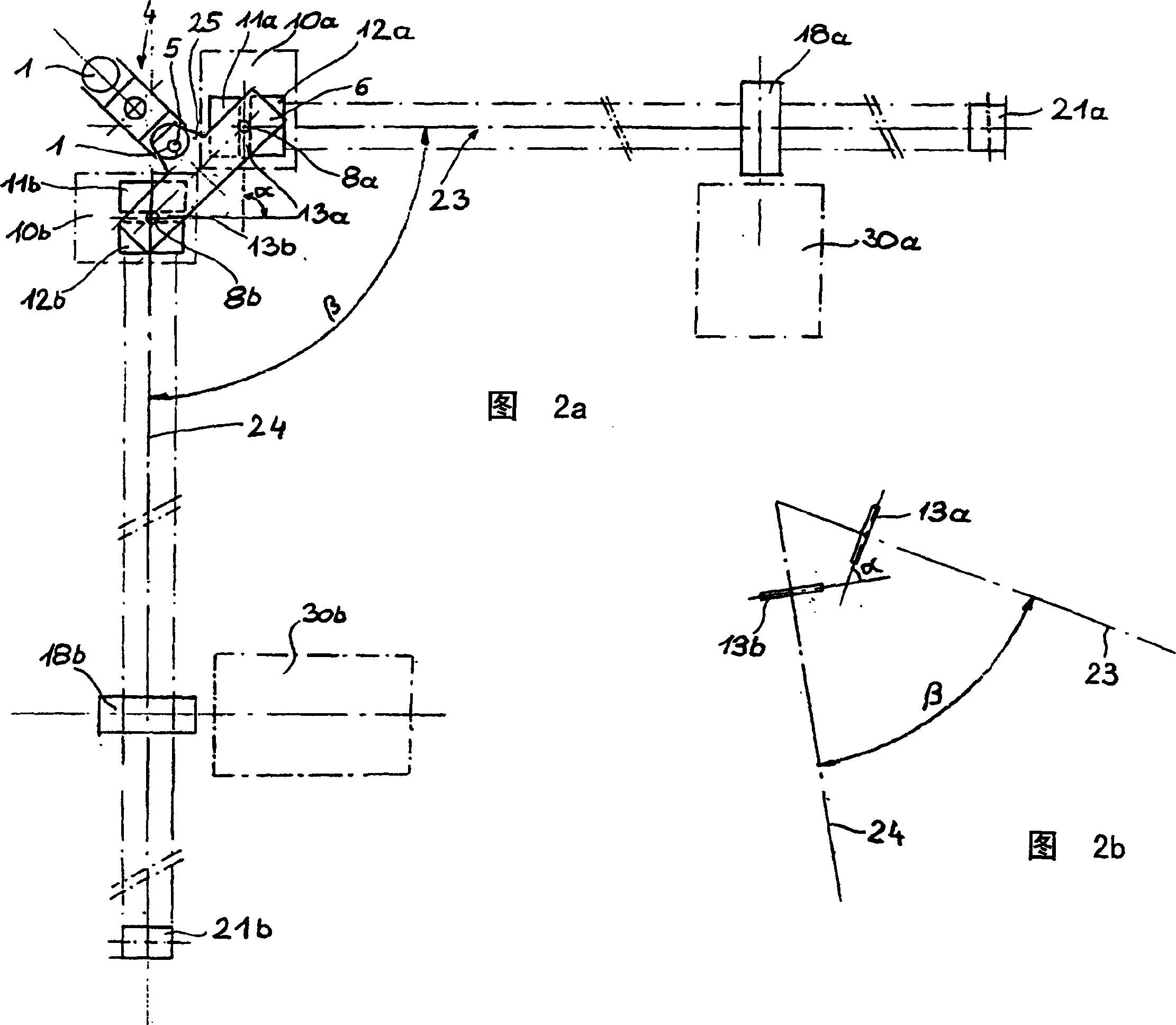

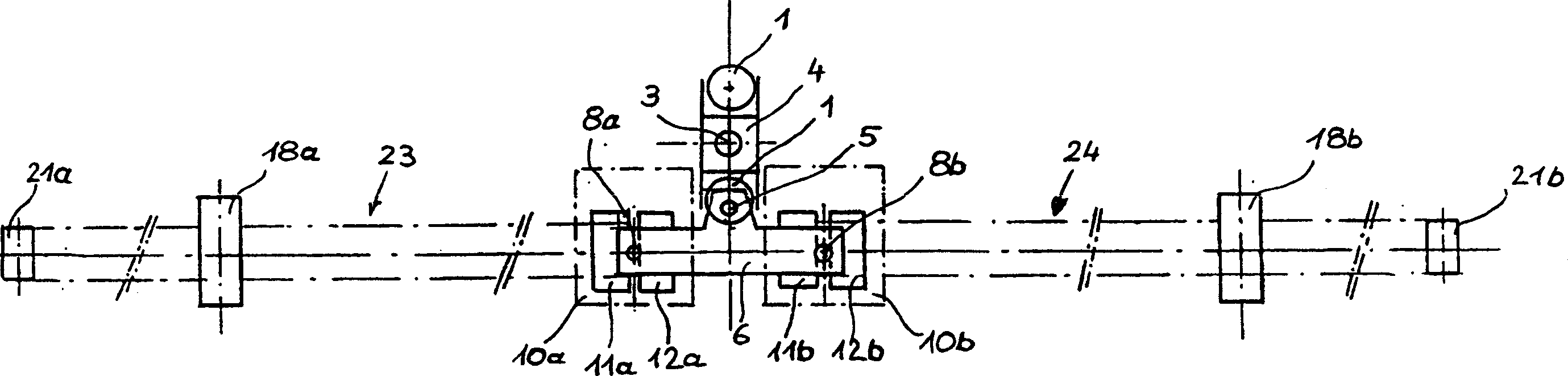

Installation for producing a hot-rolled strip

InactiveCN1501847AReduced casting timeGuaranteed melt conditionsMetal rolling arrangementsTundishCapacity limit

The invention relates to a plant for producing a hot strip from a metal melt in accordance with the twin-roll casting process. To increase the melt throughput in the tundish to above the capacity limit of a one-stranded casting plant operating according to the twin-roll casting process and at the same time to reduce the batch casting times significantly with minimal investment and operating costs, the invention proposes a plant configuration in which a casting ladle (1) with a melt outlet (5) is assigned a tundish (6) for receiving the metal melt from the casting ladle (1), in that this single tundish (6) is equipped with at least two bottom outlets (8a, 8b) for transferring the metal melt to two twin-roll casting devices (10a, 10b), in that each casting nip (13a, 13b) is assigned at least one of the bottom outlets (8a, 8b) of the tundish (6), and the two casting nips (13a, 13b) are arranged at an angle of 15 DEG to 180 DEG , or parallel and offset with respect to one another in terms of their longitudinal extents.

Owner:SIEMENS VAI METALS TECH GMBH

Melting furnace capable of isolating air in casting stage

InactiveCN107774935AAvoid quality lossAvoid contactStirring devicesCharge composition/stateWater vaporExhaust pipe

