Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Increased soluble protein content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of algae fertilizer

InactiveCN102515938APromote growth and developmentIncrease chlorophyll contentFertilizer mixturesFreeze-dryingAlgae

The invention discloses a preparation method of an algae fertilizer. The preparation method comprises the following steps: 1) removing impurities and exotic matters in algae; 2) completely soaking with ethanol for 24 hours; 3) concentrating lixivium at reduced pressure until extract is obtained; 4) carrying out freeze drying on residue; 5) evenly mixing the extract with the residue; and 6) carrying out spray drying, and carrying out dry granulation so as to obtain the algae fertilizer. The algae fertilizer prepared by using the method has specific advantages in the aspects of improving self-metabolism of a plant, adapting to external environment and providing nutrient substances, and is a natural green fertilizer which is simple in process and suitable for planting organic vegetables.

Owner:HUAQIAO UNIVERSITY

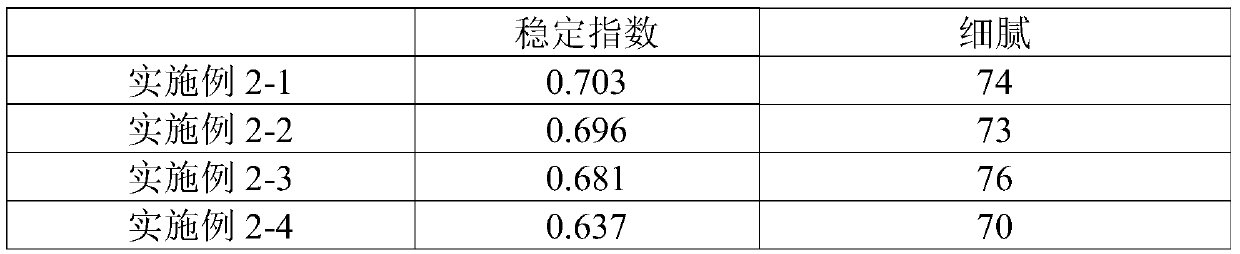

Formaldehyde-free soybean powder adhesive and preparation method thereof

ActiveCN103045160AWide variety of sourcesLarge protein content requirement rangeNon-macromolecular adhesive additivesProtein adhesivesAdhesiveEconomic benefits

The invention discloses a formaldehyde-free soybean powder adhesive. The formaldehyde-free soybean powder adhesive is prepared from the following components in parts by weight: 100 parts of water, 20 to 70 parts of soybean powder, 0.1 to 10 parts of a modifier, 20 to 120 parts of a crosslinking agent, 0.05 to 5 parts of a regulator and 0.1 to 3 parts of a reducing agent. The formaldehyde-free soybean powder adhesive is good in bonding performance and water resistance, low in production cost, long in storage period, and convenient to transport and use. A preparation method of the formaldehyde-free soybean powder adhesive is simple in preparation, good in controllability, easy to operate and realize industrial production and low in production cost, so that the formaldehyde-free soybean powder adhesive has good economic benefit, is favorable for popularization and application, and has wide application prospects.

Owner:宁波朝露新材料科技有限公司

Fermentation material for composite microorganism and preparation method thereof

InactiveCN101186896AImprove palatabilityIncrease profitFungiBacteriaCell culture mediaEnzyme inducer

The invention relates to a composite microorganism ferment material which is characterized in that production strains select production strains of which the growth rate is quick and the enzyme production quantity is large by combining with through ray inducement and production performance detection. The processing technique employs innovative symbiosis compatibility design of probiotics and multi-compound fermentation technology, the number of the live probiotics in the products achieves five billion per gram, and the products simultaneously contain polyoses, polypeptide, organized enzyme, organic acid, phytosterin, triterpennoids saponin and the like active metabolite. Specific enzyme producing inducer is added to growth medium, the latest single creature venting valve is employed on the package, which not only can be added to complete feed of livestock or poultry but also can be directly added into feedstuff, thereby effectively promoting breakdown and absorption of giant molecule nutrient substance in the intestinal canal of livestock or poultry, thereby eliminating the action of anti-nutritional factors in the feedstuff, remarkably increasing utilization ratio of the feedstuff, and reducing the feeding cost.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

