Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

304 results about "Keratinase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Keratinases are proteolytic enzymes that digest keratin.

Keratinase-proudicng bacterium and its preparation method

InactiveCN1800358AImprove stabilityImprove thermal stabilityBacteriaMicroorganism based processesWater bathsSystematic name

The invention relates to a keratinase generating bacteria and it's preparing method. The systematic name is Bacillus subtilis with the registration number: CGMCC No.1505. It sieves the best strains of the keratinase whose best PH value of the course enzyme liquid enzyme reaction is about 7.5-8.0 and the best temperature is 50-60 deg. It keeps the temperature in 70 deg. water-bath with 30 min, the surplus enzyme is about 90%; it keeps the temperature with 120 min, the surplus enzyme is about 70%.

Owner:YUNNAN NORMAL UNIV

Microbial feed additive and preparation method thereof

ActiveCN101869184AImprove conversion utilizationPromote digestion and absorptionAnimal feeding stuffAbsorption capacityMetabolite

The invention relates to a method for preparing a microbial feed additive. Feather meal, mannitol, glucose, sodium citrate, sodium chloride and the like are taken as raw materials, and inoculated with Bacullus subtilis YYW-1 with the number of CGMCC NO.2396 to prepare the microbial feed additive by submerged fermentation and spin flash drying technology. The active ingredients of the microbial feed additive are the Bacullus subtilis and cultures thereof, and the cultures contain metabolites such as keratinase capable of efficiently degrading feather. The product can be used in the breeding industry and the feed industry, and has the advantages of improving intestinal flora, improving digestion and absorption capacity of animals and the feed conversion and utilization rate, particularly promoting the digestion, absorption and utilization of protein materials such as the feather meal, and reducing cost.

Owner:山东省农业科学院高新技术研究中心

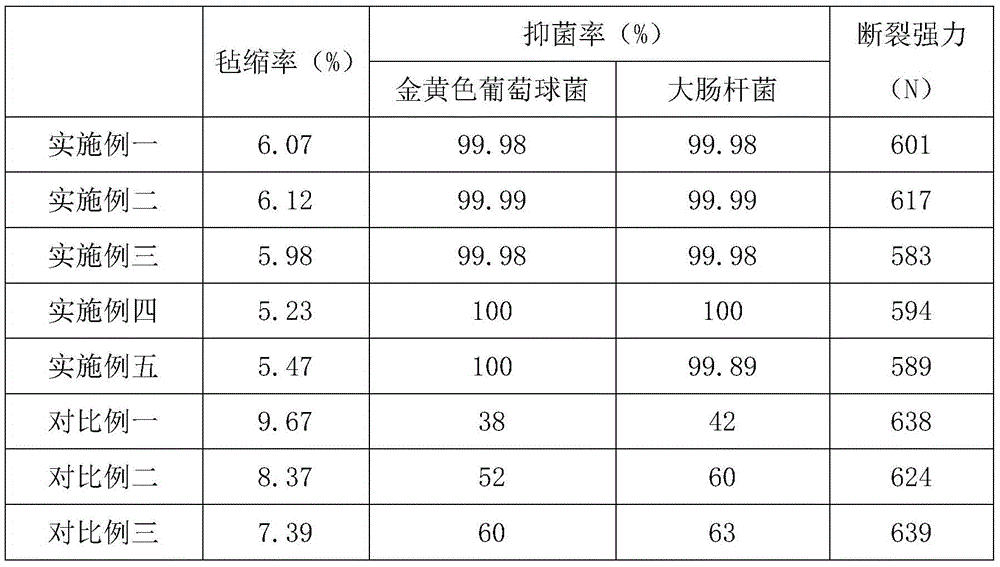

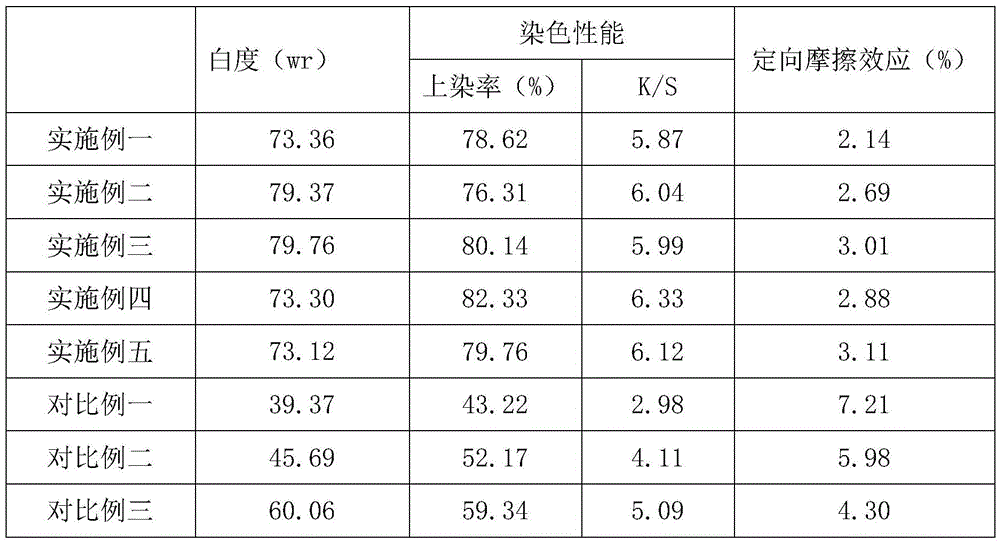

Antibacterial and anti-felting wool fabric finishing method

InactiveCN105544198AImprove antibacterial propertiesPrevent intrusionBiochemical treatment with enzymes/microorganismsShrinking resistant fibresTextile technologyFriction effect

Owner:海阳英伦纺织有限公司

Protease with improved thermal stability as well as construction method and application thereof

The invention discloses keratinase with improved thermal stability and application thereof, and belongs to the field of genetic engineering. The keratinase (ker) gene of bacillus licheniformis BBE11-1 is subjected to site-directed mutation by using a site-directed mutation technology and is cloned and linked to a bacillus subtilis expression vector pMA 0911; and bacillus subtilis WB600 is transformed, and a bacillus subtilis WB600-pMA 0911-kerTB capable of producing the keratinase with better thermal stability can be obtained through purification tests. The keratinase expressed by a strain at T1 / 2 at 60 DEG C lasts for 78min, which is improved nearby 9 folds compared with wild type keratinase at T1 / 2. The keratinase with improved thermal stability lays an excellent foundation for the application of keratinase.

Owner:JIANGNAN UNIV

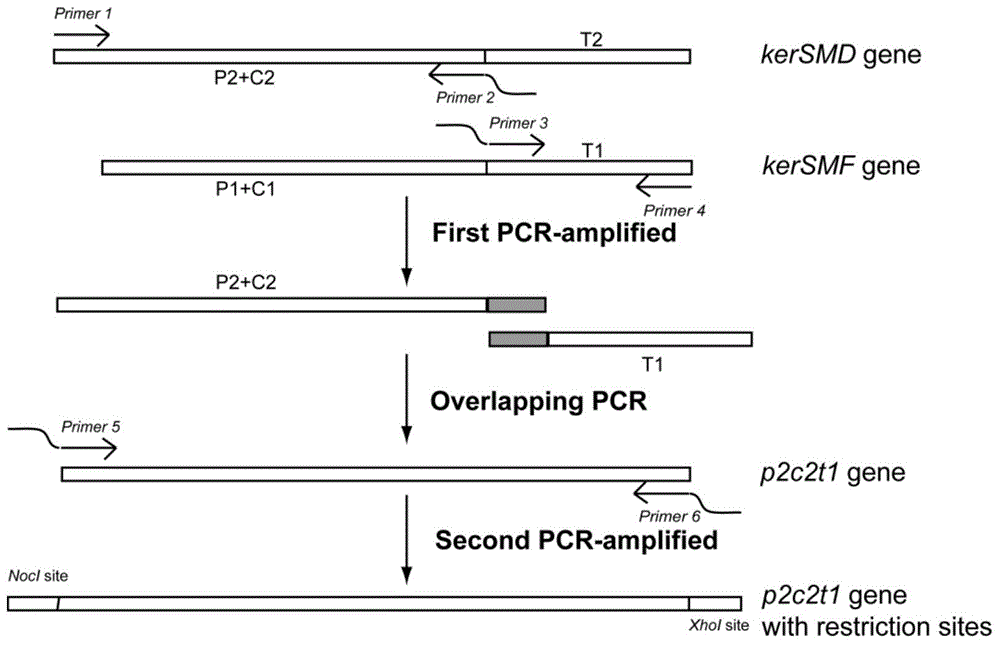

Keratinase mutant with improved thermal stability and preparation method thereof

ActiveCN104017791AImprove thermal stabilityIncrease enzyme activityBacteriaHydrolasesWater insolubleHigh homology

The invention discloses a keratinase mutant with improved thermal stability and a preparation method thereof, and belongs to the field of enzyme engineering. Thermal stability and substrate specificity of the keratinase are improved by interchanging N ends or C ends of two different keratinases with higher homology from the same bacterial strain. The keratinase and the mutant thereof can effectively hydrolyze water-insoluble keratinase substrates such as feathers, wools, and the like, and can be used for leather spinning industry and feed industry.