The invention discloses a melting furnace capable of isolating air during the casting stage, comprising a furnace shell, a furnace inner shell is arranged inside the furnace shell, the inner space of the furnace inner shell forms a melting chamber, and a feeding pipe is arranged above the furnace shell. The feeding pipe runs through the furnace shell and communicates with the melting chamber. A discharge pipe is arranged inside the furnace inner shell, and a casting box is also included. The discharge pipe communicates with the melting chamber and the casting box. The air pipe, wherein the exhaust pipe is connected with the casting box and the external space, the gas delivery pipe is connected with the casting box and the melting chamber, an air inlet pipe is arranged on the furnace shell, and the air inlet pipe is connected with the external space and the melting chamber, and a Electric heating layer. The invention prevents castings from being in contact with air during melting and casting by setting protective gas and casting boxes, and solves the problem of low casting quality caused by castings being oxidized and in contact with water vapor.

Owner:张宗发

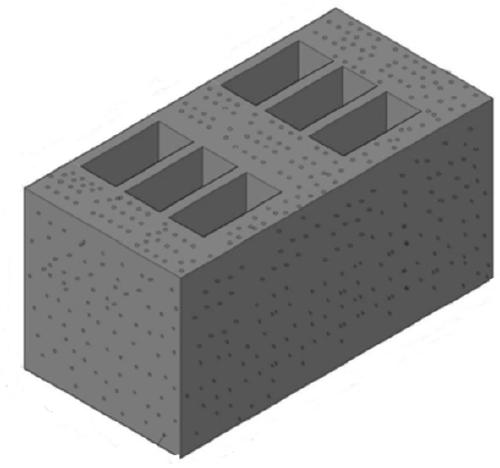

Sand mold casting mold for cylinder wallboard bracket of cotton carding machine and process method thereof

InactiveCN107584072AHigh precisionEasy to moldFoundry mouldsFoundry coresCasting moldMaterials science