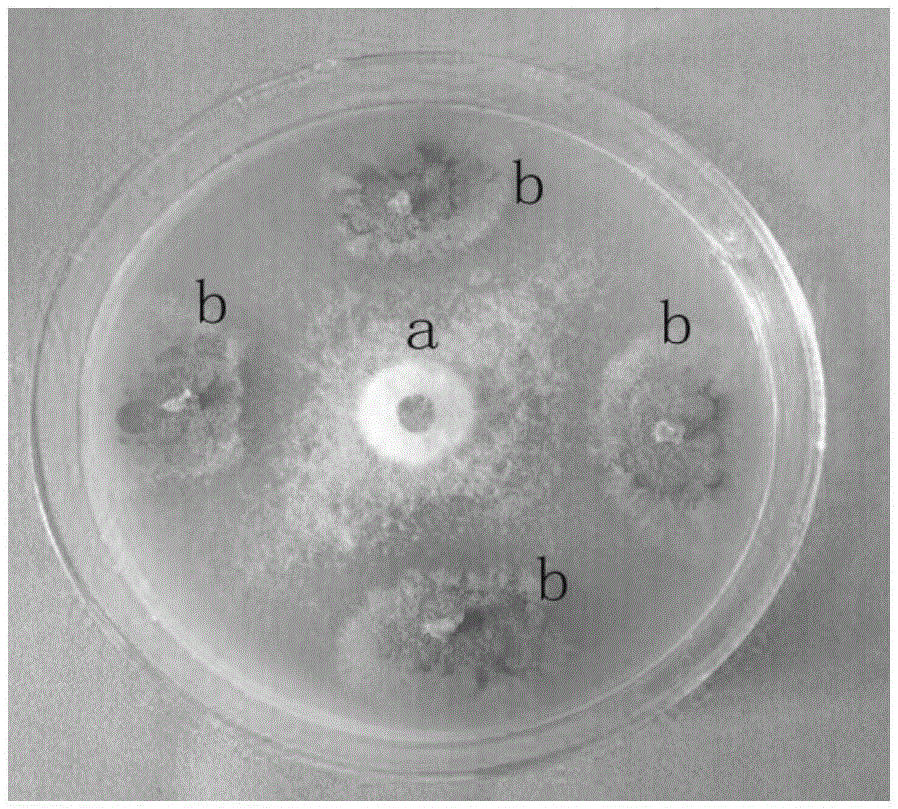

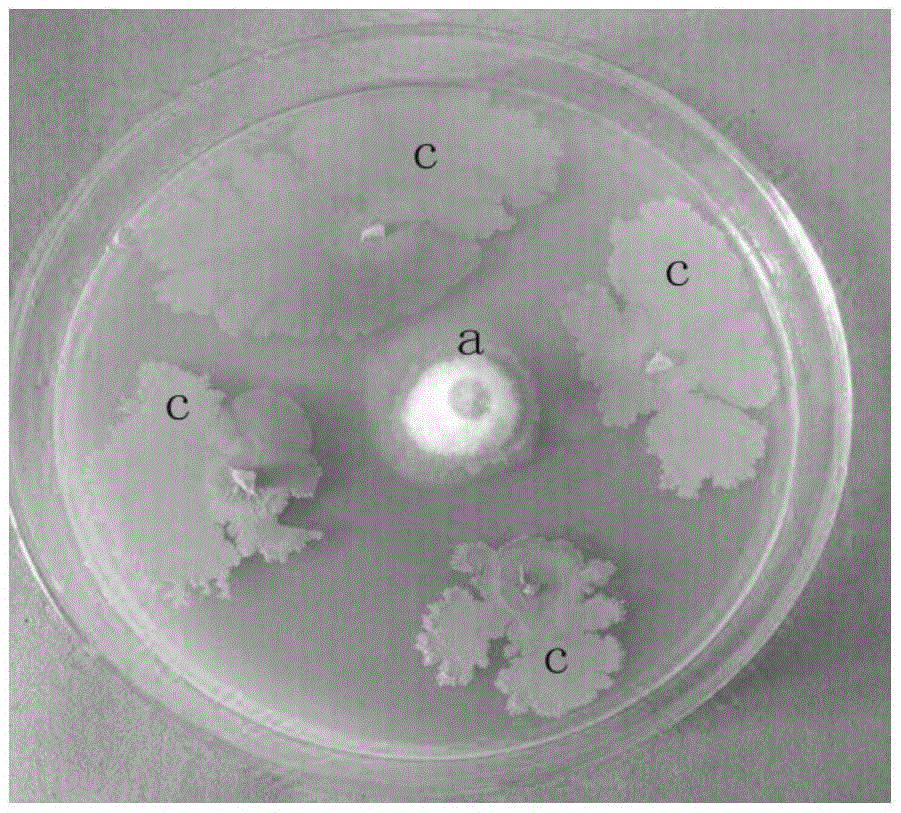

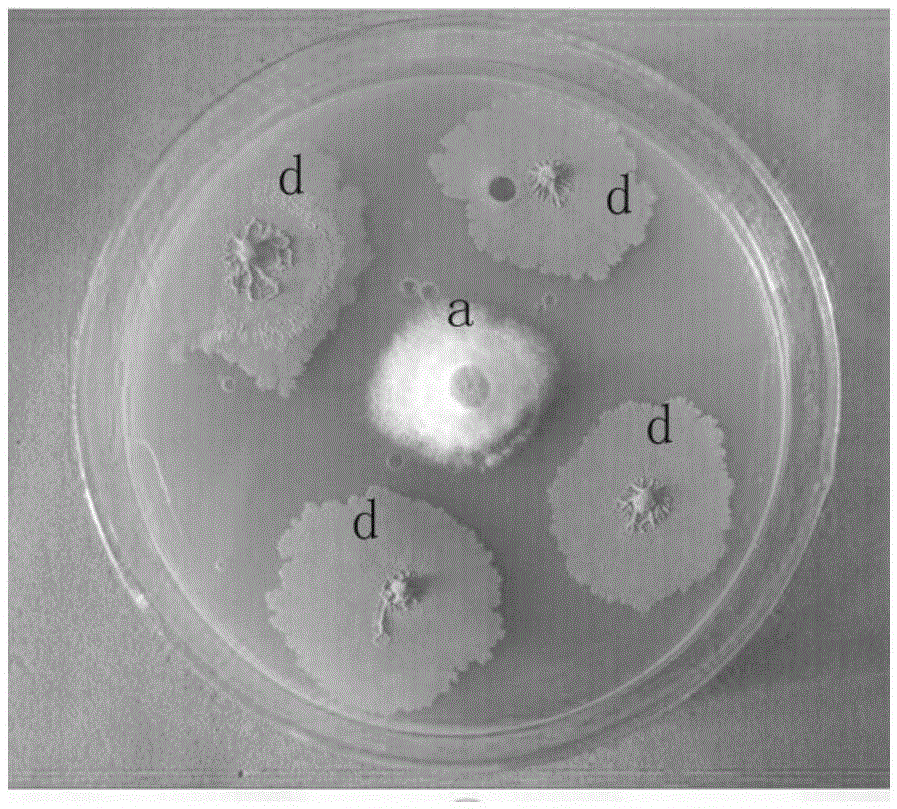

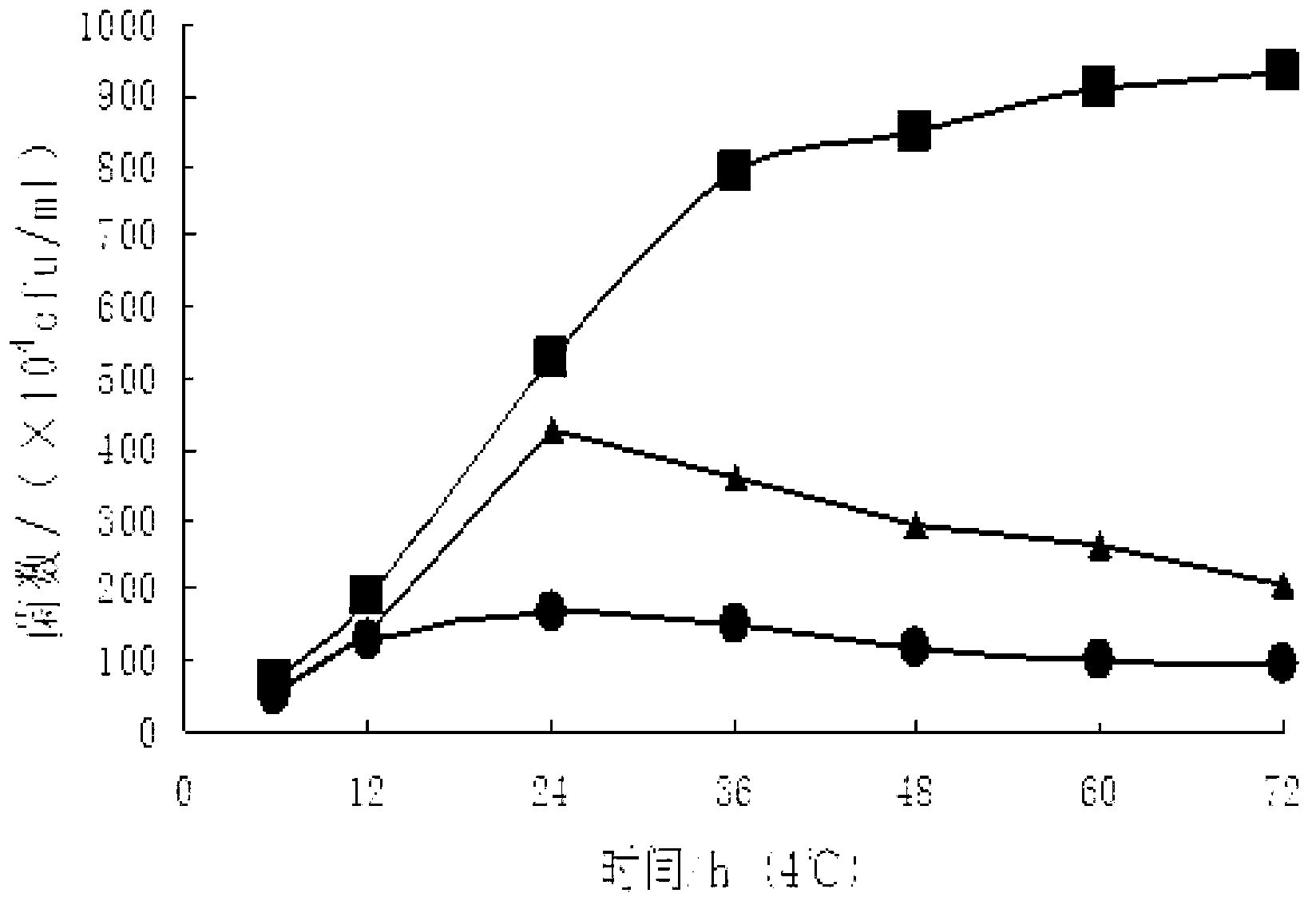

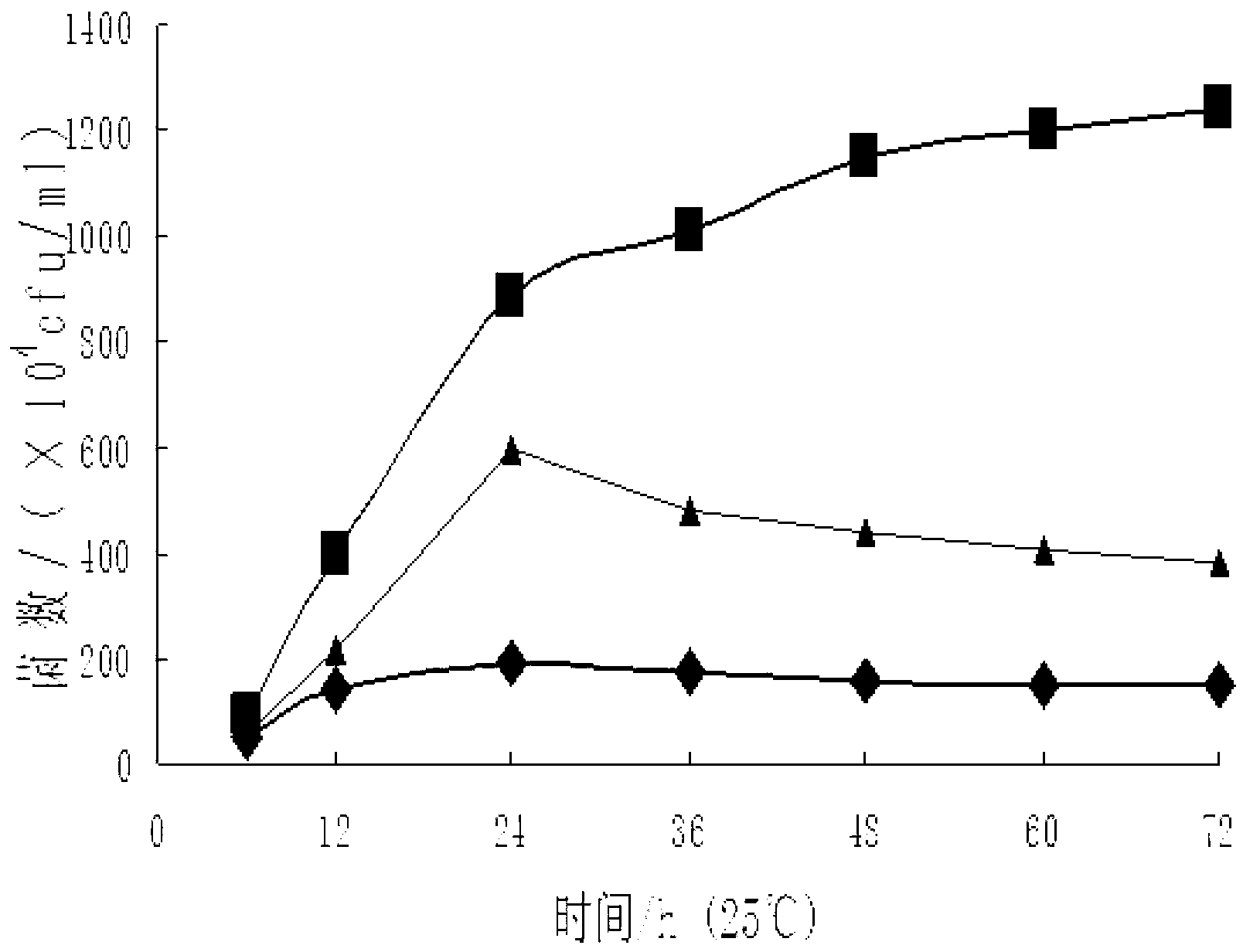

Compound microbial agent for preventing and treating banana wilt disease and prevention and treatment method

ActiveCN105385643AControl Fusarium WiltReduce morbidityBiocideFungiBacillus thuringiensisTreatment effect

The invention relates to the field of banana cultivation, in particular to a compound microbial agent for preventing and treating a banana wilt disease and a prevention and treatment method. The compound microbial agent comprises paenibacillus polymyxa, bacillus subtilis, bacillus thuringiensis, pseudomonas stutzeri, bacillus amyloliquefaciens, cold-resistant brevibacteriaceae, trichoderma and metarrhizium anisopliae. By means of a reasonable proportion, all strains are mutually influenced and promoted, and the prevention and treatment effect on the banana wilt disease is greatly improved. The prevention and treatment method of the banana wilt disease can effectively adjust the composition of bacterial colonies in soil, promote growth and propagation of probiotics and antagonistic bacteria in the soil, rapidly restore and stabilize the balance of the bacterial colonies in the soil, prevent and treat occurrence and spread of the banana wilt disease, effectively decrease the occurrence rate of the banana wilt disease and maintain the stable and high yield of bananas.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

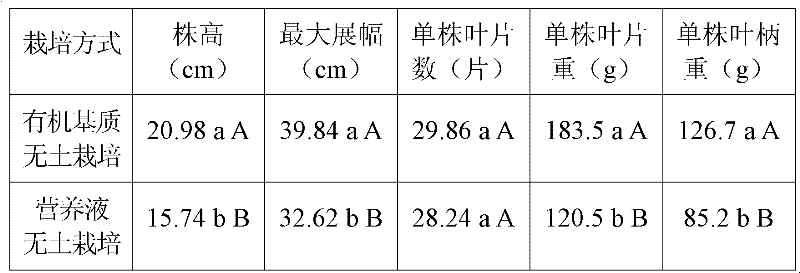

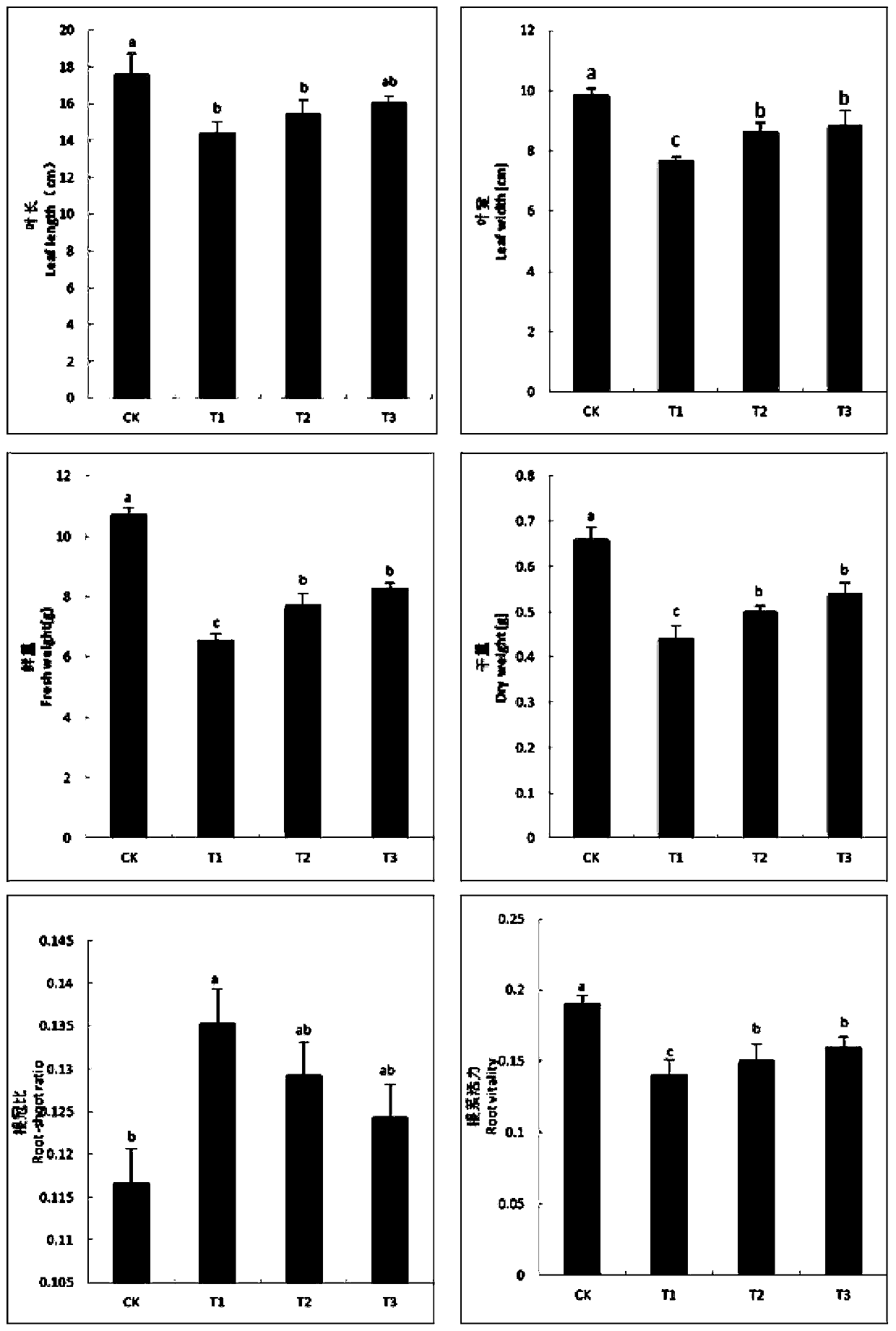

Organic Ecological Type Soilless Cultivation Method of Wutaicai

InactiveCN102265777ASimple and fast operationIncrease productionAgriculture gas emission reductionCultivating equipmentsMushroomSeedling

The invention discloses an organic ecological soilless culturing method for black cabbages. The method comprises the following steps: (1) preparing a substance; (2) sowing and raising seedlings; (3) planting seedlings; and (4) maintaining in later period, wherein the substrate is prepared by mixing sawdust, mushroom residues and pearlite at a volume ratio of 4:4:2 and then adding 10kg chicken manure and 5kg cake fertilizer in each cubic meter of the mixture. The organic ecological soilless culturing method for black cabbages has the advantages that production cost of black cabbages is lowered, environmental pollution is reduced and yield and quality of the black cabbages are promoted. The organic ecological soilless culturing method meets national conditions and is in accord with the direction of agricultural continuous development.