Owner:JIANGNAN UNIV

Strain for generating keratinase and application thereof

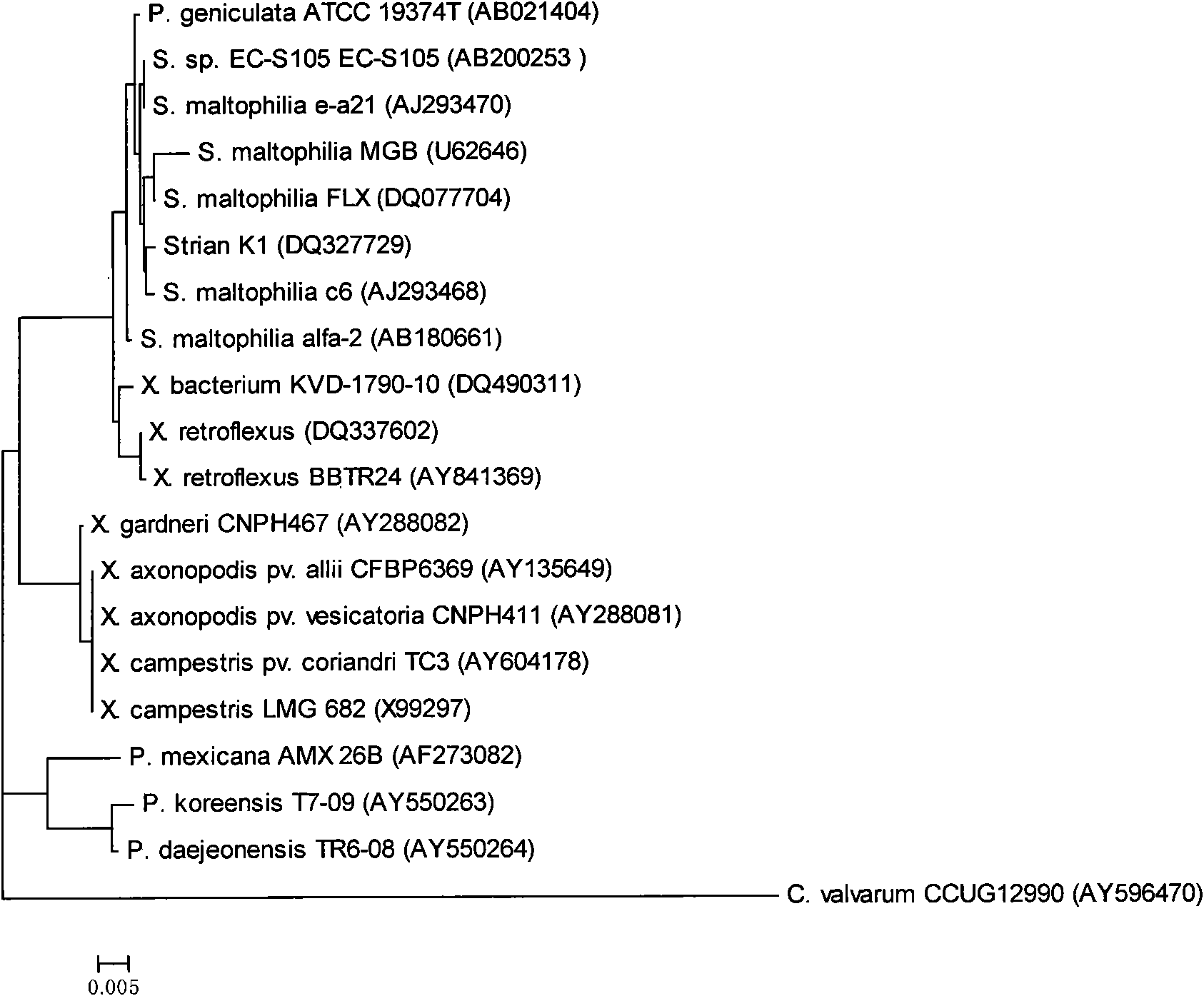

InactiveCN101580807AExtended biodegradable rangeMild degradation conditionsBacteriaHydrolasesBiotechnologyStenotrophomonas maltophilia

The invention relates to a strain for generating keratinase and an application thereof. The strain is Stenotrophomonas maltophilia) DHHJ CGMCC No.2231 applied to the degradation of soft keratin, such as chicken feathers, pigeon feathers, cow hair, wool, hair and hard keratin, such as ox horns, goat horns, sheep hoofs and nail waste. Compared with other strains for degrading the keratin, the strain has mild fermentation conditions, is convenient to apply and can generate the keratinase with higher enzymatic activity and stability.

Owner:DONGHUA UNIV

Bacillus cereus producing keratinase and application thereof

PendingCN107868762APromote degradationStable enzyme productionBacteriaAnimal feeding stuffMicroorganismBacillus cereus

The invention belongs to the field of microorganism, particularly relates to ((i) bacillus cereus ( / i)) Y-15 for efficiently degrading feather keratin, and further relates to application of the ((i) bacillus cereus ( / i)) Y-15. The ((i) bacillus cereus ( / i)) Y-15 is preserved in China General Microbiological Culture Collection Center in June 6, 2017, with the culture preservation number being CGMCCNO. 14221; the colonial morphology on a milk screening plate is as follows: bacterial colony is white and circular, the waxiness on the surface is non-transparent, and the edge is wavelike; gram staining shows a positive result, and the thallus is bacilliform. The ((i) bacillus cereus ( / i)) Y-15 screened and cultured has excellent degradation effect on keratin.

Owner:BIOTECH RES CENT SHANDONG ACADEMY OF AGRI SCI

Bio-organic fertilizer of poultry feather amino acid and preparation method of same

InactiveCN105000923AImprove biological activityReduce pollutionBio-organic fraction processingOrganic fertiliser preparationDiseaseBiotechnology

The present invention discloses a bio-organic fertilizer of a poultry feather amino acid and a preparation method of the same. According to the present invention, bacillus amyloliquefaciens, moist cellulomonas cartae and trichoderma viride that can efficiently secrete keratinase are used to perform fermentation and enzymatic hydrolysis on a mixture of poultry feathers and edible fungi residues; then anti-disease bacteria and solubilizing and potassium bacteria are added in an aging phase to perform secondary fermentation; mature materials are milled and sieved; and the bio-organic fertilizer of the poultry feather amino acid is prepared and obtained. The bio-organic fertilizer not only has a high content of organic matter and a high content of humic acid that are capable of soil amelioration, but also has a high content and various types of amino acids that are capable of crop production increasing and quality improving; the added functional microorganisms are capable of disease resisting, and further capable of releasing poorly soluble potassium and phosphorus in the soil to an absorbable and usable form; and applying the bio-organic fertilizer to the production can reduce the quantity of applied pesticides and fertilizers and produce safe and healthy agricultural products, and has a very wide application prospect.

Owner:GUANGDONG INST OF MICROORGANISM +1

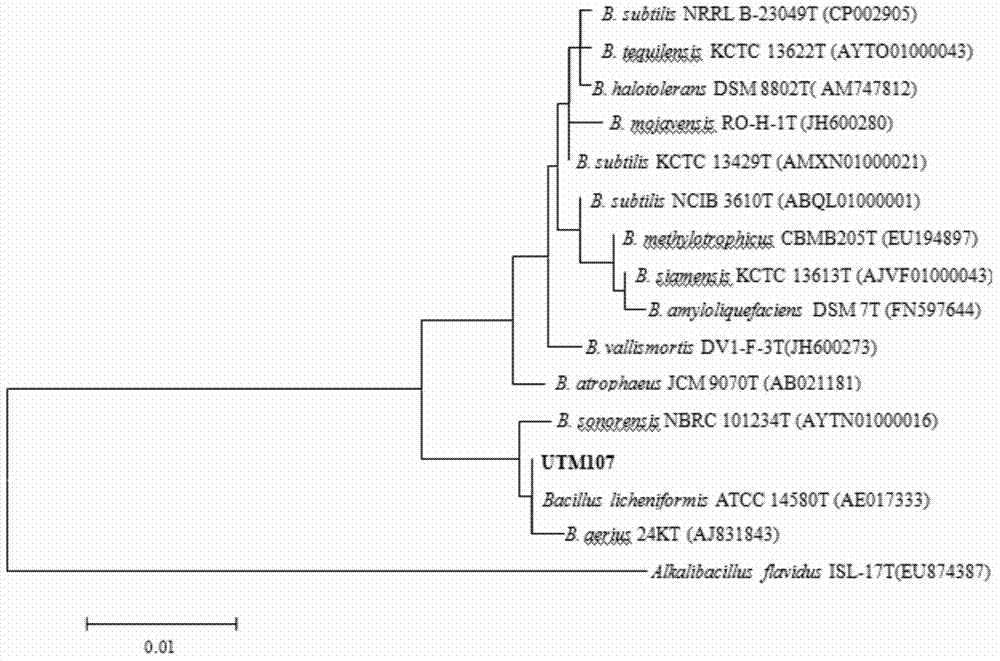

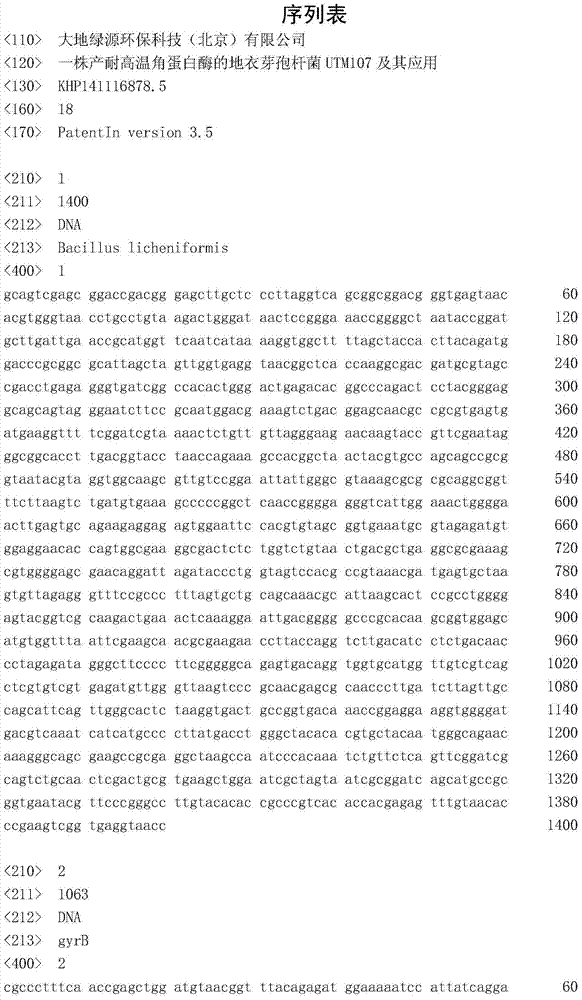

Bacillus licheniformis UTM107 producing high-temperature-resistant keratinase and application thereof

