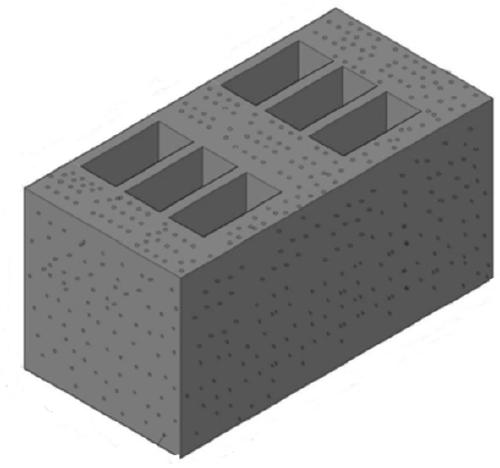

Paving brick for glass kiln and production process thereof

A glass kiln and paving brick technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of easy cracks or missing corners, delayed production cycle, low production efficiency, etc., and achieve good high temperature resistance performance. and corrosion resistance, improve thermal shock stability, reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A kind of pavement brick for glass kiln

[0041] Formula: 30 parts of natural zircon sand, 30 parts of alumina powder, 1.6 parts of soda ash, 1.5 parts of fluorite powder, 2 parts of silica powder and 8 parts of titanium dioxide.

[0042]Preparation method: specifically comprise the following steps:

[0043] (1) Mix the components in the formula dosage evenly in proportion, then heat and melt in an electric arc furnace to obtain a molten liquid, and cast the molten liquid into the sand mold of the incubator at 1820°C;

[0044] (2) The molten solution is insulated and annealed in an incubator for 12 days and then out of the case to obtain the rough product of the paving brick;

[0045] (3) After the rough product obtained in step (2) is sand-cleaned, the riser is cut and each surface is ground, it is packaged to obtain the finished paving brick.

[0046] The insulation box described in step (1) and step (2) is filled with insulation material, and the insul...

Embodiment 2

[0047] Embodiment 2 A kind of pavement brick for glass kiln

[0048] Formula: 35 parts of natural zircon sand, 38 parts of alumina powder, 1.8 parts of soda ash, 2.2 parts of fluorite powder, 3 parts of silica powder and 9.5 parts of titanium dioxide.

[0049] Preparation method: specifically comprise the following steps:

[0050] (1) Mix the components in the formula dosage evenly in proportion, then heat and melt in an electric arc furnace to obtain a molten solution, and cast the molten solution into the sand mold of the incubator at 1840°C;

[0051] (2) The molten solution is insulated and annealed in an incubator for 10 days and then out of the case to obtain the rough product of the paving brick;

[0052] (3) After the rough product obtained in step (2) is sand-cleaned, the riser is cut and each surface is ground, it is packaged to obtain the finished paving brick.

[0053] The insulation box described in step (1) and step (2) is filled with insulation material, the si...

Embodiment 3

[0054] Embodiment 3 A kind of pavement brick for glass kiln

[0055] Formula: 40 parts of natural zircon sand, 45 parts of alumina powder, 2.1 parts of soda ash, 1.8 parts of fluorite powder, 4.5 parts of silica powder and 10 parts of titanium dioxide.

[0056] Preparation method: specifically comprise the following steps:

[0057] (1) Mix the components in the formula dosage evenly in proportion, then heat and melt in an electric arc furnace to obtain a molten solution, and cast the molten solution into the sand mold of the incubator at 1850°C;

[0058] (2) The molten solution is insulated and annealed in an incubator for 13 days and then out of the case to obtain the rough product of the paving brick;

[0059] (3) After the rough product obtained in step (2) is sand-cleaned, the riser is cut and each surface is ground, it is packaged to obtain the finished paving brick.

[0060] The insulation box described in step (1) and step (2) is filled with insulation material, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com