Owner:JIANGHAN UNIVERSITY

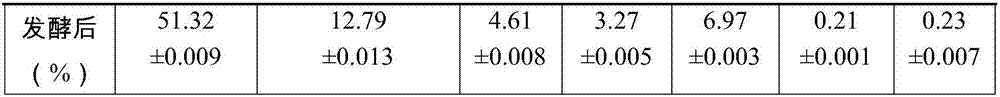

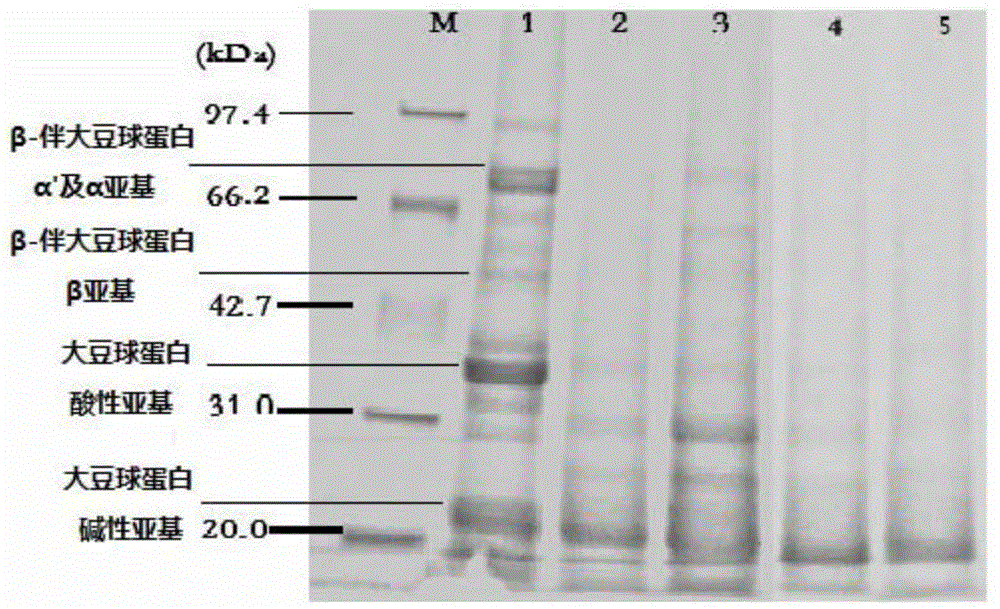

Production technology of solidly fermented and enzymatically hydrolyzed soybean meal

InactiveCN101558818AImprove qualityIncrease profitFood processingAnimal feeding stuffAntigenFood flavor

The invention discloses a production technology of solidly fermented and enzymatically hydrolyzed soybean meal, which comprises the following steps: firstly culturing strains, inoculating the strains to the fermented raw materials of the soybean meal, controlling the fermentation temperature and humidity to perform solid fermentation and drying and grinding the fermented raw materials of the soybean meal to obtain the fermented and enzymatically hydrolyzed soybean meal product. Through solid fermentation and enzymatic hydrolysis, the soybean meal contains diverse digestive enzymes and a majority of anti-nutritional factors such as antigen protein and oligose in the soybean meal are degraded, thus increasing the contents of crude protein and soluble protein, endowing the soybean meal with certain amount of organic acid and characteristic flavor and bettering solving the problems in livestock and poultry breeding, such as indigestion, diarrhea, weak disease-resistant ability of organism, etc.

Owner:SHANDONG HESHI GROUP

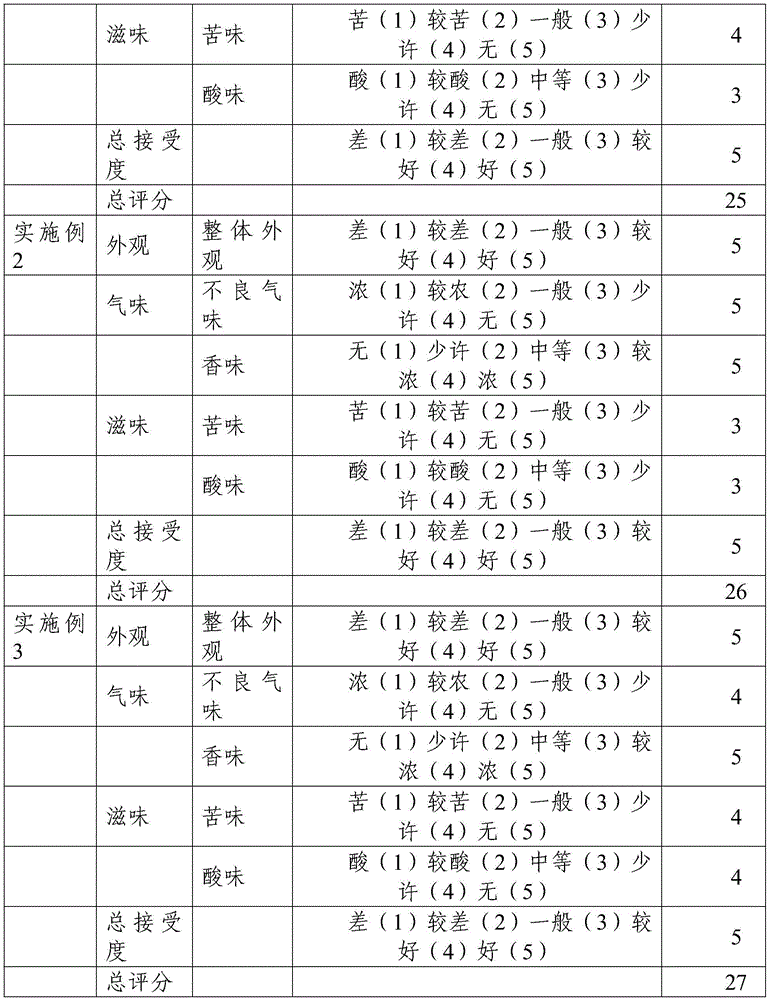

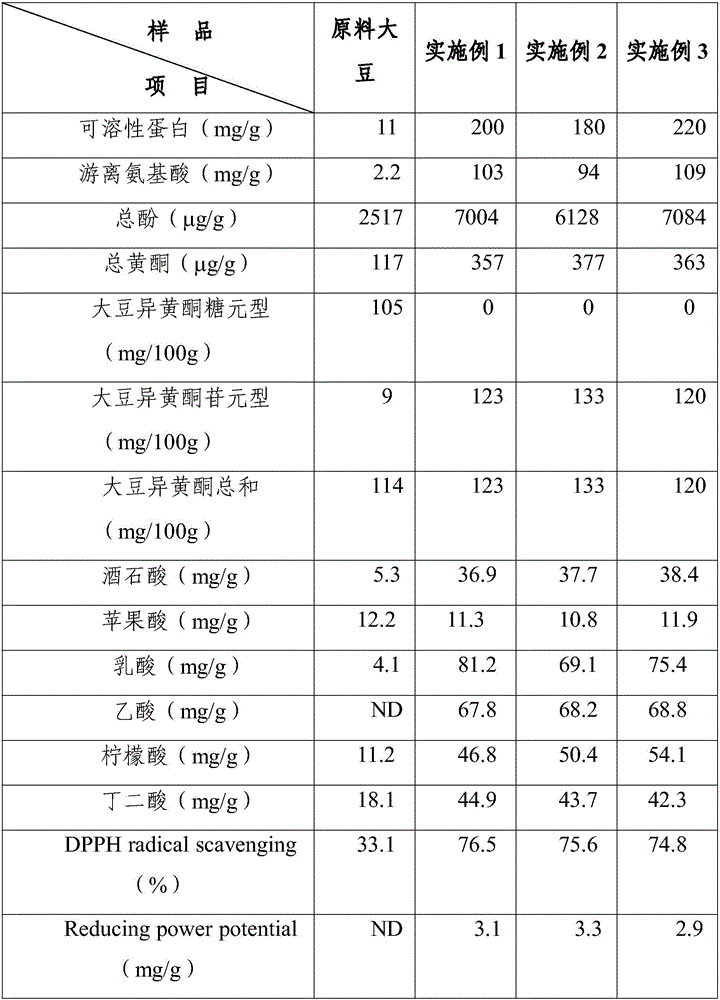

Making method of function-enhanced fermented soybean leisure food

InactiveCN106213215APollution suppressionHigh in flavonoidsFood ingredient functionsFlavorAspergillus oryzae

The invention relates to the technical field of biological fermentation food, in particular to a making method of function-enhanced fermented soybean leisure food. The making method includes following steps: (1), pre-treating: weighing, cleaning and steaming soybean, and using aspergillus oryzae composite enzyme liquid to soak the soybean to obtain zymolytic soybean; (2), fermenting: using a composite bacillus bacterium suspension to pre-ferment the zymolytic soybean, and using a composite lactobacillus bacterium suspension and a composite yeast bacterium suspension for combined post-fermentation to obtain fermented soybean; (3), blending and lyophilizing: blending, forming and lyophilizing the fermented soybean to obtain a finished product. The making method is short in production period and controllable in production process, healthcare function of the fermented soybean is enhanced, and flavor of the fermented soybean is improved.

Owner:JILIN UNIV

Kluyveromyces marxianus fermented bean residue powder

ActiveCN104905158ASoft textureStrong aromaFood ingredient functionsFood preparationHealthful foodReducing sugar

The invention discloses kluyveromyces marxianus fermented bean residue powder which is prepared by the steps: adjusting the water content of the bean residues to 70-85% and sterilizing the bean residues at 121 DEG C; inoculating kluyveromyces marxianus to the cooled bean residues; fermenting the bean residues for 40-48 hours at 28 DEG C; sterilizing the bean residues at 121 DEG C; carrying out vacuum or freeze drying; and crushing the bean residues and screening the bean residues by a 50-80-mesh sieve. The fermented bean residue powder is milk white, soft in texture, strong in aroma, fine and smooth in taste, free of residue sense and long in aftertaste time and has a unique aromatic odor. Compared with the raw bean residues, the soluble protein content is improved by 1.15 times, the content of soluble dietary fiber is improved by 1.12 times, the content of total soluble sugar is improved by 0.38 time, respectively, and the content of reducing sugar is reduced by 0.17 time; four different components of soy isoflavone have great changes in content, wherein the aglycone isoflavone monomers are improved by 0.42 time. The method disclosed by the invention is simple and strong in operability, and the processability of the fermented bean residues is remarkably improved, and the fermented bean residues are an excellent raw material for developing various healthy foods with unique flavors.

Owner:JILIN AGRICULTURAL UNIV

Strain of saccharomycopsis fibuligera and application thereof

ActiveCN108251317APromote growthImprove the quality of fruits and vegetablesFungiBio-organic fraction processingMicrobial agentSaccharomycopsis fibuligera

The invention belongs to the technical field of microbial fermentation, specifically belongs to the technical field of microbial decomposing, in particular relates to a strain which produces diversified enzymes with high enzyme activity and good acid resistance, enables distillers' grains to warm quickly and keep high temperature for a long time, and decomposes the distillers' grains completely, and relates to application of the strain. The strain is (Saccharomycopsis fibuligera)Y-1, and the preservation number is CGMCC No. 15255. The activity of an alpha-amylase produced by the strain is 2.56times higher than the currently known highest enzyme activity (7425.4 U / g); at the same time, the strain has the ability of producing glucoamylase, cellulase (CMC enzyme), cellulase (FPA enzyme), neutral protease, acid protease, lipase and other 7 enzymes, can produce diversified enzymes with high enzyme activity, and is applied to a microbial agent for fast decomposing to quickly and thoroughlydecompose the distillers' grains.

