V-process casting process for producing engineering mechanical counterweight block

A technology for production engineering and casting process, which is applied in the field of V-method casting process for producing counterweights of construction machinery, which can solve the problems of poor exhaust, poor solidification of molten metal, deformation of cavity, etc., and achieve enhanced air permeability and shortened Casting time, effect of increased firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

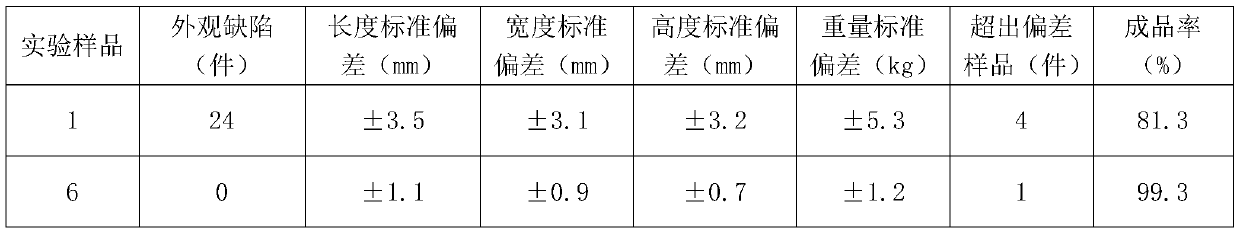

Embodiment 1

[0030] A V-method casting process for producing construction machinery counterweights, comprising the following steps:

[0031] a. Make upper and lower two models according to the appearance size of the counterweight, cover the surface of the upper model with the heated film, and then press the dead corner of the upper model, so that the film at the dead corner is close to the upper model; the same method is used for the lower model for film covering;

[0032]b. After the upper model and the lower model are all covered with film, spray paint on the covered film surface to form a coating with a thickness of 1.2mm; the paint includes the following raw materials in parts by weight: 69 parts of quartz sand powder, flake graphite powder 16 parts, 17 parts of bentonite, 14 parts of zircon powder, 10 parts of polystyrene and 10 parts of bauxite;

[0033] c. Place a sand box on the upper model that has been sprayed with paint, then fill it with dry sand, vibrate it, and then vacuumiz...

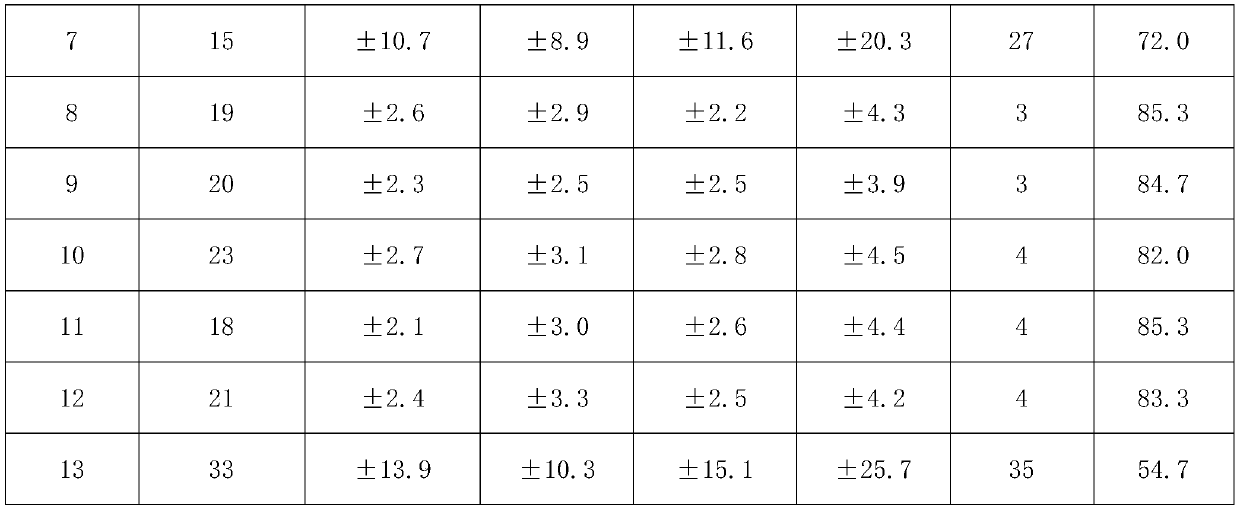

Embodiment 2

[0037] A V-method casting process for producing construction machinery counterweights, comprising the following steps:

[0038] a. Make upper and lower two models according to the appearance size of the counterweight, cover the surface of the upper model with the heated film, and then press the dead corner of the upper model, so that the film at the dead corner is close to the upper model; the same method is used for the lower model for film covering;

[0039] b. After the upper model and the lower model are covered with film, spray paint on the covered film surface to form a coating with a thickness of 0.7mm, and then immediately spray dry ice powder; the paint includes the following raw materials in weight ratio: quartz sand powder 51 parts, 4 parts of flake graphite powder, 5 parts of bentonite, 4 parts of zircon powder, 2 parts of polystyrene, 2 parts of bauxite, 5 parts of calcium fluoride, 11 parts of paris plaster powder, 3 parts of artemisia wax, seaweed 2 parts of su...