The invention discloses a sand mold casting mold for a cylinder wallboard bracket of a cotton carding machine and a process method thereof. The sand mold casting die comprises an upper mold, a lower mold and a core box mold; the upper mold, the lower mold and a mold frame are integrally formed through CNC processing; a sand mold is poured into a large textile machine plate by a melt two-channel column-shaped pouring gate, a two-channel arc-shaped feeding flow channel and a multi-channel annular inner pouring channel; a 3D simulated pouring aided design is adopted, a plurality of cold irons arearranged in the sand mold, an arc-shaped surface is arranged on an upper mold cavity and is used for blending the shrinkage ratio of the large textile machine plate; four column-shaped risers are formed in the upper mold and are used for regulating and controlling the internal rib tightness of the large textile machine plate; the lower mold is provided with bilaterally-symmetrical mold cavities with fan-shaped holes, and the mold cavities are provided with upper, lateral and lower mold cavities in an integrated winding manner; through 3D simulated pouring, the product flatness reaches 1 mm; feeding heads are arranged to solve the internal rib looseness; the two-channel pouring gate and the multi-channel annular inner pouring channel are adopted for pouring, so that the uneven flow rate phenomenon caused by wall thickness unevenness is solved.

Owner:昆山久帜金属有限公司

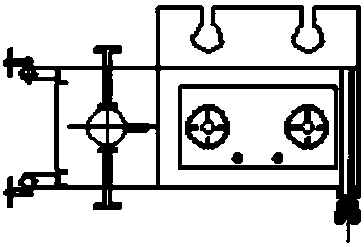

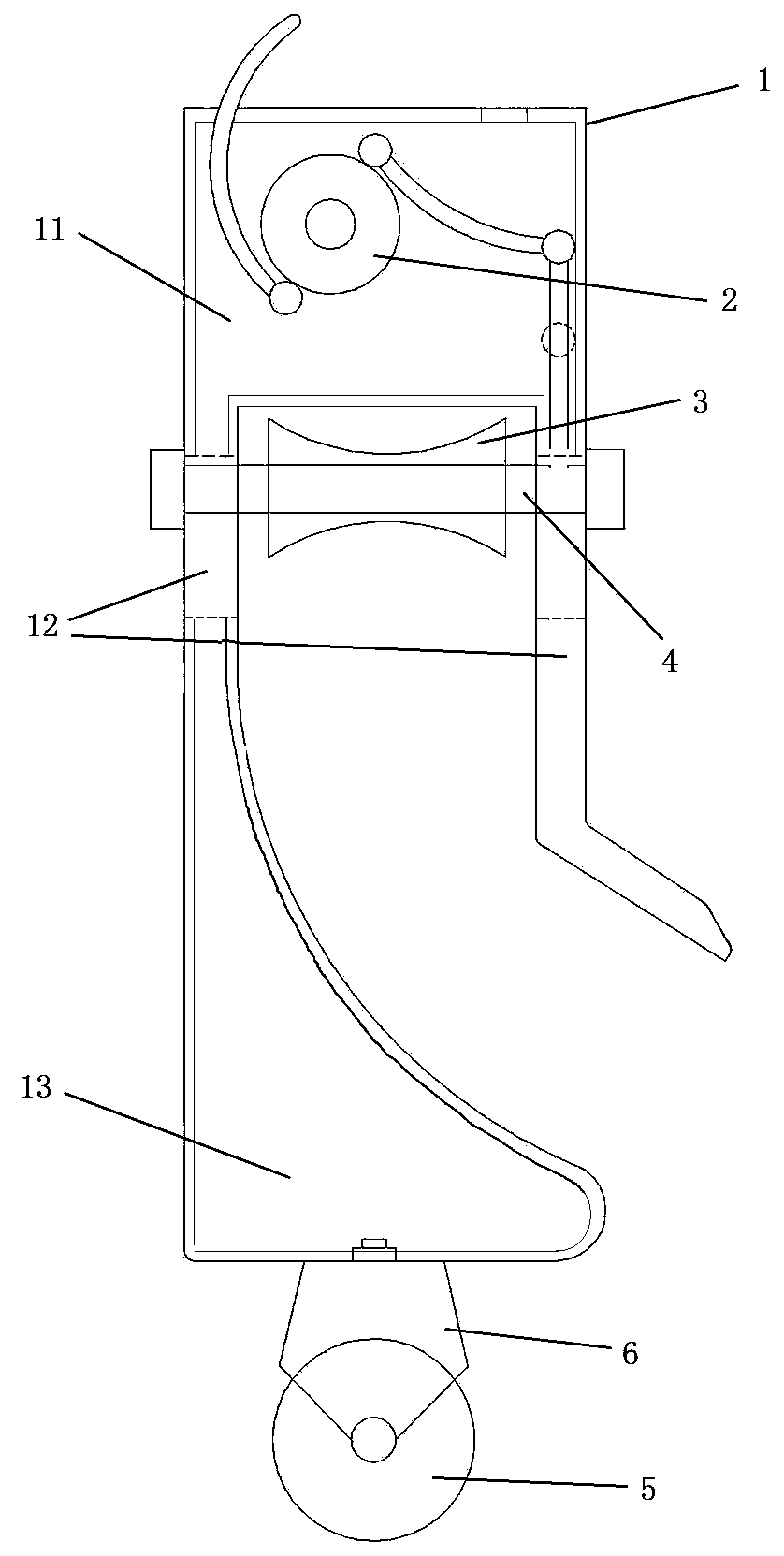

Casting device for agricultural machinery accessories

ActiveCN109530665BReduced casting timeEasy to take out laterMould handling equipmentsMolten metal conveying equipmentsAgricultural sciencePlate pressure

The invention discloses an agricultural machinery part casting device. The agricultural machinery part casting device comprises a casting rotating table, a plurality of flat plate part mold clamping grooves are formed in the top surface of the casting rotating table, the bottoms of the flat plate part mold clamping grooves are provided with a plurality of special-shaped mold clamping grooves, thebottoms of the special-shaped mold clamping grooves are provided with a jacking device used for upwards jacking molds, the bottom rod wall of a discharging guide pipe at the bottom of a melt leakage furnace is fixedly provided with a pressure plate used for pressing and covering the