Owner:陕西枫丹百丽生物科技有限公司

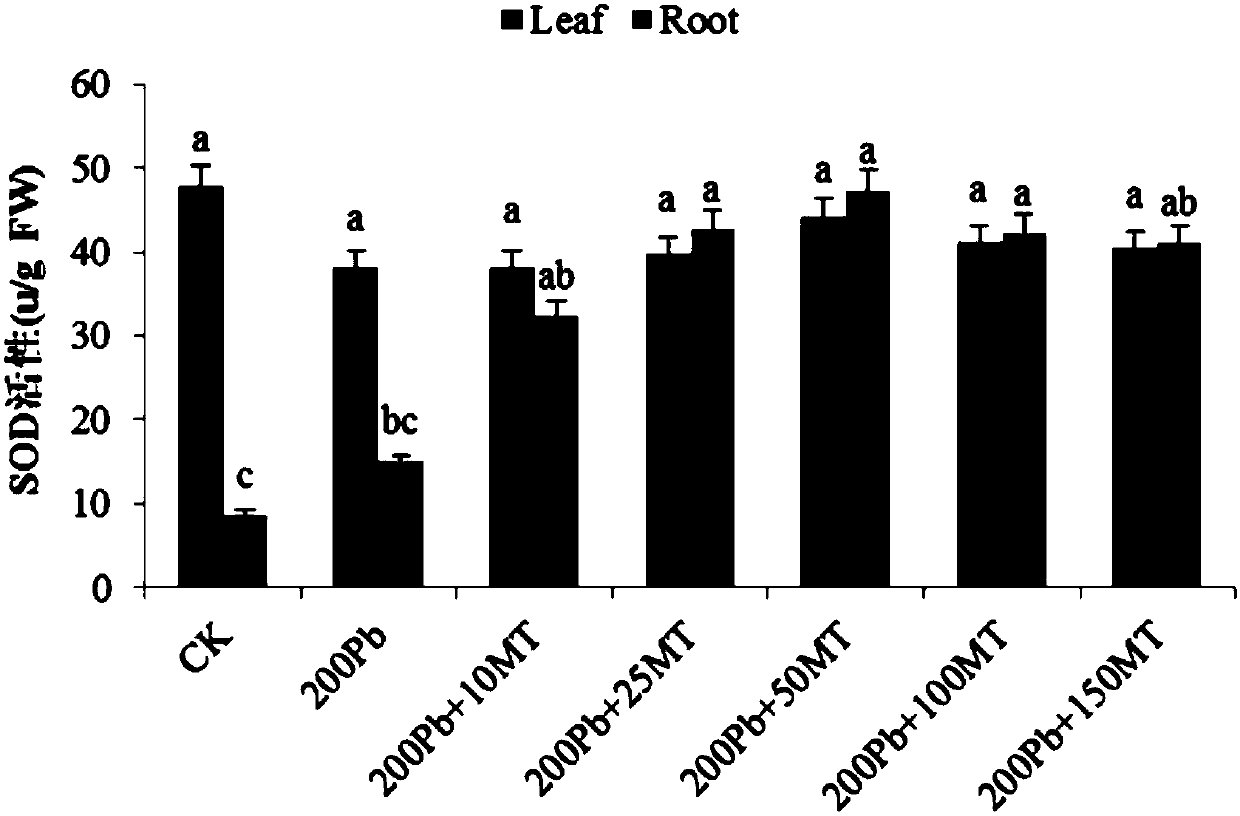

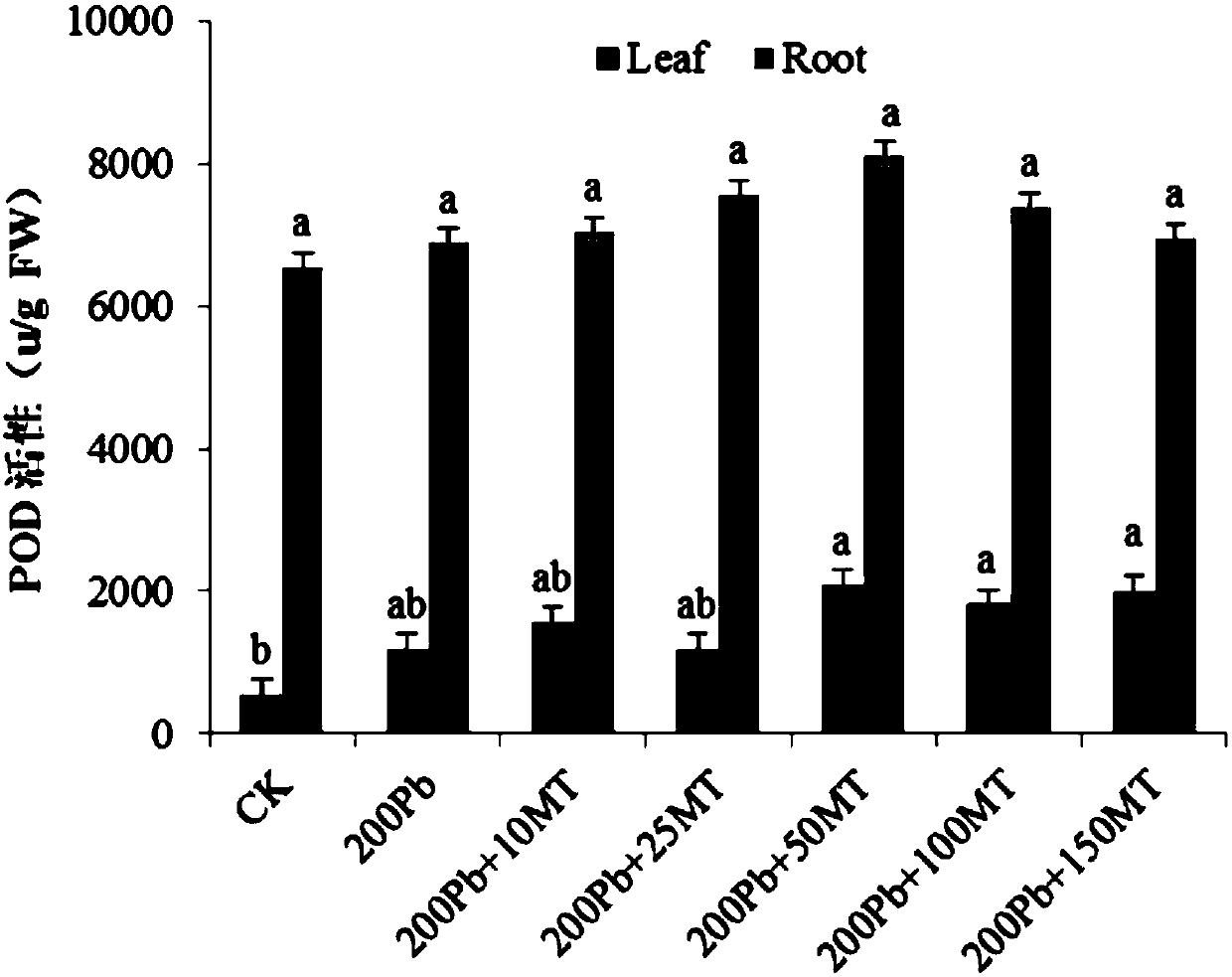

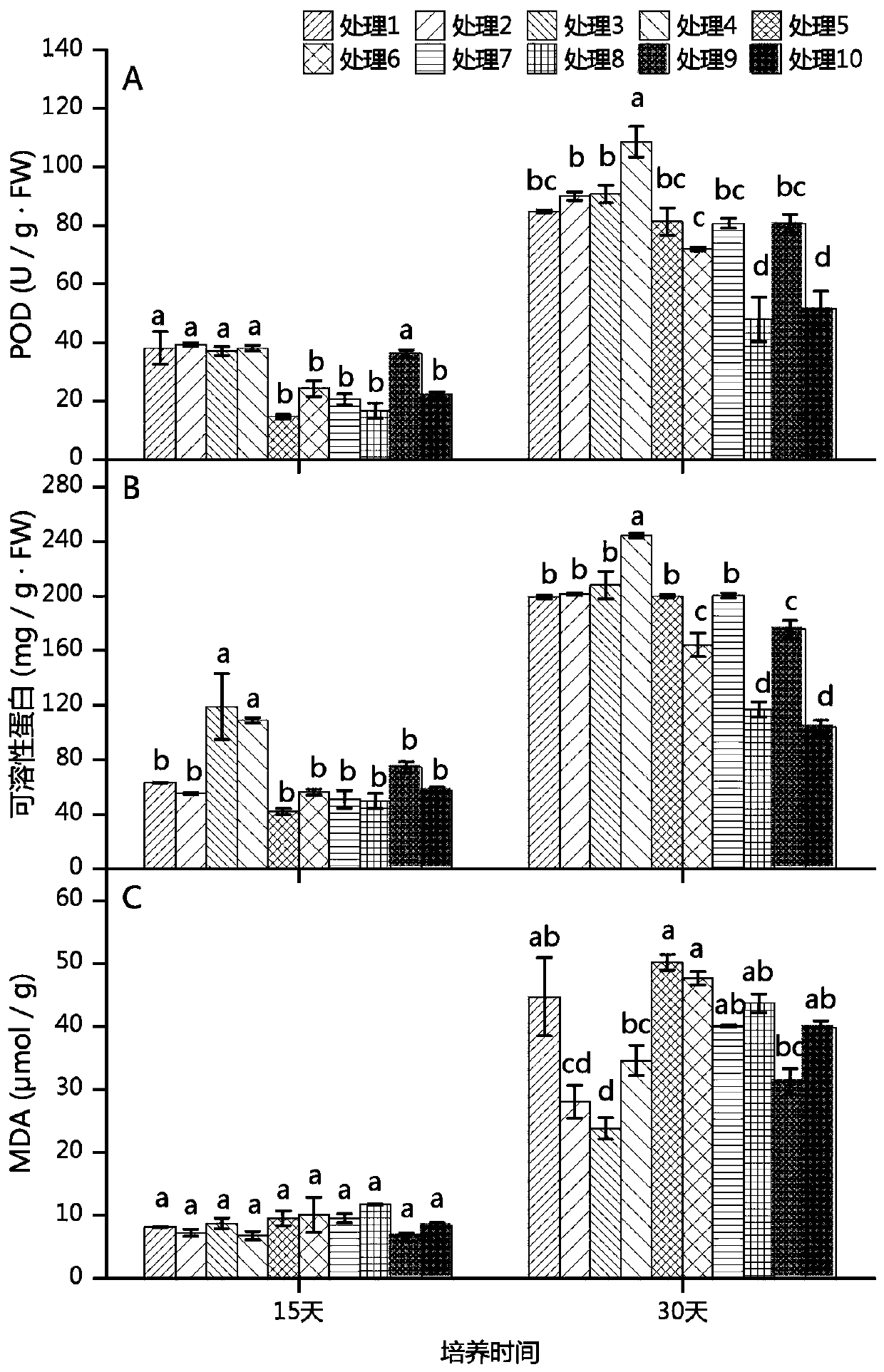

Method for utilizing melatonin to reduce Pb accumulation amount of vegetables

InactiveCN107581000AHigh activityToxic reductionRoot crop cultivationPlant protectionPollutionMelatonin

The invention discloses a method for utilizing melatonin to reduce Pb accumulation amount of vegetables. The method for reducing the Pb accumulation amount of the vegetables comprises the step of spraying a melatonin solution to vegetable crop leaves. According to the method, by spraying the melatonin solution to the radish leaves, the activity of SOD and POD in plants under the threat of Pb can be effectively improved, the increase of the content of soluble protein is facilitated, and therefore the Pb accumulation amount in the fleshy roots and leaves of radishes is obviously reduced. The method has the advantages that the preparation process is simple and convenient, no pollution or drug damage is caused, the problem can be effectively solved that excessive Pb in the fleshy roots of theradishes is accumulated, the green and safe production of radishes is facilitated, and the method has broad application prospects.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

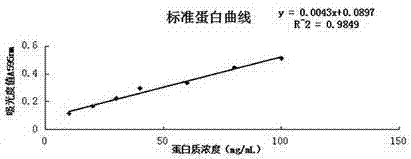

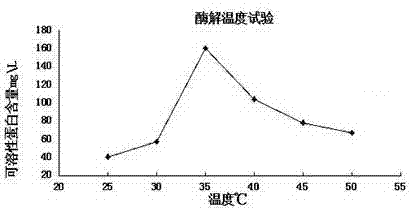

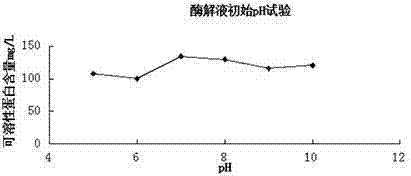

Method of preparing feather protein powder from keratinase

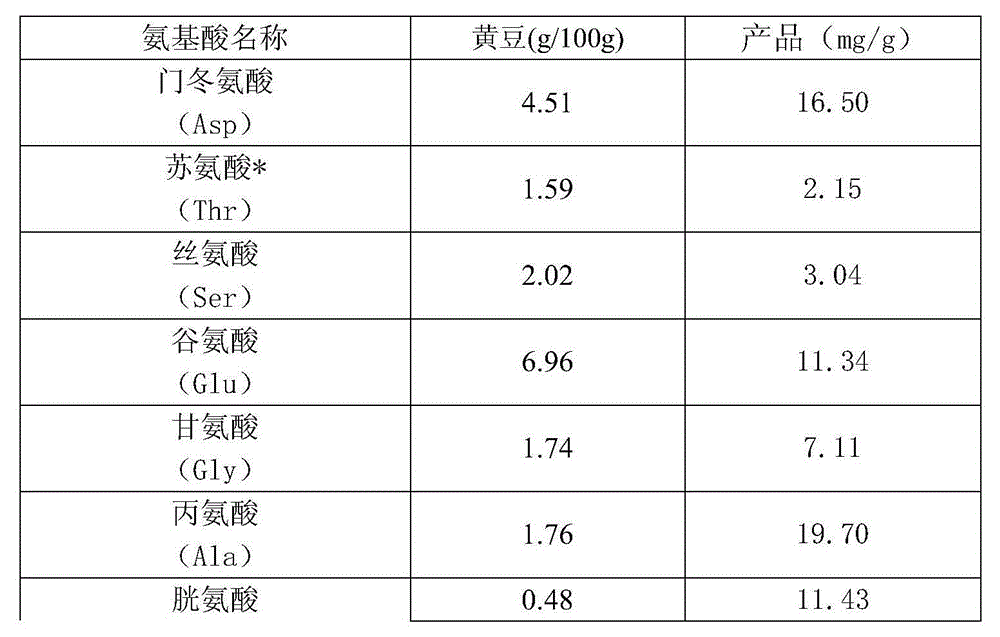

InactiveCN104770574AIncreased soluble protein contentSimple processAnimal feeding stuffFermentationPROTEIN S HEERLENPhenylalanine

