Recovery system of aluminum alloy door and window waste

A technology of aluminum alloy doors and windows and recovery system, which is applied in the direction of furnace material, charge composition/state, lighting and heating equipment, etc., can solve the problems of low casting quality, improve work efficiency, prevent low casting quality, and shorten casting molding time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

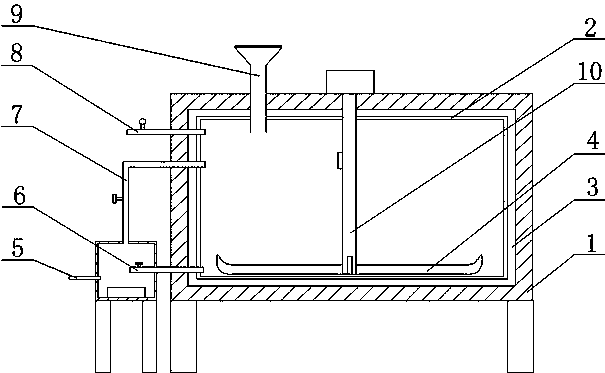

[0025] Such as figure 1 As shown, the present invention is a recycling system for aluminum alloy door and window waste, comprising a furnace shell 1, a furnace inner shell 2 is arranged inside the furnace shell 1, the inner space of the furnace inner shell 2 forms a melting chamber, and a furnace shell 1 is arranged above the furnace shell 1 Feeding pipe 9, the feeding pipe 9 runs through the furnace shell 1 and communicates with the melting chamber, the inside of the furnace inner shell 2 is provided with a discharge pipe 6, and also includes a casting box, the discharge pipe 6 communicates with the melting chamber and the casting box, and the casting An exhaust pipe 5 and a gas delivery pipe 7 are arranged outside the box, wherein the exhaust pipe 5 communicates with the casting box and the external space, the gas delivery pipe 7 communicates with the casting box and the melting chamber, and the furnace shell 1 is provided with an inlet pipe 8, which communicates An electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com