Method and mould for manufacturing valve retainer

A manufacturing method and technology of valve seat rings, applied in the direction of manufacturing tools, casting molding equipment, furnace types, etc., can solve the problems of equipment and labor increase, easy deviation, cost increase, etc., to reduce equipment investment and energy consumption, prevent Tilting and deformation, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

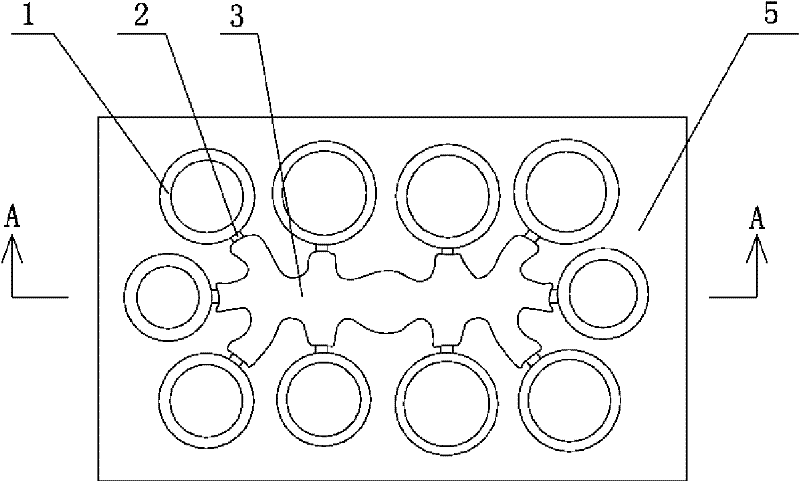

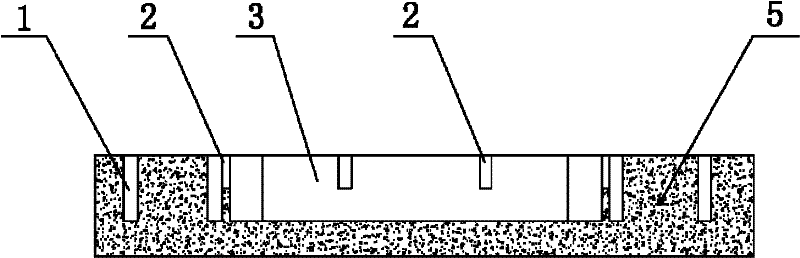

[0021] The direct forming mold of the valve seat ring of the present embodiment, as figure 1 , 2 As shown, the direct forming mold for the valve seat includes a disc-shaped body 5, on which a plurality of annular grooves 1 are opened, and the disc-shaped body 5 is also provided with a guide groove 3, the guide The runner 3 is connected with all the annular grooves; there is a shut-off 2 at the connection between the diversion groove 3 and the annular groove 1. The function of the shut-off is to make the valve seat ring easy to remove from the casting body after demoulding, and at the same time It also facilitates the grinding of the gate of the valve seat ring.

[0022] The specific steps of the manufacturing method of the valve seat ring of the present embodiment are as follows:

[0023] (1) Install the gate on the mold: seal the top of the valve seat ring directly into the mold, and install the gate to communicate with the diversion groove of the mold;

[0024] (2) smelti...

Embodiment 2

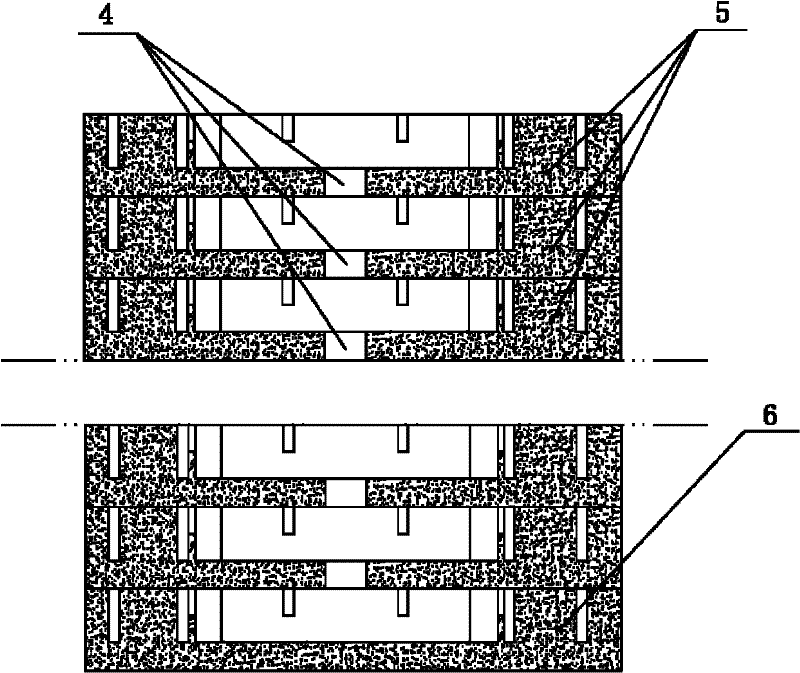

[0029] The manufacturing method of the valve seat ring of the present embodiment is the same as embodiment 1, the difference is: as image 3 As shown, the mold used is formed by stacking several disc-shaped bodies 5 up and down, and the bottom of the diversion groove of the disc-shaped body 5 above the bottom disc-shaped body 6 is provided with communicating holes 4, Make the diversion grooves of each valve seat ring direct molding mold communicate with each other through the communication holes, ensure that the upper and lower disc-shaped bodies are aligned when installing the mold, and install the gate in the diversion groove of the uppermost mold during casting, using this implementation The mold of the example can cast multiple disc-shaped valve seat rings at one time, which increases the number of valve seat rings cast at one time and greatly improves the production efficiency.

Embodiment 3

[0031] The manufacturing method of the valve seat of the present invention and the direct forming mold of the valve seat used are the same as in Example 1, the difference is that the temperature used for casting is 1475°C, and the heat treatment is quenching at 965°C for 5 hours, and then at 700°C °C annealing for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com