The invention relates to the technical field of animal fodder processing, and especially relates to a method of preparing feather protein powder from keratinase. The method takes poultry feathers as the raw material and is characterized by comprising the following steps: (1) preparing feather powder; (2) performing enzymatic hydrolysis; (3) filtering and drying. The technology is simple, the suitable field of the technology is enlarged, the temperature of enzymatic hydrolysis is low, the pH range is wide, the cost of enzymatic hydrolysis is low, and the efficiency of enzymatic hydrolysis is high. The content of soluble protein in the supernate of enzymatic hydrolysis is high, the supernate contains 8 amino acids with a high content, wherein phenylalanine, isoleucine, leucine and valine are essential amino acids; the protein powder can be used to produce amino acid products and added into the feed, thus the production cost is reduced, and the comprehensive economic benefit is increased.

Owner:QILU UNIV OF TECH

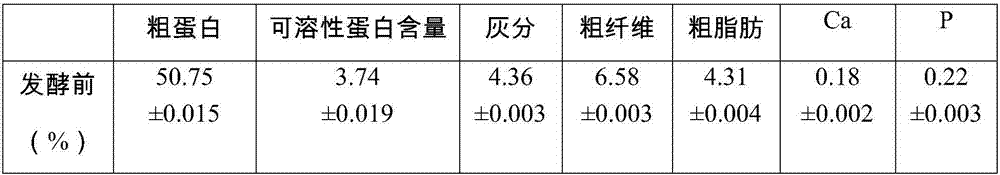

Corn gluten meal functional fermented feed and application thereof

PendingCN107006678AMultiple economic benefitsHigh social valueFood processingAnimal feeding stuffBacillus nattoProtein content

The invention provides corn gluten meal functional fermented feed and a preparation method and application thereof and belongs to the technical field of feed. The corn gluten meal functional fermented feed is a fermentation product of a culture medium containing corn gluten meal and bran under fermentation action of three bacteria. The three bacteria include bacillus subtilis and two of bacillus coagulans, thermophilic lactobacillus, bacillus natto and bear yeast. Soluble protein content in the fermented feed is increased from 3.74% to 270% at most; the novel microbial fermentation feed prepared by adding highly-symbiotic bacteria can bring about more economic benefit and has great social value. By applying the corn gluten meal functional fermented feed in animal raising, growing performance of raised animals is improved effectively while own immunity of the animals can be improved.

Owner:QIQIHAR UNIVERSITY

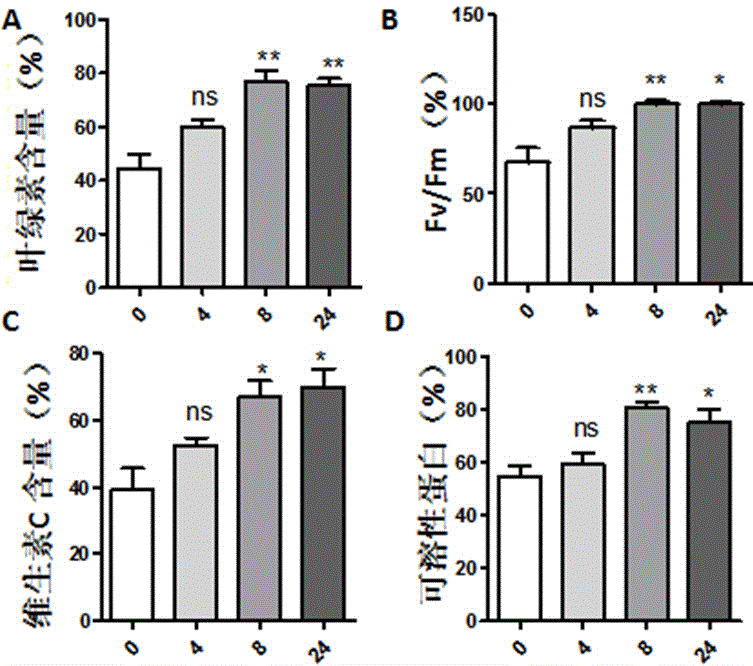

Method for inhibiting leaf senescence and quality decline of picked green-leaf vegetables on basis of red light irradiation

InactiveCN105918430AInhibit quality declineSlow down rateFruits/vegetable preservation by irradiation/electric treatmentVitamin CBiology

The invention belongs to the technical field of vegetable preservation, and especially discloses a method for inhibiting leaf senescence and quality decline of picked green-leaf vegetables on basis of red light irradiation. The red light signals are used for inhibiting the leaf senescence and quality decline processes in the method. The method particularly comprises the following steps: irradiating the picked green-leaf vegetables by utilizing a red LED cold-light source at a temperature condition of 10-20 DEG C for 6-10 hours per day, wherein intensity of the LED cold-light is 10-35 micromoles / m2.s; and preferably, continuously irradiating the picked green-leaf vegetables by utilizing the red LED cold-light source of which the intensity of the LED cold-light is 35 micromoles / m2.s for 8 hours per day. A novel preservation method is provided for transportation, storage and sales of a large amount of the picked green-leaf vegetables by the invention. The method is capable of very obviously slowing down reduction rates of chlorophyll, photosynthetic capacities, vitamin C and soluble proteins in the leaves of the picked green-leaf vegetables; moreover, the method is convenient to use, simple in equipment and low in energy consumption.

Owner:FUDAN UNIV

Fish scale collagen and preparation method and application thereof, and ice cream rich in fish scale collagen and preparation method of ice cream

ActiveCN111218495AImprove proteolysisIncreased soluble protein contentConnective tissue peptidesFrozen sweetsAlkaline proteaseAntioxidant

The invention belongs to the technical field of food processing, and particularly relates to a fish scale collagen and a preparation method and application thereof, and an ice cream rich in the fish scale collagen and a preparation method of the ice cream. The preparation method of the fish scale collagen includes the steps that fish scales are put in an acid solution for decalcifying to obtain decalcified fish scales; water is added to the decalcified fish scales, and fish gelatin is extracted under heating condition to obtain fish gelatin extract; solid-liquid separation is carried out on the fish gelatin extract to obtain fish gelatin; and the fish gelatin is sequentially in contact with alkaline protease and trypsin to be hydrolyzed separately to obtain the fish scale collagen. The fish scale collagen prepared by the preparation method has high proteolysis degree and soluble protein content, the fish scale collagen can be used in the production of ice cream, pomegranate and grape fruit pulp are added, the made ice cream is good in stability, the original product features are achieved, a higher nutritional value and delicate taste are further achieved, and the antioxidant, beauty and skin care effects of the ice cream are improved.

Owner:JIANGXI NORMAL UNIV

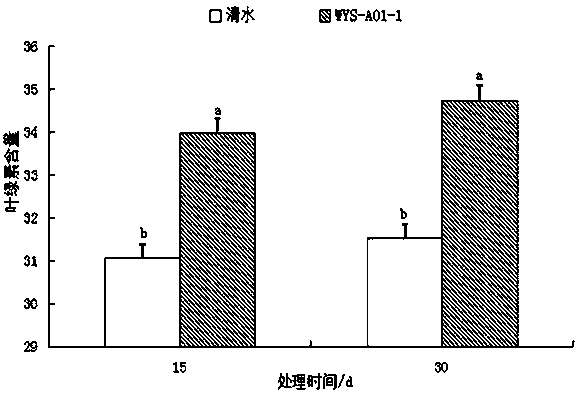

Strain of endophytic phosphate-solubilizing, potassium-solubilizing and nitrogen-fixing acinetobacter calcoaceticus and application thereof

ActiveCN108504608APromote photosynthesisImprove biological enzyme activityBiocidePlant growth regulatorsPhosphatePotassium

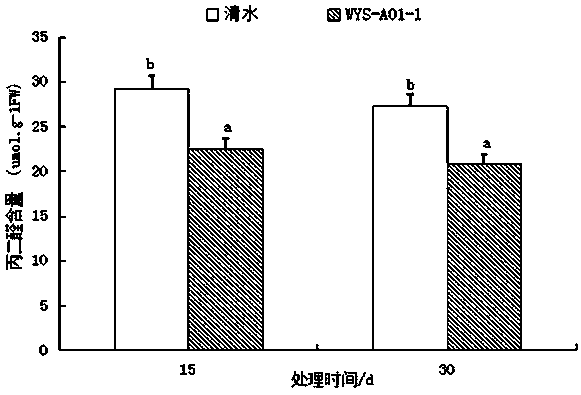

The invention provides a strain of endophytic phosphate-solubilizing, potassium-solubilizing and nitrogen-fixing acinetobacter calcoaceticus and application thereof. The acinetobacter calcoaceticus WYS-A01-1 was deposited in China General Microbiological Culture Collection Center (CGMCC) on July 3, 2017, and the preservation number is: CGMCC No.14378. The endophytic acinetobacter calcoaceticus ofphyllostachys edulis has the functions of solubilizing phosphate, solubilizing potassium and fixing nitrogen, can colonize plants, promote photosynthesis of the phyllostachys edulis, improve biological enzyme activity, and play an important role in regulating plant growth and development.

Owner:福州睿谷生物科技有限公司

Dendrobium officinale cultivation technology

InactiveCN104982169AHigh in nutrientsGood effectClimate change adaptationGreenhouse cultivationGreenhousePolysaccharide

The invention relates to dendrobium officinale cultivation technology, wherein a greenhouse is established; a light reflecting film is covered by section on the greenhouse top; a seedbed is built inside the greenhouse; substrate is set on the seedbed; tissue-cultivated seedlings of dendrobium officinale are firmly planted in the substrate; after the seedlings are firmly planted, the day temperature inside the greenhouse is maintained between 25 DEG C to 35 DEG C and the humidity is controlled between 70 percent to 85 percent; and after the seedlings are firmly planted, the light is controlled by section. According to the invention, the technology steps are simple; the production cost is low; various nutrition contents in the obtained dendrobium officinale is relatively high and the efficacy is good; the light to the dendrobium officinale is controlled by section and the temperature is controlled collaboratively, so the height of a dendrobium officinale plant and the soluble protein content are significantly improved; the metabolism intensity and the reproduction rate of the dendrobium officinale plant are increased; and the polysaccharide content in the dendrobium officinale can arrive at 18 percent, thus the medical value of the dendrobium officinale is greatly increased.