flat plate part mold clamping grooves, the bottom surface of the pressure plate is provided with an injection port which communicates with the discharging guide pipe and is connected with the molds, and the melt leakage furnace is overall supported on a base through a lifting mechanism. According to the agricultural machinery part casting device, casting positioning and automatic jacking can be rapidly performed through the flat plate part mold clamping grooves and the special-shaped mold clamping grooves whichare arranged on the casting rotating table, so that later-stage taking-out of the molds is greatly facilitated, the height adjustment of the injection port can be facilitated, the applicability is better, the casting time of casting of multiple parts is shortened, the casting efficiency is improved, and the casting speed is increased.

Owner:湖南省金峰机械科技有限公司

Casting method of thermal insulation pipeline

InactiveCN107030251AIncrease temperatureReduced casting timeFoundry mouldsFoundry coresHigh volume manufacturingThermal insulation

The invention provides a casting method of a thermal insulation pipeline. The casting method comprises the following steps: 1, taking and fully mixing silicon powder, attapulgite and crosslinking polyvingypyrrolidone (PVPP) uniformly to obtain a granular material, performing low temperature drying on the granular material to obtain a mixture I; 2, taking aggregate, a heating material, a thermal insulation material and a binder, mixing for 10-25 min to obtain a slurry; 3, filling a pipeline die with the mixture I and the slurry by using a core shooter for forming, and demolding, wherein the pipeline wall thickness is 6-10 mm; 4, placing the pipeline material after forming and demolding into a continuous drying kiln, drying for 30-40 min at the rate of 1-2 cm / s and at the temperature of 320-450 DEG C, solidifying, drying, and clearing the corners of the pipeline, so as to obtain the finished product. According to the casting method of the thermal insulation pipeline, the pipeline casting time is shortened, the pipeline casting temperature is reduced, and the overall thermal insulation effect of the pipeline is obviously improved; besides, the process is simple, complex and dangerous operation steps are avoided, the material cost is low, the production efficiency is high, and the industrial mass production is facilitated.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

