Separating and purifying method and application of keratinase

A keratinase, separation and purification technology, applied in the field of separation and purification of keratinase, can solve problems such as reduced enzyme activity, and achieve the effects of high sample concentration, large sample loading, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

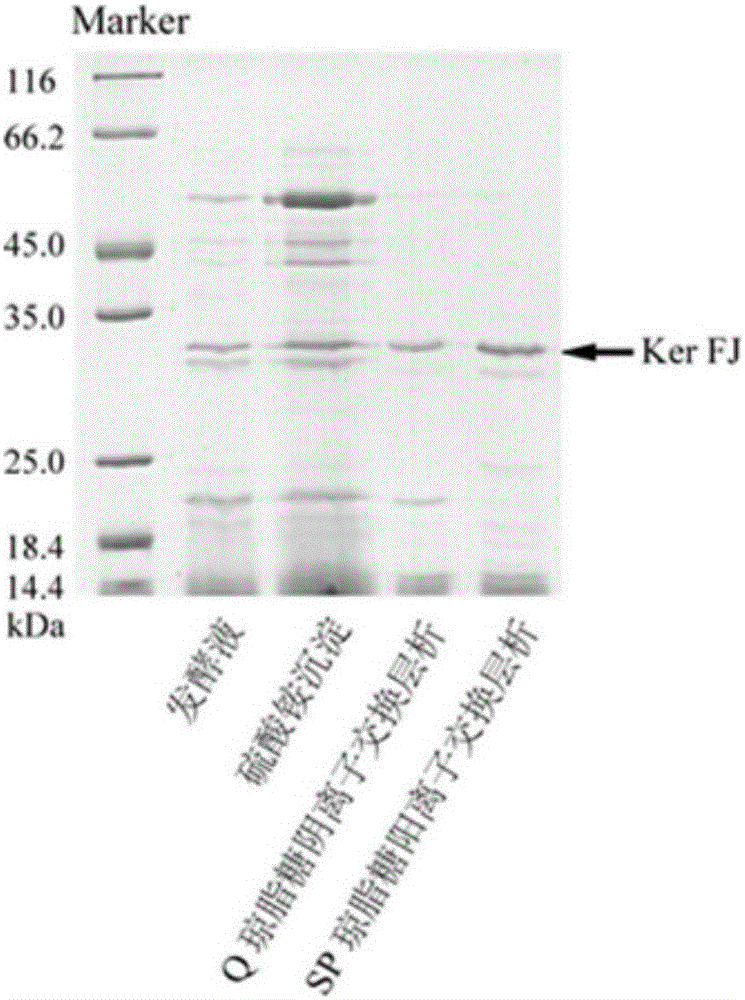

[0034] The separation and purification method of embodiment 1 keratinase, concrete steps are as follows:

[0035] (1) Inoculate a single colony of Bacillus subtilis FJ-3-16 into LB liquid medium with an inoculation needle, and cultivate it at 30°C and 200rpm for 18h;

[0036] LB liquid medium (g L -1 ): peptone 10, yeast powder 5, NaCl10, pH7.5;

[0037] (2) Inoculate the logarithmic phase seed solution in the LB liquid medium into the FM3 medium according to the inoculation amount of 6% (volume ratio), and cultivate it at 30° C. for 72 hours at 200 rpm;

[0038] FM3 medium (g·L -1 ): corn flour 20, soybean flour 20, bran 10, KH 2 PO 4 1,K 2 HPO 4 3. CaCl 2 1, pH7.5;

[0039] (3) Use gauze to filter out the culture medium dregs after step (2), and centrifuge at 11000rpm for 15min to collect the crude enzyme solution;

[0040] (4) After the ammonium sulfate gradient precipitation with a mass fraction of 40-70% of the crude enzyme solution, use pH 10.0, 50mMTris-HCl buf...

Embodiment 2B

[0043] Embodiment 2B.subtilisFJ-3-16 strain identification

[0044] LB liquid medium (g / L): peptone 10.0, yeast powder 5.0, NaCl 10.0, pH 7.5. For transformant screening, add ampicillin (Amp) at a final concentration of 50 μg / mL to the culture medium.

[0045] LB solid medium (g / L): peptone 10.0, yeast powder 5.0, NaCl 10.0, agar 15.0, pH 7.5.

[0046] A single colony of the FJ-3-16 strain was inoculated in 5 mL of liquid LB medium and cultured overnight at 37°C. Take 1mL of the cultured bacterial solution, and extract the total bacterial DNA according to the instructions of the "Bitec Bacterial Genome Extraction Kit".

[0047] 16S universal primers 27F (5'-AGAGTTTGATCCTGGCTCAG-3') and 1492R (5'-ACGGCTACCTTGTTACGACTT-3') were designed. Using the bacterial genome as a template, according to the PCR system and procedures in the instruction manual of TaqDNA polymerase, PCR was used to obtain DNA fragments.

[0048] The PCR system is shown in Table 1, and the PCR program is sh...

Embodiment 3

[0055] The enzyme activity assay of embodiment 3 keratinase KerFJ

[0056] Take 1ml of the diluted crude enzyme solution and add 1ml of keratin substrate (TCI company, K0044) with a mass fraction of 2%, add 2ml of 0.4MTCA to terminate the reaction after reacting at 55°C for 1h, centrifuge at 11000rpm for 2min, take supernatant 1ml, add 5ml. .4MNa 2 CO 3 And 1ml of Folin reagent, after developing color at 40°C for 20min, colorimetric at 660nm, the absorbance value increased by 0.1 at 660nm per minute was defined as 1 enzyme activity unit (U).

[0057] Protein Concentration Determination

[0058] According to the instructions of "BCA Protein Concentration Determination Kit" (Beiyuntian Biotechnology), the B.subtilisFJ-3-16 fermentation broth obtained in the present invention has a total activity of keratinase in 1L of 73820.16U. Utilizing the purification method of the present invention, 16.59 mg of keratinase KerFJ pure enzyme can be harvested from 1LB.subtilisFJ-3-16 fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com