Non-heat-treatment reinforced high-toughness pressure-casting aluminum alloy material for new energy automobile battery box

A technology for new energy vehicles and aluminum alloy materials, which is applied in the field of high-strength and high-toughness new energy battery box die-casting aluminum alloy materials and the preparation of battery boxes, can solve the problems of high manufacturing difficulty, inability to form at one time, and complex structure of battery boxes, etc. To achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Two 1-ton crucible furnaces are used for simultaneous materialization. This alloy is a non-heat-treated high-toughness special die-casting aluminum alloy for battery boxes.

[0043] (1) The pure aluminum ingot A00 is used as the raw material of the Al element in the alloy for smelting, the pure magnesium ingot is used as the raw material of the Mg element in the alloy, the single crystal silicon 553# is used as the main element of He Si, and the Zn element is in the form of an aluminum ingot or Block pure zinc is added, Cu element is added as master alloy, Al-Mn master alloy is used as the raw material of Mn element in the alloy, and rare earth master alloy is used as the raw material of Ce and La elements in the alloy, nano-scale refiner Al-Ti- C-Sr master alloy is added, and each raw material is weighed according to the ratio of each element;

[0044] (2) Clean the raw materials, preheat each raw material after polishing the scale on the surface, and the preheating te...

Embodiment 2

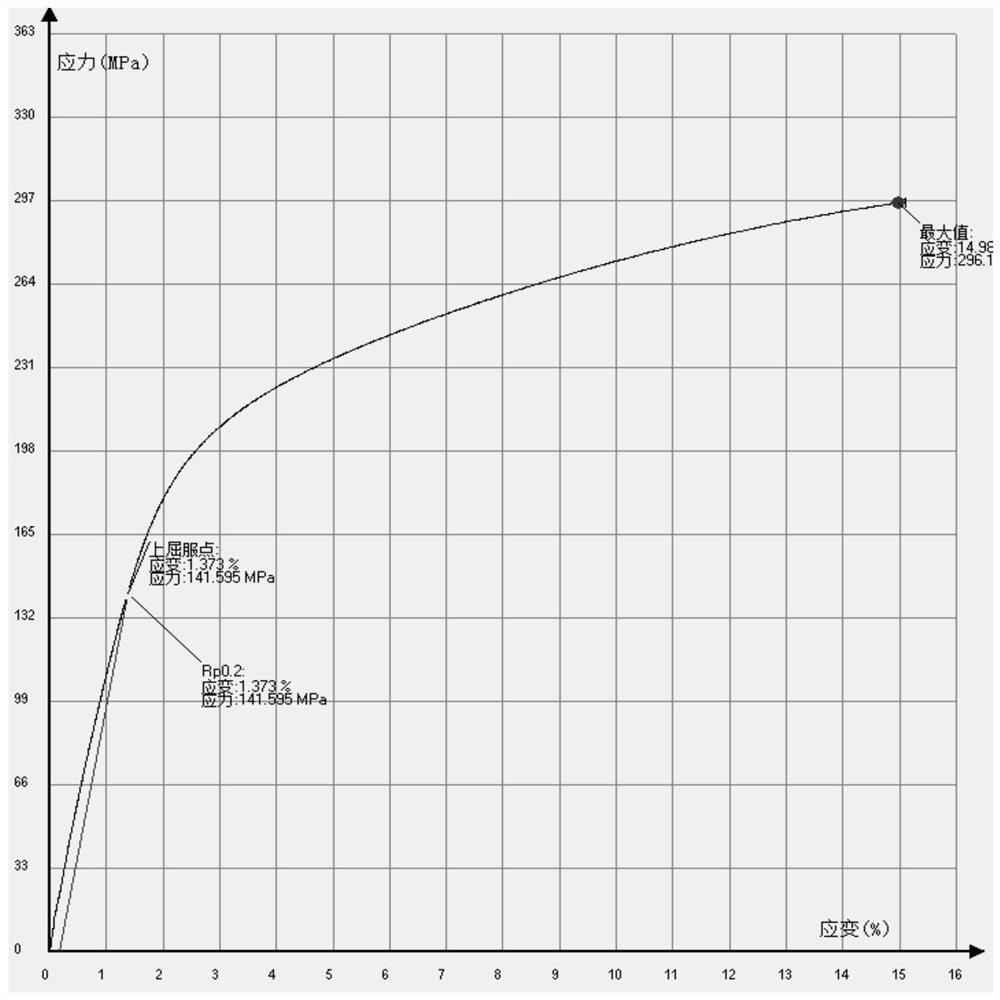

[0063] Using the preparation method described in Example 1, the crucible furnace was fed with chemical materials at the same time to obtain two kinds of die-casting aluminum alloy liquids with different alloy compositions. The machine carries out high-pressure casting, samples are taken from the body of the die-casting, and the welding performance of two different materials is compared. A 1000W laser welding machine is used for welding, with a welding power of 750W, a welding spot diameter of 1mm, a welding speed of 20mm / s, and a defocus of 1.5 mm, argon flow rate 1.0L / min. Comparison of high strength and toughness die-casting aluminum alloys with rare earths Ce and La and no rare earths is shown in Table 2

[0064] Table 2

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com