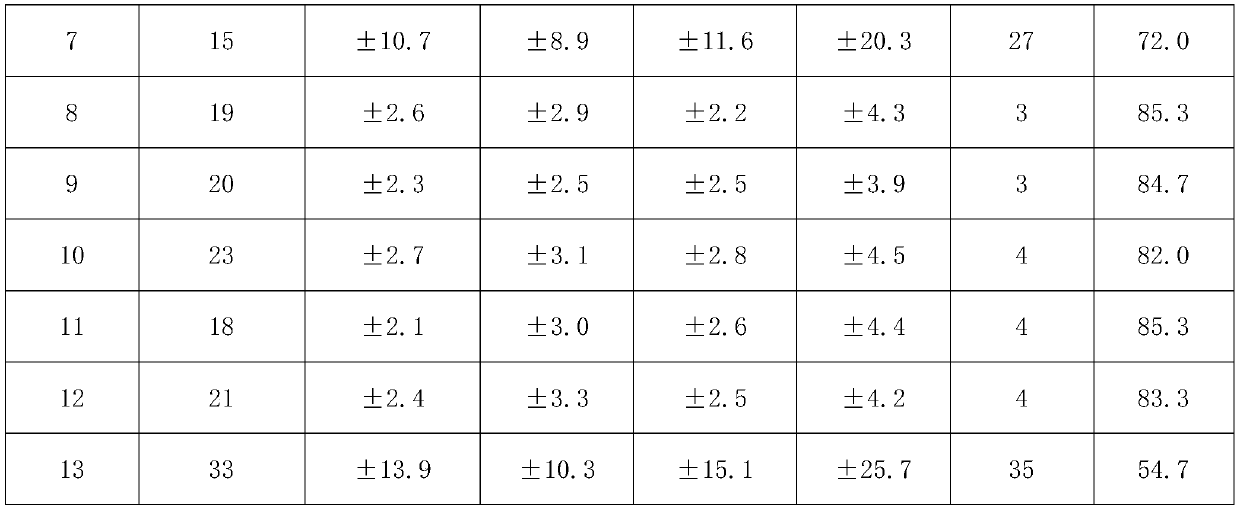

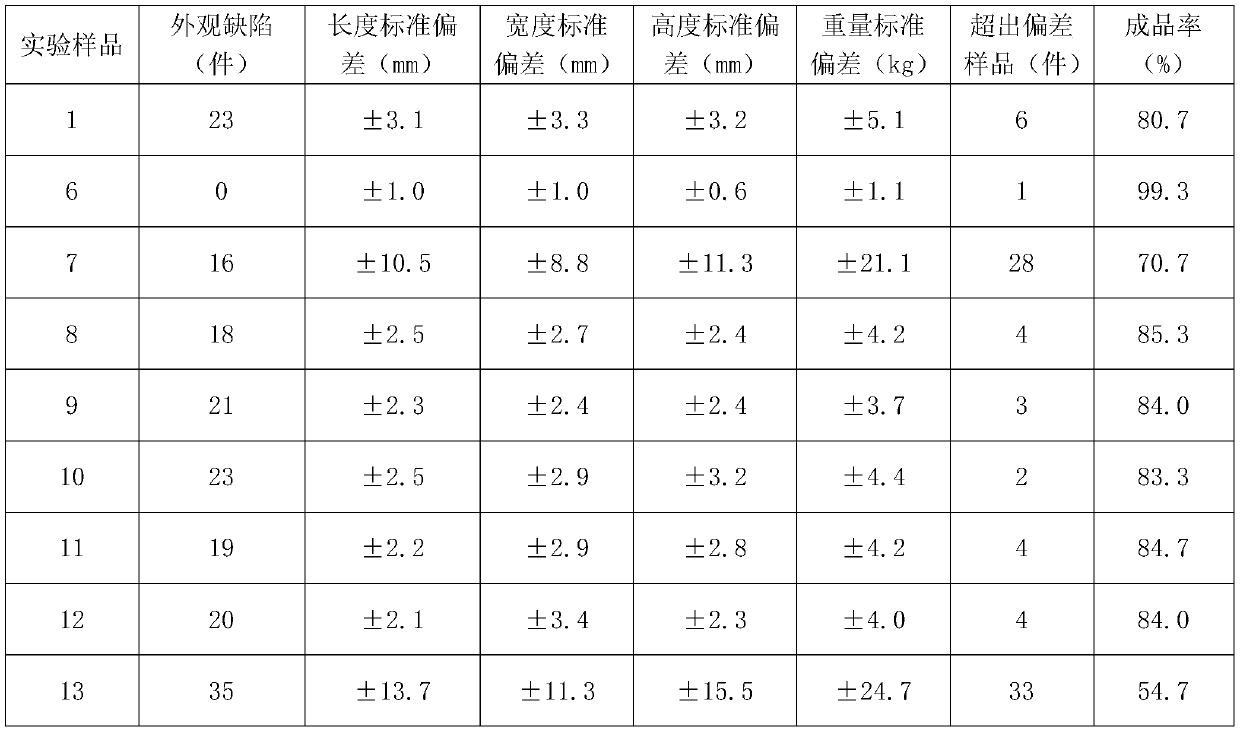

V-process casting process for producing engineering mechanical counterweight block

ActiveCN110625063AImprove wear resistanceImprove adhesionFoundry mouldsFoundry coresPolystyreneEngineering production

