Preparation method of high-purity paeoniflorin and albiflorin

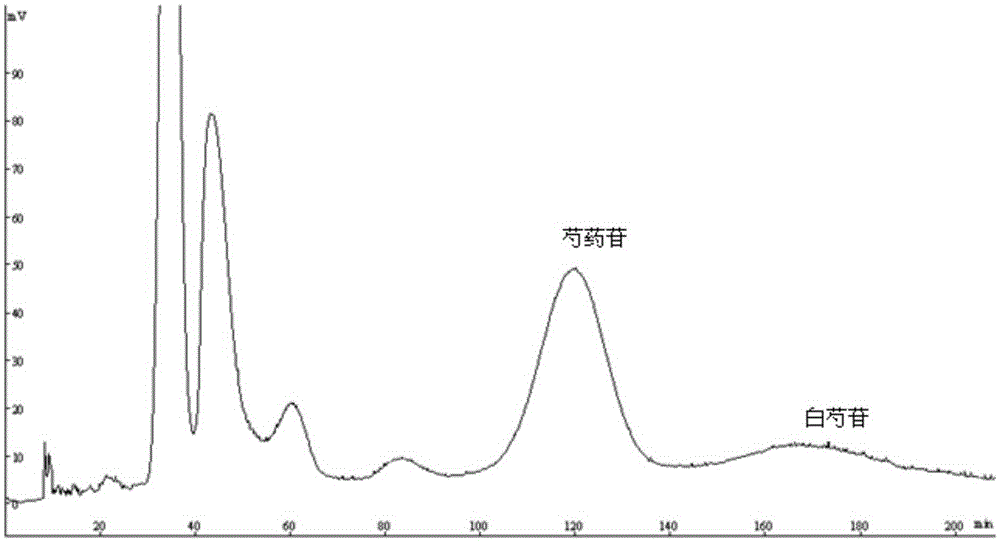

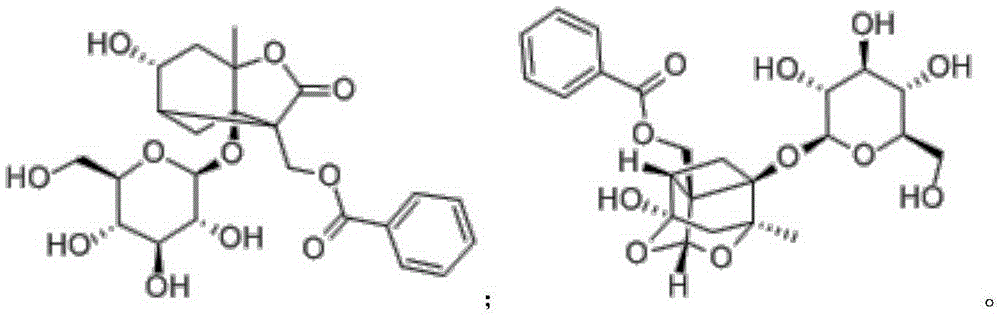

The technology of paeoniflorin and paeoniflorin is applied in the field of preparation of high-purity paeoniflorin and paeoniflorin, and can solve the problems of poor separation of paeoniflorin and paeoniflorin, unsuitable repetition and amplification, large differences in column packing, and the like, To achieve the effect of long separation cycle, large preparation volume and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the dried peony plant material and pulverize it, weigh 1000g, add 10L of 80% ethanol solution for ultrasonic extraction for 60 minutes each time, extract 3 times, and concentrate the extract under reduced pressure to obtain 200g of extract. Add 100 parts by mass of water to dissolve 1 part by mass of extract, extract with ethyl acetate, extract 3 times in total, combine the extracts to reclaim ethyl acetate to obtain 40g of extract, put the styrene macroporous resin column on the extract, and use a volume fraction of 25 % ethanol aqueous solution was used for elution, and the eluate was collected, concentrated and dried to obtain a crude extract, which was used for high-speed countercurrent separation.

[0026] Prepare a two-phase solvent system of carbon trichloride, n-butanol, methanol, and water in a separatory funnel, mix it at a volume ratio of 4:2:1:1, shake it, let it stand for stratification, and ultrasonically degas it for 30 minutes. Take the upper phase ...

Embodiment 2

[0028] Take the dried peony plant material and pulverize it, weigh 1000g, add 10L of 60% ethanol solution for ultrasonic extraction for 60 minutes each time, extract 3 times, and concentrate the extract under reduced pressure to obtain 200g of extract. Add 100 parts by mass of water to dissolve 1 part by mass of extract, extract with ethyl acetate, extract 3 times altogether, combine the extracts to reclaim ethyl acetate to obtain 40g of extract, put the styrene-based AB-8 macroporous resin column on the extract, and use Elute with 25% ethanol aqueous solution, collect the eluate, concentrate and dry to obtain a crude extract, which is used for high-speed countercurrent separation.

[0029] Prepare a two-phase solvent system of carbon trichloride, n-butanol, methanol, and water in a separatory funnel, mix it at a volume ratio of 4:1:3:2, shake it, let it stand for stratification, and ultrasonically degas it for 30 minutes. Take the upper phase and fill the high-speed countercu...

Embodiment 3

[0031] The dried peony plant material was crushed, weighed 1000g, added 10L of 70% ethanol solution for ultrasonic extraction for 60 minutes each time, extracted 3 times, and the extract was concentrated under reduced pressure to obtain 300g of extract. Add 100 parts by mass of water to dissolve 1 part by mass of extract, extract with ethyl acetate, extract 3 times altogether, combine the extracts to reclaim ethyl acetate to obtain 50g of extract, put the styrene-based AB-8 macroporous resin column on the extract, and use Elute with 50% ethanol aqueous solution, collect the eluate, concentrate and dry to obtain a crude extract, which is used for high-speed countercurrent separation.

[0032]Prepare a two-phase solvent system of carbon trichloride, isobutanol, methanol, and water in a separatory funnel, mix at a volume ratio of 4:2:2:1, shake, let stand for stratification, and ultrasonically degas for 30 minutes. Take the upper phase and fill the high-speed countercurrent chrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com