The invention provides bacillus licheniformis (Bacillus licheniformis) UTM107 producing high-temperature-resistant keratinase and application thereof. The strain has the biological collection number of CGMCC No.9678. The UTM107 strain can be used for aerobic composting fermentation in downflow sludge, household refuse, kitchen wastes, carcass, excrements of livestocks and other wastes, the temperature can reach 80-90 DEG C in the fermentation process, the highest temperature can be over 100 DEG C, the high temperature can be maintained for a long time, and organic matters in the wastes can be effectively decomposed. The bio-fertilizer prepared by the strain disclosed by the invention is environment-friendly and excellent in performance, and harmlessness, reduction and recycling can be realized when the UTM107 strain is used for treating the organic solid wastes. The bio-fertilizer prepared by the invention is environment-friendly and excellent in performance.

Owner:大地绿源环保科技(北京)有限公司

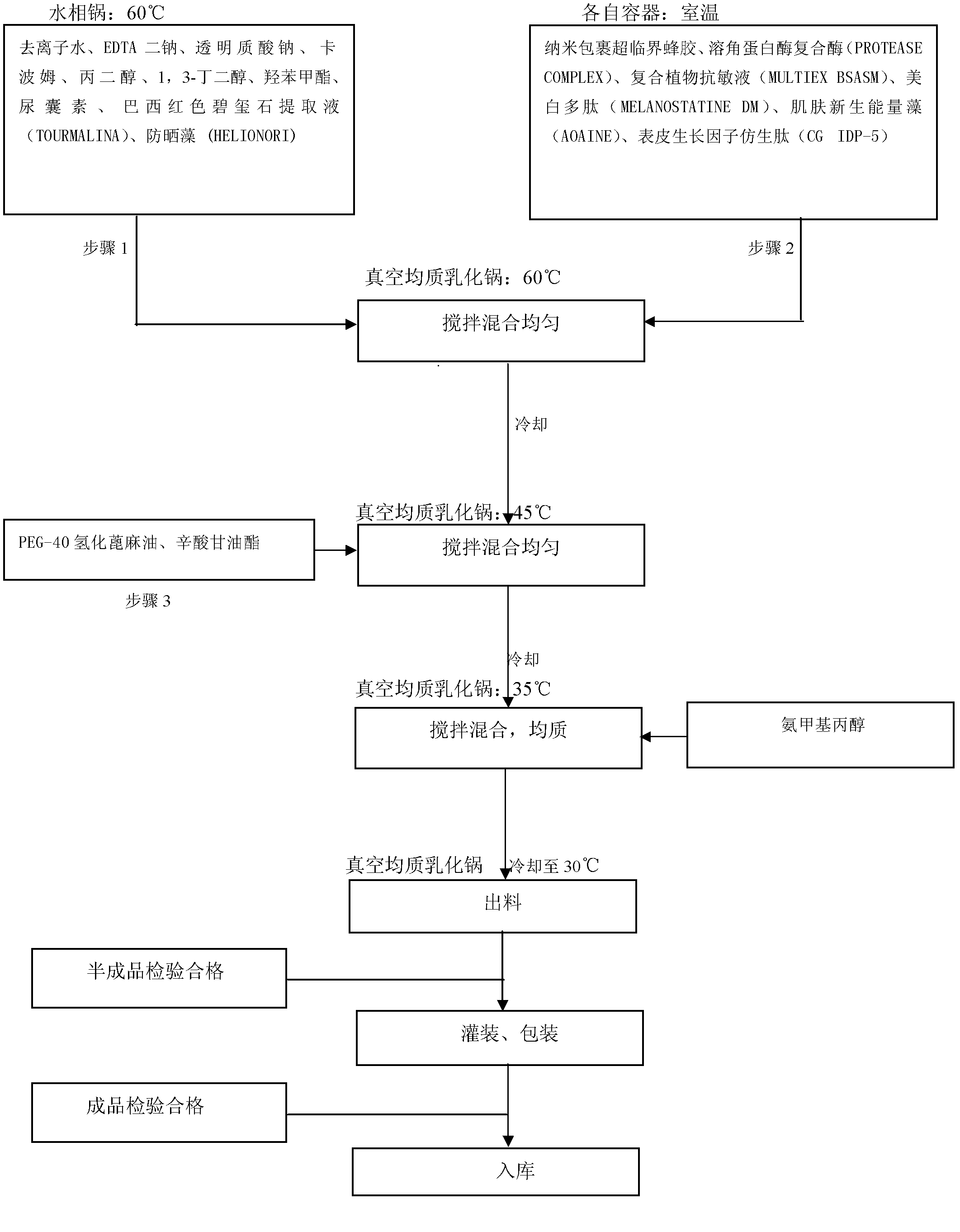

Skin-whitening and freckle-dispelling essence and preparation method thereof

ActiveCN102614104AInhibit synthesisInhibitory activityCosmetic preparationsToilet preparationsWrinkle skinCuticle

The invention relates to a skin-whitening and freckle-dispelling essence and a preparation method thereof. The skin-whitening and freckle-dispelling essence contains the following active ingredients which are selected in the aspects of eight factors according to the latest skin-whitening and freckle-dispelling mechanism: nano-wrapped supercritical bee glue, sunscreen algae (helionori), a lytic keratinase complex (protease complex), multiex bsasm, skin-whitening polypeptide (melanostatine DM), skin neogenesis energy algae (AOAINE), epidermal growth factor bionic peptide (CG IDP-5) and a brazzil tourmaline extracting solution (tourmalina). Compared with the prior art, the skin-whitening and freckle-dispelling essence is clear in mechanism, natural and efficient in sorting, and has the advantages of inhibiting melanin, screening sun, promoting metabolism, diminishing inflammation, reducing genuine melanin, accelerating the metabolism of the melanin, improving obscuration caused by wrinkle spots and the like; after skin-whitening and freckle-dispelling essence is used, skin is the fair and tender and white lucent; and the preparation method is scientific.

Owner:HEILONGJIANG NONGKEN NORTHEAST BLACK BEE DEV

Bacillus subtilislogarithmic phaseexpression system

ActiveCN106222190AIncrease concentrationHigh activityBacteriaMicroorganism based processesMicrobiologyBacillus subtilis

The invention discloses a bacillus subtilis logarithmic phase expression system and belongs to the field of genetic engineering. The expression system includes bacillus subtilis serving as a host and a logarithmic phase started plasmid expression vector. In the culture process of recombinant bacteria, a target gene carried on a plasmid is expressed only after a logarithmic phase begins but before a stable phase. A keratinase gene (ker) is expressed by utilizing the expression system,the thalli concentration and keratinase activityare improved by 10.4-15.2% and 27.8-41.5% respectively through fermentation culture compared with a traditional strongstart-up system.