The invention provides a V-process casting process for producing an engineering mechanical counterweight block, and particularly relates to the technical field of counterweight block casting. The V-process casting process for producing the engineering mechanical counterweight block simplifies a thin film covering method in the process, polystyrene, calcium fluoride, calcined gypsum powder, artemisinin wax, trehalose and zinc oxide whiskers are added to a coating, the wear resistance and adhesive force of the coating are enhanced, meanwhile, filled dry sands are pretreated, carbon aerogel, soybean protein and cyclic olefin copolymer are added, the air permeability of the dry sands is enhanced, the compactness is increased, the non-fleshiness, non-air-holes, non-sand burning and unfilled corner counterweight block with a bright and clean surface is finally obtained, the weight deviation of the counterweight block is kept within the range of + / -6 kg, the dimensional deviation is kept within + / -4 mm, and the product yield is up to 80% or above. The V-process casting process is simple to operate, controllable in parameter and easy to realize, and is suitable for large-scale production.

Owner:柳州市顺昇机械有限公司

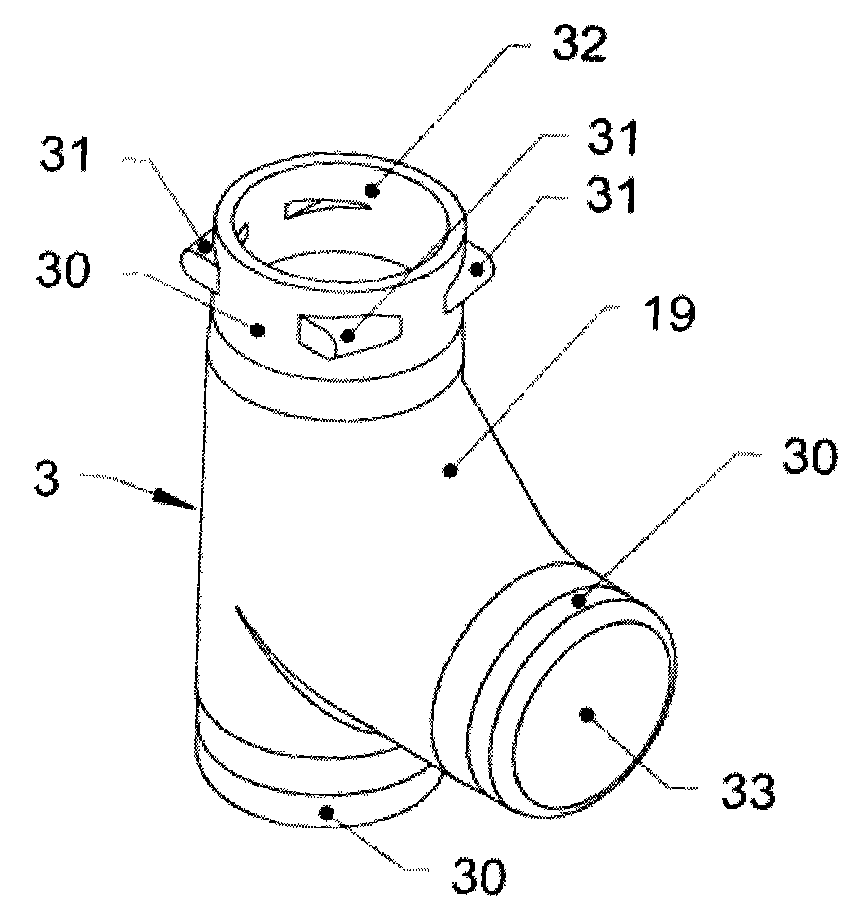

Multifunctional steel wire rope lock pouring platform and pouring method thereof

The invention relates to a multifunctional steel wire rope lock pouring platform and a pouring method thereof, and belongs to the technical field of steel wire rope lock pouring equipment. According to the technical scheme, the multifunctional steel wire rope lock pouring platform is characterized in that a worktable is arranged above a box body (1), wherein a head pulling device (2), a crucible (3), a pouring cooling device (4), a lock guide device (5) and a gas stove (21) are arranged on the worktable; a handwheel (9) is arranged at one end of a locking bolt (10) in the head pulling device (2); the locking bolt (10) is pulled to a head pulling tube (11); a lock hole (7) and a gap (19) which communicates with the lock hole (7) are formed in a lock tray (13) in the pouring cooling device (4); a hand-chain hoist lug (17) and two steel wire rope clamping buckles (18) are arranged on a lock fixing support (16) in the lock guide device (5). The multifunctional steel wire rope lock pouringplatform has the beneficial effects that the worktable integrating the functions of pulling the head of a steel wire rope, guiding the lock and casting cooling is provided, thus the pouring time is decreased, and the production efficiency is improved.

