Impellers (rotor)of Root's blower manufacturing method

A technology of Roots blower and manufacturing method, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve problems such as complicated production process, and achieve the effects of saving energy consumption, low casting temperature, and reducing air volume loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Its manufacturing method is:

[0019] Preheat the upper and lower templates 3 and 1 of the mold, the cavity mold 2, and the core to 180-200°C, apply a release agent after heating, and then fix the cavity mold 2 on the lower template 1 first, install Insert the core, cover the upper template 3, fix the pouring sleeve, pour the alloy smelted according to the general method into the mold, the casting temperature is 450°C, open the mold after hardening and take out the finished product, the casting is quenched at 180°C and placed at room temperature for 48 Available in hours.

[0020] After the mold is opened, the mold is coated with a release agent, the mold is closed for secondary casting, and the mold does not need to be reheated.

[0021] In the above method, the release agent is water glass plus talcum powder to prepare gruel.

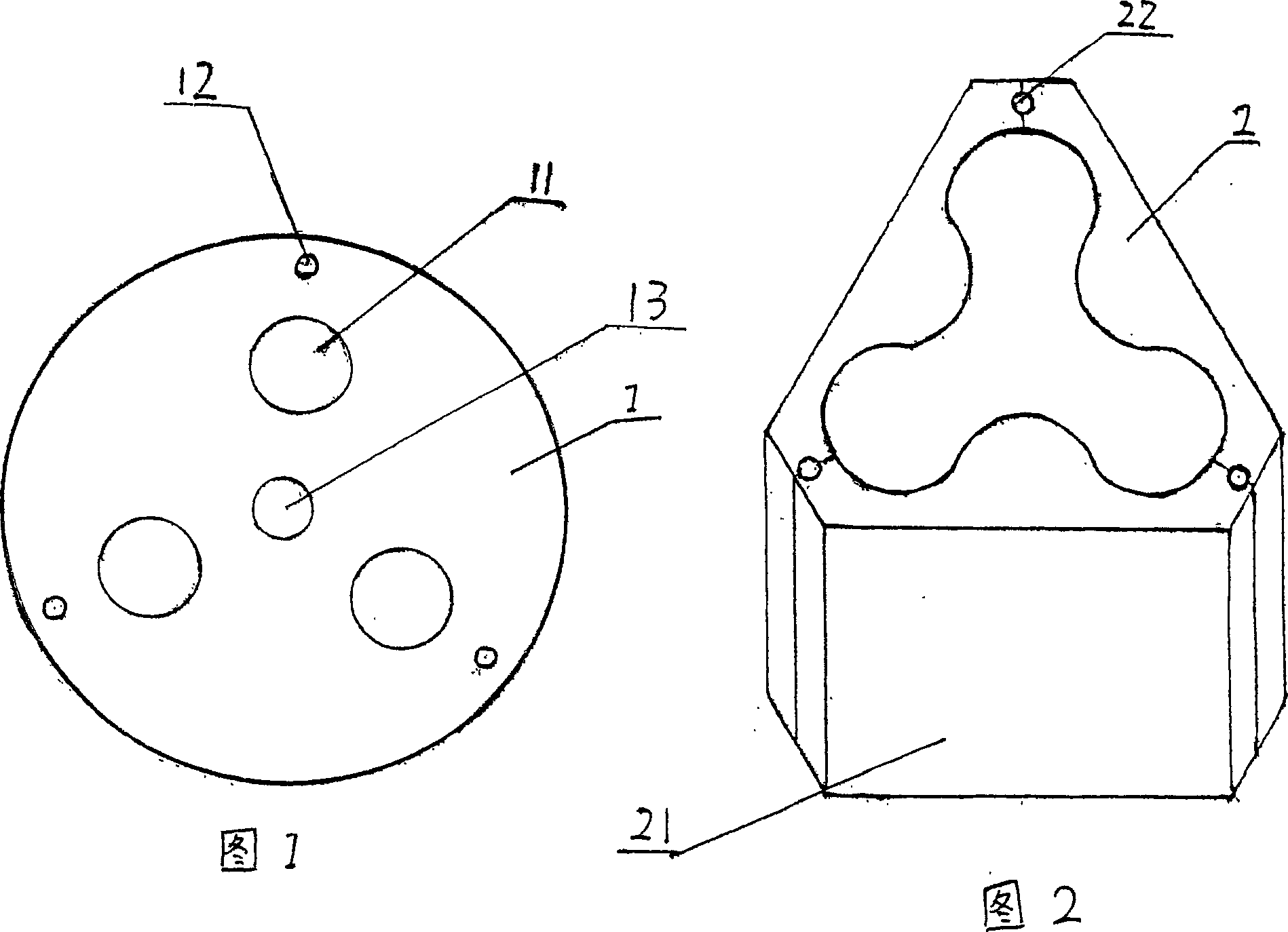

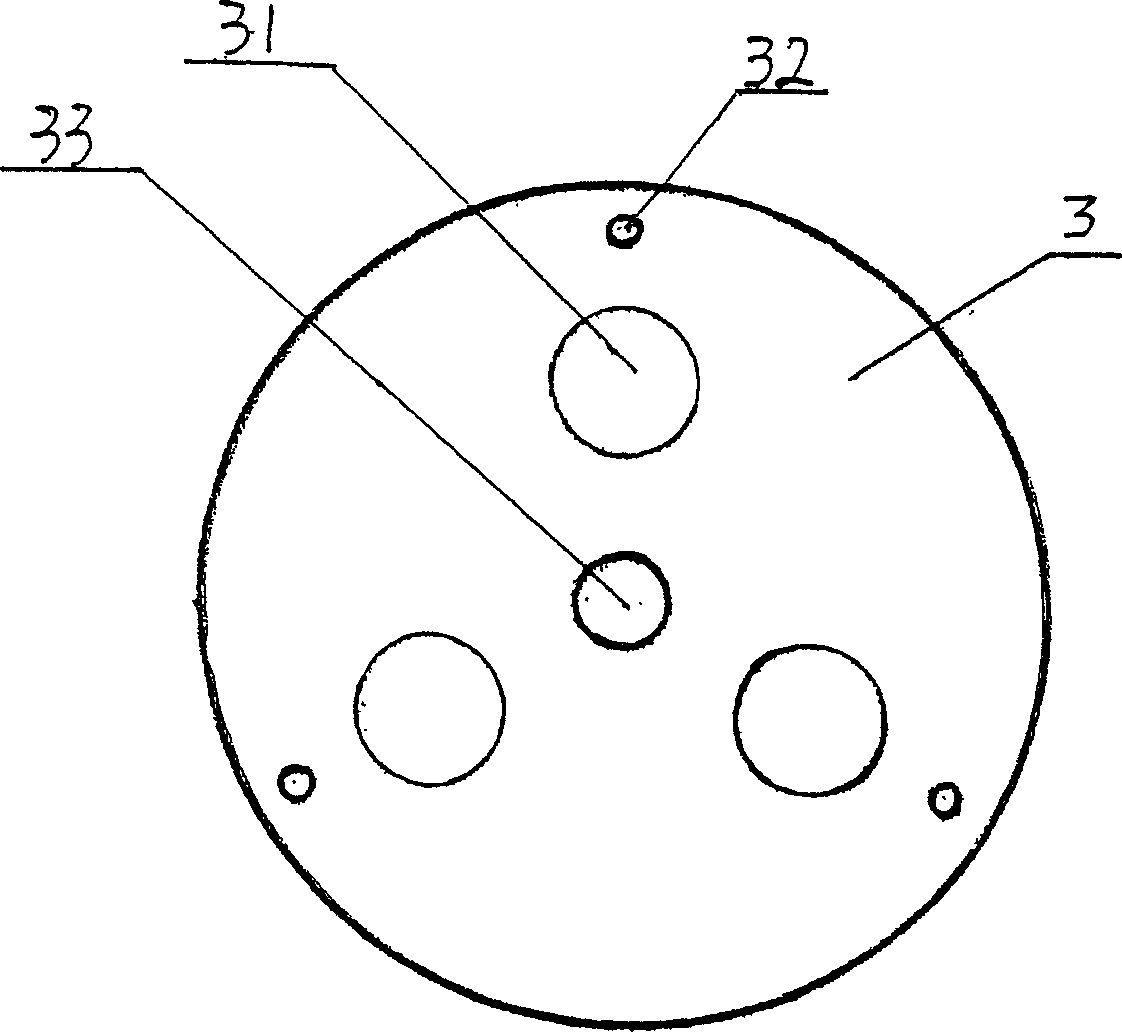

[0022] Shown in Fig. 1, 2, 3 is this Roots blower impeller (rotor) production mold. The details are as follows:

[0023] This Roots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com