Owner:JIANGNAN UNIV

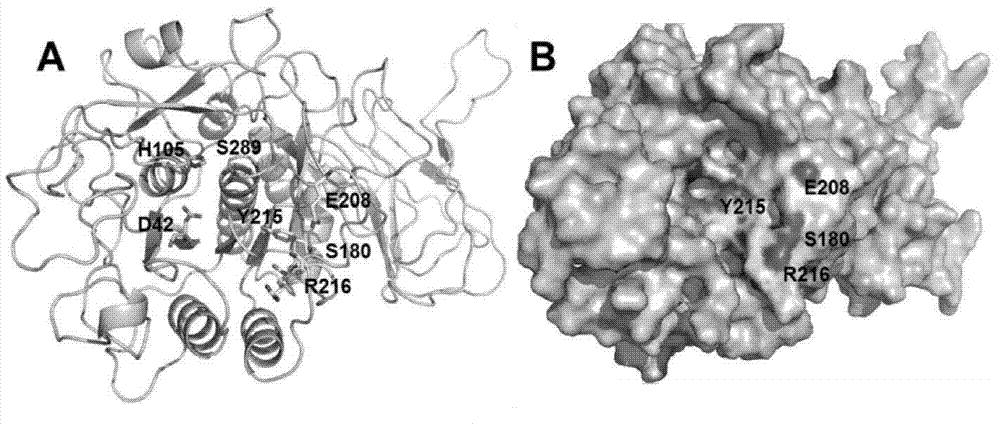

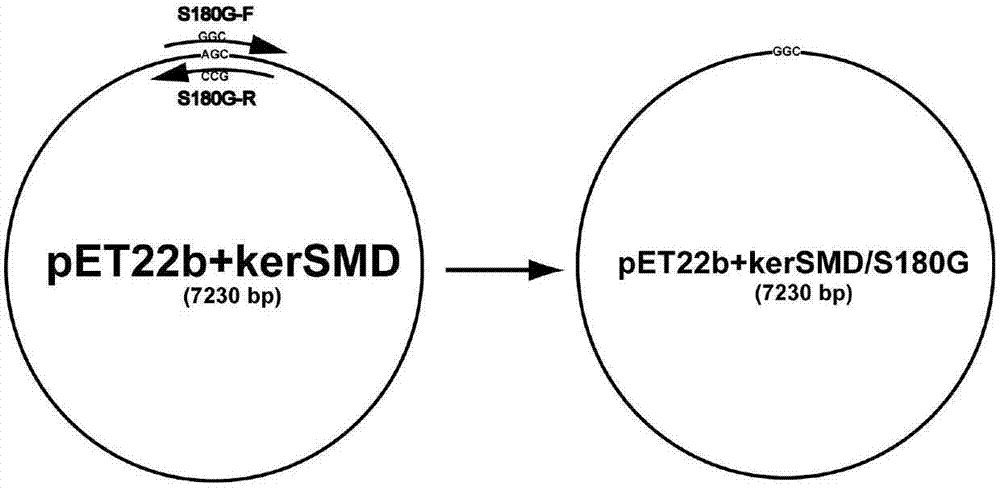

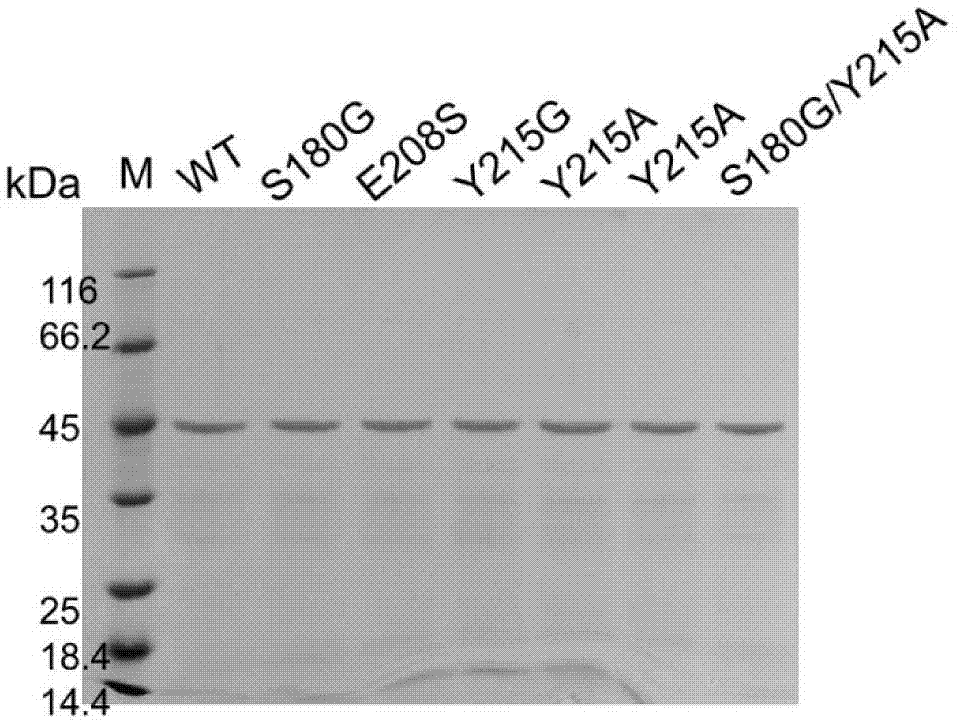

Higher-substrate-specificity keratinase mutant and preparation method thereof

ActiveCN104726436AIncrease enzyme activityStrong specificityHydrolasesAnimal feeding stuffWater solubleSite-directed mutagenesis

The invention discloses a higher-substrate-specificity keratinase mutant and a preparation method thereof, belonging to the field of enzyme engineering. Analysis is performed to obtain the optimal mutant site to perform site-directed mutagenesis, thereby obtaining the excellent mutant with higher keratinase enzyme activity and substrate specificity. The keratinase and mutant thereof can effectively hydrolyze feather, wool and other non-water-soluble keratin substrates, and can be used for leather textile industry and feed industry.

Owner:JIANGNAN UNIV

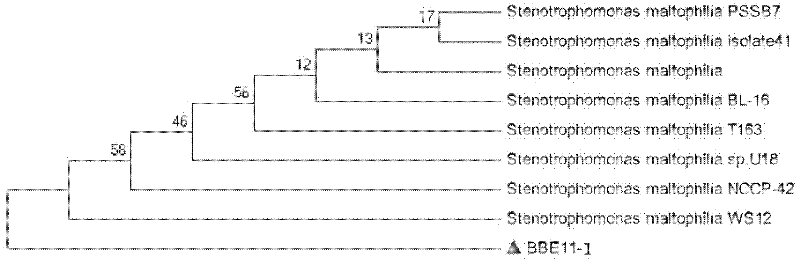

Stenotrophomonas maltophilia for generating keratinase and application of stenotrophomonas maltophilia

ActiveCN102329751AEfficient degradationEasy to handleBacteriaBiochemical fibre treatmentStenotrophomonas maltophiliaNitrogen source

The invention discloses stenotrophomonas maltophilia for generating keratinase and an application of stenotrophomonas maltophilia. A strain for generating keratinase can efficiently degrade feathers within 24 hours, the activity of the keratinase subjected to fermentation and primary optimization can reach 150U / mL. Multiple kinds of amino acids can be produced after the degraded feathers are subjected to amino acid analysis, and the degraded feathers can replace grain crops such as soybeans and the like to be used as a main nitrogen source of feeds. Meanwhile, a fermenting enzyme solution of the stenotrophomonas maltophilia has a better treatment effect on wool. The stenotrophomonas maltophilia for generating the keratinase, screened in the invention, has better application prospects in the industries of feeds and textiles.

Owner:XINYI HANLING BIO ENG

Bacillus licheniformis ZL-1 and application thereof

ActiveCN108004169AImprove degradation rateHigh temperature toleranceBacteriaHydrolasesBiotechnologyBacillus licheniformis

The invention discloses Bacillus licheniformis ZL-1 and the application thereof. The Bacillus licheniformis ZL-1 is obtained by isolating and screening from a high-temperature stack of feathers combined with edible fungus residues, the Bacillus licheniformis ZL-1 is preserved at Guangdong Provincial Microorganism Culture Collection Center, with a preservation number of GDMCC No. 60284, the preservation address is 5th floor, Building 59, Compound, No. 100 Xianlie Middle Road, Guangzhou, China, and the preservation date is November 24, 2017. Experiments determine that the Bacillus licheniformisZL-1 can be cultured in a liquid culturing medium with pure feathers for three days, the keratinase activity of the Bacillus licheniformis ZL-1 reaches 52.14 U / ml, and the degradation rate of feathersreaches 90.15%. Further more, the Bacillus licheniformis ZL-1 has good tolerance to high temperature and salinity, can grow well at a temperature of 55 DEC G and is resistant to salinity of 14%, so that the Bacillus licheniformis ZL-1 is used for degrading the feathers, preparing compound amino acid solution, conducting high-temperature compost fermentation by using the feathers as raw materialsand preparing compound amino acid fertilizers and keratinase; the Bacillus licheniformis ZL-1 has good application prospects and market value.

Owner:广州王道生物科技有限公司

Self-regulation expression system of bacillus subtilis and building method and application of self-regulation expression system

ActiveCN104212830AHigh fluorescence intensityBacteriaVector-based foreign material introductionRegulation of gene expressionGenetic engineering

The invention discloses a self-regulation expression system of bacillus subtilis, and a building method and an application of the self-regulation expression system, and belongs to the field of genetic engineering. The expression system disclosed by the system comprises bacillus subtilis for xylose-induced expression of an endonuclease gene and a plasmid expression vector for constitutive expression of an anti-endonuclease gene. In a culture medium containing an inducer xylose, only the bacillus subtilis containing stably existing expression vector can normally grow. A fluorescent protein gene (gfp), a hyaluronic acid synthase gene (hasA) and a keratinase gene (ker) are respectively expressed by using the expression system disclosed by the invention; and by fermented cultivation, the fluorescence intensity, the hyaluronic acid content and the keratinase activity are respectively improved by 21.8%, 45% and 30.2% in comparison with those of the plasmid maintained by using antibiotic.

Owner:JIANGNAN UNIV

Method for producing peptone by taking poultry feather as raw material

The invention discloses a method for producing peptone by taking poultry feather as a raw material. The method comprises the following steps: performing pretreatment on the poultry feather raw material, and then sending into a microwave puffing machine for treatment; adding keratinase for performing enzymolysis reaction and heating for enzyme deactivation; adding activated carbon to perform deodorization, peculiar smell removal, decolorization and other treatment, and filtering; and performing evaporation concentration and high-speed centrifugal spray-drying, and getting the peptone after drying. According to the method disclosed by the invention, the combination of microwave puffing and keratinase enzymolysis technologies is adopted for producing the peptone by taking the poultry feather as the raw material, a new way is opened for resource utilization and development of the waste feather, and the resource utilization is performed on the poultry feather produced during cultivation, so that environmental pollution and the waste of resources are reduced, social benefits are increased, the cost of the raw material is low, process equipment is simple, the process flow is simple and strong in operability, and the industrial production can be realized; the peptone produced by the method disclosed by the invention has good quality and high yield; and the method disclosed by the invention can fill in the technical blank in preparation of the peptone by taking the feather as the raw material.