Owner:PORT OF CAOFEIDIAN ORE TERMINAL CO LTD

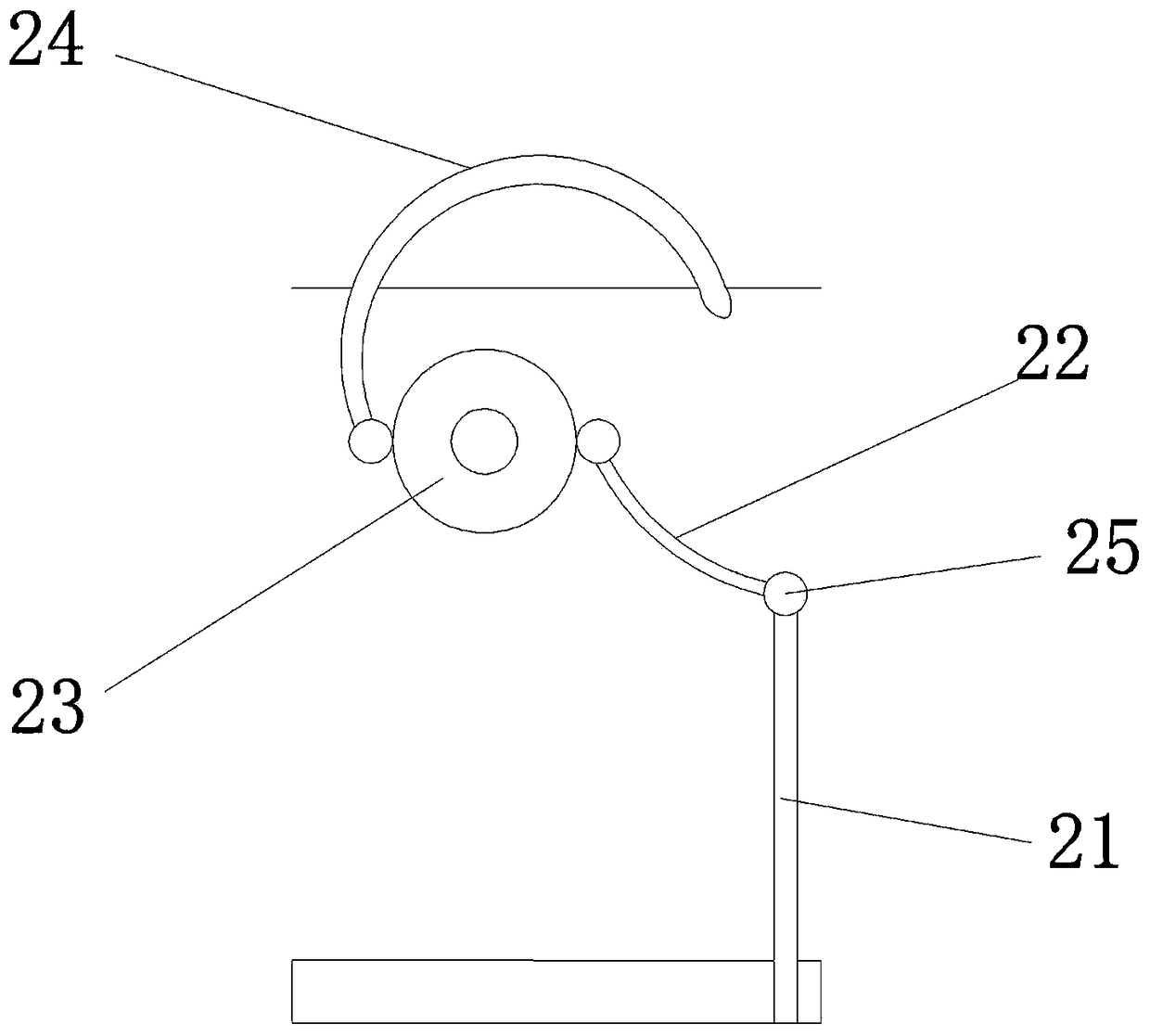

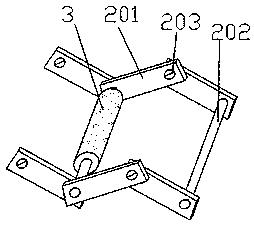

Intelligent mechanical type live working traction rope safety throwing device

PendingCN109378764AStreamline routine workflowsReduced casting timeApparatus for overhead lines/cablesSteel platesHigh voltage transmission lines