Owner:ANHUI SENYA ECOLOGICAL AGROFORESTRY CO LTD

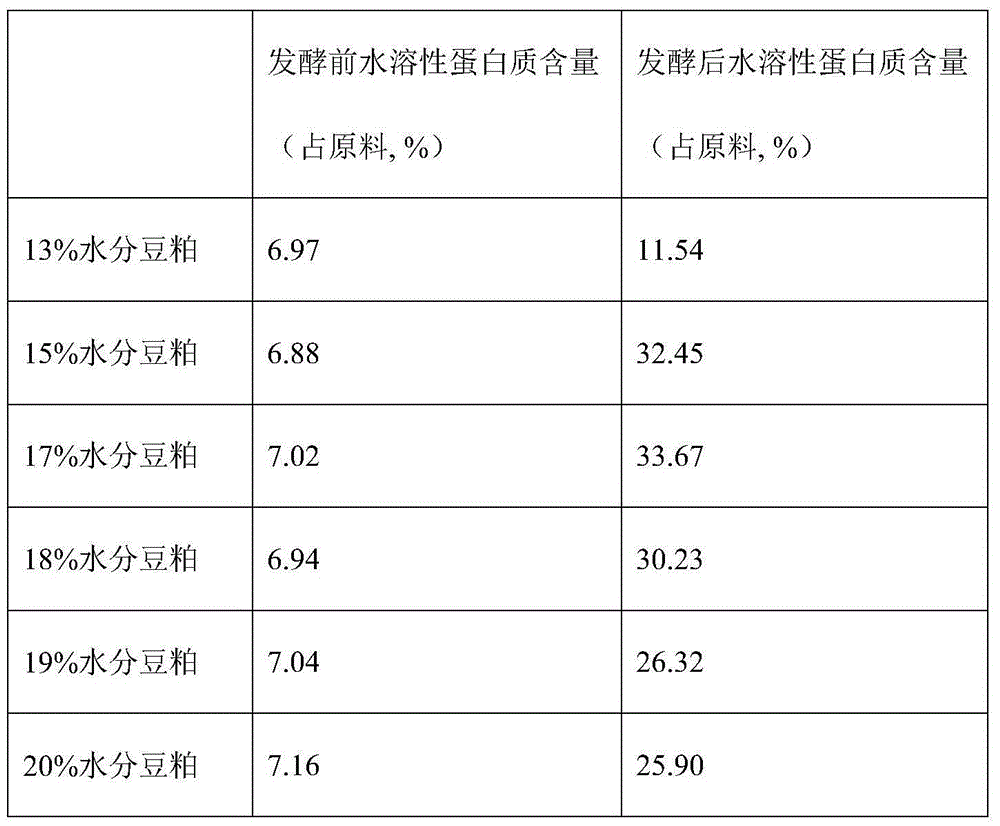

High-solubility fermented soybean meal and preparation method thereof

PendingCN104621345AReduce protein molecular weightPromote digestionAnimal feeding stuffFood processingSolubilityMicroorganism

The present invention provides a high solubility fermented soybean meal and a preparation method thereof. The preparation method comprises of: i) adding water into dried or non-dried desolventizing soybean meal; ii) inoculating microbial strains in the soybean meal after adding water; and iii) fermenting the soybean meal at a temperature of 25 DEG C to 45 DEG C to obtain the fermented soybean meal; and processing the finished products. The fermented soybean meal produced by the present invention contains a water-soluble protein content of more than 25 wt% and a moisture content of less than 13 wt%, and has a high solubility. The present invention also provides the use of the high solubility fermented soybean meal and animal feeds containing the fermented soybean meal.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Application of selenium in preparation of preparation used for improving drought resistance of tobaccos

ActiveCN110642647AImprove growthImprove drought resistanceClimate change adaptationFertilising methodsDrought resistanceAgriculture

The invention discloses application of selenium in preparation of a preparation used for improving the drought resistance of tobaccos, belonging to the technical field of agriculture. According to theinvention, the selenium is in a high valence state. With the prepared preparation, the growth condition of tobaccos in a drought can be improved, and the drought resistance of the tobaccos is enhanced; so the yield and internal quality of the tobaccos are improved, and effective reference is provided for safe production of tobaccos and other grain crops.

Owner:HENAN AGRICULTURAL UNIVERSITY

Composite initiator for improving activity of deteriorated seeds of angelicae dahurica and application of composite initiator

ActiveCN107232228AImprove germination ratePromote germinationBiocidePlant growth regulatorsActivity indexGermination

The invention discloses a composite initiator for improving the activity of deteriorated seeds of angelicae dahurica and an application of the composite initiator. The seeds of angelicae dahurica are subjected to initiation treatment through NaCl, KNO3 and PEG in different proportions, and influence of different kinds of initiation treatment on the activity of the deteriorated seeds of angelicae dahurica is analyzed by measuring germination indexes and physical indexes of the seeds subjected to different kinds of initiation treatment. Experimental results indicate that after the seeds of angelicae dahurica are subjected to initiation treatment through the composite initiator in the best treatment combination, the germination rate, the germination potential, the germination index, the activity index, soluble protein and the POD activity of the seeds of angelicae dahurica are all increased to different extents, and the electric conductivity is reduced. With the adoption of the composite initiator, damaged membrane systems of the deteriorated seeds are improved and restored, the electric conductivity of leaching liquor of the deteriorated seeds is reduced, the content of the soluble protein is increased, the POD activity and the seed vigor are improved, and a basis is provided for sowing of the seeds of angelicae dahurica in a field as well as drug production.

Owner:SICHUAN ACAD OF CHINESE MEDICINE SCI

Bio-organic fertilizer prepared from distillers' grains as well as preparation method and application of bio-organic fertilizer

ActiveCN108383580AIncrease enzyme activityMany types of enzymesFungiBioloigcal waste fertilisersSaccharomycopsis fibuligeraBacillus megaterium

The invention relates to bio-organic fertilizer prepared from distillers' grains as well as a preparation method and application of the bio-organic fertilizer, belonging to the technical field of bio-organic fertilizer. The preparation method of the bio-organic fertilizer prepared from the distillers' grains comprises the steps of adding one-thousandth biochemical potassium fulvate into decomposeddistillers' grains, evenly mixing, crushing the mixing by using a semi-wet material crusher, sieving with a 3-4mm rotary screen, then adding 5% jelly-like bacillus subtilis powder (living bacterium quantity: 10<9>cfu / g), 5% bacillus megaterium powder (living bacterium quantity: 10<10>cfu / g) and five-thousandth bacillus amyloliquefaciens powder (living bacterium quantity: 10<11>cfu / g). The decomposed distillers' grains microbial agent contains a preserved strain, i.e., saccharomycopsis fibuligera Y-1, and the preservation number of the preserved strain is China General Microbiological CultureCollection Center (CGMCC) No. 15255. The bio-organic fertilizer prepared from the distillers' grains can be used for various crops, is especially applied to winter jujubes, and can significantly improve the sizes, yield and quality of the fruits of the winter jujubes.

Owner:陕西枫丹百丽生物科技有限公司

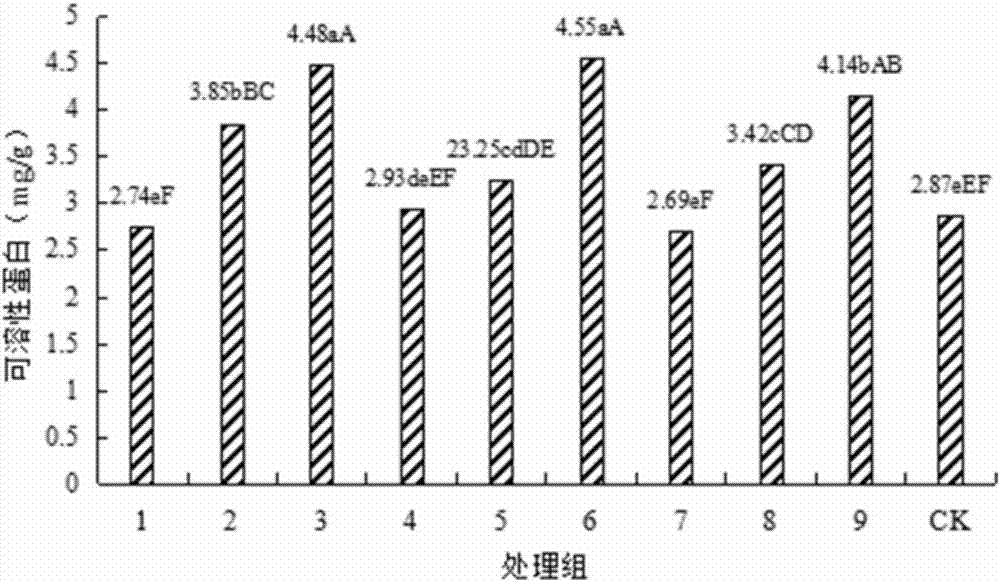

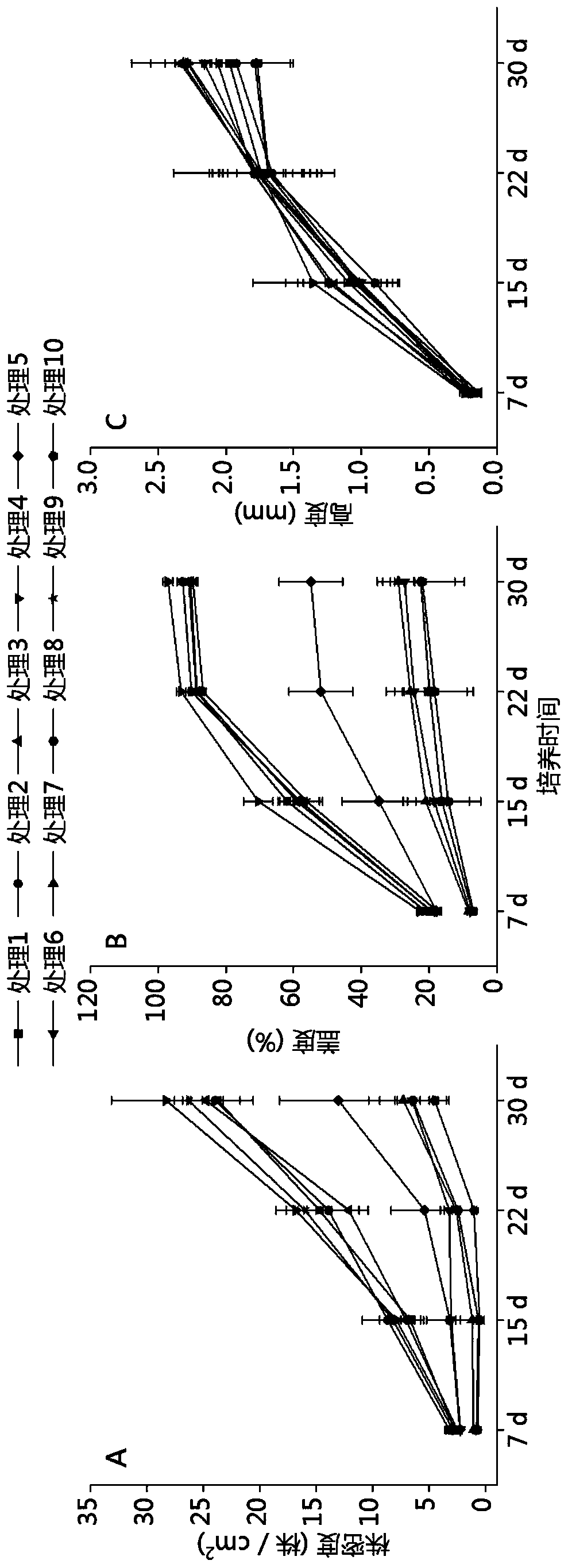

Efficient propagation method for sandy moss provenance

InactiveCN111557221AImprove water retentionHigh activityGrowth substratesCulture mediaEnvironmental engineeringChlorella sp.

The invention provides an efficient propagation method for sandy moss provenance, and relates to the technical field of environmental engineering. The method comprises the following steps: taking mosscrust naturally developed in a Mu Us Desert sand land as the provenance, taking disinfected sandy soil as a matrix, adding actinomycetes and chlorella, and inoculating and crushing the sand moss provenance, wherein only 0.24 m<2> of field moss provenance is needed, 1 m<2> of stable moss crust can be cultivated and formed within 30 days under the condition of an incubator, and 4-time propagation is achieved; and the cover degree, the plant density and the plant height respectively reach 97.14%, 28.31 plants / cm<2> and 2.28mm. The method is an effective method for efficiently cultivating the sandy moss crust under the condition of manual control, provides reference for factory propagation practice of the moss provenance in the future, and lays a foundation for solving the bottleneck problemof insufficient field engineering provenance recovery of the moss crust.

Owner:NORTHWEST A & F UNIV

Anti-stress feed capable of improving immunity of leiocassis longirostris 30-60 days old

InactiveCN106071128AMeeting nutritional needsReduce pollutionFood processingAnimal feeding stuffBiotechnologyAnti stress

The invention discloses anti-stress feed capable of improving immunity of leiocassis longirostris 30-60 days old. The feed is prepared from, by weight, 15-25 parts of extruded soybean, 10-20 parts of silkworm chrysalis meal, 5-15 parts of modified corn protein powder, 10-20 parts of cuttlefish meal, 10-20 parts of rapeseed meal, 8-16 parts of artemia, 5-15 parts of dunaliella salina, 5-12 parts of bone meal, 0.5-1.5 parts of sea mud, 12-20 parts of gulfweed, 2-10 parts of bran, 8-15 parts of greater selaginella, 1-4 parts of yeast polypeptide powder, 0.8-1.6 parts of malt, 0.5-2.5 parts of choline chloride, 0.5-2 parts of calcium dihydrogenphosphate, 1.2-2.2 parts of multi-vitamin, 1-2 parts of high-temperature-resistant phytase, 2-10 parts of soybean phospholipids oil and 0.5-1.5 parts of Chinese herbal medicine. The feed can meet nutrient requirements of leiocassis longirostris 30-60 days old, promotes quick growth of leiocassis longirostris, improves immunity and anti-stress capability, and reduces environment pollution of breeding water.