Owner:安徽华强羽绒有限公司

Keratinase with improved thermal stability and specific activity as well as preparation method and application thereof

ActiveCN103602653AIncreased specific enzyme activityImprove thermal stabilityBacteriaHydrolasesWild typeKeratin

The invention discloses keratinase with improved thermal stability and specific activity as well as a preparation method and application thereof, and belongs to the field of genetic engineering. The keratinase having wide industrial application prospect is obtained by mutating a leading peptide cleavage site of keratin and transforming the N-terminal of the keratin. The t1 / 2 of the keratinase at the temperature of 60 DEG C is 20 minutes and is increased by nearly two times in comparison with that of wild type keratinase. Meanwhile, the specific activity of a keratinase mutant is increased by nearly 50% in comparison with that of the wild type keratinase, so that a good foundation is laid for the application of the keratinase.

Owner:JIANGNAN UNIV

Signal peptide for optimizing high-level secretory expression of keratinase Ker and application of signal peptide

ActiveCN107200772AIncrease secretionImprove secretion efficiencyBacteriaHydrolasesSequence signalExtracellular

The invention discloses a signal peptide for optimizing high-level secretory expression of keratinase Ker and application of the signal peptide and belongs to the fields of genetic engineering and enzyme engineering. The signal peptide is characterized in that 46 secretory signal peptides from bacillus subtilis are preliminarily screened and 6 secretory signal peptides capable of obviously improving the secretion volume of the keratinase in the 46 secretory signal peptides are directionally transformed, so the signal peptide for optimizing the high-level secretory expression of keratinase is obtained. An N terminal of the signal peptide is provided with first nine amino acid residues of a signal peptide AbnA; an H terminal of the signal peptide is provided with a hydrophobic sequence of a signal peptide YfkN, and a C terminal of the signal peptide is provided with last four amino acid residues of a signal peptide PhoB. The signal peptide disclosed by the invention is fused at the N terminal of the keratinase Ker, so the secretion efficiency of the keratinase of recombinant bacillus subtilis is remarkably improved, and the enzyme activity of extracellular keratinase of the bacillus subtilis is improved by 3.39 times. The extracellular keratinase producing capability of a transformed strain is remarkably improved, the industrial application is better facilitated, the production cost can be reduced, and the production efficiency is improved.

Owner:INST OF MICROBIOLOGY JIANGXI ACADEMY OF SCI +1

Wool-fabric biological anti-felting method based on cutinase, keratinase and protease treatment

InactiveCN101565901AShort wetting timeLower contact angleBiochemical fibre treatmentAnimal fibresFiberCutinase

The invention provides a wool-fabric biological anti-felting method based on cutinase, keratinase and protease treatment, which belongs to the technical field of application of dyeing and finishing of wool fabric in the wool-spinning industry. The method aims to overcome the defects that the chlorination-process for wool-felting prevention seriously pollutes the environment and the single protease-method treatment is poor in fabric wettability and high in felting rate in order to achieve the aim of optimizing the protease treatment effect of the wool fabric. After all-wool grey fabric is extracted to remove free oily impurities, the all-wool grey fabric is sequentially pretreated with cutinase and keratinase solutions so as to improve the surface hydrophilicity of fiber scales and the accessibility of protease molecules, and then the wool fabric is subjected to reduction processing in a protease solution, thus biological processing combined with wool enzyme reduction is realized. The method makes the prior chlorination-process felting prevention replaced with a biological-method wool-felting prevention process, and the method not only effectively improve the reduction rate and anti-felting effect of the wool fabric, and promote the improvement of fabric wettability, but also can effectively increase the dyeing depth of fabric, and reduce fiber damage in reduction processing, and is favorable for protecting ecological environment.

Owner:JIANGNAN UNIV

Brevibacillus parabrevis producing keratinase and application thereof

The invention discloses a keratinase producing strain and culture conditions and enzymatic properties thereof, and belongs to the technical field of microorganisms. As identified, the strain is Brevibacillus parabrevis, is named as Brevibacillus parabrevis R-7 and now is preserved in China General Microbiological Culture Collection Center, with preservation number CGMCC No.10798. After preliminary optimization, the culture medium of the strain comprises 1 percent of wool, 1 percent of soluble starch, 1 percent of corn meal, 0.15 percent of NaCl, 0.05 percent of NH4Cl, 0.03 percent of K2HPO4, 0.04 percent of KH2PO4 and 0.01 percent of MgCl2 6H2O. Shaker culture conditions include initial pH 8.0, inoculation amount 2 percent, culture temperature 40 DEG C, revolving speed 220r / min, liquid volume 30mL / 250mL and fermentation period 16h, wherein the activity of the produced keratinase reaches 412U / mL. The optimum acting temperature of the keratinase is 40 DEG C and the optimum pH is 7.0. The enzyme has important application in fields such as tanning and medicines.

Owner:JIANGNAN UNIV

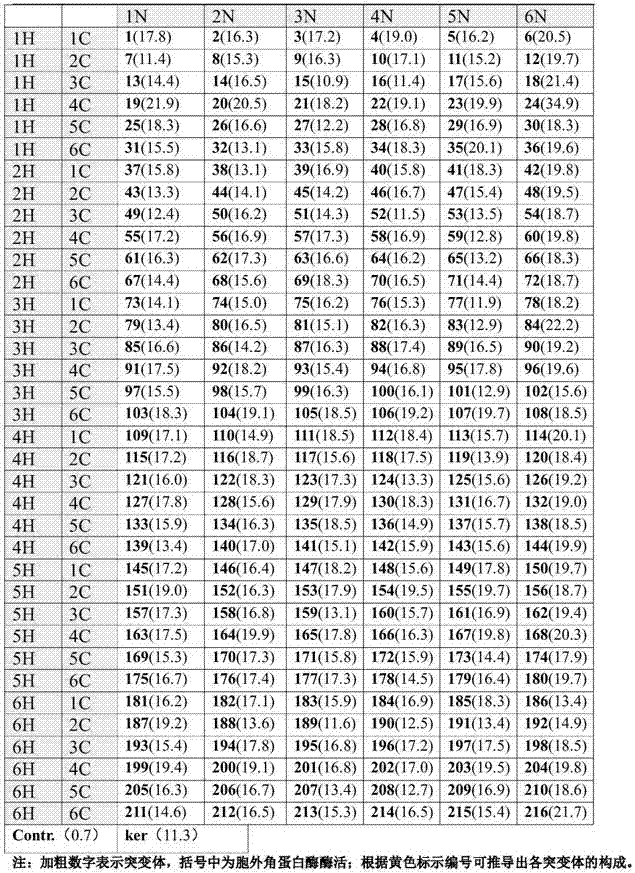

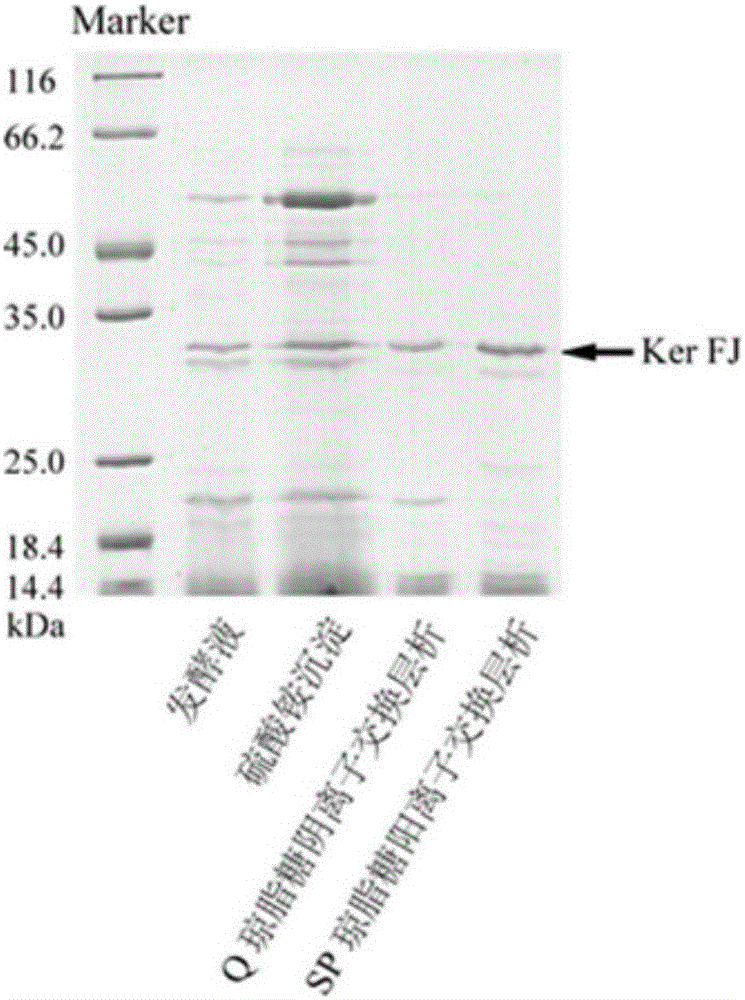

Separating and purifying method and application of keratinase

ActiveCN105821023ALarge amount of sampleFast flowHydrolasesMicroorganism based processesIon exchangeGradient elution

The invention relates to a separating and purifying method and application of keratinase. The method comprises the steps that after crude enzyme liquid is precipitated with ammonium sulfate in a gradient mode, sediment is resuspended with a buffer solution, and dialysis is carried out; an ion exchange column is balanced with a buffer solution, sample feeding is carried out, and an enzyme activity peak is in a crossing peak; components with enzyme activity are collected, and dialysis is carried out with a buffer solution; the ion exchange column is balanced with a buffer solution, sample feeding is carried out, gradient elution is carried out with NaCl, and purified keratinase is obtained. 16.59 mg of pure enzymes of keratinase Ker FJ can be harvested through 1 L of fermentation broth, and the total enzyme activity is 2989 U. Obtained keratinase Ker FJ has a very good effect on livestock and poultry waste degradation, unhairing and a detergent additive.