The invention discloses an intelligent mechanical type live working traction rope safety throwing device. The throwing device is suspended by an unmanned aerial vehicle. When a pulley is placed on a high-voltage transmission line, intelligent mechanical tripping is carried out by weight of the pulley and an insulation rope, which simplifies a conventional work flow. The throwing device consists ofa support frame, a transmission device, the upper pulley and a lower pulley. The support frame consists of an overall structure welded by steel plates an includes an upper section frame, a middle section frame and a lower section frame. The upper section frame is of a rectangular groove structure. The transmission device is fixedly connected to the inside of the rectangular groove structure. Themiddle section frame includes two side plates with sliding grooves. The upper pulley is connected to the sliding grooves through a pulley shaft. The lower section frame is a triangle groove. The lowerpulley is fixedly connected to the lower end face of the triangle groove through a pulley frame. The intelligent mechanical type live working traction rope safety throwing device has the advantages of short throwing time and high efficiency, and the transmission device system is stable and reliable.

Owner:ZHUMADIAN POWER SUPPLY ELECTRIC POWER OFHENAN +1

Antitheft-door stamping-forming leftover regeneration device

InactiveCN105861840AAvoid contactReduced casting timeProcess efficiency improvementElectricityMetallurgy

The invention discloses an antitheft-door stamping-forming leftover regeneration device. The antitheft-door stamping-forming leftover regeneration device comprises an outer furnace shell, an inner furnace shell, an electric heating layer and a feeding opening. A baffle is arranged inside the inner furnace shell, and the inside space of the inner furnace shell is divided by the baffle into a melting chamber and a standing chamber; the antitheft-door stamping-forming leftover regeneration device further comprises a casting box, and a gas discharging pipe is connected to the outer side of the casting box, and is communicated with outside space and the inside of the casting box; a connecting pipe, a discharging pipe, a gas feeding pipe and a gas delivering pipe are arranged on the outer side of the outer furnace shell, the connecting pipe is communicated with the melting chamber and the standing chamber, the discharging pipe is communicated with the casting box and the standing chamber, the gas feeding pipe is communicated with the outside space, the melting chamber and the standing chamber, and the gas delivering pipe is communicated with the standing chamber and the casting box. According to the antitheft-door stamping-forming leftover regeneration device, the melting chamber structure is designed, the melting chamber and the standing chamber are integrated, melting time and heat energy are saved, production efficiency is improved, the standing chamber is further formed, shielding gas is led, it is avoided that workpieces are in contact with air in the melting stage, the standing stage and the casting stage, and the casting quality is improved.

Owner:成都森邦世纪木业有限公司

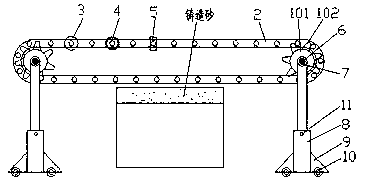

Sand scraping mechanism used for casting of pig iron casting

ActiveCN110711850AQuickly level offAchieving a flat stateMoulding machine componentsDrive shaftGear wheel

The invention discloses a sand scraping mechanism used for casting of a pig iron casting. The sand scraping mechanism comprises a chain plate erected by two gear cylinders; each gear cylinder consistsof a cylinder body and gear bars; the chain plate consists of link units; each link unit includes straight plates and a connecting shaft, wherein the straight plates are symmetrically connected in apierced manner; every two adjacent link units are connected in series by rivets; the connecting shafts are correspondingly provided with a sanding pressure roller, a hairbrush roller and a rectangularbar; each gear cylinder is sleeved and connected with a driving shaft and a shaft collar; each shaft collar is fixedly connected with a lifting rod; the bottom part of each lifting rod is fixedly connected with a triangular support and universal wheels; each driving shaft is connected with a motor; and a sand mould casting frame body is located right below the chain plate. According to the sand scraping mechanism, the sanding pressure roller, the hairbrush roller and the rectangular bar are loaded by the chain plate, and the advantages of three treatment modes of deflecting plate drag scraping, rolling brush head sweeping and rolling drum compaction are combined, so that the flat state of the surface of casting sand is rapidly realized; moreover, the whole sand scraping process is relatively simple and labor-saving; the sand scraping mechanism is suitable for pipelined scraping treatment; the casting time is shortened; formation of a uniform and normal casting standard is facilitated;and the quality of the casting is improved.

Owner:含山盛荣机械配件厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com