Owner:全椒县鮰鱼养殖专业合作社

Method for preparing soybean straw feed

InactiveCN109770060AIncreased soluble protein contentImprove palatabilityFood processingAnimal feeding stuffWeight gainingDihydrocapsaicin

The invention discloses a method for preparing soybean straw feed. After being diluted by water, cellulase and lactobacillus series are mixed proportionally, then sprayed to the surface of straw and turned and mixed to be uniform; after the sectioned straw is compacted, a plastic film coats the sectioned straw so that the straw and air can be isolated, and after sealed storage for 90 d, the soybean straw feed can be obtained. According to the method, the content of soluble protein, reducing sugar and lactic acid in soybean straw can be remarkably increased, and the palatability of the feed isimproved; on the basis, a small amount of dihydrocapsaicin and tricin is added, the sheep immunity can be effectively improved, and the weight gaining effect is obvious.

Owner:TIANCHANG PENGSHI SHEEP IND

Preparation method for rice milk beverage with pleasant flavor

InactiveCN107365653AImprove functional propertiesIncreased soluble protein contentAlcoholic beverage preparationFlavorAlkaline protease

The invention discloses a preparation method for a rice milk beverage with pleasant flavor. The preparation method comprises the following steps that rice is pretreated and then placed into a water bath vibrator, alkaline protease is added for enzymolysis, inactivation is conduced, and the system pH value is adjusted to be neutral; micronization treatment is conducted, dried yeast is added for fermentation, sterilization and spray drying are conducted, and then a first material is obtained; water is added into the first material, the system pH value is adjusted to be 6.4-6.7, gelatinization treatment is conducted, and then a second material is obtained; and maltose, sodium alginate and sodium carboxymethylcellulose are added into the second material and then are stirred to be uniform, olive oil is added to conduct emulsification treatment, then a mixture is sent to be subjected to homogenization treatment, sterilization is conducted, and then the rice milk beverage with the pleasant flavor is obtained. According to the preparation method, the obtained rice milk beverage is smooth and rich in tasting, rich in fragrance, extremely rich in nutrient substance and low in cost.

Owner:全椒县崇明米业有限公司

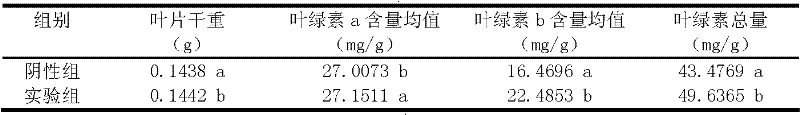

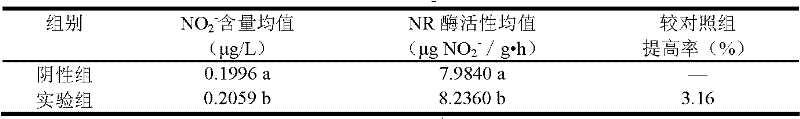

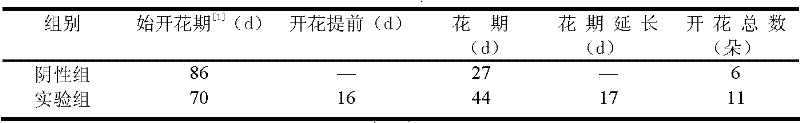

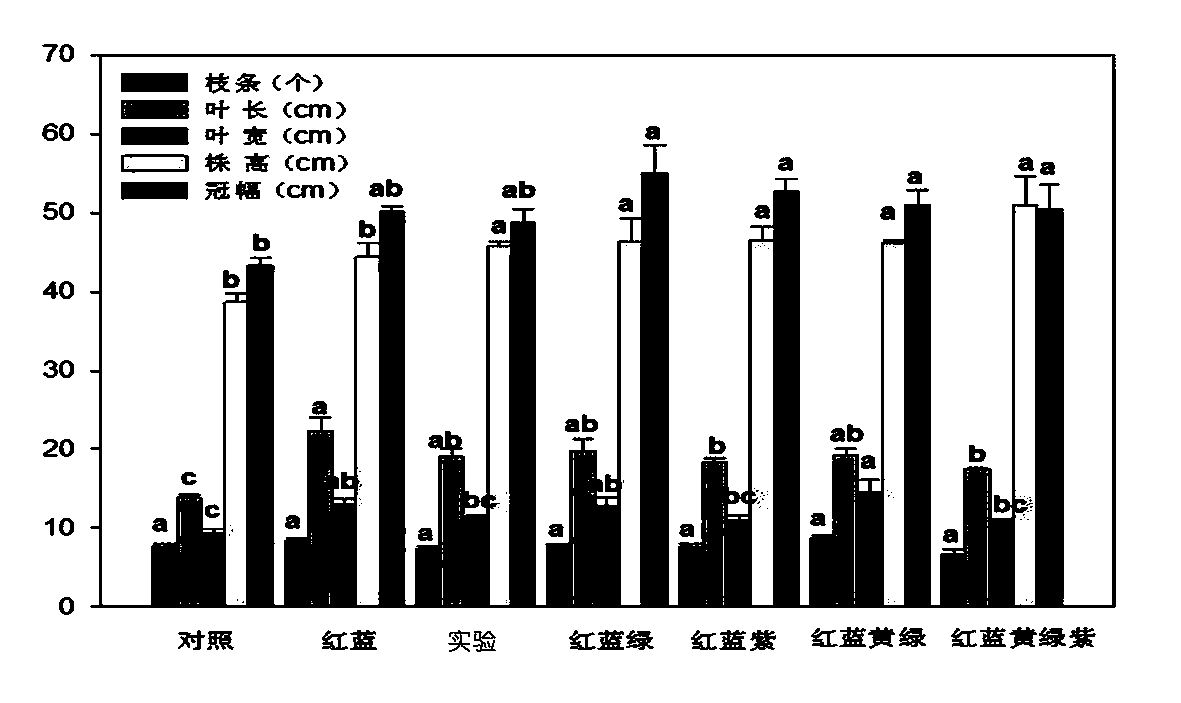

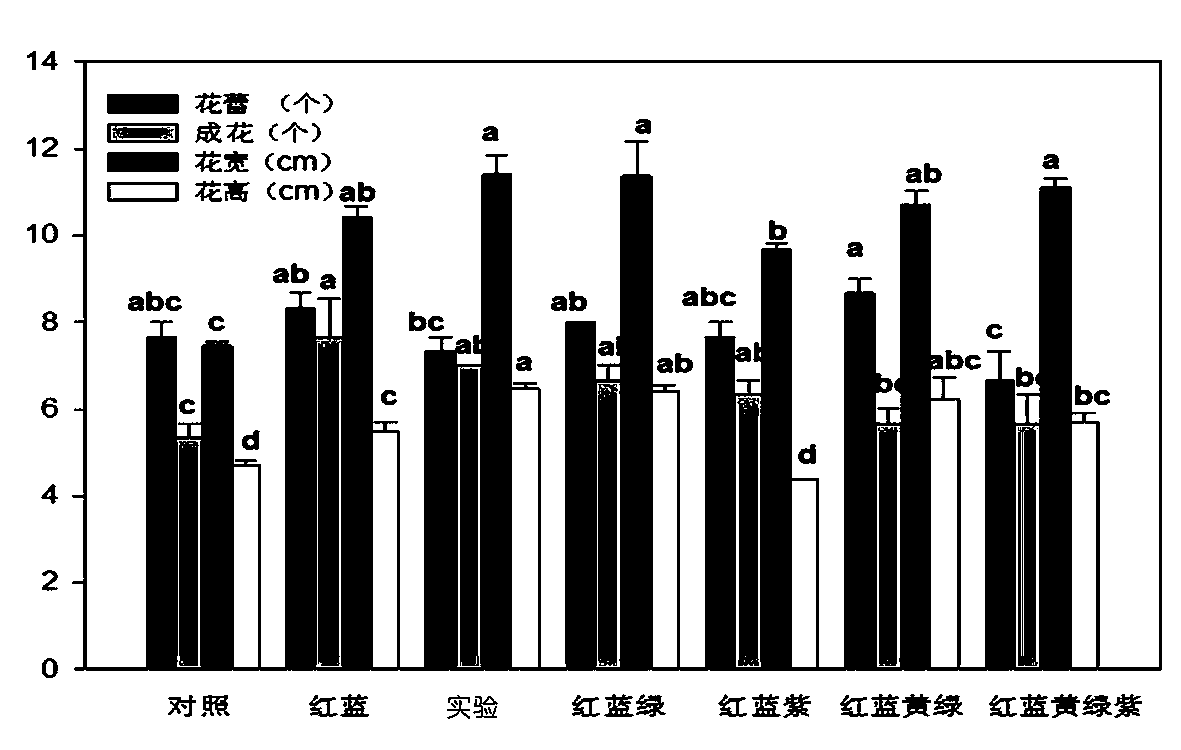

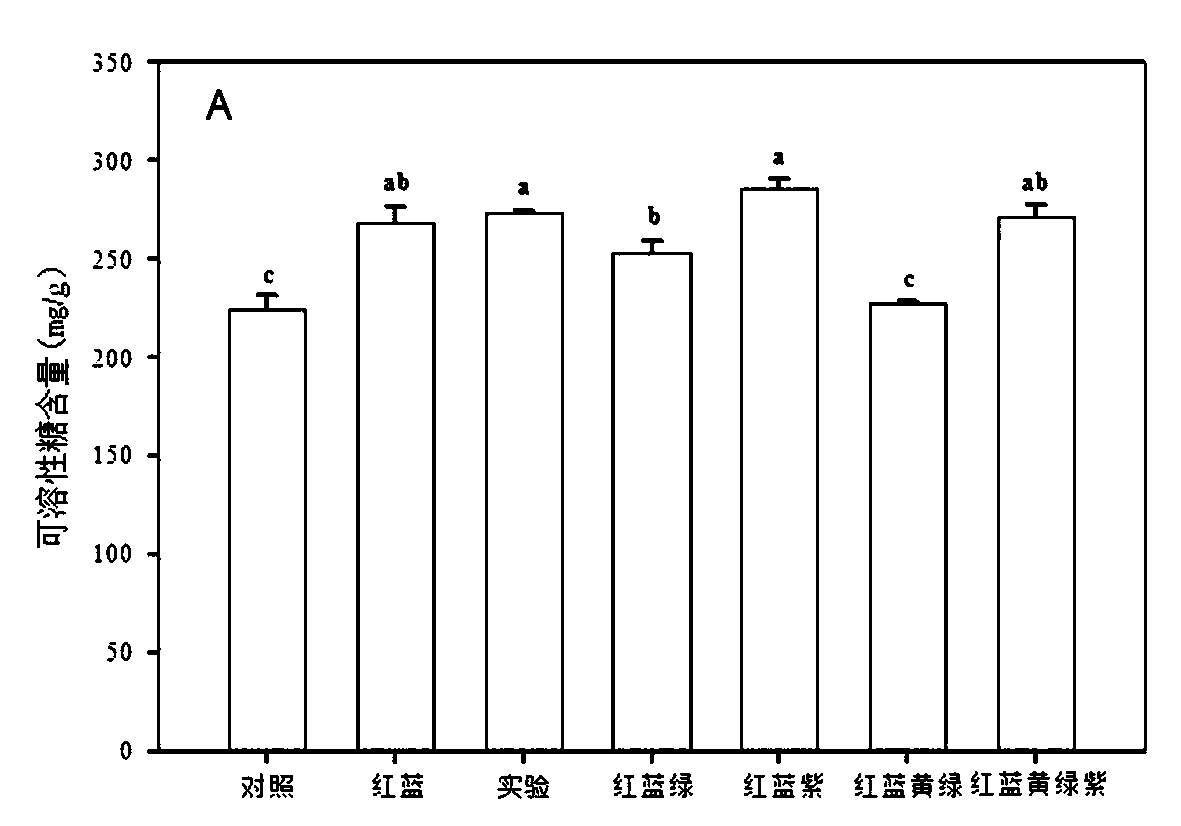

Supplementing lighting method for improving cultivating quality of peonies for Lunar New Year

ActiveCN103814762AAdequate nutritionProlong flowering periodSaving energy measuresHorticulture methodsMaterials sciencePhotochemistry

Disclosed is a supplementing lighting method for improving cultivating quality of peonies for the Lunar New Year. The supplementing lighting method includes that different light rays are adopted in different growing stages of the peonies for supplementing lighting; for the germination stage, composite light with lighting intensity of 150-180Lux and formed by blue light and yellow light according to a proportion of 3-1:2-1 is adopted; for the squaring stage, composite light with lighting intensity of 160-210Lux and formed by red light and blue light according to a proportion of 3-1:2-1 is adopted; for the small wind bell stage, composite light with lighting intensity of 170-200Lux and formed by red light, blue light and yellow light according to a proportion of 3-1:2-1:2-1; for the big wind bell stage, composite light with lighting intensity of 170-200Lux and formed by red light, blue light and yellow light according to a proportion of 3-1:2-1:2-1; for the garden-peach color transparency stage, composite light with lighting intensity of 170-200Lux and formed by red light, blue light and yellow light according to a proportion of 3-1:2-1:2-1; for a week before the flowering stage, composite light of red light, blue light and yellow light according to a proportion of 3-1:2-1:2-1 is adopted; for a week after flowering, composite light of red light and blue light according to a proportion of 3-1:2-1 is adopted. By the supplementary lighting method, influences are generated on biological characteristics of peony plants, and nutritional growing and flowering quality of the peonies for the Lunar New Year is improved remarkably.