Owner:BIOTECH RES CENT SHANDONG ACADEMY OF AGRI SCI

Preparation method of keratin

ActiveCN103981247AReduce extraction timeImprove stabilityPeptide preparation methodsFermentationKeratinAlkaline hydrolysis

The invention discloses a preparation method of a keratin. The preparation method comprises the following steps: I, adding a raw material comprising keratin to a first aqueous solution for alkaline hydrolysis, and carrying out solid-liquid separation to obtain a first keratin solid; II, adding the first keratin solid into a second aqueous solution, adding a proper amount of compound protease for enzymolysis for 4-5 hours under the conditions that the temperature is 48-52 DEG C and the pH is 8.0-9.0; then, inactivating the compound protease; then, adding a proper amount of keratinase for enzymolysis for 2.5-3.5 hours at 35-40 DEG C; and finally, carrying out solid-liquid separation to obtain a second keratin solid; III, first, shading and oxidizing the second keratin solid for 3.5-4.5 hours by using an oxidizing agent, and then, carrying out solid-liquid separation to obtain a third keratin solid; and IV, drying the third keratin solid till the water content is below 5-8%, wherein the dried third keratin solid is the target keratin.

Owner:北京中农探味科技有限公司

Biological manufacturing method for utilizing waste feathers to produce amino acid liquid fertilizer

ActiveCN109650946ARich varietyEliminate the concentration processAnimal corpse fertilisersClimate change adaptationSmall peptideNational standard

The invention discloses a method for utilizing waste feathers to produce amino acid liquid fertilizer. The method comprises the steps of carrying out enzymolysis on feather powder through compound enzyme to obtain enzymolysis liquid, adding acid protease into the enzymolysis liquid for enzymolysis, filtering the liquid after enzymolysis is finished, and carrying out enzyme inactivation on a filtrate to obtain the amino acid liquid fertilizer. The compound enzyme comprises keratinase and amino acid peptidase. According to the method, the enzymolysis rate of the feathers can reach 80% or above,the prepared amino acid liquid fertilizer contains 17 kinds of amino acids, the variety is complete, the content of the amino acids can reach 10.12% or above (mass fraction), the content of small peptide can reach 9.39% (mass fraction), and the method can meet the national standard for the amino acid liquid fertilizer without concentration. Therefore, the environment-friendly amino acid liquid fertilizer can be prepared.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY +1

Wool product two-bath process anti-felting treatment technology based on composite bio-enzyme

InactiveCN102965958AUnpacking dense structuresInfluence efficiencyBiochemical fibre treatmentAnimal fibresCutinaseDecomposition

The invention discloses a wool product two-bath process anti-felting treatment technology based on composite bio-enzyme, belonging to the technical field of wool fabric dyeing and finishing, which is aimed at solving the shortcomings that a wool chlorination anti-felting method causes serious environmental pollution, a single protease method has low wettability and high felting rate in treating fabric, a cutinase, keratinase and protease three-step method has low treatment efficiency, a cutinase, keratinase and protease one-step method requires inconsistent optimal action conditions in treating the three enzymes and the protease possibly decomposes the rest two enzymes in a one-bath method so as to realize an effect of optimizing wool fabric protease treatment. A wool sample is pretreated in a solution containing certain concentration of cutinase and keratinase to remove hydrophobic lipoids on the surface of wool and decompose the dense structure of wool scales; then, the wool sample is treated in the protease solution; and through the synergistic effect of the three-enzyme two-bath method, the acting efficiency of the protease is improved. The technology disclosed by the invention can replace the traditional chlorination anti-felting method, and improve the anti-felting performance of a wool product.

Owner:JIANGNAN UNIV

Treating agent for treating pigs died from diseases, preparation method and treating method for pigs died from diseases

ActiveCN107988112AImprove biological activityGood decomposition effectBio-organic fraction processingFungiBacillus licheniformisDecomposition

The invention provides a treating agent for treating pigs died from diseases, a preparation method and a treating method for the pigs died from diseases, and relates to the technical field of treatment for animals died from diseases. The treating agent mainly comprises raw materials such as bacillus subtilis, saccharomycetes, alkaline protease, keratinase, lipase, aspergillus niger, actinomycetesand bacillus licheniformis. The treating agent has good decomposition processing capacity for the pigs died from diseases and can completely degrade dead pig carcasses by utilizing the organic matterdegrading capacity of microorganisms, combing the synergistic characteristic between specific biological strains, and scientifically and reasonably matching the raw materials of the strains, thereby realizing innocent treatment of the dead pig carcasses; in addition, the dead pig carcasses treated by the treating agent can be finally converted into high-quality organic fertilizer raw materials, thereby turning waste into wealth and realizing resource reutilization. The invention further provides the treating method for the pigs died from diseases, and improves the defects that the treating method in the prior art is long in treating time, large in occupied area, harmful in treatment, and high in stealing possibility.

Owner:河南崤函生物科技有限公司

Enzymolysis feather powder being high in digestion coefficient and preparing method of enzymolysis feather powder

InactiveCN108497157AImprove digestibilityPromote digestion and absorptionFood processingAnimal feeding stuffBacillus licheniformisDigestion

The invention relates to enzymolysis feather powder being high in digestion coefficient and a preparing method of the enzymolysis feather powder. The preparing method comprises the following steps offirstly, mixing feather with water in the weight ratio of the feather to the water being (1 to 0.4) to (1 to 3), then performing cooking for 0.3-3h, wherein the cooking temperature is 100-200 DEG C, and the cooking pressure is 80-500kPa; adding keratinase of which the enzyme activity unit is 100-500 thousand to the cooked feather in the weight ratio of the keratinase to the feather being 0.3-2%, and performing enzymolysis under the enzymolysis condition that the enzymolysis temperature is 50-70 DEG C and the enzymolysis pH is 7-9 for 12-36h; and cooling the feather after being subjected to enzymolysis to 20-40 DEG C, inoculating the cooled feather with one or two or three kinds of strains of bacillus licheniformis, saccharomycetes or lactobacillus plantarum in the weight ratio of the strains to the feather being 0.1-0.5%, adjusting the water content by mass to 50-70%, and performing fermenting under the condition that the fermentation temperature is 20-40 DEG C, and the fermentation pHis 5-7 for 24-72h, so as to obtain the enzymolysis feather powder. An animal feed prepared from the enzymolysis feather powder high in digestion coefficient is high in the digestibility by animals, and good in palatability.