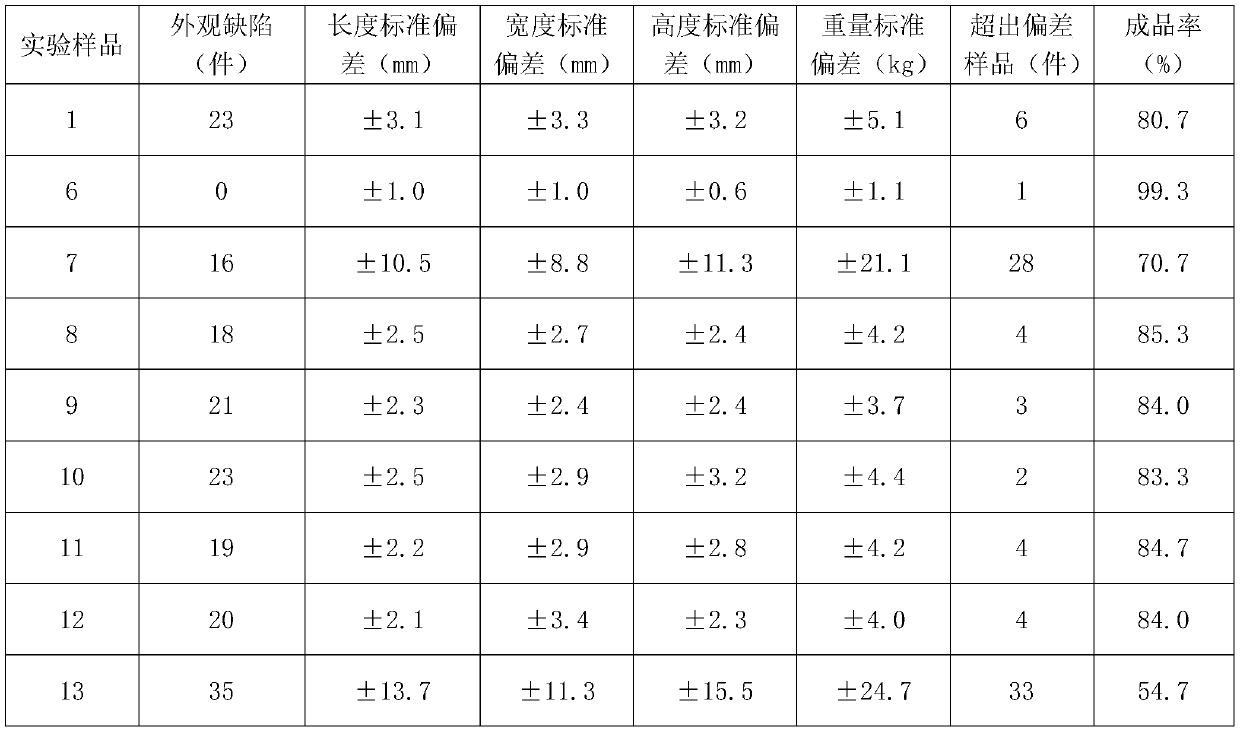

Embodiment 3

[0048] A V-method casting process for producing construction machinery counterweights, comprising the following steps:

[0049] a. Make upper and lower two models according to the appearance size of the counterweight, cover the surface of the upper model with the heated film, and then press the dead corner of the upper model, so that the film at the dead corner is close to the upper model; the same method is used for the lower model for film covering;

[0050] b. After the upper model and the lower model are covered with film, spray paint on the covered film surface to form a coating with a thickness of 0.9mm, and then immediately spray dry ice powder; the paint includes raw materials in the following weight ratio: quartz sand powder 53 parts, 5.5 parts of flake graphite powder, 6.5 parts of bentonite, 5 parts of zircon powder, 3 parts of polystyrene, 3 parts of bauxite, 15 parts of calcium fluoride, 23 parts of plaster powder, 8 parts of artemisia wax, seaweed 8 parts of sug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com