Owner:HENAN UNIV OF SCI & TECH

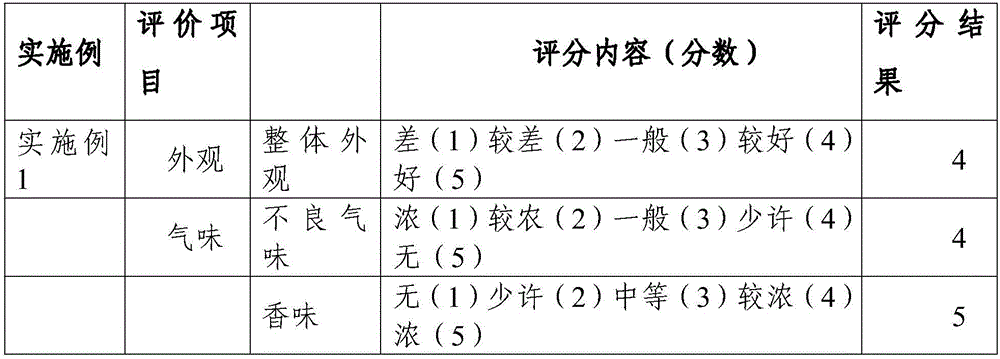

Soy sauce flavor type food nutrition additive used for flavoring and preparation method thereof

The invention discloses a soy sauce flavor type food nutrition additive used for flavoring and a preparation method thereof. The preparation method includes cooking and cooling beans subjected to water absorption treatment, making starter and fermenting; washing off mildew and fermenting without salt and insulating heat; adding water to fermented bean cake, stirring and soaking, transferring soluble components in the fermented beans into water phase; decocting and concentrating to obtain paste by water phase. The food nutrition additive has low salt, high nutrition content and long shelf life under the condition of no any other additives, is mellow in flavor and convenient to use, and has taste similar to real food and heavy fermented soy bean scent.

Owner:HUNAN AGRICULTURAL UNIV

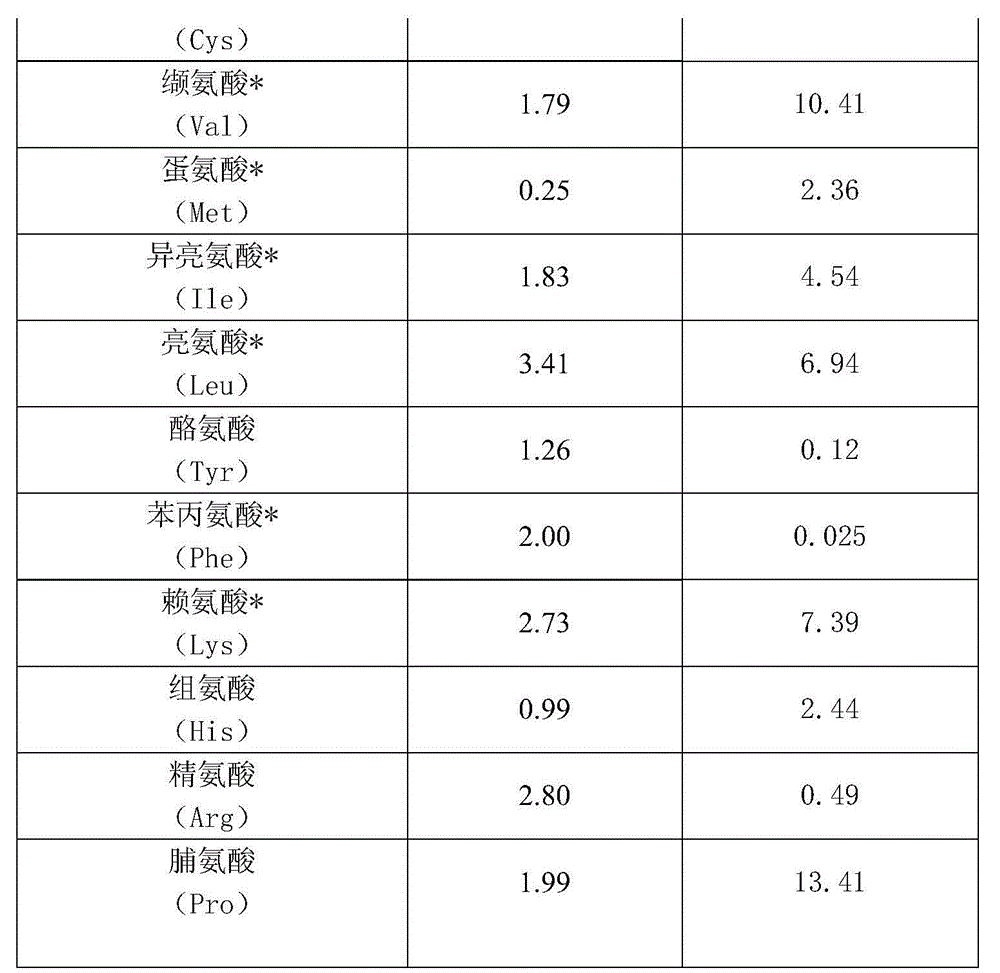

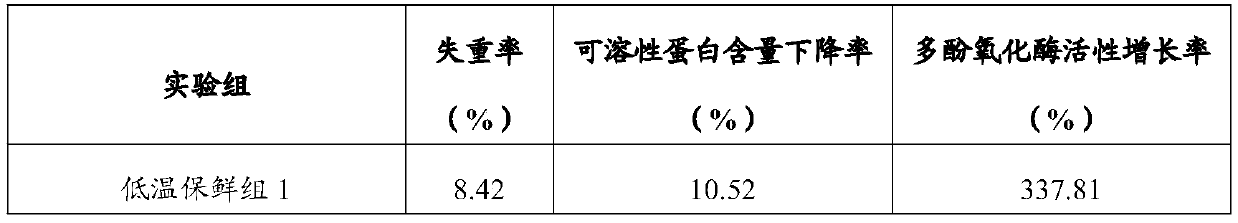

Liquid nitrogen combined liquid carbon dioxide quick-frozen and fresh-keeping method for fresh cordyceps sinensis

ActiveCN109717356AReduce weight lossIncrease soluble protein contentClimate change adaptationFood preservationProtein contentCitric acid

The invention relates to a liquid nitrogen combined liquid carbon dioxide quick-frozen and fresh-keeping method for fresh cordyceps sinensis, and belongs to the technical field of cordyceps sinensis fresh-keeping. The method includes the following steps: 1) cleaning cordyceps sinensis with water; 2) performing ultrasonic cleaning on the cleaned cordyceps sinensis; 3) soaking the cordyceps sinensisin a low temperature protective agent; 4) placing the soaked cordyceps sinensis in a tunnel quick freezing device, spraying acetic acid / citric acid and liquid nitrogen mist, continuously spraying liquid CO2; 5) spraying the quick-frozen cordyceps sinensis with an antistaling agent; 6) performing modified atmosphere packaging on the cordyceps sinensis sprayed with the antistaling agent; and 7) performing refrigeration on the modified atmosphere packaged cordyceps sinensis. The method can solve the problem of the reduction of the freshness of the cordyceps sinensis during fresh-keeping, and islow in weight loss rate, high in soluble protein content and low in polyphenol oxidase activity.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Process for preparing liquid fertilizer by using enzymolysis and fermentation of animal bloods and taking oil supply angle as defoaming agent

ActiveCN103145459AIncrease enzyme activityInhibition of reproductionBio-organic fraction processingOrganic fertilisersDecompositionFeed additive

The invention discloses a process for preparing a liquid fertilizer by using the enzymolysis and fermentation of animal bloods and taking an oil supply angle as a defoaming agent, and belongs to the technical field of bioengineering. For solving the problems that in the past, the bloods poured from slaughterhouses in the process of red overglazing are all used as a raw material for producing feed additives, once the bloods are not cleaned and transported timely, the potential safety hazards of feeds caused by the decomposition of the bloods, the environmental pollution caused by organic wastewater, and the economic losses are caused, the invention provides a process for preparing a liquid fertilizer by using the enzymolysis and fermentation of animal bloods and taking an oil supply angle as a defoaming agent, and the process is implemented by taking animal bloods (pig blood, cattle blood, sheep blood and donkey blood and the like) as the main raw materials of a fermentation substrate and being supplemented by brown sugar, white sugar, an oil supply angle, protease, associated strains, wherein the oil supply angle especially achieves an important effect of preventing the losses of materials caused by overflowing in the process of heating and sterilization of raw and auxiliary materials, thereby avoiding the secondary pollution of the environment, and meanwhile, the organic phosphorus content is increased.

Owner:HEILONGJIANG WANGTU FERTILIZER IND

Rice high-temperature-resistant preparation and application method thereof

ActiveCN108925583AImprove the ability to resist high temperature heat damageAnti agingPlant growth regulatorsBiocidePhosphateHectare

The invention discloses a rice high-temperature-resistant preparation and an application method thereof. The rice high-temperature-resistant preparation is a mixed solution of 0.2 to 0.4% of potassiumdihydrogen phosphate, 0.2 to 0.3% of calcium chloride and 0.06 to 0.08% of sodium silicate nonahydrate. When rice encounters high temperature and heat damage weather in heading and flowering periods,the rice high-temperature-resistant preparation is sprayed to a rice field at 6: 00 to 8: 00 every day, and is required to be uniformly sprayed onto rice leaves until droplets of the rice high-temperature-resistant preparation uniformly and fully cover the rice leaves; and the spraying amount of the rice high-temperature-resistant preparation is 900 to 11000 kg of the rice high-temperature-resistant preparation in per hectare of the rice field. The rice high-temperature-resistant preparation and the application method thereof provided by the invention can significantly retard senescence of the rice leaves, increases the photosynthetic rate of the rice leaves and the yield of the rice, and achieves the purpose of improving high-temperature and heat-damage resistant abilities of the rice.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Production method of raw milk lactic acid bacteria antimicrobial peptide additive for livestock and poultry

InactiveCN103250867AThe production strain is clearLow in Anti-Nutritional FactorsAnimal feeding stuffBiotechnologyAntimicrobial peptides

The invention discloses a production method of a raw milk lactic acid bacteria antimicrobial peptide additive for livestock and poultry, relates to a production method of fermentation in various plant feed proteins and solves problems that the production strains of the antimicrobial peptide additive for the livestock and the poultry is undefined and the activity of antimicrobial peptide is low. The production method comprises the following steps that 1, frozen Lactobacillus acidophilus strains and Lactobacillus casei are activated by MRS culture mediums and then are respectively inoculated in enrichment mediums so that the enrichment culture solution is obtained; 2, the enrichment culture solution is inoculated in a seed culture medium and then is fermented at 35-40 DEG C to obtain a seed culture solution; 3, the seed culture solution is inoculated to the fermentation culture medium again to be fermented to obtain fermentation products; and 4, the fermentation products are dried, dehydrated, crushed and mixed to obtain the lactic acid bacteria antimicrobial peptide additive. The bacteria antimicrobial peptide additive obtained by the production method disclosed by the invention has defined strains, the activity of the antimicrobial peptide is high, and the obtained bacteria antimicrobial peptide additive is mainly applied to prevention and cure of disease of digestive tract of the livestock and poultry.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com