Owner:广东希普生物科技股份有限公司

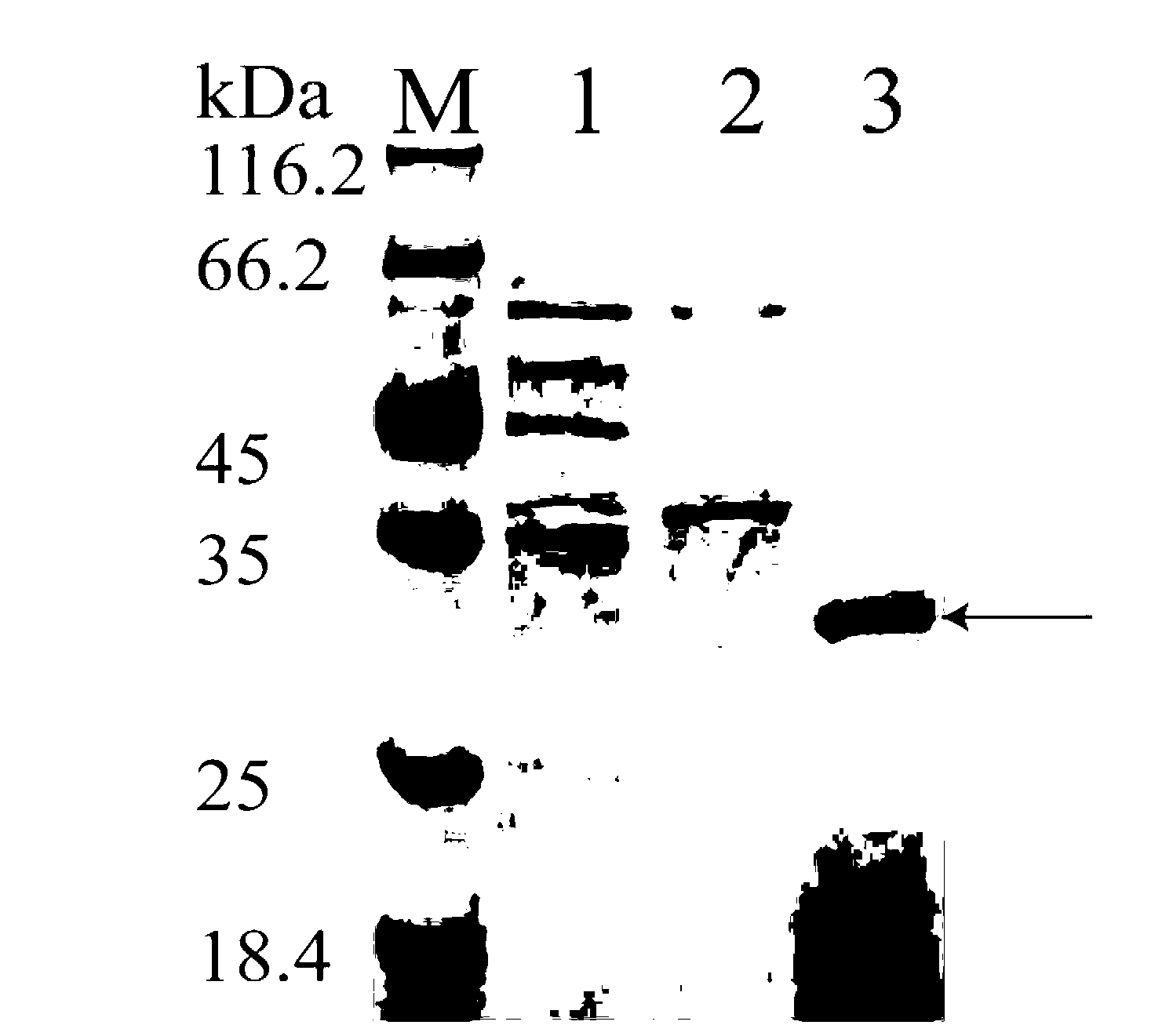

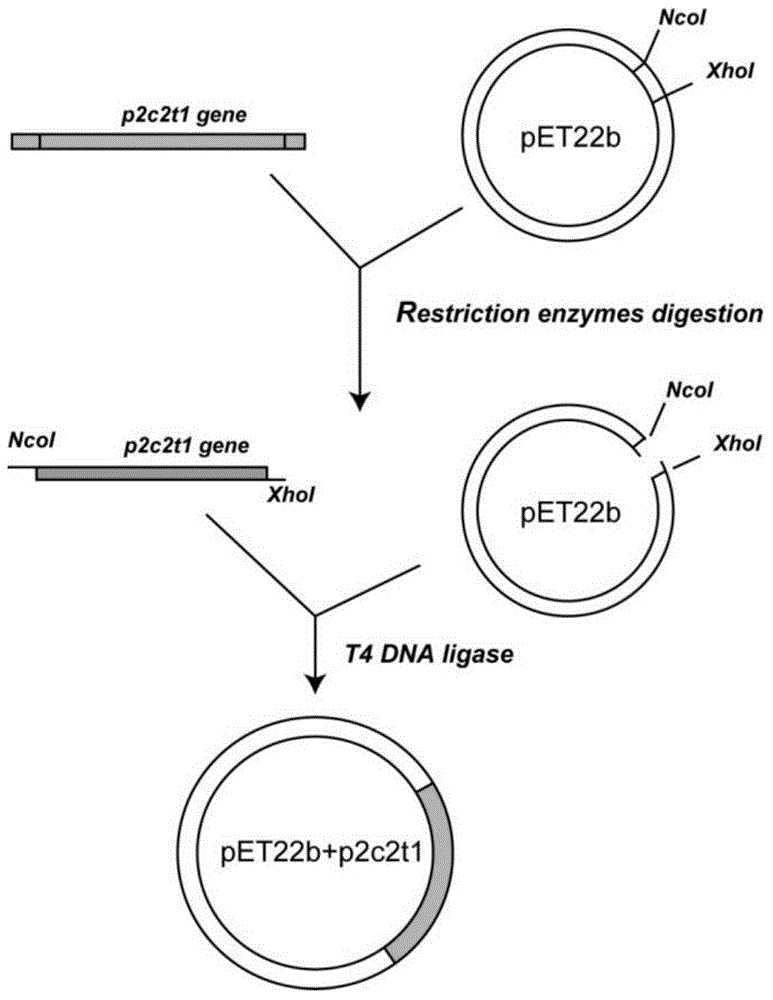

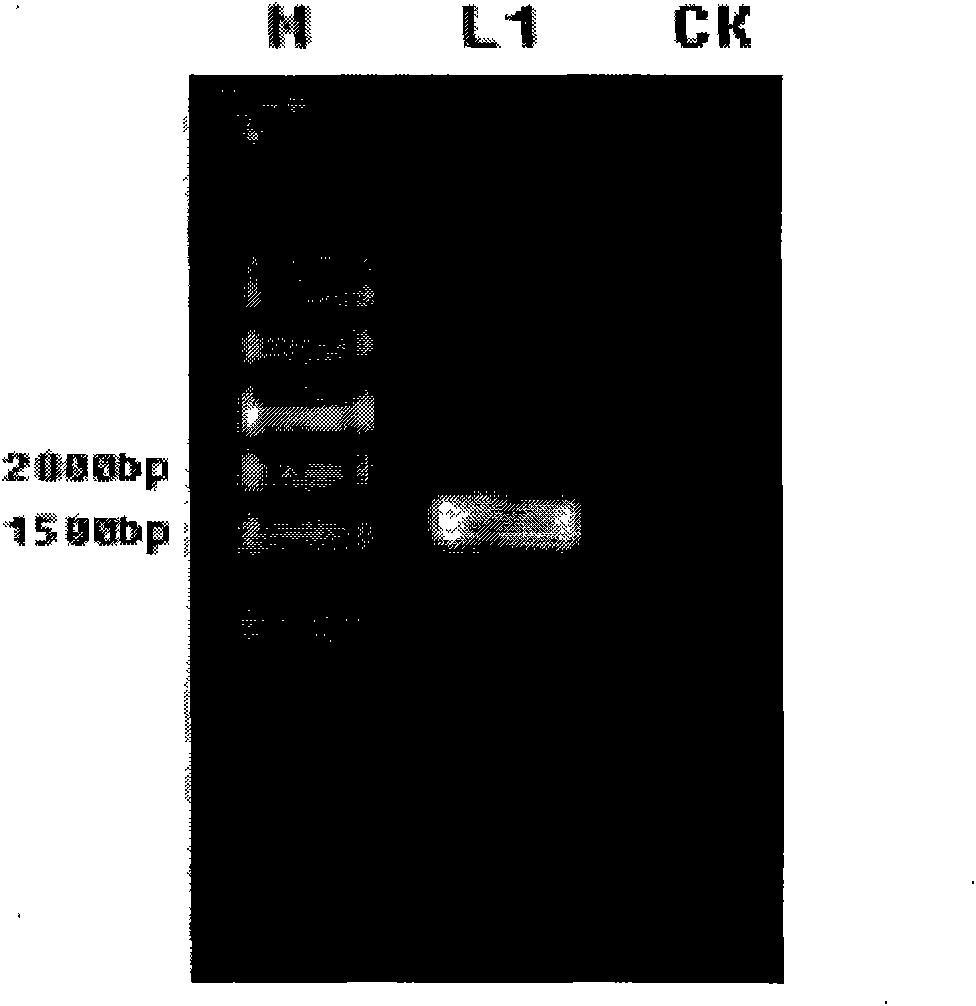

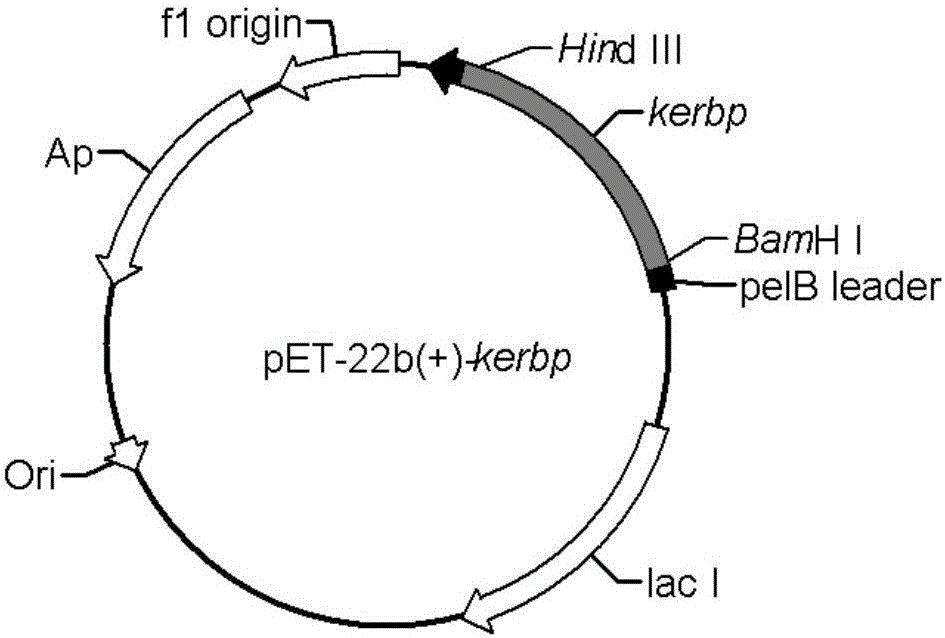

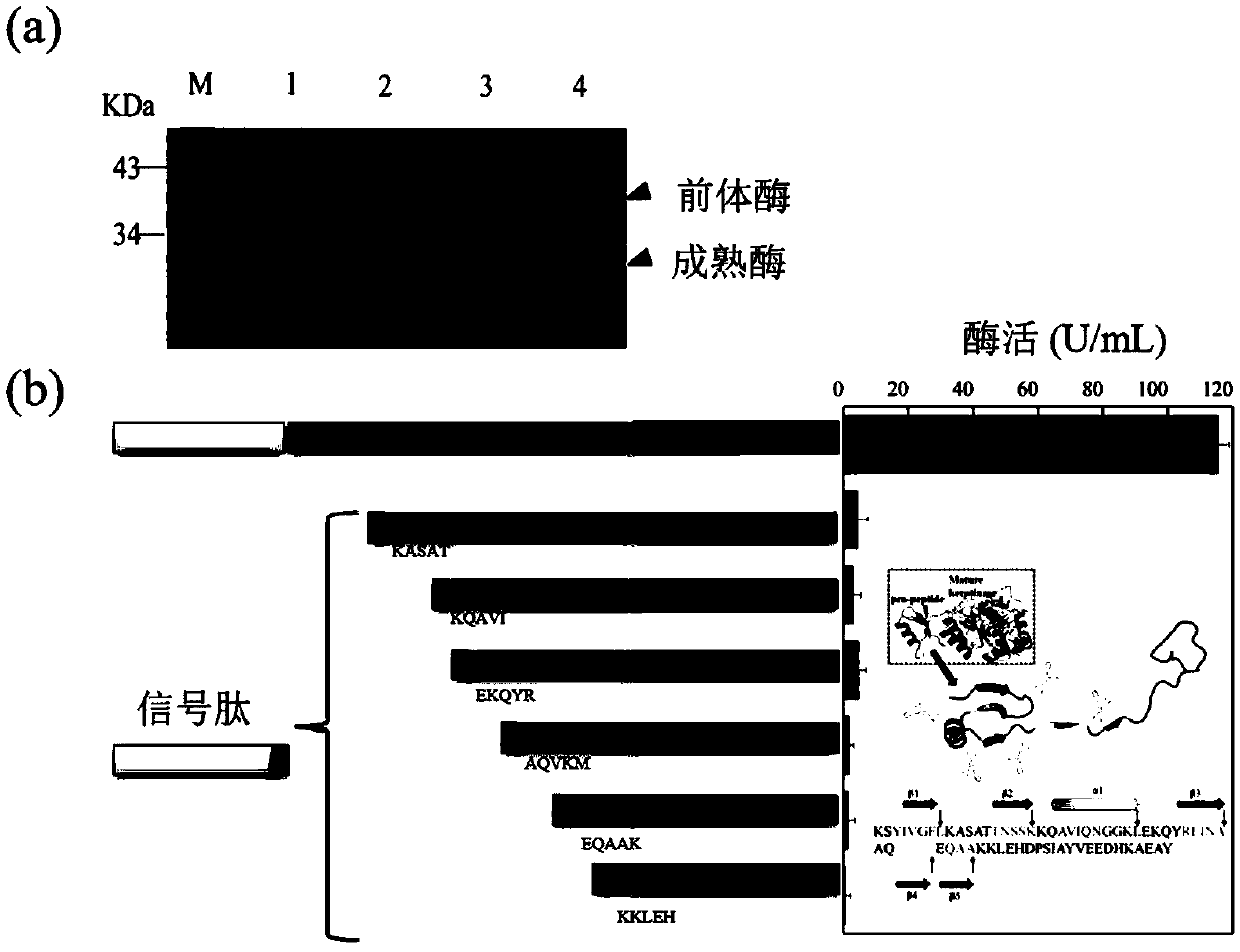

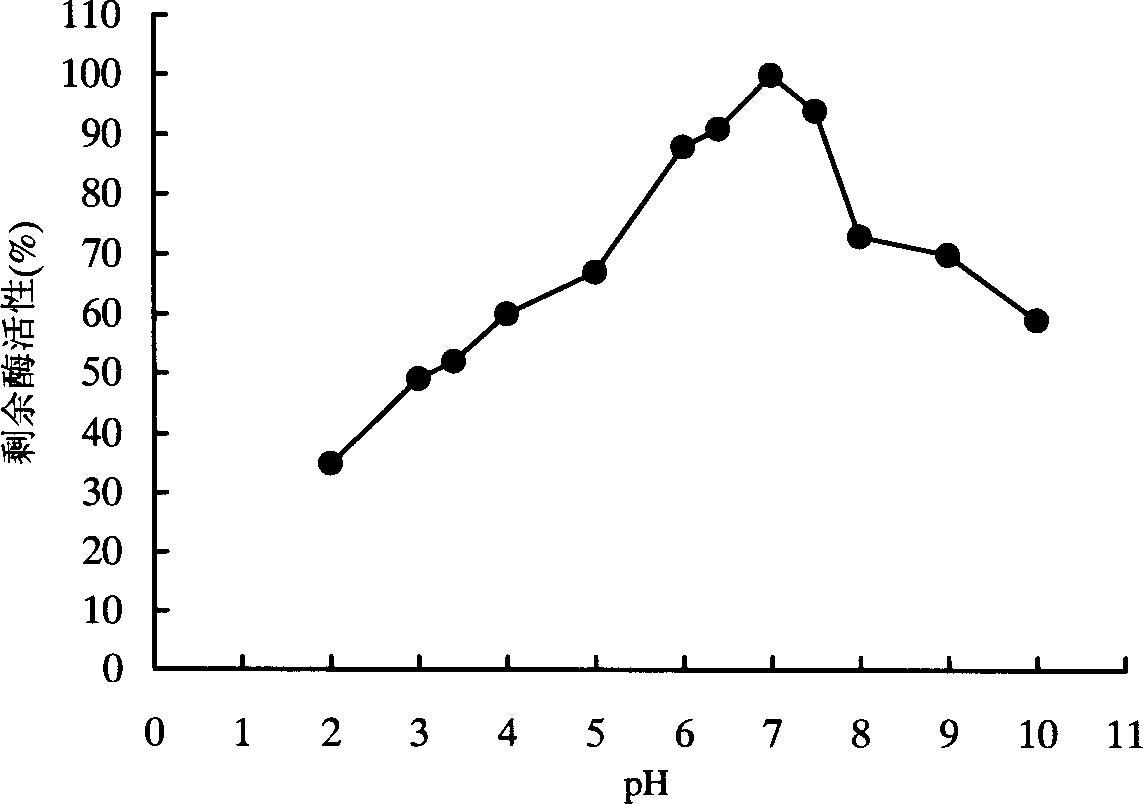

Encoding gene of keratinase and recombination expression and application thereof

InactiveCN106282210ADoes not cause looseWill not cause problems such as rotten noodlesFungiBacteriaHeterologousEscherichia coli

The invention provides an encoding gene of keratinase and recombination expression and application thereof. A keratinase encoding gene kerbp is obtained from extracting total DNA PCR from brevibacillus parabrevis CGMCC 10798, the total length of the gen is 1152 nucleotides, and 383 amino acids are encoded. The nucleotide sequence is shown in SEQ ID NO:1, and the amino acid sequence is shown in SEQ ID NO:2. The invention further discloses a recombination expression and separation purification method of the keratinase. E.coli is adopted as an example, E.coli BL21(DE3) is adopted as an expression host, and heterologous expression of the keratinase gene is achieved. The most proper acting PH of the recombination keratinase is 8.0, and the most proper temperature of the recombination keratinase is 60 DEG C; Tween 40 and Triton X-100 have the effect of promoting activity of the keratinase. The keratinase can effectively remove hair on goatskin, and has the good application prospects in the industries such as tanning, washing, spinning and egg white waste disposal.

Owner:JIANGNAN UNIV

Method for preparing organic fertilizer with kitchen waste and animal and plant wastes

InactiveCN106588463AEasy to operateSave human effortBio-organic fraction processingAnimal corpse fertilisersHydrolysateAqueous solution

The invention discloses a method for preparing organic fertilizer with kitchen waste and animal and plant wastes; the method comprises the steps of classifying kitchen waste; crushing plant waste; chopping meat into 1-1.5 cm long meat strips; mixing and grinding bones into bone powder; soaking hair in keratinase solution, and enzymatically hydrolyzing to obtain enzymatic hydrolysate; mixing the mixture and a biological bacterial agent at a mass ratio of 100:(2-5), adding to a fermentation tank, fermenting, and filtering to obtain filter residue and filtrate; soaking a slow-release carrier in the filtrate, mixing well with the filter residue, and drying and crushing. The animal waste, kitchen waste and plant waste are used as materials, wastes are turned into wealth, environmental pollution is prevented, and nutrition of the fertilizer is more complete.

Owner:广西科茂信息咨询有限公司

Keratinase mutant with improved catalytic performance and application

InactiveCN109593746AImprove thermal stabilitySuitable for industrial mass productionBacteriaHydrolasesMulti siteWater baths

The invention discloses a keratinase mutant with improved catalytic performance and an application, belongs to the technical field of genetic engineering and provides recombinant keratinase constructed on the basis of leading peptide engineering and multi-site saturated mutation and a leading peptide engineering method. A recombination strain M7 shows high keratinase catalytic potential, enzyme activity is remarkably improved from 179 U / mL to 1114 U / mL, the optimal reaction temperature is 40 DEG C, the optimal reaction pH is 10.0, over 80% enzyme activity is retained after water bath processing is performed for 90 min at 40 DEG C, heat stability is better, and the keratinase mutant is suitable for industrial large-scale production. Besides, the method for modifying protease with the leading peptide engineering can be a universal way for modifying industrial enzyme with the self-shearing characteristic.

Owner:JIANGNAN UNIV

Efficient, broad-spectrum keratinase and its gene

The invention provides a keratinase and its coding gene. It has advantages of high activity, good heat stability, wide PH range and efficient degradation of alpha & beta-keratinase. It has also the character of common protease and can degrade many kinds of protein derived from plants and animals. It can be widely used in the trades such as feed, foods, washing, wool spinning and pharmacy.

Owner:姚斌 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com